XXX . XXX install servo motor

Servo Tutorial :

Introduction

Servo motors are an easy way to add motion to your electronics projects. Originally used in remote-controlled cars and airplanes, they now crop up in all sorts of other applications. They’re useful because you can instruct these small motors how far to turn, and they do it for you.

A typical hobby servo

You ordinary, small DC motor has two hookup wires and simply turns continuously when power is applied. If you want it to spin in the opposite direction, you reverse the power. If you want to know how far it has turned, you’ll need to devise a way to measure that.

DC motor (left) and hobby servo

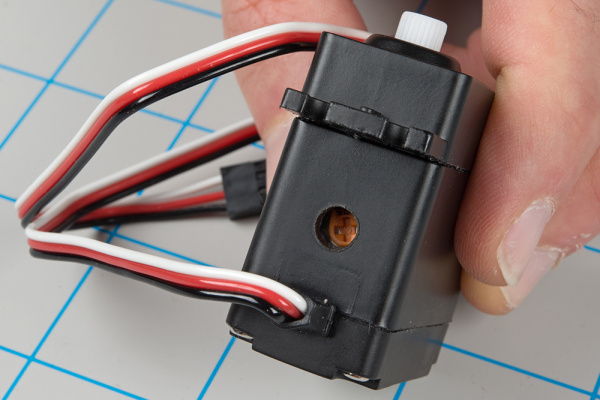

In contrast, you instruct a servomotor where to turn using a command protocol. The servo has three wires – power and ground, plus a third wire, to carry those commands.Servo Motor Background

In the most generic sense, a “servomechanism” (servo for short) is a device that uses feedback to achieve the desired result. Feedback control is used in many different disciplines, controlling parameters such as speed, position, and temperature.In the context we are discussing here, we are talking about hobby or radio-control servo motors. These are small motors primarily used for steering radio-controlled vehicles. Because the position is easily controllable, they are also useful for robotics and animatronics. However, they shouldn’t be confused with other types of servo motors, such as the large ones used in industrial machinery.

An Assortment of Hobby Servos

RC servos are reasonably standardized - they are all a similar shape, with mounting flanges at each end, available in graduated sizes, from “ultra-nano” to “giant”. Servos often come with multiple attachments, such as wheels or levers, known as “horns”, than can be attached to the shaft, to fit the device they are operating.

Example Servo Horns

Electrical Connection

Most hobby servos use a standard type of 3-pin plug, with the same control signaling, which makes RC servos reasonably interchangeable.The connector is a female, 3-pin, 0.1" pitch header. One thing that can be confusing is that the wiring color code isn’t always consistent – there are several color codes at play. The good news is that the pins are usually in the same order, just that the colors are different.

Servo Cables

The table below summarizes common color schemes. A useful mnemonic is that the most drab color (black or brown) is usually ground, and red is usually the power supply.| Pin Number | Signal Name | Color Scheme 1 (Futaba) | Color Scheme 2 (JR) | Color Scheme 3 (Hitec) |

| 1 | Ground | Black | Brown | Black |

| 2 | Power Supply | Red | Red | Red or Brown |

| 3 | Control Signal | White | Orange | Yellow or White |

Servo connection Color Coding

Control signal

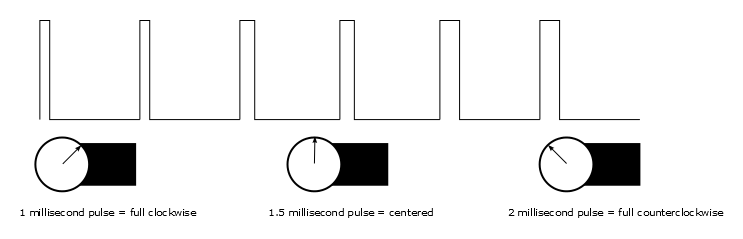

The third pin of the servo connector carries the control signal, used to tell the motor where to go. This control signal is a specific type of pulse train. The pulses occur at a 20 mSec (50 Hz) interval, and vary between 1 and 2 mSec in width. The Pulse Width Modulation hardware available on a microcontroller is a great way to generate servo control signals.Common servos rotate over a range of 90° as the pulses vary between 1 and 2 mSec – they should be at the center of their mechanical range when the pulse is 1.5 mSec.

pulse to position

Powering Servos

In RC vehicles, the nominal battery voltage is 4.8V. It will be somewhat higher after a charge, and it will droop as the batteries discharge. As the voltage drops, the available torque also drops – if you’ve driven RC vehicles, you’re no doubt familiar with the loss of control that occurs as the batteries get weaker. It starts to feel sluggish just before it dies.If you’re not using batteries, the 5VDC available from a garden variety power supply is a good option. If you’re using an Arduino or other microcontroller to control your motor, the absolute maximum supply voltage that should be applied is 5.5 VDC.

Regardless of how you’re powering them, it’s worth noting that the current consumed by the motor increases as the mechanical loading increases. A small servo with nothing attached to the shaft might draw 10 mA, while a large one turning a heavy lever might draw an Ampere or more! If your power supply isn’t up to the task, a straining or stalled servo can cause the supply to sag, which may have other unpredictable repercussions, such as causing microcontrollers to reset.

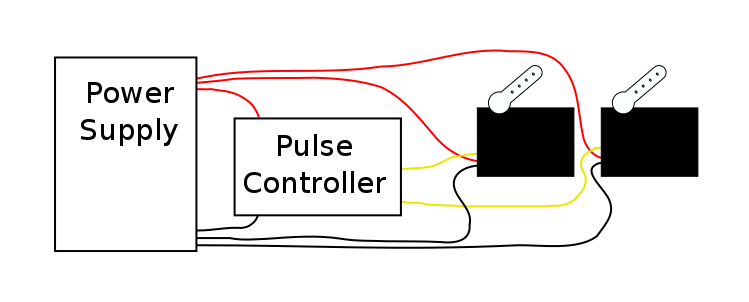

Additionally, if you’ve got multiple servos, or in applications where the motors are moving non-trivial loads, it’s best to use heavy gauge wires and give each servo a direct connection to the power supply, rather than daisy-chaining power from one to the next. This configuration is commonly known as “star power.” If one servo causes the power rail to droop, it’s less likely to effect the others when each has a direct connection.

Star power.

When in doubt, grab a multimeter, measure the current consumed, and check whether VCC sags when the servos are turning.Show Me The Guts

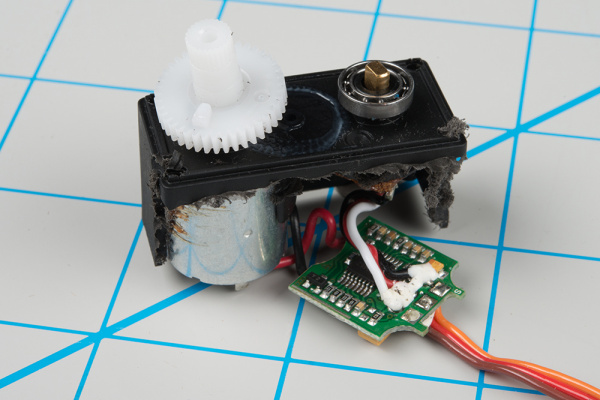

Internally, the mechanism of a servo motor uses a potentiometer attached to the rotating shaft to sense the position. It measures the width of the incoming pulse and applies current to the motor to turn the shaft, until the potentiometer indicates that the position corresponds to the incoming pulse width. This is a form of feedback control. The motor has received the desired position from the pulse width, and the actual shaft position is fed back to the circuit via the potentiometer. It compares the desired value to the actual value and drives the motor in the direction that causes actual to match desired.Here are the insides of a servo that’s been dissected. You can see the gears, DC motor, position potentiometer, and a small PCB. The PCB has a chip on one side, possibly a small microcontroller or specialized servo IC.

Inside an RC servo

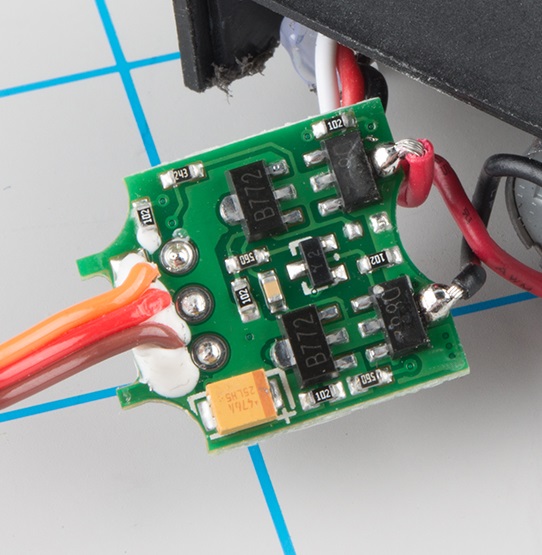

The other side of the PCB has some discrete transistors, probably in an H-bridge configuration, which allow the controller to steer current through the motor in either direction, for both clockwise and counterclockwise rotation.

Back of the PCB

A Handful of Distinctions

When you’re shopping for servos for your project, there are several parameters that you’ll want to keep in mind.Range Constraints

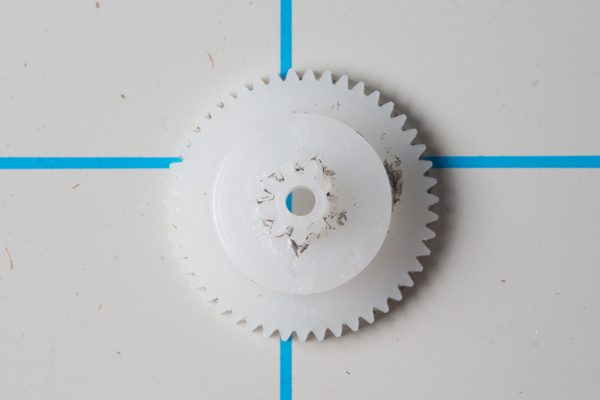

The 1-to-2 millisecond pulse range is more of a convention than a hard-and-fast standard. Some servo motors respond to even shorter or longer pulses with an extended range of motion.Be warned that there is a risk – this expanded range of motion isn’t universal. Some servos are mechanically limited to 90° rotation. Attempting to drive them beyond their limits can cause damage, such as stripped gears. The servo that we see dismantled here suffered exactly that fate.

The nub on the gear is used to constrain the range of rotation.

Position vs. Continuous Rotation

Moving even further from the 90° range, there are also full rotation, continuous rotation, or simply 360° servos. As the name states, the shaft turns continuously, making them useful as drive motors. Visually, they look just like regular servos.

Look carefully, and you’ll notice the “360°” mark on the packaging.

Rather than controlling position, the continuous rotation servo translates the 20 mSec pulse-train signal into the rotational speed and direction of the shaft. Otherwise, they’re very similar to regular RC servos – they use the same power supply, control signals, 3-pin connector, and are available in the same sizes as RC servos.The overall speed is relatively low – around 60 RPM is a common maximum rate – if you need higher rotation speed, servos aren’t the best fit – DC gearmotors or brushless DC motors are more likely candidates, but they aren’t directly compatible with servo control signals.

Nulling Trimpot

On closer inspection, continuous rotation servos have one small difference from regular servos: they usually have a “nulling” trimpot, used to adjust their response to the control signal. It’s typically set so that a 1.5 mSec pulse stops the motor. Shorter pulses will cause it to turn counterclockwise, and longer pulses cause it to turn clockwise.Analog vs. Digital

The pulse-controlled servos we’re discussing here are analog. There are also digitally-controlled servos that use a high-speed pulse train, and have a serial communication interface that allows more detailed configuration, typically with parameters that are tailored to RC vehicles.Plastic vs. Metal Gears

One last thing to look at when considering a servo is the type of gears it contains.Inexpensive servos (such as the one dismantled here) usually contain molded plastic gears, while more expensive servos have metal gears. Plastic gears are more likely to strip if the motor is jammed or overloaded. The old adage rings true: you get what you pay for.

Note the missing tooth at about 3:00 o'clock on the inner gear!

Deploying Servos

Traditional RC Application

As we stated in the introduction, the usual application of hobby servo motors is for steering radio-controlled vehicles.

RC transmitter (top left), with receiver and steering servo.

RC vehicles are controlled with a transmitter unit – the box with the joysticks and antenna. The transmitter sends control information to receiver modules (the orange box shown above), which connect to the servo motors. When the sticks on the transmitter are moved, the receiver generates corresponding pulses, instructing the motors to move.Configuring older RC craft required a fair amount of patience, because adjusting the servos meant careful mechanical tweaking of the servo horns, mechanical linkages, and trim controls on the transmitter. Modern transmitters and receivers are microcontroller-based, tweaked through the LCD on the transmitter, or even a computer interface.

Controlling a Servo with Arduino

Because they move on command, servo motors are an easy way to add motion to any project. If you’re working with an Arduino-compatible platform, the Arduino servo library provides a ready-to-go servo pulse generation solution.XXX . XXX 4%zero Slotted and Slotless Motors

The Challenge

Permanent magnet brushless motors are available in all sizes and shapes providing both linear and rotary motion. They are known for high efficiency and high torque density. They are also regularly called Brushless DC motors, Synchronous Permanent Magnet motors, Brushless AC motors, or Servo Motors. The important output of these machines is torque (rotary) or force (linear).Smooth and predictable torque/force while moving is the key challenge for numerous applications in imaging, metrology, photonics, scanning, and tracking. Traditional permanent magnet brushless motors display cogging torque, a torque disturbance from the interaction between the permanent magnet and the slots between stator teeth. Cogging is cyclical torque with angle that develops torque ripple, (and corresponding velocity ripple), adding a non-linear element to the control of the motor.

Various techniques to lessen cogging have been used for years, they include; skewing magnets, skewing laminations, special mechanical modifications, and electrical compensation in the motor controller. In the majority of applications that require smooth motion with light loads, the success of these techniques is marginal.

The Solution

Slotless motors are engineered to enhance smoothness and produce predictable torque output with marginal non-linear effects. Typically referred to as slotless motors when rotary and air core motors when linear, slotless motor designs place only copper phase coils in the air gap of the motor. These coils, when positioned properly, interact with the permanent magnetic flux to form force or torque. Cogging torque is eliminated because the discontinuous iron teeth are removed from the motor air gap. Slotless technology is particularly effective with direct drive precision systems as all torque is a function of phase current and there are no undesirable or uncontrolled torque disturbances from the motor.Motor Topology

There are two critical internal parts to a permanent magnet brushless motor – the permanent magnet assembly and the electromagnet assembly. In the rotary form, these two parts are known as the stator assembly and the rotor assembly. In linear form, they are the magnet track and forcer. The rotor/magnet track comprises of a magnetic steel component with permanent magnets affixed or buried internally. The stator/forcer is a multi-phase electromagnet with three phases as the most common construction. The following article will focus on comparing and contrasting slotted and slotless rotary motors. The same principals also apply to air core linear motors and actuators.Rotor and Stator Construction

Permanent Magnet Rotor Assembly

The rotor assembly usually takes the form of a steel ring or shaft with magnets attached. The magnets can be mechanically discrete or a single piece ring with the separate magnetic fields magnetized into it. The number of poles is directly related to the number of permanent magnets on the rotor assembly. Poles are at times defined as pole pairs, i.e. number of north-south pole pairs. The pole count is the transfer ratio between mechanical speed and electrical frequency. Usually, lower pole count motors operate mechanically faster and higher pole count motors function slower, but advanced high bandwidth electronics are progressively capable of attaining high speeds from motors with high pole counts. Figure 1a illustrates an example of a rotor with mechanically discrete magnets from a Celera Motion Omni™ Series motor..jpg)

Figure 1a. A Celera Motion Omni™ Series direct drive low profile rotor. The magnets are bonded to the surface of the rotor hub ring. This example has 32 poles and the magnets are shaped on the surface to minimize cogging torque.

Electromagnetic Stator Assembly

For a motor to rotate, many electromagnetic phases are required. There are normally three phases in the brushless permanent magnet motor. These electromagnetic phases are energized through existing outputs from a motor controller. The motor controller usually uses encoder feedback to monitor the position of the rotor and develops the precise current vector in the stator phase set to produce torque. Once torque is developed, it can be regulated together with speed and position to manage any motion control application.The stator assembly usually has soft iron laminations with radially protruding teeth. The spaces between these teeth known as slots allow electromagnetic coil wire to be inserted. This motor type is called slotted motor. Figure 1b illustrates an example of a Celera Motion Omni™ Series motor.

.jpg)

Figure 1b. A common direct drive frameless style motor with high pole count and ring type low profile construction. The teeth and slots of the stator are clearly visible in this example. The gray ring in the center of the motor is the rotor made of magnetic material with 36 magnetically skewed poles magnetized into it. Note the pictorial approximation of these poles. The skewed pattern helps to minimize cogging torque by axially altering the magnetic field and compensates for the fundamental frequency of the cogging torque.

Slotted Stator

Traditional slotted stator designs use teeth to focus electromagnetic flux towards the rotor magnets and decrease the total air gap in the magnetic circuit. There are typically multiple teeth per phase. Slotted motors are the predominant motor topology as they provide a good balance between torque output, efficiency, motor constant, and manufacturability. Slotted motors usually yield the maximum motor constant (torque/watt1/2) for a given motor size. They also offer high efficiency and high acceleration rates with the lowest inertia.As mentioned above, the spaces between stator teeth allow for electromagnetic phase wire to be inserted. The slots are the main cause of cogging torque as they create a discontinuous permeability as the magnets travel past each slot. It is standard practice to skew or stagger stator teeth or rotor magnets to reduce the fundamental frequency of the cogging torque. Figure 2 below illustrates a Celera Motion Omni™ Series stator with skewed teeth.

.jpg)

Figure 2. The teeth and slots of the stator are clearly visible in this example. The skewed pattern helps to minimize cogging torque by skew that compensates for the fundamental frequency of the cogging torque.

Cogging torque in slotted motors usually ranges from 1 to 5% of a motor’s rated torque based on the design of the motor. In applications with heavier payloads, the cogging torque is small compared to the driving torque and has a minor impact on system performance. However, in applications with lighter payloads or where smooth motion is a critical necessity, the cogging torque normally results in velocity ripple, which can have unfavorable effects on performance.Cogging torque frequency is a function of the motor’s slot count and pole count. The important frequency of this cogging is the least common multiple between the pole and slot count. However, because of manufacturing variability and 3D effects, there are also lower and higher harmonic attributes to the cogging torque profile with angle.

Slotted stators also experience magnetic saturation with growing current. This is also denoted as torque constant (Kt) linearity. To improve the motor size and output, it is common for the iron to be near magnetic saturation at the continuous thermal limit of the motor. In certain motors, as much as 10% Kt linearity error is embedded into the continuous output rating.

Slotless Stator

The ideal permanent magnet brushless motor has sinusoidal torque output with angle without any higher harmonic distortion. The slotless motor is the closest approximation to this goal. The slotless stator does not have stator teeth or their corresponding slots. Phase coils are spatially oriented around the stator to create the electromagnetic phase relationship needed for motor operation. When energized, the coils form an electromagnetic field similar to the slotted motor, but result in a torque versus angle curve that is sinusoidal. There is zero cogging torque as there are no teeth with corresponding slots.Figure 3a illustrates a Celera Motion Agility™ Series slotless motor with a rotor built with mechanically discrete magnets. Figure 3b illustrates a Celera Motion Agility™ Series slotless motor with a rotor engineered with a single piece ring magnet.

.jpg)

Figure 3a. The rotor in the center is made with 8 discrete magnets and has eight poles. Slotless stators have a very thin radial cross-section allowing for larger rotor diameter.

.jpg)

Figure 3b. The rotor in the center is a single piece ring magnet with 12 poles

With a slotless motor, all torque is a function of current applied to the winding. This streamlines the servo control system and allows for smoother running. The motor also has considerably better Kt linearity over its slotted counterpart.One consideration with slotless designs is the large magnetic air gap between the rotor and stator because of the removal of stator teeth. This results in lower flux density and correspondingly lower torque output for a particular size motor. The torque output of a slotless design is usually 70-75% of an equivalently sized slotted motor and Celera motion can improve many Agility Series motor designs to attain up to 85%. If smoothness is critical, the slotless technology is favored, but slotted motors are probably a better solution if continuous torque is the most critical need.

Torque Versus Angle Curve

The central output of a rotary motor is torque, which is a function of both position and current. The most common method used to test this phenomenon is a torque versus angle curve. The torque versus angle curve represents motor torque output, including cogging torque, and is the closest figure of merit to forecast how the motor will perform in the application. Torque versus angle can be measured by energizing a motor phase while manually rotating the rotor and measuring the torque produced with a torque transducer.All brushless permanent magnet motors have a torque versus angle profile that is commonly sinusoidal in shape. It typically contains several harmonics. Cogging torque is one of the contributors that can result in substantial harmonic distortion. This distortion causes torque ripple as the motor is operating and will affect velocity ripple.

Figures 4 and 5 show how cogging torque is the main difference between slotless and slotted motor technologies. Figure 4 plainly illustrates that when a slotted motor is not working at its full rated torque, the cogging is a relative percentage of the output and torque ripple is significantly higher. It is easy to see in Figure 5 that there is zero cogging torque in the torque versus angle curve.

.jpg)

Figure 4. The purple curve is the theoretical sinusoidal torque versus angle. The green curve is the compromised result of cogging torque. The red curve is cogging torque and the blue curve is resulting torque from all three phases operating together. All values have been normalized to 1 for ease of display. This example has cogging torque at 5% of the motors rated torque.

.jpg)

Figure 5. The absence of cogging torque allows the motor to produce a constant torque vector as it rotates or moves. All torque is directly related to the current supplied to the winding. Torque output is linear with changes in current and motion much more controllable. The purple line above is superimposed on the green line, so both curves are overlapping.

Summary and Conclusions

At Celera Motion, the product offering includes both slotless motors and slotted motors. Slotted motors are good for high acceleration and high torque density, while slotless motors are optimum for good Kt linearity and smooth operation when working in a servo control system.Cogging torque will differ significantly with different motor designs and steps are usually taken to reduce its impact, like skewing the magnet or stator laminations. Both technologies provide large through holes and can be engineered for low profile direct drive applications. The main performance characteristics of each motor type are summarized in Table 1.

Table 1. Summary of key performance characteristics of slotted and slotless motors.

| Parameter | Slotted | Slotless |

|---|---|---|

| Smoothest Motion (Lowest Velocity Ripple) | ✔ | |

| Highest Torque Constant | ✔ | |

| Torque Constant (Kt) Linearity | ✔ | |

| Largest Through Hole | ✔ | |

| Highest Acceleration Rates | ✔ |

XXX . XXX 4%zero null 0 Using PWM Drives and Slotless Motors to Optimize Performance

Smooth motion, meaning extremely low position and current loop error while at speed, is important to system performance in many precision motion applications, including industrial and surgical robotics, optical scanning and inspection, and semiconductor equipment. Slotless motors offer smooth motion because of their inherent zero cogging design. These motors, however, have extremely low inductance because of their lack of iron in the magnetic field. Low inductance can generate undesirable side-effects such as coil heating from PWM current ripple.

This article looks at how to configure a low inductance motor system to decrease current ripple and reduce position error while under motion. Configurations include PWM rate adjustment, incorporating inductors to each motor phase, and tuning the current loops. Certain background regarding motors and driving inductive loads with a PWM drive will be described to set the stage for a detailed discussion of how to improve a slotless motor system.

Motor Concepts

Slotless vs. Slotted

"Slotless" rotary motors do not possess protruding poles (or salient iron teeth), making them physically look and perform differently than a regular "slotted" motor. Rather, slotless motor phase coils are typically form wound and inserted in the stack as opposed to being wound around the teeth of a slotted motor. In contrast to a slotted motor where the rotor's magnetic poles are attracted to the steel "teeth", the absence of iron teeth in a slotless motor makes it have no naturally occurring torque cogging positions.The stable locations where a rotor of a brushless dc (BLDC) motor aligns with the stator teeth is known as a "cogging" position. The servo system must push its way through these positions so as to rotate the motor. For this reason, slotless motors are favored when smooth motion is critical. There are no cogging forces that the servo must push through, which results in less position error while at speed. For linear motors, the ironless linear motor is comparable to the rotary slotless and the linear iron-core motor is similar to the slotted rotary.

Motor Poles

The number of magnet poles (and pole pairs) is a key characteristic of a brushless dc motor. The number of pole pairs (N/2), where N is the number of poles, defines the number of electrical cycles in one mechanical revolution. This is sometimes known as the "electromagnetic gear ratio". When in motion, the electrical spatial frequency can be thought of in time as electrical cycles per second or Hertz (Hz). This frequency is the main parameter for which the current loop must be adjusted appropriately.Inductance

Any energized inductor has a voltage drop related to the time-varying current through the inductor, (V = L * di/dt, where V is the voltage drop across the inductor, L is in the Henrys and di/dt is the time rate of change of current flowing in the circuit). Alternatively, one could state the time rate of change of current as a function of the voltage across the inductor and its inductance, (di/dt=V/L). This formula is used later to calculate the current ripple formed from the PWM drive. The inductance of slotless motors tends to be a lot less than a slotted motor because the inductance is proportional to the permeance (ability to allow magnetic flux lines to pass) of the coil's magnetic circuit. The presence of iron in the magnetic circuit, acting as a very permeable path for the magnetic flux, makes the circuit permeance much higher. Thus, slotted motors with iron teeth to conduct the magnetic flux have a higher inductance than slotless motors.PWM Drive Voltage and Inductive Loads

RL Load and Voltage PWM

Pulse Width Modulation (PWM) of the bus voltage to regulate the average voltage applied across the motor phases is a typical way to drive motors. PWM motor drives are very efficient and very cost effective versus linear drives. A PWM drive creates the preferred DC current by varying the quantity of on and off time (duty cycle) of the applied voltage. When PWM is used to run a motor, which has resistance and inductance, a dynamic current waveform is created based on the time constant of the RL circuit.Figure 1 illustrates how current will rise and fall as the PWM voltage is applied across an RL circuit. Here, the PWM is at 50% duty cycle, and the RL time constant is less than the half period of the PWM rate, so the current is reaching its maximum, and minimum, before the next voltage transition. The average current illustrated is about 4 amps with 7.5 amp peak to peak of ripple.

.jpg)

Figure 1. Applied PWM voltage and subsequent current in a motor.

Duty Cycle and Average Current

To create more or less average current, the PWM duty cycle is changed. For example, the maximum current would be available if the duty cycle were 99.9% and conversely, the minimal current available when the duty cycle is at 0.1%. Figures 2, 3, and 4 signify 50, 1, and 99% duty cycles, respectively..jpg)

Figure 2. 50% PWM duty cycle.

The 50% duty cycle is the worst case for current ripple. The current flowing in the coil has an equal amount of time to build up and decay, making the peak to peak ripple the worst case. For low inductance motors, the peak to peak ripple can be a significant percentage of the average value. Figure 2 for a 50% duty cycle, illustrates a 3 ohm, 0.1 mH motor, having 2.85 amps pk-pk and a 4 amp average. The blue curve, signifying a motor with a more typical inductance of 1 mH, is displaying a slow build up to a steady state current.This reaction is caused by the larger RL time constant of resistive and inductive load. The 1% duty cycle is illustrated below. In this case, current ripple for low inductance motors is considerably lower than the 50% duty cycle case, yet it is still a large percentage of the average. In the 1% PWM case illustrated in Figure 3, the 3 ohm, 0.1 mH motor has 0.12 amps pk-pk and an average of 0.1 amps.

.jpg)

Figure 3. 1% PWM duty cycle.

The final case (presented in Figure 4) is the 99% duty cycle. Here, the peak to peak current ripple is the same as the 1% case, but versus its average, it is a much smaller percentage..jpg)

Figure 4. 99% PWM Duty Cycle.

PWM Rate and Current Ripple

Motor power dissipation (motor heating) is frequently a concern for precision mechanisms. Based on the application, current ripple formed from PWM drives and low inductance motors can be a key contributor to motor heating. In the 50% duty cycle case illustrated in Figure 2 above, the peak to peak ripple is nearly as large as the average current. For a motor with 1 amp of average current, and 0.6 amps of peak to peak (proportionally similar to the case illustrated in Figure 2), the RMS of the total current is 1 + 1/sqrt(3)*0.3 = 1.17 amps.This is a 17% increase over the average current. In motor power dissipation, the current is squared, so 1.17 amps squared becomes 1.37 amps and power dissipation increases by 37%. Thermal resistance is the measure of temperature rise per watt, so a 37% increase in dissipated power will equate to a 37% increase in temperature of the motor coil.

A simple way to decrease the dissipated power is to boost the PWM rate. Not all drive manufacturers will recommend doing this, as it puts more thermal load on the drive devices, which has probably not been assessed at the proposed PWM rate and motor load. It is best to discuss these issues with the drive company's Applications Engineers and inform them of any motor power dissipation apprehensions when driving a low inductance motor.

The formula for voltage drop across an inductor (described previously) can be used to calculate the maximum quantity of current ripple in a motor. In this calculation, care must be taken in using the correct voltage. For instance, when assessing current ripple at very low speeds, one can typically ignore Vbemf.

When the back emf becomes greater than 10% of the bus voltage, it has to be subtracted out to get an accurate current ripple calculation.

.jpg)

In this section, current ripple versus PWM rate is compared using a low inductance motor (0.1 mH). Figure 5 illustrates how doubling the PWM rate will half the peak to peak current ripple. The reduction in ripple is due to the reduced time available for current to rise and fall based on the RL time constant.

.jpg)

Figure 5. Current Ripple vs. PWM for 1 amp command (Red- 20 KHz, Blue- 40 KHz).

15-20 KHz is a common PWM rate found on most drives. 30-40 KHz is available from a number of manufacturers but requires significant arrangement and discussion to implement and is frequently not clearly documented. 60-100 KHz is available from a small number of suppliers and can greatly decrease current ripple. Figure 6 is a compilation of locked rotor test data from three common drive manufacturers. A locked rotor test means that the rotor is not permitted to spin while a constant current is being commanded to the drive.A current probe was utilized across one of the motor phase leads. The rotor was rotated manually to locate an electrical angle such that the phase current for the probe was at its maximum. The data evidently displays three key points. Observation 1 is that higher PWM rates result in lower quantities of current ripple. Observation 2 illustrates how all three drive companies have similar performance. The third point, which is less apparent, is that one of the three drive companies did not offer an 80 KHz PWM rate. PWM rates are the parameter that should be talked about with the targeted drive manufacturer when using slotless motors.

.jpg)

Figure 6. Current Ripple vs. Drive Company vs. Drive Level.

Add On Inductors

If a drive does not support medium to high PWM rates, meaning greater than the standard 15-20 KHz range, and current ripple (motor heating) is still an issue, integrating inductors in series with each motor phase is an option. The integrated inductance does come with integrated resistance and a loss of efficiency, but it can greatly decrease current ripple and make the motor run cooler. Figure 7 illustrates how doubling the inductance accomplishes the same ripple and doubling the PWM rate. When using add on inductors, care must be taken in properly sizing the inductors by current capability or power dissipation.Usually, this is only a feasible option with low current drives as inductor sizes can swiftly exceed motor sizes as the vital current levels increase. Other factors related to add on inductors is that they require new current loop tuning, as the RL pole in the plant will have moved, and require extra cabling for connecting to each motor phase. In a number of applications, this option is just too complicated because of space limitations.

.jpg)

Figure 7. Current Ripple with Added Inductance.

Control Architecture

Inner and Outer Loop Architecture

Rotary motion control is usually realized through the use of at least two nest control loops – an outer position loop and an inner current loop, (see Figure 8). A velocity loop is sometimes incorporated between the fast current loop and slow position loop..jpg)

Figure 8. Nested motion system architecture.

In the nested loop architecture, the current loop's function is to supply current based on the torque required to make the outer position loop error a minimum. Normally the current loop bandwidth is 10 to 20 times higher than the position loop bandwidth, putting it near or greater than 1 KHz. Tuning of these two servo loops has a direct effect on how well slotless motors act in any motion system.Target Current Loop Bandwidth

Before any current tuning starts, the highest operating speed and pole count must be used to calculate the electrical cycle frequency for the system. The formula is just; N/2 * RPM/60, where N is the number of poles and the units are electrical cycles per second. The current loop gains must be tuned so that the bandwidth is at least 2 to 3 times more than the electrical cycle frequency, allowing the drive to create phase current instantly, as the commutation algorithm switches the applied current into the correct phases throughout a mechanical revolution.Current Loop Tuning

Two phases of a BLDC motor can be signified as a simple RL circuit, which when represented in the LaPlace domain takes the form of a 1st order systemThis intense change in the transfer function would generally be considered harmful to a fixed PI control law. Here, however, the change is towards stability, not away from it (meaning phase is integrated, not removed), making the loop stable when the motor is at rest, and while moving.

.jpg)

Figure 9. Block Diagram of the motor transfer function.

.jpg)

Figure 10. Motor Plant Transfer Function vs. Back Emf Factor.

Regulating the plant transfer function illustrated in Figure 10 requires only a Proportional + Integral (PI) controller with an extra first order low pass filter on the current sensor. The low pass filter is usually at a fixed value in the drive software, thus the user doesn't usually tune this value. Tuning the current loop is nearly always done with a step response tool within the drive software. In certain cases, a higher fidelity tuning technique is required to get the absolute maximum performance out of the current loop. In that case, tuning is recommended to be done in the frequency domain using Bode Plots. First current loop tuning within the time domain will be discussed, then move into some more advanced tuning in the frequency domain using Bode Plots.Figure 11 shows simulated data from a low inductance slotless motor. The plot has many curves, each with different PI gains. As the PI gains are increased, the response gets closer and closer to the commanded step in current. The green trace would be considered by many to be the best combination of response time and overshoot. In certain applications, however, more performance is required, and overshoot is a metric that can be relaxed at the benefit of improved disturbance rejection. Having a small quantity of overshoot, without ensuing oscillation is a stable gain set and is the maximum gain possible for the system.

Many drive manufacturers do not propose this level of tuning, as in certain cases it can interact with high-frequency structural resonances and produce an audible tone, or worst case, instability. Based on the application, however, this level of tuning can give the system the additional performance it requires. In the Section “Advanced Current Loop Tuning”, optimal I gain tuning is discussed and it is revealed how higher I gain values yield improved disturbance rejection.

Position Loop Tuning

Position loop tuning is critical in establishing how a precision mechanism or motor system moves and settles. Tuning the position loop, however, is not directly impacted by the motors' inductance. The "Plant" for the position loop is really the inner current loop plus the inertia of the motor shaft (or moving structure) and any structural dynamics it may have. The challenges of position loop tuning are connected to these structural dynamics and any time lags between the sensor and the motor. These concepts are not covered here, as this article is focusing on tuning for low inductance motors.Advanced Current Loop Tuning

In the Section “Control Architecture”, time domain tuning of the current loop's PI gains was discussed. In that section, it was illustrated how P and I gain impact the time response from a step input of current. This section shows how the P and I gains shape the loop transfer function in the frequency domain.Frequency Domain Tuning

Position and integral control are signified in the LaPlace domain as , where A = Ki/Kp and Gain = Kp. This form of PI control is crucial to note as it tells the control designer that at frequency "A" the integrator turns on (or off). Turning the integrator "on" at a higher frequency means that the gain will be higher for all frequencies below A (see Figure 13). The beauty of frequency domain tuning is that the control designer can visually see how the Ki gain just increases loop gain below the corner frequency A, and not above. When tuning in the time domain, this impact is not observable. Increasing just low-frequency gain is important when the system has high-frequency resonances above frequency A that might have Gain Margin sensitivities.

, where A = Ki/Kp and Gain = Kp. This form of PI control is crucial to note as it tells the control designer that at frequency "A" the integrator turns on (or off). Turning the integrator "on" at a higher frequency means that the gain will be higher for all frequencies below A (see Figure 13). The beauty of frequency domain tuning is that the control designer can visually see how the Ki gain just increases loop gain below the corner frequency A, and not above. When tuning in the time domain, this impact is not observable. Increasing just low-frequency gain is important when the system has high-frequency resonances above frequency A that might have Gain Margin sensitivities.In control design, one must frequently make decisions and tradeoffs based on the applications needs. Here, the benefit one gets from increasing low-frequency gain causes lost phase near the targeted servo bandwidth. Turning the integrator on at a higher frequency means the quantity of phase margin at the bandwidth is decreased. Figure 13 illustrates how the phase from PI control alters with frequency and specifically, one can see that at the targeted bandwidth (the green circle), there is about 15° of phase loss from the 10xKi case versus the Ki gain case.

.jpg)

Figure 11. I gain effect on Bode Plot.

To finish this discussion of frequency domain tuning, a discussion on how Kp gain affects the loop transfer function is needed. Above it was stated that a PI controller is signified as  , where A=Ki/kp and Gain = Kp. In Figure 14, one will notice that if Kp is changed, both the integrator frequency A and the high-frequency gain value are also changed. The combined effect of a change in "Gain" and the corner frequency A, basically keeps low-frequency gain unaffected and boosts high-frequency gain. It also impacts the phase curve in that more phase margin would be available since the corner frequency has been decreased.

, where A=Ki/kp and Gain = Kp. In Figure 14, one will notice that if Kp is changed, both the integrator frequency A and the high-frequency gain value are also changed. The combined effect of a change in "Gain" and the corner frequency A, basically keeps low-frequency gain unaffected and boosts high-frequency gain. It also impacts the phase curve in that more phase margin would be available since the corner frequency has been decreased..jpg)

Figure 12. Changing only Kp.

Example Using High I Gain

This section shows an example of how increased I gain compensation can be used to enhance current loop performance. As stated earlier, an ironless linear motor is in many ways comparable to a rotary slotless motor. Below is a streamlined image of the workings of a linear motor..jpg)

Figure 13. Linear Ironless Motor.

In this image, forces are produced from the interaction of the current running through motor phases A, B, and C and the corresponding magnetic field because of the individual magnets. This interaction of current and magnetic field is captured in the motor parameter Kf (N/amp). Each separate magnet, however, has marginally different magnetic strength causing the magnetic fields to correspondingly differ in strength. This, in turn, causes the motor's Kf to differ in strength as a function of position and eventually causes the forces Fa1 through Fc2 to differ in strength with position. Other contributors to position-dependent force variability are magnet spacing, motor coil to coil spacing, and motor coil turn spacing. All of these integrate to create a varying Kf with position.As mentioned previously, the motor parameter that captures this conversion of applied current to force is the force constant of the motor (Kf). When using SI units, the back emf constant is numerically the same as the force constant. So, as the coil moves through the varying magnetic field, the back emf constant also varies, thus generating a fluctuating back emf voltage. The varying loss of voltage as a function of position is subtracted from the bus voltage, and the remainder is applied across the coil to create current. The block diagram below illustrates where the back emf loss is accounted for in relation to the current loop and a simplified RL motor model. The current loop's job is to keep the preferred current correct while any voltage disturbances are occurring. Here, as the coil moves through the varying magnetic fields, there is a voltage disturbance (in the form of back emf) that the current loop must correct for. In the block diagram, this is captured through at the sum block just before the coil model.

.jpg)

Figure 14. Block diagram for current loop and motor with varying Kf (ke).

The frequency of the voltage disturbance is important. For slow speeds, the frequency is also slow, as the frequency is the linear speed in mm/second divided by the magnetic pitch (mm/pole pair or electrical cycle). The units here become electrical cycles per second or "Hz". At the low speeds (and low frequencies), the loop gain is very high (see Figure 17). In these regions, it may be hard to see any advantage of optimal integrator tuning because the gain is so high that improvement may be in the noise of the measurement. At higher speeds (and frequencies), however, maximizing I gain could result in a two or three times improvement in current ripple from varying Kf..jpg)

Figure 15. RL Plant and Loop Transfer Function plot for low and high gain current loop.

For this example, a 200 Hz sinusoidal signal was injected into the voltage summation block. The amplitude of the sinewave was fixed using a Ke value of 10 volts per m/second, at a speed of 0.5 m/second and a variation of 10% of that value. What this means is that Kf (or Ke), will differ +/- 10% at a frequency of 200 Hz. This is used to signify how a linear coil moves through a motor track with differing magnets strength. The varying Ke will cause a fluctuation at 200 Hz of the back emf component of coil voltage. This fluctuation will act as a disturbance to the voltage being applied to the coil.Figure 17 illustrates the two Loop Transfer functions that were assessed. Both have a 0 dB crossover frequency of approximately 2 KHz (bandwidth) but have different low-frequency gains because of the different I gain used. At 200 Hz, the gain difference is around 10 dB, which is a factor of 3. The net benefit of the 3x in gain is illustrated in Figure 18 where the higher Ki case is clearly performing better by about 2 to 1. It should be noted that if the back emf voltage model were applied for this example, the red curve would be shaped like the red trace of Figure 10, but with a peak at 400 Hz, and the slope of the green and blue curves would flat below 400 Hz, separated in amplitude by the same amount as illustrated here.

Drive companies will normally not suggest this level of advanced tuning as it tends to decrease phase margin of the current loop. The amount of acceptable Phase Margin is not the same for every application. In mechanical systems, closing loops with 30° in margin is common practice, while in electrical engineering disciplines, like op-amp design, loops are closed with a minimum of 60° margin. The I gain optimization detailed here can become a very beneficial tool for the right application. The higher level takes away from this discussion, however, is that when tuning a control law to reject tonal frequencies, gain is what is vital, not bandwidth. As presented above, two systems with the same bandwidth perform a lot differently against a tonal disturbance.

.jpg)

Figure 16. Current Loop Error vs. I gain.

Summary and Conclusions

Enhancing the performance of a slotless motor driven by a PWM voltage drive requires knowledge of how a resistive and inductive load acts under varying applied voltage. Understanding the tuning principals of the proportional and integral controlled current loops is also vital for making the most out of the slotless motor system.This article covers some elementary motor and drive concepts including inductance, pole count, and PWM voltage. The difference between a slotless and slotted rotary motor was discussed and it was noted how slotless motors usually have low inductance. The fast RL time constant of a slotless motor, along with a PWM drive, creates current ripple that can be a great contributor to dissipated power in a motor. Different methods to decrease current ripple, including PWM rate, and added inductance were also discussed. Increasing the PWM rate or incorporating inductance were both revealed to be extremely effective in reducing current ripple. Three common PWM drive manufacturers were analyzed and compared for current ripple and all were found to be similar in their performance, but not all offered an 80 KHz PWM rate.

Time domain current loop tuning was looked at and it was revealed how current loop proportional and integral gains impact rise time and overshoot. Advanced frequency domain tuning was discussed where it was shown how P and I gain shape the gain and phase vs. frequency curves. The take away from frequency domain tuning is that changing I gain modifies only the low-frequency part of the gain curve, so as to not unfavorably affect any resonances in the system at a higher frequency. This advantage of increased low-frequency gain is at the expense of lost phase at the targeted bandwidth, so care must be taken to not destabilize the loop when enhancing I gain.

The theory of maximizing I gain was taken to a simple motor example, where a voltage disturbance was an input to the commanded voltage across a resistive and inductive load (i.e. a motor). It was demonstrated that the current error was decreased by a factor of 2 with optimizing I gain tuning. Additive inductance, PWM rate, and current loop tuning are all "tools" one can use to improve the performance of slotless motors with PWM drives. Using these methods will improve the inherent smooth motion benefit of a slotless motor .

micro - linier motor

to provide motor and encoder components that allow customers to highly integrate their mechatronic assemblies. One particular challenge involved integrating multiple linear motor actuators into a tight package, where the components could work together to focus a beam. Multiple motors needed to work within 1 mm of each other, without interfering with the adjacent motor. Benefits to the solution included a small form factor, direct drive simplicity and performance, high accuracy and reliability, and reduced complexity.

.jpg)

an example of this would be the integration of micro-linear motors in the radiation therapy field. Our ability to design virtual any style of electromagnetic motor has allows us to integrate them into a high density array, in order to provide many motion axes in a compact form for beam collimation. This has allowed our customers to develop machines that can radiate cancer tumors with a high degree of accuracy.

XXX . XXX 4%zero null 0 1 2 How to install stepper motor

This library allows you to control unipolar or bipolar stepper motors. To use it you will need a stepper motor, and the appropriate hardware to control it.

Circuits

Examples

- Motor Knob: Control a highly accurate stepper motor using a potentiometer.

- Stepper One Revolution: Turn the shaft one revolution clockwise and one counterclockwise.

- Stepper One Step At A Time: Turn the shaft step by step to check the proper wiring of the motor.

- Stepper Speed Control: Control the stepping speed with a potentiometer.

Stepping Up to the Challenge

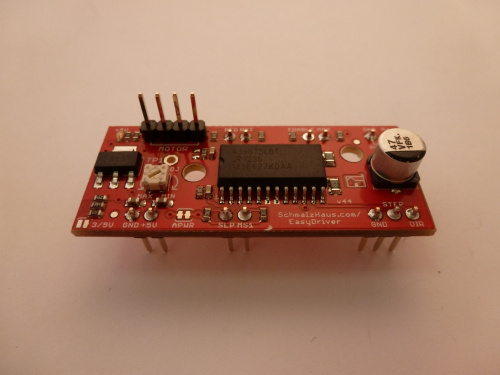

There are a handful of motors to choose from, and sometimes it’s unclear as to which one will be best suited for your particular application. In this tutorial, we will discuss one of these motors, the stepper motor, and when it best to choose a stepper motor over the alternatives. We will also discuss how to use this motor with the Easy Driver Stepper Motor Driver board, one of the simplest driver boards around.How it Works

Stepper motors vary from regular DC motors in that, rather than just spinning in one direction or another, they can spin in very precise increments. Imagine a motor on an RC airplane. The motor spins very fast in on direction or another. You can vary the speed with the amount of power given to the motor, but you cannot tell the propeller to stop at a specific position. Now imagine a printer. There are lots of moving parts inside a printer, including motors. One such motor acts as the paper feed, spinning rollers that move the piece of paper as ink is being printed on it. This motor needs to be able to move the paper an exact distance to be able to print the next line of text or next line of an image. There is another motor attached to a threaded rod that moves the print head back on forth. Again, that threaded rod needs to be moved an exact amount to print one letter after another. This is where stepper motors come in handy.Stepper motors can move an exact amount of degrees (or steps) when told to do so. This gives you total control over the motor, allowing you to move it to an exact location and hold that position. It does so by powering coils inside the motor for very short periods of time. The trade off is that you have to power the motor all the time to keep it in the position that you desire. All you need to know for now is that, to move a stepper motor, you tell it to move a certain number of steps in one direction or the other, and tell it the speed at which to step in that direction.

There are numerous varieties of stepper motors as well as driver boards with which to control them. The methods described here can be used to infer how to use other motors and drivers not mentioned in this tutorial. However, it is always recommended that you consult the datasheets and guides of the motors and drivers specific to the models you have.

How to Use it

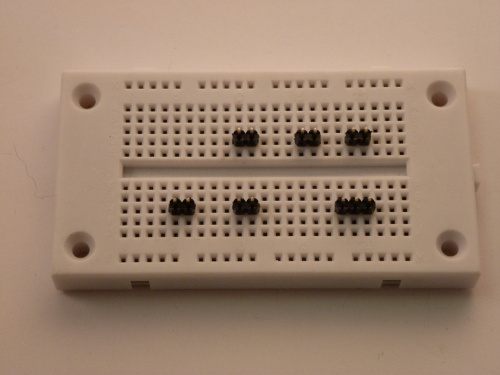

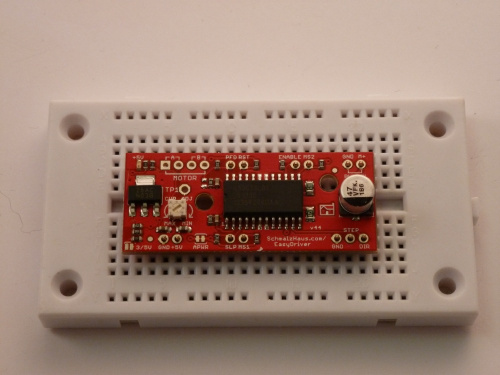

Here we will discuss how to assemble, hook up and control your motor with firmware uploaded to the Arduino.Assembly

The simplest way to use the EasyDriver is to attach headers to it for easy insertion onto a breadboard. Alternatively, you could solder the wires straight to the board. These instructions will assume you are using the breadboard method.The first step is to solder straight male headers to the EasyDriver. Very few of the actual pins on the EasyDriver will be used in this example. However, soldering headers on all the broken out pins is recommended to give the board more stability when attached to a breadboard. A simple method for this is to break off the desired amount of headers, place them in the breadboard in the appropriate locations, place the EasyDriver on top, and then solder all the connections.

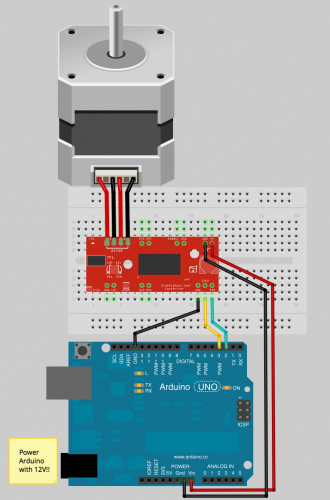

Hook-up

Once you have all the headers soldered on, it’s time to hook up the EasyDriver to your Arduino. Using the picture below, make all the necessary connections.Note: The small stepper motor looks different than the one pictured. It should have a 4-pin connector on the end. This will be attached to the 4-pin male header facing upward (see picture #3 in Assembly). Because of the nature of this particular stepper, you can hook up the connector in either orientation, i.e. either the black wire on the left or the yellow wire on the left. It will work either way. If you are using a different motor, consult its documentation to find out which wires should go where.

IMPORTANT: Stepper motors require more power than can be supplied by the Arduino. In this example we will be powering the Uno with a 12V external supply. Notice that the power input (M+) on the EasyDriver is attached to the Vin pin on the Arduino. This will allow you to power both the Arduino and the motor with the same power supply.

Firmware

Once you have everything hooked up correctly, you can upload firmware to the Arduino. The following is some very simple example code to get you up and running. There are numerous examples online, as well as a Stepper library included with the Arduino IDE. Feel free to play around with this code, changing values to see what happens, and feel free to explore other code./*************************

Joel Bartlett

SparkFun Electronics

December 27, 2012

This code controls a stepper motor with the

EasyDriver board. It spins forwards and backwards

***************************/

int dirpin = 2;

int steppin = 3;

void setup()

{

pinMode(dirpin, OUTPUT);

pinMode(steppin, OUTPUT);

}

void loop()

{

int i;

digitalWrite(dirpin, LOW); // Set the direction.

delay(100);

for (i = 0; i<4000; i++) // Iterate for 4000 microsteps.

{

digitalWrite(steppin, LOW); // This LOW to HIGH change is what creates the

digitalWrite(steppin, HIGH); // "Rising Edge" so the easydriver knows to when to step.

delayMicroseconds(500); // This delay time is close to top speed for this

} // particular motor. Any faster the motor stalls.

digitalWrite(dirpin, HIGH); // Change direction.

delay(100);

for (i = 0; i<4000; i++) // Iterate for 4000 microsteps

{

digitalWrite(steppin, LOW); // This LOW to HIGH change is what creates the

digitalWrite(steppin, HIGH); // "Rising Edge" so the easydriver knows to when to step.

delayMicroseconds(500); // This delay time is close to top speed for this

} // particular motor. Any faster the motor stalls.

}

Going further

you’ve figured out how to operate your stepper motor at the simplest level, it’s time to take it to the next level.

Stepper Motors & Drivers

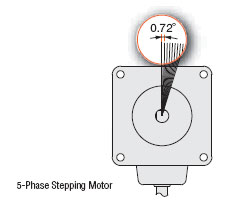

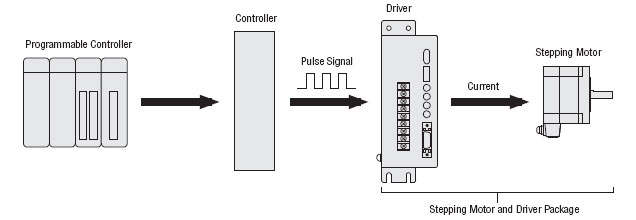

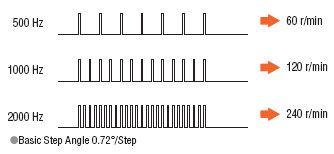

A stepper motor is used to achieve precise positioning via digital control. The motor operates by accurately synchronizing with the pulse signal output from the controller to the driver. Stepper motors, with their ability to produce high torque at a low speed while minimizing vibration, are ideal for applications requiring quick positioning over a short distance.Stepper motors enable accurate positioning with ease. They are used in various types of equipment for accurate rotation angle and speed control using pulse signals. Stepper motors generate high torque with a compact body, and are ideal for quick acceleration and response. Stepper motors also hold their position at stop, due to their mechanical design. Stepper motor solutions consist of a driver (takes pulse signals in and converts them to motor motion) and a stepper motor. Oriental Motor offers many solutions for a wide variety of applications.

Accurate Positioning in Fine Steps

Easy Control with Pulse Signals

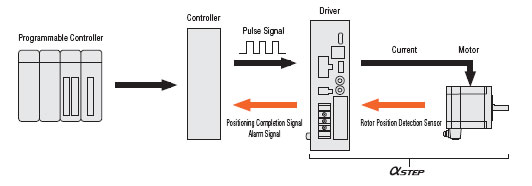

A system configuration for high accuracy positioning is shown below. The rotation angle and speed of the stepper motor can be controlled with precise accuracy by using pulse signals from the controller.

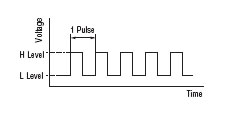

What is a Pulse Signal?

A pulse signal is an electrical signal whose voltage level changes repeatedly between ON and OFF. Each ON/OFF cycle is counted as one pulse. A command with one pulse causes the motor output shaft to turn by one step. The signal levels corresponding to voltage ON and OFF conditions are referred to as "H" and "L" respectively.

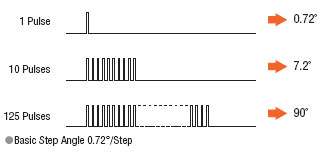

The Amount of Rotation is Proportional to the Number of Pulses

The amount the stepper motor rotates is proportional to the number of pulse signals (pulse number) given to the driver. The relationship of the stepper motor's rotation (rotation angle of the motor output shaft) and pulse number is expressed as follows:

The Speed is Proportional to the Pulse Speed

The speed of the stepper motor is proportional to the speed of pulse signals (pulse frequency) given to the driver. The relationship of the pulse speed [Hz] and motor speed [r/min] is expressed as follows:

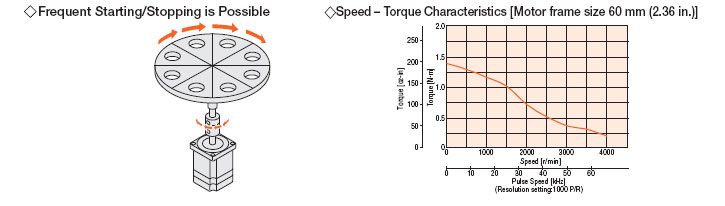

Generating High Torque with a Compact Body

Stepper motors generate high torque with a compact body. These features give them excellent acceleration and response, which in turn makes these motors well-suited for torque-demanding applications where the motor must start and stop frequently. To meet the need for greater torque at low speed, Oriental Motor also has geared motors combining compact design and high torque.

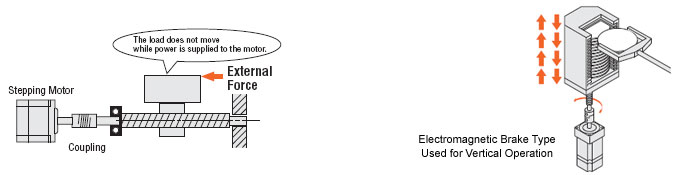

The Motor Holds Itself at a Stopped Positioning

Stepper motors continue to generate holding torque even at standstill. This means that the motor can be held at a stopped position without using a mechanical brake.Once the power is cut off, the self-holding torque of the motor is lost and the motor can no longer be held at the stopped position in vertical operations or when an external force is applied. In lift and similar applications, use an electromagnetic brake type.

Closed Loop Stepper Motor and Driver Package - AlphaStep

The AlphaStep consists of package products designed to draw out the maximum features of a stepper motor. These packages normally operate synchronously with pulse commands, but when a sudden acceleration or load change occurs, a unique control mode maintains positioning operation. AlphaStep models can also output positioning completion and alarm signals, which increase the reliability of the equipment which they operate.

Types of Operation Systems

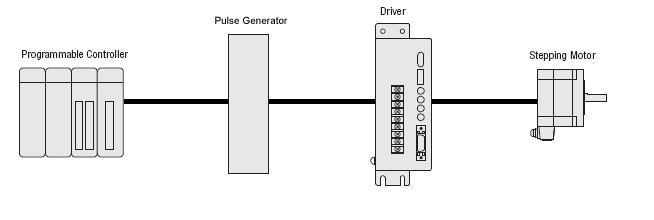

Each stepper motor and driver package combines a stepper motor selected from various types, with a dedicated driver. Drivers that operate in the pulse input mode and built-in controller mode are available. You can select a desired combination according to the required operation system.Pulse Input Package

The motor can be controlled using a pulse generator provided by the user. Operation data is input to the pulse generator beforehand. The user then selects the operation data on the host programmable controller, then inputs the operation command.

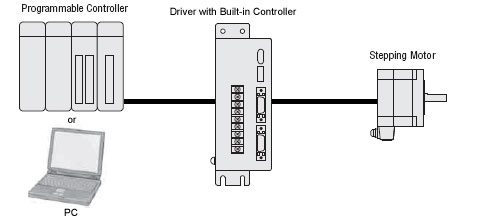

Built-in Controller Package

The built-in pulse generation function allows the motor to be driven via a directly connected personal computer or programmable controller. Since no separate pulse generator is required, drivers of this type save space and simplify wiring.

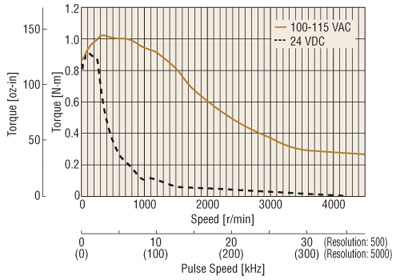

Difference Between AC Input and DC Input Characteristics

A stepper motor is driven by a DC voltage applied through a driver. In Oriental Motor's 24 VDC input motor and driver systems, 24 VDC is applied to the motor. In the 100-115 VAC motor and driver systems, the input is rectified to DC and then approximately 140 VDC is applied to the motor (certain products are exceptions to this.)This difference in voltage applied to the motors appears as a difference in torque characteristics at high speeds. This is due to the fact that the higher the applied voltage is, the faster the current rise through the motor windings will be, facilitating the application of rated current at higher speeds. Thus, the AC input motor and driver system has superior torque characteristics over a wide speed range, from low to high speeds, offering a large speed ratio.

It is recommended that AC input motor and driver systems, which are compatible over a wider range of operating conditions than DC input systems, be considered for your application.

Stepper Motors Installation

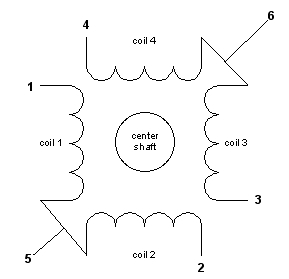

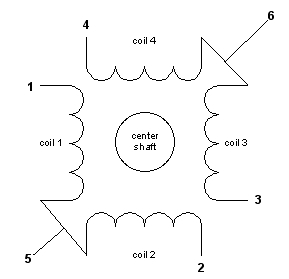

A stepper motor is a motor controlled by a series of electromagnetic coils. The center shaft has a series of magnets mounted on it, and the coils surrounding the shaft are alternately given current or not, creating magnetic fields which repulse or attract the magnets on the shaft, causing the motor to rotate.

This design allows for very precise control of the motor: by proper pulsing, it can be turned in very accurate steps of set degree increments (for example, two-degree increments, half-degree increments, etc.). They are used in printers, disk drives, and other devices where precise positioning of the motor is necessary.

There are two basic types of stepper motors, unipolar steppers and bipolar steppers.

Unipolar Stepper Motors

The unipolar stepper motor has five or six wires and four coils (actually two coils divided by center connections on each coil). The center connections of the coils are tied together and used as the power connection. They are called unipolar steppers because power always comes in on this one pole.

Bipolar stepper motors

Bipolar stepper motors

The bipolar stepper motor usually has four wires coming out of it. Unlike unipolar steppers, bipolar steppers have no common center connection. They have two independent sets of coils instead. You can distinguish them from unipolar steppers by measuring the resistance between the wires. You should find two pairs of wires with equal resistance. If you’ve got the leads of your meter connected to two wires that are not connected (i.e. not attached to the same coil), you should see infinite resistance (or no continuity).

Like other motors, stepper motors require more power than a microcontroller can give them, so you’ll need a separate power supply for it. Ideally you’ll know the voltage from the manufacturer, but if not, get a variable DC power supply, apply the minimum voltage (hopefully 3V or so), apply voltage across two wires of a coil (e.g. 1 to 2 or 3 to 4) and slowly raise the voltage until the motor is difficult to turn. It is possible to damage a motor this way, so don’t go too far. Typical voltages for a stepper might be 5V, 9V, 12V, 24V. Higher than 24V is less common for small steppers, and frankly, above that level it’s best not to guess.

To control the stepper, apply voltage to each of the coils in a specific sequence. The sequence would go like this:

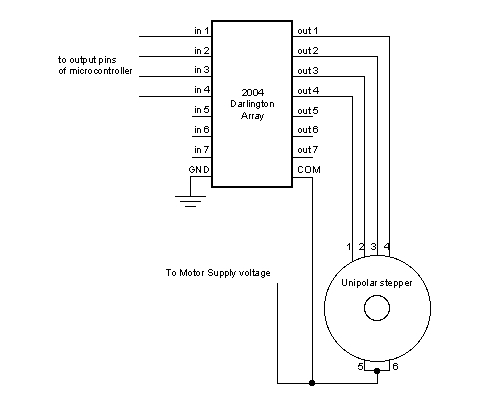

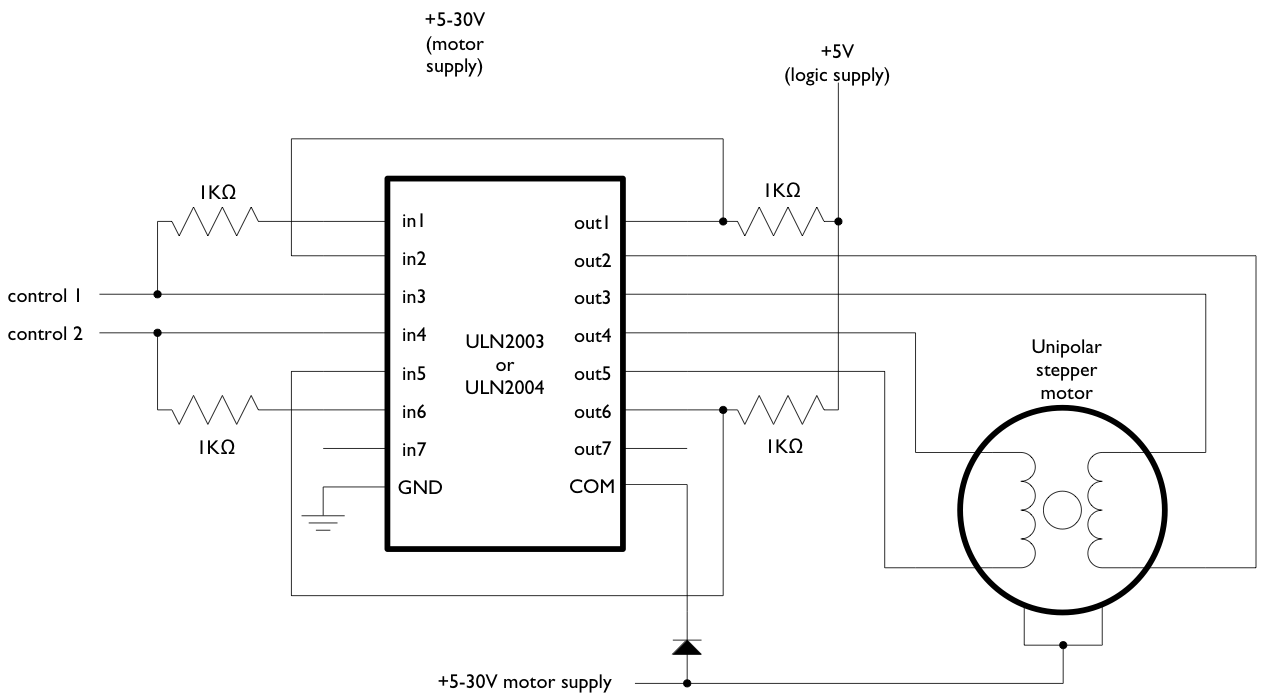

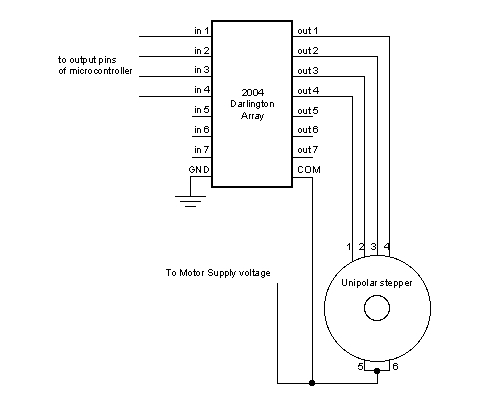

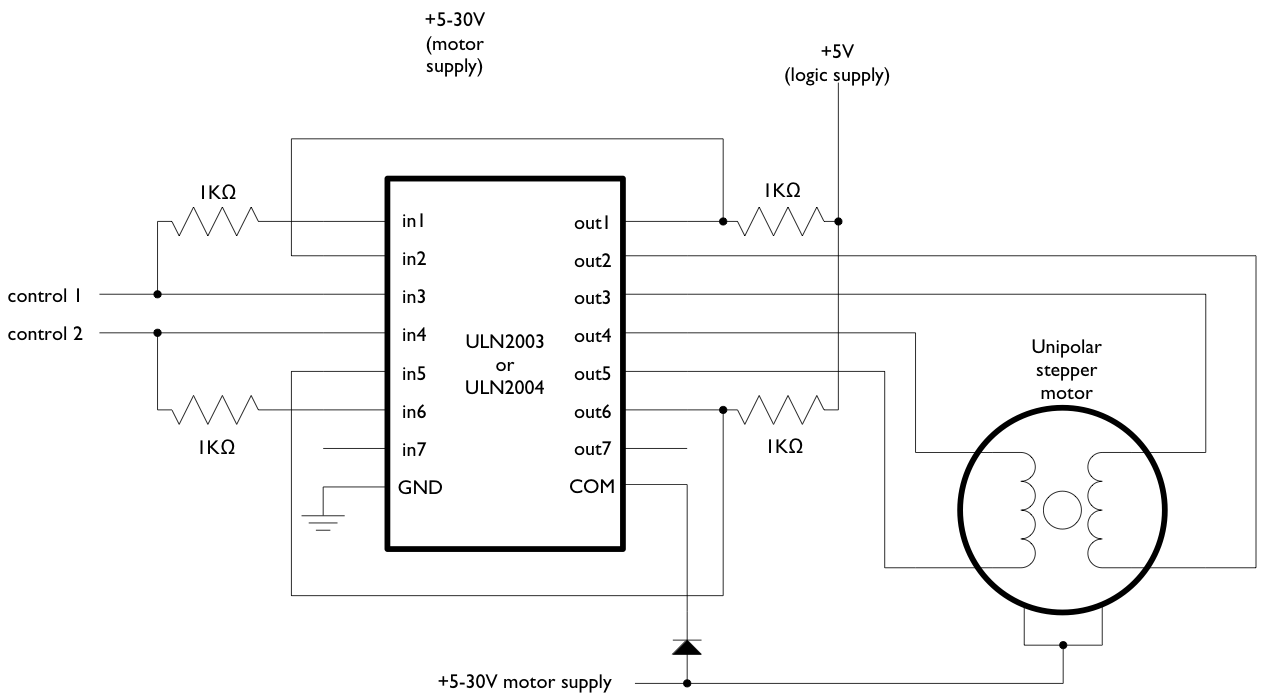

To control a unipolar stepper, you use a Darlington Transistor Array. The stepping sequence is as shown above. Wires 5 and 6 are wired to the supply voltage.

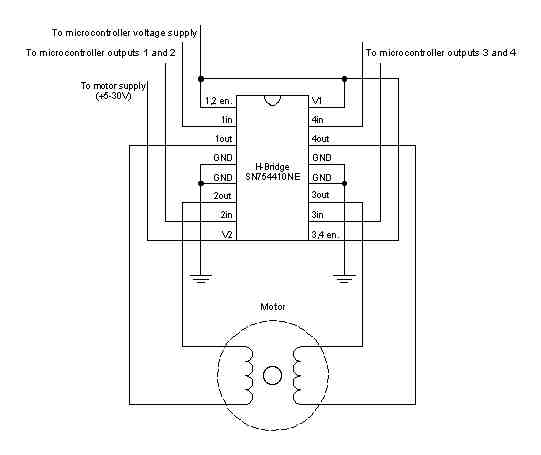

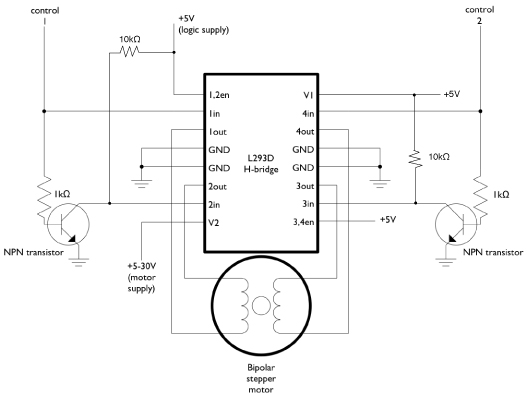

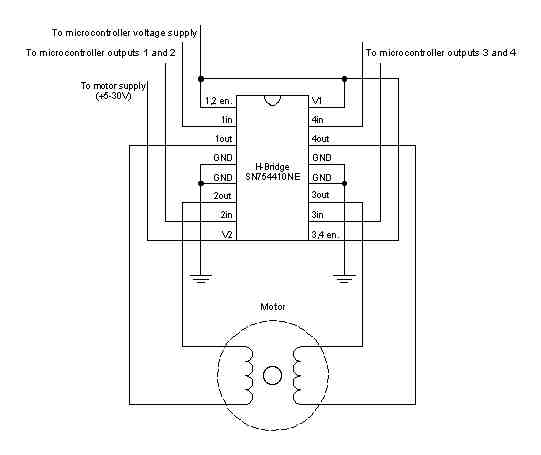

To control a bipolar stepper motor, you give the coils current using to the same steps as for a unipolar stepper motor. However, instead of using four coils, you use the both poles of the two coils, and reverse the polarity of the current.

The easiest way to reverse the polarity in the coils is to use a pair of H-bridges. The L293D dual H-bridge has two H-bridges in the chip, so it will work nicely for this purpose.

Once you have the motor stepping in one direction, stepping in the other direction is simply a matter of doing the steps in reverse order.

Knowing the position is a matter of knowing how many degrees per step, and counting the steps and multiplying by that many degrees. So for examples, if you have a 1.8-degree stepper, and it’s turned 200 steps, then it’s turned 1.8 x 200 degrees, or 360 degrees, or one full revolution.

Two-Wire Control

Thanks to Sebastian Gassner for ideas on how to do this.

In every step of the sequence, two wires are always set to opposite polarities. Because of this, it’s possible to control steppers with only two wires instead of four, with a slightly more complex circuit. The stepping sequence is the same as it is for the two middle wires of the sequence above:

The circuits for two-wire stepping are as follows:

Unipolar stepper two-wire circuit:

Biolar stepper two-wire circuit:

Programming the Microcontroller to Control a Stepper

Because both unipolar and bipolar stepper motors are controlled by the same stepping sequence, we can use the same microcontroller code to control either one. In the code examples below, connect either the Darlington transistor array (for unipolar steppers) or the dual H-bridge (for bipolar steppers) to the pins of your microcontroller as described in each example. There is a switch attached to the microcontroller as well. When the switch is high, the motor turns one direction. When it’s low, it turns the other direction.

The examples below use the 4-wire stepping sequence. A two-wire control program is shown for the Wiring/Arduino Stepper library only.

Wire pins 9-12 of the BX-24 to inputs 1-4 of the Darlington transistor array, respectively. If you’re using the PicBasic Pro code, it’s designed for a PIC 40-pin PIC such as the 16F877 or 18F452. Use pins PORTD.0 through PORTD.3, respectively. If you’re using a smaller PIC, you can swap ports, as long as you use the first four pins of the port.

Note that the wires read from left to right. Their numbers don’t correspond with the bit positions. For example, PORTD.3 would be wire 1, PORTD.2 would be wire 2, PORTD.1 would be wire 3, and PORTD.0 would be wire 4. On the BX-24, pin 9 is wire 1, pin 10 is wire 2, and so forth.

BX-24 code:

This example uses the Stepper library for Wiring/Arduino. It was tested using the 2-wire circuit. To change to the 4-wire circuit, just add two more motor pins, and change the line that initalizes the Stepper library like so:

Stepper myStepper(motorSteps, motorPin1,motorPin2,motorPin3,motorPin4);

This design allows for very precise control of the motor: by proper pulsing, it can be turned in very accurate steps of set degree increments (for example, two-degree increments, half-degree increments, etc.). They are used in printers, disk drives, and other devices where precise positioning of the motor is necessary.

There are two basic types of stepper motors, unipolar steppers and bipolar steppers.

Unipolar Stepper Motors

The unipolar stepper motor has five or six wires and four coils (actually two coils divided by center connections on each coil). The center connections of the coils are tied together and used as the power connection. They are called unipolar steppers because power always comes in on this one pole.

The bipolar stepper motor usually has four wires coming out of it. Unlike unipolar steppers, bipolar steppers have no common center connection. They have two independent sets of coils instead. You can distinguish them from unipolar steppers by measuring the resistance between the wires. You should find two pairs of wires with equal resistance. If you’ve got the leads of your meter connected to two wires that are not connected (i.e. not attached to the same coil), you should see infinite resistance (or no continuity).

Like other motors, stepper motors require more power than a microcontroller can give them, so you’ll need a separate power supply for it. Ideally you’ll know the voltage from the manufacturer, but if not, get a variable DC power supply, apply the minimum voltage (hopefully 3V or so), apply voltage across two wires of a coil (e.g. 1 to 2 or 3 to 4) and slowly raise the voltage until the motor is difficult to turn. It is possible to damage a motor this way, so don’t go too far. Typical voltages for a stepper might be 5V, 9V, 12V, 24V. Higher than 24V is less common for small steppers, and frankly, above that level it’s best not to guess.

To control the stepper, apply voltage to each of the coils in a specific sequence. The sequence would go like this:

| Step | wire 1 | wire 2 | wire 3 | wire 4 |

| 1 | High | low | high | low |

| 2 | low | high | high | low |

| 3 | low | high | low | high |

| 4 | high | low | low | high |

To control a bipolar stepper motor, you give the coils current using to the same steps as for a unipolar stepper motor. However, instead of using four coils, you use the both poles of the two coils, and reverse the polarity of the current.

The easiest way to reverse the polarity in the coils is to use a pair of H-bridges. The L293D dual H-bridge has two H-bridges in the chip, so it will work nicely for this purpose.

Once you have the motor stepping in one direction, stepping in the other direction is simply a matter of doing the steps in reverse order.

Knowing the position is a matter of knowing how many degrees per step, and counting the steps and multiplying by that many degrees. So for examples, if you have a 1.8-degree stepper, and it’s turned 200 steps, then it’s turned 1.8 x 200 degrees, or 360 degrees, or one full revolution.

Two-Wire Control

Thanks to Sebastian Gassner for ideas on how to do this.

In every step of the sequence, two wires are always set to opposite polarities. Because of this, it’s possible to control steppers with only two wires instead of four, with a slightly more complex circuit. The stepping sequence is the same as it is for the two middle wires of the sequence above:

| Step | wire 1 | wire 2 |

| 1 | low | high |

| 2 | high | high |

| 3 | high | low |

| 4 | low | low |

Unipolar stepper two-wire circuit:

Biolar stepper two-wire circuit:

Programming the Microcontroller to Control a Stepper

Because both unipolar and bipolar stepper motors are controlled by the same stepping sequence, we can use the same microcontroller code to control either one. In the code examples below, connect either the Darlington transistor array (for unipolar steppers) or the dual H-bridge (for bipolar steppers) to the pins of your microcontroller as described in each example. There is a switch attached to the microcontroller as well. When the switch is high, the motor turns one direction. When it’s low, it turns the other direction.

The examples below use the 4-wire stepping sequence. A two-wire control program is shown for the Wiring/Arduino Stepper library only.

Wire pins 9-12 of the BX-24 to inputs 1-4 of the Darlington transistor array, respectively. If you’re using the PicBasic Pro code, it’s designed for a PIC 40-pin PIC such as the 16F877 or 18F452. Use pins PORTD.0 through PORTD.3, respectively. If you’re using a smaller PIC, you can swap ports, as long as you use the first four pins of the port.

Note that the wires read from left to right. Their numbers don’t correspond with the bit positions. For example, PORTD.3 would be wire 1, PORTD.2 would be wire 2, PORTD.1 would be wire 3, and PORTD.0 would be wire 4. On the BX-24, pin 9 is wire 1, pin 10 is wire 2, and so forth.

BX-24 code:

dim motorStep(1 to 4) as byte

dim thisStep as integer

Sub main()

call delay(0.5) ' start program with a half-second delay

dim i as integer

' save values for the 4 possible states of the stepper motor leads

' in a 4-byte array. the stepMotor routine will step through

' these four states to move the motor. This is a way to set the

' value on four pins at once. The eight pins 5 through 12 are

' represented in memory as a byte called register.portc. We will set

' register.portc to each of the values of the array in order to set

' pins 9,10,11, and 12 at once with each step.

motorStep(0) = bx0000_1010

motorStep(1) = bx0000_0110

motorStep(2) = bx0000_0101

motorStep(3) = bx0000_1001

' set the last 4 pins of port C to output:

register.ddrc = bx0000_1111

' set all the pins of port C low:

register.portc = bx0000_0000

do

' move motor forward 100 steps.

' note: by doing a modulo operation on i (i mod 4),

' we can let i go as high as we want, and thisStep

' will equal 0,1,2,3,0,1,2,3, etc. until the end

' of the for-next loop.

for i = 1 to 100

thisStep = i mod 4

call stepMotor(thisStep)

next

' move motor backward

for i = 100 to 1 step -1

thisStep = i mod 4

call stepMotor(thisStep)

next

loop

End Sub

sub stepMotor(byref whatStep as integer)

' sets the value of the eight pins of port c to whatStep

register.portc = motorStep(whatStep)

call delay (0.1) ' vary this delay as needed to make your stepper step.

end sub

PicBasic Pro code:start:

High PORTB.0

' set variables:

x VAR BYTE

steps VAR WORD

stepArray VAR BYTE(4)

clear

TRISD = %11110000

PORTD = 255

input portb.4

Pause 1000

stepArray[0] = %00001010

stepArray[1] = %00000110

stepArray[2] =%00000101

stepArray[3] = %00001001

main:

if portb.4 = 1 then

steps = steps + 1

else

steps = steps - 1

endif

portD = stepArray[steps //4]

pause 2

GoTo main

pBasic (Basic Stamp 2) code:' set variables:

x var byte

stepper var nib

steps var word

' set pins 8 - 10 as outputs, using DIRS to do so:

dirs.highbyte = %00001111

main:

steps = 200

gosub clockStep

pause 1000

gosub counterClockStep

pause 1000

goto main

clockStep:

debug "counter" , cr

for x = 0 to steps

lookup x//4, [%1010,%1001,%0101,%0110], stepper

outs.highbyte.lownib = stepper

pause 2

next

return

counterclockStep:

debug "clockwise", cr

for x = 0 to steps

lookup x//4, [%0110,%0101,%1001,%1010], stepper

outs.highbyte.lownib = stepper

pause 2

next

return

Wiring Code (for Arduino board):This example uses the Stepper library for Wiring/Arduino. It was tested using the 2-wire circuit. To change to the 4-wire circuit, just add two more motor pins, and change the line that initalizes the Stepper library like so:

Stepper myStepper(motorSteps, motorPin1,motorPin2,motorPin3,motorPin4);

/*

Stepper Motor Controller

language: Wiring/Arduino

This program drives a unipolar or bipolar stepper motor.

The motor is attached to digital pins 8 and 9 of the Arduino.

The motor moves 100 steps in one direction, then 100 in the other.

Created 11 Mar. 2007

Modified 7 Apr. 2007

by Tom Igoe

*/

// define the pins that the motor is attached to. You can use

// any digital I/O pins.

#include <Stepper.h>

#define motorSteps 200 // change this depending on the number of steps

// per revolution of your motor

#define motorPin1 8

#define motorPin2 9

#define ledPin 13

// initialize of the Stepper library:

Stepper myStepper(motorSteps, motorPin1,motorPin2);

void setup() {

// set the motor speed at 60 RPMS:

myStepper.setSpeed(60);

// Initialize the Serial port:

Serial.begin(9600);

// set up the LED pin:

pinMode(ledPin, OUTPUT);

// blink the LED:

blink(3);

}

void loop() {

// Step forward 100 steps:

Serial.println("Forward");

myStepper.step(100);

delay(500);

// Step backward 100 steps:

Serial.println("Backward");

myStepper.step(-100);

delay(500);

}

// Blink the reset LED:

void blink(int howManyTimes) {

int i;

for (i=0; i< howManyTimes; i++) {

digitalWrite(ledPin, HIGH);

delay(200);

digitalWrite(ledPin, LOW);

delay(200);

}

}

XXX . XXX 4%zero null 0 1 2 3 Install DC Motor

we will explain how to do all that safely and properly so you don damage the brushes and the commutator while placing everything back as before.

Step 1: Brushes & Slot Gaps:

There is a small cleavage at the back end of every brush of most DC motors. that leave it should be identical to the one shown in the picture.

Now the slots in which the brushes are held have small gaps.These small gap gaps and cleavages are together responsible for holding the brushes when the armature is placed back.

It is really important for the brushes to be held back in their slots so that the armature can slide in easily and this can be achieved with the help of a simple wire.

Step 2: Installing the Brushes:

For installing the brushes, you will need a simple strong thin metallic wire as shown in the picture.

If your DC motor has 4 brushes, divide the wire into 4 equal parts and if it has 2 brushes then divided into two equal parts.