Air Conditioning Work

Air conditioning system

keeps your home or business cool in the hot summer months, but have you

ever wondered how it works? One interesting fact you might not know is

that your air conditioner and your refrigerator work primarily the same

way. The difference is your refrigerator cools a small, insulated space,

and an air conditioner keeps your home, office, or commercial space at a

comfortable temperature.

The entire process of making the air in your property a comfortable

temperature is based on a very simple scientific principle, and the rest

is achieved by mechanical means.

The Process of Cooling Your Home with AC

air conditioning unit uses chemicals that convert from gas to liquid and back again quickly. These chemicals transfer the heat from the air inside your property to the outside air.

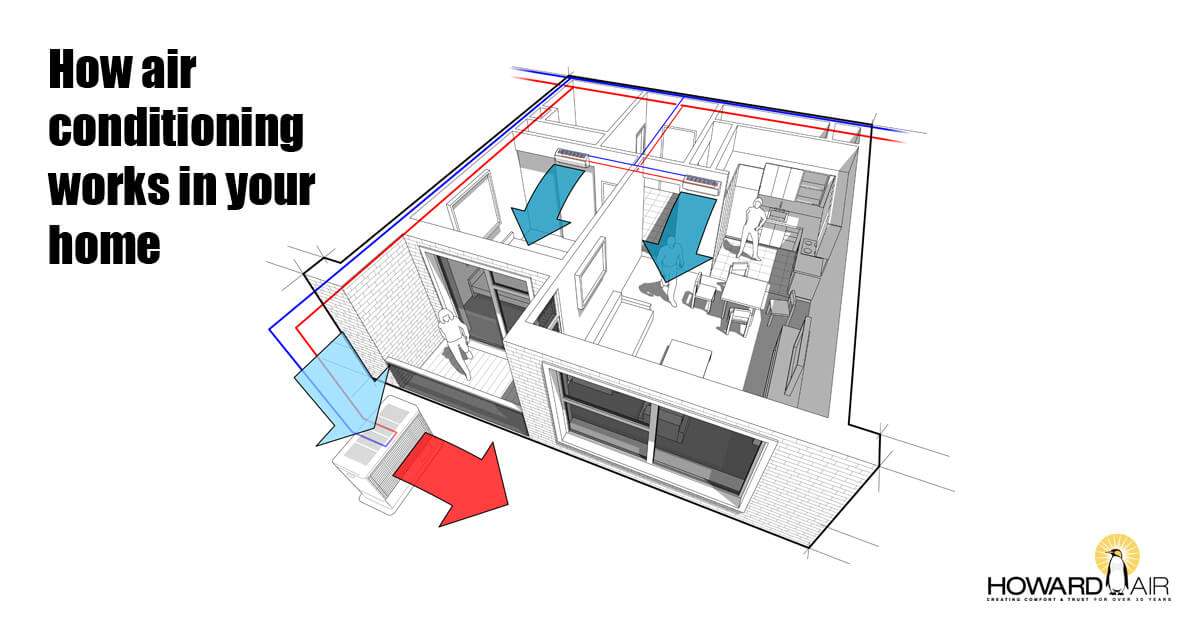

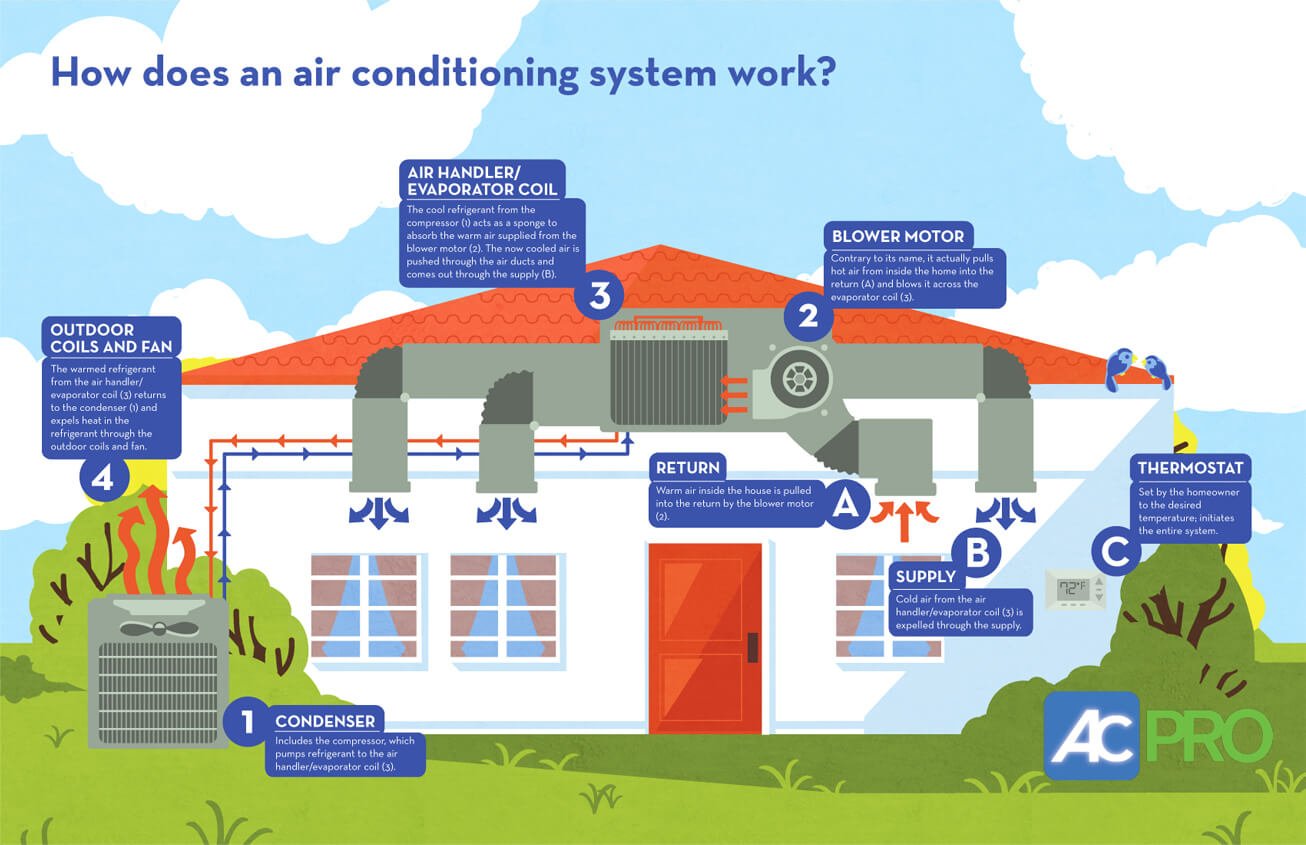

The AC unit has three key parts. These are the compressor, the

condenser, and the evaporator. Your unit’s compressor and condenser are

typically located in the outside part of the air conditioning system.

Inside the house is where you will find the evaporator.The cooling fluid reaches the compressor as a low-pressure gas. The compressor squeezes this gas/fluid, and the molecules in the liquid are packed closer together. The closer the compressor forces these molecules together, the higher the temperature and energy rise.

How Your Air Conditioner Removes Hot Air & Blows Cold Air

This is how an air conditioner works to cool your home:

This working fluid exits the compressor as a high-pressure, hot gas, and it moves to the condenser. The outside unit of an air conditioning system has metal fins all around the housing. These fins work like the radiator on a vehicle, and they help dissipate heat more quickly.

When the fluid leaves the condenser, it is much cooler. It’s also changed from a gas to liquid because of the high pressure. The fluid makes its way into the evaporator through a minuscule, narrow hole and when the liquid reaches the other side of this passage, its pressure drops. When this happens, the fluid begins to evaporate to gas.

As this occurs, the heat is extracted from the surrounding air. This heat is required to separate the molecules of the liquid into a gas. The metal fins on the evaporator also help exchange thermal energy with the surrounding air.

When the refrigerant leaves the evaporator, it is once again a low-pressure, chilled gas. The process starts all over when it goes back to the compressor. There is a fan that’s connected to the evaporator, and it circulates air around the inside of the property and across the fins of the evaporator.

The air conditioner sucks air into the ducts through a vent. This air is used to cool gas in the evaporator, and as the heat is removed from the air, it’s cooled. Ducts then blow air back into the house.

This process continues until the inside air of your home or business reaches the desired temperature. When the thermostat senses that the interior temperature is at the desired level, it shuts the air conditioner off. When the room heats up again, the thermostat turns the air conditioner back on until the preferred ambient temperature is achieved again.

How does a Air Conditioner Work?

Air conditioners work the same way as refrigerators. Instead of cooling just the inside of a refrigerator, an air conditioner cools a room, a whole house, or an office. The first modern air conditioning system was developed in 1902 by a young electrical engineer named Willis Carrier.

Principle

Air conditioners use refrigeration to chill indoor air, taking advantage of a remarkable physical law: When a liquid converts to a gas (in a process called phase conversion), it absorbs heat. Air conditioners exploit this feature of phase conversion by forcing special chemical compounds to evaporate and condense over and over again in a closed system of coils.

How Does it Work?

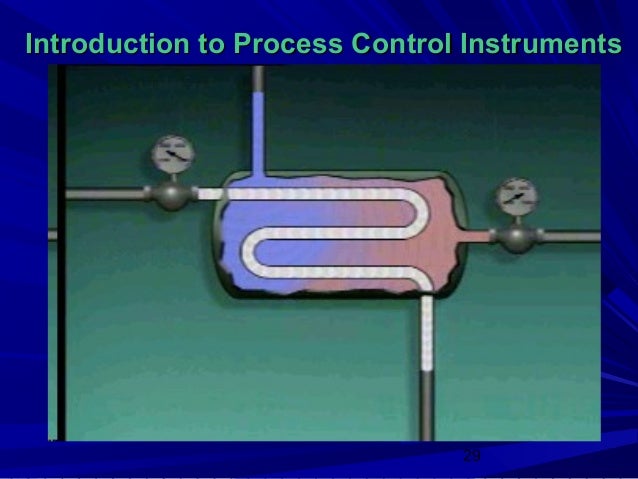

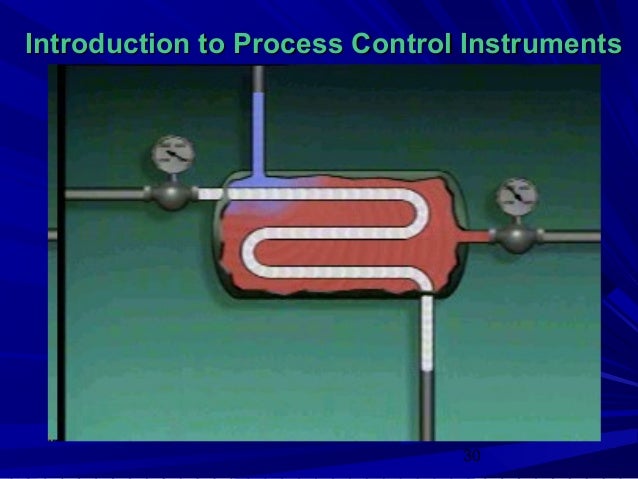

The machine has three main parts. They are a compressor, a condenser and an evaporator. The compressor and condenser are usually located on the outside. The evaporator is located on the inside of the house. When hot air in the room or house flows over the cold, low-pressure evaporator coils, the refrigerant inside absorbs heat as it changes from a liquid to a gaseous state. To keep cooling efficiently, the air conditioner has to convert the refrigerant gas back to a liquid again. To do that, a compressor puts the gas under high pressure, a process that creates unwanted heat. All the extra heat created by compressing the gas is then evacuated to the outdoors with the help of a second set of coils called condenser coils, and a second fan. As the gas cools, it changes back to a liquid, and the process starts all over again.

Air conditioners use refrigeration to chill indoor air, taking advantage of a remarkable physical law: When a liquid converts to a gas (in a process called phase conversion), it absorbs heat. Air conditioners exploit this feature of phase conversion by forcing special chemical compounds to evaporate and condense over and over again in a closed system of coils.

How Does it Work?

The machine has three main parts. They are a compressor, a condenser and an evaporator. The compressor and condenser are usually located on the outside. The evaporator is located on the inside of the house. When hot air in the room or house flows over the cold, low-pressure evaporator coils, the refrigerant inside absorbs heat as it changes from a liquid to a gaseous state. To keep cooling efficiently, the air conditioner has to convert the refrigerant gas back to a liquid again. To do that, a compressor puts the gas under high pressure, a process that creates unwanted heat. All the extra heat created by compressing the gas is then evacuated to the outdoors with the help of a second set of coils called condenser coils, and a second fan. As the gas cools, it changes back to a liquid, and the process starts all over again.

Air Conditioner or often abbreviated as AC is a device that functions to regulate the air in the room. AC is able to produce a cool room that is comfortable for its occupants. As

air conditioner, the air conditioner works by absorbing and then

cooling the air by absorbing the heat that is carried by the air with

the freon gas contained in the evaporator. Here's how the AC works briefly:

Indoor air is absorbed and then cooled by freon gas in the evaporator. The

heat energy absorbed by the Freon gas will be delivered by the gas flow

to the condensor and then discharged in the form of hot air. To

carry out the work process as above, it is necessary to have a pump

that regulates the circulation of freon in the system, the working tool

is a compressor.

Air conditioning consists of an Indoor (indoor) unit and an outdoor (outdoor) unit. The way the two units work is as we explained above.

AC damage

In general, the air conditioner will function properly if it produces cool or cold air in the room. If the air produced is not cold, the air conditioner has a problem. AC service issues include

AC not cold

AC is not cold

AC is totally dead

AC Off - live

AC is noisy

The AC can't be on the remote

AC Leaking / dirty

The

AC problem is caused by various factors which include: freon

installation leaks, electronic component damage, mechanical parts

damage, dirty units and damage to units and pipes. To

overcome the above, it is very necessary that a tool that is able to

control the damage to the air conditioner automatically without having

the technician come to the location. of course this is very helpful for you to know various ac problems from anywhere and anytime.

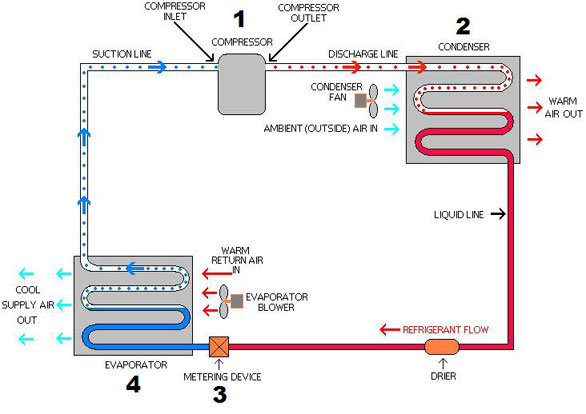

As the refrigerant passes through the metering device (3), its temperature, pressure and state change once again. Some of the low pressure liquid refrigerant instantly boils off forming “flash gas”. As this mixture of liquid and gas pass through the evaporator (4) heat is absorbed and the remaining liquid refrigerant changes it state back into a vapor. At the outlet of the evaporator 100% of the low pressure vapor flows back through the suction line to the compressor.

Specially colored coils on the window air conditioner below aid the student in visualizing and understanding the flow of the refrigerant, and the different changes in the state of the refrigerant as it traverses through the system.

What Does HVAC Stand For?

H: HEATINGV: VENTILATION

A: AIR

C: CONDITIONING

Is there only one type of home air conditioning system?

Actually, there are many options for installing air-conditioning systems into your home and many factors to consider when choosing the product that is right for you.

Split System: What is it?

Though we commonly refer to air conditioning as “central,” it’s actually most likely to be a Split System. Just as it sounds, a split system is divided into two main parts: an evaporator coil inside the home, which typically sits atop the furnace, and these units are attached by the lines/pipes to a condensing unit outside.When the temperature in your house begins to rise, warm air is drawn across the evaporator coil. The evaporator coil has a chemical inside, called a refrigerant (you will often hear people mistakenly refer to refrigerant as “Freon,” which is a brand, not the chemical) — this keeps the coil cold.

The evaporator coil absorbs warmth from the air, which causes that humidity to condense and drain away. Thus, a central air conditioning system not only reduces the temperature in your house, it also lowers the humidity.

When air conditioners pull humidity from the air, it funnels the resulting water, commonly referred to as condensate, into a drain. Though the amount can vary, people are often surprised by how much condensate a modern air conditioner will produce, which is between 5 and 20 gallons of water per day! Central air conditioners are connected to the plumbing in your home, so there is always an exit for condensate.

It’s only when these outlets are blocked that leaks occur inside the home. If this happens, call an HVAC professional as soon as possible to fix the issue and prevent further damage.

Refrigerant running through the lines contributes to the cooling aspect of an air conditioning system. If you currently have an air conditioning system in your residential home, this is probably what you have. A detached home usually has ductwork, either located in the attic or under a crawl space. While the condenser and evaporator coil work to dehumidify and cool the home, the ducts help facilitate the forced air process of the split system — this moves the air internally to reach the registers that push air into individual rooms/spaces.

It is important to note that the ductwork is what centralizes the system — it is a closed circuit that continues the same process in order to maintain a set temperature in your home.

A central split system is most ideal for whole-house temperature control. Though it is possible to set up a zoning system to control certain areas, if you are looking to cool separate spaces, a ductless mini split is the way to go.

The biggest job an air conditioner has to do is to cool the indoor

air. That's not all it does, though. Air conditioners monitor and

regulate the air temperature via a thermostat. They also have an onboard filter that removes airborne particulates from the circulating air. Air conditioners function as dehumidifiers.

Because temperature is a key component of relative humidity, reducing

the temperature of a volume of humid air causes it to release a portion

of its moisture. That's why there are drains and moisture-collecting

pans near or attached to air conditioners, and why air conditioners

discharge water when they operate on humid days.

Still, the major parts of an air conditioner manage refrigerant and move air in two directions: indoors and outside:

- Evaporator - Receives the liquid refrigerant

- Condenser - Facilitates heat transfer

- Expansion valve - regulates refrigerant flow into the evaporator

- Compressor - A pump that pressurizes refrigerant

Although this is a conventional setup for an air conditioner, there are a couple of variations you should know about. Window air conditioners have all these components mounted into a relatively small metal box that installs into a window opening. The hot air vents from the back of the unit, while the condenser coils and a fan cool and re-circulate indoor air. Bigger air conditioners work a little differently: Central air conditioners share a control thermostat with a home's heating system, and the compressor and condenser, the hot side of the unit, isn't even in the house. It's in a separate all-weather housing outdoors. In very large buildings, like hotels and hospitals, the exterior condensing unit is often mounted somewhere on the roof.

Window and Split-system AC Units

A window air conditioner unit implements a complete air conditioner in a small space. The units are made small enough to fit into a standard window frame. You close the window down on the unit, plug it in and turn it on to get cool air. If you take the cover off of an unplugged window unit, you'll find that it contains:

- A compressor

- An expansion valve

- A hot coil (on the outside)

- A chilled coil (on the inside)

- Two fans

- A control unit

When you get into larger air-conditioning applications, its time to start looking at split-system units. A split-system air conditioner splits the hot side from the cold side of the system, as in the diagram below.

The cold side, consisting of the expansion valve and the cold coil, is generally placed into a furnace or some other air handler. The air handler blows air through the coil and routes the air throughout the building using a series of ducts. The hot side, known as the condensing unit, lives outside the building.

The unit consists of a long, spiral coil shaped like a cylinder. Inside the coil is a fan, to blow air through the coil, along with a weather-resistant compressor and some control logic. This approach has evolved over the years because it's low-cost, and also because it normally results in reduced noise inside the house (at the expense of increased noise outside the house). Other than the fact that the hot and cold sides are split apart and the capacity is higher (making the coils and compressor larger), there's no difference between a split-system and a window air conditioner.

In warehouses, large business offices, malls, big department stores and other sizeable buildings, the condensing unit normally lives on the roof and can be quite massive. Alternatively, there may be many smaller units on the roof, each attached inside to a small air handler that cools a specific zone in the building.

In larger buildings and particularly in multi-story buildings, the split-system approach begins to run into problems. Either running the pipe between the condenser and the air handler exceeds distance limitations (runs that are too long start to cause lubrication difficulties in the compressor), or the amount of duct work and the length of ducts becomes unmanageable. At this point, it's time to think about a chilled-water system.

Chilled-water and Cooling-tower AC Units

Although standard air conditioners are very popular, they can use a lot of energy and generate quite a bit of heat. For large installations like office buildings, air handling and conditioning is sometimes managed a little differently.

Some systems use water as part of the cooling process. The two most well-known are chilled water systems and cooling tower air conditioners.

- Chilled water systems - In a chilled-water system, the entire air conditioner is installed on the roof or behind the building. It cools water to between 40 and 45 degrees Fahrenheit (4.4 and 7.2 degrees Celsius). The chilled water is then piped throughout the building and connected to air handlers. This can be a versatile system where the water pipes work like the evaporator coils in a standard air conditioner. If it's well-insulated, there's no practical distance limitation to the length of a chilled-water pipe.

- Cooling tower technology - In all of the air conditioning systems we've described so far, air is used to dissipate heat from the compressor coils. In some large systems, a cooling tower is used instead. The tower creates a stream of cold water that runs through a heat exchanger, cooling the hot condenser coils. The tower blows air through a stream of water causing some of it to evaporate, and the evaporation cools the water stream. One of the disadvantages of this type of system is that water has to be added regularly to make up for liquid lost through evaporation. The actual amount of cooling that an air conditioning system gets from a cooling tower depends on the relative humidity of the air and the barometric pressure.

Another option is geo-thermal heating. It varies, but at around 6 feet (1.8 meters) underground, the earth's temperature ranges from 45 to 75 degrees Fahrenheit (7.2 to 23.8 degrees Celsius). The basic idea behind geo-thermal cooling is to use this constant temperature as a heat or cold source instead of using electricity to generate heat or cold. The most common type of geo-thermal unit for the home is a closed-loop system. Polyethylene pipes filled with a liquid mixture are buried underground. During the winter, the fluid collects heat from the earth and carries it through the system and into the building. During the summer, the system reverses itself to cool the building by pulling heat through the pipes to deposit it underground.

For real energy efficiency, solar powered air conditioners are also making their debut. There may still be some kinks to work out, but around 5 percent of all electricity consumed in the U.S. is used to power air conditioning of one type or another, so there's a big market for energy-friendly air conditioning options .

BTU and EER

Most air conditioners have their capacity rated in British thermal units (Btu). A Btu is the amount of heat necessary to raise the temperature of 1 pound (0.45 kilograms) of water one degree Fahrenheit (0.56 degrees Celsius). One Btu equals 1,055 joules. In heating and cooling terms, one ton equals 12,000 Btu.

A typical window air conditioner might be rated at 10,000 Btu. For comparison, a typical 2,000-square-foot (185.8 square meters) house might have a 5-ton (60,000-Btu) air conditioning system, implying that you might need perhaps 30 Btu per square foot. These are rough estimates. To size an air conditioner accurately for your specific application, you should contact an HVAC contractor.

The energy efficiency rating (EER) of an air conditioner is its Btu rating over its wattage. As an example, if a 10,000-Btu air conditioner consumes 1,200 watts, its EER is 8.3 (10,000 Btu/1,200 watts). Obviously, you would like the EER to be as high as possible, but normally a higher EER is accompanied by a higher price.

Let's say you have a choice between two 10,000-Btu units. One has an EER of 8.3 and consumes 1,200 watts, and the other has an EER of 10 and consumes 1,000 watts. Let's also say that the price difference is $100. To determine the payback period on the more expensive unit, you need to know approximately how many hours per year you will be operating the air conditioner and how much a kilowatt-hour (kWh) costs in your area.

Assuming you plan to use the air conditioner six hours a day for four months of the year, at a cost of $0.10/kWh. The difference in energy consumption between the two units is 200 watts. This means that every five hours the less expensive unit will consume one additional kWh (or $0.10) more than the more expensive unit.

Let's do the math: With roughly 30 days in a month, you're operating the air conditioner:

4 months x 30 days per month x 6 hours per day = 720 hours

[(720 hours x 200 watts) / (1000 watts/kilowatt)] x $0.10/kilowatt hours = $14.40

The more expensive air conditioning unit costs $100 more to purchase but less money to operate. In our example, it'll take seven years for the higher priced unit to break even.

Energy Efficient Cooling Systems

Because of the rising costs of electricity and a growing trend to "go green," more people are turning to alternative cooling methods to spare their pocketbooks and the environment. Big businesses are even jumping on board in an effort to improve their public image and lower their overhead.

Ice cooling systems are one way that businesses are combating high electricity costs during the summer. Ice cooling is as simple as it sounds. Large tanks of water freeze into ice at night, when energy demands are lower. The next day, a system much like a conventional air conditioner pumps the cool air from the ice into the building. Ice cooling saves money, cuts pollution, eases the strain on the power grid and can be used alongside traditional systems. The downside of ice cooling is that the systems are expensive to install and require a lot of space. Even with the high startup costs, more than 3,000 systems are in use worldwide .

An ice cooling system is a great way to save money and conserve energy, but its price tag and space requirements limit it to large buildings. One way that homeowners can save on energy costs is by installing geo-thermal heating and cooling systems, also known as ground source heat pumps (GSHP). The Environmental Protection Agency recently named geo-thermal units "the most energy-efficient and environmentally sensitive of all space conditioning systems" .

Although it varies, at six feet underground the Earth's temperatures range from 45 to 75 degrees Fahrenheit. The basic principle behind geo-thermal cooling is to use this constant temperature as a heat source instead of generating heat with electricity.

The most common type of geo-thermal unit for homes is the closed-loop system. Polyethylene pipes are buried under the ground, either vertically like a well or horizontally in three- to six-foot trenches. They can also be buried under ponds. Water or an anti-freeze/water mixture is pumped through the pipes. During the winter, the fluid collects heat from the earth and carries it through the system and into the building. During the summer, the system reverses itself to cool the building by pulling heat from the building, carrying it through the system and placing it in the ground .

Homeowners can save 30 to 50 percent on their cooling bills by replacing their traditional HVAC systems with ground source heat pumps. The initial costs can be up to 30 percent more, but that money can be recouped in three to five years, and most states offer financial purchase incentives. Another benefit is that the system lasts longer than traditional units because it's protected from the elements and immune to theft .

Passive cooling is the greenest of trends and a great way to save money. Passive cooling revolves around the concept of removing warm air from your home using the interaction between the house and its surroundings. There are several ways to block and remove heat, including shading through landscaping, using a dark exterior paint, installing a radiant barrier in the roof rafters and good old- fashioned insulation. Another way is through thermal siphoning, the process of removing heat through controlled airflow. Opening the lower windows on the breezy side of your house and the upper windows on the opposite side creates a vacuum that draws out the hot air. Ceiling fans and roof vents are other ways to direct heat out at low cost .

XO___XO These 3 New Devices Can Suck Water From The Air

Even in the middle of a desert, the device can pull drinking water out of thin air. “We’re using air, sunlight, and salt, and we’re making water,”. The Silicon Valley lab to work on technologies that can help solve the growing global problem of drought.By pushing air over salt, the SunToWater device–that’s it in the bottom left of the house in the picture above–can suck drops of water out of the air and then pull the water out of the salt when it needs to be used. It’s designed to work even in the driest air in the planet. We created an artificial environment with 14% relative humidity, and we were still able to produce water. Wherever people can live, it can provide water.” .

if people want to take their house off of the water grid, the same way that they took their house off of the power grid using solar panels, they could put one or two units in their home and they’d be water independent.”Even if the technology was used at a large scale, the startup says it wouldn’t have an effect on the weather. “The water cycle is truly enormous . water in what is essentially an ocean above our heads. If you were to prick your finger and drop a little bit of blood into the ocean at the beach, have you bloodied the ocean? Technically, yes, but statistically, not at all. That’s the same principle here.”The catch: The technology is right now even more expensive than desalination. desalination only makes sense along the coast, where ocean water is plentiful.“If you want to move desalinated water inland, you either need to build a billion-dollar pipe infrastructure, or you need to pipe water, which leaves you with the uncomfortable problem of burning gasoline to move a small amount of water,” Taking water from air, on the other hand, can happen anywhere.SunToWater, which is a spinoff from the electronics company Flextronics, isn’t the only startup working on this type of device.

“We’re mimicking the spiderweb in the morning, where the dew droplets would appear in the surface of the fiber, but on a big scale,” a process that used to happen more naturally–redwoods and some other trees also collect fog and drip it down to their roots, but as trees have been cut down, some of that has been lost. Producing water was actually an unintended benefit: The company started by trying to find a new way to produce wind power. While most wind power requires high wind speeds–around 20 miles an hour–the new machine works with winds as low as two miles an hour, when it’s barely possible to feel a breeze. The device compresses air to store it, but as the engineers designed the device, they realized it only worked with dry air. They had to squeeze humidity out of the air–and that meant they suddenly had a new source of water. “It isn’t just a wind-driven energy device, but a water-extracting device that doesn’t require energy to work. It produces water and produces energy, solving two problems at once.”

Each unit can produce between three and 120 million gallons of water in a year. “The small units are more for natural disaster or emergency response, or remote communities,” the large-scale devices could compete with large wind or solar farms. A better position to take on global environmental challenges than more established companies, even those already working in something like renewable energy. “If you look at water and wind, even to some extent solar, there haven’t been real breakthroughs in the last 40 years. … If you look at wind, the turbines are much the same as they were in the 1980s . We think we live in interesting times because now there’s high pressure to serve the environment, climate change, water problems, and small companies can really address these problems fast.” We thinks there’s room for several new startups in the space.

solar panels turn air into drinking water

Water circuit analogy to electric circuit

Atmospheric Water Generation

An

atmospheric water generator (AWG) is a device that extracts water from

humid ambient air. Water vapor in the air is condensed by cooling the

air below its dew point, exposing the air to desiccants, or pressurizing

the air. Unlike a dehumidifier, an AWG is designed to render the water

potable. AWGs are useful where pure drinking water is difficult or

impossible to obtain, because there is almost always a small amount of

water in the air that can be extracted. The two primary techniques in

use are cooling and desiccants

small

water from air generator that provides renewable source of clean and

fresh drinking water for homes and offices. Requiring no infrastructure

what so ever but electricity, it is literally a plug and drink solution,

that can be installed in minutes anywhere, eliminating the daily

dependency on bottled water.

XO___XO++DW Instrument And Control

XO___XO ++DW DW Sensors of temperature, humidity and flow for air conditioning equipment

How do portable air conditioners work?

An intelligent system at work

Monobloc portable air conditioners are equipped with a refrigeration system and elements that are in a single compartment and a ventilation hose that exhausts warm air out. For added comfort, it is best to place the end of the hose outside the room where the air conditioner is placed.The principle is that portable air conditioners capture hot air, process it, and then evacuate it through the exhaust duct.

Reversible models work the same way, however, in winter, they treat cold air, which is warmed and diffused throughout the room.

Easy installation

Contrary to popular belief, it is very easy to install mobile air conditioners . Indeed, this can be done by almost anyone and does not require the presence of a professional. Simply connect the unit to the wall outlet, set it to the temperature you require and it’s ready to go.If you want the cooling unit to circulate cool air in other rooms in your home, you can simply switch it off and wheel it into another room. Once you have reached the right location, plug it in again and set it to run.

Easy upkeep

Unlike large wall air conditioners, it is very easy to service portable air conditioners . In fact, they just need to be cleaned regularly with a natural-fiber cloth. The filter should be removed and washed every two weeks, and the whole unit thoroughly cleaned once a year.

A nice, simple setup allowed by the LG

In terms of deep cleaning and maintenance, all you need to do is check that the cooling system is working well .

Wrapping up : how do portable air conditioners work?

Now you know how these devices can keep you cool in summer and bring some warmth in winter.

Sensors of temperature, humidity and flow for air conditioning equipment

One of the tasks of air-conditioning, depending on the existing internal and external effects, is to provide optimal temperature in the air-conditioned room. The company Sensit s.r.o. is engaged in development and production of temperature sensors that are integral components of air-conditioning systems and units.

The most important customers of the company Sensit s.r.o. include manufacturers of air-conditioning and cooling units as well as installation companies that are supported by sale warehouses of our business representatives within territory of the Czech Republic and Slovakia and other countries not only inside the EU.

MEASUREMENT OF TEMPERATURE IN A ROOM

S 110

K 110

S 100

MEASUREMENT OF TEMPERATURE OF RETURN WATER

TR 080

S 140

S 150A

MEASUREMENT OF SUPPLY AIR TEMPERATURE

MINI

S 120

PTS 4x a PTS 6x

HUMIDITY SENSORS

PTSV 110

PTSV 120

PTSV 130

FLOW SENSORS AND SWITCHES

Flow sensors are designed for contact measurement of flow rate of

gaseous media. Flow switches are designed for switching on load when air

flow set value has been achieved. By combining the flow sensor or

switch and the central holder, it is possible to use the meter in air

conditioning ducts or pipes with voltage outputs.

sensors are in an Inverter air conditioner

a

lot, there are the cut off pressure sensors that stop it from going

beyond limits(ie. too much refrigerant pressure on high pressure side).

Temperature sensors include inlet temp (room temp) coil temp (used for

heating, as the a/c will wait till the coil has warmed up before turning

on the fan for heating), and the temperature of the outside coil (for

heating, deciding for defrost mode).

Air conditioning sensors and switches

Air Conditioner Cutout Relay

The air conditioner (A/C) cutout relay is designed to shut off the air conditioner compressor, by disengaging the A/C compressor clutch. Normally, when the air conditioner is active, the compressor users power from a fan belt to convert refrigerant (R12 or R134a, often referred to as Freon™) from a gas to a liquid. This takes a great deal of power. If the air conditioning compressor clutch is disengaged, the pulley will spin but the compressor won't operate, reducing drag on the engine. There are several normal conditions when the cutout relay is activated:- When the throttle position sensor indicates a wide open throttle (WOT) — in other words, when the gas pedal is floored — the logic module sends a signal to the A/C cutout relay to disengage the air conditioning (A/C) compressor clutch, so more of the engine’s power can be used for acceleration.

- The A/C cutout relay keeps the clutch disengaged for 10 seconds after the engine has started, partly to avoid stalling, and partly so the logic module can accurately set the target idle using the AIS motor.

- If the idle drops below 500 rpm, the logic module disengages the A/C clutch to prevent the engine from stalling.

A/C Damped Pressure Switch

The air conditioning (A/C) damped pressure switch is used by the logic module to determine if the A/C clutch is engaged. This information is used to adjust the opening of the AIS motor to compensate for the extra load that the A/C compressor exerts on the engine. This adjustment adjusts the idle (typically to 1000 RPM) to insure proper A/C performance at idle.On manual transmission cars, the AIS motor holds the idle speed up just a second longer than automatics, so that the compressor load will not pull the RPMs down too fast as you shift, and cause jerky shifting.

Smart Sensors Enable Smart Air Conditioning Control

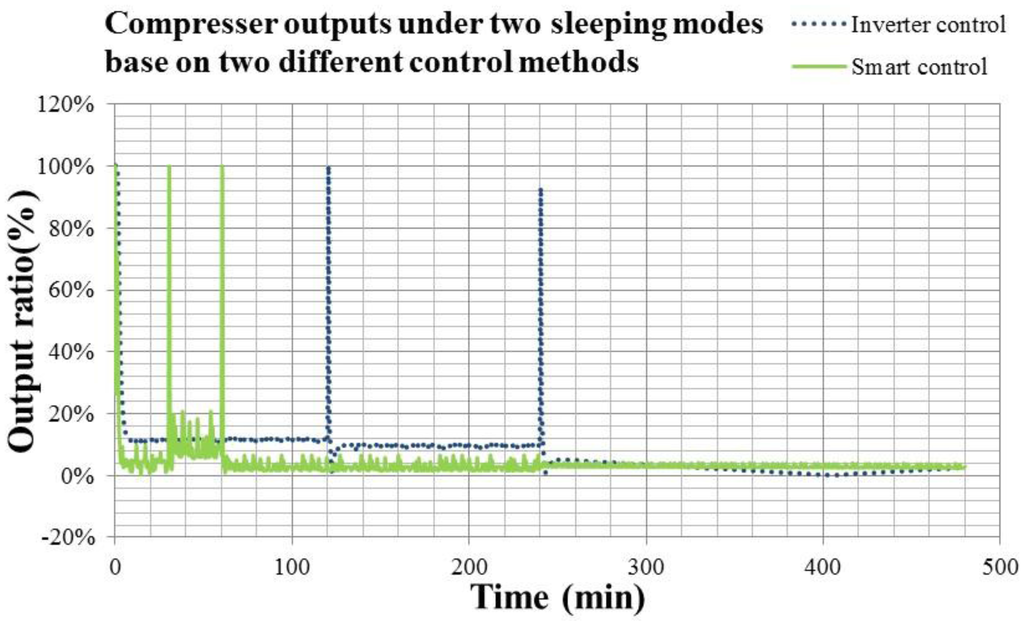

In this study, mobile phones, wearable devices, temperature and human motion detectors are integrated as smart sensors for enabling smart air conditioning control. Smart sensors obtain feedback, especially occupants' information, from mobile phones and wearable devices placed on human body. The information can be used to adjust air conditioners in advance according to humans' intentions, in so-called intention causing control. Experimental results show that the indoor temperature can be controlled accurately with errors of less than ±0.1 °C. Rapid cool down can be achieved within 2 min to the optimized indoor capacity after occupants enter a room. It's also noted that within two-hour operation the total compressor output of the smart air conditioner is 48.4% less than that of the one using On-Off control. The smart air conditioner with wearable devices could detect the human temperature and activity during sleep to determine the sleeping state and adjusting the sleeping function flexibly. The sleeping function optimized by the smart air conditioner with wearable devices could reduce the energy consumption up to 46.9% and keep the human health. The presented smart air conditioner could provide a comfortable environment and achieve the goals of energy conservation and environmental protection.

Keywords:

smart sensors; mobile phone; smart air conditioner; intention causing control; energy conservation; human comfort1. The Development of Air Conditioning Technology

For a higher quality and comfortable modern lifestyle, people rely on air conditioners (ACs) much more than before. In both developed and developing countries, ACs increase the occupancy ratio of building areas. This also leads to a rapid growth in the energy consumption by ACs. According the static data [1], HVAC almost consumed half of the energy in buildings and 20% of the overall national energy consumption. Therefore, it is important to decrease the energy consumption of ACs in residential and commercial buildings.The methods of developing new energy-efficient equipment, applying complex control strategies, using solar energy as a new energy source, etc., are all being considered for saving energy in ACs. Among them, applying control strategies may be the more economical and efficient method. Energy-efficient control strategies for controlling variable speed pumps in a central AC are illustrated by Ma and Wang [2]. The results show that the energy consumption of pumps can be lowered by using these control strategies. A feedback controller for ACs is designed and improves the energy efficiency of an AC [3]. Zhao et al. [4] presented a temperature- and humidity-independent control strategy to reduce the energy consumption of an AC in an office building. The experimental results show that the strategy can provide a better coefficient of performance of the AC and a comfortable indoor environment even in very hot and humid weather. For multi-unit ACs, a fuzzy logic control strategy is used to control the operational number of compressors and fans to enhance energy efficiency [5]. The previous researches of applying control strategies on ACs are based on the difference of parameters and cause the reaction. This is one kind of passive responses and may not be suitable for human comfort.

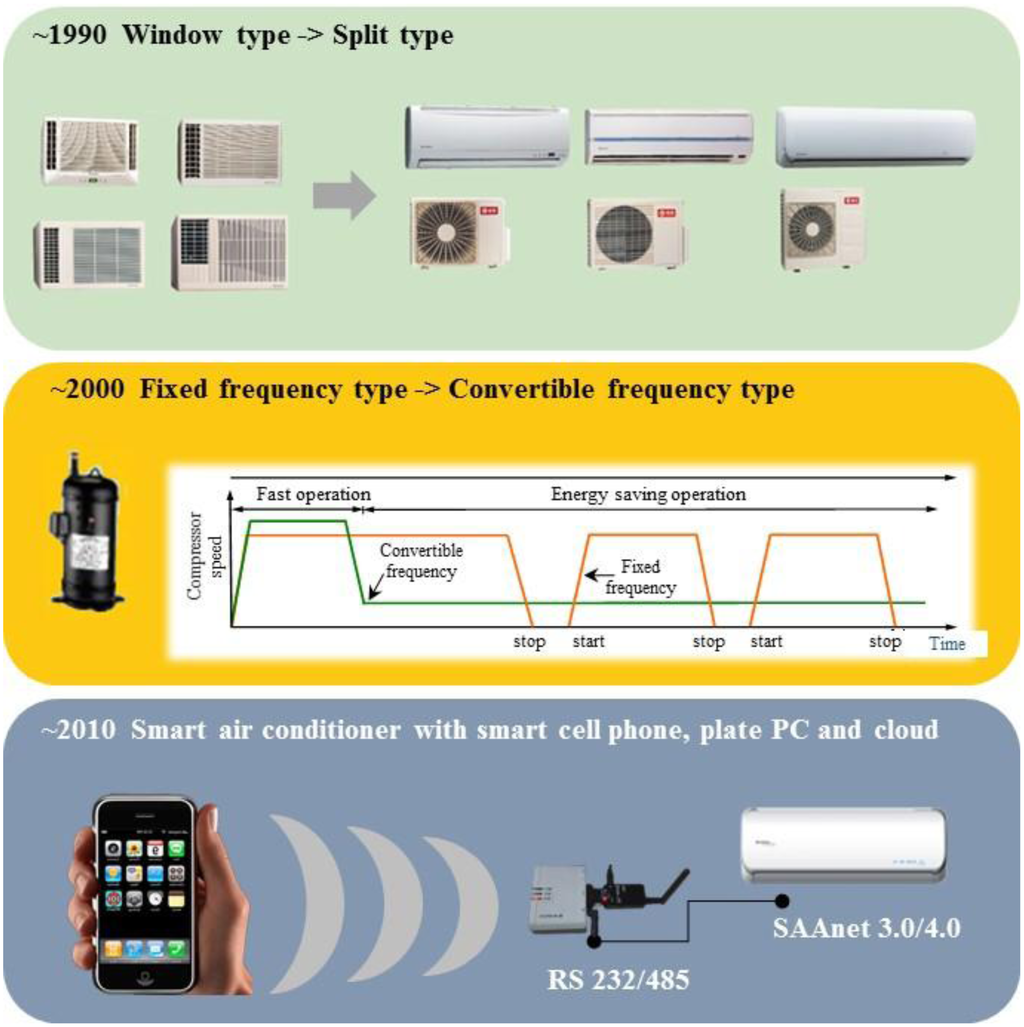

The developing history of ACs is related to the efficiency, technology, human comfort, and energy consumption. ACs' progress includes window type, split type, fixed frequency, convertible frequency, and the recently presented smart type. In the 1990s, in order to reduce noise and satisfy consumers, window type air conditioners was modified to the split type by moving the compressor outdoors. Since 2000, the high oil price and the demands for energy conservation have forced the control of compressors to be modified from fixed frequency to convertible. The fixed frequency control of compressors adopts full power as the On-Off output, and causes temperature variations and waste of energy. However, by using an electronic expansion valve, the modified convertible frequency control could adjust the compressor output and the flow rate of refrigerant continuously according to the indoor thermal mass for energy conservation.

Since 2010, mobile phones (also called smart phones), tablet personal computers, and cloud computing and 4th generation (4G) communication in 2014 were widely utilized and have caused an information revolution. These novel technologies were also adopted for the control of air conditioners, and this resulted in further air conditioning technology improvements to become smart air conditioners [6,7]. By using communication technologies, the adjustment of air conditioners is not only a single feedback of setting information. A smart air conditioner can be combined with an infrared sensor for human position sensing [8], meteorological webs for outdoor weather information, wearable devices for human activity and intention awareness. Henceforth, air conditioners are expected to adjust the indoor temperature efficiently considering human comfort and energy conservation. The development of the control of the air conditioner is briefly illustrated in Figure 1.

Figure 1.

Development of air conditioning technology: (a) From widow air conditioner to split type, (b) fixed to convertible frequency, the Inverter control air conditioner (c) smart air conditioner.

2. Mathematical Modeling of Air Conditioning Control

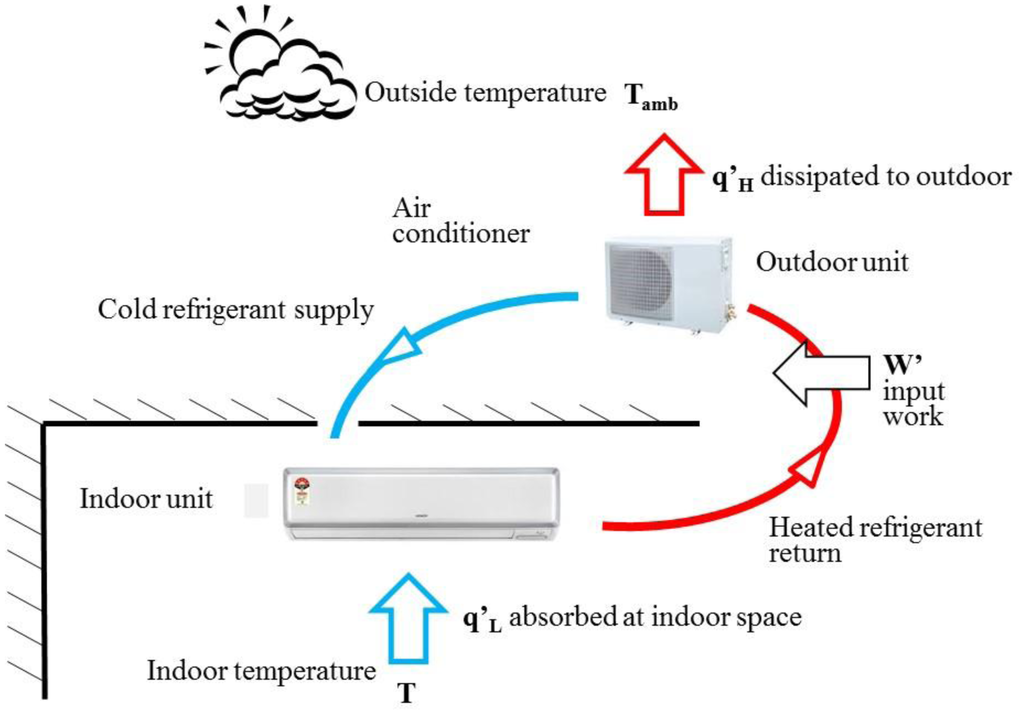

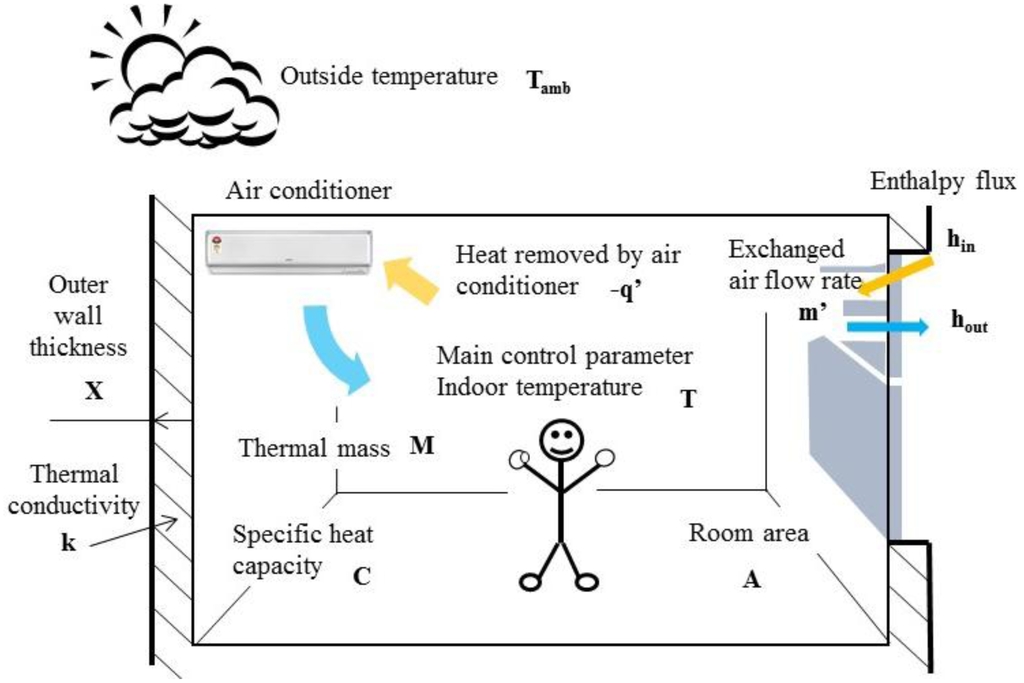

This study focused on smart control of air conditioners using mobile phones and wearable devices as smart sensors. It's the newest trend in air conditioner development. Before introducing the design, a mathematical model of air conditioning control is derived from fundamental theorems. That would help to illustrate the following concepts clearly. The fundamental operating principle of the air conditioner is the vapor cycle introduced by thermodynamics [9]. The vapor cycle includes the following steps: (1) the saturated refrigerant is compressed to a higher pressure vapor, known as superheated vapor; (2) rejecting heat from the system by either the circulating water or air and is condensed into saturated liquid; (3) undergoing an abrupt reduction in pressure through the throttle and expansion process, and becoming a liquid and vapor refrigerant mixture with lower temperature and pressure; (4) absorbing the heat of an enclosed space by a circulating fan in the evaporator and expands into the saturated vapor; (5) vapor is routed back into the compressor to complete cooling cycle by cycle. The vapor cycle includes compression, heat extraction, expansion, and heat absorption. This process is accomplished by the compressor, condenser, expansion valve and evaporator [10]. The detailed operating principles of the vapor cycle include the variation of temperature, pressure, enthalpy and entropy, described in [10].For a traditional window type air conditioner, these four devices were installed in an air conditioner to carry out the vapor cycle and cool down the closed space. The traditional window type air conditioner has almost been 90% replaced by the split type recently in Taiwan. The compressor and condenser of the split type air conditioner are organized in the outdoor unit to avoid the compressor noise. The expansion valve and evaporator are organized as the indoor unit. One advantage of split type air conditioner is its quietness, and this has made it become the main trend of air conditioners for home and business. Figure 2 presents the operating procedures of the split type air conditioner. In this study, smart design is only applied to split type air conditioners since they are the main air conditioning product used in Taiwan.

Figure 2.

Working principals of a split type air conditioner. Smart control design will be applied to this type of air conditioner.

The relationship between the input power w', absorbed heat flow qL and rejected heat flow qH could be determined by the 1st Law (energy conservation equation) and 2nd Law (Clausius theorem) laws of thermodynamics, as shown in Equations (1) and (2):

The circulation integral in Equation (2) includes the four air conditioning processes, i.e., compression, rejection of heat, evaporation, and heat absorbtion. According to Equation (2), the air conditioner needs the input power to remove the heat flow from indoor to outdoor. Therefore, Equation (2) can be rewritten as:

The efficiency and energy saving inferences of air conditioner mentioned in Equations (1)–(6) are in the steady state, i.e., d/dt→0. However, the practical air conditioning space is in the time variant state. Whether the air conditioning system is energy saving or not cannot be decided only by the indoor and outdoor temperature, especially when there is the controlling system to consider and the energy saving ratio is time variant.

In order to simulate the time variant situation, the governing equation of hydrodynamics, the mentioned Navier-Stokes equations [11], is necessary. The equations set, including the mass conservation, momentum conservation and energy conservation, is adopted for analyzing the temperature drop process caused by the air flow from the air conditioner in the closed space. To avoid a complex situation, the prototype of Navier-Stokes equations, Reynolds transport theorem, is utilized to analyze the energy balance process of indoor space under the air circulating environment. The Reynolds transport theorem is described as:

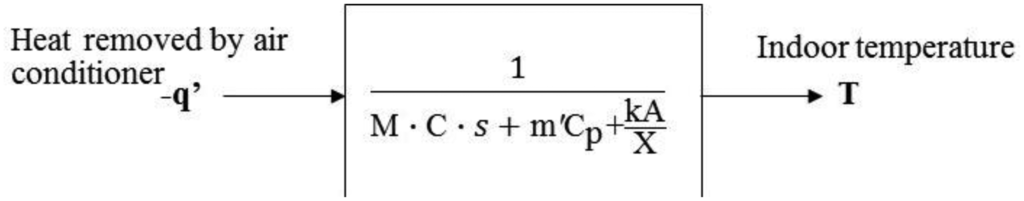

Figure 4.

Transfer function model of air conditioning space converting from Mathematical modeling.

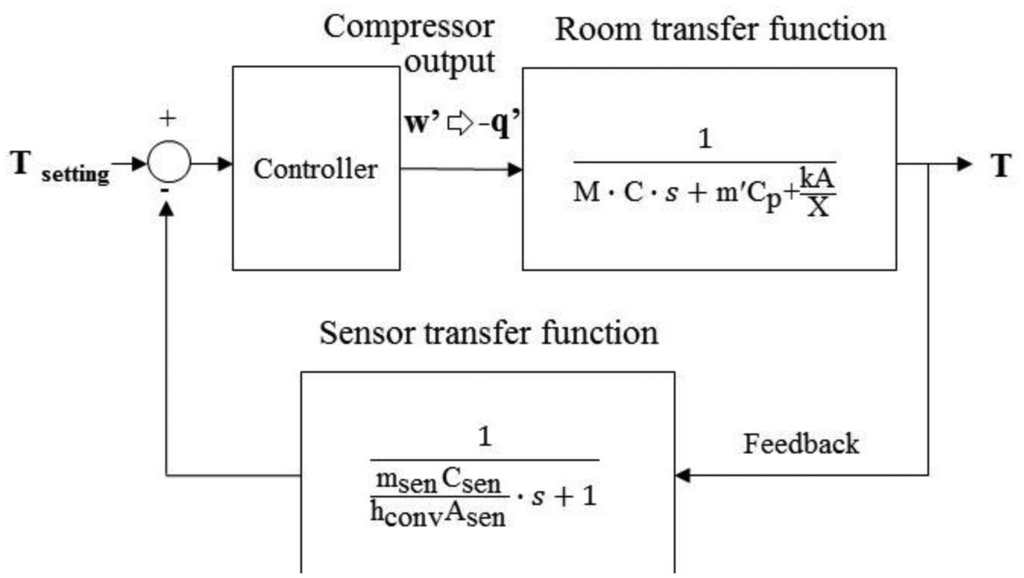

Figure 5.

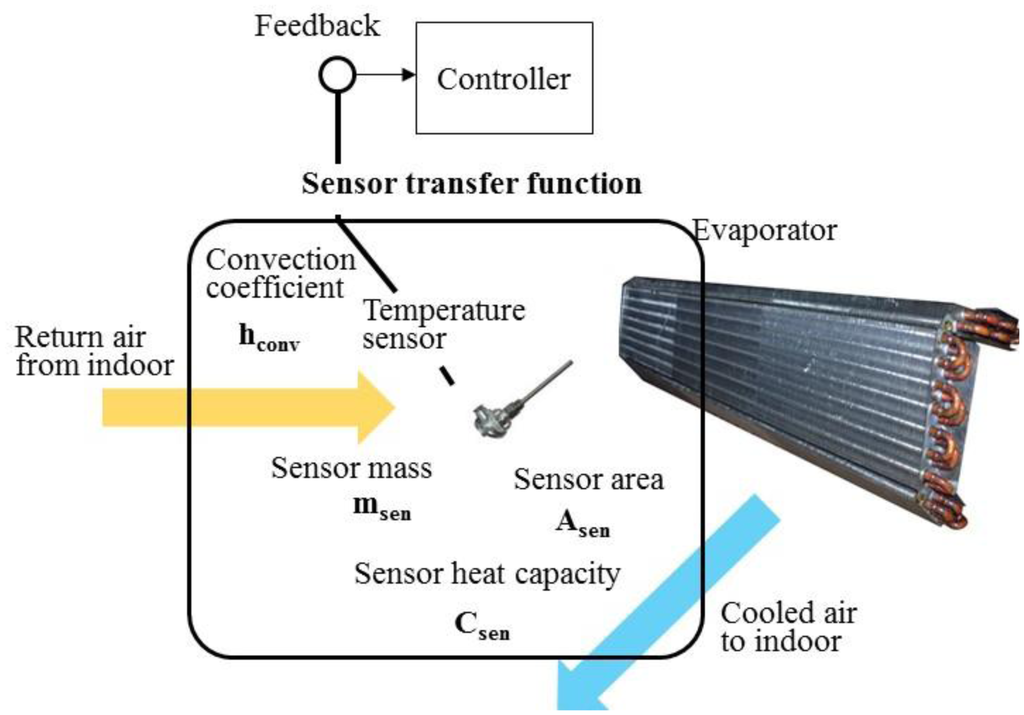

A closed-loop air conditioning space model with the feedback signal of temperature sensor.

Figure 6.

Traditional air conditioner uses a temperature sensor installed on

the evaporator of indoor unit for feedback control. It yields a sensor

transfer function to enable the difference causing control.

The room transfer functions of air conditioning space, sensor and controller are organized to simulate the responses of indoor temperature and compressor output for air conditioning control design. As illustrated in Figure 6, a traditional air conditioner uses a temperature sensor for feedback. It causes differences causing control problems. That means the control output relies on sensing differences between setting point and real feedback signal. The difference causing control works for either fixed or convertible frequency air conditioners. By error status feedback from sensor, the compressor of fixed frequency air conditioner is switched on or off, so called On-Off control. With respect to errors, the convertible frequency one changes compressor output power to the adjust room temperature by inverter control.

As illustrated in Figure 1, these two methodologies have been transformed to smart control. By communication with a mobile phone, the novel air conditioner has the ability to get human intention feedback. For an example, the global position system (GPS) on mobile phone may sense that man will come home immediately. Then the air conditioner can directly cool down the space before sensing the temperature differences. It's thus called intention causing control. That's also the main development of smart air conditioner for reaching the goals of human comfort and energy conservation. The design will be discussed in detail in the following section.

Figure 3.

Mathematical modeling of temperature control in the air conditioning space.

3. Smart Controller Design Based on Smart Sensors

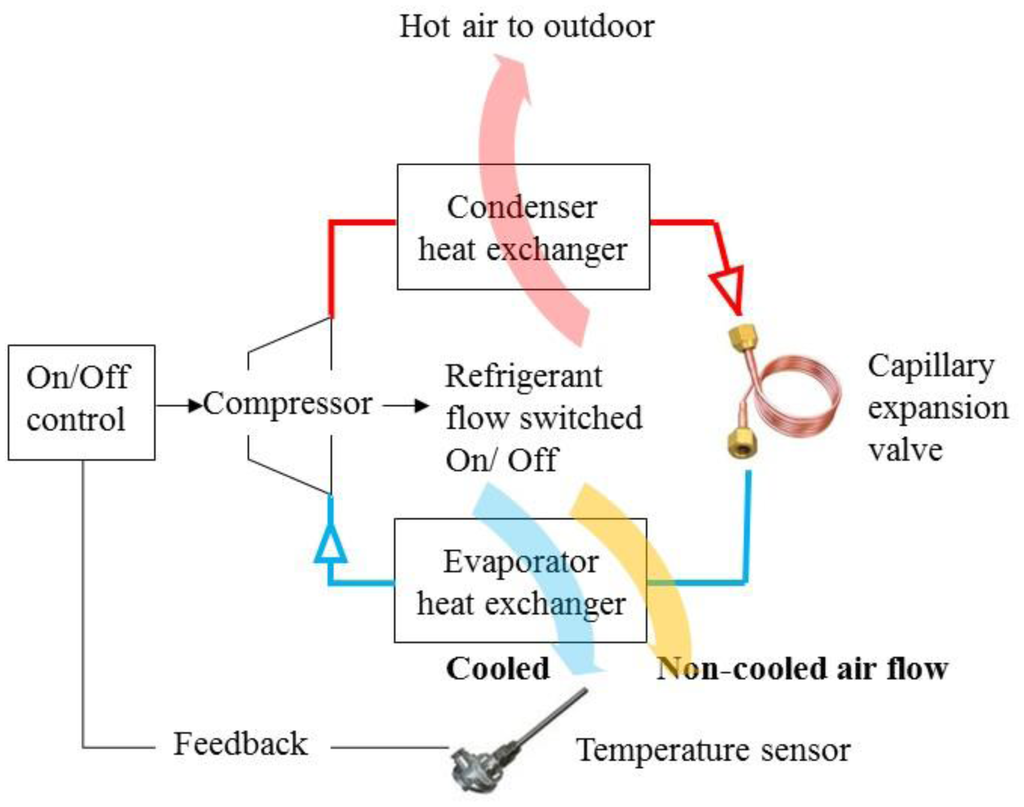

Before introducing the smart control, the On-Off and Inverter control are briefly described in the following two sub-sections. Both of them, compared with smart control, represent the difference causing control. Then the smart sensors, including mobile phone, wearable device and other sensors, are introduced. They are the key elements to determine human intentions. Finally, the design of a smart controller based on smart sensors is illustrated to illustrate the intention causing control.3.1. On-Off Control of the Fixed Frequency Air Conditioner

Fixed frequency means that the compressor of the air conditioner operates in the fixed rotation speed. The relationship between the rotation speed of motor and electrical frequency can be described as:

Figure 7.

The control scheme of a fixed frequency air conditioner with

On/Off control: It adopts a temperature sensor as the feedback to

determine the ON/Off status of compressor. Cooled and non-cooled air

flow will be delivered to air conditioning space to adjust the

differences between feedback temperature and setting point. It's a kind

of difference causing control.

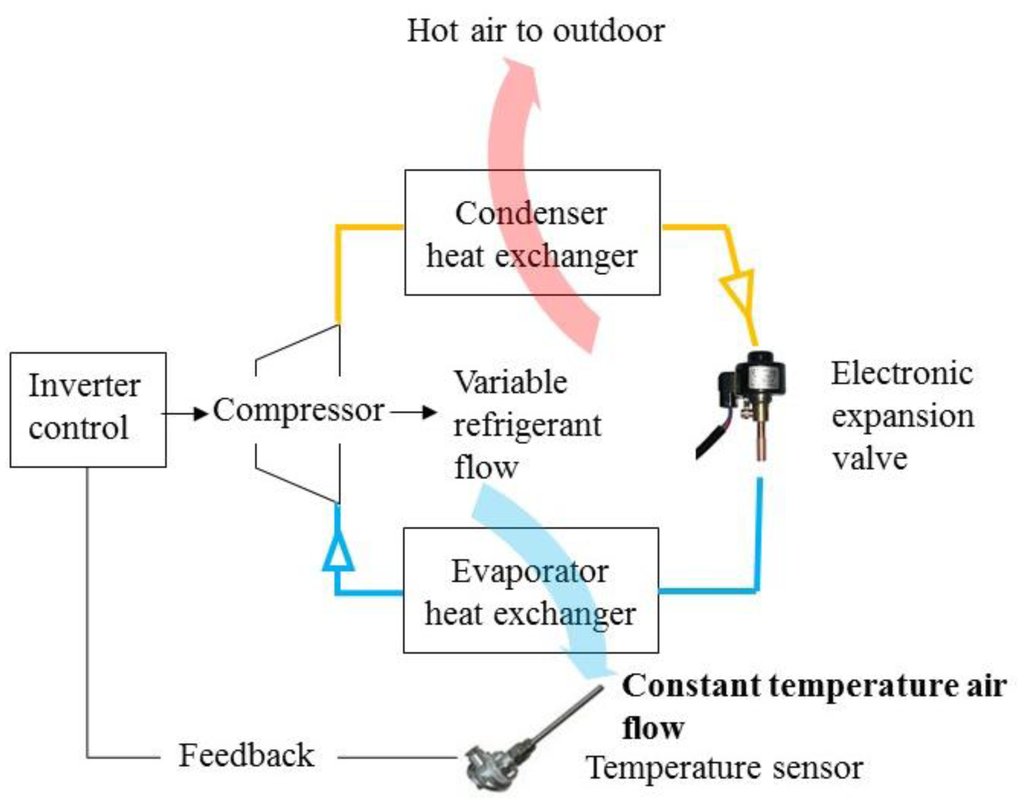

3.2. Inverter Control of the Convertible Frequency Air Conditioner

The convertible frequency air conditioner is the main air conditioning product for energy conservation. It is defined as the situation where the motor rotation speed could be adjusted continuously for regulating the refrigerant energy output by changing the input electric power frequency. One can refer to Equation (16) to check how the rotation speed changes with respect to the input frequency. The control scheme is illustrated in Figure 8.

Figure 8.

The control scheme of a convertible frequency air conditioner with

Inverter control: different from the fixed frequency air conditioner,

convertible frequency one has an electronic expansion valve to adjust a

refrigerant flow. Inverter control changes the output continuously with

respect to the different refrigerant flow rate. Even though the Inverter

control would keep the constant temperature of cooling air flow, it's

still a difference causing control.

The center control scheme of convertible frequency type is the “PID(s)” (proportion, integration, differentiation) function, described as:

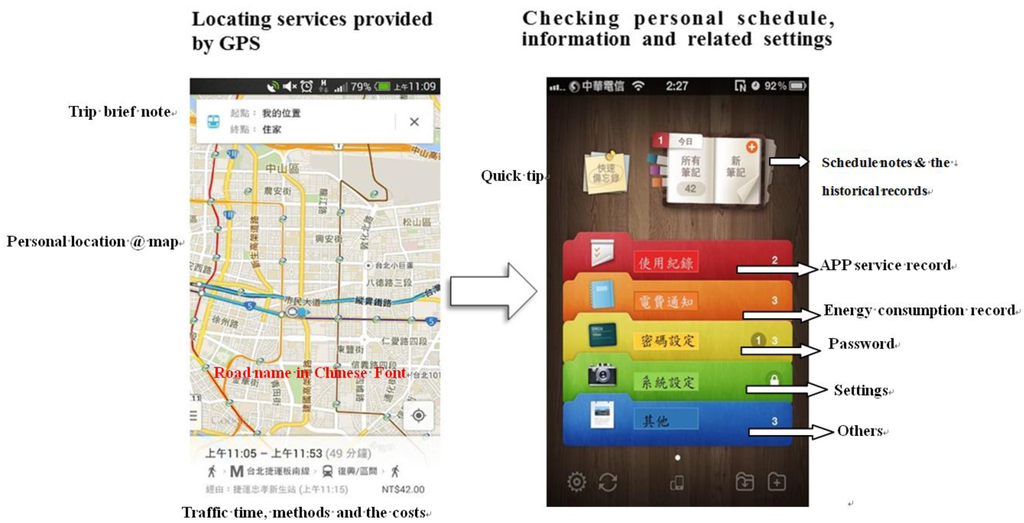

3.3. Smart Sensors

Smart sensors, including mobile phones, wearable devices and other sensors, are introduced. They are the key elements of smart control for obtaining the human's intention. Mobile phones would provide occupants' information by connecting to the GPS and personal schedule for collecting the position and intentions. The air conditioner could cool down the indoor temperature rapidly before the occupants enter, as shown in Figure 9.

Figure 9.

Smart sensor 1: Mobile phone providing occupants' position and intention by connecting to the GPS and personal schedule.

Figure 10.

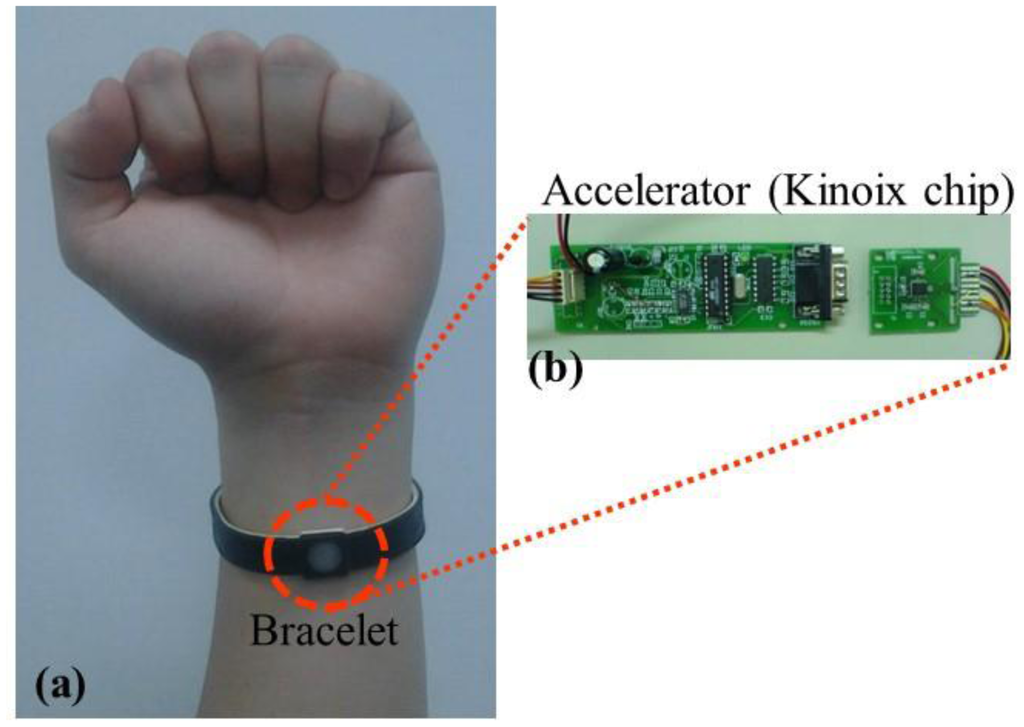

Smart sensor 2: (a) bracelet combining with (b) accelerator (Kinoix chip).

3.4. Smart Control Based on Smart Sensors

Including the comparison of the fixed and convertible frequency control schemes, the quantitative analysis of the smart control based on the smart sensors is the main target in this paper. Smart control, based on the information collected by the use of mobile phones and wearable devices, intensifies the interaction with occupants and carries out the intention causing control. It may include the following aspects:- (1)

- Mobile phones with GPS and personal schedules, for detecting the occupants' position and intentions, could foresee the occupants' intention of entering the enclosed space. At this moment, the compressor, which is off in the general situation, could turn on in the full power. Before entering, the circulating fan turns on at the highest speed, and the air deflector swings for 10 min to enhance the air circulation. Therefore, smart control may enable the enclosed space could be cooled down rapidly after the occupant enters.

- (2)

- The bracelet with the accelerator could detect the movement of occupants while the sleeping. After the occupant falls into a deep sleep, the air conditioner would lift the indoor temperature flexibly to avoid energy consumption.

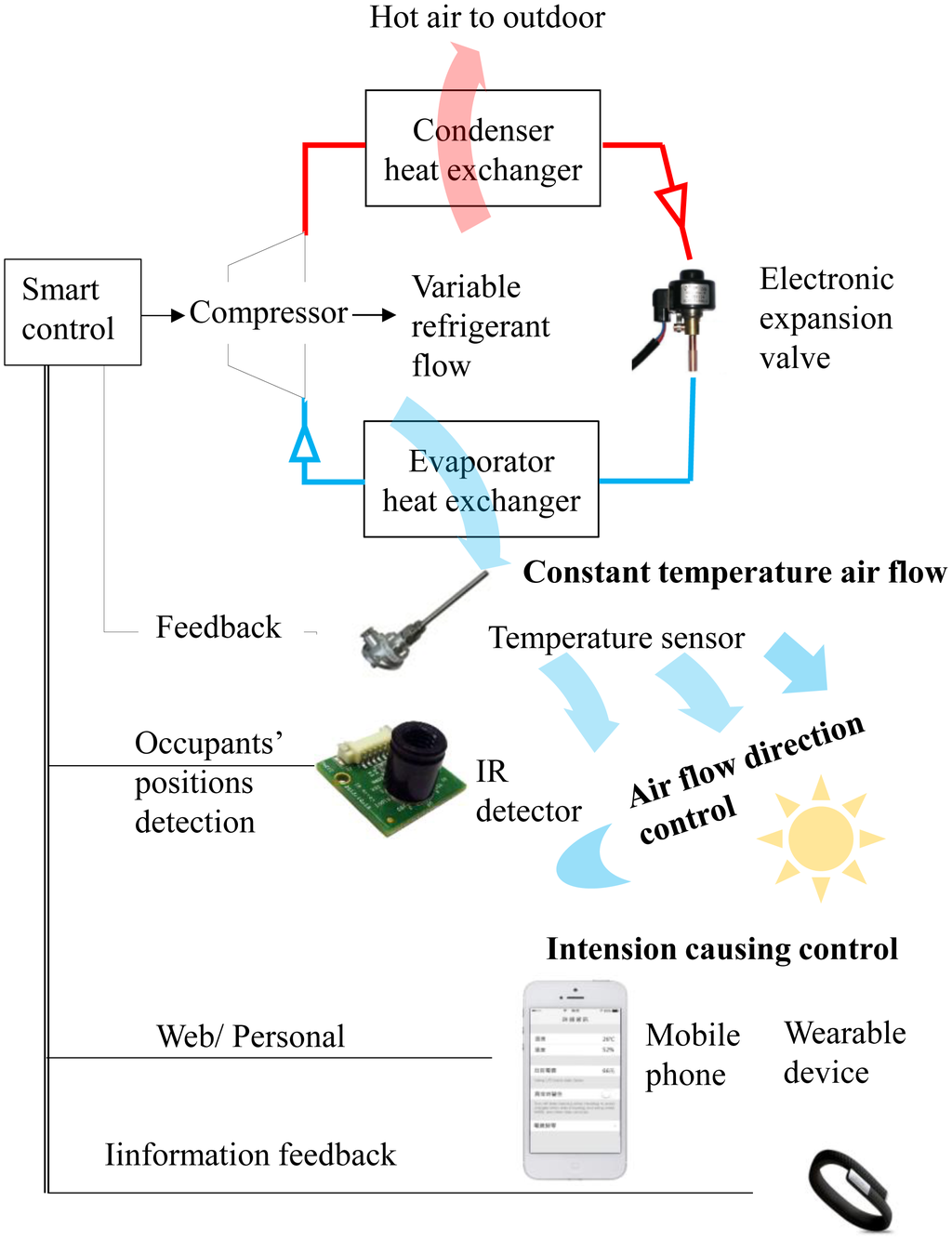

The smart air conditioner includes the following devices: (1) air conditioner with adjustable refrigeration power; (2) novel sensors capable of interacting with occupants; (3) communicating units for mobile phone and network. Figure 11 shows the controlling structure of smart air conditioner, including air conditioner, temperature sensor, IR detector, mobile phone and wearable devices.

Figure 11.

The control scheme of a smart air conditioner with Inverter

control: different from the fixed and convertible frequency air

conditioner with difference causing control, it's an intention causing

control that adjusts the compressor output actively according to the

occupants' active intention (going home) and passive one (falling in a

deep sleep) for the goals of human comfort and energy conservation.

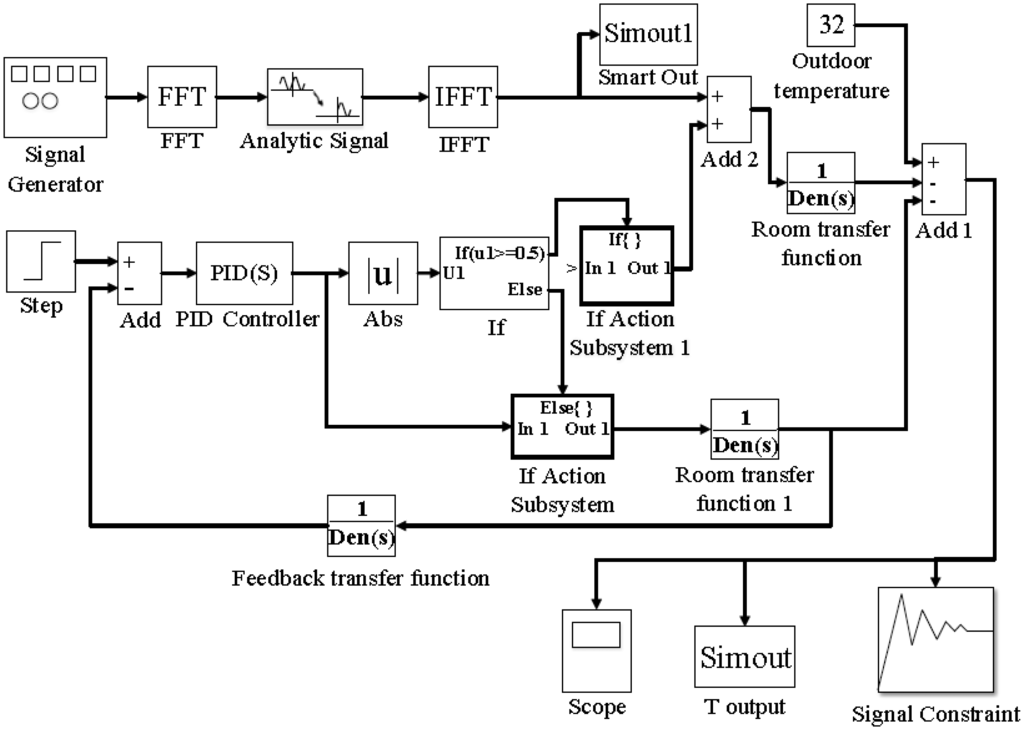

In this paper, the smart control logic will be developed from the air conditioning principles and the controlling logics of fixed and convertible frequency air conditioners. Figure 12 presents the developed smart control scheme developed using the Matlab software. The control scheme is based on the mathematic analysis of Section 2. It will be carried out in the electric circuit after the stability analysis of the control method.

Figure 12.

Smart control scheme based on the mathematic analysis of Section

2. It will be carried out in the electric circuit after the stability

analysis of the controlling method by Matlab software.

The design of the smart control is different from the control logics of IF and PID functions, which is difference causing control. For the On-Off and Inverter controls, when the indoor temperature is higher than the setting value, the compressor starts to operate according to the designed controlling logics. This would result in the energy waste and human uncomfortableness. For the developed smart control, based on the multiple information from the multiple sensors, mobile phones, network and sensor network, the air conditioner is able to provide the proper response by the FFT function of the predictive control before the demand occurs. This will solve the present problems of unstable temperature and energy waste. This may be called intention causing control. This control strategy will be predominant the development of smart air conditioners in the coming future. It can foresee the refrigerant output of the air conditioner precisely. All these developments would dominate the manufacturing industry improvement and business environment of air conditioners and electricity.

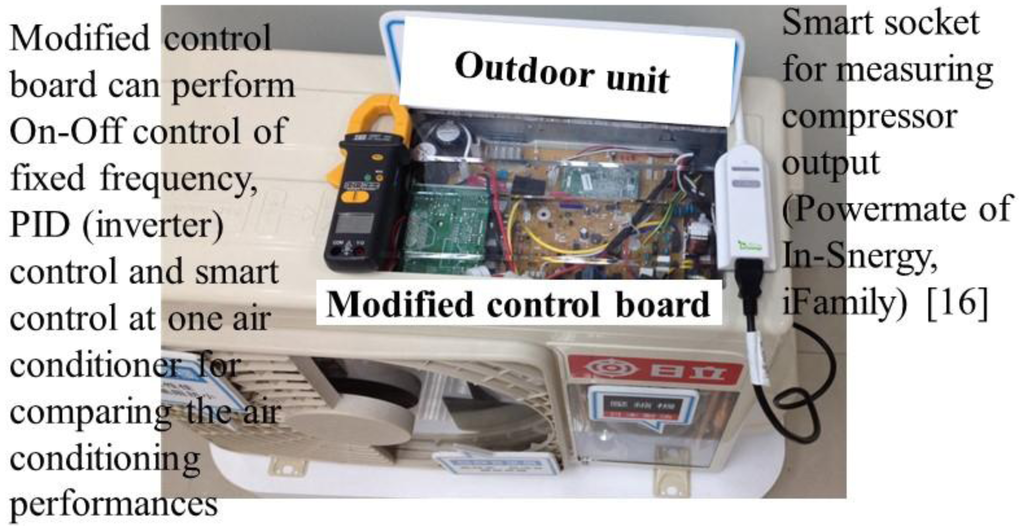

4. Experiments

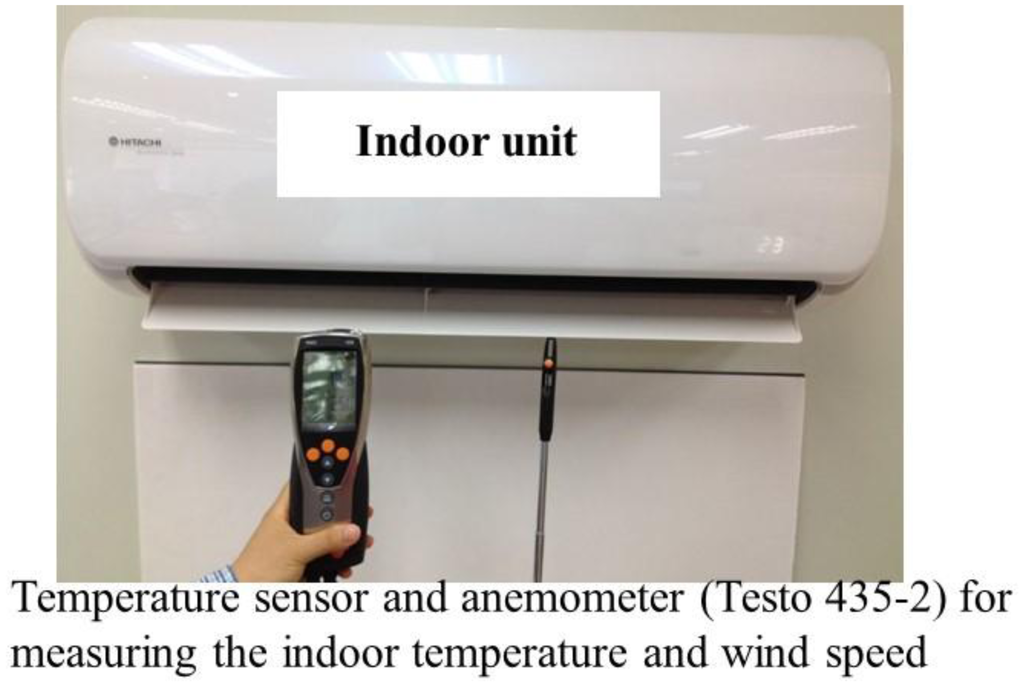

One convertible frequency air conditioner with a cell phone communication function for carrying out the smart control was chosen. After modifying the control board, the chosen air conditioner could perform the mentioned controlling strategies, i.e., On-Off control of fixed frequency, Inverter (PID) control of convertible frequency, and smart control. The power consumption and cooling time of these three controlling strategies will be compared in the following sections. Figure 13 demonstrates the modified controlling circuit plate of the air conditioner, and the digital power meter (Powermate of In-Snergy, iFamily) [16] for measuring the compressor output. Figure 14 shows the experimental setup of temperature sensor and anemometer (Testo 435-2) for measuring the indoor temperature and wind speed.

Figure 13.

Modified controlling circuit plate at the outdoor unit of the air

conditioner, and digital power meter embedded smart socket for measuring

the compressor output.

Figure 14.

Experimental setup of temperature sensor and anemometer for measuring the indoor temperature and wind speed.

In Figure 13, the compressor output is measured by the digital power meter embedded smart socket. The specification is illustrated in Table 1.

Table 1.

Specification of smart socket used for measuring compressor output.

Table 2.

Specification of temperature sensor and anemometer (Testo 435-2).

There are two experimental cases for comparing these three types of air conditioners with respect to difference causing control and intention causing control. The experimental conditions for the 1st case are: the indoor space is 26.48 m2, three persons of average weight (70 kg) as the air conditioning load. The air conditioners with three control logics, such as fixed frequency, convertible frequency and smart control, turn on for two hours separately. The energy saving ratio is calculated from the compressor output energy. The temperature response is recorded to represent the human comfort status.

The experimental conditions for the 2nd case are: an indoor space of 13.24 m2, one person of 70 kg weight as the air conditioning load. The air conditioners with convertible frequency and smart controls turn on for 8 h at the night separately. The air conditioner with convertible frequency control operates in the sleeping mode. In this mode, the indoor space temperature starts at the set one and increases in the speed at 1 °C/h in the following period until reaching 28 °C. For the air conditioner with the smart control, the operating mode would include multiple information as the feedback. The information comes from the personal wearable devices. The accelerometer of the bracelet would detect human activity and determine the sleeping state for adjusting the indoor space temperature accordingly. This operating mode of smart control would reach the goals of energy conservation. The energy saving ratio is calculated from the compressor outputs of two control methodologies, sleeping mode with Inverter control and smart control. Due to the limitation of experimental environment, the testing temperature is set in the range from 21 to 32 °C.

5. Results and Discussion

The expected goals of smart control for air conditioner include human comfort and energy conservation. They could be evaluated by:- (1)

- Human comfort represented by temperature response: the time to reach the indoor temperature of the setting value, oscillating amplitude of temperature after the steady state and the level of temperature shift.

- (2)

- Energy conservation calculated by compressor energy: a smart socket is used for measuring compressor output during two experiment cases.

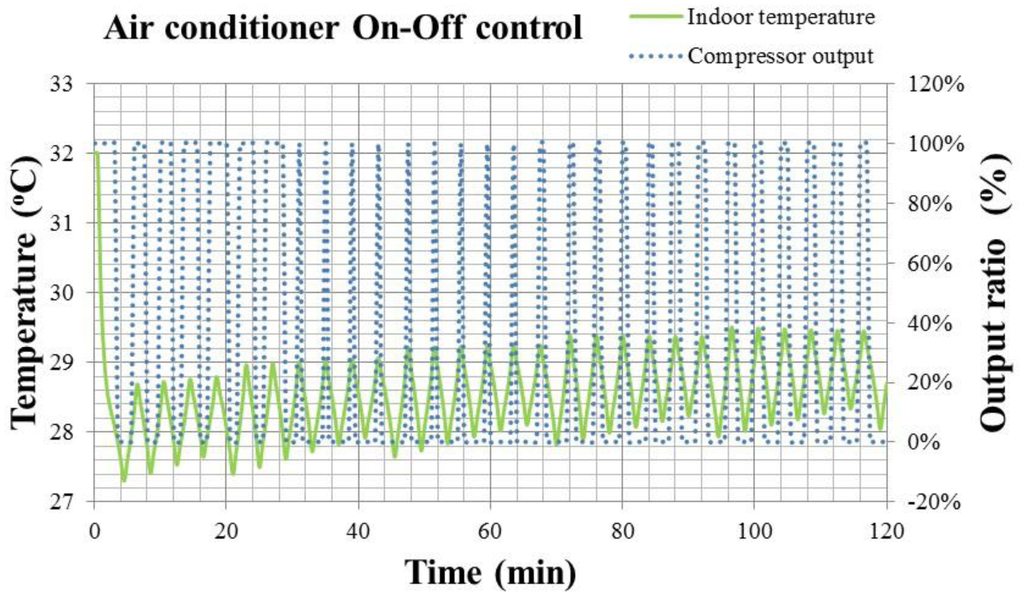

Figure 15.

The results of indoor temperature response and compressor output

for the fixed frequency air conditioner with On-Off control.

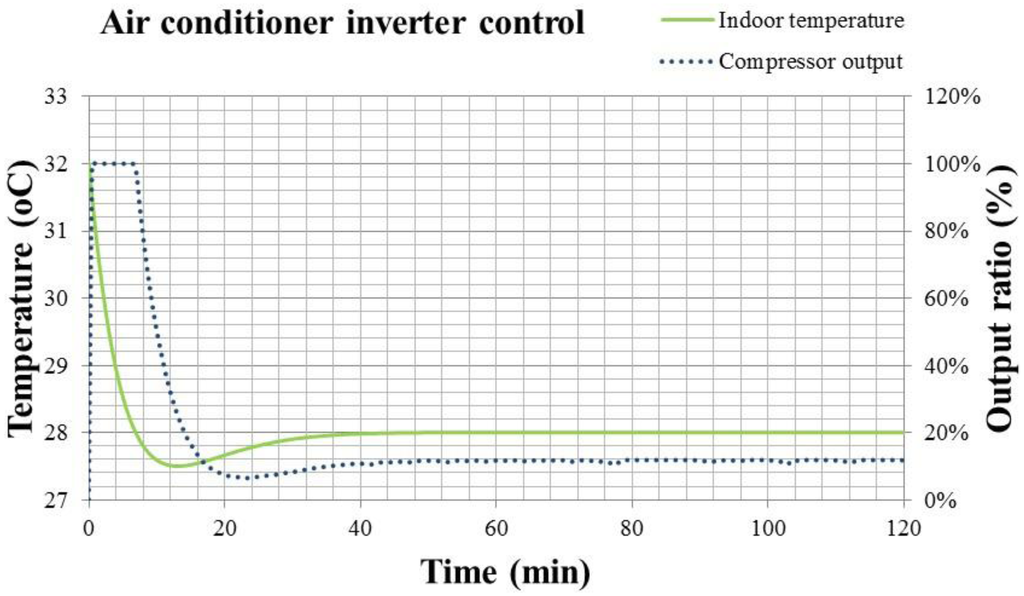

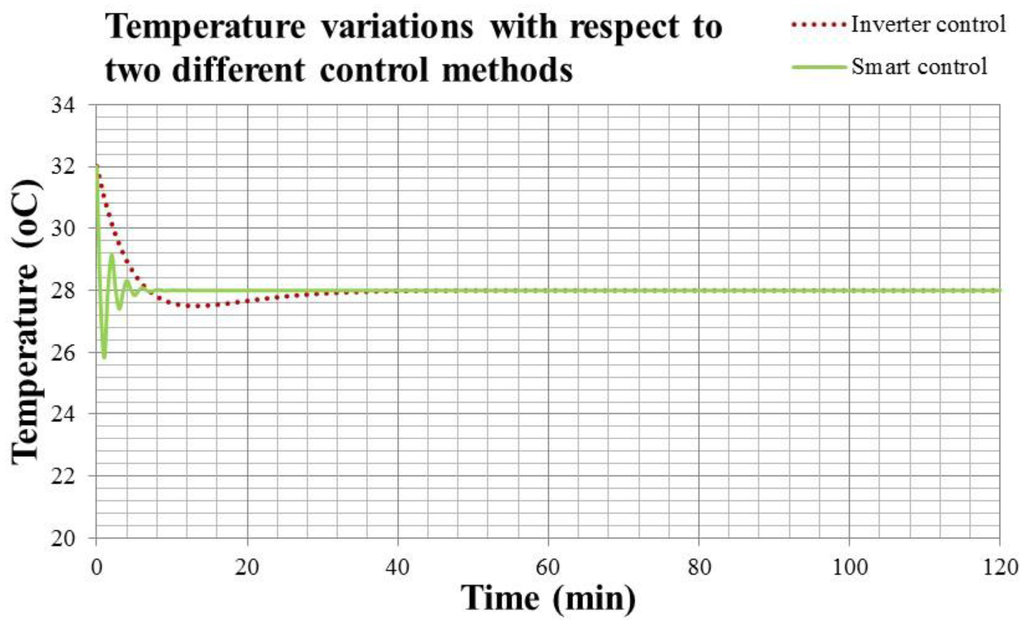

For Inverter control of convertible frequency air conditioner, the results of the indoor temperature response and the compressor output from the beginning to the steady state of 28 °C are shown in Figure 16.

Figure 16.

The results of indoor temperature response and compressor output

for the convertible frequency air conditioner with Inverter control.

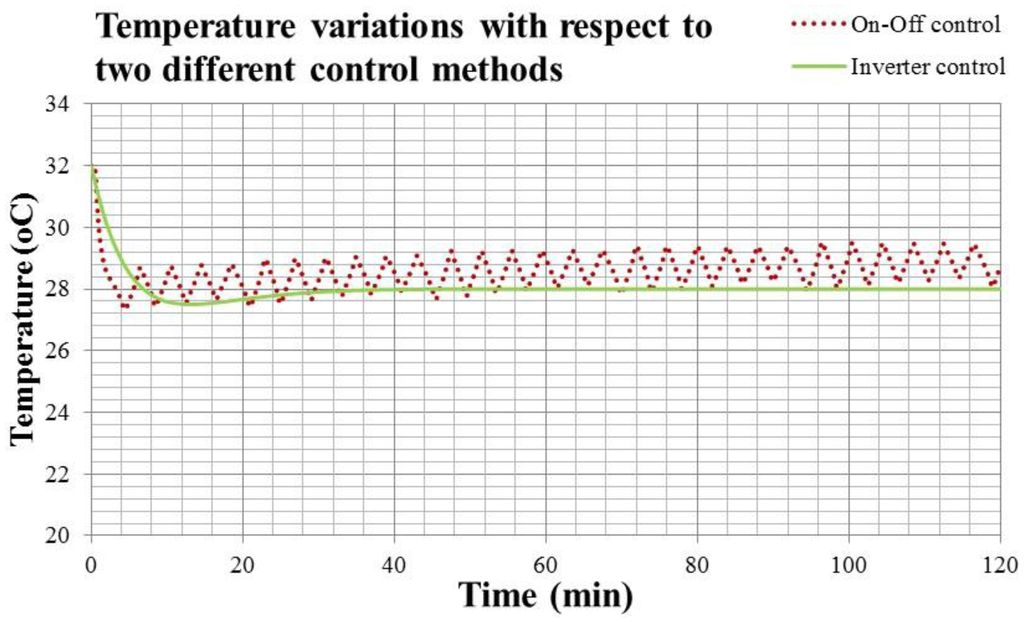

Figure 17.

The indoor temperature responses of the Inverter and On-Off controls.

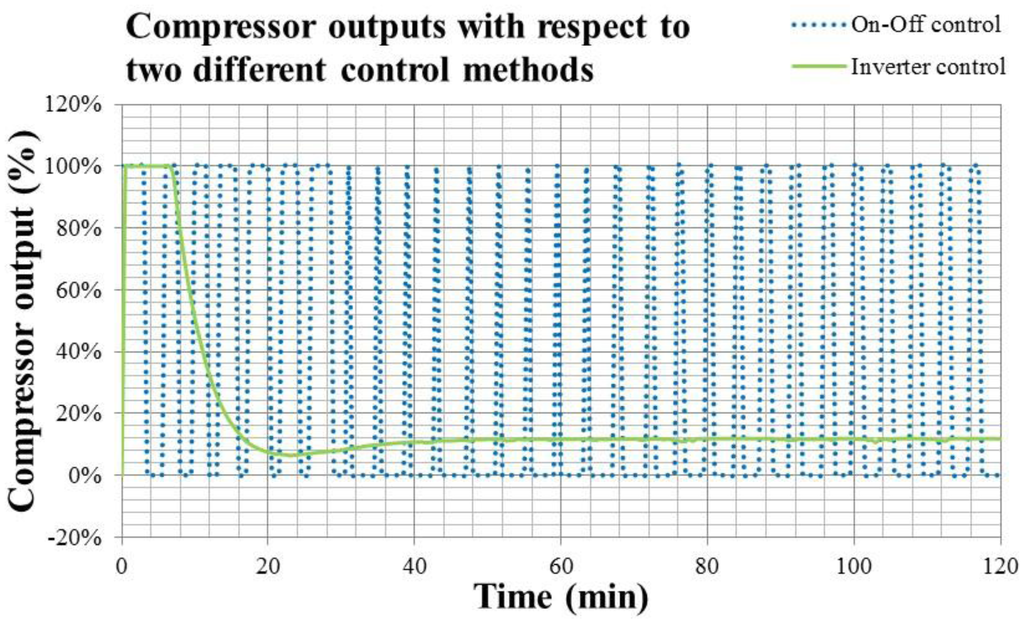

The comparison of the energy consumption between the fixed and convertible frequency air conditioners can be evaluated by compressor output, as shown in Figure 18.

Figure 18.

The compressor output (in % related to full load) of On-Off and Inverter control air conditioners.

From Figures 17 and 18, the drawbacks of the difference causing control can be observed clearly. Both On-Off and Inverter control methodologies operate according to the temperature difference between the setting one and measured one from the sensor, then adjust the compressor output in a postponed pattern. If the occupant wants to cool down the air conditioning space rapidly and adopts the On-Off control, he may suffer the temperature fluctuation. On the other hand, if the occupant won't suffer the fluctuating situation and uses the Inverter control, he may endure the discomfort for almost double the response time. When using the PID algorithm, the integration of errors causes the system response to be slow. How to achieve the rapid cool down and stable temperature control is still a problem for the existing control systems of air conditioners.

In this study, smart control may provide a solution. Smart air conditioners adopt a convertible frequency air conditioner to carry out diversified functions through the connection with smart phones. The smart phone would provide occupants' information by connecting to the GPS and personal schedule for collecting the position and intention information. The air conditioner could cool down the indoor temperature rapidly before the occupants' enter. Then, by connecting with the data of humidity, wind speed and direction, smart control is able to predict the demand of the air conditioning space and adjust the output of air conditioner in advance according to human's intentions. Therefore, this smart control is also called intention causing control.

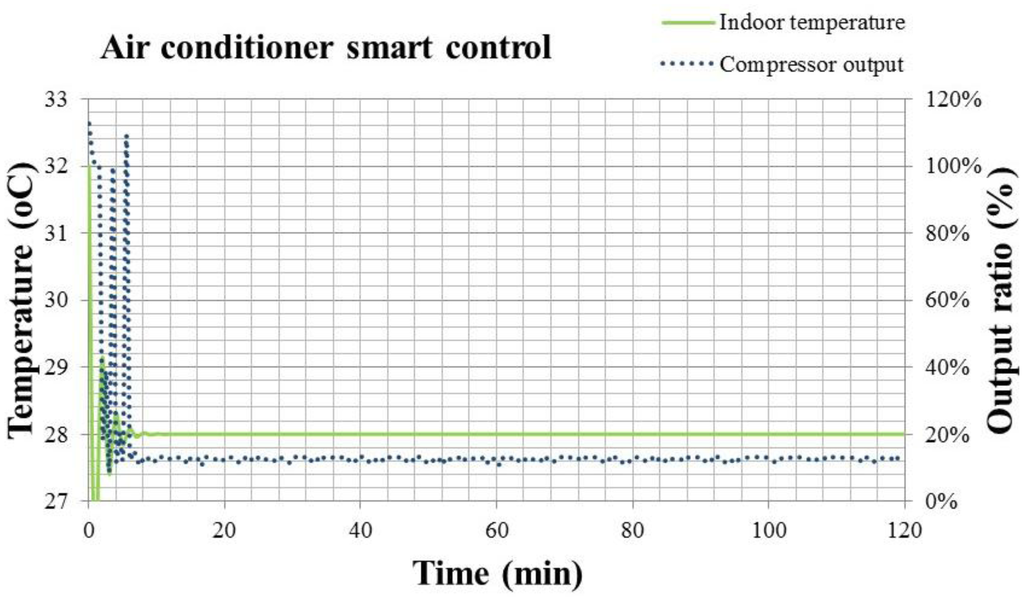

For a room with 26.48 m2 space, occupied by three persons of average weight (70 kg) as the air conditioning load, the temperature response and the compressor output ratio according to the setting point estimated by the smart control function are shown in Figure 19.

Figure 19.

Indoor temperature response and compressor output of smart air conditioner with smart control.

Figure 20.

The temperature responses of smart control and Inverter control.

Hence, the smart control could predict the air conditioning demand by collecting the occupants' information, such as position and personal schedule, through the GPS and mobile phones. This information would be analyzed by the FFT function in the frequency domain and provide the proper feedback response. That yields the “intension causing control” and solves the fundamental problem of On-Off and Inverter controls, which is “difference causing control”. Through the smart control, rapid cool down, less than 2 min, and stable temperature control with errors less than ±0.1 °C are achieved to benefit the human comfort and energy conservation.

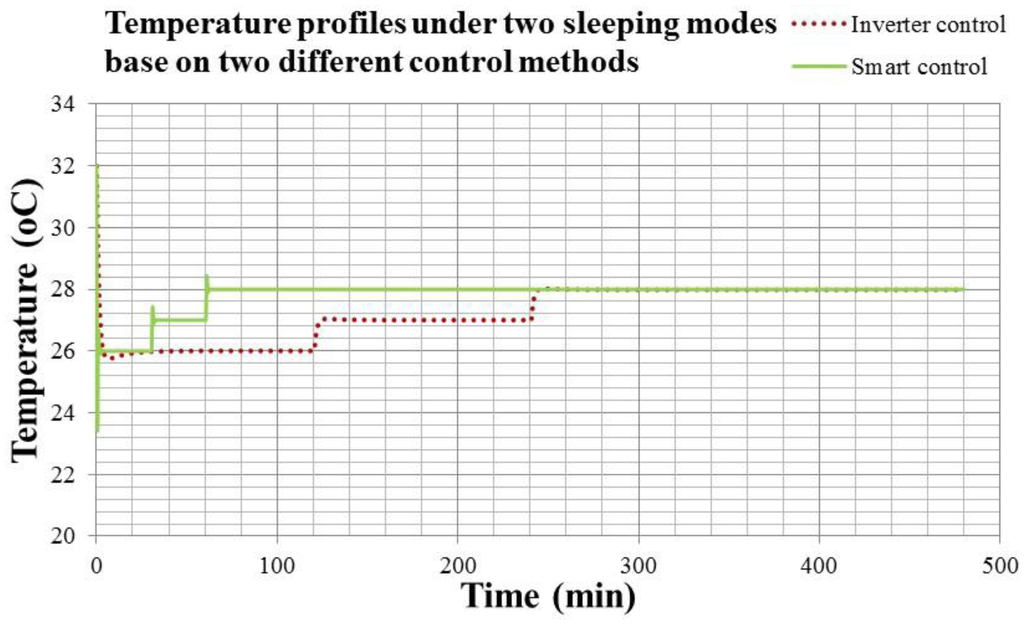

In addition to benefit human comfort and energy conservation, the smart air conditioner is also useful when humans are sleeping at night. The experimental setup is described above. Mobile phones and wearable devices like bracelets equipped with accelerometer, are adopted for detecting the human sleeping state as the feedback signals of the sleeping function. They could collect the information of human temperature, pulse and action, and feed it back to the smart air conditioner for further control. The sleeping function of traditional air conditioner would increase the temperature in the speed of 1 °C/h until the setting value of 28 °C. However, the sleeping function of the smart air conditioner with the wearable devices would adjust the temperature setting right after the user enters deep sleep.

Figure 21 shows the temperature response of sleeping functions in the night under the Inverter and smart controls. Figure 22 shows the compressor output of sleeping functions in the night under the Inverter and smart controls.

Figure 21.

The temperature response of sleeping functions in the night under the Inverter and smart controls.

Figure 22.

The compressor output of sleeping functions in the night under the Inverter and smart controls.

6. Conclusions

From the theoretical analysis and experimental results, the design of a smart air conditioner with mobile phones and wearable devices could be carried out the intention causing control as the a significant improvement of air conditioner technology. There are some conclusions and recommendations for the smart air conditioners as follows:- (1)

- The total compressor output of a smart air conditioner is 48.4% less than the fixed frequency one. Indoor temperature can be controlled accurately with errors less than 0.1 °C. Rapid cool down can be achieved in 2 min to the optimized indoor capacity after occupants enter.

- (2)

- The intention causing control of smart air conditioner could be practiced by combing with the GPS, personal schedule and setting information of the mobile phone for the optimized setting of compressor output.

- (3)

- The smart air conditioner with wearable devices could detect the human temperature and action during sleep for determining the sleeping state and adjusting the sleeping function flexibly. The sleeping function optimized by the smart air conditioner with wearable devices could reduce the energy consumption up to 46.9% and maintain the human health.

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

e- Working Air conditioning Modern

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

Tidak ada komentar:

Posting Komentar