Development Battery Management System

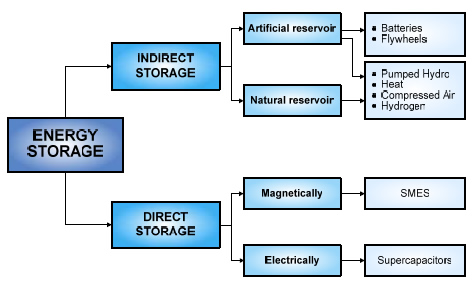

Energy Harvesting & Storage

Ambient light, thermal gradients, vibration/motion or electromagnetic radiation can be harvested to power electronic devices. EnerChips enable high-efficiency Energy Harvesting (EH) designs that convert the relatively low levels of energy into an amount that can provide the power for an electronic system. The diagram below shows the major components of an autonomous wireless sensor which are the EH transducer, Energy Processing, Sensor, Microcontroller and the Wireless Radio. There are 3 key areas in the Energy Processing stage that must be addressed for successful EH implementations: Energy Conversion, Energy Storage, and Power Management.

Energy Harvesting Hybrid for Battery Extension

There are cases where there is not enough ambient energy to power a device and a larger battery must be used. However, energy harvesting can be used to significantly extend the life of the battery. Cymbet EH solutions (especially solar) can be combined with primary or rechargeable batteries to extend their life.

system must be capable of capturing, converting, storing and delivering energy in a form that can be used to provide the power needed by the system it serves. A typical Energy Harvesting system starts with an energy collector or transducer device and depends on the type of energy one is trying to convert. These are typically solar or photovoltaic cells for light energy, piezoelectric for pressure, kinetic for movement, inductive for rotational or motion, thermoelectric for heat or temperature differential, and electromagnetic.

The energy collected from these transducers must be converted to a form that can be stored for later use. In remote sensor systems or portable device applications that use Energy Harvesting a small rechargeable battery or storage capacitor is often employed to store the collected energy the system needs for operation. The drawbacks to each of these storage methods are numerous in that even rechargeable batteries wear out after a few hundred charge/discharge cycles and need to be replaced and super caps while they eventually change their characteristics, will self discharge rapidly, as much as 20% per day, causing much of the converted energy to be wasted. A more robust and permanent solution is to use an EnerChip solid state battery as the energy storage element in the system to eliminate the need for replacement since it can support in excess of 5000 cycles and has a minimal self-discharge of less than 3% per month.

The final stage of the system conditions to stored energy to suit the requirements of the system. This could be as simple as a regulator and level shifter to a complex power control circuit that intelligently manages the power distribution to the system based on power needs and system operation.

Calculating Power Requirements

In order to power systems using ambient energy harvesting, several factors must taken into consideration to calculate the power required to operate the system in various states:

1 - Identify the sources of ambient energy to be used and the type of Energy Harvesting transducer to be used

2 - Characterize the power output of the EH transducer over various ambient conditions

3 - Looking at all the system components, calculate the power required for all states operation (e.g. sleep, sensing, wireless)

4 - Identify the EH conversion and power management electronics to be used and add the power used to the overall total.

5 - Size the energy storage device (solid state battery) to cover all the system energy storage and power delivery requirements.

Energy Transactions

The definition of an energy transaction is "the amount of discrete energy required to perform a certain task or functional transaction". This concept of energy transaction is very useful in the design of energy harvesting-based systems. In order to calculate the power budget and power boundary conditions for an EH-based system, all operating and quiescent power states of the system must identified. Each of these states requires an energy transaction level to function. Identifying all the various energy transactions will determine the sizing of the Energy Harvesting transducer and the energy storage devices.

Maximum Peak Power Tracking

To optimize the performance of energy harvesting based systems, it is critical the high efficiency energy conversion technique of maximum peak power tracking (MPPT) be used. MPPT can adapt to either constant impedance or variable impedance EH transducers. MPPT is used to match the impedance between the energy harvesting transducer and the system load as seen in the diagrams below. The EnerChip EP Energy Processor CBC915 implements an optimized version of MPPT.

Design Tips

When building energy harvesting based systems the following 10 Tips and Techniques will help improve system performance:

1 - Optimize for low average power in the system.

2 - Firmware efficiency is key; no loops, etc.

3 -Use hardware timers and interrupts. Isolate loads; all loads should be switchable.

4 - Watch power leaks via back-feeding other devices.

5 - Net power is a tradeoff between dynamic and static power. Quick processing with high power may be better than slow processing with low power.

6 - Usually better to process data and send result vs. sending data for processing elsewhere.

7 - Wireless protocols and topology must be minimized.

8 - Power up sequencing – must understand implications of when to power each device along with other devices.

9 - Every MCU vendor provides hints and tricks to minimize power.

10 - Use Energy Processing devices that provide status indications so informed power management choices can be made.

As climate change garners more attention around the world, have made critical advances in understanding the physical properties of an emerging class of solar cells that have the potential to dramatically lower the cost of solar energy.

Solar cells remain a focal point of scientific investigation because the sun offers the most abundant source of energy on earth.

The concern, however, with conventional solar cells made from silicon is their cost. Even with recent improvements, they still require a significant amount of electricity and industrial processing to be manufactured.

The concern, however, with conventional solar cells made from silicon is their cost. Even with recent improvements, they still require a significant amount of electricity and industrial processing to be manufactured.

we need to be able to scale up this process while maintaining or even improving the efficiency of the solar cell. To do that, we need to understand how this material crystallizes and grows from solution into a thin film."

By adding different chemicals to the solution, they were able to control how fast the MHP crystals formed and what direction they grew on a surface. The specific orientation of the MHP crystals on a surface affected how well a solar cell performed .

"MHP solar cells can be used in flexible, lightweight materials," Choi said. The ultimate goal would be to make manufacturing MHP solar cells as easy as printing newspapers, generating rolls of thin solar cell material that could be easily applied to houses, cars, or anywhere else they were needed.

One significant drawback with many current MHP solar cells is that they contain lead. Researchers are working on identifying viable alternative compositions that are not toxic.

Elsewhere, MHPs have already been used in lasers, photo detectors, transistors and light emitting diodes (LEDs).

Still, it is the solar cell that arguably offers MHPs the best chance to address pressing global problems.

"To mitigate the impact of climate change and also to ensure the energy security .

it is very important to come up with renewable energy sources rather than just be relying on fossil fuel-based energy,"

XO____XO Electronic Smart Lock

Electronic smart locks are growing as a result of IoT. These battery-powered locks often require features such as BLE, Sub-1 GHz, Wi-Fi connectivity, interactive RGBW HMI, audio and sensing etc.

Electronic smart lock designs require:

- Energy efficiency and long battery life with a wide operating temperature range

- Secure management of keys and access control

- Low power HMI like RGBW LEDs, touch, proximity sensing and audio notification

- Support of multiple industry standards like ZigBee®, 6LoWPAN, and ZigBee RF4CE remote control applications

- Configurable BLE advertisement intervals to reduce power consumption

Electronic door locks are primarily battery powered. High-efficiency buck converters provide the voltage rails needed by the system components and maximize battery life. Boost converters provide higher voltage rails to operate motors and sourcing LED arrays. Linear regulators can also be used to reduce BOM cost at the expense of battery life.

Power Management

How does light appear from electricity?

how does actually electrons produce light energy in the bulb? What I know is there is so-called the filament, a thing with great resistance, and this thing heat-up when current is flowing and it produce light, but I still don't understand how it's possible. Light energy includes photons. Electrons can emit or absorb photons. Does that mean, that they already had photons?

Photons are not conserved. They can be created by the energy of charged particles moving in electric and/or magnetic fields

Rather than looking at an incandescent bulb, let us consider an LED (light emitting diode). In terms of building a circuit out of it, it is no different from a light bulb (at least the differences are not relevant here). The point is, that in an LED, the microscopic mechanism simply is that an excited electron relaxes to its ground state, emitting light. that this is a concept you are familiar with. In contrast, a filament emits light because it is hot. The microscopic description (with electrons and atoms) is much more complicated here.

the intuition tells you that 'the number of photons' must be conserved. Actually, the conserved quantity you are looking for is energy. Some quantum of energy (e.g. potential or electrical, or, in the case of an LED, it's the excited energy of an electron) is converted into a quantum of radiation. This quantum of radiation is called a photon. The same energy existed before! It was just present in a different form, but still in quanta. We just don't usually give special names to it. Still, sometimes physicists talk about phonons, vibrons, magnons, etc. They all describe quanta of some energy degree of freedom.

As to why hot things emit light; heat is energy and the increase in energy in the filament means that electrons can jump to higher energy levels in the atoms (excitation). When they de-excite, they emit photons.

Think about how the filament heats up when the current flows through it. As the electrons move along through the filament, they are constantly bumping into the atoms that make up the filament, transferring their energy to them. The energy of each impact vibrates an atom -- in other words, the current heats the atoms up.

Now, the bound electrons in the vibrating atoms may be boosted temporarily to a higher energy level when they're hit by on-coming high-energy electrons that form the electric current. After the energy is transferred to the bound electrons, they fall back to their normal levels. This happens when the electrons release the extra energy, that they had absorbed via the collision, in the form of photons.

Note that the absorbed energy may be released in other forms energy than photons depending on the material in question etc. So the electrons(ones inside the filament) did not already have photons- they were given some energy, which for the choice of material in the bulb, leads to an emission of photons when the electrons relax from that excited high-energy state.

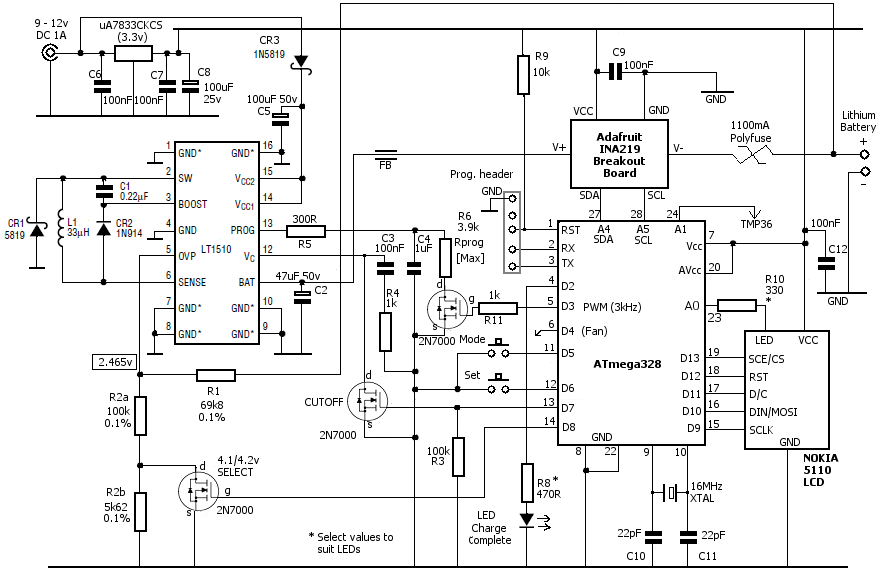

Lithium Battery Charger

XO___XO DW Power Management ICs.

Universal Laptop Power Supply Adapter Circuit

XO___XO DW Power Management ICs.

Reset ICs (Voltage Detectors)

reset IC (voltage detector) product lineup has features of a high-accuracy output voltage with ±0.5%, a lower consumption current of 290nA, and the wide operating voltage range of 0.5 V to 60 V. The reset IC product offers Manual Reset pin, SENSE pin, Power-on Reset, and the function to monitor not only undervoltage but also overvoltage, suited for functional safety.

These products are available for various applications as voltage supervisor.

reset IC (voltage detector) product lineup has features of a high-accuracy output voltage with ±0.5%, a lower consumption current of 290nA, and the wide operating voltage range of 0.5 V to 60 V. The reset IC product offers Manual Reset pin, SENSE pin, Power-on Reset, and the function to monitor not only undervoltage but also overvoltage, suited for functional safety.

These products are available for various applications as voltage supervisor.

These products are available for various applications as voltage supervisor.

Watchdog Timers (WDT)

Reset Timers

DCDC Converters (Switching Regulators)

corresponding to different output characteristics such as low input voltage to high input voltage and small output current to large output current.

Our portfolio of DCDC converters includes step-up, step-down and inverting DCDC converters that are all manufactured by CMOS technology to ensure high voltage accuracy and high efficiency.

Our portfolio of DCDC converters includes step-up, step-down and inverting DCDC converters that are all manufactured by CMOS technology to ensure high voltage accuracy and high efficiency.

- PWM Control and VFM Control

- Internal or External Output Transistors

- Output Voltage Setting

- Diode Rectifier and Synchronous Rectifier

- Undervoltage Lockout (UVLO) Function

- Soft-Start Function

- Externally Programmable Maximum Duty Cycle

- Externally Adjustable Phase Compensation

- Overvoltage Protection (OVP)

- Overcurrent Protection

- Sequence Control

- Shutdown Function

- LED High-speed Dimming Control

Switch ICs

Technical notes of Switch ICs are :

LDO Regulators (Linear Regulatorssuperior voltage regulator lineup from a maximum input voltage 42 V to a maximum output current 3 A.

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

e- PRM ( Power Request Management ) for e- SWITCH electronic Automatic

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

Tidak ada komentar:

Posting Komentar