X . I

Design Eye Spear and Arrow Wood

in us making spears and arrows from wood to hunt various animals from fish, Couscous, Wild Boar, birds, lizards and so on. Shape spearheads and arrowheads of wood in different designs as needed to hunt certain species of animals. How can it be?

example example :

Edge Spear and Arrow attributed quarry type:

Carving shaft white accented with lime, a tiny dot on the end designed bamboo, used for hunting wild boar

Scallop shells of tiny fastened with straps on the shaft also used for hunting wild boar

Spearhead-shaped three sharp branches and bending used for hunting birds, which form almost the same but bigger and stronger used for fishing

Arrowheads from bone made a pointed and sharp for the war and for hunting various kinds of animals

The tip of bamboo with small bones attached, used for hunting lizards and birds

![[Detail of 9 arrowheads from the upper Sepik River area, ESP, PNG: 54k]](http://www.art-pacific.com/images/arrowhds.gif)

Jagged ends of wood used for hunting lizards and birds

Black jagged end of the timber used for hunting lizards and birds

Two ends of bamboo inscribed with tiny pieces of colored yarn store wrapped around the shaft used to hunt wild boar

Spear guns in use as a weapon to kill game animals and are also used as tools or weapons of war.

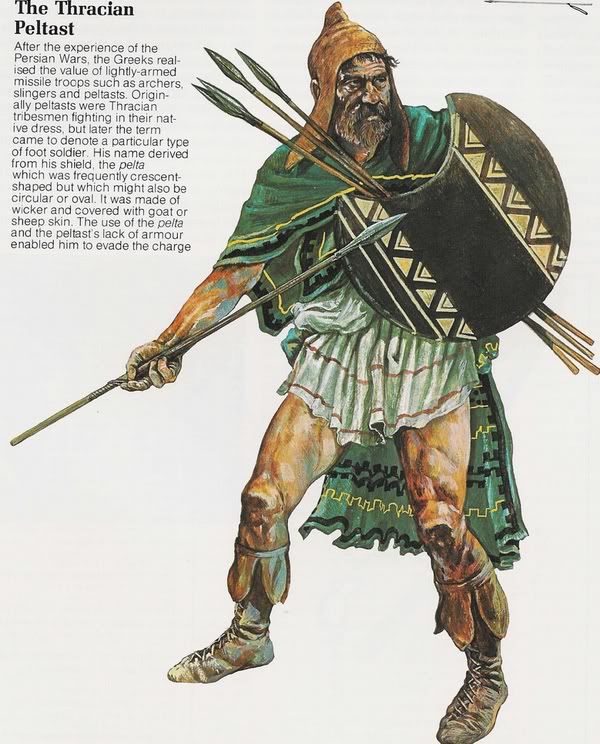

Various models, shapes and materials scattered earth spear. Starting from Europe, Asia, Africa, America.

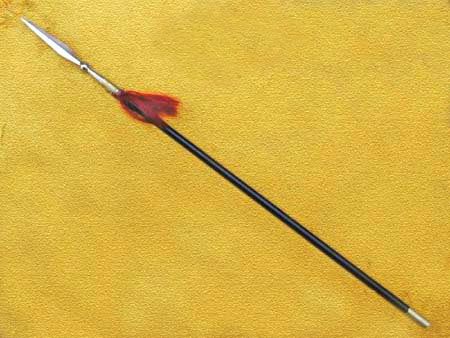

spear guns can be divided into two of the ways of use. The first spears are made and designed and used in a way thrown. Usually spear page. used for hunting game animals. The eye's spear is usually not large, but thin, flat and tapered. Left and right side spear is not so sharp as a knife. The desired effect of the spear page. is lightweight, easy to throw and can easily penetrate the target as the bodies of animals and so on.

Spear mostly made of iron "Prestige" is a mixture of two or more different metal materials and in forging tens, or even hundreds of times. wooden spears made of ironwood made circular with a diameter of no more than 1 inch. At the lower end of the lance also made tapered. The spear can be easily plug the ground.

In addition there is also a hunting spear to spear a bigger wooden handle. This is usually used to fight .

Here is a list of the names of the spear ( not yet translated ) across the world :

Boar spear

* Bohemian ear spoon

* Dung

* Falarica

* Trisula / Trident

* Hasta

* Jousting lance

* Lance

* Magari yari

* Ox tongue

* Pike

* Qi膩ng

* Sarissa

* Spontoon

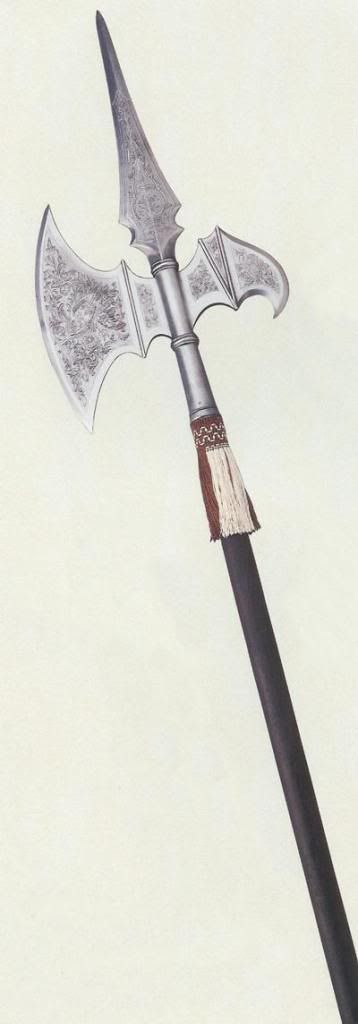

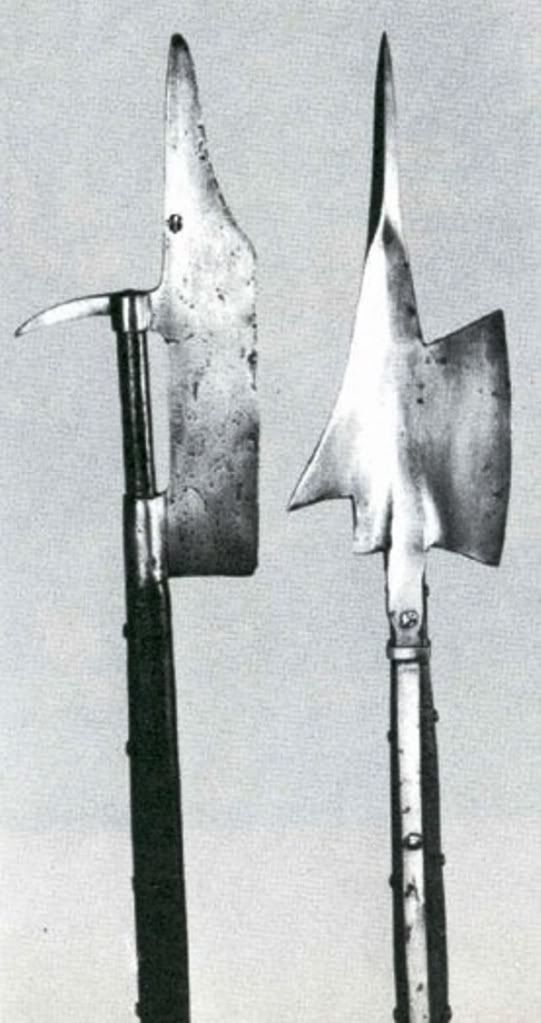

* Halberd

* Voulge

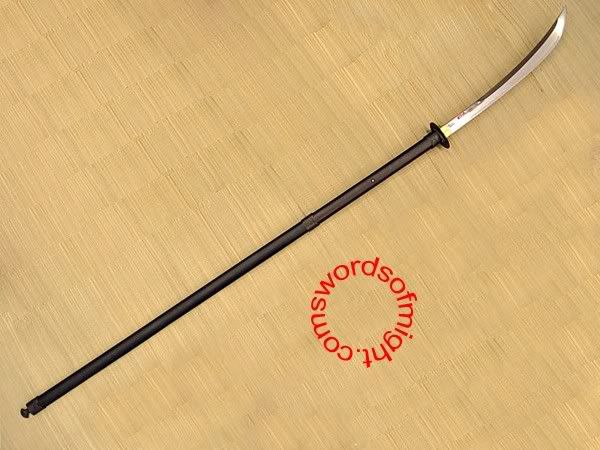

* Naginata

Spear / javelin is thrown

Spear / javelin is thrown in common with a spear shape not thrown, but the difference is how to use that to throw it. Therefore, javelin usually lighter or at least lighter than the spear.

Here are the names that are usually thrown spear in its use:

* Angon

* Assegai

* Budiak

* Fal-feg

* Jarid

* Kamayari

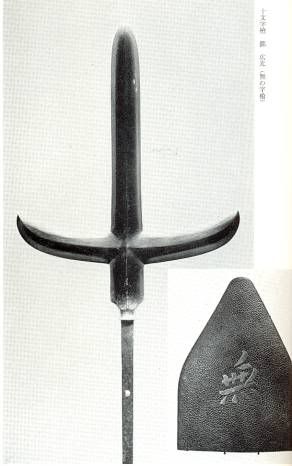

* Jumonji Yari

* Ancient Weapon Katar

Survival Spear Fishing

Bamboo spear to spear fish. The material should not be out of bamboo but from wood can.

X . II

Tools weapon cleaver

how to manufacture a machete acquired from various sources :

1. Iron or steel, as the main ingredients to make a machete.2. Paron hammered as the base, in the form of iron weighing approximately 50-60 kg.3. Puputan / funnel used to create wind that is necessary to maintain the coals, works the same way as wind pumps. It is made of boards long enough.4. The claw is used to clamp or take a machete material is still in a state of smoldering. This tool resembles a pair of pliers.5. Chisel used to divide and cut the material to be used as a dagger. This tool is made of steel.6. Hammer, used for diluting flattened or iron and one of her again for clicking pounding chisel.7. Files, used to smooth the dagger that is perfect nearing completion.8. regulator embers, as the name suggests is used to ferret-Orek embers. This tool is made of steel whose length is approximately 50 cm section curved edges, while the other end of a handle made of wood.9. tubs, used to cool the saber by dipping iron or steel that is being worked on becomes a machete. This tool is made from former roar of the cut, with a height of approximately 50 cm.10. Sweep stick, used to clean hammered (coaster) of iron or steel debris.11. Charcoal, serve as fuel.12. Stone sharpening, is used to soften and simultaneously to make into a sharp machete.13. Kliwaan / forgings are used to straighten the cleaver blade.14. Sweep the fire is used to rake or collect the scattered charcoal.Manufacture tablets machete was not easy, but it is quite complicated.

First of all the iron is heated for approximately 10 minutes on a fire until flushed, lifted with tweezers, then forged plated or dipped into a bath of water. The second phase will be the cutting iron machete. The third stage of cleavage, but the iron scrap was preheated to a new burning cleaved by putting on a new anvil then split with a chisel. The fourth stage of the formation of a machete while preheated while flaked. The fifth stage, smoothing with a file on a device called a trowel. The sixth stage, gilding by immersion into a water bath in order. The seventh stage, rubbing eyes sharpening with a machete on the whetstone to be sharp. Eighth stage, a kind of ring ooze manufacture pointless to strengthen the grip. Usually made of iron with iron straight way and then burned as a ring-shaped circular. The last stage, the manufacture of the handle and a sheathed dagger made of wood.

the materials used are selected from iron or steel quality steel such as a car or on a car

there are other ways of making a machete

Machete in its manufacture through a long process and complicated. There are at least fourteen tooling used for the manufacture of knives, namely:

1. marquetry or anvil as the base hammered, such as iron, weighing 60-75 kg. The shape varies exist in the form of the letter "T".2. trowel used to clamp or grip the dagger that was still in a state of semi-finished, especially if it will be smoothed with a file. The shape resembles a wrench but large in size.3. Pungsong used to create wind that is necessary to maintain the coals, works the same way as wind pumps. It is made of boards long enough.4. tongs or tweezers used to clamp or take a machete material is still in a state of smoldering. This tool resembles a pliers, but his hold up to 50 cm long.5. Chisel used to divide and cut the material to be used as a dagger. This tool is made of steel.6.

Its manufacture is quite complicated, first, of iron or steel is heated for approximately 10 minutes on pungsong up flushed, lifted with tweezers, then plated into a tub of water. The second stage of cutting iron or steel that will be used as a machete. The third stage of cleavage, but the iron scrap was preheated to a new burning cleaved by putting on a new placemat and then split with a steel chisel. The fourth stage of the formation of a machete while preheated while flaked. The fifth stage, smoothing with a file on a device called a trowel. The sixth stage, gilding by immersion into a water bath in order (the "old" = elders) quality is good. The seventh stage, rubbing eyes sharpening with a machete on the whetstone to be sharp. Eighth stage, a kind of ring ooze manufacture pointless to strengthen the handle (upstream). Usually made of iron with iron straight way and then burned as a ring-shaped circular. Phase ninth (last), manufacture and handles made of wood.

Tidak ada komentar:

Posting Komentar