glimpse the meaning of automated are: a technology that connects the mechanical system, electrical, and electronics in conjunction with the information system with a view to controlling production .

Secondly, this automatic also can be interpreted a tool by increasing the quality, productivity, safety, and consistency (provision) of a series of operations are repeated. Third, it can also automatically translate the technology integration of measurement, control and information to manage a process or a complicated system. Overall automatically be defined as a technology in which a process or procedure is executed without human assistance. It all can be implemented by using a program instruction, combined with a control system which executes an instruction. To automate a process, in need of energy, either to move the process itself as well as to operate the program and control system.

X . I

process control

Control refers to the process control system that oversees some industrial processes so that a uniform and correct output can be maintained. Process control can do this by monitoring and adjusting the control parameters (such as temperature and flow rate) to ensure product output remains as it should be.

Examples of process control is closed loop system that maintains a predetermined temperature of the electric oven

In this case, the actuator is a heating element, controlled variable is the temperature, and the sensor is a thermo couple (a device that converts temperature into voltage). The controller controls the power to the heating element such that maintaining the temperature (as reported by a thermo couple) at the value set by reference.

Process control are classified as:

continuous process

batch process

Continuous processes in the flow of materials or products that continually, while the batch process has a beginning and the end point (which is usually done repeatedly).

X . II

Sequential control system

Sequentially controlled system [sequentially controlled system] control process that is defined as a set of functions that must be implemented in other words, a series of operations, one by one. Each operation in the row implemented, either for a given period, in this case called driven-time [time-driven], or until the task is complete (as indicated by, for example, a switch divider [limit switch]), in this case called event-driven [event-driven]. Row

driven-time is an open loop since no feedback, while event-driven tasks that are close loop for feedback signal is required to establish when the task is completed.

Examples of the system being controlled sequence is fully automatic washing machine.

The first step in the washing cycle is filling the washing tube. It is a task-driven event because the water is allowed to enter up to achieve true high-surface. The next two tasks, rinse [wash] and turn-dry [spin-drain], each carried out over a certain period and the steps that are driven time.

X . III

motion control

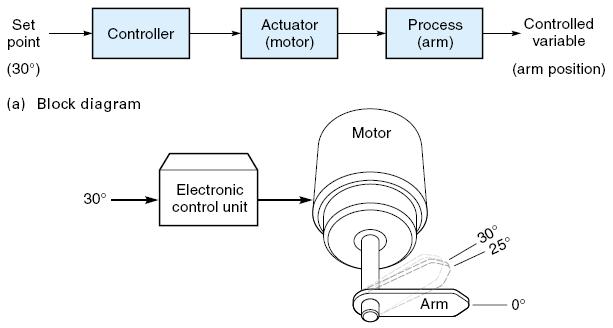

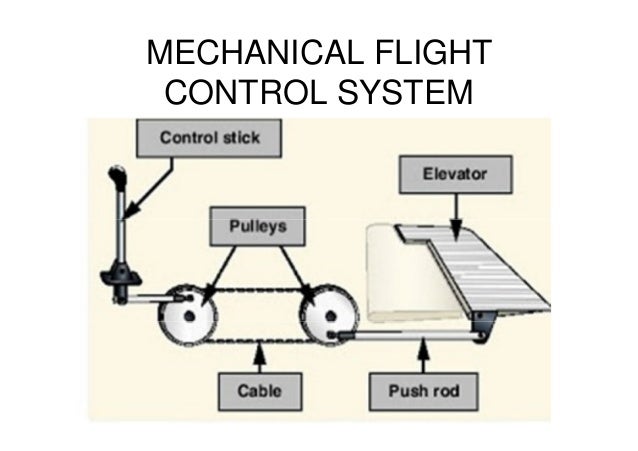

Electromechanical motion control system is an open loop and closed loop control in which objects undergo displacement. Such systems typically include motors, mechanical parts are moving, and (in many cases) sensors feedback.

Various motion control:

a. Servo-mechanism [servomechanism]

Servo-mechanism [servomechanism] is the term traditionally used to describe electro mechanical control system closed-loop directing a careful displacement of a physical object such as a radar antenna or a robotic arm. Typically, could-be-controlled output position or velocity output (or both). An example of a servo-mechanism is positioning systems for radar antenna, as shown in Figure

b. Numerical control [Numerical Control or NC]These machines can automatically cut and form-work objects without a human operator. Each engine has a set of axes [axis] and its own parameters that must be controlled; as an example, consider forging machine shown in Fig. object-work [work piece] that is being formed is attached to the table to move. The table can be moved (using electric motors) in three directions: X, Y, and Z. The rate-cutting tools also automatically controlled. To make a piece, the table moving objects passing through the gear-cutting work [cuttingtool] on the speed and depth of cuts that have been set. In this example, four parameters (X, Y, Z, and rpm) continuously and independently controlled by the controller. As an input controller receives a series of numbers which are more fully described how the part should be made. These numbers include measures of physical and details such as rate cuts and the pace of bribes [feed].

c. Robo

Robo ( Ringing on Boat ) industry is a classic example of a position control system. In most cases, the robo has a single arm with joints of the shoulder, elbow, and wrist, as well as a kind of hand called the end effector

six-axis industrial robots are controlled independently-known as having six degrees of freedom [degree of freedom]

X . IIII

Infra Red

Infra red (infra red) light is electromagnetic wavelengths than visible light is between 700 nm and 1 mm. Infrared ray is light that is not visible. When

viewed with the spectroscope light then radiation of infrared light

will be visible on the electromagnetic spectrum with wavelengths over

the wavelength of red light. With

these wavelengths, the infrared light will not be visible to the eye

but the resulting heat radiation still feels / detected. Infrared can be divided into three regions namely:

* Near Infra Red .................. 0.75 - 1.5 μm* Mid Infra Red .. ............... ... 1:50 - 10 μm* Far Infrared .................. .10 - 100 μm [wikipedia]Direct sunlight contained 93 lumens per watt radiant flux including

infrared (47%), visible light (46%), and ultra violet light (6%).Infrared rays contained in the light of the fire, sunlight, radiator reflection vehicle or exposed to heat asphalt road. Nerves in our skin can senses a difference in skin surface temperature, but we can not feel the infrared rays.Even infrared light is used to heat the food. For example in the fast-food restaurant.How can we utilize the principle of infrared to see the object?We utilize infra red detector each object emitted and infra red will

reflect or absorb infra-red so the detector captures the different

wavelengths emitted by things appropriate temperature."Since the main source of infra-red radiation is thermal radiation or

heat, every object has a particular hot temperatures even what we think

is not hot enough to radiate visible light can emit energy in the

infrared and visibleThe more heat something more can he radiate infrared radiation. "[NASA]This is the basis of human body temperature detection and detection

sensors to identify people who fell turquoise bird flu or swine flu at

international airports.Many objects absorb infra-red radiation but some are reflecting

particularly near infrared rays, near infrared rays is not related to

the temperature of the object unless the object is very hot temperature.Infrared

films (infrared detector) on the camera can see objects aided by

sunlight and other light sources that ouput infra red rays from

him then reflected and absorbed by the object. We can get the color of the object with the help of reflected and

absorbed infrared object, the color of the object is a combination of

red color blue, green (RGB) and infra red.Infra

red can be used also as a wave carier that can extend the distance

limit wave reception, but the transmitted wave to be line of sight (LOS)

or straight-infrared can not turn if the radius of vertical transmit light barrier by an object even if it is transparent. This theory we apply the digital wave modulation on the remote tv .Mobile is now integrated with infrared and blue tooth devices to communicate with a pc.Examples of its application, namely the delivery of mobile

applications pc or vice versa, takes note of the telephone number pc

very much that it can not be stored in the phone memory is usually used

for broadcasting sms.What is the difference infrared light with blue tooth?First, using infrared light to emit a signal, such as TV remote, while

blue tooth uses radio frequency (RF) (2.4 GHz) to broadcasts its

signal.second,

infra red can not penetrate objects that prevented him from reaching

the receiver or need reflection, because of its light .However Bluetooth

can penetrate objects such as walls so far do not have a high skin

depth.

X . IIIII

Electromagnetic control components and the insight

In the type of electrical control panel is divided into two categories: conventional circuits and digital circuits, conventional circuits using a relay, digital timer counter while using PLC, micro controller to process.

On the control panel component there are two categories of components, namely components of control and power components. Component control functions move the power components, power components drive the load function.

Examples of control components, namely switches, push button, relay, fuse, timer, etc. while the power components, namely: contactor , MCCB , motorcycles, etc.

Components of Control is often used:

Switch

The switch has a contact ON Contact OFF, the switch has a mechanical made always in position and can be changed when in motion

The switch has a contact ON Contact OFF, the switch has a mechanical made always in position and can be changed when in motion

Symbol:

Button

Button is divided into two: the key normaly Open (NO) and normaly Close button (NC), which distinguishes buttons and switches is the button after the emphasis will return to the starting position as there are per in mechanical

Button is divided into two: the key normaly Open (NO) and normaly Close button (NC), which distinguishes buttons and switches is the button after the emphasis will return to the starting position as there are per in mechanical

Symbol:

NC NO

![clip_image002[9] clip_image002[9]](https://plctutor.files.wordpress.com/2014/04/clip_image0029_thumb.gif?w=37&h=74)

![clip_image002[5] clip_image002[5]](https://plctutor.files.wordpress.com/2014/04/clip_image0025_thumb.gif?w=45&h=74)

rotary switch

image

Rotary switch (Selector switch) is a sugar that can change position by rotating the position, rotary switch can have 2 to over 8 positions

·

Symbol:

![clip_image002[11] clip_image002[11]](https://plctutor.files.wordpress.com/2014/04/clip_image00211_thumb.gif?w=77&h=94)

Emergency Stop

image

Emergency Stop is a type of switch that, when in the press will be locked and to remove it to be in the play, called the emergency stop to allow users to know the function of this switch is to shut down the system in an emergency

Symbol:

![clip_image002[13] clip_image002[13]](https://plctutor.files.wordpress.com/2014/04/clip_image00213_thumb.gif?w=46&h=53)

indicator lights

image

Indicator lights normally used for indication of phase R, S, T and alarm, too often for the indication of the running process

Symbol:

![clip_image002[15] clip_image002[15]](https://plctutor.files.wordpress.com/2014/04/clip_image00215_thumb.gif?w=38&h=41)

relay

image

Relay is because the magnetic switch for driving the relay contacts must provide a voltage to the coil resulting in an iron rod in coil turns into a magnet attracting the contact lever

Symbol:

contact coil

timer

image

On Timer electronic circuit there is delay turning on the relay coil, the relay there are two functions: On delay and delay timer Off, On delay time will count when the supply is On while Off delay time will count when the supply timer off

Symbol:

ODT coil OFT

Electromagnetic control components and the insight

In the type of electrical control panel is divided into two categories:

conventional circuits and digital circuits, conventional circuits

using a relay, digital timer counter while using

P L C , micro controller to process.

Some information about the elements of the automatic control system:

Process (Process) is the order of the equipment that has a specific function. Input process can vary, which certainly is a quantity that is

manipulated by the final control element or control valve so that the

variable is equal to the set point.

Input is also described manipulated variables.Manipulated variables is the input of a process that can be

manipulated or altered magnitude that process variable or variables that

are controlled equal to the set point.

Disruption is the amount other than the manipulated variable, which can cause changes in the controlled variable. This quantity is commonly called load.

The gauge element is the very tip of a measurement system (measuring system). Examples of the measuring element that is widely used for example termocouple or oriface plate. This section also commonly called a sensor or the primary element.

Transmitter is a device used to read the signal sensing element, and

convert it into signals that can be understood by the controller.

Transducer is a signal switcher unit. Said transmitter, often confused with the word transducer. Both do have a function similar, although not equally true. Transducer is more general in nature, while the transmitter more specifically on the use in the measurement system.

The variables in question or measured variable is the signal coming out of the transmitter. This measurement is a reflection of the magnitude of the signal measurement system.

Set Point is great desired process variable. A control will always try to equalize the variable that is controlled by the set point.

Error is the difference between the set point dikurangivariabel question. Error can be negative, it could be positive. Conversely, if the set point is smaller than the variable in question, the error becomes negative.

Controllers

are the elements that make up to three of the four stages of control

measures which compares the set point with a measurement variable,

calculates how much correction needs to be done, and issued a correction

signal in accordance with the results of our calculations. Controller completely replace the role of the user in control of a process. The controller is a control device.

Control Unit is part of the controller that calculates the amount of correction needed. Input control unit is an error, and the output is a signal coming out of the controller (manipulated variable).

Unit controller has a transfer function that depends on the type of controller. Output control unit is the result of the completion of the transfer function by entering a mathematical error value as input.

Final control element, such as the name suggests, is the final part of the instrumentation control system. This

section serves to change the measurement variable by manipulating the

amount of manipulated variable, based on the command controller.

error detector = X = PID = PITa

X . IIIIII

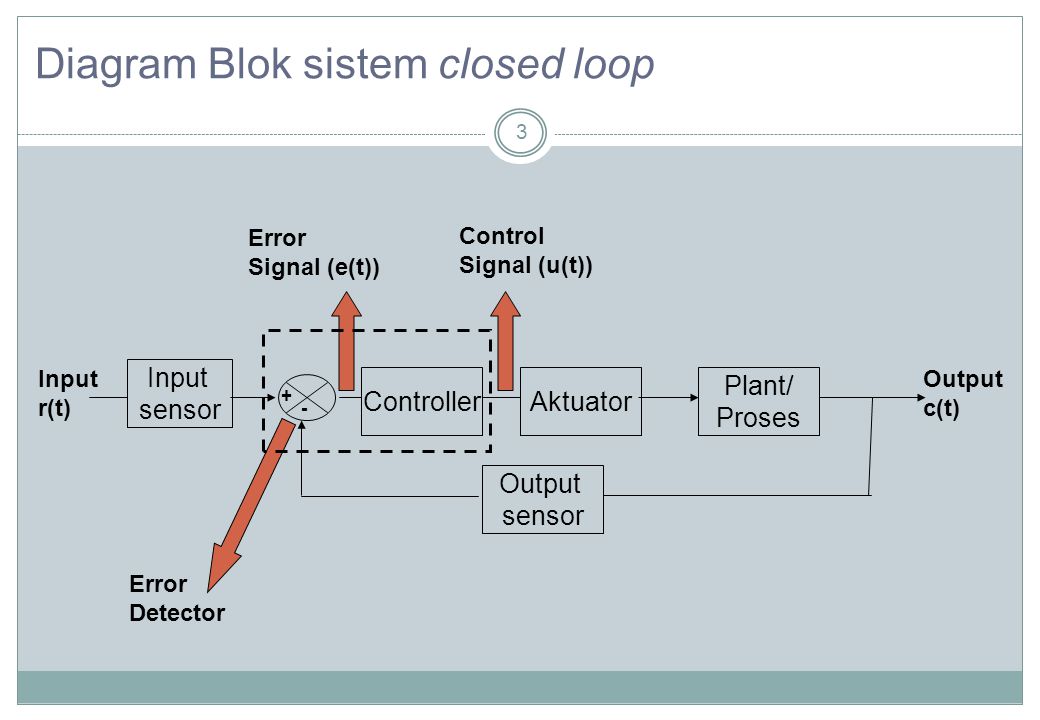

CONCEPT OF CONTROL SYSTEM, CONTROL SYSTEM OPEN and CLOSED AND EXAMPLES OF APPLICATIONDefinition Control Systems

In everyday life, consciously or unconsciously we continue to meet with a device or equipment that works controlled automatically either controlled in part or completely, such as when driving a car, when using the washing machine, using mobile phones, and many others, in a nutshell the system used to create a device be controlled in accordance with the desire of man is usually referred to as a control system (control system). Control system not only man-made control system, but also a lot of control that occurs naturally from the smallest element of the human body to the complexity of the universe.

How important is the human need ?, control system without control system, is likely to be found cars and airplanes, the flight into space? Satellite communication? Smartphone? And there are many things that are questionable. So it is understandable how important and how significant the presence of science in the development of control systems of human life.

Control system: What they are? What system control of it? 1. The system definition is an arrangement, set, or a set of things that are connected or related in such a way so as to form something as a whole, the definition of 2. The system is the physical arrangement of the components are connected or linked so that an entire unit or to act as a single unit. While the control or the control word is usually interpreted, directing, or command. The second meaning of the word and control system / control, the control system is an arrangement of the physical components that are connected or related in such a way so that it can govern, direct, or regulate itself or another system [[1]. In the world of engineering and science control system tends intended for dynamic control system.

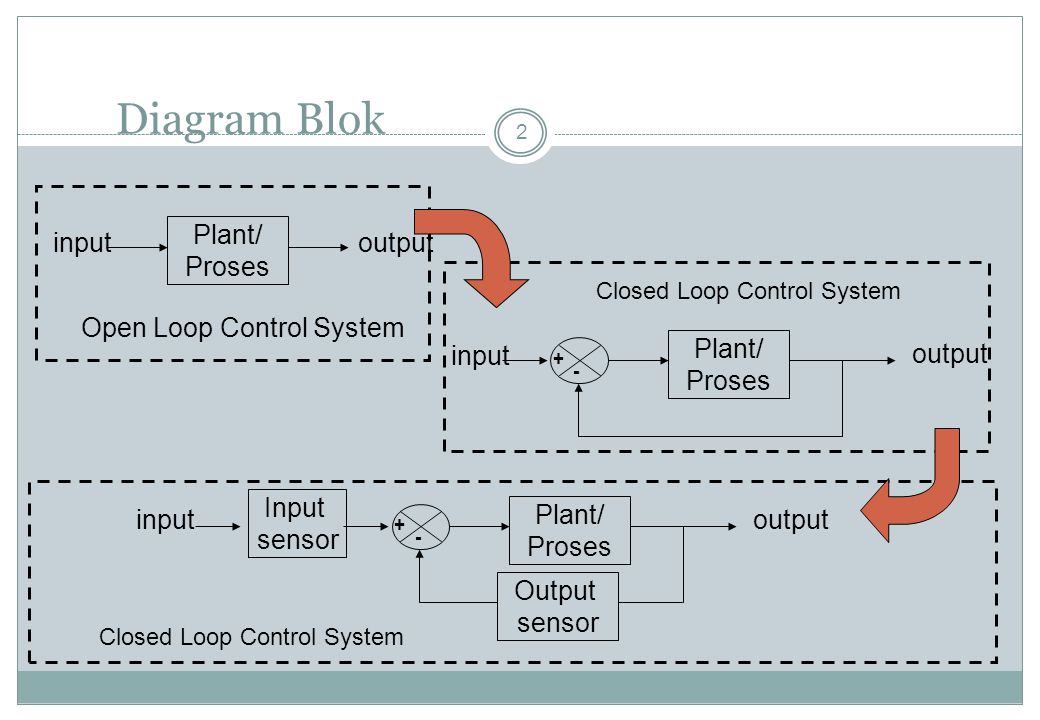

Control system consists of sub-systems and processes (or plants) are arranged to receive the output (output) and the desired performance of a given input [2]. Figure 1 below to strength block diagram for the simplest control system, the control system makes the system with a given input produces the expected output.

For example, suppose the use of an elevator (lift), when the button showing the destination floor number is pressed, the elevator will move up / down to the floor of the goal. Button is pressed numbered destination floor is input that indicates the output that we want. This system is a step function shown in the figure, the performance of the elevators can be seen from the elevator response curve.

Elevator respons

Two main scalable performance that can be seen is, first, transient response, second, steady-state error. In the example of this elevator, the convenience and the time needed to arrive at the destination users rely on transient response. If the response is too fast, passenger comfort is sacrificed, if it is too slow, the time required is also greater. Steady-state error is also a very important performance indicators for passenger safety and comfort will be sacrificed if the output is not as desired.

Classification System Control / Control

In general, the control system can be classified as follows:

Manual and Automatic Control System

Rim Systems Open (Open Loop) and the Rim Closed (Closed Loop)

Continuous and Discrete Control System

According to the driving source: Electrical, Mechanical, Pneumatic and Hydraulic

A brief explanation of the types of control systems above will be discussed below.

Manual Control System is a control carried out by humans who acts as the operator, while the Automatic Control System is performed by controlling the equipment that works automatically and operating under the supervision of a human. Manual control systems are found in everyday life such as the setting of the radio, television, television layer of light, water flow through the tap settings, controlling the speed of the vehicle, and others. While the Automatic Control Systems commonly found in industrial processes (both chemical process industry and automotive processes), air control, power generation and others.

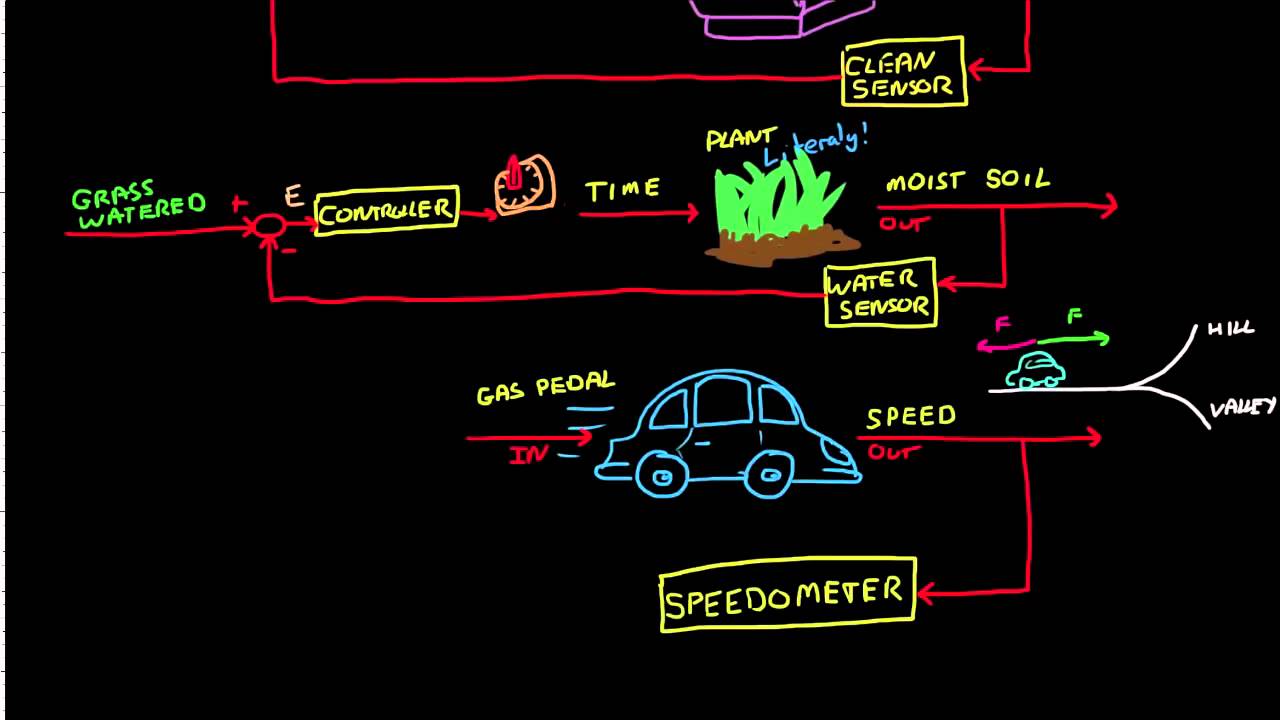

Rim Open Control System (Open Loop) is a control system in which the amount of output does not give effect to the amount of input, so that the controlled variable can not be compared to the desired price. While the Control System Closed Rim (Closed Loop) is a control system in which the amount of output an effect on the amount of input, so that the amount of controlled can be compared against the desired price. Furthermore, the price difference that occurs between the amount of which is controlled by the desired price is used as a correction which is the target of control.

Open Control System (Open Loop) and Control Systems Closed (Close Loop)

Open control system (Open Loop)

As was mentioned above that the open-loop control system is a system whose output has no effect on the control action. That is, the open control system output can not be used as a feedback in the insert.

Open Loop Control System

In an open control system, the output can not be compared with the input reference. Thus, for each input reference relates to a specific operation, as a result of the provision depends on the calibration system. With the disruption, open control system can not perform the appropriate tasks expected. Open control system can be used only if the relationship between inputs and outputs are known and there are no internal or external interference.

Feature - Feature Open Loop Control System:

Simple

The price is cheap

Can be trusted

Less accurate because there are no corrections to errors

based time

Open Loop System Application Examples:

Time-based traffic controller

Washing machine

electric oven

Escalator

Rolling detector at airports

Closed Control System (Close Loop)

Closed-loop control system is a control system output signal has a direct effect on the control action. closed loop control system is also a control system baited behind. Driving error signal, which represents the difference between the input signal and the feedback signal (which can be a function of the output signal or output signal or its derivatives). Fed to the controller to minimize errors and to make the system output near desired values. In other words, the term "closed-loop" means using feedback action to minimize the system error.

Closed loop controler

The image above shows the relationship input and output of the closed loop control system. If in this case the man worked as an operator, then these people will keep the system at the desired state, when there is a change in the human system will perform the initial steps of setting so the system back to work in the desired state.

Here are the components of control systems covered:

Input (input), the stimulus given to the control system, a desired price for the controlled variable for controlling. This price does not depend on the system output

Output (output, response), is a response to the control system, the price will be maintained for the controlled variable, and the price indicated by the recording device

Load / Plant, a physical system to be controlled (eg mechanical, electrical, hydraulic or pneumatic).

Control device / controller, the equipment / circuit to control the load (the system). This tool can be combined with the amplifier

Feedback element, show / returns the detector to the paint of the results that can be compared against the desired price (in sets)

Error Detector (error detection tool), an error detection tool that shows the difference between the input (input) and response through feedback (feedback path)

Disturbance signals an unwelcome addition. These disorders tend to result in output prices different from the prices at input , this disorder is usually caused by changes in system load, for example a change in environmental conditions, vibration or otherwise.

Examples of closed control system applications:

Servo mechanisme

Process control system

Refrigerator

Automatic Water Heater

Thermostatic control

air conditioning

example control system :

![clip_image002[21] clip_image002[21]](https://plctutor.files.wordpress.com/2014/04/clip_image00221_thumb.gif?w=56&h=56)

Tidak ada komentar:

Posting Komentar