The schematics are categorized in clear and self-explained categories in order to help you find what you are looking for fast and easy.

every time you choose to view a document. This is done for several reasons:

- 1. For copyright reasons

- 2. Space economy: Most of the circuits belong to hobbyists that may host up to some tens of circuits or even less. This would require a very small amount of disk space. Our archive has gather some thousands of circuits. This would require a significant amount of disk space.

- 3. PCB Heaven circuits archive is a the librarian, not the library. This means that our intention is to find, categorize and help you discover the circuit you want

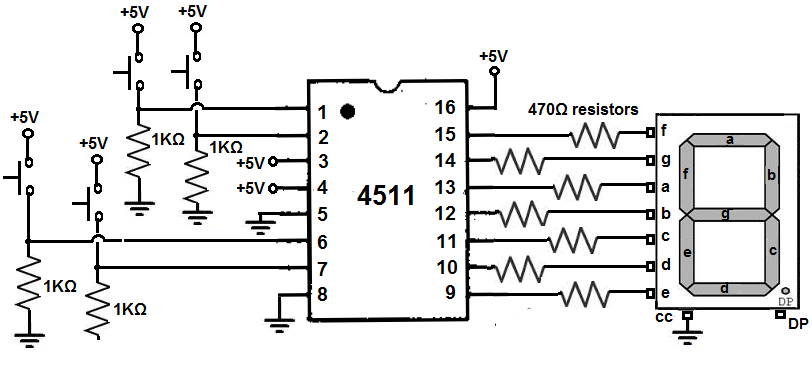

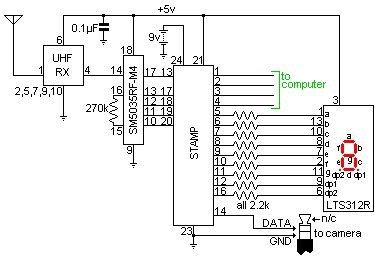

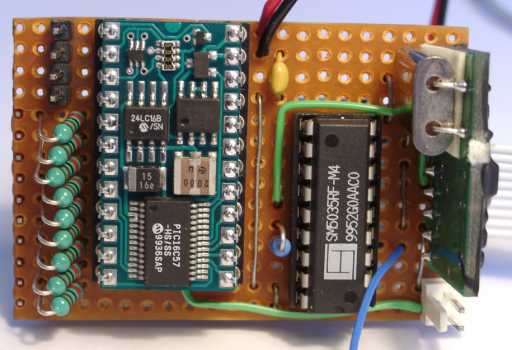

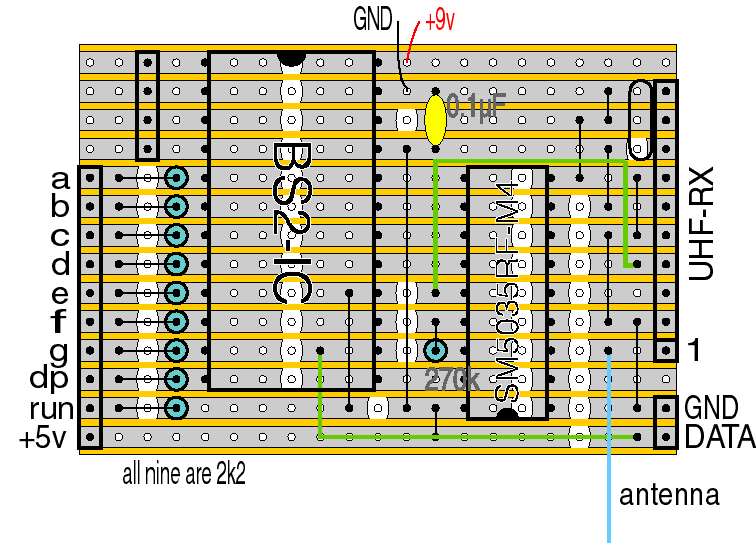

Q . I 4511B BCD to 7-segment decoder driver

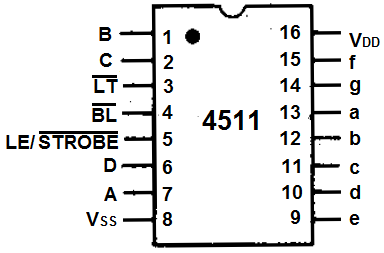

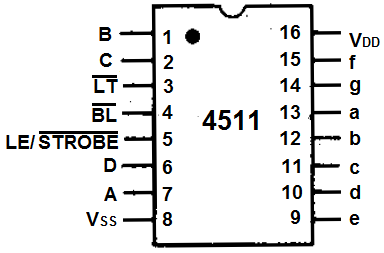

1. Pin connections

| 4511B pin connections |

How to Build a 4511 BCD to 7 Segment Decoder Circuit

In this circuit, we will build a BCD to 7 segment display decoder circuit using the 4511 chip.

A BCD to 7 segment decoder circuit is a circuit that intakes a binary value and displays the equivalent decimal value on the 7 segment display.

Using binary coded decimal (BCD), we can display any numerical digit on the 7 segment display from 0 to 9- using only 4 pins. Otherwise, without this chip, to display all the decimal digits (0-9), you would have to use 7 pins; so it saves us 3 pins.

How the 4511 BCD to 7 segment display decoder works is it has 4 pins that intake a binary value. Each of these 4 pins can hold a 0 (LOW) or a 1 (HIGH). These data pins are referred to in the datasheet as D, B, C, and A. We can choose what digit we want to display by inputting the equivalent binary value into these data pins. For example, if we want to display 6 on the 7 segment display, we input the value 0110 into the DBCA data pins. The binary value 0110 is the equivalent of the decimal value of 6. This is why it's called binary coded decimal. With the binary value input, the equivalent decimal value of that binary number is displayed on the 7 segment display. Otherwise, you would have to know which pins on the 7 segment display to turn on or off, making it much more complicated. This chip saves us a lot of work for that reason.

In this circuit, we will start the 4511 BCD to 7 segment display decoder with the most basic circuit. We will connect this chip by itself to pushbuttons. Using the pushbuttons, you can manually see how depending on which pushbuttons we press, how the output changes in response. So we can see which combinations of pushbuttons turned on displays which decimal values.

Below, we will also explain how BCD to 7 segment display decoders work in great detail, specifically the 4511 chip.

Components

- 4511 BCD to 7 Segment Display Decoder

- 7 segment display

- 4 1KΩ resistors

- 7 470Ω resistors

- 4 pushbuttons

The 4511 BCD to 7 segment display decoder can be gotten very cheaply for under $1 on ebay.

The 4511 chip takes in a binary value and displays the equivalent decimal value on the 7 segment display.

The 4511 is a 16-pin chip. The pinout of the 4511 is shown below.

To power the chip, VDD, pin 16 to 5V and VSS, pin 8, connects to ground. The 4511 chip is capable of handling up to 20V.

The 4 input data pins, which control the digit which is shown on the 7-segment LED display, are D, C, B, and A which are pins 6, 2, 1, and 7, respectively. These 4 data pins are fed binary values. Connecting a pin to VCC puts the pin in a HIGH state or value. Connecting a pin to ground or 0V puts the pin in a LOW state or value. This is how we adjust the value of these data pins. There are 4 data pins hold a binary value. The decimal equivalent of the binary value that it holds will be displayed on the 7 segment display. So, for example, if we want to show the decimal number 5, we give a value of 0101 to the DCBA data pins.

Pin 3 is the LT pin, which is the Lamp Test pin. This pin is active LOW. When HIGH, the lamp test is activated. This makes all the outputs HIGH, so if LEDs are attached to all of the outputs, all of the LEDs will turn on if this pin is HIGH. When LOW, this feature is not activated. It's simply to test all the outputs to check if they turn on.

Pin 4 is the Blanking pin. This pin is active LOW. When HIGH, all the outputs go LOW, so they'll all shut off, like a reset pin. When HIGH, this feature is not ativated.

The LE/STROBE pin is the Latch Enable/STROBE has dual purposes depending on whether it's HIGH or LOW. When LOW, the pin is in strobe mode, meaning it strobes the output to a given device, which in this case is a 7 segment LED display. This mode is the mode we usually want it in for display purposes. So in normal operation, it's held LOW. When HIGH, it is store mode. So it simply stores latches or stores the data without transferring to a device.

Lastly, the 8 output pins are labeled a, b, c, d, e, f g, which are pins 12, 12, 11, 10, 9, 15, and 14. These are the pins we attach to each of the corresponding pins on the 7 segment LED display. For example, a on the 4511 matches to a on the 7 segment LED display, b matches with b, etc.

The decimal digit that the 7 segment display shows out depends on the binary value fed into the 4 input data pins DBCA.

The table below summarizes the binary input values to the decimal digit shown on the 7 segment display.

| Binary Coded Decimal Chart | |||||

| Decimal Number | Binary Word | B8 | B4 | B2 | B1 |

| 0 | 0000 | Low | Low | Low | Low |

| 1 | 0001 | Low | Low | Low | High |

| 2 | 0010 | Low | Low | High | Low |

| 3 | 0011 | Low | Low | High | High |

| 4 | 0100 | Low | High | Low | Low |

| 5 | 0101 | Low | High | Low | High |

| 6 | 0110 | Low | High | High | Low |

| 7 | 0111 | Low | High | High | High |

| 8 | 1000 | High | Low | Low | Low |

| 9 | 1001 | High | Low | Low | High |

You can see based on this chart why it's a binary coded decimal system.

If we input a binary value into the data pins, we get the corresponding decimal digit equivalent shown out on the 7 segment display.

So, for example, if we input 0000 into the data pins, we get the number 0.

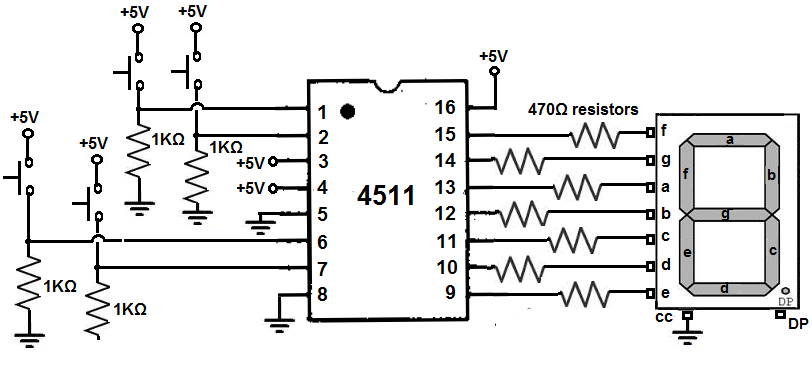

4511 BCD to 7 Segment Display Decoder Circuit

The 4511 BCD to 7 segment display decoder circuit we will build is shown below.

First, to power the 4511 chip, we connect VDD, pin 16, to +5V and VSS, pin 8, to ground. This establishes sufficient power to the 4511 chip.

The LT pin, pin 3, is connected to +5V. This pin would turn on all the outputs if connected LOW. Being that we don't wish to use this feature, we simply connect it permanently HIGH. However, if you do want to use this feature, you can simply connect it to a pull-up resistor with a pushbutton. When unpressed, the pin will be HIGH. When pressed down, it would be LOW and turn on all the outputs.

The Blanking pin, pin 4, is connected to +5V. This pin would blank all the outputs if connected LOW or to ground. Being that we don't want the blanking feature activated, we simply connect it permanently to HIGH. However, if you want to use this feature in your circuit, you simply connect a pull-up resistor to this pin with a pushbutton. When unpressed, the pin will be HIGH. When pressed, it will go LOW and turn off all the outputs.

The LE/STROBE pin, pin 5, is connected to ground. This is because we want to strobe the outputs to the 7 segment LED display.

The 4 data pins are D, B, C, and A. These pins are all connected to pull-down resistors. Without the pushbuttons being pressed, the pins are all in a LOW state. If the pushbuttons are pressed, they go to a HIGH state. Depending on the combination of pushbuttons being pressed determines the decimal digit that will be shown on the 7 segment LED display; this is summarized in the table above.

To each of the output pins, a through g, we connect an LED with a 470Ω current-limiting resistor.

How the Circuit Works

The circuit works directly through the control of the 4 pushbuttons which control the binary value we feed into the data input pins.

Being that they are all connected to pull-down resistors, they are all initially LOW when unpressed. So the 7 segment LED display will show a 0 initially.

The combination of pushbuttons pressed and unpressed determines the decimal digits, according to the binary value. The equivalent decimal value of the binary value we feed into the data input pins will be shown.

We can show the digits 0 through 9. We cannot show any other digits on the 7 segment display. So the highest value we can feed into is 1001, which is 9 in decimal. Any value above this amount cannot be shown on the 7 segment LED display.

So if we want to show a 4, we pressed down on pushbutton C while having all the other pushbuttons unpressed. You should now see a 4 on the 7 segment LED display.

The 4511 really makes it much simpler to work with single 7 segment LED displays.

To see how to make a 7 segment display count up from 0 to 9 or count down from 9 to 0 automatically without any manual pushbutton intervention, we can connect a binary up/down counter to this circuit. 7 Segment LED Counter This simple counter can be used to count pulses, as the basis for a customer counter (like you see at the doors of some stores), or for anything else that may be counted. The circuit accepts any TTL compatible logic signal, and can be expanded easily (see Notes).

Interfacing to 7-Segment Numeric Displays

7-Segment Numeric LED Displays

In industrial PLC applications, one of the old, but simpler methods of displaying numeric information is to use one or more 7-Segment numeric displays connected to an output card of a PLC... Although it is possible to build such a display yourself, it is far more common to employ a pre-manufactured product such as the 4-digit panel mount unit shown at the top of this page...

To correctly interface a PLC to such a display, it helps to first understand what basic electronic components are typically employed in their makeup, and how this effects our task of interfacing to, and programming such a unit... Although both LED and LCD numeric displays are readily available, and interfaced similarly, we'll concentrate on the more common LED units in the examples to follow...

BCD to 7-Segment Decoder c/w 4-bit Latch

Once 7-Segment LED displays became readily available, a simple IC known as a "BCD to 7-Segment decoder" was quickly developed to simplify their use... Binary formatted data presented to this IC's inputs results in the IC's outputs being placed into the correct state to display the equivalent numeral (0 to 9) on a 7-Segment display...

Although BCD to 7-Segment decoder ICs are available without built in latches, this particular IC includes a built in 4-bit latch which we will make use of in later examples... For now the latch is set to simply allow input data to freely pass through to the decoder...

In the above diagram, the 4 toggle switches, SW0 to SW3 are used to select the desired numeral (0-9) that will appear on the 7-Segment display... By using a decoder, it's now simply a matter of setting the correct 4-bit BCD pattern feeding the inputs of the decoder, and the decoder takes care of the rest...

The decoder section also has two additional inputs... Lamp Test (LT) turns all segments on so you can verify at once that all display segments are working, or identify display units that need to be replaced... This input is normally left at logic 1... The Blanking (BL) input is just the reverse; it forces the entire display off... This is used in many cases to blank out leading or trailing zeros from a long display... LT will override BL so you can test even blanked-out display digits...

One should also note that the same circuit could conceivably be controlled by a PLC, if 4 output bits from a 5VDC PLC output card were used in place of the 4 switches shown... If an 8-bit output card were available, then two such circuits (2 digits) could be controlled... A 16-bit card would in turn allow us to control four such circuits (4 digits)..etc...

Parallel Non-Multiplexed Multiple Digit Display

The figure (above) on the left is taken from the LogixPro I/O simulator screen, and depicts a common method of interfacing to a 4 digit display... The figures on the right are taken from the data sheet of a pre-manufactured 4 digit display unit which could be readily employed in this particular application...

The manufactured unit does contain four separate circuits, and each circuit (digit) has it's own decoder, but compared to our earlier circuit example, this unit employs additional components and circuitry making it far more versatile and easy to use...

Note that there are 4 "Strobe" lines shown; one for each digit... These strobe lines control built in IC latches which provide us with the option of multiplexing the digits, or displays, if we wished to do so... In the above non-multiplexed application, the strobes are permanently enabled allowing data to simply pass through from the BCD inputs and be displayed as normal...

Also note that this particular unit is designed for 24VDC use... This is by far the most common DC voltage level used in industrial installations, and PLC I/O cards designed for such use are therefore extremely common... In comparison to 5VDC circuits, 24VDC circuits can typically tolerate far greater supply voltage excursions, are less sensitive to the effects of contact resistance, and more tolerant of electrically noisy environments...

Multiplexed Digits

By making use of the 4-bit latches that are built into the 4511 IC, we can easily multiplex the digits if so desired... By properly controlling the state of each latch enable pin (LE) we can use the same input data lines (4 switches) to selectively write to each 7-Segment display independently... With just a minor modification to our circuit, we will be able to essentially treat each digit as a unique 4-bit memory location where BCD data of our choosing can be stored and retained...

In the above schematic diagram, each display may be written to separately... First the BCD equivalent of the desired numeral (0-9) is set using the 4 data switches... If SW1 is then closed, the current BCD input data will enter the latch of the upper 4511 IC, and will be passed on to the decoder causing the numeral to displayed... if SW1 is then opened, the latch will retain the current data, but will now ignore any changes on it's inputs... The desired numeral will continue to be displayed by the upper LED display until power is lost, or SW1 is again closed and new data is allowed to enter it's latch...

The Lower 7-Segment display may be written to in a similar fashion... Set the BCD equivalent of the desired digit using the 4 data switches, then close SW2 momentarily to store and retain the current BCD data... We might say that we are strobing the data into the display...

We could readily replace the 4 data switches and 2 latch switches if we had 6 5VDC outputs available on our PLC... If we wished to add additional digits, we would require 1 more PLC output for each digit added... By multiplexing the data in this fashion we would only require 8 PLC outputs to control a 4 digit display...

4 Digit Display configured for Multiplexed Digits

By using multiplexed data lines as shown above, we can dramatically reduce the number of PLC outputs required (8) to control this 4 digit display... The down side is that writing a ladder logic program to update a display wired in this fashion will be somewhat more complicated then one written to control 4 digits wired in parallel...

If you have been looking closely, you may have questioned the purpose of the dual inline sockets located on the wiring PCB of this manufactured display unit.. Well essentially the 16 data lines are internally connected in parallel with these sockets, and this allows us to easily add additional units by simply interconnecting them using a flat ribbon cable assembly...

Multiple 4 Digit Displays configured for Multiplexed Digits

For those with a fundamental knowledge of computers, you'll likely note that we have essentially created a 4-bit data bus, and the strobe lines are in effect our address bus... We can continue to add additional digits, and for each digit added we will require 1 additional PLC output, or 4 outputs per quad display...1 Quad Display requires 4 data + 4 strobes = 8 outputs

2 Quad Displays requires 4 data + 8 strobes = 12 outputs

3 Quad Displays requires 4 data + 12 strobes = 16 outputs

4 Quad Displays requires 4 data + 16 strobes = 20 outputs

If you are reading through this tutorial because you are having difficulty determining how to control the 4 quad displays in the Bottle Line Simulation, you may already have noted that the displays in that simulation do not employ muxed (multiplexed) digits, but rather the quad displays themselves are muxed... Why this method was chosen, will be investigated now...

Multiplexed 4 Digit Displays ..... (Bottle Line Simulation)

The above diagram functionally depicts how the 4 panel mounted display units in the Bottle Line simulation are deemed to be configured... In this case, the 4 manufactured displays are wired to a shared 16-bit data bus (wires) which is connected to a 16-bit 24VDC output card (O:4) that is dedicated to this purpose... 4 unused outputs from card O:2 were selected, and appropriately wired to allow control of the strobe lines associated with each display unit...

Each unit may be written to individually by first sending the 16 bit BCD representation of the 4 decimal numerals to output card O:2... If one of the four output bits 0:2/11 to O:2/14 is then taken from an initial low, to high state, the BCD data will enter the selected latches, and the numerals will be displayed... If this strobe line is then returned to the initial low state, the BCD data will (be latched) remain in the latches, and continue to be displayed... Any changes in the state of the data lines will now be ignored, and this will continue until the next low-to-high transition of this unit's strobe line occurs...

You may have noted that this configuration requires a high level on the strobe line to allow data to enter the latch, while some of our earlier examples required a low state... The polarity of the strobe is non critical, and with this particular make of display, the choice of polarity is set by simply positioning a configuration DIP switch appropriately...

Multiplexed Digits vs Displays

There are no hard and fast rules relating to this issue, but a quick look at the following chart does provide some food for thought...

................................Muxed Digits....Muxed Displays

1 Quad Display requires.......8 outputs......16 outputs (no muxing)

2 Quad Displays requires.....12 outputs......18 outputs

3 Quad Displays requires.....16 outputs......19 outputs

4 Quad Displays requires.....20 outputs......20 outputs

5 Quad Displays requires.....24 outputs......21 outputs

6 Quad Displays requires.....28 outputs......22 outputs

10 Quad Displays requires....44 outputs......26 outputs

Another consideration relates to ease of programming... The task of writing digits one at a time is obviously going to be a greater challenge then writing 4 digits at a time... Also, fewer instructions typically equates to an easier to read program, plus a quicker scan... If you need to control 4 quad displays, muxed displays would be my choice... Need 10 displays, and it might be time to consider some other means of presenting information to the operator... Human machine interface

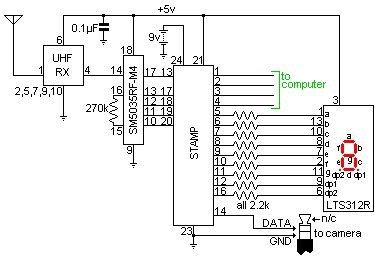

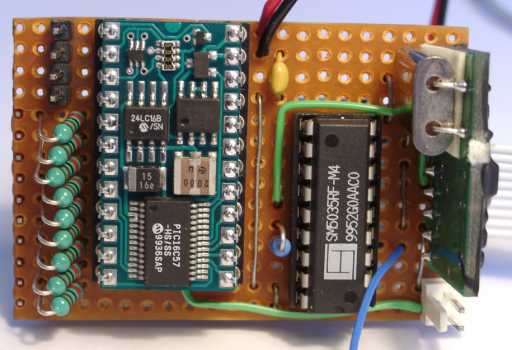

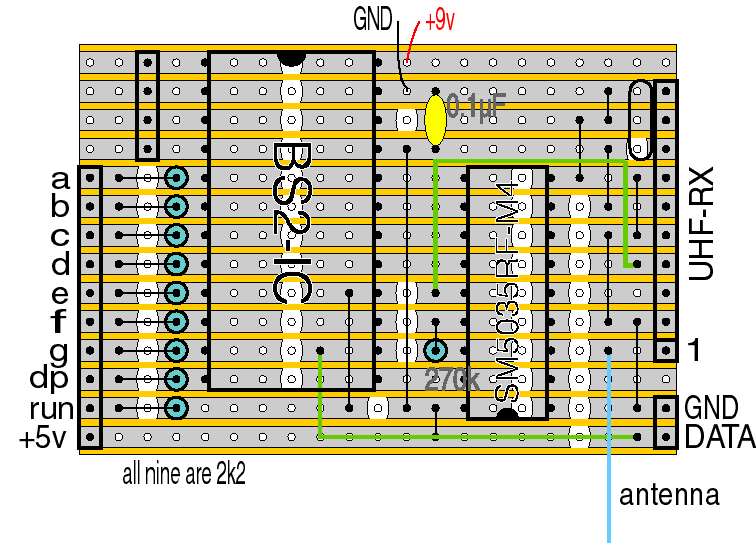

micro engineer

some way to get input to the microcontroller and some way to display information from the micro. Let's start taking a look at I/O, with the concentration this time on the O.

Sometimes you just need to be able to light up an indicator to give you an idea of what is happening - power on. At other times it would be nice to display several numbers, or even words. We'll start with a simple light, move up to numbers, and maybe next time, words.

The most common indicator these days is the light emitting diode, or LED. Just a few years ago, they didn't exist. Now they are in everything, because of their low cost, long life, low current requirements and overall colorful personality.

LEDs come in red, orange, yellow, green and even blue is becoming reasonably priced. In general, they require around 2 volts to operate, though some have built-in regulators to run from 5 volts and some even have flasher circuits built-in. You can get a single LED for an indicator light, or you can buy several all packaged up in a matrix of dots or numeric segments.

Since LEDs run on about 2 volts, you can't shove 5 volts through them and expect them to take it like a man. You need a simple resistor in series to absorb some of the voltage and limit the current the LED can draw. You should check the specifications for your particular LED to calculate the exact resistor value. Of course, you can rarely find the specs on the generic LED you just got from your parts house, so we'll just use generic specs: 2 volts at 10 milliamps (ma) of current. You can choose more or less current depending on how bright you want the LED (up to a point) and how efficient your LED is (some light up with just 1ma of current.)

So if we start with 5 volts and the LED drops 2 volts, our series resistor needs to drop the remaining 3 volts. Using the old V = IR equation (no, it isn't just for infrared LEDs), V is 3 volts, I is 10ma (.010 amps), we can solve for R: R = V/I = 3/.010 = 300 ohms. That didn't hurt too much did it?

Of course, finding a 300 ohm resistor could be a pain. The more common ones have odd, non-decimal values. The closest ones for us are 270 ohms and 330 ohms. I'm going to choose 270 ohms which will increase our current a little, making the LED slightly brighter. Rearranging our equation once more: I = V/R = 3/270 = .0111 amps or 11ma.

The last little gotcha is that LEDs are one-way, one side is plus, the anode, and the other is minus, the cathode. If you hook it up backwards, you can damage the LED, but usually it just won't light up. Most LEDs have one lead longer than the other, the longer one being the plus side (anode.) If you have cut off the legs before checking, you may find that the plastic case is flat towards the minus lead (cathode.)

After all of this, we can finally hook up our power LED as shown:

As you can see from Figure 1, it doesn't really matter which side of the LED the series resistor is connected to. I know this may be way too basic for some readers, but judging from the phone calls I get, this all needs to be said. Besides, we'll get in over everybody's head by the end of this article.

As you can see from Figure 1, it doesn't really matter which side of the LED the series resistor is connected to. I know this may be way too basic for some readers, but judging from the phone calls I get, this all needs to be said. Besides, we'll get in over everybody's head by the end of this article.

So far we have an LED that lights up any time power is applied, but how do we control it? We have a choice of connecting one end to ground and turning on and off 5 volts from an I/O pin, or we can connect that end to 5 volts and turn on and off ground. Depending on the application, one way or the other might be appropriate. In many cases, I/O pins can sink more current than they can source. In other words, the drivers that put out ground are more powerful than the drivers that put out 5 volts. So it might be better to connect the LED directly to 5 volts and turn on and off ground to the other end. This confuses some people, so feel free to connect one end to ground and turn on and off 5 volts from the I/O pin. One final consideration is to be sure that the I/O pin of the microcontroller you are using can actually sink or source the necessary 11ma of current. In the case of a PIC®, we can drive well beyond that puny amount.

Now let's hook up 2 LEDs. It should be about as simple as one and besides, we only need one current limit resistor right? Well, not exactly. Take a look at Figure 3. In the drawing on the left, you can see 2 LEDs connected to 2 I/O lines with 2 series resistors. This is usually what you want to do. Consider the drawing on the right. It should do the same thing with only one current limit resistor - you just saved .005 cents. And if you only turn on one LED at a time, it actually will work fine.

Now let's hook up 2 LEDs. It should be about as simple as one and besides, we only need one current limit resistor right? Well, not exactly. Take a look at Figure 3. In the drawing on the left, you can see 2 LEDs connected to 2 I/O lines with 2 series resistors. This is usually what you want to do. Consider the drawing on the right. It should do the same thing with only one current limit resistor - you just saved .005 cents. And if you only turn on one LED at a time, it actually will work fine.

But look what happens when you turn on both LEDs at the same time. The resistor will still follow Ohm's law as described above, drop 3 volts and limit the current to 11ma. However, now that current has to be shared by 2 LEDs. If you are lucky, each LED will get 5.5ma. But it is more likely that the split will be uneven and one will draw more current than the other. In either case, the LEDs will be quite a bit dimmer than if each had its own allotment of 11ma.

But look what happens when you turn on both LEDs at the same time. The resistor will still follow Ohm's law as described above, drop 3 volts and limit the current to 11ma. However, now that current has to be shared by 2 LEDs. If you are lucky, each LED will get 5.5ma. But it is more likely that the split will be uneven and one will draw more current than the other. In either case, the LEDs will be quite a bit dimmer than if each had its own allotment of 11ma.

The normal end to this story would be: use 2 resistors. But we have a microcontroller on duty. Perhaps the biggest benefit of a microcontroller is its ability to trade hardware for software. Maybe you just don't have the extra .005 cents for the resistor, not to mention the assembly cost and board space required for it. Remember we said earlier that as long as we don't turn on both LEDs at the same time, things will work out fine with only one resistor. What we can do with a microcontroller is time-multiplex the LEDs so that only one LED is on at a time. By rapidly turning on and off each LED in sequence, it will appear as if both are on at the same time. It has something to do with the way our eyeballs and brains work, persistence of vision. It is similar to the way that TV works, we can see a steady picture even though there is nothing good on.

Next let's step up to 7 LEDs. And let's arrange them in the shape of a figure 8 like this:

Wow, with this kind of configuration we can build the numbers 0 - 9 and even some letters. I should patent this idea. Anyway, a 7 segment display consists of 7 individual LEDs with one end of each LED connected together. If all of the plus ends are connected together, it is called common anode. If all of the minuses are connected together, it is called common cathode.

Wow, with this kind of configuration we can build the numbers 0 - 9 and even some letters. I should patent this idea. Anyway, a 7 segment display consists of 7 individual LEDs with one end of each LED connected together. If all of the plus ends are connected together, it is called common anode. If all of the minuses are connected together, it is called common cathode.

Whether you choose common anode or common cathode depends on how you want to hook things up. I am going to choose common anode with all the pluses connected together for reasons you will see shortly. Figure 5 shows one way to connect the display to a PIC. The 8 cathode lines are connected to the 8 PortB lines through series resistors. 8? What happened to 7 segments? I have also connected the decimal point for good measure. The common anode line is connected to 5 volts.

We could use the technique described above and put only one current limit resistor in the common line to 5 volts. However we would have to light up each segment one at a time over and over again in order to display a complete character. We would need to do this at least 100 times per second (1000 times per second is better) to cut down flicker. If you only have one 7 segment display in your project, this could be workable. But we are going to add more.

We could use the technique described above and put only one current limit resistor in the common line to 5 volts. However we would have to light up each segment one at a time over and over again in order to display a complete character. We would need to do this at least 100 times per second (1000 times per second is better) to cut down flicker. If you only have one 7 segment display in your project, this could be workable. But we are going to add more.

To add another display, we could use 8 more I/O lines, connecting the next display to PortC, for example. While it makes programming easier, it eats up I/O pins in a hurry. You could also add separate latches or even decoders for each display, but, once again, we are going to use software instead of hardware.

As you can see in Figure 6, the cathodes from a particular segment of each display are all connected together and then connected to a PIC I/O line through a series resistor. We have also removed each common anode from 5 volts and made it controllable by a PIC I/O pin. In this manner, we can set up the segment value for a given display and then briefly turn on the anode for that display. If we do each one fast enough, we will see the entire display, flicker free.

As you can see in Figure 6, the cathodes from a particular segment of each display are all connected together and then connected to a PIC I/O line through a series resistor. We have also removed each common anode from 5 volts and made it controllable by a PIC I/O pin. In this manner, we can set up the segment value for a given display and then briefly turn on the anode for that display. If we do each one fast enough, we will see the entire display, flicker free.

Remember earlier we chose common anode? Let's take a look at current considerations to see why. The PIC is now driving up to 8 LEDs (segments) at a time off a single port. Just as each I/O pin has a limit to the amount of current it will source or sink, each port also has a limit. To do the least damage, we are sinking the current to ground rather than sourcing it to 5 volts.

You'll also note in the figure that I snuck in a transistor between the PIC and the common anode to each display. Since the current for the entire display runs through this one pin, it could overload a single I/O line. The transistor amplifies the current drive capability of the I/O line to solve this dilemma. It is easy to operate, put ground on the I/O pin to turn on the transistor and enable a given display, put 5 volts on the pin to turn off the transistor and the display.

Now all we need is software. The first task is to figure out how to get numbers (and even some letters) on the display. All we really have right now are a bunch of individual LEDs connected to I/O pins. To form characters, we need to come up with a way to turn on specific ones while leaving others off.

Let's look at the case of 8. Eight is pretty simple. It is all the LEDs (except the decimal point) on. To display 8 we need to put a binary 1000 0000 on PortB. This will turn on all the LEDs except the decimal point. 0 = on? Remember, we are controlling the minus side of the LEDs. We also need to put a value onto PortA to address a specific LED digit, 1110. Once again, 0 will turn on one of the transistors and 1 will ensure the others are off.

The number 0 is simply an 8 with the middle segment off, 1100 0000. Now we could have a subroutine to decode each digit, but that gets long and I hate to type (hard to tell?) The easiest way to proceed is by using a lookup table. This method is particularly effective when you have a limited number of combinations of desired states, in our case 10 (0-9.)

Now by simply using the number we wish to display, 0 - 9, as the index into the lookup table, we can easily find the proper value to put onto the I/O port. You can even extend the lookup table to include some letters, a - f perhaps.

In Microchip assembler, the code looks something like this:

The jump table feature of PICs is pretty amusing. There is actually no other way to get constant data into a program, other than moving literals, of course. The jump works like this: You load W with the index to the particular item you want out of the table. You then call the jump routine. There is one instruction at the top of your jump table. It says to add W to the current program counter. This effects the jump right to your item. The item itself is a line that says return the constant value you want in W, right back to the caller. It is pretty quick and simple, once you get the hang of it. The one gotcha here is that the table must be all in one page. You also need to preset PCLATH if it is not in the page you are in.

In PICBASIC, the display routine looks something like this:

This gets you the basic format to light up a single digit. All that remains is to write the code that separates a binary number into the 4 decimal digits and display each digit. It's kind of a pain to write in assembler, so here's some more PICBASIC code:

Don't forget you want to call this routine continuously, or at least as often as possible, to reduce the amount of flicker. Of course, this is the biggest drawback with using LEDs: You have to continuously scan the data out to the displays.

Another American company called Motorola, quickly realized what was going on, so they launched 8-bit microprocessor 6800. Their chief constructor was Chuck Peddle. Apart from the processor itself, Motorola was the first company that also manufactured other peripherals such as the 6820 and 6850. At that time many companies recognized the greater importance of microprocessors and began their own development. Chuck Peddle left Motorola to join MOS Technology and kept working intensively on developing microprocessors.

At the WESCON exhibition in the USA in 1975, a crucial event in the history of the microprocessors took place. MOS Technology announced that it was selling processors 6501 and 6502 at $25 each, that interested customers could purchase immediately. It was such a sensation that many thought it was a kind of fraud, considering that competing companies were selling the 8080 and 6800 at $179 each. On the first day of the exhibit, in response to the competitor, both Motorola and Intel cut the prices of their microprocessors to $69.95. Motorola accused MOS Technology and Chuck Peddle of plagiarizing the protected 6800. Because of that, MOS Technology gave up further manufacture of the 6501, but kept manufacturing the 6502. It was the 8-bit microprocessor with 56 instructions and ability to directly address 64Kb of memory. Due to low price, 6502 became very popular so it was installed into computers such as KIM-1, Apple I, Apple II, Atari, Commodore, Acorn, Oric, Galeb, Orao, Ultra and many others. Soon several companies began manufacturing the 6502 (Rockwell, Sznertek, GTE, NCR, Ricoh, Commodore took over MOS Technology). In the year of its prosperity 1982, this processor was being sold at a rate of 15 million processors per year!

Other companies did not want to give up either. Frederico Faggin left Intel and started his own company Zilog Inc. In 1976 Zilog announced the Z80. When designing this microprocessor Faggin made a crucial decision. The 8080 had already been developed and he realized that many would remain loyal to that processor because of the great expenditures which rewriting of all the programs would result in. Accordingly he decided that a new processor had to be compatible with the 8080, i.e. it had to be able to perform all the programs written for the 8080. Apart from that, many other features have been added so that the Z80 was the most powerful microprocessor at that time. It was able to directly address 64Kb of memory, had 176 instructions, a large number of registers, a built-in option for refreshing dynamic RAM memory, a single power supply, greater operating speed etc. The Z80 was a great success and everybody replaced the 8080 by the Z80. Certainly the Z80 was commercially the most successful 8-bit microprocessor at that time. Besides Zilog, other new manufacturers such as Mostek, NEC, SHARP and SGS appeared soon. The Z80 was the heart of many computers such as: Spectrum, Partner, TRS703, Z-3 and Galaxy.

In 1976 Intel came up with an upgraded version of the 8-bit microprocessor called the 8085. However, the Z80 was so much better that Intel lost the battle. Even though a few more microprocessors appeared later on the market (6809, 2650, SC/MP etc.), the die had already been cast. There were no such great improvements which could make manufacturers to change their mind, so the 6502 and Z80 along with the 6800 remained chief representatives of the 8-bit microprocessors of that time.

Simply, In order to communicate with peripheral environment, the microprocessor must use specialized circuits added as external chips. In short microprocessors are the pure heart of the computers. This is how it was in the beginning and remains the same today.

Excepting strictly controlled laboratory conditions, the most complicated electronic circuits cannot accurately determine the difference between two sizes (two voltage values, for example) if they are too small (lower than several volts). The reasons are electrical noises and something called the “real working environment” (unpredictable changes of power supply voltage, temperature changes, tolerance to values of built in components etc.). Imagine a computer which would operate upon decimal numbers by recognizing 10 digits in the following way: 0=0V, 1=5V, 2=10V, 3=15V, 4=20V… 9=45V !? Did anybody say batteries? A far simpler solution is the use of binary logic where 0 indicates that there is no voltage and 1 indicates that there is voltage. It is easier to write 0 or 1 instead of “there is no voltage” or “there is voltage”. It is called logic zero (0) and logic one (1) which electronics perfectly conforms with and easily performs all those endlessly complex mathematical operations. It is electronics which in reality applies mathematics in which all numbers are represented by two digits only and in which it is only important to know whether there is voltage or not. Of course, we are talking about digital electronics.

110 = 1*2^2 + 1*2^1 + 0*2^0 = 6

It should be noted that for decimal numbers from 0 to 3 you only need two binary digits. For greater values, extra binary digits must be added. Thus, for numbers from 0 to 7 you need three digits, for numbers from 0 to 15- four digits etc. Simply speaking, the largest binary number consisting of n digits is obtained when the base 2 is raised by n. The result should be then subtracted by 1. For example, if n=4:

2^4 – 1 = 16 – 1 = 15

Accordingly, using 4 binary digits it is possible to represent decimal numbers from 0 to 15, including these two digits, which amounts to 16 different values in total.

Don’t be confused if you find some bit has value 4, 16 or 64. It means that bit’s values are represented in decimal system. Simply, we have got so much accustomed to the usage of decimal numbers that these expressions became common. It would be correct to say for example, “the value of sixth bit in binary number is equivalent to decimal number 64”. But we are human and habits die hard… Besides, how would it sound “number: one-onezero- one-zero…”

A nibble is referred to as half a byte. Depending on which half of the byte we are talking about (left or right), there are “high” and “low” nibbles.

The operation of these elements is based on the principles established by British mathematician George Boole in the middle of the 19th century- even before the first bulb was invented! In brief, the main idea was to express logical forms through algebraic functions. Such thinking was soon transformed into a practical product which far later evaluated in what today is known as AND, OR and NOT logic circuits. The principle of their operation is known as Boolean algebra. As some program instructions used by the microcontroller perform the same way as logic gates except in the form of commands, the principle of their operation will be discussed here.

Another important pin function is that it can have pull-up resistors. These resistors connect pins to the positive power supply voltage and their effect is visible when the pin is configured as an input connected to mechanical switch or push button. Newer versions of microcontrollers have pull-up resistors configurable by software.

Usually, each I/O port is under control of another SFR, which means that each bit of that register determines the state of the corresponding microcontroller pin. For example, by writing logic one (1) to one bit of that control register SFR, the appropriate port pin is automatically configured as input. It means that voltage brought to that pin can be read as logic 0 or 1. Otherwise, by writing zero to the SFR, the appropriate port pin is configured as an output. Its voltage (0V or 5V) corresponds to the state of the appropriate bit of the port register.

Masked ROM. Microcontrollers containing this ROM are reserved for the great manufacturers. Program is loaded into the chip by the manufacturer. In case of large scale manufacture, the price is very low. Forget it…

One Time Programmable ROM (OTP ROM). If the microcontroller contains this memory, you can download a program into this memory, but the process of program downloading is a “one-way ticket”, meaning that it can be done only once. If an error is detected after downloading, the only thing you can do is to download the corrected program to another chip.

Flash memory. This type of memory was invented in the 80s in the laboratories of INTEL and were represented as the successor to the UV EPROM. Since the contents of this memory can be written and cleared practically an unlimited number of times, the microcontrollers with Flash ROM are ideal for learning, experimentation and small-scale manufacture. Because of its popularity, the most microcontrollers are manufactured in flash versions today. So, if you are going to buy a microcontroller, the type to look for is definitely Flash!

Flash memory. This type of memory was invented in the 80s in the laboratories of INTEL and were represented as the successor to the UV EPROM. Since the contents of this memory can be written and cleared practically an unlimited number of times, the microcontrollers with Flash ROM are ideal for learning, experimentation and small-scale manufacture. Because of its popularity, the most microcontrollers are manufactured in flash versions today. So, if you are going to buy a microcontroller, the type to look for is definitely Flash!

Random Access Memory (RAM)

Once the power supply is off the contents of RAM (Random Access Memory) is cleared. It is used for temporary storing data and intermediate results created and used during the operation of the microcontroller. For example, if the program performs an addition (of whatever), it is necessary to have a register representing what in everyday life is called the “sum”. For that purpose, one of the registers in RAM is called the “sum” and used for storing results of addition.

Electrically Erasable Programmable ROM (EEPROM)

The contents of the EEPROM may be changed during operation (similar to RAM), but remains permanently saved even upon the power supply goes off (similar to ROM). Accordingly, an EEPROM is often used to store values, created during operation, which must be permanently saved. For example, if you design an electronic lock or an alarm, it would be great to enable the user to create and enter a password, but useless if it is lost every time the power supply goes off. The ideal solution is the microcontroller with an embedded EEPROM.

The microcontroller has learnt during its evolution a trick. Instead of checking each pin or bit constantly, the microcontroller delegates the “wait issue” to the “specialist” which will react only when something attention worthy happens.

The signal which informs the central processor about such an event is called an INTERRUPT.

Today, most microcontrollers have built in several different systems for serial communication as a standard equipment. Which of these systems will be used depends on many factors of which the most important are:

It should be noted that it refers to bits, not bytes! It is usually required by the protocol that each byte is transferred along with several control bits. It means that one byte in serial data stream may consist of 11 bits. For example, if the baud rate is 300 bps then maximum 37 and minimum 27 bytes may be transferred per second, which depends on type of connection and protocol in use.

The most commonly used serial communication systems are:

UART (Universal Asynchronous Receiver/Transmitter)

UART (Universal Asynchronous Receiver/Transmitter)

This connection is asynchronous, which means that a special line for clock signal transmission is not used. In some situations this feature is crucial (for example, radio connection or infrared waves remote control). Since only one communication line is used, both receiver and transmitter operate at the same predefined rate in order to maintain necessary synchronization. This is a very simple way of transferring data since it basically represents conversion of 8-bit data from parallel to serial format. Baud rate is not high up to 1 Mbit/sec.

Brown-out is a potentially dangerous state which occurs at the moment the microcontroller is being turned off or in situations when power supply voltage drops to the limit due to electric noise. As the microcontroller consists of several circuits which have different operating voltage levels, this state can cause its out-of-control performance. In order to prevent it, the microcontroller usually has built-in circuit for brown out reset. This circuit immediately resets the whole electronics when the voltage level drops below the limit.

Reset pin is usually marked as MCLR (Master Clear Reset) and serves for external reset of the microcontroller by applying logic zero (0) or one (1), depending on type of the microcontroller. In case the brown out circuit is not built in, a simple external circuit for brown out reset can be connected to this pin.

Most programs use these miniature electronic “stopwatches”. These are commonly 8- or 16-bit SFRs and their content is automatically incremented by each coming pulse. Once a register is completely loaded – an interrupt is generated!

If the timer registers use an internal quartz oscillator for their operation then it is possible to measure time between two events (if the register value is T1 at the moment measurement has started, and T2 at the moment it has finished, then the elapsed time is equal to the result of subtraction T2-T1). If the registers use pulses coming from external source then such a timer is turned into a counter.

This is only a simple explanation of the operation itself.

One prescaler is usually shared by timer and watch-dog timer, which means that it cannot be used by both of them simultaneously.

If the watchdog timer is enabled, every time it counts up to the program end, the microcontroller reset occurs and program execution starts from the first instruction. The point is to prevent this from happening by using a specific command. The whole idea is based on the fact that every program is executed in several longer or shorter loops.

If instructions which reset the watchdog timer are set at the appropriate program locations, besides commands being regularly executed, then the operation of the watchdog timer will not affect program execution. If for any reason (usually electrical noises in industry), the program counter “gets stuck” on some memory location from which there is no return, the watchdog will not be cleared and the register’s value being constantly incremented will reach the maximum et voila! Reset occurs!

Briefly, they are two different ways of data exchange between CPU and memory.

von-Neumann Architecture

Harvard Architecture

The advantages of such design are the following:

The advantages of such design are the following:

RISC (Reduced Instruction Set Computer)

RISC (Reduced Instruction Set Computer)

In this case, the microcontroller recognizes and executes only basic operations (addition, subtraction, copying etc.). All other more complicated operations are performed by combining these (for example, multiplication is performed by performing successive addition). The constrains are obvious (try by using only a few words, to explain to someone how to reach the airport in some other city). However, there are also some great advantages. First of all, this language is easy to learn. Besides, the microcontroller is very fast so that it is not possible to see all the arithmetic “acrobatics” it performs. The user can only see the final result of all those operations. At last, it is not so difficult to explain where the airport is if you use the right words. For example: left, right, kilometers etc.

CISC (Complex Instruction Set Computer)

CISC is the opposite of RISC! Microcontrollers designed to recognize more than 200 different instructions can do much and are very fast. However, one needs to understand how to take all that such a rich language offers, which is not at all easy…

Before you start designing some device based on the microcontroller, think of the following: how many input/output lines will I need for operation? Should it perform some other operations than to simply turn relays on/off? Does it need some specialized module such as serial communication, A/D converter etc. When you create a clear picture of what you need, the selection range is considerably reduced, then it is time to think of price. Is your plan to have several same devices? Several hundred? A million? Anyway, you get the point…

If you think of all these things for the very first time then everything seems a bit confusing. For that reason, go step by step. First of all, select the manufacturer, i.e. the family of the microcontrollers you can easily obtain. After that, study one particular model. Learn as much as you need, do not go into details. Solve a specific problem and something incredible will happen- you will be able to handle any model belonging to that family.

Remember learning to ride a bicycle: after several unavoidable bruises at the beginning, you will manage to keep balance and will be able to easily ride any other bicycle. And of course, you will never forget the skill in programming just as you will never forget riding bicycles!

The real name of this microcontroller is PICmicro (Peripheral Interface Controller), but it is better known as PIC. Its first ancestor was designed in 1975 by General Instruments. This chip called PIC1650 was meant for totally different purposes. About ten years later, by adding EEPROM memory, this circuit was transformed into a real PIC microcontroller. Nowadays, Microchip Technology announces a manufacturing of the 5 billionth sample…

In order that you can better understand the reasons for its popularity, we will briefly describe several important things.

All PIC microcontrollers use harvard architecture, which means that their program memory is connected to CPU via more than 8 lines. Depending on the bus width, there are 12-, 14- and 16-bit microcontrollers. The table above shows the main features of these three categories.

As seen in the table on the previous page, excepting “16-bit monsters”- PIC 24FXXX and PIC 24HXXX- all PIC microcontrollers have 8-bit harvard architecture and belong to one out of three large groups. Therefore, depending on the size of a program word there are first, second and third category, i.e. 12-, 14- or 16-bit microcontrollers. Having similar 8- bit core, all of them use the same instruction set and the basic hardware ‘skeleton’ connected to more or less peripheral units.

In order to avoid tedious explanations and endless story about the useful features of different microcontrollers, this book describes the operation of one particular model belonging to “high middle class”. It is about PIC16F887- powerful enough to be worth attention and simple enough to be easily presented to everybody.

Q . II A / D

This 555 timer based circuit is a kind of voltmeter, also an analog to digital converter, that converts the analog input voltage to digital output pulses. The output pulse width is proportional to the difference between the analog input voltage and the voltage across the 4.7 uF capacitor namely 2.5V. It can measure from +5V to +18V

The accuracy is high in the range of 6V to 18V. The readings are about the same with the 10 bit ADC readings. The accuracy depends on only the +5V supply voltage and the microcontroller’s clock frequency.

Wide angle shot of the memory microchip shown in detail below. The microchips have a transparent window, showing the integrated circuit inside. The window allows the memory contents of the chip to be erased, by exposure to strong ultraviolet light in an eraser device.

Wide angle shot of the memory microchip shown in detail below. The microchips have a transparent window, showing the integrated circuit inside. The window allows the memory contents of the chip to be erased, by exposure to strong ultraviolet light in an eraser device.

Integrated circuit from an EPROM memory microchip showing the memory blocks, the supporting circuitry and the fine silver wires which connect the integrated circuit die to the legs of the packaging.

An integrated circuit or monolithic integrated circuit (also referred to as an IC, a chip, or a microchip) is a set of electronic circuits on one small plate ("chip") of semiconductor material, normally silicon. This can be made much smaller than a discrete circuit made from independent components.

Integrated circuit from an EPROM memory microchip showing the memory blocks, the supporting circuitry and the fine silver wires which connect the integrated circuit die to the legs of the packaging.

An integrated circuit or monolithic integrated circuit (also referred to as an IC, a chip, or a microchip) is a set of electronic circuits on one small plate ("chip") of semiconductor material, normally silicon. This can be made much smaller than a discrete circuit made from independent components.

Integrated circuits are used in virtually all electronic equipment today and have revolutionized the world of electronics. Computers, mobile phones, and other digital home appliances are now inextricable parts of the structure of modern societies, made possible by the low cost of producing integrated circuits.

ICs can be made very compact, having up to several billion transistors and other electronic components in an area the size of a fingernail. The width of each conducting line in a circuit (the line width) can be made smaller and smaller as the technology advances, in 2008 it dropped below 100 nanometers and in 2013 it is expected to be in the tens of nanometers

Introduction

Synthetic detail of an integrated circuit through four layers of planarized copper interconnect, down to the polysilicon (pink), wells (greyish), and substrate (green)

ICs were made possible by experimental discoveries showing that semiconductor devices could perform the functions of vacuum tubes and by mid-20th-century technology advancements in semiconductor device fabrication. The integration of large numbers of tiny transistors into a small chip was an enormous improvement over the manual assembly of circuits using discrete electronic components. The integrated circuit's mass production capability, reliability, and building-block approach to circuit design ensured the rapid adoption of standardized Integrated Circuits in place of designs using discrete transistors.

Synthetic detail of an integrated circuit through four layers of planarized copper interconnect, down to the polysilicon (pink), wells (greyish), and substrate (green)

ICs were made possible by experimental discoveries showing that semiconductor devices could perform the functions of vacuum tubes and by mid-20th-century technology advancements in semiconductor device fabrication. The integration of large numbers of tiny transistors into a small chip was an enormous improvement over the manual assembly of circuits using discrete electronic components. The integrated circuit's mass production capability, reliability, and building-block approach to circuit design ensured the rapid adoption of standardized Integrated Circuits in place of designs using discrete transistors.

There are two main advantages of ICs over discrete circuits: cost and performance. Cost is low because the chips, with all their components, are printed as a unit by photolithography rather than being constructed one transistor at a time. Furthermore, much less material is used to construct a packaged IC die than to construct a discrete circuit. Performance is high because the components switch quickly and consume little power (compared to their discrete counterparts) as a result of the small size and close proximity of the components. As of 2012, typical chip areas range from a few square millimeters to around 450 mm2, with up to 9 million transistors per mm2.

The idea of the integrated circuit was conceived by a radar scientist working for the Royal Radar Establishment of the British Ministry of Defence, Geoffrey W.A. Dummer (1909–2002). Dummer presented the idea to the public at the Symposium on Progress in Quality Electronic Components in Washington, D.C. on 7 May 1952.[7] He gave many symposia publicly to propagate his ideas, and unsuccessfully attempted to build such a circuit in 1956.

A precursor idea to the IC was to create small ceramic squares (wafers), each one containing a single miniaturized component. Components could then be integrated and wired into a bidimensional or tridimensional compact grid. This idea, which looked very promising in 1957, was proposed to the US Army by Jack Kilby, and led to the short-lived Micromodule Program (similar to 1951's Project Tinkertoy).[8] However, as the project was gaining momentum, Kilby came up with a new, revolutionary design: the IC.

Robert Noyce credited Kurt Lehovec of Sprague Electric for the principle of p-n junction isolation caused by the action of a biased p-n junction (the diode) as a key concept behind the IC.[9]

Jack Kilby's original integrated circuit

Newly employed by Texas Instruments, Kilby recorded his initial ideas concerning the integrated circuit in July 1958, successfully demonstrating the first working integrated example on 12 September 1958.[10] In his patent application of 6 February 1959, Kilby described his new device as “a body of semiconductor material ... wherein all the components of the electronic circuit are completely integrated.”[11] The first customer for the new invention was the US Air Force.[12]

Jack Kilby's original integrated circuit

Newly employed by Texas Instruments, Kilby recorded his initial ideas concerning the integrated circuit in July 1958, successfully demonstrating the first working integrated example on 12 September 1958.[10] In his patent application of 6 February 1959, Kilby described his new device as “a body of semiconductor material ... wherein all the components of the electronic circuit are completely integrated.”[11] The first customer for the new invention was the US Air Force.[12]

Kilby won the 2000 Nobel Prize in Physics for his part of the invention of the integrated circuit.[13] Kilby's work was named an IEEE Milestone in 2009.[14]

Noyce also came up with his own idea of an integrated circuit half a year later than Kilby. His chip solved many practical problems that Kilby's had not. Produced at Fairchild Semiconductor, it was made of silicon, whereas Kilby's chip was made of germanium.

Fairchild Semiconductor was also home of the first silicon gate IC technology with self-aligned gates, which stands as the basis of all modern CMOS computer chips. The technology was developed by Italian physicist Federico Faggin in 1968, who later joined Intel in order to develop the very first Central Processing Unit (CPU) on one chip (Intel 4004), for which he received the National Medal of Technology and Innovation in 2010.

SSI circuits were crucial to early aerospace projects, and aerospace projects helped inspire development of the technology. Both the Minuteman missile and Apollo program needed lightweight digital computers for their inertial guidance systems; the Apollo guidance computer led and motivated the integrated-circuit technology,[16] while the Minuteman missile forced it into mass-production. The Minuteman missile program and various other Navy programs accounted for the total $4 million integrated circuit market in 1962, and by 1968, U.S. Government space and defense spending still accounted for 37% of the $312 million total production. The demand by the U.S. Government supported the nascent integrated circuit market until costs fell enough to allow firms to penetrate the industrial and eventually the consumer markets. The average price per integrated circuit dropped from $50.00 in 1962 to $2.33 in 1968.[17] Integrated circuits began to appear in consumer products by the turn of the decade, a typical application being FM inter-carrier sound processing in television receivers.

The next step in the development of integrated circuits, taken in the late 1960s, introduced devices which contained hundreds of transistors on each chip, called "medium-scale integration" (MSI).

They were attractive economically because while they cost little more to produce than SSI devices, they allowed more complex systems to be produced using smaller circuit boards, less assembly work (because of fewer separate components), and a number of other advantages.

Further development, driven by the same economic factors, led to "large-scale integration" (LSI) in the mid 1970s, with tens of thousands of transistors per chip.

Integrated circuits such as 1K-bit RAMs, calculator chips, and the first microprocessors, that began to be manufactured in moderate quantities in the early 1970s, had under 4000 transistors. True LSI circuits, approaching 10,000 transistors, began to be produced around 1974, for computer main memories and second-generation microprocessors.

Upper interconnect layers on an Intel 80486DX2 microprocessor die

The final step in the development process, starting in the 1980s and continuing through the present, was "very large-scale integration" (VLSI). The development started with hundreds of thousands of transistors in the early 1980s, and continues beyond several billion transistors as of 2009.

Upper interconnect layers on an Intel 80486DX2 microprocessor die

The final step in the development process, starting in the 1980s and continuing through the present, was "very large-scale integration" (VLSI). The development started with hundreds of thousands of transistors in the early 1980s, and continues beyond several billion transistors as of 2009.

Multiple developments were required to achieve this increased density. Manufacturers moved to smaller design rules and cleaner fabrication facilities, so that they could make chips with more transistors and maintain adequate yield. The path of process improvements was summarized by the International Technology Roadmap for Semiconductors (ITRS). Design tools improved enough to make it practical to finish these designs in a reasonable time. The more energy efficient CMOS replaced NMOS and PMOS, avoiding a prohibitive increase in power consumption.

In 1986 the first one megabit RAM chips were introduced, which contained more than one million transistors. Microprocessor chips passed the million transistor mark in 1989 and the billion transistor mark in 2005.[18] The trend continues largely unabated, with chips introduced in 2007 containing tens of billions of memory transistors.[19]

Wafer-scale integration (WSI) is a system of building very-large integrated circuits that uses an entire silicon wafer to produce a single "super-chip". Through a combination of large size and reduced packaging, WSI could lead to dramatically reduced costs for some systems, notably massively parallel supercomputers. The name is taken from the term Very-Large-Scale Integration, the current state of the art when WSI was being developed.

A system-on-a-chip (SoC or SOC) is an integrated circuit in which all the components needed for a computer or other system are included on a single chip. The design of such a device can be complex and costly, and building disparate components on a single piece of silicon may compromise the efficiency of some elements. However, these drawbacks are offset by lower manufacturing and assembly costs and by a greatly reduced power budget: because signals among the components are kept on-die, much less power is required (see Packaging).

A three-dimensional integrated circuit (3D-IC) has two or more layers of active electronic components that are integrated both vertically and horizontally into a single circuit. Communication between layers uses on-die signaling, so power consumption is much lower than in equivalent separate circuits. Judicious use of short vertical wires can substantially reduce overall wire length for faster operation.

Among the most advanced integrated circuits are the microprocessors or "cores", which control everything from computers and cellular phones to digital microwave ovens. Digital memory chips and ASICs are examples of other families of integrated circuits that are important to the modern information society. While the cost of designing and developing a complex integrated circuit is quite high, when spread across typically millions of production units the individual IC cost is minimized. The performance of ICs is high because the small size allows short traces which in turn allows low power logic (such as CMOS) to be used at fast switching speeds.

ICs have consistently migrated to smaller feature sizes over the years, allowing more circuitry to be packed on each chip. This increased capacity per unit area can be used to decrease cost and/or increase functionality—see Moore's law which, in its modern interpretation, states that the number of transistors in an integrated circuit doubles every two years. In general, as the feature size shrinks, almost everything improves—the cost per unit and the switching power consumption go down, and the speed goes up. However, ICs with nanometer-scale devices are not without their problems, principal among which is leakage current (see subthreshold leakage for a discussion of this), although these problems are not insurmountable and will likely be solved or at least ameliorated by the introduction of high-k dielectrics. Since these speed and power consumption gains are apparent to the end user, there is fierce competition among the manufacturers to use finer geometries. This process, and the expected progress over the next few years, is well described by the International Technology Roadmap for Semiconductors (ITRS).

In current research projects, integrated circuits are also developed for sensoric applications in medical implants or other bioelectronic devices. Particular sealing strategies have to be taken in such biogenic environments to avoid corrosion or biodegradation of the exposed semiconductor materials.[20] As one of the few materials well established in CMOS technology, titanium nitride (TiN) turned out as exceptionally stable and well suited for electrode applications in medical implants.[21][22]

Digital integrated circuits can contain anything from one to millions of logic gates, flip-flops, multiplexers, and other circuits in a few square millimeters. The small size of these circuits allows high speed, low power dissipation, and reduced manufacturing cost compared with board-level integration. These digital ICs, typically microprocessors, DSPs, and micro controllers, work using binary mathematics to process "one" and "zero" signals.

Analog ICs, such as sensors, power management circuits, and operational amplifiers, work by processing continuous signals. They perform functions like amplification, active filtering, demodulation, and mixing. Analog ICs ease the burden on circuit designers by having expertly designed analog circuits available instead of designing a difficult analog circuit from scratch.

ICs can also combine analog and digital circuits on a single chip to create functions such as A/D converters and D/A converters. Such mixed-signal circuits offer smaller size and lower cost, but must carefully account for signal interference.

Modern electronic component distributors often further sub-categorize the huge variety of integrated circuits now available:

Rendering of a small standard cell with three metal layers (dielectric has been removed). The sand-colored structures are metal interconnect, with the vertical pillars being contacts, typically plugs of tungsten. The reddish structures are polysilicon gates, and the solid at the bottom is the crystalline silicon bulk.

Rendering of a small standard cell with three metal layers (dielectric has been removed). The sand-colored structures are metal interconnect, with the vertical pillars being contacts, typically plugs of tungsten. The reddish structures are polysilicon gates, and the solid at the bottom is the crystalline silicon bulk.

Schematic structure of a CMOS chip, as built in the early 2000s. The graphic shows LDD-MISFET's on an SOI substrate with five metallization layers and solder bump for flip-chip bonding. It also shows the section for FEOL (front-end of line), BEOL (back-end of line) and first parts of back-end process.

The semiconductors of the periodic table of the chemical elements were identified as the most likely materials for a solid-state vacuum tube. Starting with copper oxide, proceeding to germanium, then silicon, the materials were systematically studied in the 1940s and 1950s. Today, silicon monocrystals are the main substrate used for ICs although some III-V compounds of the periodic table such as gallium arsenide are used for specialized applications like LEDs, lasers, solar cells and the highest-speed integrated circuits. It took decades to perfect methods of creating crystals without defects in the crystalline structure of the semiconducting material.

Schematic structure of a CMOS chip, as built in the early 2000s. The graphic shows LDD-MISFET's on an SOI substrate with five metallization layers and solder bump for flip-chip bonding. It also shows the section for FEOL (front-end of line), BEOL (back-end of line) and first parts of back-end process.

The semiconductors of the periodic table of the chemical elements were identified as the most likely materials for a solid-state vacuum tube. Starting with copper oxide, proceeding to germanium, then silicon, the materials were systematically studied in the 1940s and 1950s. Today, silicon monocrystals are the main substrate used for ICs although some III-V compounds of the periodic table such as gallium arsenide are used for specialized applications like LEDs, lasers, solar cells and the highest-speed integrated circuits. It took decades to perfect methods of creating crystals without defects in the crystalline structure of the semiconducting material.

Semiconductor ICs are fabricated in a layer process which includes these key process steps:

Mono-crystal silicon wafers (or for special applications, silicon on sapphire or gallium arsenide wafers) are used as the substrate. Photolithography is used to mark different areas of the substrate to be doped or to have polysilicon, insulators or metal (typically aluminium) tracks deposited on them.

A random access memory is the most regular type of integrated circuit; the highest density devices are thus memories; but even a microprocessor will have memory on the chip. (See the regular array structure at the bottom of the first image.) Although the structures are intricate – with widths which have been shrinking for decades – the layers remain much thinner than the device widths. The layers of material are fabricated much like a photographic process, although light waves in the visible spectrum cannot be used to "expose" a layer of material, as they would be too large for the features. Thus photons of higher frequencies (typically ultraviolet) are used to create the patterns for each layer. Because each feature is so small, electron microscopes are essential tools for a process engineer who might be debugging a fabrication process.

Each device is tested before packaging using automated test equipment (ATE), in a process known as wafer testing, or wafer probing. The wafer is then cut into rectangular blocks, each of which is called a die. Each good die (plural dice, dies, or die) is then connected into a package using aluminium (or gold) bond wires which are thermosonic bonded[23] to pads, usually found around the edge of the die. . Thermosonic bonding was first introduced by A. Coucoulas which provided a reliable means of forming these vital electrical connections to the outside world. After packaging, the devices go through final testing on the same or similar ATE used during wafer probing. Industrial CT scanning can also be used. Test cost can account for over 25% of the cost of fabrication on lower cost products, but can be negligible on low yielding, larger, and/or higher cost devices.

As of 2005, a fabrication facility (commonly known as a semiconductor fab) costs over US$1 billion to construct,[24] because much of the operation is automated. Today, the most advanced processes employ the following techniques:

A Soviet MSI nMOS chip made in 1977, part of a four-chip calculator set designed in 1970[26]

The earliest integrated circuits were packaged in ceramic flat packs, which continued to be used by the military for their reliability and small size for many years. Commercial circuit packaging quickly moved to the dual in-line package (DIP), first in ceramic and later in plastic. In the 1980s pin counts of VLSI circuits exceeded the practical limit for DIP packaging, leading to pin grid array (PGA) and leadless chip carrier (LCC) packages. Surface mount packaging appeared in the early 1980s and became popular in the late 1980s, using finer lead pitch with leads formed as either gull-wing or J-lead, as exemplified by small-outline integrated circuit – a carrier which occupies an area about 30–50% less than an equivalent DIP, with a typical thickness that is 70% less. This package has "gull wing" leads protruding from the two long sides and a lead spacing of 0.050 inches.

A Soviet MSI nMOS chip made in 1977, part of a four-chip calculator set designed in 1970[26]

The earliest integrated circuits were packaged in ceramic flat packs, which continued to be used by the military for their reliability and small size for many years. Commercial circuit packaging quickly moved to the dual in-line package (DIP), first in ceramic and later in plastic. In the 1980s pin counts of VLSI circuits exceeded the practical limit for DIP packaging, leading to pin grid array (PGA) and leadless chip carrier (LCC) packages. Surface mount packaging appeared in the early 1980s and became popular in the late 1980s, using finer lead pitch with leads formed as either gull-wing or J-lead, as exemplified by small-outline integrated circuit – a carrier which occupies an area about 30–50% less than an equivalent DIP, with a typical thickness that is 70% less. This package has "gull wing" leads protruding from the two long sides and a lead spacing of 0.050 inches.

In the late 1990s, plastic quad flat pack (PQFP) and thin small-outline package (TSOP) packages became the most common for high pin count devices, though PGA packages are still often used for high-end microprocessors. Intel and AMD are currently transitioning from PGA packages on high-end microprocessors to land grid array (LGA) packages.

Ball grid array (BGA) packages have existed since the 1970s. Flip-chip Ball Grid Array packages, which allow for much higher pin count than other package types, were developed in the 1990s. In an FCBGA package the die is mounted upside-down (flipped) and connects to the package balls via a package substrate that is similar to a printed-circuit board rather than by wires. FCBGA packages allow an array of input-output signals (called Area-I/O) to be distributed over the entire die rather than being confined to the die periphery.

Traces out of the die, through the package, and into the printed circuit board have very different electrical properties, compared to on-chip signals. They require special design techniques and need much more electric power than signals confined to the chip itself.

When multiple dies are put in one package, it is called SiP, for System In Package. When multiple dies are combined on a small substrate, often ceramic, it's called an MCM, or Multi-Chip Module. The boundary between a big MCM and a small printed circuit board is sometimes fuzzy.

The manufacturing date is commonly represented as a two-digit year followed by a two-digit week code, such that a part bearing the code 8341 was manufactured in week 41 of 1983, or approximately in October 1983.

The possibility of copying by photographing each layer of an integrated circuit and preparing photomasks for its production on the basis of the photographs obtained is the main reason for the introduction of legislation for the protection of layout-designs.

A diplomatic conference was held at Washington, D.C., in 1989, which adopted a Treaty on Intellectual Property in Respect of Integrated Circuits (IPIC Treaty).

The Treaty on Intellectual Property in respect of Integrated Circuits, also called Washington Treaty or IPIC Treaty (signed at Washington on 26 May 1989) is currently not in force, but was partially integrated into the TRIPS agreement.

National laws protecting IC layout designs have been adopted in a number of countries.