Ultra-thin chips for high-performance flexible electronics

Flexible electronics has significantly advanced over the last few years, as devices and circuits from nano scale structures to printed thin films have started to appear. Simultaneously, the demand for high-performance electronics has also increased because flexible and compact integrated circuits are needed to obtain fully flexible electronic systems. It is challenging to obtain flexible and compact integrated circuits as the silicon based CMOS electronics, which is currently the industry standard for high-performance, is planar and the brittle nature of silicon makes bend ability difficult. For this reason, the ultra-thin chips from silicon is gaining interest. This review provides an in-depth analysis of various approaches for obtaining ultra-thin chips from rigid silicon wafer. The comprehensive study presented here includes analysis of ultra-thin chips properties such as the electrical, thermal, optical and mechanical properties, stress modelling, and packaging techniques. The underpinning advances in areas such as sensing, computing, data storage, and energy have been discussed along with several emerging applications (e.g., wearable systems, m-Health, smart cities and Internet of Things etc.) they will enable. This paper is targeted to the readers working in the field of integrated circuits on thin and bendable silicon; but it can be of broad interest to everyone working in the field of flexible electronics.

INTRODUCTION

Flexible electronics is changing the way we make and use electronics.

Many existing applications such as implantable systems that require

bend ability to conform to the curved surface of tisues1

are driving the progress in the field, which in turn is the enabler for

numerous futuristic applications such as mHealth, wearable systems,

smart cities, and Internet-of-Things (IoT). Several initiatives from

governments and industry have also contributed to the progress and it is

now estimated that the market for flexible electronics will reach $300

billion by 2028,2,3 with growth from $29.28 billion in 2017 to over $63 billion in 20234

for printed, flexible and organic electronics alone. The

high-performance, at par with today’s complementary metal oxide

semiconductor (CMOS) electronics, will be critical to this growth in

flexible electronics as several current and future electronics would

need fast communication and computation. For example, large drive

currents and fast readout is needed in application such as interactive

flexible displays. Likewise, wireless communication in mHealth or IoT

(where wearable sensors patches are needed for continuous measurements)

will require data handling in frequency bands up to ultra-high

frequencies (0.3 – 3 GHz).5

The faster communication, higher bandwidth, and efficient distributed

computation with very high clock speed will make the high-performance

requirement inevitable in connected objects. This high-performance

requirement calls for investigations into new materials, fabrication

technology, methodologies, and design techniques6—all

of which influence the device performance. For example, the transistor

switching frequency is influenced by the mobility and channel

length—while mobility is a material property, the channel length depends

on the technology. To demonstrate how various materials link to

performance, we have compared in Table 1 some of the materials used in flexible electronics. This comparison is in terms of carrier mobility (µ), channel length (L), transit frequency (f

t

), and the Ion/Ioff

ratio of transistors that use these semiconducting materials as current

channel. Assuming fixed FET parameters such as channel width, oxide

capacitance etc. and the voltages such as terminal and threshold

voltage, the dependency of transit frequency (which is a measure of

transistor speed) boils down to mobility and channel length.

The technology readiness to obtain devices down to nanoscale dimensions

and the possibility to exponentially scale the device densities up to

billions of devices per mm2, makes silicon based

microelectronics a good candidate for addressing immediate

high-performance needs in flexible electronics. For this the first issue

that need to be overcome is the lack of flexibility (and hence

conformability) of silicon wafers. This has been achieved by thinning

the wafers down to <50 µm using a range of technologies, which are

discussed here. Silicon chips from such thinned wafers, or ultra-thin

chips (UTCs), are ideal for high-performance flexible electronics as

they are physically bendable and have stable electronic response for

particular bending state.13

The excellent form factor of UTCs make their integration on flexible

substrates better than the conventional thick chips. Further, due to

reduced package volume and lower parasitic capacitance, the UTCs have

better high-frequency performances and lower power consumption. With

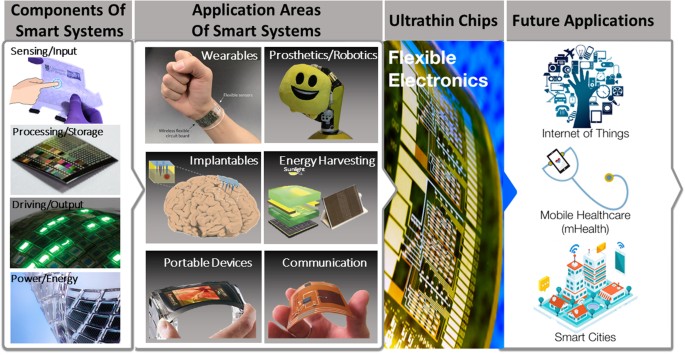

these features UTCs can underpin advances in areas such as sensing,

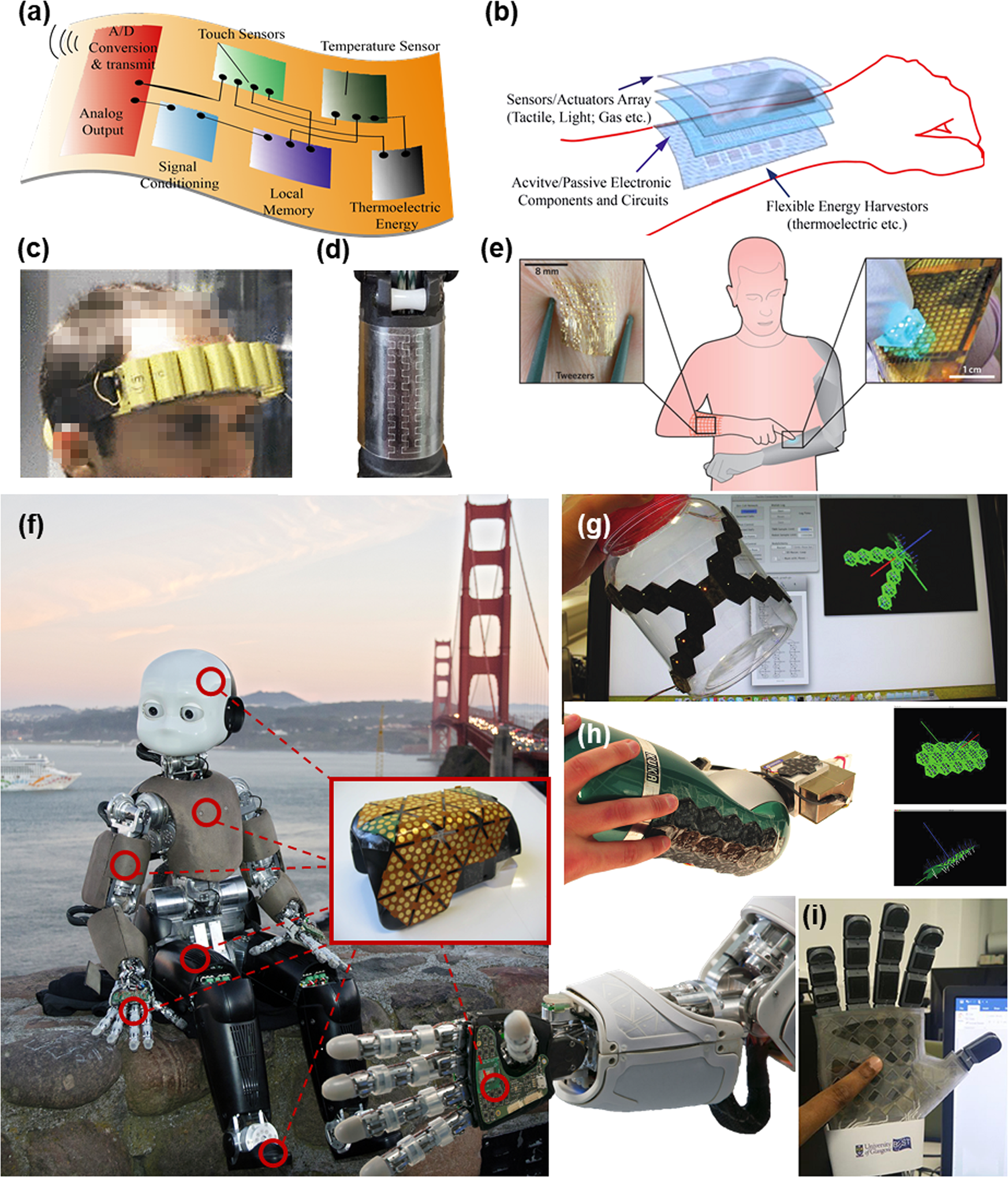

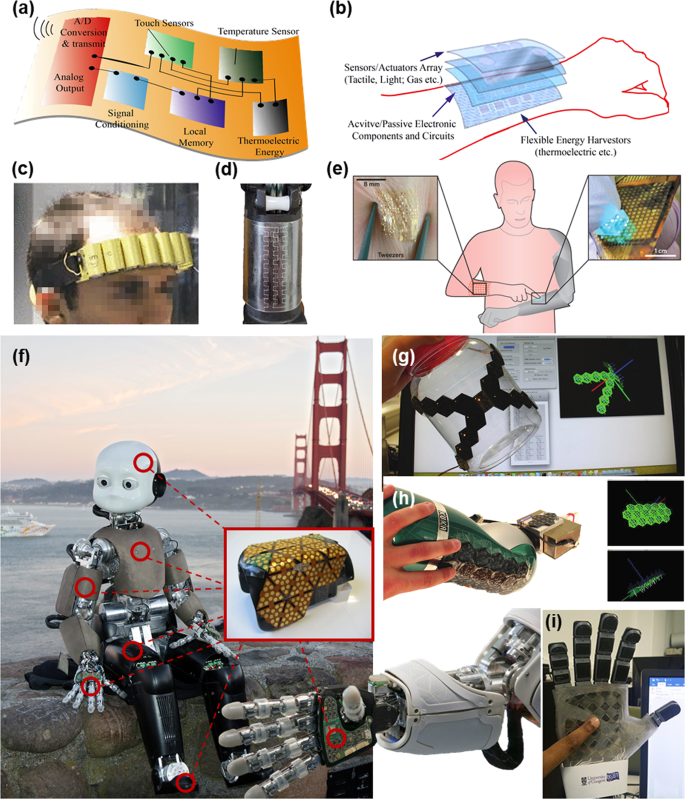

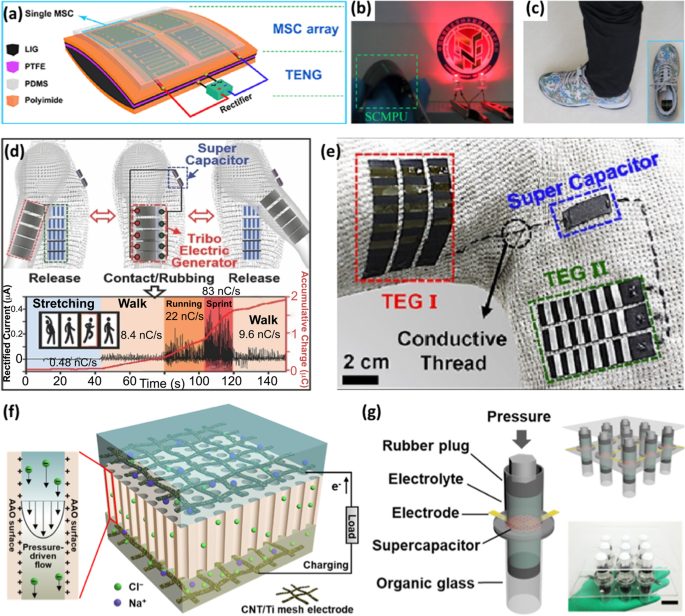

computing, data storage, and energy (Fig. 1)

and several emerging applications (e.g., robotics, wearable systems,

m-Health, smart cities and Internet of Things etc.) they will enable.

Applications enabled by UTCs through underpinning research in areas such as sensing, computing, data storage, and energy.

Given the wide scope of UTCs, a comprehensive review of various

technological and applied aspects will complement several other reviews

that have mainly focussed on organic semiconductors and their processing

techniques such as printing or vacuum deposition etc. A few review articles have also discussed layer transfer processes and thin film silicon for solar cells.

Related to UTCs, only a few review articles have been published and

they have covered limited areas such as wafer thinning methods such as

back grinding and integration on flexible substrate using stretchable

interconnects.

The analysis of UTCs covering topics such as changes in

electrical-mechanical-optical-thermal properties, packaging, and

stress-induced response variations, and comparison of various thinning

methods has not been reported thus far.

UTC properties

The physical dimensions could influence the material properties and

carrier transport mechanism and therefore could affect the performance

of electronics devices. Compared to their bulk counterparts, the UTCs

exhibit different behavior in terms of mechanical flexibility, optical

transmittance, and carrier surface mobility (e.g., upon experiencing

stress) etc. These variations can be challenging to handle, for example

when one attempts to apply on UTCs the methods and designs developed for

conventional bulk silicon. At the same time, such variations also offer

multiple new opportunities, which are otherwise difficult with bulk

silicon. For example, Si starts to become optically transparent for

thicknesses below 10 µm—starting in the red region and progressing

towards blue region as the wafer gets thinner. Such thinning led

variations in optical transparency of Si could be exploited to improve

photodetectors and solar cells etc., as explained later in this section.

An extensive analysis of variations in properties with respect to

thickness has not been reported and this section should fill the gap in

literature.

Mechanical properties

The thinning process impacts the mechanical properties of thinned electronic substrate. For example, during thinning by back grinding, the sub-surface damage (SSD) and deep cracks in Si result in poor bendability and eventually lead to early breakage of UTCs. Likewise, the etch pits and hillocks produced during thinning by wet etching could lead to localized stress and can decrease the breaking strength of Si. The localised stress or stress distribution at different locations in UTCs are typically studied with Finite Element Analysis and Micro-Raman Spectroscopy. The FEM analysis can provide an estimate of the residual stress at critical position like hinge and centre and the shift in Raman peak could provide deep insight into localised mechanical stresses. The mechanical strength of UTCs is also influenced by their thickness and the stress generated during the bending .Thermal properties

Temperature is known to have significant impact on the performance and reliable operation of electronics and therefore discussion on thermal properties of UTCs gain importance. The heat dissipation, particularly in the UTCs realized from SOI wafers having top Si thickness in the nanoscale, significantly differ from conventional bulk Si based chips. For example, the thermal conductivity of <100 nm Si is half the value of undoped bulk Si (~148 Wm−1 K−1). The lower thermal conductivity means the heat generated is not easily transferred to the package and therefore appropriate heat management may also be needed for UTCs, especially for high-performance flexible electronics. Another important factor is the dependence of mobility on temperature, which is determined by four types of scattering (phonon scattering, surface roughness scattering, bulk charge coulombic scattering, and interface charge coulombic scattering). The net effect of this complex dependence is that higher the temperature, lower is the mobility and therefore increase in the temperature due to low thermal conductivity of UTCs could degrade the system performance. Likewise, the threshold voltage decreases because the metal to semiconductor work function and fermi potential decrease with temperature. The thermal issues can be overcome by incorporating on-chip cooling architecture such as micro-coolers and thermo-electric fluidic cooler. However, this is cumbersome process and will typically require a liquid cooling mechanism. A potential alternative is to use large size UTCs. As an example, with COMSOL simulation . it has been shown that a 1 mm × 1 mm conventional chip (0.5 mm thick) on a 0.5 mm thick polyimide can heat up the substrate to 40 °C even with a small power density of 1 Wcm−2. However, in larger chips, the heat is distributed over larger area and therefore local heating is reduced. Applying the same argument to thin chips (~100 µm thick) on polyimide substrates, with same power but bigger area (10 mm × 10 mm), the simulation result show only 2 °C more temperature than ambient. This much increase in the local temperature is within acceptable limit for applications such as biomedical implants and wearables where higher temperatures can damage tissues. Embedding of air-channels in thin chips could alleviate the issue as it helps in the cooling of the chip. However, such solutions put a restriction on the type of methodology used to develop UTCs.Optical properties

Owing to varying absorption coefficients at different wavelengths, Si starts to become optically transparent as the thickness decreases—starting with the red region and progressing towards blue region.Electrical behaviour

The fundamental electrical properties of Si such as its bandgap, dielectric constant, density of states, will not change until the thickness reaches nanoscale. For most of the flexible electronics applications, the flexibility requirements could be fulfilled with UTCs having thickness in the range of 5–50 µm. Therefore, for practical purposes the fundamental electrical properties of ultra thin Si remains unchanged when they are realized by thinning bulk Si. To reach <50 µm, the thickness of a conventional bulk wafer or SOI wafer undergoes thinning process, which is known to induce stress in Si. The Si chip could also be stressed by various fabrication steps such as deposition of different material layers like oxide, dielectrics, and metal etc., which have different elastic modulus. On top of these, there is additional stress when the UTCs are externally loaded or strained, for example, during bending. Whereas the thinning and process induced stress are intrinsic to chip, the bending induced stress during usage is external. These stresses induce changes in the band structure and the piezoresistive property of Si, which eventually show up as variation in the electrical response of devices on UTCs. Through electromechanical tests and modelling, a few works have attempted to capture the stress induced changes in electrical response of devices. For example, in the case of uniaxial bending, n-type MOSFETs show increase in mobility with increase in bending stress. In n-type MOSFETs, this behaviour is independent of the direction of bending, but variations in the response of p-type MOSFETs is direction dependent. The models in these works have taken into account the process strategies, dimensions of the structure (active Si, dielectric, metal thicknesses, etc.), initial substrate (e.g., Si, SOI, UTSOI, ETSOI etc.), mechanical strain etc. The stressed induced changes could lead to significant deviations in the response of device and circuits from their specified value , where bending induced changes in device and circuit parameters are reported. For complex circuit design in flexible electronics and to predict their response under different bending condition precisely, it is necessary to understand these variations and implement predictive models in electronics design tools. The variations in device response could be reduced by using suitable compensation techniques in the layout. On other hand, these changes in the device parameters could also be seen as the signature for a particular bending state and therefore could be used to predict or sense the state/shape of bending.Technologies for realizing UTC

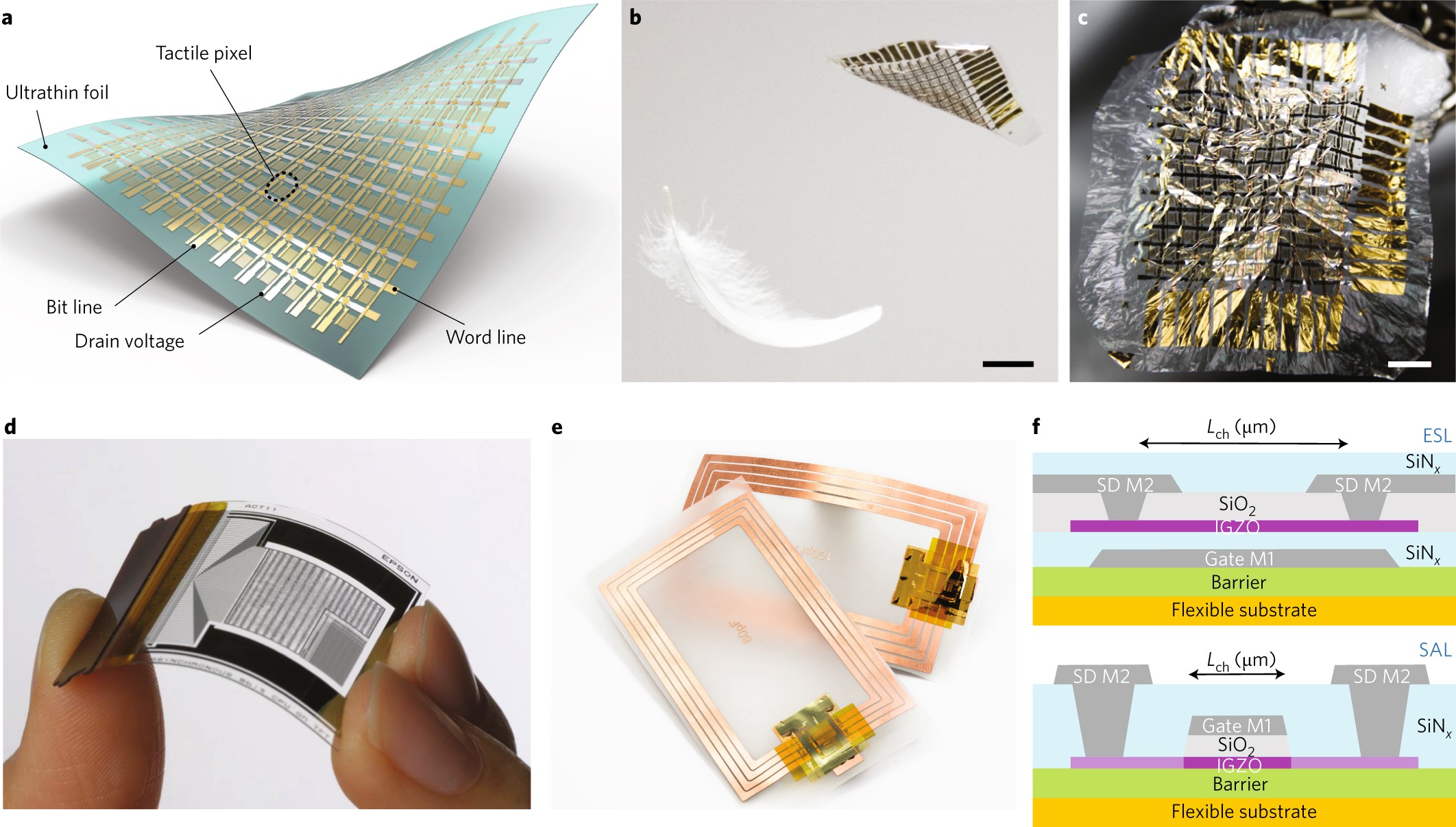

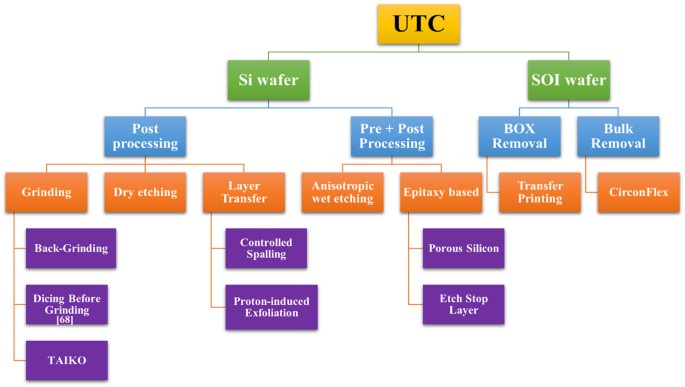

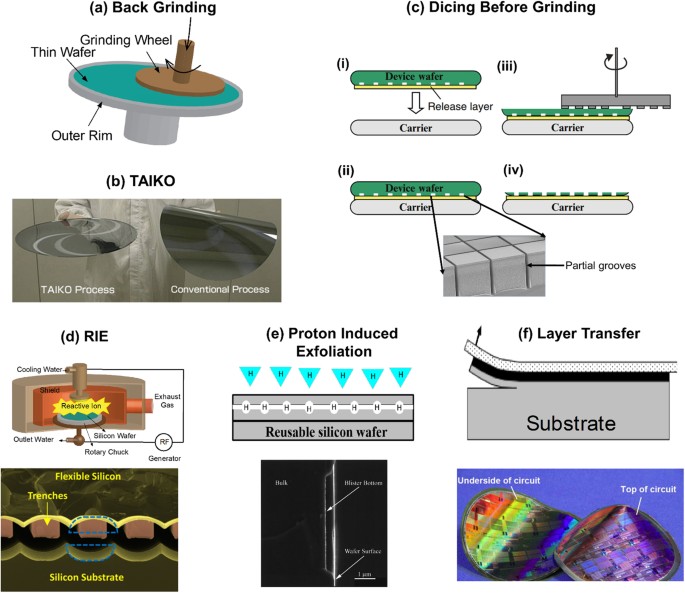

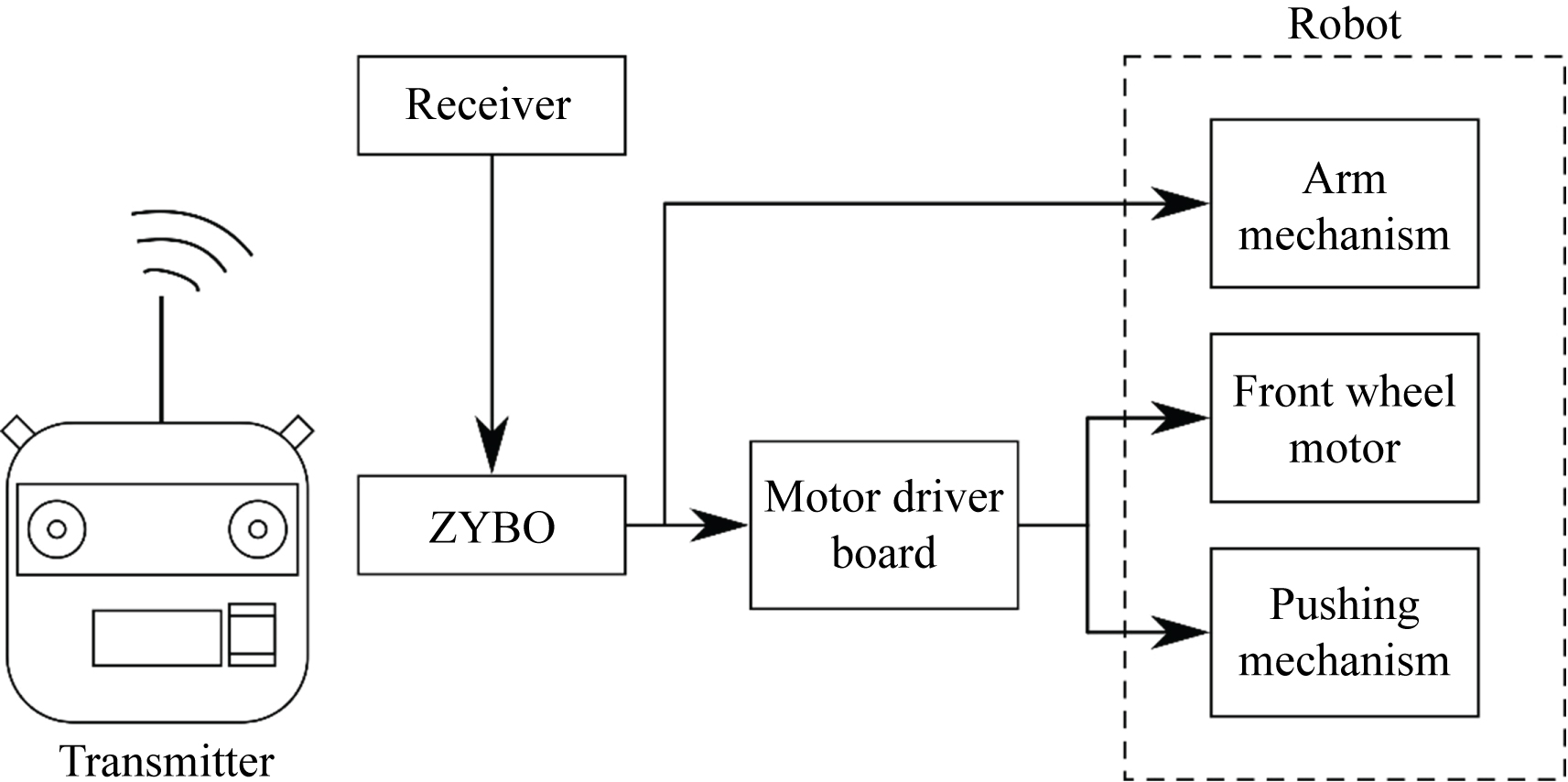

A wide range of technologies have been explored for realizing UTCs . For the sake of completeness, the technologies involving either bulk Si wafer or SOI wafer are briefly discussed in this section. Figure 4 also gives a summary of these technologies, classified based on the fabrication stage at which the thinning is carried out. For example, when the thinning is carried out after the fabrication of electronic devices it is termed as post-processing, and when wafer undergoes some processing before the device fabrication then it is termed as pre-processing. Generally, the thinning is carried out after the device fabrication is completed. the choice of technological approach to realize UTC requires careful consideration.

Classification of various thinning methodologies for realizing UTC

Using Si Wafer

UTC via post-processing techniques

In post-processing approaches, the UTCs are typically obtained by physical removal of electronic substrate such as Si through either grinding, dry etching, chemical reaction or combination of these. In these techniques, the crystal structure of active Si area (for example, in the case of MOSFETs, the area up to well-depth) is unaffected and therefore their electrical response is at par with their bulk counterparts. However, as discussed in previous section the possibility of mechanical degradation cannot be ruled out. The techniques used as post-processing step can be broadly divided into: (i) grinding, (ii) dry etching, and (iii) layer transfer.Grinding

Back grinding is a popular and well established method for wafer thinning. The protective tape, which holds the wafer to chuck during grinding, plays a significant role in determining the total thickness variation (TTV) as the wafer gets thinner. Wafers with thickness as low as 3 µm have been obtained with this technique. Back grinding is faster with respect to other techniques, but it is also known to damage the crystal structure deep inside the material. The sub surface damage could induce high stress in the thinned wafer and can cause thin wafer or UTCs to warp. This type of stress concentration can also lead to breakage during handling, for example, while removing the thin wafer from chuck or during dicing of thin wafer. Therefore, stress-relieving techniques such as slow ion etching and chemical-mechanical polishing are recommended after back grinding. Dicing before grinding (DBG) is also sometime used to prevent breakage of thinned wafers during dicing. In DBG, the wafers are first partially-grooved and then grinded .occurring when the wafer is thinned below the level of this cut. A major problem with grinding is that there is high potential for the thin wafer getting damaged while it is being delaminated from the protection tape. This issues could be overcome by TAIKO technique in which back-grinding is done only for non-peripheral part of the rear side of wafer and the periphery is left intact as a ring . The ring-shaped periphery strengthens the overall structure and significantly reduces the issue of warpage during handlingA Illustration of Back Grinding. b TAIKO wafer vs. conventionally thinned wafer. c Steps involved in Dicing Before Grinding . d Illustration of RIE and SEM image of trenches etched between released top layer and bulk substrate. e Proton-Induced Exfoliation technique and blister created after heating hydrogen implanted wafer. f Illustration of controlled spalling and flexible wafer over polyimide .

Dry etching

Physical dislodging of Si atoms from the bulk could also be achieved with high-energy ions and gaseous reactive species. Depending on the mechanism, the process can be classified as: (i) physical ion etching (PIE), and (ii) reactive ion etching (RIE). In PIE, the atoms from the back of the substrate are removed by bombarding it with energetic ions or gas assisted etching. The etch rate depends on parameters such as scanning style, substrate chuck table angle, beam angle etc. There is always some re-deposition in this process, which reduces the effective etch rate and selectivity. In the case of RIE, the high-energy ions impacting the substrate remove the atoms physically and open-up the area for chemical reaction as illustrated in Figure . RIE gives high anisotropic behaviour but it comes with low level of selectivity (in absence of any additive) and surface damage. A few examples of RIE based UTCs include a 18 µm thick Si based thermoelectric energy generators and Si probes of thickness 20 µm for floating chronic implantation in the cortex.Layer transfer processes

This method involves removal or exfoliation of the top processed layer. Two major processes developed based on this technique are: (i) proton-induced exfoliation and (ii) controlled spalling. In the case of proton-induced exfoliation, wafer is placed in a vacuum chamber after device fabrication and exposed to a beam of hydrogen ions. When heated, these ions which were implanted beneath the surface, expand as microscopic hydrogen bubbles—thus causing a very thin Si layer to detach from the surface, as shown in Figure. The wafer can be reused to exfoliate another layer of ultra-thin Si. However, this method is not suitable for post-processing as electronic devices may be damaged because of high-energy proton exposure. Another layer transfer process is the controlled spalling technique, which takes advantage of strained conditions to obtain thin Si layer. Under specific strain conditions, a fracture on the edge of a brittle substrate can propagate parallel to the surface, as shown in Figure . This results in the detachment of thin slice of the brittle. This process can be carried out at room temperature and therefore it has advantages in terms of integration on flexible substrates. The techniques has been demonstrated with nanoscale flexible circuits (functional ring oscillators and memory cells) on 60 Å thick ultra thin Si over the oxide of SOI. One of the challenges with controlled spalling is that it requires pre-calculation and monitoring of stress level to minimize the spontaneous fracture. This can be overcome with appropriate material and thickness of top film used as stress layer.UTC via pre-processing techniques

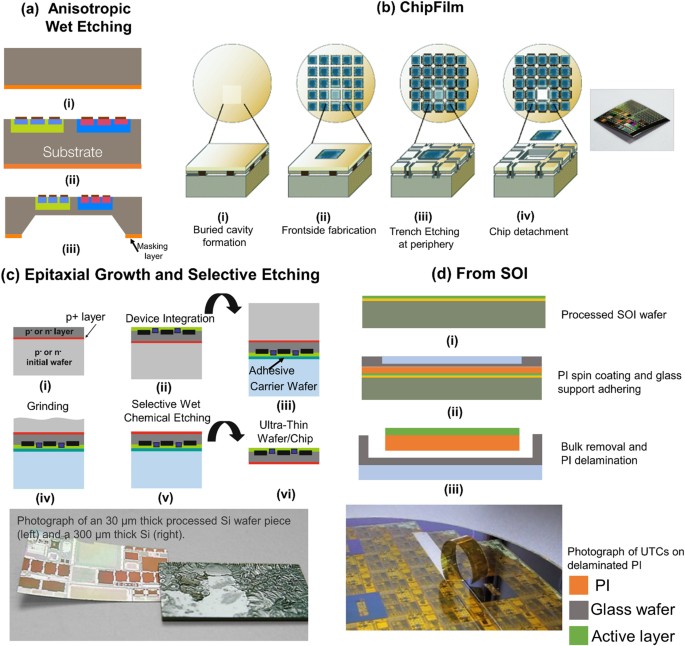

Some technologies for UTCs require processing of wafers before initiating the device fabrication. These steps are termed as pre-processing steps and the front-end fabrication follows thereafter. The techniques for realizing UTCs which require pre-processing are discussed below:Anisotropic wet etching

This well-established technology has been used traditionally to realize MEMS (microelectromechanical systems) structures. The pre-processing steps for realizing UTCs involve depositing suitable mask layers (usually a combination of high quality SiO2 and Si3N4) at defined locations on the back side of the wafer . This is followed by the device-processing steps on the front-side, and then etching of wafer from backside. The commonly used etchants for Si are hydrazine, EDP (Ethylene-Diamine-Pyrocatechol), TMAH (Tetra methyl ammonium hydroxide), and KOH (potassium hydroxide). The etching duration can be in hours depending on the concentration of etchant, the temperature and thickness of the wafer. The contamination from etchant and their CMOS compatibility is an important requirement, among others including modulating etching with dopants or electrical bias, surface roughness, availability of suitable masking films, health hazards, and disposal issues. TMAH is the most commonly used etchant as it is IC-compatible, nontoxic, and has very good anisotropic etching characteristics. One drawback with TMAH is that it leads to higher undercutting than other etchants such as KOH. To overcome this issue the isopropyl alcohol (IPA) and surfactants are generally added to TMAH. The wet etching can provide thin wafers at batch scale since many wafers can be processed at once. The wafer scale UTCs with TMAH etching and transfer to flexible substrate has been reported in literature. The protection of front-side of the wafer from etchant is a critical for this route to obtain UTCs as otherwise the etchant may render the devices on the front side useless. To provide front-side protection, a custom wafer holder made from etchant resistant material or polymeric protection layer are used. The concentration of etchant is maintained regularly during this process to have better control over the total etch time leading to UTCs with desired thickness. A potential solution for monitoring the etch process is to exploit the change in optical transmittance with thickness, as discussed in the section “Ultra-thin chip properties”.

Illustration of pre-processing and post-processing modules of a Wet Etching, b ChipFilm, c various steps in epitaxial growth and selective etching approach and d CirconFlex technique using SOI wafer.

Epitaxial Si based UTCs

The UTCs with devices having higher operating speed and better bipolar performance can be obtained by lifting-off Si epitaxial layer from the substrate. The two key approaches used for this purpose are: (a) Porous Si Approach, and (b) Etch Stop Layer Approach. The porous Si method, developed in 1990s, involves creation of a porous layer between substrate and the epitaxial layer. Examples for this approach included the ChipFilm technology , which uses two layers of porous Si with different porosity and results in ~15 µm thick UTCs. This technology allows good dimensional control and the mother wafer can be used repeatedly until exhausted. The yield of this technology heavily depends on the design and pitch of pillars in porous structure and hence the pre-processing step is critical. While this method is well suited for die-size UTCs needed in 3D ICs, the large area UTCs may not be practical due to cost considerations and risk of breaking due to warpage. One possible solution to address this issue is to use double transfer technique (i.e., using flexible carrier and substrate) instead of pick-place tool.The etch stop layer method, typically used in a MEMS, takes advantage of the fact that doping could be used to stop etching. It involves developing a highly doped (p++ type) film at certain depth (roughly equal to desired thickness of UTCs) on the front side of wafer, followed by lightly doped epitaxial layer which act as active layer for device fabrication. Post device fabrication the wafer is chemically etched from back side until the chemical hits the p++ layer, which stops the etch process. The final thickness of UTC is the equivalent to the thicknesses of the epitaxial and p++ layer. With a good control over the final thickness and uniformity of UTCs, this method . offers an alternative solution to the SOI wafer based approach. During growth process, the diffusion of impurities between Si wafer and p++ film may prevent the fabrication of an ideal step junction, which may lead to lower switching current ratio and hence the poor performance of electronics on UTCs. One way to control the impurity diffusion is to adopt low temperature epitaxial growth with a trade-off between high quality epitaxial film and higher impurity diffusion.

Using SOI wafer

SOI wafers provide a range of benefits relative to conventional wafer, such as, lower parasitic capacitance, resistance to latch up, lower leakage current, and immunity to radiation induced soft errors. While these features of SOI wafers enable high-performance electronics, their higher cost (~$1000 vs. ~$25 for a 6-inch bulk Si wafer) is a barrier. Nonetheless, despite this cost-performance trade-off, the SOI wafers are used in many niche applications such as low power high performance RF chipsand commercial devices such as IBM’s PowerPC,Global Foundry’s 22FDX, AMD’s dual core module. SOI wafer could also be used for high performance UTCs with precise thickness. This is achieved by fabricating electronic devices on the top active layer of SOI wafer, followed either by: (a) etching the buried oxide layer (i.e., BOX removal), or (b) thinning the backside of the wafer up to the required thickness or buried oxide (i.e., bulk removal) in which case the oxide acts as the etch stop layer.BOX removal

In this method, the trenches are etched around the chip on the front side and then etchant such as HF or XeF2 is passed through these trenches to etch the oxide layer underneath, eventually detaching the top chip from the mother wafer. Since the trench formation is critical, the area available for device realization is limited and therefore well laid out design scheme is needed. Moreover, it calls for proper support of top Si layer as soon as it is detached from the bulk. Such challenges can be overcome through transfer printing using PDMS or similar intermediate carrier. Transfer printing of UTC based devices such as transistors, logic gates, RF components has been demonstrated for numerous applications.Bulk removal

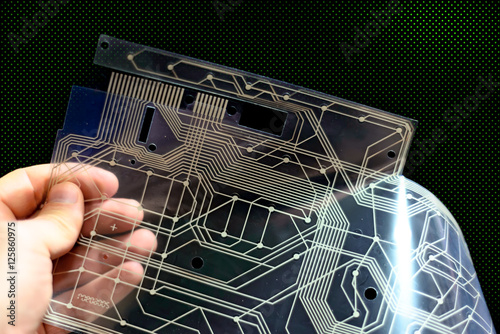

In this process, the bulk Si is removed from backside by wet etching until the etchant reaches the buried oxide. In this case, the buried oxide acts as the etch stop layer and UTC thickness is sum of active layer and BOX thicknesses. A variant of this technique developed by Philips is named as Circonflex. Based on substrate transfer technology, this process enables the transfer of top functional layer of SOI wafer to practically any flexible substrate . The method has been demonstrated for realizing 10 µm thick RF-ID tag chipsIntegration of UTCs on flexible substrates

For fully flexible systems with reliable operation, the UTCs need to be

packaged over flexible substrates, sometimes with more than one chip on

the same substrate. The choice of substrate is critical and depends on

the inherent material properties and the intended application. The

materials which have been used as flexible substrate can be broadly

divided into two categories, i.e., polymeric and metallic .

An insulation coating is generally needed for electrical isolation of

UTCs and to connect them to various components on flexible substrate and

external connections. However, there are some exceptions such as solar

cells where the required common back contact is achieved by transferring

UTSi (Ultra-Thin Si) on flexible metallic or conductive-material-coated

polymeric substrates.

The metallic substrates for flexible electronics have an added

advantage as they can serve as heat sink or means for thermal reliefs.

Further, they can be useful in applications such as electrical wave guide

or where electromagnetic shielding is required. This can also be

achieved with polymeric substrates coated with a thin conductive

material including metals .

However, metallic substrates have inherent tendency towards retaining

the shape on deformation, which may not be desirable. In this regard,

thin polymeric substrates are advantageous as they are inherently

elastic and flexible with ability to regain their normal shape. An

alternative approach is to use a stack of both polymeric and metallic

substrates and engineer the structure to realize smart substrates with

desired properties. Thermal properties of substrate such as coefficient

of thermal expansion and thermal conductivity should also be considered

as they influence integration and thermal management of UTCs. As the

stress level in UTCs is influenced by elastic properties of the

substrate, generally a material with lower Young’s Modulus is preferred.

With the increasing interest in health or bio related applications such

as implantable systems, bio-compatibility of substrate is also an

important parameter to consider. Bacterial cellulose membrane, collagen,

silicone gel and silk fibroin etc. have been used in such applications

as they also offer better integration with tissues.

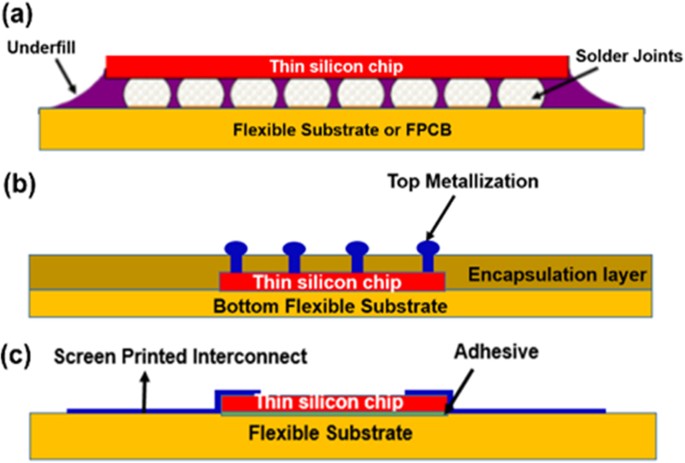

The most challenging task in the packaging of UTCs comes when the contact pads on the chip are to be connected to the extended pads on the substrates. Wire bonding technique, which is widely used for traditional packaging is not suitable for UTCs, which are fragile and can crack due to the impact of bonding head-tool. Further, the bond wires protruding out of plane of UTCs add to the thickness and affect the form factor. These challenges are driving the search for suitable materials and techniques for UTC packaging. The integration of UTCs on flexible substrate have been achieved mainly by the following three techniques.

Flip chip assembly on flexible substrate

In this style of packaging, UTCs in face down configuration are assembled on polyimide or liquid crystal polymer (LCP) substrate through flip chip bonder . In the case of polyimide substrate, the solder bumped die are reflow soldered to the patterned flex. In the case of LCP, vias are etched through to expose the underside of contact pads. However, these solder bumps become coarse due to ageing and the growth of intermetallic compound, which eventually results in a changing shear mode and increase of resistance. A right combination of temperature and pressure at the curing step is needed during flip chip technique to get reliable electrical joints from bumps. The major limitation of flip chip techniques is seen in the case of packaging of sensors requiring their sensing area to be exposed, as in the case of POSFET (Piezoelectric oxide semiconductor field effect transistor), ISFET (ion sensitive field effect transistor) etc.

Major schemes of packaging UTC: a Flip-Chip packaging of UTC, b UTC lamination between two flexible layers and c UTC on flexible substrate with screen-printed connection

Laminating UTCs between two flexible layers

This type of packaging generally aims to put UTCs in the neutral plane by embedding it between the substrate and encapsulation layer . The advantage of this approach is that it leads to a reduced stress on UTCs and as a result the electrical response of UTC is minimally affected by bending. The integration of UTCs between two polyimide layers has been demonstrated for conformable and wearable wireless ECG monitoring system. A challenge with this type of packaging is that the heat produced during device operation cannot escape to ambient. This could lead to high local temperature and can damage or degrade the device performance, as also discussed in the section “Ultra-thin chip properties”. Moreover, the adhesion between the polyimide and the Si may vary due to localized area of high temperatures and this could lead to uneven adhesion of package or air bubbles formation within the package. In this direction, the on-chip cooling mechanism could be explored. For example, the nanostructured super lattice-based thin-film thermoelectric material (e.g., Be2Te3) integrated with Si based electronics results in reduction of temperature by ~14.9 °C at target site. Similar advances could be explored for UTCs to improve the reliability of package. Recently, embedding of micro-air vertical channels in UTCs have been reported for faster cooling and lower constant load saturation temperature. Use of flexible materials with high thermal conductivity (e.g., copper, graphene, etc.) and structuring them as fins to act as a heat sink or using commercial thermal conductive tape outside the package are other potential solution.UTCs on foil with printed connections

In this approach, UTC are placed in the face-up configuration on the flexible substrate using epoxy based adhesive. Conductive wires are printed-on top of flexible substrate to realize electrical connections between the chip and the substrate . Screen printing or ink-jet printing is used to connect the contact pads on chip to the external connections on the flexible substrate. Silver based conductive ink and polymer based conductive material like Poly (3,4-ethylenedioxythiophene): polystyrene sulfonate (PEDOT:PSS) have been used for this purpose. The silver ink provides much higher conductivity than PEDOT:PSS but it is susceptible to cracking during bending. On other hand, PEDOT:PSS provides more flexibility than silver ink but shows low conductivity. A durable connection by combining screen printed silver grid with PEDOT:PSS could be a potential solution. Although printing is simple and can be extended to large area, due to poor resolution of printers the contact pads and wires realized through printing are usually big in comparison to contact pads on the chip. This issue will be overcome with advances in printing technologies.For fully flexible electronics system other materials may also be used in conjunction with UTCs. For example a:Si/Poly-Si, inkjet or transfer printed nanowires, 3,3‴-didodecylquarterthiophene (PQT), solution processed organic/inorganic materials such as peri-xanthenoxanthene (PXX), Lithium Super Ionic CONductor (LISICON), pentacene, dinaphthothienothiophene (DNTT), copper hexadecafluorophthalocyanine (F16CuPc), PEDOT, and thixotropy materials, etc. could be used to obtain advanced multifunctional flexible electronics systems.

Energy autonomous electronic skin

Design UTC in e- S H I N to A/ D / S Tour Route

Applications of UTCs

A

wide range of applications require UTCs as through underpinning

high-performance electronics they enable advances in several areas, as

illustrated in Fig. 1.

The UTCs form the key components of various smart systems as sensing

units, data processing or storage unit, driving or output unit and power

or energy management units etc. Depending on the application

requirements, the specification of electronics/sensing components on

UTCs may vary. Some of the applications where UTCs are used as sensing

units, data processing or storage unit, driving or output unit, and

power or energy management units are described below.

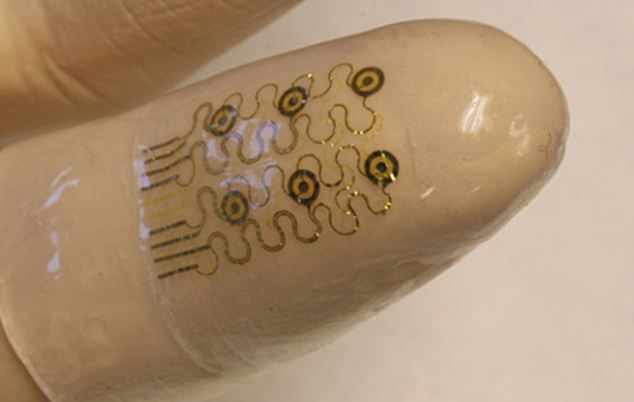

In order to achieve biomimetic tactile sensing, about 250 MRs/cm2 are required in the fingertip of prosthetic limb, which could be achieved by high density tactile sensors such as flexible POSFET that can conform to fingertips.Further, UTCs could be useful for large area tactile skin based on planar off-the-shelf electronics integrated on FPCBs. Lack of bendability of electronics has often limited the use of large area skin to body parts with large curvature. UTCs are ideal to address such applications as besides high-performance sensing they could also conform to the curved surface of prosthesis.

Implantable systems have brought a distinctive transformation in the field of medical diagnosis and treatments. Flexible microchips with integrated sensors or microelectrodes are advantageous for applications such as brain interfaces as they can conform to soft tissues and hence allow recording of reliable data. Flexible UTCs with RFIDs encapsulated with biocompatible liquid crystal polymers has been successfully implanted and tested. UTCs also find application in video endoscopy, smart catheters, diagnostic pills, sub-retinal implants, neural interfaces,swallowable smart pill and tactile functional prosthetics etc. In the field of medical diagnosis, UTCs find application as conformal retinal implant for blind vision, electromyographic and/or neural prosthetic implant, and blast sensor patch in sports/military helmets to detect trauma injury. Neurotechnology is another area which will greatly benefit from electronics that bends, stretches and conforms to curved surfaces. For example, complementing current in vivo studies, the flexible and conformal microelectrode arrays will offer powerful new tool in traumatic brain injury research. UTCs are attractive for such applications as in addition to the active microelectrodes they could also offer functionalities such as wireless communication. Thanks to the flexibility and conformability, the UTCs will be far more comfortable for people using them.

In applications for health monitoring where the devices are worn or wrapped around the body the high-performance and compact electronics on UTCs could provide solutions such as measuring human pulses on wrist, and orthodontic forces of invisible aligners for dental treatment. The convergence of soft and deformable textiles technologies with high-speed computational capacity of UTCs is another application. The rough and uneven surface of fabric makes it difficult to have seamless integration of UTC, which could be solved by using smoother intermediate layer between textile and UTC. The UTCs can have sensors, interconnects and processor for on-chip processing of the data. This type of arrangement will greatly influence the applications such as military garment devices, antibacterial textiles, and personal electronics like MP3 jacket and smart carpet.

Flexible portable devices, smart contact lenses or augmented reality systems are some other areas where UTCs could trigger advances as they could enable high-speed computation at lower power and high-density storage. The Ferroelectric Random Access Memory (FeRAM) based on flexible silicon shows superior performance and can be good choice for flexible memory applications for IoT. Emerging memory devices such as RRAM (Resistive random-access memory), memristors, and other high density nanoelectronic non-volatile memories could also be integrated with UTC technology.

In applications such as bidirectional prosthesis at par with human hand, the electronics on e-skin should process data from 18k mechanoreceptors (MRs) to mimic the glabrous palm area of a hand. As number of sensory components increase, there is demand to handle large data. The on-site processing and signal conditioning of the raw data can be fulfilled by UTCs integrated on the e-skin. While the active tactile layer could comprise of large area flexible material such as graphene, the sensory data from array of taxels should be processed locally by a tactile interface IC before it is fed into the computing chip. The high-performance UTC serve are ideal for such task. They could also reduce the load on the computing block or could enable new features such as multitouch input, 2D and 3D gestures, handwriting recognition, pen/stylus input, pressure sensitivity, fingerprint recognition, and security operations. In areas such as wearable systems, where different modules need to communicate within and outside the system, the UTCs could be used to develop components for body area networks, and RF communication such as Bluetooth 4.0 low energy communication etc.

In applications such as smart portable display, there is a growing interest in manufacturing portable devices with flexible display that can undergo bending, flexing and rolling. While flexible AMOLED display are commercially available, for flexible smartphone various components such as battery, driving unit, communication chip etc. are not bendable yet. Some of these form the areas of active research, for example, flexible batteries. With high performance flexible circuits, UTC could remove the current bottlenecks for flexible displays.

Thus, with several applications, the UTCs could bridge the gap between CMOS technology and several of the above mentioned emerging applications of flexible electronics.

Sensing/input

UTCs smart sensing units offer interesting solution for several existing applications such as implantable systems, neurotechnology, wearables, robotics and prosthetics etc. Futuristic applications such as body area network, body-dust, neural interfaces, bidirectional prosthesis, internet of everything and smart homes etc. will also benefit from UTCs based sensing units. As tactile interface chip for flexible touch panel, the UTCs will bring transformation in flexible portable devices and e-skin for prosthesis or robotics (a flexible and transparent electronic skin as illustration for sensing/input in Portable devices such as smartphones are expected to be flexible in the future, and for this to happen various components including touch panel should be flexible. In such cases, the active tactile layer could comprise of large area flexible material such as graphene, but the sensory data from array of taxels will be processed locally by a tactile interface IC or neuromorphic ICs before the data is transferred to complex computing hardware. UTCs will strengthen the capability of such systems by enabling features that require high-performance such as multitouch sensing, 2D/3D gestures, handwriting recognition, pen/stylus input, pressure sensitivity, fingerprint recognition, and security operations.In order to achieve biomimetic tactile sensing, about 250 MRs/cm2 are required in the fingertip of prosthetic limb, which could be achieved by high density tactile sensors such as flexible POSFET that can conform to fingertips.Further, UTCs could be useful for large area tactile skin based on planar off-the-shelf electronics integrated on FPCBs. Lack of bendability of electronics has often limited the use of large area skin to body parts with large curvature. UTCs are ideal to address such applications as besides high-performance sensing they could also conform to the curved surface of prosthesis.

Implantable systems have brought a distinctive transformation in the field of medical diagnosis and treatments. Flexible microchips with integrated sensors or microelectrodes are advantageous for applications such as brain interfaces as they can conform to soft tissues and hence allow recording of reliable data. Flexible UTCs with RFIDs encapsulated with biocompatible liquid crystal polymers has been successfully implanted and tested. UTCs also find application in video endoscopy, smart catheters, diagnostic pills, sub-retinal implants, neural interfaces,swallowable smart pill and tactile functional prosthetics etc. In the field of medical diagnosis, UTCs find application as conformal retinal implant for blind vision, electromyographic and/or neural prosthetic implant, and blast sensor patch in sports/military helmets to detect trauma injury. Neurotechnology is another area which will greatly benefit from electronics that bends, stretches and conforms to curved surfaces. For example, complementing current in vivo studies, the flexible and conformal microelectrode arrays will offer powerful new tool in traumatic brain injury research. UTCs are attractive for such applications as in addition to the active microelectrodes they could also offer functionalities such as wireless communication. Thanks to the flexibility and conformability, the UTCs will be far more comfortable for people using them.

In applications for health monitoring where the devices are worn or wrapped around the body the high-performance and compact electronics on UTCs could provide solutions such as measuring human pulses on wrist, and orthodontic forces of invisible aligners for dental treatment. The convergence of soft and deformable textiles technologies with high-speed computational capacity of UTCs is another application. The rough and uneven surface of fabric makes it difficult to have seamless integration of UTC, which could be solved by using smoother intermediate layer between textile and UTC. The UTCs can have sensors, interconnects and processor for on-chip processing of the data. This type of arrangement will greatly influence the applications such as military garment devices, antibacterial textiles, and personal electronics like MP3 jacket and smart carpet.

Data processing/storage

The consumer electronic devices such as smart phones, mobile gaming systems, and ultrabook computers etc. have fueled the growth of semiconductor industry in recent years. Consumer prefer smaller, thinner, and lighter systems with additional features such as wearable to meet their mobile lifestyles. Thanks to Moore’s law and ITRS roadmaps, CMOS technology has come a long way breaking many challenges with many material and technology innovation leading to the current state-of-the-art. Commercially, 14 nm technology FinFET based microprocessors are available which operates at >4 GHz and now gearing to 10 nm. Considering the huge number of objects, with different size, shape and rigidity, which will be connected in IoT environment, high performance, and mechanical flexibility of devices employed in these objects is inevitable. As discussed in the section “Introduction”, the wireless communication in IoT will require data handling ultra-high frequency range. UTCs will be useful here as they could support faster communication, high bandwidth, and efficient distributed computation with very high switching speed. With interconnect schemes such as through-silicon-vias, low power consumption and excellent high performance, the UTCs have potential for 3D integrated circuits (3D ICs) to handle large amount of data and processing in IoT concept.Flexible portable devices, smart contact lenses or augmented reality systems are some other areas where UTCs could trigger advances as they could enable high-speed computation at lower power and high-density storage. The Ferroelectric Random Access Memory (FeRAM) based on flexible silicon shows superior performance and can be good choice for flexible memory applications for IoT. Emerging memory devices such as RRAM (Resistive random-access memory), memristors, and other high density nanoelectronic non-volatile memories could also be integrated with UTC technology.

In applications such as bidirectional prosthesis at par with human hand, the electronics on e-skin should process data from 18k mechanoreceptors (MRs) to mimic the glabrous palm area of a hand. As number of sensory components increase, there is demand to handle large data. The on-site processing and signal conditioning of the raw data can be fulfilled by UTCs integrated on the e-skin. While the active tactile layer could comprise of large area flexible material such as graphene, the sensory data from array of taxels should be processed locally by a tactile interface IC before it is fed into the computing chip. The high-performance UTC serve are ideal for such task. They could also reduce the load on the computing block or could enable new features such as multitouch input, 2D and 3D gestures, handwriting recognition, pen/stylus input, pressure sensitivity, fingerprint recognition, and security operations. In areas such as wearable systems, where different modules need to communicate within and outside the system, the UTCs could be used to develop components for body area networks, and RF communication such as Bluetooth 4.0 low energy communication etc.

Driving/output

The UTCs could also offer solution for efficient driving or output unit for many applications such as optogenetics, flexible portable devices, antenna, actuators. The drive units should provide precise control on current and/or power and/or voltage and/or timing. As an example, in optogenetics pulses of light with spatiotemporal precision are needed to stimulate the neurons and UTCs could be used to achieve this. Typically, optogenetic stimulation is carried out by external light source with fiber-optics to deliver the light to the targeted location. Typical driving requirements is such application are precise temporal requirement i.e., rise time and fall time (10–90% and vice-versa) of current pulses <100 µs and in some specific applications <1 µs and current level up to 1.5 A. Such an arrangement is cumbersome and involves tether. Tether-free implantable miniaturized optogenetic systems are preferred in such cases and UTCs based drivers could provide the required temporal and spatial resolution. Further, with UTCs it will be possible to achieve multi-wavelength and multi-array microLEDs (µLED) targeting various optogenetic channels (corresponding to various opsins) such as channelrhodopsin, halorhodopsin, archaerhodopsin,bacteriorhodopsin. The typical current requirement for such µLED driving is 2–5 mA. Depending on the requirements, the compound semiconductor layers for µLEDs could also be grown or transfer printed on Si, from which UTC is fabricated. Such implantable optogenetic chips can communicate with external transceivers through RF communication in which case UTCs could drive the antennas. Similarly the UTCs could provide the drive/output unit in bidirectional prosthesis, treatments for epilepsy, cardio-arrhythmias, drug addiction, and brain/neural circuit mapping. UTC could also find application in driving flexible pacemakers and defibrillators. For example, the UTC chips integrated with EMG sensing electrodes could process the signal in real-time to identify potential arrhythmia. Wherever needed, they could drive the electrodes to provide stimulus for pacing, cardioversion or defibrillation. UTCs could also drive various components in wearable systems such as LED drivers for pulse oximetry, electro-tactile stimulation, haptic communication gloves for deaf-blind, bendable oral systems (for example to control prosthesis or wheelchair,) smart insole for health monitoring and prosthesis control.In applications such as smart portable display, there is a growing interest in manufacturing portable devices with flexible display that can undergo bending, flexing and rolling. While flexible AMOLED display are commercially available, for flexible smartphone various components such as battery, driving unit, communication chip etc. are not bendable yet. Some of these form the areas of active research, for example, flexible batteries. With high performance flexible circuits, UTC could remove the current bottlenecks for flexible displays.

Power management and energy harvesting

Optimizing battery life for portable systems presents a significant engineering challenge for system designers. While low power high efficiency FETs help in achieving this goal to some extent, alternative approaches are being explored by researchers to harvest energy to develop energy autonomy. Current solutions such as batteries require charging at regular intervals. However, for applications such as health monitoring devices it is advantageous to power the device with energy harvested from the ambient, such as light, heat or motion. UTSi and UTC technology could help in addressing the need for power management and energy harvesting using high efficient flexible solar cells, buck or boost DC-to-DC convertors, power electronics drivers. Photovoltaic technology is one area where thin Si was initially used as explained in the section “Historical perspective”. Due to continuous growth rate over the last decade, the cumulative installed capacity of photovoltaics have exceeded 303 GW-peak by the end of 2016. Monocrystalline silicon based PV with their long life span (up to 40 years) and high conversion efficiency (15–26%) is a better choice. However, the higher cost of monocrystalline silicon (compared to amorphous or micro-crystalline silicon) makes it expensive. In this scenario, UTCs present an interesting avenue. The solar grade large wafers (>8” diameter) are best choice for manufacturing solar panels with ultra-thin Si as active material. However, with lesser thickness the special optical trapping techniques are required to harvest maximum light energy as explained in the section “Ultra-thin chip properties”. The energy harvesting component shows array of micro photovoltaic cells made of monocrystalline Si. Further, a graphene based transparent coplanar capacitive touch sensor combined with solar cells forming a smart energy autonomous electronic skin system . Thermal energy harvesting is another possibility, where a flexible harvester realized on the top of thin Si has been reported to produce around 30% more output power than that of realized on bulk Si.Thus, with several applications, the UTCs could bridge the gap between CMOS technology and several of the above mentioned emerging applications of flexible electronics.

Area Working

The international roadmap for semiconductors (ITRS) highlighted the need for thin chips almost 15 years ago in context with 3D IC staking for system-in-package. In fact, the 2005 ITRS report laid emphasis on UTCs thinner than 20 μm as well as wafer thinning and handling, small and thin die assembly and packaging of thin chips. Until few years ago the demand for UTCs was primarily for 3D system integration, where multiple active dies having active and lateral interconnects are vertically connected through silicon vias. However, this is changing with emerging applications such as mHealth, wearable systems, smart cities, and IoT. The high-performance and flexibility of electronics needed in these applications are primarily pushing the interest in UTCs. In fact, these requirements have fuelled the research for high-mobility materials such as graphene, which owing to excellent electrical, mechanical and optical properties holds the promise for high-performance flexible electronics. However, the technology for these new high-mobility materials is not mature yet for large-scale integration. The limited success of electronics from these high-mobility materials and well-established Si based high-performance electronics respectively act as the push and pull factors of UTC research. A range of silicon based non-bendable devices are already being used in ad hoc arrangements in a wide ranging applications. With this background, this review article has presented and compared the ways to make bendable Si and variations in the response of devices on UTCs because of changes in electrical, optical and mechanical behaviour. Tremendous progress has been made for obtaining UTCs and a range of thinning methods.Going forward, the major hurdles for UTCs will be in the areas related to packaging, modelling and dealing with the effect of stress and strain on electrical response of UTCs. The handling of thin fragile wafers and packaging of UTCs needs more attention. Unlike conventional chips, UTCs cannot be bonded easily with wire-bonder because of high chances of cracks when the bonder tip hits the bonding pad. Reliable and durable connection from chip to the substrate is a challenging task because of the bumps coarsening (in the case of flip-chip bonding) and chances of electrical discontinuity (in the case of screen-printing). With suitable thermal management and embedding the chip between two layers of pre-patterned electrical connection it is possible to overcome the bonding related issues. While much has been done to realize UTCs, the stress induced effects and related models are scarcely researched. A major reason behind the success of Si technology was the availability of accurate models to predict device response. However, this is challenging in the case of UTCs as they experience stress because of external bending. The modelling and simulation of devices on UTCs has not received sufficient attention and this will pose major challenge to the circuit designers. The cost of fabrication of UTCs is also argued as an area that requires attention, especially when they are realized from SOI wafer. However, with mass manufacturing of UTCs the costs will come down and this is likely to be a non-issue. In conclusion, despite many challenges the UTCs hold great promise for advances in many areas where high-performance flexible or conformable electronics are needed.

________________________________________________________________________________

The development of flexible integrated circuits based on thin-film transistors

The use of thin-film transistors in liquid-crystal display applications

was commercialized about 30 years ago. The key advantages of thin-film

transistor technologies compared with traditional silicon complementary

metal–oxide–semiconductor(CMOS) transistors are their ability to be

manufactured on large substrates at low-cost per unit area and at low

processing temperatures, which allows them to be directly integrated

onto a variety of flexible substrates. Here, I discuss the potential of

thin-film transistor technologies in the development of low-cost,

flexible integrated circuits for applications beyond flat-panel

displays, including the Internet of Things and lightweight wearable

electronics. Focusing on the relatively mature thin-film transistor

technologies that are available in semiconductor fabrication plants

today, the different technologies are evaluated in terms of their

potential circuit applications and the implications they will have in

the design of integrated circuits, from basic logic gates to more

complex digital and analogue systems. I also discuss microprocessors and

non-silicon, near-field communication tags that can communicate with

smartphones, and I propose the concept of a Moore’s law for flexible

electronics.

_________________________________________________________________________________

Energy autonomous electronic skin

Energy autonomy is key to the next generation portable and wearable

systems for several applications. Among these, the electronic-skin or e-skin

is currently a matter of intensive investigations due to its wider

applicability in areas, ranging from robotics to digital health, fashion

and internet of things (IoT). The high density of multiple types of

electronic components (e.g. sensors, actuators, electronics, etc.)

required in e-skin, and the need to power them without adding

heavy batteries, have fuelled the development of compact flexible energy

systems to realize self-powered or energy-autonomous e-skin. The

compact and wearable energy systems consisting of energy harvesters,

energy storage devices, low-power electronics and efficient/wireless

power transfer-based technologies, are expected to revolutionize the

market for wearable systems and in particular for e-skin. This paper reviews the development in the field of self-powered e-skin,

particularly focussing on the available energy-harvesting technologies,

high capacity energy storage devices, and high efficiency power

transmission systems. The paper highlights the key challenges, critical

design strategies, and most promising materials for the development of

an energy-autonomous e-skin for robotics, prosthetics and wearable systems. This paper will complement other reviews on e-skin, which have focussed on the type of sensors and electronics components.

bionic skin for cyborg

An electronic-skin or e-skin is an artificial smart skin consisting of multiple sensors distributed either along the same surface or stacked . With various sensors spread over a large area, mimicking some of the features of human skin, the e-skin could bestow robots and prostheses with sense of touch.Moreover, the e-skin can also act as a ‘second skin’ in humans i.e. sticking onto the body surface, with sensors augmenting the natural sensory capacity by measuring various body parameters (e.g. blood pressure, body temperature, heartbeat, etc.) or ambient parameters (e.g. gases, chemical, materials, radiation, etc.). The e-skin also require integration of large number of sensing/electronic components on flexible and conformal surfaces, as evident from the growing trend of high density of sensors in medical patches, active-matrix for touch screens and tactile sensitive artificial skins for robots/prosthesis. This also leads to a higher demand of energy, requiring energy harvesting/storage devices with high energy densities and capacities. In addition, the development of high-performance energy transfer technologies is also needed, comprising new strategies to deliver energy, e.g. wireless protocols. A self-powered e-skin, also called here as energy-autonomous e-skin, can harvest sufficient energy from the ambient to power all its sensors and electronic components, and storing the excess of energy for future use. In this scenario, e-skin could have continuous and stable operation, even during short absence of energy sources. In this sense, the energy autonomy of e-skin will also improve the acceptance of flexible and wearable systems using this technology.

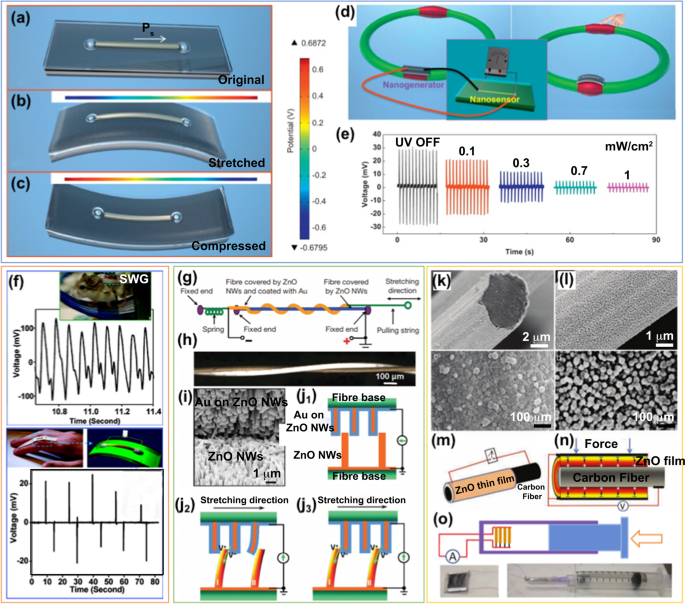

Multi-sensing and flexible electronic skin for robots and humans. 3D schema of a flexible e-skin with multiple electronic components (sensors, electronics, memory, energy harvesters, etc.)

Currently, the energy requirements of e-skin are met with bulky batteries or energy harvesters . that do not always produce sufficient energy, and also affect the portability and overall wearability of the e-skin. The batteries offer a limited life span and short charging/discharging cyclic stability and durability, risky over-heating effects, and are often heavy . Because of the need, and currently the lack of suitable solutions, significant efforts have been devoted during the last decades to develop alternative solutions such as light-weight e-skin with wearable energy harvesters (e.g. photovoltaics, thermo-electricity, piezo-electricity and tribo-electricity) and energy storage devices (e.g. flexible batteries and supercapacitors). Considering the key role of energy, this paper focuses on the e-skin requirements and potential solutions with integrated energy harvesting/storing technologies. Among all potential energy sources, light, thermal and mechanical energies, have demonstrated excellent performance for powering e-skin due to abundance in the environments where the e-skin could be used. In addition, the chemical energy from various human body fluids (e.g. tears, saliva, sweat, etc.) and biofuels are attracting interest as promising energy sources for powering e-skin in wearables. The progresses in the field of energy-harvesting technologies include the fabrication of energy harvesters on rigid as well as non-conventional flexible/stretchable substrates, e.g. stretchable PV cells, light thermocouple energy generators, or flexible triboelectric energy nanogenerators.In this regard, the future of e-skin is sometimes subjected to the success of energy harvesters and storage technologies developed on flexible/stretchable substrates. The performance of some of the above technologies is still far from the requirements for fully autonomous e-skin, i.e. an e-skin that can work continuous for 24 h with high stability and reliability. Low power conversion efficiency of technology developed on flexible substrates and discontinued energy supply are the two main drawbacks observed in energy harvesters based on light, mechanical and thermal energies. Although there are already some examples of continuous powering of e-skin, the latest progress reported on multi-sensing e-skin and the reduction of the sensors and electronics size, have drastically increased the energy requirements for this technology. Therefore, current challenges on energy-autonomous e-skin are not focused only on the discovery of new sources of energy (e.g. chemical and electrochemical energy) and high-efficient energy-harvesting mechanisms (e.g. triboelectrics), but also on the integration of different energy harvesting and storage technologies, resulting in a portable power pack.

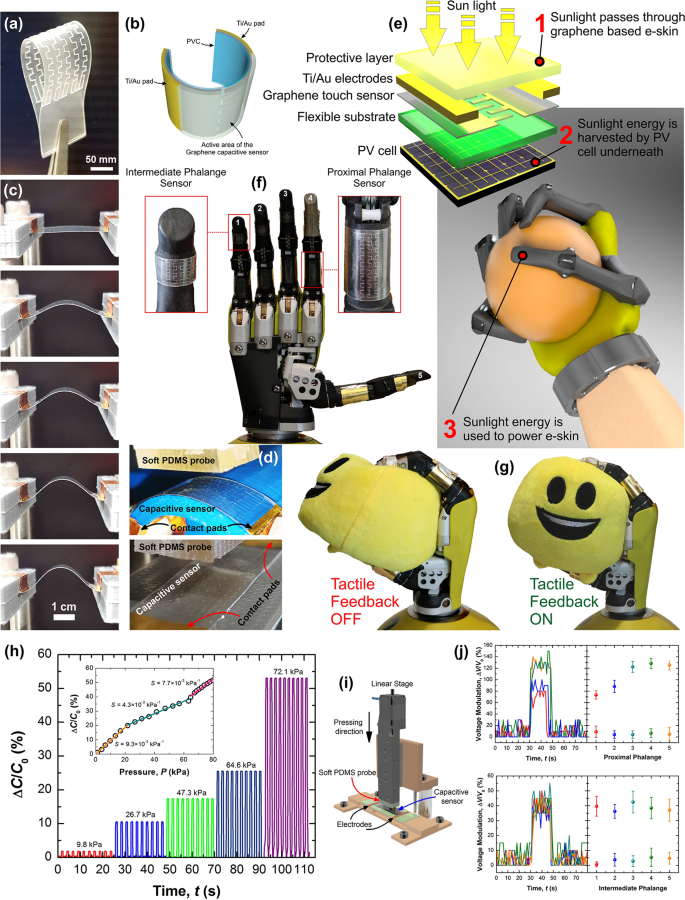

Prior to the discussion about the potential strategies to harvest, store and deliver energy to e-skin, it is important to mention the power requirements of this technology so that suitable energy could be explored. A large number of sensors and electronic components, made from different materials (e.g. graphene . piezoelectric polymers such as polyvinylidene fluoride (PVDF) or transparent conductive oxides such as indium tin oxide (ITO) are needed for various sensors in large-area e-skin for robots. The power requirement multiplies with the increasing number of sensing and associated electronic components. For example, the flexible printed circuit boards based e-skin, developed through ROBOSKIN research project . to cover the body of a humanoid robot ‘iCub’ has about 1000 capacitive touch sensors, requiring about 7.5 W to power the e-skin. This calculation considers the macroscopic sensing modules only. In reality the power consumption will be much higher if we reduce the size of sensors down to the micro- or even nano-scale, to mimic the touch sensitivity of human body (where an estimated 4.5 × 104 mechanoreceptors are present in about 1.5 m2 area) with increased the number of touch sensors. This number of sensors will be further going up if we also consider thermo-sensors, and chemical-sensors, etc. Likewise, the Hex-O-Skin made with off-the-self components requires 4.5 W. For continuous operation of e-skin, the energy requirements can be high—particularly when robots are battery powered. In this regard, new materials such as graphene or ITO have demonstrated great potential as they require much lower power (~20 nW/cm2 for graphene1 and ~100 μW/cm2 for ITO8). With these conditions, the power consumption of graphene-based e-skin to cover the 1.5 m2 surface of a robot body will be of 3.9 μW, which is about six order of magnitude less than the off-the-shelf components based on large-area tactile skins discussed above. This significantly low energy needed by latest e-skin makes it feasible to use ambient energy sources such as light, mechanical or thermal energies as potential sources to power e-skin

Energy-autonomous electronic skin: potential energy sources. The schematic diagram of self-powered e-skin,

comprising: (i) energy harvesting (light, mechanical, chemical and

thermal energy), (ii) energy storage (batteries and supercapacitors) and

(iii) examples of self-powered e-skin solutions. Energy

harvesting: the illustration compiles the best performance energy

harvesters and their corresponding energy outcome (i.e. power density)

depending on the energy source (light, mechanical, chemical and thermal energy),

highlighting successful devices exhibiting features including

stretchability, lightweight, output powers and wearability. Energy

storage: highlighting various flexible active electrodes that enhance

the performance of LiBs and textile/fibre/cloth-based supercapacitors for wearable systems. Examples of self-powered e-skin

solutions: the illustration shows representative examples of electronic

devices continuously self-powered by various energy sources, including

tactile e-skin for robots self-powered by sunlight.

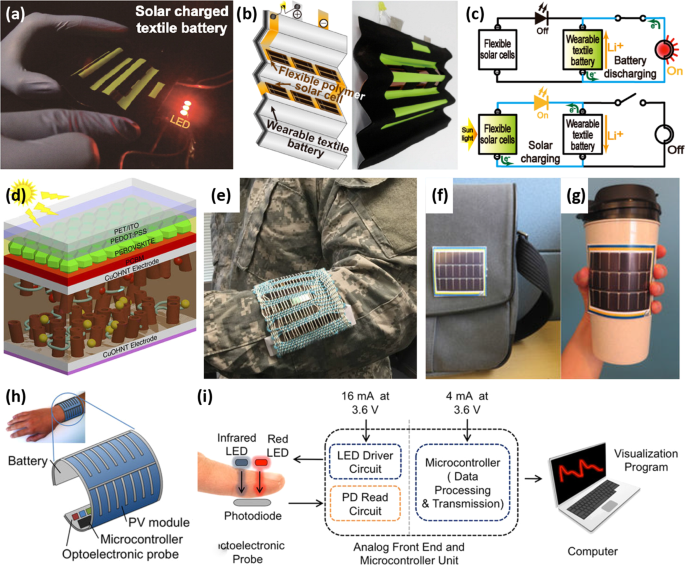

summarizes the state-of-the art energy harvesting and storage technologies successfully utilized in e-skin-like systems such as graphene-based tactile skin powered by sunlight, a pulse oximeter powered by thermal energy from human body, healthcare e-patch powered by human finger vibrations and multi-sensing e-skin on fabrics powered by human arm actions.The best reported performances (e.g. power density and capacity) . The energy harvesting, and storage solutions on their suitability for a wide range of e-skin applications.

The following section presents the advances in the energy harvesting with particular focus on the solutions relevant to e-skin.

This is followed by a discussion in the section 'Towards continuous

energy supply: technologies for energy storage and wireless charging' on

the energy storage and transmission technologies, including wireless

energy transfer. Few examples of self-powered e-skin systems are presented in the section 'Self-powered e-skin'.

The key challenges and potential solutions, critical design strategies,

and most promising materials for the development of energy-autonomous e-skin have been discussed in the section 'Key challenges and potential solutions for future self-powered e-skin' . With several reviews on e-skin focussing on the sensing and electronics components only,

the most promising energy sources available in the ambient for self-powering of e-skin and other similar technologies presented in the section 'Self-powered e-skin'.

The fundamental mechanism behind each type energy-harvesting method,

their approximate energy budget, i.e. power conversion efficiency (PCE)

and power density (PD), etc. are thoroughly discussed. Since several

applications require e-skin to be flexible or to conform to 3D

surfaces, the discussion here considers the energy-harvesting solutions

with features such as bendability, conformability, wearability,

stretchability, and compatibility to low-temperature fabrication

procedures.

Light energy

Among all, solar energy is one of the most abundant renewable energies available from the environment. The solar energy that is provided to the earth surface during 1 h exceeds by far the energy consumed globally by humans in 1 year. This is the main reason to consider light energy as a potential source for self-powered systems. A solar-powered e-skin integrated on the body of a robot would allow the robot to execute tasks in wide ranging environments, either on the Earth or in space, thanks to the great amount of energy supplied by the sun.Photovoltaic (PV) materials that are typically used to transform sunlight energy into electricity are based on semiconductor solid-state thin films made of crystalline Si (c-Si), amorphous-Si (a-Si), polycrystalline-Si (poly-Si) and monocrystalline Si (mc-Si).Flexible PV cells, which could meet the conformability requirements of e-skin, have also been fabricated successfully using a-Si (PCE ~ 8%), and enormous effort is being put to fabricate the new generation of low-cost PV cells with higher PCE, lightweight, and using print technology. These technologies mainly include dye-sensitized PV cells and the PV cells based on organic materials, quantum dots and perovskites. The lightweight, conformability, compatibility to low-temperature processing and to textile/fabrics like substrates of PV cells, mechanical strength, low-cost fabrication process, and biocompatibility (e.g. for e-skin applications on humans or animals) are also crucial properties for the use of PVs as energy source in portable and wearable self-powered e-skin.61 For the sake of comparison, the PCE (obtained using an A.M. 1.5 solar illumination with 100 mW/cm2 intensity) of various PV technologies

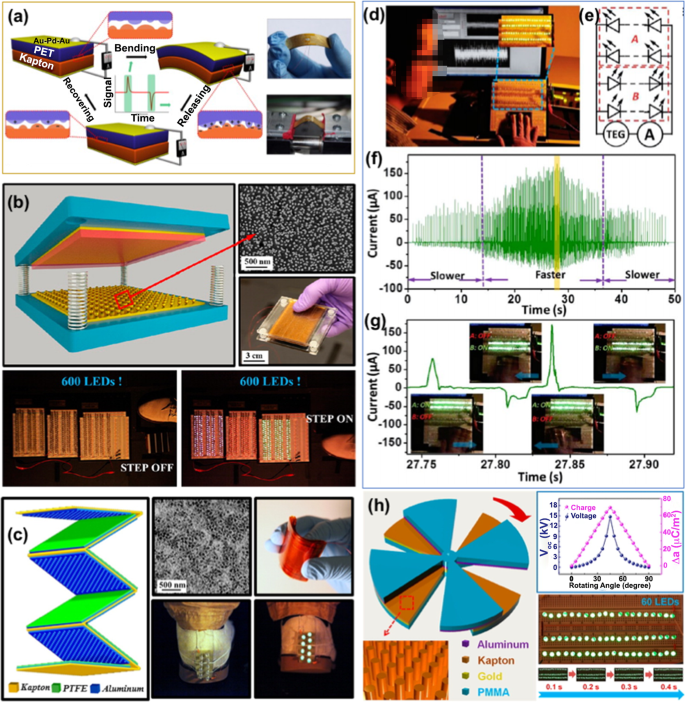

Piezoelectric energy generators. a 3D schema of a single NW-based piezoelectric nanogenerator fabricated on a flexible substrate and subjected to b stretching and c compression conditions. d 3D schema presenting the working principle of a self-powered touch nano-sensors powered by a piezoelectric nanogenerator .

Triboelectric energy generators. a 3D schema (left) and photograph (right) of flexible TEG under bending conditions.

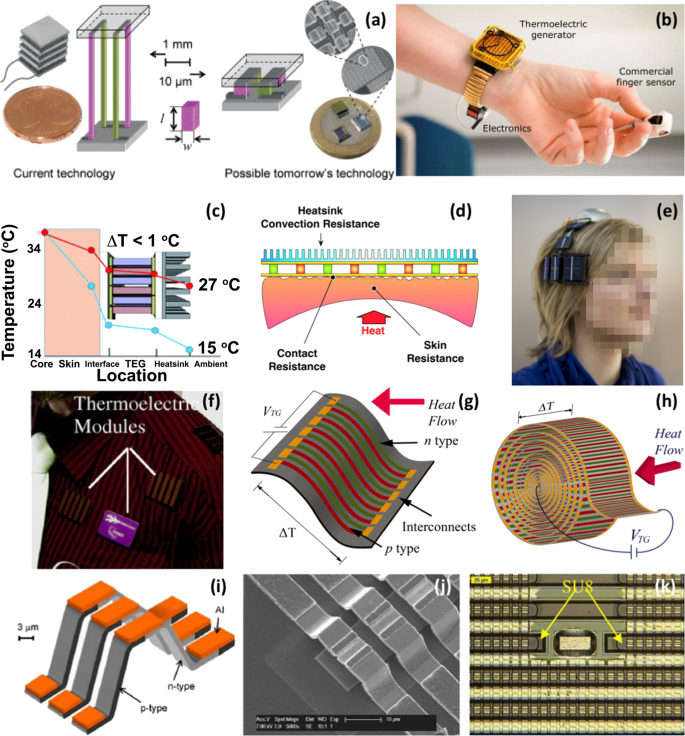

Thermal energy generators. a Current (left) and futuristic (right) view of TE generators. b Body-powered wireless pulse oximeter. c Temperature difference from core body to the ambient air.

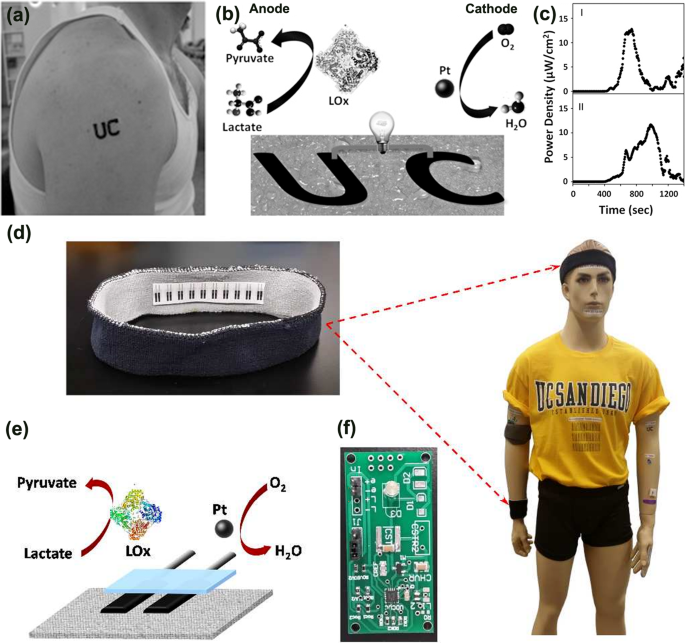

Chemical energy generators. a Photograph of a UC-inspired tBFC integrated on the deltoid of a volunteer.

In e-skin applications, the use of soft and stretchable electronics is common because it improves the conformability. BFCs have also demonstrated great applicability as they meet such requirements due to their biocompatibility, flexibility/stretchability, and scalability towards high-power-density generation, compatibility to soft substrate to minimize the impact on skin irritation and wearers comfort. For such wearable systems, an alternative approach consisting of a layered flexible biofuel based on biobattery with bioanode fabrics for fructose oxidation, hydrogel sheets containing fructose as fuel, and O2-diffusion biocathode fabrics, has also been reported with maximum power of 0.64 mW at 1.21 V. High energy density and stretchability are the key challenges for this type of biofuels. Highly stretchable textile BFCs have been fabricated by screen printing of stretchable inks with CNT and Ag2O/Ag electrodes, exhibiting stable power outputs after 100 cycles of 100% stretching. The fabricated BFCs produces power densities of 160 and 250 mW/cm2 with single-enzyme and membrane-free configurations, respectively, and potential application for self-powered biosensors. In this regard, stretchability feature is currently a matter of intensive investigations in BFCs due to the possibility to complement other technologies such as energy storage devices and sensors currently fabricated on stretchable substrates.

Towards continuous energy supply: technologies for energy storage and wireless charging

While the efficient harvesting and management of renewable energy sources available in the environment (see the section 'Sources of electrical energy'), are key to the development of self-powered systems (see the section 'Self-powered e-skin'), ensuring the continuous supply of energy is also important. To this end, the e-skin should also have suitable scheme for energy storage and among various solutions available today the flexible batteries and supercapacitors are the most promising as summarized . The integration of both energy harvesting and storage technologies forming a self-powered pack (SPP), is currently an intensive subject of investigation due to its tremendous potential for wearable systems.

Energy storage devices. a Comparison between batteries and SC technologies performance. b 3D schema of wire-shaped SCs. c Flexible wire-shaped SC characterized under different bending conditions.

One of the main drawbacks of the current portable energy storage technology for e-skin

and wearable systems is the high dependence on bulky wires for energy

transfer, which hinders the portability and autonomy. The wearable

systems including sensors for health monitoring electronic patches, and e-skin

for robots and artificial limbs, require a drastic reduction of wires

density (and size), or even the development of a wireless energy

transfer technology. Electric vehicles, robots, or artificial limbs are

good examples of applications that would strongly benefit by flexible

and low-weight energy storage and wireless energy transfer technologies.

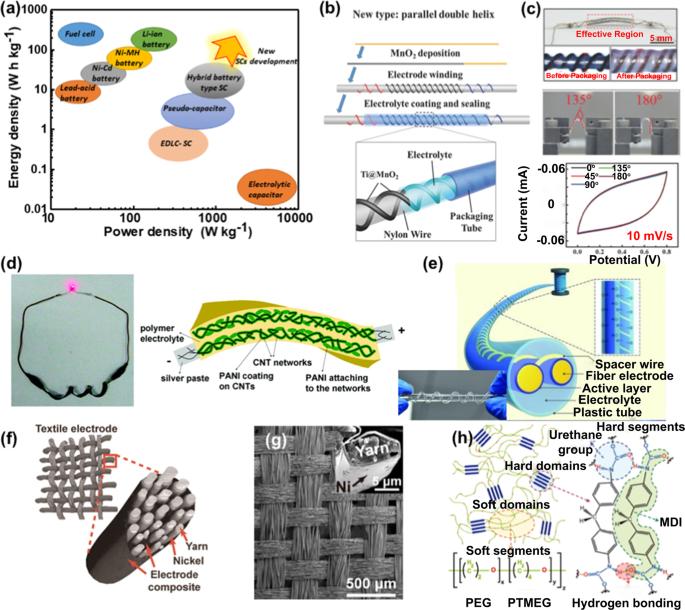

Supercapacitors

Supercapacitors (SCs) have emerged as a promising energy storage alternative to the conventional Li-batteries (LiB), mainly due to properties such as high energy density (17.6 Wh/kg), power density (98 kW/kg), specific capacitance (790 F/g), volumetric capacitance (205.4 F/cm3), lightweight (10 mg), flexibility (capacitance change <1% under bending angles of 180°) , cyclic stability (98.3% capacitance retention after 5000 charge/discharge cycles) and stretchability (~30%) , State-of-art SCs are generally made of conductive polymers , metal oxides nanostructures, carbon-based materials (carbon nanotubes (CNTs) and graphene), or hybrid combination of these materials . In addition to their excellent energy storage capacity, the SCs are also exceptional because of their quick energy delivery (charging/discharging rates ~50 V/s).This is an attractive feature as in addition to enabling continuous operation of e-skin, the SCs could also allow provide energy to operate actuators in artificial limbs in prosthesis and robotics. Further, the fabrication of SCs on non-conventional substrates such as clothes, glove, woven and fabric materials, make them a promising candidate for application such as wearable systems or e-skin for fashion industry. In this regard, the fabrication of flexible SCs has been demonstrated by integrating electrochemically active materials such as metal oxides and conducting polymers with flexible fibres made of graphene, carbon, metal and plastic.Wearable batteries