Electronics inside the space shuttle

360 Degree View Of Space Shuttle Discovery’s Flight Deck

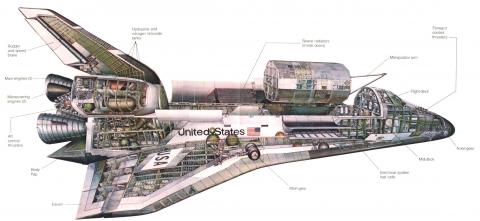

This cutaway image depicts the STS (Space Transportation System) Orbiter. NASA describes it: “The Orbiter is both the brains and heart of the Space Transportation System. About the same size and weight as a DC-9 aircraft, the Orbiter contains the pressurized crew compartment (which can normally carry up to seven crew members), the huge cargo bay, and the three main engines mounted on its aft end.” Image online, courtesy NASA.

NASA’s New Space Shuttle Is a Work of Futuristic Art

Sierra Nevada Corporation’s Dream Chaser Cargo Spacecraft on Runway

A recent, NASA-awarded cargo pact worth billions means smoother sailing for the development of Dream Chaser, a new space shuttle built by Sierra Nevada Corp (SNC), based in Louisville, CO.

The unique spacecraft has had a long and arduous journey from its Soviet-era beginnings to its thrust into today’s escalating private industry space race.

The Phase 2 Commercial Resupply Services (CRS2) is contracted for at least six Dream Chaser missions to the International Space Station. The announcement comes roughly two years after SNC lost a bid to taxi astronauts to the station against competitors, Boeing and SpaceX.

SNC’s resolve did not wane and the company survived by transforming their vehicle to successfully compete for cargo missions to the ISS. This innovative spirit puts the future of SNC on an exciting trajectory.

Mark Sirangelo, Vice President of SNC, says the company has addressed the concerns NASA had voiced when it decided against awarding the previous contract to SNC. He also remarked that the government “gets a terrific vehicle to add to its fleet.”

The capabilities of the newly designed Dream Chaser Cargo System meet the upper end of the technical requirements for a cargo mission. Including the ability to carry up to 5,550 kilograms, roughly the size of one well-fed African bush elephant. This allows more space inside pressurized chambers for critical science experiments and external space to carry large components to be installed on the body of the ISS.

Sierra Nevada Corporation’s un-crewed Dream Chaser with Cargo Module and visible cargo (Image: SNC)

The lifting body vehicle will be launched on a United Launch Alliance (ULA) Atlas V rocket and will have the ability to return—along with cargo—by landing at any available airport. SNC’s Dream Chaser is made of non-toxic materials meaning it can touch down on commercial runways and be accessed immediately.

The chance to showcase a reusable spacecraft on government funded missions bodes well for a potential pivot to commercial use. SNC is at the leading edge of private space companies that one day might cater to a more diverse base of consumers like universities, medical companies and individuals.

To learn more about Dream Chaser’s history and development, we spoke to John Roth, Vice President of Business Development for SNC’s Space Systems.

how the Dream Chaser was inspired by a space shuttle built by the Soviet Union?

The history stems from the BOR-4, a subscale test version of a manned spaceplane that the Soviets experimented with (some orbital launches and sub-orbital launches) back in the 1980s. The way that it has a heritage to the Dream Chaser—it’s not a direct heritage, but the BOR-4 had been captured by some intelligence originally from an Australian surveillance aircraft that caught a Russian frigate pulling a BOR-4 out of the water after one of its flights.

They didn’t know what the BOR-4 was. It looked like some sort of space vehicle. They sent the information to the United States to see if the US had any intel on this vehicle and that made its way to NASA.

NASA did not have any intel on the vehicle but they thought it was a very interesting design and that prompted some of the early design work they did in lifting bodies that eventually led to the development of NASA’s own spaceplane concept, the HL-20. So the NASA HL-20, if you look at it, looks very looks very similar to the BOR-4. There’s sort of a direct link in that they have some intelligence on the BOR-4 and that led to the development of the HL-20 at NASA.

We took over the technical details, information and drawings etc. of the HL-20 from NASA and migrated that into the Dream Chaser.

LEFT: BOR-4 – Photo by Australian P-3 Naval Reconnaissance Aircraft. RIGHT: An HL-20 mockup (Images: NASA)

What was SNC’s reaction to the claim made by NASA that Dream Chaser wouldn’t be ready for commercial crew missions and what were the main points made when SNC appealed their contract refusal?

It was kind of an interesting back and forth. The purpose for filing against the decision was not a simple few page thing. We took exception to a dozen or so elements of the decision process. One of those elements happened to be the schedule and NASA’s concern that because our vehicle was less mature than capsule designs in general, that we wouldn’t be ready.

That’s one of the things that we didn’t quite understand. Some of the language just implied that capsules are easier so they should be built faster. We don’t really buy that logic. We flew the shuttle for 30 years and it’s not like lifting bodies had no heritage. So the fact that they were trying to say “capsules are going to take less time to develop than your lifting bodies,” doesn’t really have any definitive facts to back that up. That’s just one of the things that we took exception to.

The schedule that we developed, which had us launching in 2017, met their requirements. NASA chose to just be skeptical that we were actually going to be able to hold to the schedule.

And the reaction to finally winning the Commercial Resupply Contract?

As you can image we were thrilled. There are people that have been literally working on this vehicle for more than ten years from when they were at Spacedev. People at Spacedev were initially the ones that took the HL-20 and thought it could be a very cool lifting body for the future. And so just the long haul to getting from where we started to finally knowing that were were going to get at least six missions to the space station was just an incredibly thrilling moment.

Shouts, hugs, tears and every emotion you can imagine. It was just relief that we were going to be able to bring this vehicle to life.

We are still absolutely committed to eventually getting a crew version of Dream chaser. The team wants to do that very badly. We don’t have a current path forward but we are not giving up hopes that we can find a path to making a crewed variant in addition to a cargo variant. So really the mental shift that you are talking about came after we lost the crew competition and of course it was a very disheartening time when we were thinking about the options for moving forward.

Originally we weren’t going to build for cargo contract, the CRS2, because we were still in the midst of trying to find out if we were going to win the current program and we didn’t think we wanted to divert staff from crew program over to do this cargo thing. Obviously once we lost the crew, we took another look at the cargo and we had to go through major rethinking about how we could optimize the Dream Chaser vehicle for cargo.

It wasn’t as easy as simply looking at the crew vehicle and saying, “OK we’re going to pull seats, pull out people and stick in cargo.” It would not have been a good vehicle for the cargo program. It would not have been competitive. We had to go through an incredible redesign process to come up with the idea of the cargo module and to come up with a way to make room for additional cargo.

Taking out the abort engines for example which we don’t need for cargo. We needed to fit inside a fairing so we had to come up with a redesign for the wings to be able to fold. There was about a dozen major things that we had to address to see if we could really make this crew vehicle to what we thought would be an exceptional cargo vehicle.

Amazingly, we did that and were able to turn our vehicle into what we think is the most optimum cargo vehicle for NASA because we’re the only ones that can do all three of the missions they want to do in every single flight. Which means pressurized and unpressurized cargo up, disposal and return. We can do all three of those in every flight and we’re the only vehicle that can.

What are the plans for launch and landing sites? Will the Kennedy Space Centerplay a major role?

The contract right now for the cargo missions is based on launches out of Kennedy and landing at the shuttle landing site facility at Kennedy. Obviously we’d have an option—if they wanted—to discuss with us launching and landing from somewhere else but that’s our baseline concept in the CRS2 proposal. We have been working with a lot of different airports and spaceports both in the US and internationally who are interested in being able to land Dream Chaser at their facilities. We have had a number of discussions with those airports and spaceports. We have a few that are public like Houston and Alabama and a few others that we have been working with that have elected not to go public yet.

We are moving forward towards plans to look at eventual FAA licensing for landing Dream Chaser at other places than Kennedy. That right now is not part of our cargo contract.

Launch Initiated for SNC’s Dream Chaser Cargo System Aboard an Atlas V Rocket at Kennedy Space Center. (Image: SNC)

Will the Dream Chaser eventually be utilized for other types of missions?

We are looking at other variants or modifications to the current structure. For example, we’ve done a lot of work on a free-flying science mission. We’ve installed more standard racks very similar to the racks that are inside the space station. So they can put the same kind of science experiments they run on the ISS, on a free-flying science mission for Dream Chaser.

We’ve done some conceptual designs of how it would look if we did that. We’ve done designs for longer duration vehicles meaning you want to be in orbit for some months or a year instead of the days or few weeks that we would do on cargo missions. Those are variants of the same vehicle and we have looked at a number of different ones like that. We’ve been in discussions with different customers about those kinds of variants.

There is going to be a commercial market. NASA is certainly a customer now. We think Europe is certainly going to close on missions. We still believe that there is potential for missions with commercial customers like pharmaceutical companies and bio-farm companies that are interested in starting to look at doing zero-g manufacturing and zero-g experiments like they do on the space station.

SNC’s Dream Chaser Science Mission Mock-Up (Image: SNC)

Will SNC compete for the next round of commercial crew contracts that NASA is expected to award in 2020?

That is certainly on our radar scope, yes. That is something we are very interested in doing. We do need to try and find the best route in working on the crew version. First, it’s going to take some investment funding and that could be either internal, external, or a combination. The second thing is that we absolutely want to make sure we are successful on the cargo missions. So we’ve got to make sure the resources are directed towards making that cargo design and getting that vehicle built.

Whether we can actually go after that contract or not when it gets to that point, is going to be matter of whether we can get the right resources to get there.

When will the public see Dream Chaser fly for the first time?

Well that’s really up to NASA. NASA has not yet signed any of the task orders for specific missions. We have our first meetings in the next few weeks but they announced as part of the contract that the first cargo missions will begin in 2019. It doesn’t mean all three providers will be contracted to do cargo mission in 2019 so we still have to wait on NASA to see what our schedule will be for the first flight.

SNC’s Dream Chaser Spacecraft and Cargo Module Attached to the ISS (Image: SNC)

/https://public-media.smithsonianmag.com/filer/15/b8/15b849d3-80cf-48b4-a77c-55c821c1d23f/02j_sep2015_bigelow-and-garver-web-resize.jpg)

Robert T. Bigelow has developed the inflatable Bigelow Expanded Activity Module, an aluminum habitation, to test in space

NASA will build an addition to the International Space Station, increasing the orbital laboratory’s size from eight rooms to nine. The new room is like no other on the station, and will be very easy to construct: Just connect to a docking port, fill with compressed air, and voilà! Instant space habitat.

The hard part was the 15 years of research and development that Bigelow Aerospace in North Las Vegas needed to create the Bigelow Expandable Activity Module, or BEAM. Initially scheduled for a September launch, BEAM’s test deployment is now delayed due to the post-launch explosion of a SpaceX Falcon 9 rocket bound for the ISS on June 28 — and no one yet knows how long that delay will be. Once BEAM does reach its destination, it will undergo two years of intensive testing, a trial run for a technology that could play a significant role in future human spaceflight and low-Earth-orbit commercial ventures: inflatable spacecraft.

Bigelow’s inflatable is, in a sense, the resurrection of a canceled NASA program. In the 1990s, NASA developed TransHab, or Transit Habitat, an inflatable living area to test in space with the goal of using such a container to transport humans to Mars and to replace the International Space Station’s aluminum habitation module. TransHab got only as far as ground testing before Congress cut the program’s funding in 2000. Real estate billionaire and space enthusiast Robert T. Bigelow purchased the rights to the patents that NASA filed for the technology.

Bigelow Aerospace picked up where TransHab left off, advancing research and development and eventually putting two inflatable test modules—Genesis I and II—into orbit in 2006 and 2007. Both modules, each the size of a van, remain in orbit today. Their batteries ran out years ago; eventually they’ll reenter the atmosphere and burn up. But they served their purpose. “Genesis I and II validated our basic architecture,”. “From a technical perspective, these spacecraft showed that expandable systems could survive the rigors of launch, that our deployment process would work, and that we could successfully integrate windows into an expandable habitat structure.”

Inflatable habitats in space have advantages over conventional metal structures. First, they’re a lot cheaper to get into orbit. One reason is weight: BEAM, designed to expand to 16 cubic meters, or about the size of a 10- by 12-foot room, weighs only 3,000 pounds at launch. Its density—that is, its mass divided by its volume—is 88 kilograms per cubic meter. By comparison, the density of the U.S. lab at the International Space Station, Destiny, is 137 kilograms per cubic meter. The ISS’s Tranquility module has a density of 194 kilograms per cubic meter.

Inflatables are also appealingly compact. Folded into its launch configuration, BEAM takes up a space five feet by seven feet. Gold cites BEAM’s modest cost— 17.8 million—as one of its key advantages over older technologies: “I can’t think of any other substantial hardware that has been done, or almost any other project that’s been done, for such a relatively minor amount of money,” .

Reducing the size and weight of the payload at launch is what saves taxpayers money. “You gain tremendously in terms of launch efficiency, and that’s the hardest, most expensive thing about space—getting out of Earth’s gravity well, a former shuttle astronaut who worked for the FAA’s Office of Commercial Space Transportation before joining Bigelow Aerospace last year.

Rajib Dasgupta, BEAM project manager for NASA, says inflatables are one concept that the space agency is studying for habitation inside cislunar space—the sphere formed by the moon’s orbit of Earth. “Successful BEAM demonstration on ISS will certainly be a giant stepping stone to future deep-space exploration habitats,” he says.

Inflation Evaluation

BEAM was scheduled to be launched by SpaceX CRS-8, a cargo resupply mission to the ISS intially scheduled for September 2, though it will now be delayed as a result of the SpaceX explosion. (Bigelow’s Gold will only say he remains hopeful that BEAM will reach the station “this calendar year.”) Once BEAM arrives, it will face two years of engineering tests. But its first hurdle maybe be simply overcoming negative associations with the word “inflatable.”

“People sometimes have a bad perception of inflatable structures because of their experience with low-cost, poorly made products such as pool toys that leak, or party balloons that burst, this now developing spacesuits, airbags for the Mars rovers, and airbags for Boeing’s proposed Crew Space Transportation-100 vehicle. But every day we entrust our lives to inflatable structures: car tires and air bags, emergency escape slides in airplanes, angioplasty surgeries.

Of course, inflatable habitats have never housed human beings in space before. NASA and its contractors have half a century’s worth of experience with aluminum pressure vessels; they know how to assemble them in space, how to inspect and maintain them, how to analyze their structural loads, and how to control fractures in them. They also know aluminum’s tolerance of—and vulnerability to—impacts from micrometeoroids and orbital debris. Engineers have developed ways to monitor impacts, find leaks, analyze damage, and even make limited repairs.

Steve Stich, director of exploration, integration and science at NASA’s Johnson Space Center, says inflatable habitats may someday be integrated with metal pressure vessels, but the agency needs to learn a lot more about how inflatables hold up against the hazards of space: radiation exposure, thermal cycling, debris impact. For example, BEAM has a metal structure at the end that berths to the ISS—it’s known as a common berthing mechanism. Loading forces from the station will place stresses on BEAM, particularly where the berthing mechanism attaches to the station, and also where the berthing mechanism attaches to BEAM’s fabric shell.

No one yet knows whether inflatable habitats can safely dock to other spacecraft, and whether an airlock can be integrated into an inflatable habitat. it is believes that for high-stress applications like docking, aluminum will likely remain: “I don’t see us totally ever phasing out metallic structures,” he says.

One challenge, Stich adds, is how to develop inflatables that can be outfitted with life support, crew quarters, and other systems prior to launch; if not, astronauts will have to set those up once the habitat is deployed in space. Conventional modules at the space station typically arrive with equipment already integrated into the structure.

A retired NASA senior project engineer who now consults, through various contractors, for the NASA Engineering and Safety Center, says inflatable habitats face an uphill battle to win the kind of confidence NASA has in the metal ships it has been building for half a century.

“It takes heritage to have confidence in a technology. “Even if the inflatable Bigelow space station turns out really great, it doesn’t mean that there aren’t faults with that thing…. There haven’t been enough of them made. There hasn’t been enough materials experience and testing. It becomes a more risky space venture than what we would normally do. But because of its potential, NASA has been working with Bigelow for many years to help the technology mature.”

An Idea Nearly as Old as NASA

NASA first began studying the possibilities of inflatable structures around 1960, when researchers at NASA’s Langley Research Center in Virginia drew up plans for a doughnut-shaped space station. In another inflatables project, known as Echo, NASA launched giant Mylar-coated balloons into orbit in 1960 and 1964 and bounced radio signals off them. In 1965, the agency developed concepts for inflatable moon habitats, and in 1967 it studied the idea of an air-filled space station nicknamed Moby Dick, apparently due to its large dimensions.

TransHab emerged 30 years later as a project at NASA’s Johnson Space Center. The effort was led by William Schneider, who had worked on micrometeoroid protection for the space shuttle. Schneider had already retired when TransHab was canceled in 2000, but he has consulted with Bigelow Aerospace.

TransHab faced skepticism from the start. NASA’s Kriss Kennedy, a space architect who helped create the inflatable and coined the name, recalled in Air & Space (“Launch. Inflate. Insert Crew,” May, 1999) that during public talks he would pop a balloon to drive the point home that this is a balloon; inflatable structures are not. During the short-lived TransHab program, NASA engineers developed inflatable habitats with a foot-thick, 16-layer shell of foam and fabric that stood up to ballistics tests designed to simulate strikes by micrometeoroids and orbital debris.

The actual architecture of TransHab included three thin-film air bladders covered by alternating layers of ceramic fabric, polyurethane foam, and Kevlar. The ceramic fabric, called Nextel, was sandwiched by three-inch layers of foam.Together, the layers served to protect against micrometeoroids. The Kevlar webbing made up TransHab’s pressure-holding restraint layer, which was woven like a rug to reduce the number of seams and maximize strength. Inside TransHab, two-inch-thick walls surrounding bedrooms would be filled with water to shield crew members from radiation.

BEAM represents a generation of refinement to that earlier design. From inside to outside , it includes a bladder, restraint system, micrometeoroid/orbital debris protection, insulation, and an external thermal blanket. (BEAM’s precise makeup is proprietary.) Gold says BEAM’s “Kevlar-like” protective layers will measure up. “We have done side-by-side hyper-velocity impact testing with portions of the ISS’s [micrometeoroid/orbital debris protection] layers,” he says. “Our system offers equal if not superior protections to what’s on the ISS today.”

He pauses before choosing a dramatic example. “If you’re about to get shot, would you rather have aluminum in front of you or a Kevlar vest?”

Trial in Space

Once SpaceX’s uncrewed Dragon cargo spacecraft reaches the ISS, the station’s robotic arm will be used to attach BEAM to the aft section of the Node 3 module. With the hatch to the station closed, air tanks inside BEAM will pressurize the module. Inside, a telescoping structure will expand as BEAM inflates. Made of an aluminum alloy, the structure is designed to provide rigidity in case a micrometeoroid or piece of orbital debris penetrates the habitat .

The primary performance requirement for BEAM is to demonstrate that it can be launched, deploy on the ISS, inflate, and maintain long-term pressure without leakage. Another key objective is to determine how well an inflatable structure in low Earth orbit can protect astronauts from radiation. BEAM will be outfitted with radiation sensors, and data from them will be compared to corresponding data collected on the ISS aluminum modules. Solar flares pose an additional radiation risk.

Gold says BEAM should offer better radiation protection than metal: When metallic structures absorb radiation, the shielding material can itself emit “secondary radiation.” When high-energy particles smash into atoms in a spacecraft’s metallic shielding, the collisions produce a shower of nuclear byproducts—neutrons and other particles—that then enter the spacecraft. Secondary radiation can be more dangerous than the original radiation from space. “The non-metallic structure of the BEAM substantially reduces the secondary radiation effect that otherwise occurs within metallic structures,” Gold adds.

Once you’re beyond low Earth orbit and exposure to cosmic radiation increases, neither metallic nor fabric construction can fully protect astronauts—a longer-term concern as future astronauts travel to the moon, Mars, and beyond. “The only thing you could do there is provide a very massive dense material to absorb it .

Apart from the need to protect astronauts, the greatest engineering challenge for BEAM is likely maintaining structural integrity over time—specifically, avoiding a phenomenon known as “creep rupture. Creep rupture occurs when the constant loading of materials at high percentages of their ultimate strength leads to an elongation of the material, and eventual failure.

However, if you can design and test a structure so loading is kept below 25 percent of the materials’ ultimate strength (for most structural materials), creep rupture shouldn’t be a problem. Although some materials are more susceptible to this type of stress than others, all materials have some degree of susceptibility. Good engineering can mitigate the problem. One familiar example? Window glass. Two hundred years ago, glass would sag over time—an effect of gravity. Modern materials design has solved this vulnerability.

that BEAM’s manufacturing challenges are even more daunting than its engineering challenges. For example, ILC Dover welds polymer-coated fabrics to create bladders that retain inflation gas. These seals are made by applying heat and pressure to the materials in a highly controlled process. “Then there are the sewing operations that are used to create the restraint—the part that goes over the bladder and supports all the pressurization and structural loads. “Sewing also has parameters that require control, including thread tension, needle sharpness, stitches per inch, etc….You just have to set up the machines correctly, have proficient operators, and inspect and test everything well before flight.”

At the end of BEAM’s two-year mission, its last test will be when the station’s robotic arm successfully jettisons it from the ISS. The robotic jettison of a large, 3,000-pound structure from the station has never been attempted. Once detached, BEAM is expected to enter the atmosphere and burn up within a year.

Room to Move

Inflatables offer another clear benefit: more habitable space. BEAM is relatively small, but an operational module that Bigelow is developing, called B330, will offer 330 cubic meters of habitable volume. The International Space Station contains 916 cubic meters of pressurized volume—only about three times that of a single B330 module.

As a rule, astronauts enjoy about double the volume of a similar space on Earth, because in micro-gravity they have access to the entire area, from ceiling to floor, and in any orientation. The space station is a massive structure—with its extended solar arrays, about the size of a football field. But thinking about the ISS in that way can be deceiving. “Inside, you don’t get all that. “It’s small and constrained by whatever node you happen to be in, whether it’s Tranquility or Serenity or Unity…. You’re in this kind of tube-like existence.”

Inflatable modules would offer astronauts more space. “I think they’ll notice that difference, particularly if they look at this expanded volume for traveling on long missions in deep space, .

The current plan calls for crew members to enter BEAM once every three months, although that may change, says Dasgupta. Their job will be to collect sensor data, perform surface sampling, change out radiation area monitors, and inspect the general condition of the module. BEAM’s ventilation is passive; it takes air pushed from the station through a duct. Air circulation inside BEAM will help prevent condensation. The module has no windows, though future designs could conceivably accommodate them.

“No hard time limit has been established for crew ingress, but since the ISS crew is busy all year round conducting ISS research, we would like to limit crew ingress to a few hours,” Dasgupta says.

NASA doesn’t plan to stow any equipment or hardware inside BEAM, and the module will have no internal power. Inside, crew members will carry battery-operated lights.

BEAM could become popular with astronauts, not only because of the extra space but also because it should be relatively quiet compared with other modules. Gold says, “We believe the BEAM could be an oasis.”

Assuming BEAM performs well, Bigelow Aerospace envisions B330 modules used as stand-alone space stations for the private sector. Pharmaceutical and materials science firms, for example, could use B330 modules as laboratories for product development, says Gold. (He declines to say how the B330 modules will be priced.) The B330s accommodate six, and Bigelow hopes they will become integral to deep-space missions—crashpads to keep astronauts from being confined to a capsule, like NASA’s planned Orion spacecraft.

“Obviously there is not sufficient volume [with Orion alone] for long-duration missions,” says Gold. However, if “you attach a habitat to a propulsion system and/or capsule, you’ve got a pretty robust system for beyond-LEO exploration to the moon, Mars and beyond.”

In this respect, NASA’s shelved TransHab program is truly on the verge of being reborn. Zamka says the B330 perfectly complements NASA’s Orion spacecraft. “[Orion] is a transfer vehicle. It’s supposed to transfer astronauts from Earth to another place.

XXX . XXX . XXX Spacecraft and Instruments

MESSENGER's dual-mode, liquid chemical propulsion system is integrated into the spacecraft's structure to make economical use of mass. The structure is primarily composed of a graphite epoxy material. This composite structure provides the strength necessary to survive launch while offering lower mass. Two large solar panels, supplemented with a nickel-hydrogen battery, provide MESSENGER's power.

The "brains" of the spacecraft are redundant integrated electronics modules (IEMs) that house two processors each -- a 25-megahertz (MHz) main processor and a 10-MHz fault-protection processor.

Attitude determination -- knowing where the spacecraft is and in which direction it's facing -- is performed using star-tracking cameras and an Inertial Measurement Unit containing four gyroscopes and four accelerometers, with six Digital Solar Sensors as a backup. Attitude control is mostly accomplished using four reaction wheels inside the spacecraft and, when necessary, MESSENGER's small thrusters. MESSENGER will receive commands and send data primarily through its circularly polarized X-band phased-array antennas.

A key MESSENGER design element deals with the intense heat at Mercury. The Sun is up to 11 times brighter than we see on Earth and surface temperatures can reach 450 degrees Celsius (about 840 degrees Fahrenheit), but MESSENGER will operate at room temperature behind a sunshade made of heat-resistant ceramic cloth.

MESSENGER's science payload -- its instruments -- was carefully chosen to answer the mission's six key science questions. Most of the instruments are fixed rigidly to the spacecraft's body, so coverage of Mercury is obtained by spacecraft motion over the planet.

Credits: Johns Hopkins University/Applied Physics Laboratory

The Payload

Mercury Dual Imaging System (MDIS): This instrument consists of wide-angle and narrow-angle imagers that will map landforms, track variations in surface spectra and gather topographic information. A pivot platform will help point it in whatever direction the scientists choose. The two instruments will enable MESSENGER to "see" much like our two eyes do.

Gamma-Ray and Neutron Spectrometer (GRNS): This instrument will detect gamma rays and neutrons that are emitted by radioactive elements on Mercury's surface or by surface elements that have been stimulated by cosmic rays. It will be used to map the relative abundances of different elements and will help to determine if there is ice at Mercury's poles, which are never exposed to direct sunlight.

Gamma rays and high-energy X-rays from the Sun, striking Mercury's surface, can cause the surface elements to emit low-energy X-rays. XRS will detect these emitted X-rays to measure the abundances of various elements in the materials of Mercury's crust.

Magnetometer (MAG): This instrument is at the end of a 3.6 meter (nearly 12-foot) boom, and will map Mercury's magnetic field and will search for regions of magnetized rocks in the crust.

Magnetometer (MAG): This instrument is at the end of a 3.6 meter (nearly 12-foot) boom, and will map Mercury's magnetic field and will search for regions of magnetized rocks in the crust.

Mercury Laser Altimeter (MLA): This instrument contains a laser that will send light to the planet's surface and a sensor that will gather the light after it has been reflected from the surface. Together they will measure the amount of time for light to make a round-trip to the surface and back. Recording variations in this distance will produce highly accurate descriptions of Mercury's topography.

Mercury Atmospheric and Surface Composition Spectrometer (MASCS): This spectrometer is sensitive to light from the infrared to the ultraviolet and will measure the abundances of atmospheric gases, as well as detect minerals on the surface.

Energetic Particle and Plasma Spectrometer (EPPS): EPPS measures the composition, distribution, and energy of charged particles (electrons and various ions) in Mercury's magnetosphere.

Radio Science (RS): RS will use the Doppler effect to measure very slight changes in the spacecraft's velocity as it orbits Mercury. This will allow scientists to study Mercury's mass distribution, including variations in the thickness of its crust.

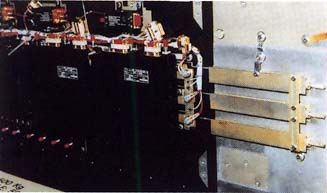

Thermal control of space electronics

Introduction

Telecommunication satellites are all based on the same overall design usinga 3 axis stabilization process, in which the North and South panels act asradiators and so ensure heat removal.

This basic principle is illustrated in Figure 1. The ever-increasing demandfor national and international space-based communications in parallel with theevolution of space electronics (miniaturization, complexity, integration)dictate that the thermal control subsystem (TCS) can accommodate significantincreases in spacecraft dimensions and waste heat generation. At the same time,for obvious economic reasons, the operational life time in orbit has to reach 15years for most satellite programs.

Figure 1: Thermal design of geostationarysatellites

Figure 1: Thermal design of geostationarysatellitesRequirements and Design Goals

Methodology

Space programs, generally limited to very few models characterized by highcost (typically $50,000-100,000/Kg), must follow a specific methodology. Themain design features of this methodology are:

- The TCS design has traditionally been a conservative process. Use ofpreviously flown materials, technology and concepts is encouraged.

- The design is mainly based on an important use of analytical models (seeFigure 2). The simulation is achieved by using CAD software (CATIA) as a meshgenerator and ESATAN (European Agency Thermal Analysis) as a thermal solver.Mock up and thermal tests are considered for final verification.

- Assumptions obtained by thermal modeling are a possible source of errors,thus uncertainty margins (typically ±5°C) are taken into account bythermal designers in order to make “guaranteed predictions”.

Figure 2 – Thermal map of a geostationarysatellite

Figure 2 – Thermal map of a geostationarysatelliteElectronic Equipment Temperature Limits and Design

A spacecraft contains many components which will function properly only ifthey are maintained within specified temperature ranges. Figure 3 illustrates aclassical set of temperature limits for on board equipment.

| EQUIPMENT | ON-ORBIT TEMPERATURE RANGE (°C) | QUALIFICATION RANGE (°C) | ||||

| Minimum during non operating phase | Operating | Operating | ||||

| Electronic Units | MIN | MAX | MIN | MAX | ||

| “ | TWT (traveling wave tubes) | -30 | 0 | +75 | -10 | +85 |

| “ | Electronic power conditioner | -30 | 0 | +50 | -10 | +60 |

| “ | Input filters | -30 | +5 | +50 | -5 | +60 |

| “ | Microwave equipment (transponders, receivers, ….) | -30 | -10 | +50 | -20 | +60 |

| “ | Output multiplexers | -30 | +20 | 70 | +10 | +80 |

| “ | Data processing units | -30 | -10 | +50 | -20 | +60 |

| “ | IR and sun sensors | -45 | -30 | +50 | -40 | +60 |

| “ | Battery Ni-H2 | -20 | -5 | +25 | -15 | +35 |

| Non-electronic units | Tanks | 0 | 0 | 40 | -10 | 50 |

| Solar generator | -180 | -165 | +70 | -175 | +80 | |

| Propellant lines | 0 | 05 | 0 | -10 | +60 | |

| Momentum wheels | -40 | -15 | 45 | -25 | +55 | |

Figure 3 – Temperature limits for on-boardequipment

In order to meet the challenge of the increasing complexity of communicationsatellite payloads, the packaging of space electronic equipment must minimizethe imposition of severe constraints on electronic designers.

From a reliability point of view, the fundamental goal of TCS is to ensure amaximum junction temperature of 110°C; therefore, Printed Circuit Boardswith high thermal conductivity are used in conjunction with local heatspreaders. In some critical areas, heat pipes are used to provide efficient andlow mass technical solutions.

An overall view of the implementation of electronic equipment inside atelecommunication satellite is illustrated in Figure 4.

Figure 4 – CAD illustration of Telecom 2satellite

Figure 4 – CAD illustration of Telecom 2satelliteSpacecraft Thermal Control Subsystem Description

Radiators

The radiators use primary heat rejection surfaces:

- they support high dissipating electronic units (traveling wave tubes andconverters). The structural composition of these panels is generally aluminumface sheet and honeycomb core.

- they are designed for a maximum thermal efficiency achieved by usingembedded heat pipes in association with a specific coating providing a highinfrared emittance with a low solar absorptance (so called Optical SolarReflectors). For end of life conditions, heat rejection capability may reach upto 350 W/m2 for a typical 40°C radiator temperature.

A concept of a flexible radiator, acting as a ‘thermal diode’, which allowsheat to pass from an internal to external side has been designed andsuccessfully qualified by Alcatel Espace to reduce TCS weight for low earthorbit missions.

Heat Pipes

The vast majority of heat-pipe applications use an axially groovedaluminum/ammonia Constant Conductance Heat Pipe (CCHP) (See Figure 5).Successful ground testing and flight experiences indicate CCHP to be a reliablethermal control element.

Figure 5 – Constant conductance heat-pipes(CCHP) fixed on a panel support structure

Figure 5 – Constant conductance heat-pipes(CCHP) fixed on a panel support structure

Non condensable gas generation caused by impurities is controllable by themanufacturers process.

Liquid slug formation in zero gravity still remains a problem and is takeninto account during CCHP layout on the spacecraft panels.

Insulation Design

With the exception of the radiator areas used for heat rejection, asatellite is covered by a blanket of Multi Layer Insulation (MLI) intended forprotection from solar flux and to protect surfaces submitted to large diurnalenvironmental fluctuations -180°C up to +150°C.

MLI design consists basically of a number of layers of vapor-depositedaluminum, silver or gold on Kapton or Mylar. Conductive insulation betweenlayers is insured by interleaved fabric netting.

Another important requirement for MLI design is to provide an efficientprotection against Electro Static Discharge (ESD), which may appear betweenseparated parts when formed from different materials or submitted to sunlight orshadow.

Heaters

Thermal control of electronic equipment within a narrow range of temperature(ambient ±20°C), with external surface temperature differences rangingfrom -180°C up to + 150°C, is generally achieved with the help ofactive heaters controlled by mechanical thermostats or on-board computers.Heating elements are generally thermofoil conductive electrical elementsembedded in a thin Kapton substrate.

Solar Simulation

A thermal vacuum test environment with solar simulation is essential forverification of the thermal mathematical models and TCS performances in asimulated orbital environment.

Solar heat fluxes are simulated by a set of Xenon lamps which illuminate theSpacecraft by focusing into a single collimated beam.

These huge test facilities are only available in a few locations in theworld: Interspace in Toulouse has a facility (see Figure 6), which includesother environmental tests (mechanical, EMC), thus permitting a certification of”flight aptitude” for spacecraft before launch.

Figure 6 – Thermal test chamber: 600 m3Vacuum: 10 -6mmHg Temperature: -170°C up to 120°C

Figure 6 – Thermal test chamber: 600 m3Vacuum: 10 -6mmHg Temperature: -170°C up to 120°CConclusion

The continued strong growth in communication satellite requirements hasresulted in a need for more complex satellites which must be delivered in theshortest time possible.

TCS designers will be required to enhance flight-proven technologies, whiledeveloping new techniques such as fluid loops and micro heat-pipes.

Spacecraft thermal control

In spacecraft design, the function of the thermal control system (TCS) is to keep all the spacecraft's component systems within acceptable temperature ranges during all mission phases. It must cope with the external environment, which can vary in a wide range as the spacecraft is exposed to deep space or to solar or planetary flux, and with ejecting to space the internal heat generated by the operation of the spacecraft itself.

Thermal control is essential to guarantee the optimum performance and success of the mission because if a component is subjected to temperatures which are too high or too low, it could be damaged or its performance could be severely affected. Thermal control is also necessary to keep specific components (such as optical sensors, atomic clocks, etc.) within a specified temperature stability requirement, to ensure that they perform as efficiently as possible.

The thermal control subsystem can be composed both of passive and of active items and works in two ways:

- protects the equipment from overheating, either by thermal insulation from external heat fluxes (such as the Sun or the planetary infrared and albedo flux), or by proper heat removal from internal sources (such as the heat emitted by the internal electronic equipment).

- protects the equipment from temperatures that are too cold, by thermal insulation from external sinks, by enhanced heat absorption from external sources, or by heat release from internal sources.

Passive Thermal Control System (PTCS) components include:

- Multi-layer insulation (MLI), which protects the spacecraft from excessive solar or planetary heating as well as from excessive cooling when exposed to deep space

- coatings that change the thermo-optical properties of external surfaces

- thermal fillers to improve the thermal coupling at selected interfaces (for instance on the thermal path between an electronic unit and its radiator)

- thermal washers to reduce the thermal coupling at selected interfaces

- thermal doublers to spread on the radiator surface the heat dissipated by equipment

- mirrors (secondary surface mirrors, SSM, or optical solar reflectors, OSR) to improve the heat rejection capability of the external radiators and at the same time to reduce the absorption of external solar fluxes

- radioisotope heater units (RHU), used by some planetary and exploratory missions to produce and store electrical power for TCS purposes

Active Thermal Control System (ATCS) components include:

- thermostatically controlled resistive electric heaters to keep the equipment temperature above its lower limit during the mission's cold phases

- fluid loops to transfer the heat emitted by equipment to the radiators. They can be:

- single-phase loops, controlled by a pump

- two-phase loops, composed of heat pipes (HP), loop heat pipes (LHP) or capillary pumped loops (CPL)

- louvers (which change the heat rejection capability to space as a function of temperature)

- thermoelectric coolers

Sunshade of MESSENGER, orbiter of planet Mercury

Thermal Control Systems

- Environment interaction

- Includes the interaction of the external surfaces of the spacecraft to the environment. Either the surfaces need to be protected from the environment or there has to be improved interaction. Two main goals of environment interaction are the reduction or increase of absorbed environmental fluxes and reduction or increase of heat losses to the environment.

- Heat collection

- Includes the removal of dissipated heat from the equipment in which it is created to avoid unwanted increases in the spacecraft’s temperature.

- Heat transport

- Is taking the heat from where it is created to a radiating device.

- Heat rejection

- The heat collected and transported has to be rejected at an appropriate temperature to a heat sink, which is usually the surrounding space environment. The rejection temperature depends on the amount of heat involved, the temperature to be controlled and the temperature of the environment into which the device radiates the heat.

- Heat provision and storage.

- Is to maintain a desired temperature level where heat has to be provided and suitable heat storage capability has to be foreseen.

Environment

For a spacecraft the main environmental interactions are the energy coming from the sun and the heat radiated to deep space. Other parameters also influence the thermal control system design such as the spacecraft’s altitude, orbit, attitude stabilization, and spacecraft shape. Different types of orbit, such as low earth orbit and geostationary orbit, also affect the design of the thermal control system.

- Low Earth Orbit (LEO)

- This orbit is frequently used by spacecraft that monitor or measure the characteristics of the Earth and its surrounding environment and by unmanned and manned space laboratories, such as EURECA and the International Space Station. The orbit's proximity to the Earth has a great influence on the thermal control system needs, with the Earth's infrared emission and albedo playing a very important role, as well as the relatively short orbital period, less than 2 hours, and long eclipse duration. Small instruments or spacecraft appendages such as solar panels that have low thermal inertia can be seriously affected by this continuously changing environment and may require very specific thermal design solutions.

- Geostationary orbit (GEO)

- In this 24-hour orbit, the Earth's influence is almost negligible except for the shadowing during eclipses, which can vary in duration from zero at solstice to a maximum of 1.2 hours at equinox. Long eclipses influence the design of both the spacecraft's insulation and heating systems. The seasonal variations in the direction and intensity of the solar input have a great impact on the design, complicating the heat transport by the need to convey most of the dissipated heat to the radiator in shadow, and the heat-rejection systems via the increased radiator area needed. Almost all telecommunications and many meteorological satellites are in this type of orbit.

- Highly Eccentric Orbits (HEO)

- These orbits can have a wide range of apogee and perigee altitudes, depending on the particular mission. Generally, they are used for astronomy observatories and the TCS design requirements depend on the spacecraft's orbital period, the number and duration of the eclipses, the relative attitude of Earth, Sun and spacecraft, the type of instruments onboard and their individual temperature requirements.

- Deep space and planetary exploration

- An interplanetary trajectory exposes spacecrafts to a wide range of thermal environment more severe than those encountered around earth’s orbits. Interplanetary mission includes many different sub-scenarios depending on the particular celestial body. In general, the common features are a long mission duration and the need to cope with extreme thermal conditions, such as cruises either close to or far away from the Sun (from 1 to 4–5 AU), low orbiting of very cold or very hot celestial bodies, descents through hostile atmospheres, and survival in the extreme (dusty, icy) environments on the surfaces of the bodies visited. The challenge for the TCS is to provide enough heat-rejection capability during the hot operating phases and yet still survive the cold inactive ones. The major problem is often the provision of the power required for that survival phase.

Temperature Requirements

The temperature requirements of the instruments and equipment on board are the main factors in the design of the thermal control system. The goal of the TCS is to keep all the instruments working within their allowable temperature range. All of the electronic instruments on board the spacecraft, such as cameras, data collection devices, batteries, etc., have a fixed operating temperature range. Keeping these instruments in their optimal operational temperature range is crucial for every mission. Some examples of temperature ranges include

- Batteries, which have a very narrow operating range, typically between −5 and 20˚C

- Propulsion components, which have a typical range of 5 to 40˚C for safety reasons, however, a wider range is acceptable

- Cameras, which have a range of −30 to 40˚C

- Solar arrays, which have a wide operating range of −150 to 100˚C

- Infrared spectrometers, which have a range of −40 to 60˚C

Current Technologies

Coating

Coatings are the simplest and least expensive of the TCS techniques. A coating may be paint or a more sophisticated chemical applied to the surfaces of the spacecraft to lower or increase heat transfer. The characteristics of the type of coating depends on their absorptivity, emissivity, transparency, and reflectivity. The main disadvantage of coating is that it degrades quickly due to the operating environment.

Multilayer Insulation (MLI)

Multilayer insulation (MLI) is the most common passive thermal control element used on spacecrafts. MLI prevent both heat losses to the environment and excessive heating from the environment. Spacecraft components such as propellant tanks, propellant lines, batteries, and solid rocket motors are also covered in MLI blankets to maintain ideal operating temperature. MLI consist of an outer cover layer, interior layer, and an inner cover layer. The outer cover layer needs to be opaque to sunlight, generate a low amount of particulate contaminates, and be able to survive in the environment and temperature to which the spacecraft will be exposed. Some common materials used for the outer layer are fiberglass woven cloth impregnated with PTFE Teflon, PVF reinforced with Nomex bonded with polyester adhesive, and FEP Teflon. The general requirement for the interior layer is that it needs to have a low emittance. The most commonly used material for this layer is Mylar that is aluminized on one or both sides. The interior layers are usually thin compared to the outer layer to save weight and are perforated to aid in venting trapped air during launch. The inner cover faces the spacecraft hardware and is used to protect the thin interior layers. Inner covers are often not aluminized in order to prevent electrical shorts. Some materials used for the inner covers are Dacron and Nomex Netting. Mylar is not used because of flammability concerns. MLI blankets are an important element of the thermal control system.

Louvers

Louvers are active thermal control elements that are used in many different forms. Most commonly they are placed over external radiators, louvers can also be used to control heat transfer between internal spacecraft surfaces, or be placed on openings on the spacecraft walls. A louver in its fully open state can reject six times as much heat as it does in its fully closed state, with no power required to operate it. The most commonly used louver is the bimetallic, spring-actuated, rectangular blade louver also known as venetian-blind louver. Louver radiator assemblies consist of five main elements: baseplate, blades, actuators, sensing elements, and structural elements.

Heaters

Heaters are used in thermal control design to protect components under cold-case environmental conditions or to make up for heat that is not dissipated. Heaters are used with thermostats or solid-state controllers to provide exact temperature control of a particular component. Another common use for heaters is to warm up components to their minimum operating temperatures before the components are turned on.

- The most common type of heater used on spacecraft is the patch heater which consists of an electrical-resistance element sandwiched between two sheets of flexible electrically insulating material, such as Kapton. The patch heater may contain either a single circuit or multiple circuits, depending on whether or not redundancy is required within it.

- Another type of heater, the cartridge heater, is often used to heat blocks of material or high-temperature components such as propellants. This heater consists of a coiled resistor enclosed in a cylindrical metallic case. Typically a hole is drilled in the component to be heated and the cartridge is potted into the hole. Cartridge heaters are usually a quarter-inch or less in diameter and up to a few inches long.

- Another type of heater used on spacecraft is the radioisotope heater units also known as RHUs. RHUs are used for traveling to outer planets past Jupiter due to very low solar radiance, which greatly reduces the power generated from solar panels. These heaters do not require any electrical power from the spacecraft and provide direct heat where it is needed. At the center of each RHU is a radioactive material which decays to provide heat. The most commonly used material is plutonium-dioxide. A single RHU weighs just 42 grams and can fit in a cylindrical enclosure 26mm in diameter and 32mm long. Each unit also generates 1 W of heat at encapsulation however the heat generation rate decreases with time. A total of 117 RHUs were used on the Cassini mission.

Radiators

Excess waste heat created on the spacecraft is rejected to space by the use of radiators. Radiators come in several different forms, such as spacecraft structural panels, flat-plate radiators mounted to the side of the spacecraft, and panels deployed after the spacecraft is on orbit. Whatever the configuration, all radiators reject heat by infrared (IR) radiation from their surfaces. The radiating power depends on the surface's emittance and temperature. The radiator must reject both the spacecraft waste heat and any radiant-heat loads from the environment. Most radiators are therefore given surface finishes with high IR emittance to maximize heat rejection and low solar absorptance to limit heat from the sun. Most spacecraft radiators reject between 100 and 350 W of internally generated electronics waste heat per square meter. Radiators weight typically varies from almost nothing, if an existing structural panel is used as a radiator, to around 12 kg/m2 for a heavy deployable radiator and its support structure.

The radiators of the International Space Station are clearly visible as arrays of white square panels attached to the main truss.

Heat pipes

Heat pipes use a closed two-phase liquid-flow cycle with an evaporator and a condenser to transport relatively large quantities of heat from one location to another without electrical power.

Future of Thermal Control Systems

- Composite materials

- Heat rejection through Advanced Passive Radiators

- Spray cooling devices (e.g. liquid droplet radiator)

- Lightweight thermal insulation

- Variable-emittance technologies

- Diamond films

- Advanced thermal control coatings

- Microsheets

- Advanced spray on thin films

- Silvered quartz mirrors

- Advanced metallized polymer-based films

Events

A major event in the field of space thermal control is the International Conference on Environmental Systems, organized every year by AIAA.

Sun shield

In spacecraft design, a sun shield restricts or reduces heat caused by sunlight hitting a spacecraft.[2] An example of use of a thermal shield is on the Infrared Space Observatory.[3] The ISO sunshield helped protect the cryostat from sunlight, and it was also covered with solar panels.[4]

Not to be confused with concept of a global scale sun shield in geoengineering, often called a Space sunshade or "sun shield", in that case the spacecraft itself is used to block sunlight on a planet, not as part the spacecraft's thermal design.[5]

An example of a sunshield in spacecraft design is the Sunshield (JWST) on the planned James Webb Space Telescope.

Spacecraft Systems and Components

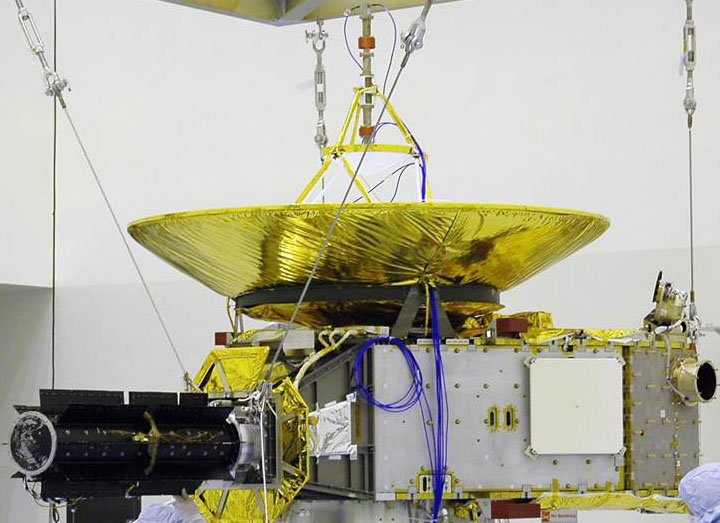

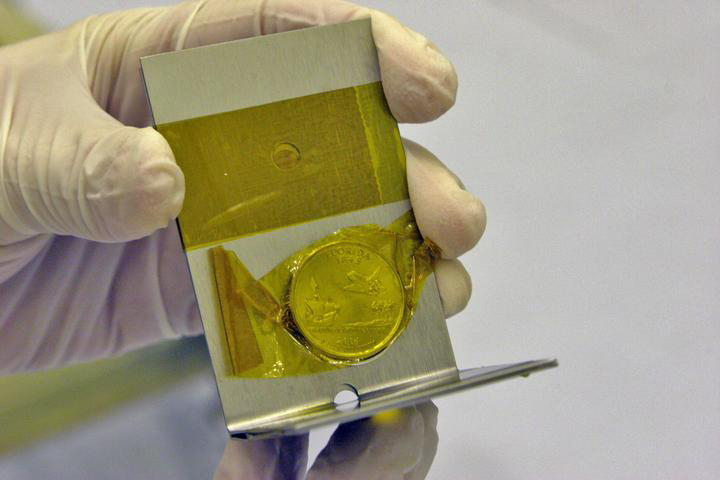

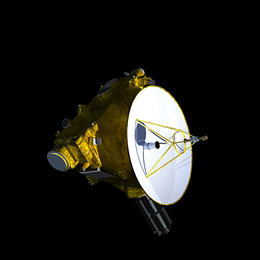

The New Horizons science payload was developed under direction of the Southwest Research Institute (SwRI), with instrument contributions from SwRI, APL, NASA's Goddard Space Flight Center, the University of Colorado, Stanford University and Ball Aerospace Corporation. Fully fueled, the agile, piano-sized probe weighed 478 kilograms (1,054 pounds) at launch. Designed to operate on a limited power source — a single radioisotope thermoelectric generator — New Horizons needs less power than a pair of 100-watt light bulbs to complete its mission at Pluto.On average, each of the seven science instruments uses between 2 and 10 watts — about the power of a night light — when turned on. The instruments send data to one of two onboard solid-state memory banks, where data is recorded before later playback to Earth. During normal operations, the spacecraft communicates with Earth through its 2.1-meter (83-inch) wide high-gain antenna. Smaller antennas provide backup communications. And when the spacecraft was in hibernation through long stretches of its voyage, its computer was programmed to monitor its systems and report its status back to Earth with a specially coded, low-energy beacon signal.

New Horizons' "thermos bottle" design retains heat and keeps the spacecraft operating at room temperature without large heaters. Aside from protective covers on five instruments that were opened shortly after launch, and one small protective cover opened after the Jupiter encounter, New Horizons has no deployable mechanisms or scanning platforms. It does have backup devices for all major electronics, its star-tracking navigation cameras and data recorders.

New Horizons has operated mostly in a spin-stabilized mode while cruising between planets, and also in a three-axis “pointing” mode that allows for pointing or scanning instruments during calibrations and planetary encounters (like the Jupiter flyby and, of course, at Pluto). There are no reaction wheels on the spacecraft; small thrusters in the propulsion system handle pointing, spinning and course corrections. The spacecraft navigates using onboard gyros, star trackers and Sun sensors. The spacecraft's high-gain antenna dish is linked to advanced electronics and shaped to receive even the faintest radio signals from home — a necessity when the mission's main target is more than 3 billion miles from Earth and round-trip transmission time is nine hours.+

Structure

New Horizons' primary structure includes an aluminum central cylinder that supports the spacecraft body panels, supports the interface between the spacecraft and its radioisotope thermoelectric generator (RTG) power source, and houses the propellant tank. It also served as the payload adapter fitting that connected the spacecraft to the launch vehicle.

Keeping mass down, the panels surrounding the central cylinder feature an aluminum honeycomb core with ultra-thin aluminum face sheets (about as thick as two pieces of paper). To keep it perfectly balanced for spinning operations, the spacecraft was weighed and then balanced with additional weights just before mounting on the launch vehicle.

Command and Data Handling

The command and data handling system – a radiation-hardened 12 megahertz Mongoose V processor guided by intricate flight software – is the spacecraft’s “brain.” The processor distributes operating commands to each subsystem, collects and processes instrument data, and sequences information sent back to Earth. It also runs the advanced “autonomy” algorithms that allow the spacecraft to check the status of each system and, if necessary, correct any problems, switch to backup systems or contact operators on Earth for help.

For data storage, New Horizons carries two low-power solid-state recorders (one backup) that can hold up to 8 gigabytes each. The main processor collects, compresses, reformats, sorts and stores science and housekeeping (telemetry) data on the recorder – similar to a flash memory card for a digital camera – for transmission to Earth through the telecommunications subsystem.

The Command and Data Handling system is housed in an Integrated Electronics Module that also contains a vital guidance computer, the communication system and part of the REX instrument.

Thermal Control

New Horizons is designed to retain heat like a thermos bottle. The spacecraft is covered in lightweight, gold-colored, multilayered thermal insulation – like a survival camping blanket – which holds in heat from operating electronics to keep the spacecraft warm. Heat from the electronics has kept the spacecraft operating at between 10-30 degrees Celsius (about 50-85 degrees Fahrenheit) throughout the journey.

New Horizons’ sophisticated, automated heating system monitors power levels inside the craft to make sure the electronics are running at enough wattage to maintain safe temperatures. Any drop below that operating level (about 150 watts) and it will activate small heaters around the craft to make up the difference. When the spacecraft was closer to Earth and the Sun, louvers (essentially heat vents) on the craft opened when internal temperatures were too high.

The thermal blanketing – 18 layers of Dacron mesh cloth sandwiched between aluminized Mylar and Kapton film – also helps to protect the craft from micrometeorites.

Propulsion

The propulsion system on New Horizons is used for course corrections and for pointing the spacecraft. It is not needed to speed the spacecraft to Pluto; that was done entirely by the launch vehicle, with a boost from Jupiter’s gravity.The New Horizons propulsion system includes 16 small hydrazine-propellant thrusters mounted across the spacecraft in eight locations, a fuel tank, and associated distribution plumbing. Four thrusters that each provide 4.4 newtons of force (1 pound) are used mostly for course corrections. Operators also employ 12 smaller thrusters – providing 0.8 newtons (about 3 ounces) of thrust each – to point, spin up and spin down the spacecraft. Eight of the 16 thrusters aboard New Horizons are considered the primary set; the other eight comprise the backup (redundant) set.

At launch, the spacecraft carried 77 kilograms (170 pounds) of hydrazine, stored in a lightweight titanium tank. Helium gas pushes fuel through the system to the thrusters. Using a Jupiter gravity assist, along with the fact that New Horizons does not slow down or go into orbit around Pluto, reduced the amount of propellant needed for the mission.

Guidance and Control

New Horizons must be oriented precisely to collect data with its scientific instruments, communicate with Earth, or maneuver through space.Attitude determination – knowing which direction New Horizons is facing – is performed using star-tracking cameras, Inertial Measurement Units (containing sophisticated gyroscopes and accelerometers that measure rotation and horizontal/vertical motion), and digital Sun sensors. Attitude control for the spacecraft – whether in a steady, three-axis pointing mode or in a spin-stabilized mode – is accomplished using thrusters.

The IMUs and star trackers provide constant positional information to the spacecraft’s Guidance and Control processor, which like the Command and Data Handling processor is a 12-MHz Mongoose V. New Horizons carries two copies of each of these units for redundancy. The star-tracking cameras store a map of about 3,000 stars; 10 times per second one of the cameras snaps a wide-angle picture of space, compares the locations of the stars to its onboard map, and calculates the spacecraft’s orientation. The IMU feeds motion information 100 times a second. If data shows New Horizons is outside a predetermined position, small hydrazine thrusters will fire to re-orient the spacecraft. The Sun sensors back up the star trackers; they would find and point New Horizons toward the Sun (with Earth nearby) if the other sensors couldn’t find home in an emergency.

Operators use thrusters to maneuver the spacecraft, which has no internal reaction wheels. Its smaller thrusters are used for fine pointing; thrusters that are approximately five times more powerful are used during the trajectory course maneuvers that guide New Horizons toward its targets. New Horizons spins – typically at 5 revolutions per minute (RPM) – during trajectory-correction maneuvers and long radio contacts with Earth, and while it “hibernated” during long cruise periods. Operators steady and point the spacecraft during science observations and instrument-system checkouts.

Communications

Accurate Ranging:

New Horizons is the first mission to use onboard regenerative ranging to track the distance between the spacecraft and Earth. When a spacecraft is far from home, the ranging tone sent from the ground to measure distance is weak (or “noisy”) by the time it reaches the spacecraft’s communications system. In normal ranging, the spacecraft simply amplifies and sends the noisy tone back to Earth, which adds errors to the range measurement. In regenerative ranging, the spacecraft’s advanced electronics track and “regenerate” the tone without the noise. The ground station on Earth receives a much clearer signal – giving navigators and operators a more accurate lock on the spacecraft’s distance, and improving their ability to guide New Horizons through the solar system.The system includes two broad-beam, low-gain antennas on opposite sides of the spacecraft, used mostly for near-Earth communications; as well as a 30-centimeter (12-inch) diameter medium-gain dish antenna and a large, 2.1-meter (83-inch) diameter high-gain dish antenna. The antenna assembly on the spacecraft’s top deck consists of the high, medium, and forward low-gain antennas; this stacked design provides a clear field of view for the low-gain antenna and structural support for the high and medium-gain dishes. Operators aim the antennas by turning the spacecraft toward Earth. The high-gain beam is only 0.3 degrees wide, so it must point directly at Earth. The wider medium-gain beam (4 degrees) is used in conditions when the pointing might not be as accurate. All antennas have Right Hand Circular and Left Hand Circular polarization feeds.

Data rates depend on spacecraft distance, the power used to send the data and the size of the antenna on the ground. For most of the mission, New Horizons has used its high-gain antenna to exchange data with the Deep Space Network’s largest antennas, 70 meters across. Even at Pluto, because New Horizons will be more than 3 billion miles from Earth and radio signals will take more than four hours to reach the spacecraft, it can send information at about 1,000 bits per second. It will take 16 months to send the full set of Pluto encounter science data back to Earth.

New Horizons is flying the most advanced digital receiver ever used for deep space communications. Advances include regenerative ranging and low power – the receiver consumes 66% less power than earlier deep-space receivers. The Radio Science Experiment (REX) to examine Pluto’s atmosphere is also integrated into the communications subsystem.

The entire telecom system on New Horizons is redundant, with two of everything except the high gain antenna structure itself.

Power

Flying with an RTG

How hot is the RTG? Sensors attached to the outside of the RTG case before launch pegged the case temperature at about 245 C (nearly 475 F). When New Horizons reaches Pluto, engineers estimate the temperature will have dropped to around 208 C (406 F) – thanks to a combination of distance from the Sun and fuel decay.The RTG is not hot enough to produce visible light, but it does emit infrared (or thermal) radiation.

At launch the fuel produced almost 4,000 watts of thermal power; of that, New Horizons used about 25 watts of the waste heat to warm the spacecraft. Electrical power output of the RTG was about 245 watts. Some of that electrical power (about 120 watts) is also reused after powering components to help heat the spacecraft. The rest of the RTG heat and any extra electrical power are radiated into space.

Many scientific instruments work better when they are cold; that’s one reason why they are located on the opposite side of the spacecraft from the RTG. New Horizons also has a heat shield around the base of the RTG to avoid a direct line of sight from the instruments to the RTG. These design features help avoid any interference from the RTG with scientific measurements.

The New Horizons RTG, provided by the U.S. Department of Energy, carries approximately 11 kilograms (24 pounds) of plutonium dioxide. Onboard systems manage the spacecraft’s power consumption so it doesn’t exceed the steady output from the RTG, which has decreased by about 3.5 watts per year since launch.

Typical of RTG-based systems, as on past outer-planet missions, New Horizons does not have a battery for storing power.

At the start of the mission, the RTG supplied approximately 245 watts (at 30 volts of direct current) – the spacecraft’s shunt regulator unit maintains a steady input from the RTG and dissipates power the spacecraft cannot use at a given time. By July 2015 (when New Horizons flies past Pluto) that supply will have decreased to about 200 watts at the same voltage, so New Horizons will ease the strain on its limited power source by cycling science instruments during the encounter.

The spacecraft’s fully redundant Power Distribution Unit (PDU) – with 96 connectors and more than 3,200 wires – efficiently moves power through the spacecraft’s vital systems and science instruments.

Dawn Spacecraft & Mission Overview

Outfitted with a series of remote sensing instruments, Dawn lifted off in 2007 and arrived at asteroid Vesta in July 2011 for a 14-month survey mission before heading off on a two-and-a-half-year journey to Ceres, the largest object in the asteroid belt. Arriving at Ceres in March 2015, Dawn is set to explore a second world that formed early in the history of the solar system, but shows noticeable differences to Vesta.

Ceres and Vesta were chosen for the Dawn mission as two contrasting protoplanets, one icy and cold while the other was believed to be rocky. Evidence suggests that both objects formed early in the history of the Solar System, however, it is believed that Vesta differentiated rapidly while Ceres may have a differentiated interior and likely formed several million years after the first solar system bodies were formed.

Studying these two objects will fill a gap in the scientific understanding of the solar system as they fit in between the formation of the inner rocky planets and the icy bodies of the outer solar system.

Spacecraft Overview

Dawn consists of a central spacecraft body that houses all subsystems and instruments and provides mounting structures for a large parabolic High Gain Antenna and two deployable solar arrays. Overall, the spacecraft platform measures 1.64 by 1.27 by 1.77 meters with a total launch mass of 1,217.7 Kilograms – 747.1kg spacecraft dry mass, 425kg of Xenon propellant for the ion engines, and 45.6kg of Hydrazine propellant for the chemical propulsion system. In its stowed configuration, with the solar arrays locked in the launch position, the spacecraft is 2.36 meters wide. When deployed in space, the spacecraft measures 19.8 meters from tip to tip with both solar arrays fully extended.The Dawn spacecraft platform was manufactured by Orbital Sciences (now Orbital ATK) and its instruments and a range of other components were developed at NASA’s Jet Propulsion Laboratory, the University of California and participating institutions in Germany (Max Planck Institute & German Aerospace Center) and Italy (Italian Space Agency and INAF). Dawn is Orbital’s first purely scientific spacecraft headed beyond Earth orbit and the first purely scientific spacecraft to employ ion propulsion.

The spacecraft was designed for an operational life of ten years with at least one level of redundancy in all critical systems and onboard fault detection and protection to allow the spacecraft to autonomously switch between primary and secondary systems. Dawn uses heritage from previous missions including GALEX, SORCE, and Orbital’s Star Satellite bus as well as the Deep Space 1 mission, the first spacecraft to demonstrate the long-term use of ion thrusters for maneuvering in space.

Mechanical Subsystem

A graphite composite cylinder builds the core of the Dawn spacecraft, running the entire length of the vehicle to provide mounting surfaces for internal and external panels and to transfer forces to the spacecraft, especially during the launch sequence. Inside the cylinder are the propellant tanks for the ion engines holding Xenon propellant and the tank feeding the hydrazine thrusters.

The central cylinder is surrounded by internal panels that consist of aluminum cores and graphite-epoxy face sheets. These panels provide most of the mounting structure for the various satellite subsystems. External panels, also consisting of aluminum cores with facesheets, provide mounting structures for external systems such as thrusters and radiators.

The panels and –Z deck section are joined with composite L-band brackets. The external +/-X and +Z deck panels consist of graphite-epoxy honeycomb structures while the Y panels use aluminum facesheets and aluminum honeycomb cores to facilitate the radiators and heat pipes.

Power System

A 80-140-Volt raw power supply from the solar arrays is accepted by the High Voltage Electronics Assembly that delivers the two spacecraft power buses. Dedicated avionics control the state of charge of the single 35 Amp-hour Nickel-Hydrogen battery of the. The spacecraft uses a 28-Volt main bus for all satellite subsystems except the ion engine system, distributed by a Power Distribution System.The Dawn spacecraft is equipped with two power-generating solar arrays, each consisting of five rectangular panels for a total area of 38.2 square meters. Each of the arrays is 8.3 by 2.3 meters in size and weighs 63 Kilograms. On the front side, each array is covered with 5,740 InGaP/InGaAs/Ge triple-junction solar cells to deliver a total power of 10.3 Kilowatts at a distance to the sun of 1 Astronomical Unit (Earth’s Orbit) and 1.3kW at 3AU and at the end of the spacecraft’s operational life. The solar arrays are pointed to the sun by two Solar Array Drive Mechanisms controlled by dedicated electronics.

The bus operates at an operational range of 22 to 35 Volts that is maintained depending on the state of charge of the battery. Bus protection is provided a Fuse Protect Assembly. A separate Power Conditioning Unit delivers a second power bus at 80 to 140 Volts to run the ion engines of the vehicle.

The cable harness installed on the Dawn spacecraft consists of over 9,000 individual cables with a cumulative length of 25 Kilometers and a mass of 83 Kilograms.

Propulsion System

Dawn’s chemical propulsion system uses Hydrazine monopropellant that is fed to 12 thrusters from two separate tanks that are pressurized before flight using Helium gas.The Dawn Spacecraft combines the advantages of an electrical propulsion system using the ionization and acceleration of Xenon in an electric field, and a traditional chemical propulsion system consisting of low-thrust engines used for attitude control and delta-v maneuvers. Three different types of propulsion are required for the Dawn mission: 1) large changes of the velocity of the spacecraft to reach its destinations, 2) small changes in delta-v in a short period of time for trajectory corrections and the setup of flybys and orbital insertion, and 3) momentum management on the spacecraft’s reaction wheels.

Six 0.9-Newton thrusters are part of one thruster string, each with redundant Seat Control Valves interfacing with the main propellant line that connects each string with the tank through a latch valve and filter. Each of the tanks is equipped with a redundant pressure transducer.

The thrusters use the catalytic decomposition of Hydrazine over a heated metal catalyst bed to generate combustion gases that are expelled at pressure to generate thrust. Dawn’s chemical propulsion system launches with a total propellant mass of 45.6 Kilograms. Six of the thrusters are needed for three-axis control, the other serve a redundant function. They are used during momentum dumps from the reaction wheels, can assist in spacecraft attitude control and deliver short-duration delta-v changes for the correction of the spacecraft trajectory and the setup of flybys and orbital insertions.

The engines are capable of operating in pulse mode for spacecraft attitude control and in steady-state mode for Cruise Maneuvers and other translational burns. The thrusters also provide de-saturation of the reaction wheels – spinning the wheels down while countering the resulting force with the engines. Thrusters are installed on the +/-X and –Z decks of the spacecraft.