MARIA PREFER on energy efficiency and effectiveness in reviewing the meeting points of the elasticity of electrons that affect the working system of electronic circuits, starting from large currents to small to wireless and EINSTEIN PROG :

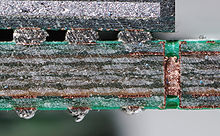

1. electrical cable connection point

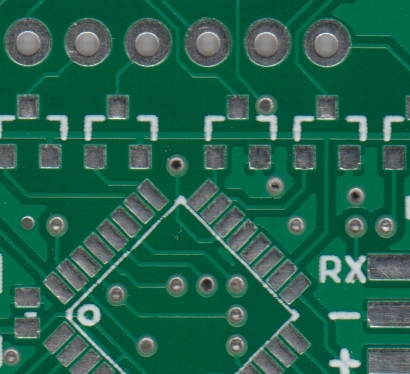

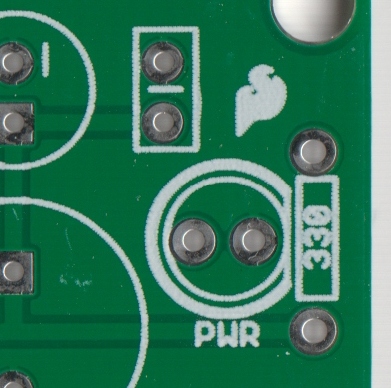

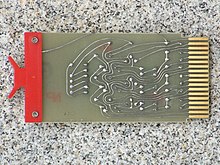

2. Solder point on the PCB board

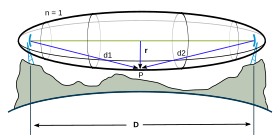

3. hot spot points on wireless networks and the internet

4. satellite as an electronic network server point.

MARIA PREFER is very much shaped by the continuous arrangement of electrons and photons of photons that make up MARIA PREFER' description so that it becomes more accurate and slow.

LOVE and JESI__ ISE

Gen . MAC TECH Zone EINSTEIN PROGRAM VIEW

--------------------------------------------------------------------------------------------------------------------------

The 3 Rules, The Humble Circuit, and Its Place in Our World of Electronics

Before diving into a complete circuit, it’s wise to first wrap your mind around the individual pieces that make up the whole, being flow, load, and conductivity. We’ve organized these principles into three basic rules:- Rule 1 – Electricity will always want to flow from a higher voltage to a lower voltage.

- Rule 2 – Electricity always has work that needs to be done.

- Rule 3 – Electricity always needs a path to travel.

Rule 1 – It’s All About the Flow

Every electronic circuit needs some a power source, whether that’s from an AA battery that you can pop into your Xbox One controller or something with a bit more force like your wall outlet that can power a large number of devices. The electricity that comes flowing out from these sources is measured in voltage, or volts, or simply V. .Regardless of where this power flows from, its purpose is always the same – to get from one area to another, and in the process to do some work, like charging your computer or turning on your lights.

The fundamental component of this flow of power is that electricity will always want to flow from a higher voltage to a lower voltage. Always. This is called potential. You could say that it’s the potential electricity has to move from one area to another.

Flow of High (Positive) Voltage to Low (Negative) Voltage.

- A battery has two sides, the negative side is the low voltage, measuring in at 0v, the positive side is the high voltage, measuring in at 1.5v.

- Energy will always want to flow out of the positive side of the battery to get to the negative side to find balance.

- To do this, it needs to flow along something, usually a copper wire, and do some work in the process, like turn on a light or spin a motor.

This all amounts to Rule 1 – Electricity will always want to flow from a higher voltage to a lower voltage. Remember this; it will never change.

Rule 2 – Getting Some Work Done

Now, you might have some electricity that wants to flow from a higher voltage to a lower voltage, but what’s the point? The only reason to make electricity flow is to give it some work to do. This process of electricity doing work in a circuit is called load. Without having a load, or some work for electricity to do, then there is no point in having a circuit. A load can be anything you can imagine, such as:- Spinning a motor which turns the propellers of a drone.

- Turning on a LED on a charging cable to indicate that your laptop is plugged in.

- Connecting your headset wirelessly with your laptop to listen to music.

Tis’ the season, electric load comes in many forms, one of which is powering these LEDs. (Image source)

Remember Rule 2 – Electricity always has work that will need to be done. Without work, then a circuit has no use.

Rule 3 – Following a Path

The third and final rule is what makes the first two rules possible – electricity needs a path to travel. This path acts as a kind of middleman. Let’s say you plug your laptop charger into a wall socket, and then into your laptop. It charges, obviously, but without that cord between your computer and wall outlet, nothing would happen.This is because electricity needs a path to follow to get from one destination to another. And the journey is always the same:

- Power – Electricity always starts from a source, like a battery or an outlet.

- Journey – It then takes its journey along a path, doing its work along the way.

- Destination – It then arrives at its final destination, finding rest at the lowest voltage point.

See all of those copper wires? Electricity loves traveling on this conductive material.

Putting It All Together – The Complete Circuit

Let’s put all of these rules together now in a complete definition of a circuit.A circuit is simply a path that electricity can flow through.

And with that simple concept right there, men and women have gone on to build some insanely complex circuits that have sent the human race to space and the depths of our deepest oceans. For now, we’ll keep things simple and put together our first circuit. Here’s what you’ll need if you want to follow along:

- (1) 9-volt battery

- (1) 470 Ω resistor

- (1) Generic LED

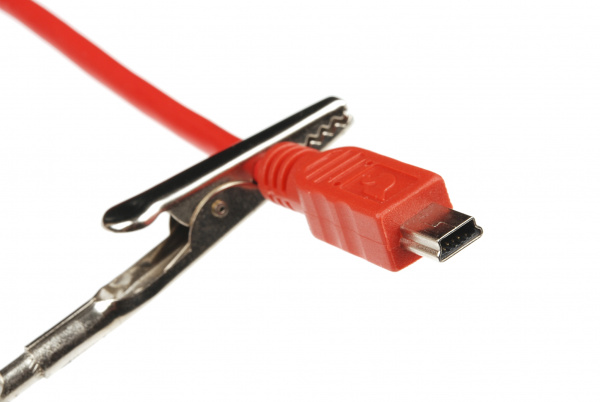

- (3) Test leads with alligator clips

Step 1 – Adding a Power Source

Going back to our Rule of Three’s, the first says that electricity will always want to flow from a higher voltage to a lower voltage. Okay, so this means we need some kind of power source in this circuit, we’ll add our 9v battery.

The beginning of our circuit starts with a 9v battery.

Step 2 – Adding Some Work

We now want our electricity to do some work for us before it can come to rest, so let’s have it turn on a simple LED light. You’ve likely seen these everywhere, in your Christmas tree, flashlights, light bulbs, etc… So we’ll take this LED and place it on the other side of our battery.Now, the one thing to mention about a LED is that it’s really sensitive and can’t have too much power running through it, so we need to add what’s called a resistor. We won’t go into the details now, but just know that a resistor will do like its name says – resist the flow of electricity enough for our LED to handle it. Let’s place that resistor to the left of our LED.

Adding some work to our circuit with a LED and resistor.

Step 3 – Providing a Path

This part is simple, we just need to connect our alligator clips between all of the components on our circuit. If you do this correctly, then your LED will shine bright! Remember, when connecting wires to a battery, always connect the positive end first, then the negative. Check out the picture below for how it all needs to be connected together.

Our electricity now has a path to flow through with the added alligator clips

Types of Circuits

Now, before you go running off into the wild and building your own circuits, you need to know about two ways to describe a circuit, one of which might ruin your circuit’s day, they include:Closed or Open Circuit

A circuit is considered a closed circuit when there is a complete path available for electricity to travel on. This is also referred to as a complete circuit. Now, if your circuit isn’t working as intended, then this means that it’s an open circuit. This can be caused by several things, including a loose connection or a broken wire.Here’s an easy, visual way to understand the difference between a closed or open circuit, check out the circuit diagram below and notice that it’s the same circuit we made above, except now it has a switch.

Here’s a diagram of the circuit we made above. Notice the addition of a switch.

Now our switch is triggered, which completes the circuit, allowing electricity to flow to our LED!

Short Circuit

Then there’s the short circuit. When you don’t give your circuit any work to do, but you still provide some power, prepare for some problems. Check out our circuit below, we took out the LED, resistor, and switch, leaving just our copper wire and battery.

Here’s a circuit well on its way to becoming a short circuit! Without any work to do this battery will soon burn out.

But the minute you take any of that work out of your circuit, the electricity goes crazy and runs around its path at full speed without anything holding it back. If you let this happen for an extended period of time, then you’ll find yourself with a damaged power supply, a drained battery, or maybe something even worse, like a fire!

Whoa! Don’t try this at home. Here’s a hefty 12v lantern battery being short-circuited in the name of science. (Image source)

You Are Now Dangerous

There you go, young electronics master, you now have all the information you need to control the humble circuit. By understanding how a circuit works, you’ll soon be able to tackle projects of all shapes and sizes. But before beginning your own journey, remember the Guiding Rule of Threes:- Rule 1 – Electricity will always want to flow from a higher voltage to a lower voltage.

- Rule 2 – Electricity always has work that needs to be done.

- Rule 3 – Electricity always needs a path to travel on.

__________________________________________________________________________________

A connection point is a point in an electrical connector where a cable begins or ends. ... You can use one connection point to represent all of the connector's pins, and route all wires or cables to that connection point. The pin connectivity data is held as internal data.

The part of a cable that plugs into a port or interface to connect one device to another. Most connectors are either male (containing one or more exposed pins) or female (containing holes in which the male connector can be inserted).

Terminal blocks are modular, insulated blocks that secure two or more wires together. ... Terminals are useful for connecting wiring to a ground or, in the case of electrical power, for connecting electrical switches and outlets to the mains.

Analog Audio Connectors:

- RCA Connectors: ...

- XLR Connectors: ...

- XLR Male: This is used to connect a variety of hardware inputs.

- XLR Female: It is used to connect a microphone and a variety of hardware inputs.

- TRS: It is used to connect both input and output devices.

- ¼” Audio Connectors: ...

- S/PDIF: ...

- AES/EBU:

The following cabling media types will be most commonly seen in LAN environments.

- Unshielded Twisted Pair (UTP) ...

- Shielded Twisted Pair (STP) ...

- Multi-Mode Fiber (MMF) ...

- Single Mode Fiber (SMF) ...

- Registered Jack 45 (RJ45) ...

- Straight Tip (ST) ...

- Subscriber Connector (SC) ...

- Lucent Connector (LC)

Three Types Of Cable Joints

There are three main types of electrical joints,

also known as splices: The Western Union splice, the tap splice and the

fixture splice. The Western Union splice connects two conductors

together and is particularly useful in repairing a broken wire.People often have difficulty choosing the correct gender termination on cable assemblies. Plugs are considered male gendered connectors which utilize a center pin. Jacks are considered female gendered connectors utilizing a center socket. What is the difference between a plug and a jack?

Slots and ports are physical connection points that allow the hardware of a computer to be expanded. A port is a socket. A slot is a dock for a printed circuit board. This board contains a port and fits into a slot.

Connection Points for Electrical Connectors

Connector Basics

Introduction

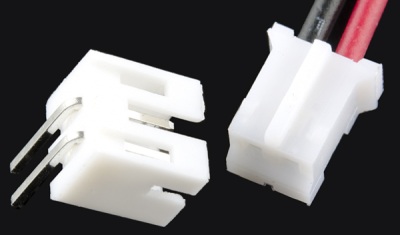

Connectors are used to join subsections of circuits together. Usually, a connector is used where it may be desirable to disconnect the subsections at some future time: power inputs, peripheral connections, or boards which may need to be replaced. .Connector Terminology

Before we get started discussing some commonly used connectors, let's explore the terminology used to describe connectors.Gender

Gender - The gender of a connector refers to whether it plugs in or is plugged into and is typically male or female, respectively (kids, ask your parents for a more thorough explanation). Unfortunately, there are cases where a connector may be referred to as "male" when it would appear to be female; in the examples section, we'll point a few of those out as we discuss individual component types and explain why that's the case.

Male (left) and female 2.0mm PH series JST connectors. In this case, gender is determined by the individual conductor.

Polarity

Polarity - Most connectors can only be connected in one orientation. This trait is called polarity, and connectors which have some means to prevent them being connected wrong are said to be polarized, or sometimes keyed.

A polarized North

American wall plug. By having two different widths for the plug blades,

the plug will only go into the outlet one way.

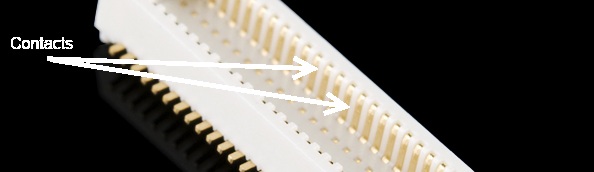

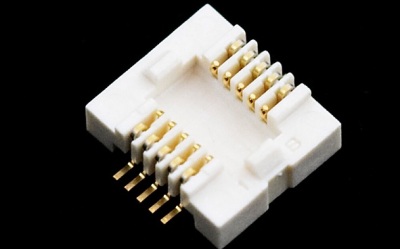

Contact

Contact - Contacts are the business portion of the connector. They are the metal parts which touch each other, forming an electrical connection. This is also where problems occur: the contacts can become soiled or oxidized, or the springiness required to hold the contacts together may fade with time.

The contacts on this connector are clearly visible.

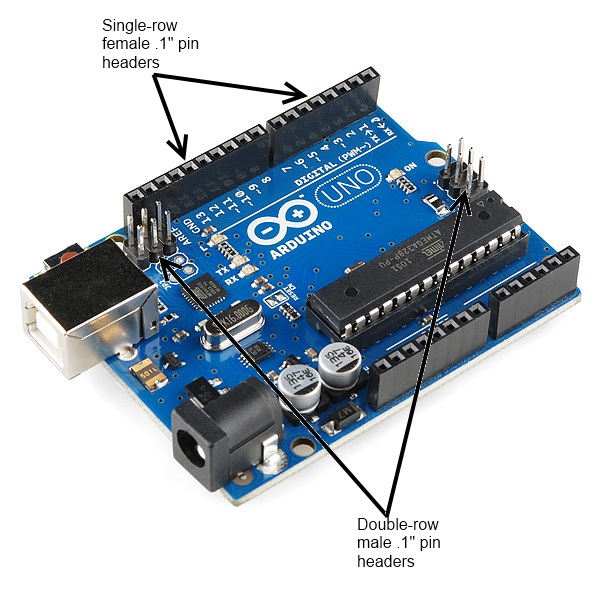

Pitch

Pitch - Many connectors consist of an array of contacts in a repeated pattern. The pitch of the connector is the distance from the center of one contact to the center of the next. This is important, because there are many families of contacts which look very similar but may differ in pitch, making it difficult to know that you are purchasing the right mating connector.

The pitch of the pins on the headers on a standard Arduino is .1".

Mating Cycles

Mating cycles - Connectors have a finite life, and connecting and disconnecting them is what wears them out. Datasheets usually present that information in terms of mating cycles, and it varies widely from one technology to another. A USB connector may have a lifetime in the thousands or tens of thousands of cycles, while a board-to-board connector designed for use inside of consumer electronics may be limited to tens of cycles. It's important that you select a connector with a suitable life for the application.

Mating connector for the GS406 GPS module. The connector's datasheet indicates a maximum of 50 insertion cycles for this part.

Mount

Mount - This one has the potential for being confusing. The term "mount" can refer to several things: how the connector is mounted in use (panel mount, free-hanging, board mount), what the angle of the connector is relative to its attachment (straight or right-angle), or how it is mechanically attached (solder tab, surface mount, through hole). We'll discuss this more in the examples section for each individual connector.

A comparison of three

different methods of mounting the same barrel connector: (left to right)

board mount, inline cable mount, and panel mount.

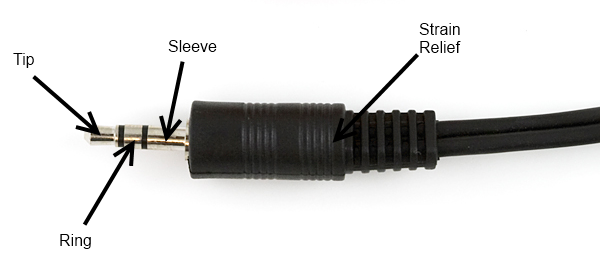

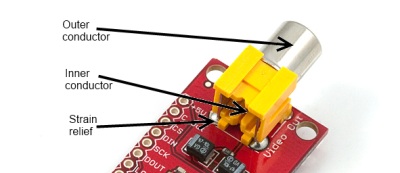

Strain Relief

Strain relief - When a connector mounts to a board or cable, the electrical connections tend to be somewhat fragile. It is typical to provide some kind of strain relief to transfer any forces acting on that connector to a more mechanically sound object than the fragile electrical connections. Again, there will be some good examples of this later on.

This 1/8" headphone

jack comes with a strain relief "boot" slid over the cable to prevent

forces on the cable from being transmitted directly to the electrical

joints.

USB Connectors

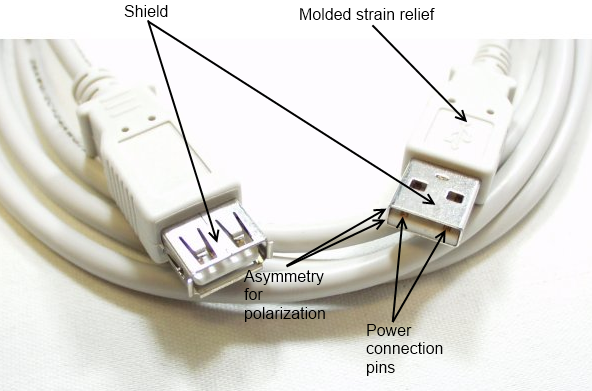

USB connectors come in two flavors: host and peripheral. In the USB standard, there is a difference between the two, and the connectors on cables and devices reflect this. However, all USB connectors will have some things in common:- Polarization - A USB connector can only nominally be inserted one way. It may be possible to force a connector in wrong, but that will result in damage to the device.

- Four contacts - All USB connectors have at least four contacts (although some may have five, and USB 3.0+ connectors have even more). These are for power, ground, and two data lines (D+ and D-). USB connectors are designed to transmit 5V, up to 500mA.

- Shielding - USB connectors are shielded, such that a metal shell which is not part of the electrical circuit is provided. This is important to keep the signal intact in environments with a lot of electrical "noise".

- Robust power connection - It's important for the power pins to make connection before the data lines, to avoid trying to power the device over the data lines. All USB connectors are designed with this in mind.

- Molded strain relief - All USB cables have plastic overmolding at the connector to prevent strain on the cable that could potentially damage the electrical connections.

A USB extension cable, with some of the common features of USB connectors labeled.

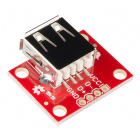

USB-A Connectors

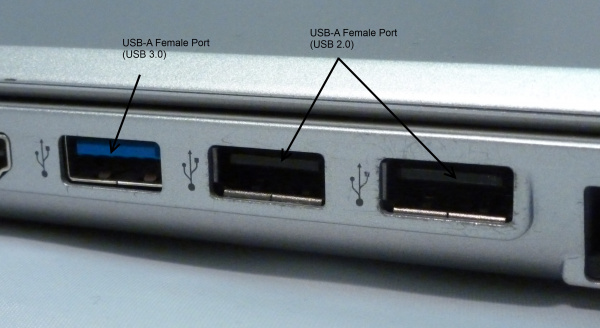

USB-A female is the standard "host" connector type. This is found on computers, hubs, or any device intended to have peripherals plugged into it. It is also possible to find extension cables with a female A connector and a male A connector on the other end.

Female USB-A ports on the side of a laptop. The blue connector is USB 3.0 compliant.

USB-A male is the standard "peripheral" connector

type. Most USB cables will have one end terminating in a USB-A male

connector, and many devices (such as keyboards and mice) will have a

built-in cable terminated with a USB-A male connector. It's also

possible to find USB-A male connectors that are board mountable, for

devices like USB memory sticks.

Two types of Male USB-A connectors, on a SparkFun Cerberus cable and an AVR Stick development board.

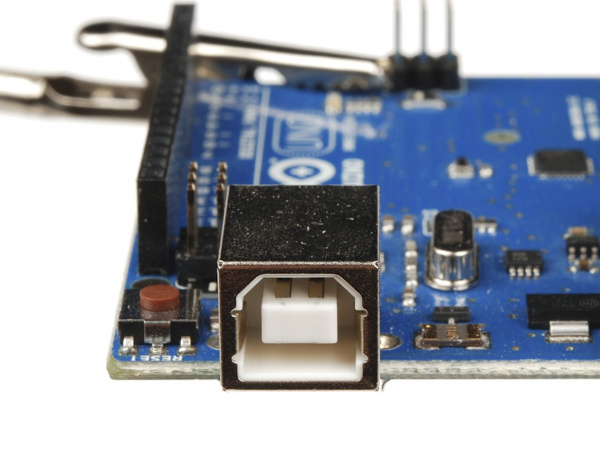

USB-B Connectors

USB-B female is a standard for peripheral devices. It's bulky, but robust, so in applications where size is not an issue, it's the preferred means for providing a removable connector for USB connectivity. It is usually a through-hole board mount connector, for maximum reliability, but there are panel-mount options for it as well.

Arduino boards, including this Uno, have long used the female USB-B connector, due to its low cost and durability.

USB-B male is almost exclusively found at the end of

a cable. USB-B cables are ubiquitous and inexpensive, which also

contributes to the popularity of the USB-B connection.

USB-B male connector on the end of a SparkFun Cerberus cable.

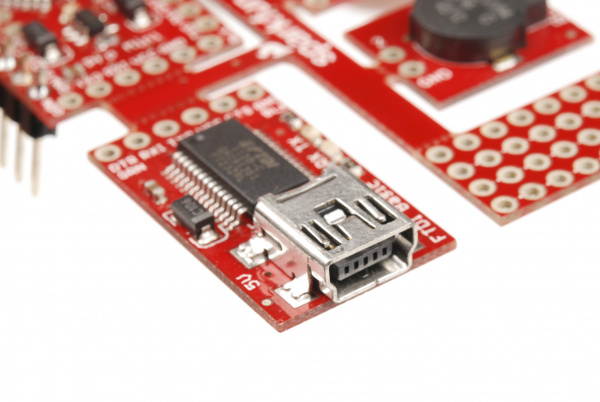

USB-Mini Connectors

The USB-Mini connection was the first standard attempt to reduce the size of the USB connector for smaller devices. USB-Mini female is typically found on smaller peripherals (MP3 players, older cellphones, small external hard drives), and is usually a surface mount connector, trading robustness for size. USB-Mini is slowly being phased out in favor of the USB-Micro connector.

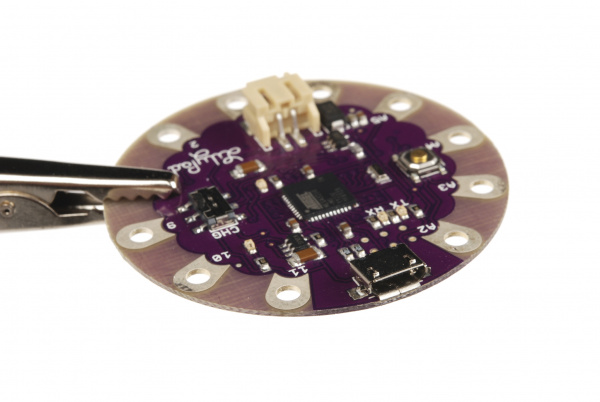

USB-Mini female connector on a Protosnap Pro Mini.

USB-Mini male is another cable-only connector. As with USB-B, it's extremely common, and cables can be found cheaply almost anywhere.

USB-Mini male connector on the end of a SparkFun Cerberus cable.

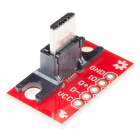

USB-Micro Connectors

USB-Micro is a fairly recent addition to the USB connector family. As with USB-Mini, the primary concern is size reduction, but USB-Micro adds a fifth pin for low-speed signalling, allowing it to be used in USB-OTG (On-the-go) applications where a device may want to operate as either a host or a peripheral depending on circumstances.USB-Micro female is found on many newer peripherals, such as digital cameras and MP3 players. The adoption of USB-micro as a standard charge port for all new cellular phones and tablet computers means that chargers and data cables are becoming increasingly common, and USB-Micro is likely to supplant USB-Mini in the coming years as the small-factor USB connector of choice.

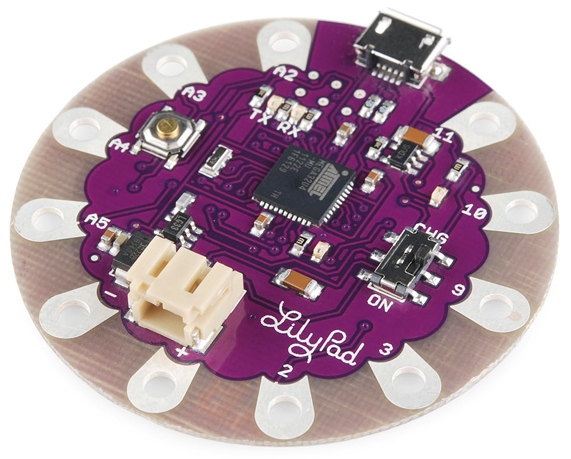

USB-Micro female connector on a LilyPad Arduino USB board.

USB-Micro male is also a cable-only connector. There

are generally two types of cables with USB-Micro male ends: one for

connecting a device with a USB-Micro port as a peripheral to a USB host

device and one for adapting the USB-Micro female port to a USB-A female

port, to be used in USB-OTG capable devices.

USB-Micro male connector on the SparkFun Cerberus cable.

Adapter pigtail

for using USB-OTG capable devices having only a USB-Micro port with

standard USB peripherals. Note that not all devices supporting USB-OTG

will work with this pigtail.

USB 3.0 micro-B Cable

USB 3.0 micro-B cables look similar to USB 2.0 micro-B connectors but they include additional pins for two differential pairs and a ground.USB 3.1 C Cable

USB C packs 24 pins into the USB connector. Unlike the previous versions predecessors, this version is reversable! The design of the USB C cable also allows for current above 500mA for your power hungry devices.

Heads up! Depending on the cable, not all of the pins

are broken out for USB C. Some cables may be limited to the USB 2.0

specification with 4 pins as opposed to the full USB 3.1 specification.

The reversible USB A to C cables and SuzyQable

are a few examples. Depending on the USB port that is used, you may

also be limited in the amount of current that can be provided to your

device.

Reversible USB

With the advancements in technology and manufacturing, USB connectors can be inserted either way! Below are examples of a reversible type A and type micro-b connector from the catalog. |

|

|

|

| Reversible Type A Connector End | Reversible Type Micro B Connector End |

If you are looking for a USB connector or cable, check out our USB Buying Guide or catalog.

Audio Connectors

Another familiar connector group are those used for audio-visual applications--RCA and phono. While these can't truly be considered to be of the same family, as the various USB connectors are, we'll consider both of them to be in the same vein."Phone" Type Connectors

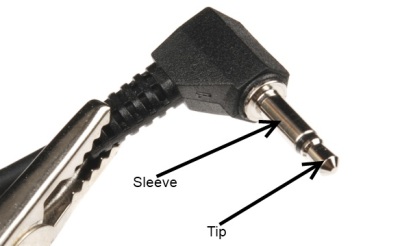

You'll probably immediately recognize the 1/8" version of this connector as a the plug on the end of a pair of headphones. These connectors actually come in three common sizes: 1/4" (6.35mm), 1/8" (3.5mm), and 2.5mm. ¼" size connectors find a lot of use in the professional audio and music community- most electric guitars and amplifiers have 1/4" tip-sleeve (TS) jacks on them. 1/8" tip-ring-sleeve (TRS) is very common as the connector for headphones or audio output signals on MP3 players or computers. Some cell phones will provide a 2.5mm tip-ring-ring-sleeve (TRRS) jack for connecting to headphones that also include a microphone for hands-free communications.The common availability of these connectors and cables makes them a good candidate for general purpose connectivity applications--for instance, long before USB, Texas Instruments graphing calculators used a 2.5mm TRS connector for a serial programming connector. It should be remembered that tip-sleeve connector types are not designed for carrying power; during insertion, the tip and the sleeve can be momentarily shorted together, which may damage the power supply. The lack of shielding makes them poor candidates for high-speed data, but low speed serial data can be passed through these connectors.

Headphone-type TRS phone plug, 1/8". Typically, tip and ring will carry the stereo audio signals while sleeve will be connected to ground.

1/8" phone plug. Note the lack of a ring contact on this connector.

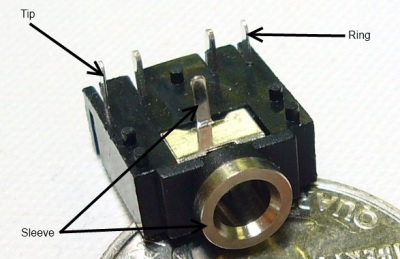

1/8" board mount headphone jack

with pins corresponding pin connections labeled. When no jack is

inserted, an internal switch connects the tip and ring pins to the

adjacent unmarked pins, allowing insertion detection.

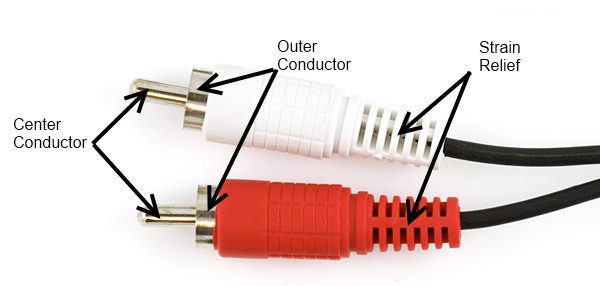

RCA Connectors

Familiar as the home-stereo connector of choice for many decades, the RCA connector was introduced in the 1940s by RCA for home phonographs. It is slowly being supplanted by connections like HDMI in the audio-visual realm, but the ubiquity of the connectors and cables makes it a good candidate for home-built systems. It will be a long time before it is obsolete.Female RCA connectors are usually found on devices, although it is possible to find extension or conversion cables with female jacks on them. Most RCA connectors are connected to one of four types of signals: component video (PAL or NTSC, depending on where the equipment was sold), composite video, stereo audio, or S/PDIF audio.

Female RCA connector, for video signals. Typically, NTSC or PAL video signal connectors will be yellow.

Male RCA connectors are usually found on cables.

Male RCA plugs. Red and white are usually for audio applications, with red denoting the "right" audio channel.

Power Connectors

While many connectors carry power in addition to data, some connectors are used specifically to provide power connections to devices. These vary widely by application and size, but we will only focus on some of the most common ones here.Barrel Connectors

Barrel connectors are typically found on low-cost consumer electronics which can be plugged into wall power via bulky AC wall adaptors. Wall adaptors are widely available, in a variety of power ratings and voltages, making barrel connectors a common means for connecting power to small projects.The female barrel connector, or "jack", can be purchased in several varieties: PCB mounted (surface mount or through hole), cable mount, or panel mount. Some of these connectors will have an additional contact that allows the application to detect whether a power supply is plugged into the barrel jack or not, thus allowing the device to bypass batteries and save battery life when running on external power.

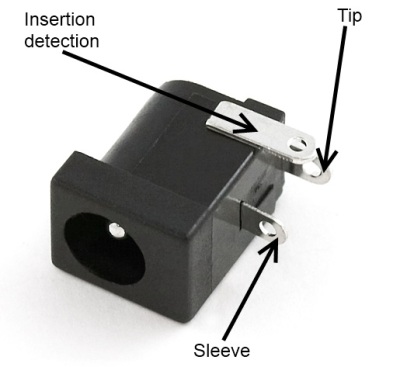

Female barrel connector. When no plug is inserted, the "insertion detection" pin will be shorted to the "sleeve" pin.

The male barrel connector, or "plug", is usually only found in a wire

termination variety, although there are multiple methods of attaching

the plug to the end of the wire. It's also possible to get plugs that

come pre-attached to a cable.

Unattached male barrel plug,

for attachment to any power supply. Note that the sleeve connection is

designed to be crimped onto the wire for extra strain relief.

Barrel connectors provide only two connections, frequently referred

to as "pin" or "tip" and "sleeve". When ordering, there are three

differentiating characteristics of a barrel connection- inner diameter

(the diameter of the pin inside the jack), outer diameter (the diameter

of the sleeve on the outside of the plug), and polarity (whether the

sleeve voltage is higher or lower than the tip voltage).Sleeve diameter is most commonly either 5.5mm or 3.5mm.

Pin diameter is contingent upon sleeve diameter; a 5.5mm sleeve will have either a 2.5mm or 2.1mm pin. Unfortunately, this means that a plug designed for a 2.5mm pin will fit in a 2.1mm jack, but that the connection will be, at best, intermittent. 3.5mm sleeve plugs usually mate to a jack with a 1.3mm pin.

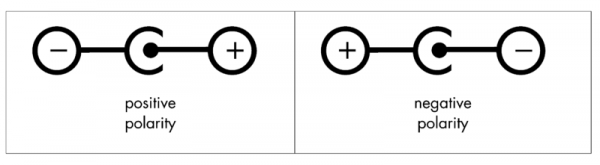

Polarity is the final aspect to consider; most often, the sleeve will be considered 0V and the tip will be a positive voltage relative to the sleeve. Many devices will have a small diagram indicating the polarity expected by the device; care should be taken to adhere to this, as an improper power supply may damage the device.

Plugs of both sleeve sizes are usually 9.5mm long, but longer and shorter ones do exist. All SparkFun products use a negative 5.5mm sleeve and a positive 2.1mm pin; we recommend sticking to that standard where possible, as it seems to be the most common flavor found in the wild.

Common polarity

diagrams for AC adaptors with barrel plugs. Positive polarity (tip

positive, sleeve 0V) is most common. Diagram courtesy Wikipedia user Three-quarter-ten.

"Molex" Connectors

Most computer hard drives, optical drives, and other internal peripherals get power through what is typically called a "Molex" connector. To be more accurate, it's a Molex series 8981 connector--Molex is actually the name of the company which initially designed this connector back in the 1950s--but common usage has denuded that fact somewhat.Molex connectors are designed to carry a lot of current: up to 11A per pin. For projects where a lot of power may be needed--a CNC machine, for instance, or a 3D printer- a very common method for powering the project is to use a desktop PC power supply and connecting the various system circuits through Molex connectors.

The Molex connector is one where the male/female terminology is a bit odd. The female connector is usually found on the end of a cable, and it slips inside of a plastic shell which surrounds the male pins on the male connector. Usually, the connectors are press-fit only, and very, very tight--they are intended to be connected and disconnected only a few times and, as such, are a bad choice for systems where connections will frequently be changed.

Male Molex connector. The gender of the pins inside the connector is what signifies the gender of the connector as a whole.

Female Molex connector on a project power supply.

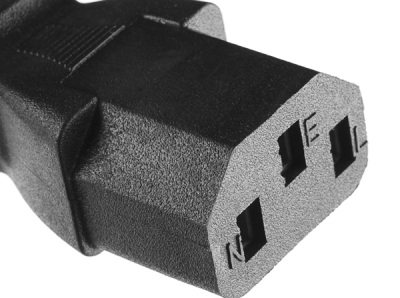

IEC Connector

As with the Molex connector, this is a case where a generalized component name has come to be synonymous with a single, particular item. IEC connector usually refers to the power supply inlet which is commonly seen on desktop PC power supplies. Strictly speaking, that's an IEC 60320-1 C13 (female) and C14 (male) connector.

C14 male IEC power inlet, on a DC project power supply. Note that, as with the Molex connector, the gender of the connector is defined by the pins within the hood.

C13 female IEC power connector, on a fairly standard AC power supply cable. Cables with this end can be found all around the world, usually with the dominant local AC connector at the other end.

IEC connectors are used almost exclusively for AC power input. The

nice thing about using one on a project is that IEC-to-wall cables are

extremely common and available with localized wall plugs for most international locations!JST Connector

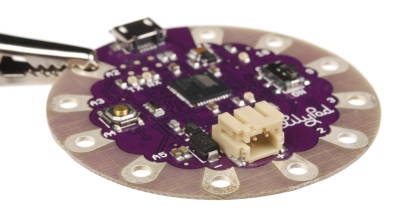

At SparkFun, we frequently refer to "2.0mm JST Connectors". This is yet another generalization of a specific product- JST is a Japanese company which makes high-quality connectors, and our 2.0mm JST connector of choice is the PH series two-position polarized connector.All of SparkFun's single-cell lithium-polymer ion batteries come standard with this type of JST connector, and many of our boards include this connector (or a footprint for it) as a power supply input. It has the advantage of being compact, durable, and difficult to connect backwards. Another feature, which can be an advantage or a disadvantage, depending on how you look at it, is that the JST connector is wicked hard to disconnect (although a carefully applied diagonal cutter can be helpful!) once it's mated. While this makes it unlikely to fail during use, it also means that disconnecting the battery for charging can damage the battery connector.

2-Pin JST male connector on a LilyPad Arduino USB board. Again, as with the Molex, the pins inside the hood determine the gender of the connector.

There are PH series connectors with more than two positions; SparkFun

even sells them. However, our most frequent application is for the

2-position battery connection.SMA Antenna Connectors

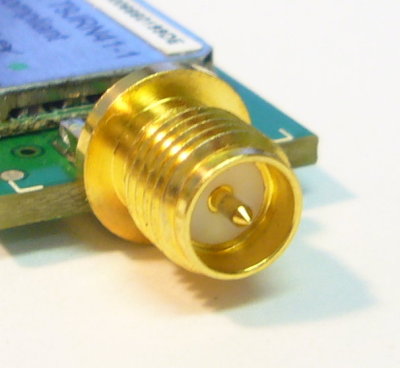

Next up is the explanation of the confusing naming conventions for SMA connectors. If you would rather not understand why the convention is the way it is, you can just look at the 4 pictures and move on. Otherwise, have fun with the read!RF Connector Conventions

SparkFun uses SMA-type connectors on a few boards that need a 50 Ohm impedance connection to an external antenna (GPS, Bluetooth, cellular, Nordic, and XBee). However, some of these boards use different genders and polarities of the SMA connector. Therefore, we need different antennas to match the specific gender or polarity of the RF connections.There are 4 different types of SMA connectors using a combination of gender, which refers to the center pin and polarity, which refers to…..uh, this is where it gets confusing. Wikipedia tries to explain it. But from what I have found there was an original “old” design for SMA connectors.

SMA Connectors

The original SMA design called for two compliant connectors: |

|

| SMA Male Center Pin, Inner Threads |

SMA Female Center Hole, Outer Threads |

There is one consistency however; all antennas, cables or anything was being attached to a potential stationary object used an outer nut or inner thread design and all stationary devices used the outer thread design. This applies for all SparkFun products. All of our antennas are either SMA male or RP-SMA female. All of our boards are either SMA female or RP-SMA male.

RP-SMA Connectors

The only thing that changed with the Part 15 compliance was the center pin, thus reversing the polarity of the connection and forming a “new” standard; the reversed polarized SMA (RP-SMA). The RP (reverse polarity) is named after its “thread gender” and has an opposite-gender pin.The next two photos are considered reversed polarized (RP-SMA).

|

|

| RP-SMA Male Center Hole, “Male” Inner Threads |

RP-SMA Female Center Pin, “Female” Outer Threads |

- Cellular and GPS (900/1700/1800MHz and 1.57542GHz respectively) generally use the old convention: SMA male for the antennas and SMA female for the modules.

- Anything 2.4GHz (Bluetooth, ZigBee, WiFi, and Nordic) generally use the new convention: RP-SMA male on the antennas and RP-SMA female on the modules.

And just in case if you happen to find the old and new mixing, we sell a SMA male to RP-SMA male and a RP-SMA female to RP-SMA male connector that will most combinations of antenna and connector to be mated.

Pin Header Connectors

Pin header connectors comprise several different means of connection. Generally, one side is a series of pins which are soldered to a PCB, and they can either be at a right-angle to the PCB surface (usually called "straight") or parallel to the board's surface (confusingly referred to as "right-angle" pins). Such connectors come in a variety of pitches, and may have any number of individual rows of pins.

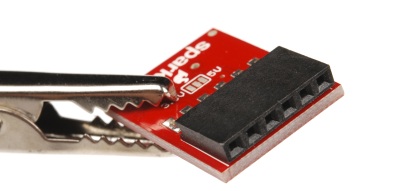

Right-angle female header pin connection on an FTDI basic board.

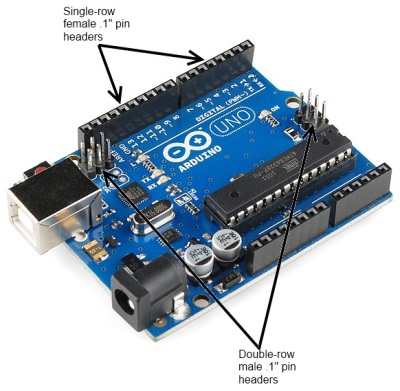

The most commonly seen pin headers are .1" single or double row connectors. These come in male and female

versions, and are the connectors used to connect Arduino boards and

shields together. Other pitches are not uncommon; for instance, the XBee wireless module uses a 2.0mm pitch version of the same connector.

.1" pin header connectors, male and female, on an Arduino Uno board.

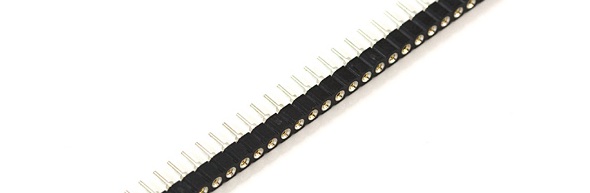

A common variation on this part is a "machine pin" version. While the

normal version is formed out of stamped and folded sheet metal, machine

pin connectors are formed by tooling the metal into the desired shape.

The result is a more robust connector, with a better joint and longer

life, making it somewhat more expensive.

Female machine pin headers.

Note that these are designed to be snapped apart into smaller sections,

while standard .1" female header pin connectors are not. It's also

important to note that not all non-machine pin header connectors will

mate with the machine pin variety.

Cables made to connect to these pin headers are usually one of two types: individual wires with crimp connectors on them or ribbon cables with insulation displacement

connectors. These can simply be clamped onto the end of a ribbon cable,

which creates a connection to each one of the conductors in the ribbon

cable. Generally, cables are only available as female gender and expect a

male pin to mate with.

Six-position crimp-type cable. Each wire is individually stripped, a connector crimped to it, and then the connectors are inserted into the plastic frame.

2x5 insulation displacement connectors (IDC) on a ribbon cable.

This type of cable can be quickly assembled because it does not require

stripping of individual connectors. It also has polarizing tabs on each

end, to prevent incorrect insertion in the mating board-side connector.

Temporary Connectors

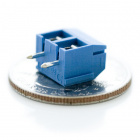

Screw Terminals

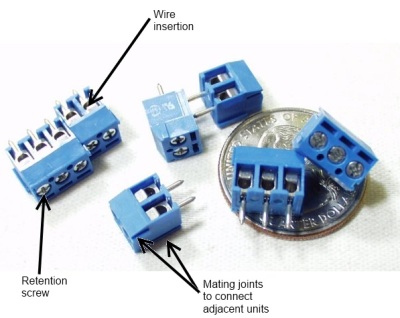

In some cases, it may be desirable to be able to connect bare, unterminated wire to a circuit. Screw terminals provide a good solution for this. They are also good for situations in which a connection should be capable of supporting multiple different connecting devices.The downside of screw terminals is that they can come undone fairly easily, leaving a bare wire waving around in your circuit. A small dab of hot glue can address this without being too difficult to remove later.

Screw terminals are typically designed for a narrow range of wire gauges, and wires that are too small can be as big a problem as wires that are too big. SparkFun carries four types of screw terminal – a 2.54mm (0.1" breadboard standard), a 3.5mm, 5mm, and 10mm pitch version.

Most screw terminals are highly modular, and they can easily be

extended at the same pitch by simply connecting two or more smaller

sections together.

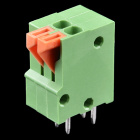

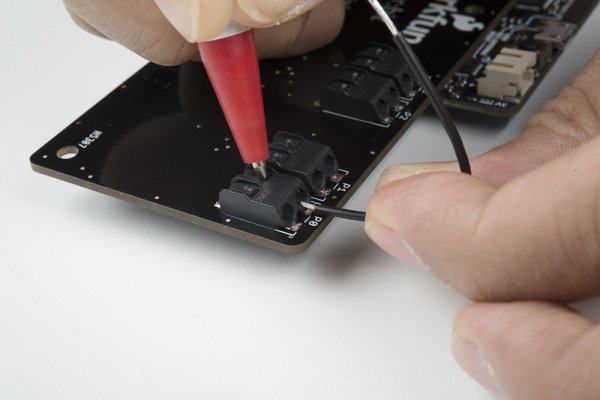

Spring terminals provide an alternative to screw terminals. They work better in environments with a lot of vibrations (i.e. automotive applications) or when a wire expanding/contracting due to temperature cycling. Additionally, the tension is automatically adjusted to the wire gauge (assuming it is within the accepted wire thickness) as opposed to variances in tension when a user tightens the screw terminal. Below are a few spring terminal connectors that SparkFun carries in the catalog.

Certain boards (like the gamer:bit, LumiDrive, and Qwiic MP3 Trigger to name a few) are populated with a spring terminal for easy access to I/O pins.

3.5mm pitch screw terminals,

showing the insertion point of the wire to be connected, the retention

screw which holds the wire in place, and the modular connectors on the

sides of the individual units allowing multiple pieces to be ganged

together.

Spring Terminals

Alternatives to screw terminals include spring terminals (a.k.a. "push-in", "cage-clamp", or "poke-home" connectors). Spring terminals work in a similar fashion as screw terminals. However, instead of tightening a screw to make a connection with piece of wire, a spring clamps together pieces of metal together.Spring terminals provide an alternative to screw terminals. They work better in environments with a lot of vibrations (i.e. automotive applications) or when a wire expanding/contracting due to temperature cycling. Additionally, the tension is automatically adjusted to the wire gauge (assuming it is within the accepted wire thickness) as opposed to variances in tension when a user tightens the screw terminal. Below are a few spring terminal connectors that SparkFun carries in the catalog.

A ball-point pen pressing down on the tab of the gamer:bit's poke-home connector to connect a piece of wire.

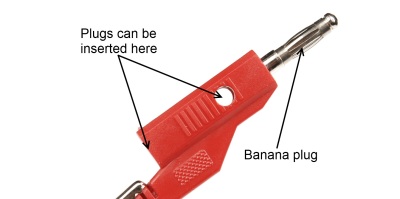

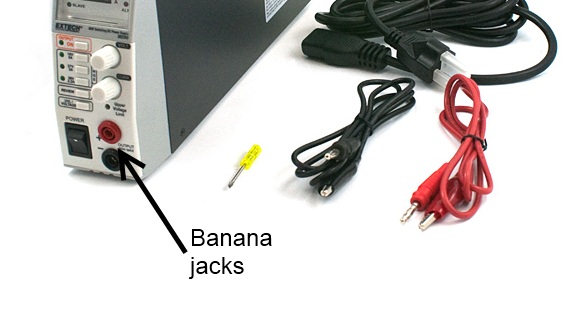

Banana Connector

Most pieces of power test equipment (multimeters, power supplies) have a very simple connector called a "banana jack" on it. These mate to "banana plugs", crimped, sprung metal plugs, meant to make a single power connection. They are frequently available in a stackable configuration and can be easily connected to any type of wire. They are capable of carrying several amps of current and are inexpensive.

Stackable banana plug. Note that there are two different ways to plug in an additional banana plug.

Extech variable bench supply with banana jacks on the front.

Alligator Clip

Named for obvious reasons, alligator clips are good for test connections to posts or bare wires. They tend to be bulky, easily cause shorts to nearby bare metal, and have a reasonably poor grip that can be easily compromised. They are primarily used for low-cost connections during debugging.

A "third hand" tool, which uses alligator clips to hold work pieces, holding a wire terminated with an alligator clip for electrical test. Note the plastic boot surrounding the alligator clip, to make it less likely to short to other connections.

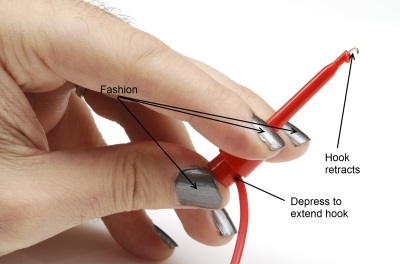

IC Clip (or IC Hook)

For more delicate probing operations, there are a variety of IC clips on the market. These are sized to allow a user to clip them onto the pins of an IC without contacting adjacent pins; some of them are delicate enough to be clipped onto even fine-pitched SMD component legs. These smaller clips can be found on logic analyzers as well as test leads, which are great for prototyping or troubleshooting circuits.

A large IC clip on the end of a wire.

This clip is still small enough to be connected to a single leg on a

through-hole chip without causing a problem for adjacent pins.

Other Connectors

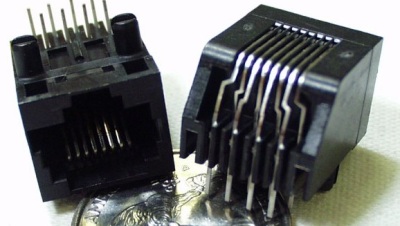

RJ-type Modular Connectors

Registered jack connectors are standard for telecommunications equipment into a local exchange. The names one normally hears associated with them (RJ45, RJ12, etc) are not necessarily correct, as the RJ designator is a based on a combination of the number of positions, the number of conductors actually present, and the wiring pattern. For example, while the ends of a standard ethernet cable are usually referred to as "RJ45", RJ45 actually implies not only an 8 position, 8 conductor modular jack, it also implies that it is wired for ethernet.These modular connectors can be very useful, since they combine ready availability, multiple conductors, moderate flexibility, low cost, and moderate current carrying capacity. While not originally intended to deliver a great deal of power, these cables can be used to deliver data and a couple of hundred milliamps from one device to another. Care should be taken to ensure that jacks provided for applications like this are not connected to conventional ethernet ports, as damage will result.

A standard 8p8c (8-position, 8-conductor) "RJ45" modular jack. Be aware that if you intend to use this type of jack to pass DC signals and power, you must avoid using connectors with built-in signal transformers.

D-sub Type Connectors

Named for the shape of their shell, D-subminiature connectors are a classic standard in the computing world. There are four very common varieties of this connector: DA-15, DB-25, DE-15, and DE-9. The pin number indicates the number of connections provided, and the letter combination indicates the size of the shell. Thus, DE-15 and DE-9 have the same shell size, but a different number of connections.

Female DE-9 board-mount connector.

Gender is defined by the pins or sockets associated with each signal,

not the connector as a whole, making this connector female despite the

fact that it effectively inserts into the shell of the mating connector.

DB-25 and DE-9 are the most useful to the hardware hacker; many

desktop computers still include at least one DE-9 serial port, and often

one DB-25 parallel port. Cables terminated with DE-9 and DB-25

connectors are widely available, too. As with the modular connector

above, these can be used to provide power and point-to-point

communications between two devices. Again, since the common usage of

these cables does not include power transmission, it is very

important that any repurposing of the cables be done cautiously, as a

non-standard device plugged into a standard port can easily cause

damage._________________________________________________________________________________

SOLDERING

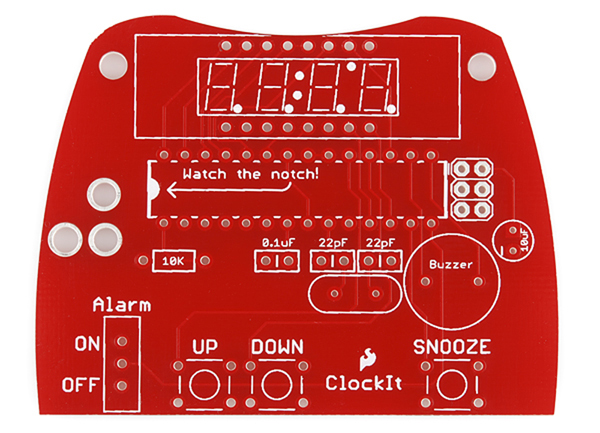

PCB Basics

Overview

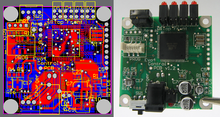

One of the key concepts in electronics is the printed circuit board or PCB. It's so fundamental that people often forget to explain what a PCB is. This tutorial will breakdown what makes up a PCB and some of the common terms used in the PCB world.Over the next few pages, we'll discuss the composition of a printed circuit board, cover some terminology, a look at methods of assembly, and discuss briefly the design process behind creating a new PCB.

What's a PCB?

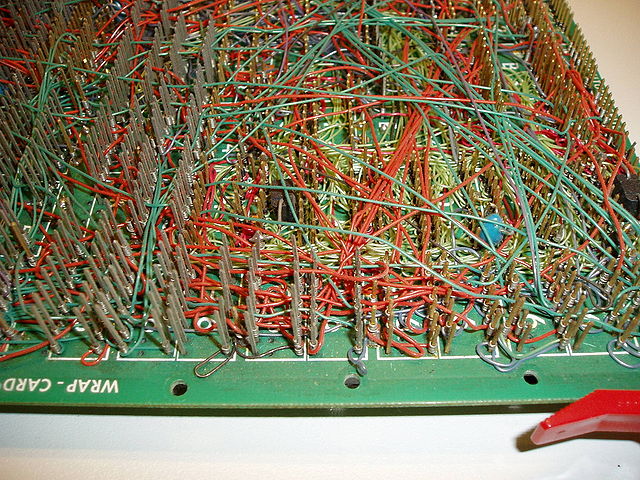

Printed circuit board is the most common name but may also be called "printed wiring boards" or "printed wiring cards". Before the advent of the PCB circuits were constructed through a laborious process of point-to-point wiring. This led to frequent failures at wire junctions and short circuits when wire insulation began to age and crack.->

courtesy Wikipedia user Wikinaut <-

A significant advance was the development of wire wrapping, where a small gauge wire is literally wrapped around a post at each connection point, creating a gas-tight connection which is highly durable and easily changeable.

As electronics moved from vacuum tubes and relays to silicon and integrated circuits, the size and cost of electronic components began to decrease. Electronics became more prevalent in consumer goods, and the pressure to reduce the size and manufacturing costs of electronic products drove manufacturers to look for better solutions. Thus was born the PCB.

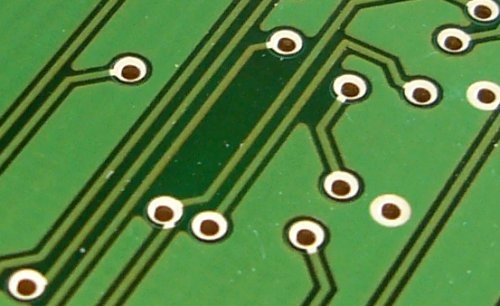

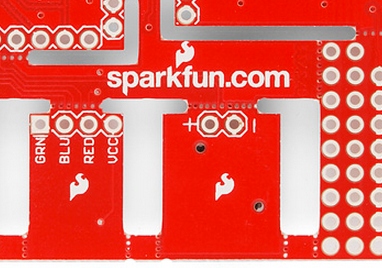

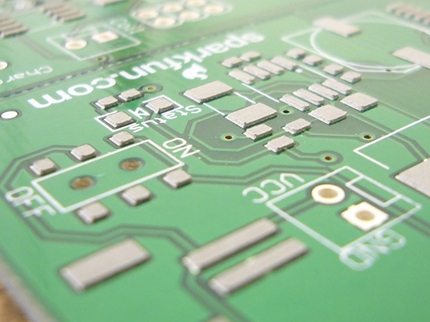

PCB is an acronym for printed circuit board. It is a board that has lines and pads that connect various points together. In the picture above, there are traces that electrically connect the various connectors and components to each other. A PCB allows signals and power to be routed between physical devices. Solder is the metal that makes the electrical connections between the surface of the PCB and the electronic components. Being metal, solder also serves as a strong mechanical adhesive.

Composition

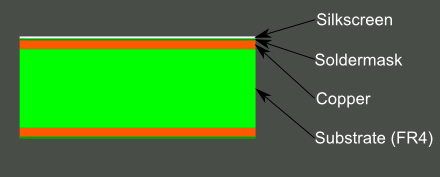

A PCB is sort of like a layer cake or lasagna- there are alternating layers of different materials which are laminated together with heat and adhesive such that the result is a single object.Let's start in the middle and work our way out.

FR4

The base material, or substrate, is usually fiberglass. Historically, the most common designator for this fiberglass is "FR4". This solid core gives the PCB its rigidity and thickness. There are also flexible PCBs built on flexible high-temperature plastic (Kapton or the equivalent).You will find many different thickness PCBs; the most common thickness for SparkFun products is 1.6mm (0.063"). Some of our products- LilyPad boards and Arudino Pro Micro boards- use a 0.8mm thick board.

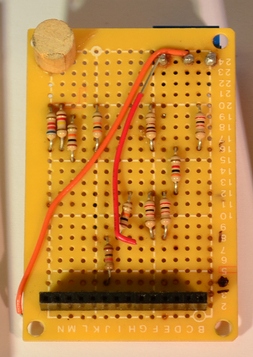

Cheaper PCBs and perf boards (shown above) will be made with other materials such as epoxies or phenolics which lack the durability of FR4 but are much less expensive. You will know you are working with this type of PCB when you solder to it - they have a very distictive bad smell. These types of substrates are also typically found in low-end consumer electronics. Phenolics have a low thermal decomposition temperature which causes them to delaminate, smoke and char when the soldering iron is held too long on the board.

Copper

The next layer is a thin copper foil, which is laminated to the board with heat and adhesive. On common, double sided PCBs, copper is applied to both sides of the substrate. In lower cost electronic gadgets the PCB may have copper on only one side. When we refer to a double sided or 2-layer board we are referring to the number of copper layers (2) in our lasagna. This can be as few as 1 layer or as many as 16 layers or more.

PCB with copper exposed, no solder mask or silkscreen.

The copper thickness can vary and is specified by weight, in ounces

per square foot. The vast majority of PCBs have 1 ounce of copper per

square foot but some PCBs that handle very high power may use 2 or 3

ounce copper. Each ounce per square translates to about 35 micrometers

or 1.4 thousandths of an inch of thickness of copper.Soldermask

The layer on top of the copper foil is called the soldermask layer. This layer gives the PCB its green (or, at SparkFun, red) color. It is overlaid onto the copper layer to insulate the copper traces from accidental contact with other metal, solder, or conductive bits. This layer helps the user to solder to the correct places and prevent solder jumpers.In the example below, the green solder mask is applied to the majority of the PCB, covering up the small traces but leaving the silver rings and SMD pads exposed so they can be soldered to.

Soldermask is most commonly green in color but nearly any color is possible. We use red for almost all the SparkFun boards, white for the IOIO board, and purple for the LilyPad boards.

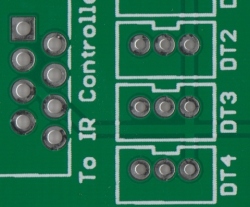

Silkscreen

The white silkscreen layer is applied on top of the soldermask layer. The silkscreen adds letters, numbers, and symbols to the PCB that allow for easier assembly and indicators for humans to better understand the board. We often use silkscreen labels to indicate what the function of each pin or LED.Silkscreen is most commonly white but any ink color can be used. Black, gray, red, and even yellow silkscreen colors are widely available; it is, however, uncommon to see more than one color on a single board.

Terminology

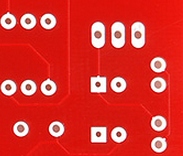

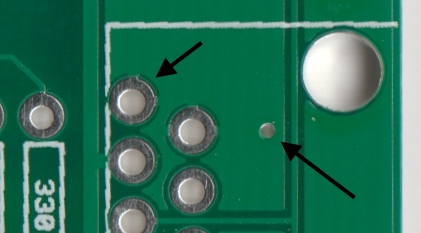

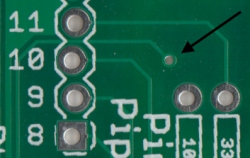

Now that you've got an idea of what a PCB structure is, let's define some terms that you may hear when dealing with PCBs:- Annular ring - the ring of copper around a plated through hole in a PCB.

Examples of annular rings.

- DRC - design rule check. A software check of your design to make sure the design does not contain errors such as traces that incorrectly touch, traces too skinny, or drill holes that are too small.

- Drill hit - places on a design where a hole should be drilled, or where they actually were drilled on the board. Inaccurate drill hits caused by dull bits are a common manufacturing issue.

Not so accurate, but functional drill hits.

- Finger - exposed metal pads along the edge of a board, used to create a connection between two circuit boards. Common examples are along the edges of computer expansion or memory boards and older cartridge-based video games.

- Mouse bites - an alternative to v-score for separating boards from panels. A number of drill hits are clustered close together, creating a weak spot where the board can be broken easily after the fact. See the SparkFun Protosnap boards for a good example.

Mouse bites on the LilyPad ProtoSnap allow the PCB to be snapped apart easily.

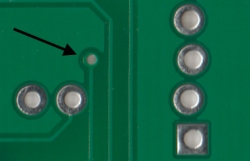

- Pad - a portion of exposed metal on the surface of a board to which a component is soldered.

PTH (plated through-hole) pads on the left, SMD (surface mount device) pads on the right.

- Panel - a larger circuit board composed of many smaller boards which will be broken apart before use. Automated circuit board handling equipment frequently has trouble with smaller boards, and by aggregating several boards together at once, the process can be sped up significantly.

- Paste stencil - a thin, metal (or sometimes plastic) stencil which lies over the board, allowing solder paste to be deposited in specific areas during assembly.

- Plane - a continuous block of copper on a circuit board, define by borders rather than by a path. Also commonly called a "pour".

Various portions of the PCB that have no traces but has a ground pour instead.

- Plated through hole - a hole on a board which has an annular ring and which is plated all the way through the board. May be a connection point for a through hole component, a via to pass a signal through, or a mounting hole.

A PTH resistor inserted into the FabFM

PCB, ready to be soldered. The legs of the resistor go through the

holes. The plated holes can have traces connected to them on the front

of the PCB and the rear of the PCB.

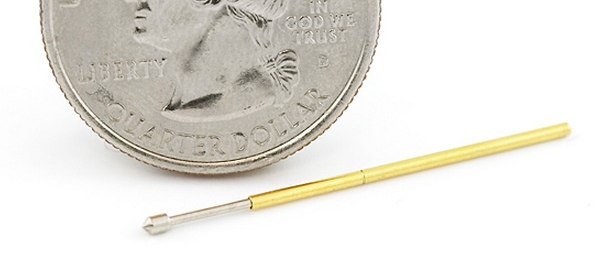

- Pogo pin - spring-loaded contact used to make a temporary connection for test or programming purposes.

The popular pogo pin with pointed tip. We use tons of these on our test beds.

- Reflow - melting the solder to create joints between pads and component leads.

- Silkscreen - the letters, number, symbols, and imagery on a circuit board. Usually only one color is available, and resolution is usually fairly low.

Silkscreen identifying this LED as the power LED.

- Slot - any hole in a board which is not round. Slots may or may not be plated. Slots sometimes add to add cost to the board because they require extra cut-out time.

Complex slots cut into the ProtoSnap - Pro Mini. There are also many mouse bites shown. Note: the corners of the slots cannot be made completely square because they are cut with a circular routing bit.

- Solder paste - small balls of solder suspended in a gel medium which, with the aid of a paste stencil, are applied to the surface mount pads on a PCB before the components are placed. During reflow, the solder in the paste melts, creating electrical and mechanical joints between the pads and the component.

Solder paste on a PCB shortly before the components are placed. Be sure to read about *paste stencil above as well.*

- Solder pot - a pot used to quickly hand solder boards with through hole components. Usually contains a small amount of molten solder into which the board is quickly dipped, leaving solder joints on all exposed pads.

- Soldermask - a layer of protective material laid over the metal to prevent short circuits, corrosion, and other problems. Frequently green, although other colors (SparkFun red, Arduino blue, or Apple black) are possible. Occasionally referred to as "resist".

Solder mask covers up the signal traces but leaves the pads to solder to.

- Solder jumper - a small, blob of solder connecting two adjacent pins on a component on a circuit board. Depending on the design, a solder jumper can be used to connect two pads or pins together. It can also cause unwanted shorts.

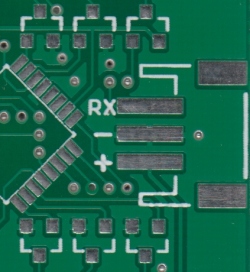

- Surface mount - construction method which allows components to be simply set on a board, not requiring that leads pass through holes in the board. This is the dominant method of assembly in use today, and allows boards to be populated quickly and easily.

- Thermal - a small trace used to connect a pad to a plane. If a pad is not thermally relieved, it becomes difficult to get the pad to a high enough temperature to create a good solder joint. An improperly thermally relieved pad will feel "sticky" when you attempt to solder to it, and will take an abnormally long time to reflow.

On the left, a solder

pad with two small traces (thermals) connecting the pin to the ground

plane. On the right, a via with no thermals connecting it completely to

the ground plane.

- Thieving - hatching, gridlines, or dots of copper left in areas of a board where no plane or traces exist. Reduces difficulty of etching because less time in the bath is required to remove unneeded copper.

- Trace - a continuous path of copper on a circuit board.

- V-score- a partial cut through a board, allowing the board to be easily snapped along a line.

- Via - a hole in a board used to pass a signal from one layer to another. Tented vias are covered by soldermask to protect them from being soldered to. Vias where connectors and components are to be attached are often untented (uncovered) so that they can be easily soldered.

Front and back of the

same PCB showing a tented via. This via brings the signal from the front

side of the PCB, through the middle of the board, to the back side.

- Wave solder - a method of soldering used on boards with through-hole components where the board is passed over a standing wave of molten solder, which adheres to exposed pads and component leads.

Designing Your Own!

How do you go about designing your own PCB? The ins and outs of PCB design are way too in depth to get into here, but if you really want to get started, here are some pointers:- Find a CAD package: there are a lot of low-cost or free options out

there on the market for PCB design. Things to consider when choosing a

package:

- Community support: are there a lot of people using the package? The more people using it, the more likely you are to find ready-made libraries with the parts you need.

- Ease-of-use: if it's painful to use it, you won't.

- Capability: some programs place limitations on your design- number of layers, number of components, size of board, etc. Most of them allow you to pay for a license to upgrade their capability.

- Portability: some free programs do not allow you to export or convert your designs, locking you in to one supplier only. Maybe that's a fair price to pay for convenience and price, maybe not.

- Look at other people's layouts to see what they have done. Open Source Hardware makes this easier than ever.

- Practice, practice, practice.

- Maintain low expectations. Your first board design will have lots of problems. Your 20th board design will have fewer, but will still have some. You'll never get rid of them all.

- Schematics are important. Trying to design a board without a good schematic in place first is an exercise in futility.

Printed circuit board

A printed circuit board (PCB) mechanically supports and electrically connects electronic components or electrical components using conductive tracks, pads and other features etched from one or more sheet layers of copper laminated onto and/or between sheet layers of a non-conductive substrate. Components are generally soldered onto the PCB to both electrically connect and mechanically fasten them to it.Printed circuit boards are used in all but the simplest electronic products. They are also used in some electrical products, such as passive switch boxes.

Alternatives to PCBs include wire wrap and point-to-point construction, both once popular but now rarely used. PCBs require additional design effort to lay out the circuit, but manufacturing and assembly can be automated. Specialized CAD software is available to do much of the work of layout. Mass-producing circuits with PCBs is cheaper and faster than with other wiring methods, as components are mounted and wired in one operation. Large numbers of PCBs can be fabricated at the same time, and the layout only has to be done once. PCBs can also be made manually in small quantities, with reduced benefits.

PCBs can be single-sided (one copper layer), double-sided (two copper layers on both sides of one substrate layer), or multi-layer (outer and inner layers of copper, alternating with layers of substrate). Multi-layer PCBs allow for much higher component density, because circuit traces on the inner layers would otherwise take up surface space between components. The rise in popularity of multilayer PCBs with more than two, and especially with more than four, copper planes was concurrent with the adoption of surface mount technology. However, multilayer PCBs make repair, analysis, and field modification of circuits much more difficult and usually impractical.

The world market for bare PCBs exceeded $60.2 billion in 2014. In 2018, the Global Single Sided Printed Circuit Board Market Analysis Report estimated that the PCB market would reach $79 billion by 2024.

A basic PCB consists of a flat sheet of insulating material and a layer of copper foil, laminated to the substrate. Chemical etching divides the copper into separate conducting lines called tracks or circuit traces, pads for connections, vias to pass connections between layers of copper, and features such as solid conductive areas for EM shielding or other purposes. The tracks function as wires fixed in place, and are insulated from each other by air and the board substrate material. The surface of a PCB may have a coating that protects the copper from corrosion and reduces the chances of solder shorts between traces or undesired electrical contact with stray bare wires. For its function in helping to prevent solder shorts, the coating is called solder resist.

A printed circuit board can have multiple copper layers. A two-layer board has copper on both sides; multi layer boards sandwich additional copper layers between layers of insulating material. Conductors on different layers are connected with vias, which are copper-plated holes that function as electrical tunnels through the insulating substrate. Through-hole component leads sometimes also effectively function as vias. After two-layer PCBs, the next step up is usually four-layer. Often two layers are dedicated as power supply and ground planes, and the other two are used for signal wiring between components.

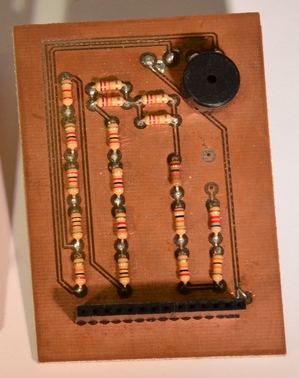

"Through hole" components are mounted by their wire leads passing through the board and soldered to traces on the other side. "Surface mount" components are attached by their leads to copper traces on the same side of the board. A board may use both methods for mounting components. PCBs with only through-hole mounted components are now uncommon. Surface mounting is used for transistors, diodes, IC chips, resistors and capacitors. Through-hole mounting may be used for some large components such as electrolytic capacitors and connectors.

The pattern to be etched into each copper layer of a PCB is called the "artwork". The etching is usually done using photoresist which is coated onto the PCB, then exposed to light projected in the pattern of the artwork. The resist material protects the copper from dissolution into the etching solution. The etched board is then cleaned. A PCB design can be mass-reproduced in a way similar to the way photographs can be mass-duplicated from film negatives using a photographic printer.

In multi-layer boards, the layers of material are laminated together in an alternating sandwich: copper, substrate, copper, substrate, copper, etc.; each plane of copper is etched, and any internal vias (that will not extend to both outer surfaces of the finished multilayer board) are plated-through, before the layers are laminated together. Only the outer layers need be coated; the inner copper layers are protected by the adjacent substrate layers.

FR-4 glass epoxy is the most common insulating substrate. Another substrate material is cotton paper impregnated with phenolic resin, often tan or brown.

When a PCB has no components installed, it is less ambiguously called a printed wiring board (PWB) or etched wiring board. However, the term "printed wiring board" has fallen into disuse. A PCB populated with electronic components is called a printed circuit assembly (PCA), printed circuit board assembly or PCB assembly (PCBA). In informal usage, the term "printed circuit board" most commonly means "printed circuit assembly" (with components). The IPC preferred term for assembled boards is circuit card assembly (CCA), and for assembled backplanes it is backplane assemblies. "Card" is another widely used informal term for a "printed circuit assembly". For example, expansion card.

A PCB may be "silkscreen" printed with a legend identifying the components, test points, or identifying text. Originally, an actual silkscreen printing process was used for this purpose, but today other, finer quality printing methods are usually used instead. Normally the screen printing is not significant to the function of the PCBA.

A minimal PCB for a single component, used for prototyping, is called a breakout board. The purpose of a breakout board is to "break out" the leads of a component on separate terminals so that manual connections to them can be made easily. Breakout boards are especially used for surface-mount components or any components with fine lead pitch.

Advanced PCBs may contain components embedded in the substrate

Characteristics

Through-hole technology

Through-hole (leaded) resistors

Through-hole manufacture adds to board cost by requiring many holes to be drilled accurately, and it limits the available routing area for signal traces on layers immediately below the top layer on multi-layer boards, since the holes must pass through all layers to the opposite side. Once surface-mounting came into use, small-sized SMD components were used where possible, with through-hole mounting only of components unsuitably large for surface-mounting due to power requirements or mechanical limitations, or subject to mechanical stress which might damage the PCB (e.g. by lifting the copper off the board surface).

- Through-hole devices mounted on the circuit board of a mid-1980s Commodore 64 home computer

- A box of drill bits used for making holes in printed circuit boards. While tungsten-carbide bits are very hard, they eventually wear out or break. Drilling is a considerable part of the cost of a through-hole printed circuit board.

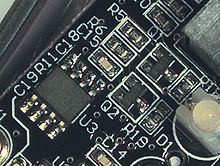

Surface-mount technology

Surface mount components, including resistors, transistors and an integrated circuit

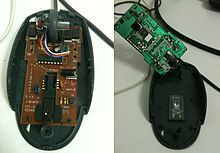

A PCB in a computer mouse: the component side (left) and the printed side (right)

Circuit properties of the PCB

Each trace consists of a flat, narrow part of the copper foil that remains after etching. Its resistance, determined by its width, thickness, and length, must be sufficiently low for the current the conductor will carry. Power and ground traces may need to be wider than signal traces. In a multi-layer board one entire layer may be mostly solid copper to act as a ground plane for shielding and power return. For microwave circuits, transmission lines can be laid out in a planar form such as stripline or microstrip with carefully controlled dimensions to assure a consistent impedance. In radio-frequency and fast switching circuits the inductance and capacitance of the printed circuit board conductors become significant circuit elements, usually undesired; conversely, they can be used as a deliberate part of the circuit design, as in distributed element filters, antennae, and fuses, obviating the need for additional discrete components.Materials

RoHS compliant PCB

The European Union bans the use of lead (among other heavy metals) in consumer items, a piece of legislature called the RoHS, for Restriction of Hazardous Substances, directive. PCBs to be sold in the EU must be RoHS-compliant, meaning that all manufacturing processes must not involve the use of lead, all solder used must be lead-free, and all components mounted on the board must be free of lead, mercury, cadmium, and other heavy metals.Laminates

Laminates are manufactured by curing under pressure and temperature layers of cloth or paper with thermoset resin to form an integral final piece of uniform thickness. The size can be up to 4 by 8 feet (1.2 by 2.4 m) in width and length. Varying cloth weaves (threads per inch or cm), cloth thickness, and resin percentage are used to achieve the desired final thickness and dielectric characteristics. Available standard laminate thickness are listed in ANSI/IPC-D-275.The cloth or fiber material used, resin material, and the cloth to resin ratio determine the laminate's type designation (FR-4, CEM-1, G-10, etc.) and therefore the characteristics of the laminate produced. Important characteristics are the level to which the laminate is fire retardant, the dielectric constant (er), the loss factor (tδ), the tensile strength, the shear strength, the glass transition temperature (Tg), and the Z-axis expansion coefficient (how much the thickness changes with temperature).

There are quite a few different dielectrics that can be chosen to provide different insulating values depending on the requirements of the circuit. Some of these dielectrics are polytetrafluoroethylene (Teflon), FR-4, FR-1, CEM-1 or CEM-3. Well known pre-preg materials used in the PCB industry are FR-2 (phenolic cotton paper), FR-3 (cotton paper and epoxy), FR-4 (woven glass and epoxy), FR-5 (woven glass and epoxy), FR-6 (matte glass and polyester), G-10 (woven glass and epoxy), CEM-1 (cotton paper and epoxy), CEM-2 (cotton paper and epoxy), CEM-3 (non-woven glass and epoxy), CEM-4 (woven glass and epoxy), CEM-5 (woven glass and polyester). Thermal expansion is an important consideration especially with ball grid array (BGA) and naked die technologies, and glass fiber offers the best dimensional stability.

FR-4 is by far the most common material used today. The board stock with unetched copper on it is called "copper-clad laminate".

With decreasing size of board features and increasing frequencies, small nonhomogeneities like uneven distribution of fiberglass or other filler, thickness variations, and bubbles in the resin matrix, and the associated local variations in the dielectric constant, are gaining importance.

Key substrate parameters

The circuitboard substrates are usually dielectric composite materials. The composites contain a matrix (usually an epoxy resin) and a reinforcement (usually a woven, sometimes nonwoven, glass fibers, sometimes even paper), and in some cases a filler is added to the resin (e.g. ceramics; titanate ceramics can be used to increase the dielectric constant).The reinforcement type defines two major classes of materials: woven and non-woven. Woven reinforcements are cheaper, but the high dielectric constant of glass may not be favorable for many higher-frequency applications. The spatially nonhomogeneous structure also introduces local variations in electrical parameters, due to different resin/glass ratio at different areas of the weave pattern. Nonwoven reinforcements, or materials with low or no reinforcement, are more expensive but more suitable for some RF/analog applications.

The substrates are characterized by several key parameters, chiefly thermomechanical (glass transition temperature, tensile strength, shear strength, thermal expansion), electrical (dielectric constant, loss tangent, dielectric breakdown voltage, leakage current, tracking resistance...), and others (e.g. moisture absorption).

At the glass transition temperature the resin in the composite softens and significantly increases thermal expansion; exceeding Tg then exerts mechanical overload on the board components - e.g. the joints and the vias. Below Tg the thermal expansion of the resin roughly matches copper and glass, above it gets significantly higher. As the reinforcement and copper confine the board along the plane, virtually all volume expansion projects to the thickness and stresses the plated-through holes. Repeated soldering or other exposition to higher temperatures can cause failure of the plating, especially with thicker boards; thick boards therefore require a matrix with a high Tg.

The materials used determine the substrate's dielectric constant. This constant is also dependent on frequency, usually decreasing with frequency. As this constant determines the signal propagation speed, frequency dependence introduces phase distortion in wideband applications; as flat a dielectric constant vs frequency characteristics as is achievable is important here. The impedance of transmission lines decreases with frequency, therefore faster edges of signals reflect more than slower ones.

Dielectric breakdown voltage determines the maximum voltage gradient the material can be subjected to before suffering a breakdown (conduction, or arcing, through the dielectric).

Tracking resistance determines how the material resists high voltage electrical discharges creeping over the board surface.

Loss tangent determines how much of the electromagnetic energy from the signals in the conductors is absorbed in the board material. This factor is important for high frequencies. Low-loss materials are more expensive. Choosing unnecessarily low-loss material is a common engineering error in high-frequency digital design; it increases the cost of the boards without a corresponding benefit. Signal degradation by loss tangent and dielectric constant can be easily assessed by an eye pattern.

Moisture absorption occurs when the material is exposed to high humidity or water. Both the resin and the reinforcement may absorb water; water also may be soaked by capillary forces through voids in the materials and along the reinforcement. Epoxies of the FR-4 materials aren't too susceptible, with absorption of only 0.15%. Teflon has very low absorption of 0.01%. Polyimides and cyanate esters, on the other side, suffer from high water absorption. Absorbed water can lead to significant degradation of key parameters; it impairs tracking resistance, breakdown voltage, and dielectric parameters. Relative dielectric constant of water is about 73, compared to about 4 for common circuit board materials. Absorbed moisture can also vaporize on heating, as during soldering, and cause cracking and delamination, the same effect responsible for "popcorning" damage on wet packaging of electronic parts. Careful baking of the substrates may be required to dry them prior to soldering.

Common substrates

Often encountered materials:- FR-2, phenolic paper or phenolic cotton paper, paper impregnated with a phenol formaldehyde resin. Common in consumer electronics with single-sided boards. Electrical properties inferior to FR-4. Poor arc resistance. Generally rated to 105 °C.

- FR-4, a woven fiberglass cloth impregnated with an epoxy resin. Low water absorption (up to about 0.15%), good insulation properties, good arc resistance. Very common. Several grades with somewhat different properties are available. Typically rated to 130 °C.

- Aluminum, or metal core board or insulated metal substrate (IMS), clad with thermally conductive thin dielectric - used for parts requiring significant cooling - power switches, LEDs. Consists of usually single, sometimes double layer thin circuit board based on e.g. FR-4, laminated on aluminum sheet metal, commonly 0.8, 1, 1.5, 2 or 3 mm thick. The thicker laminates sometimes also come with thicker copper metalization.

- Flexible substrates - can be a standalone copper-clad foil or can be laminated to a thin stiffener, e.g. 50-130 µm

- Kapton or UPILEX, a polyimide foil. Used for flexible printed circuits, in this form common in small form-factor consumer electronics or for flexible interconnects. Resistant to high temperatures.

- Pyralux, a polyimide-fluoropolymer composite foil. Copper layer can delaminate during soldering.

- FR-1, like FR-2, typically specified to 105 °C, some grades rated to 130 °C. Room-temperature punchable. Similar to cardboard. Poor moisture resistance. Low arc resistance.

- FR-3, cotton paper impregnated with epoxy. Typically rated to 105 °C.

- FR-5, woven fiberglass and epoxy, high strength at higher temperatures, typically specified to 170 °C.

- FR-6, matte glass and polyester

- G-10, woven glass and epoxy - high insulation resistance, low moisture absorption, very high bond strength. Typically rated to 130 °C.

- G-11, woven glass and epoxy - high resistance to solvents, high flexural strength retention at high temperatures. Typically rated to 170 °C.

- CEM-1, cotton paper and epoxy

- CEM-2, cotton paper and epoxy

- CEM-3, non-woven glass and epoxy

- CEM-4, woven glass and epoxy

- CEM-5, woven glass and polyester

- PTFE, ("Teflon") - expensive, low dielectric loss, for high frequency applications, very low moisture absorption (0.01%), mechanically soft. Difficult to laminate, rarely used in multilayer applications.

- PTFE, ceramic filled - expensive, low dielectric loss, for high frequency applications. Varying ceramics/PTFE ratio allows adjusting dielectric constant and thermal expansion.

- RF-35, fiberglass-reinforced ceramics-filled PTFE. Relatively less expensive, good mechanical properties, good high-frequency properties.

- Alumina, a ceramic. Hard, brittle, very expensive, very high performance, good thermal conductivity.

- Polyimide, a high-temperature polymer. Expensive, high-performance. Higher water absorption (0.4%). Can be used from cryogenic temperatures to over 260 °C.

Copper thickness

Copper thickness of PCBs can be specified directly or as the weight of copper per area (in ounce per square foot) which is easier to measure. One ounce per square foot is 1.344 mils or 34 micrometers thickness. Heavy copper is a layer exceeding three ounces of copper per ft2, or approximately 0.0042 inches (4.2 mils, 105 μm) thick. Heavy copper layers are used for high current or to help dissipate heat.On the common FR-4 substrates, 1 oz copper per ft2 (35 µm) is the most common thickness; 2 oz (70 µm) and 0.5 oz (18 µm) thickness is often an option. Less common are 12 and 105 µm, 9 µm is sometimes available on some substrates. Flexible substrates typically have thinner metalization. Metal-core boards for high power devices commonly use thicker copper; 35 µm is usual but also 140 and 400 µm can be encountered.

Safety certification (US)

Safety Standard UL 796 covers component safety requirements for printed wiring boards for use as components in devices or appliances. Testing analyzes characteristics such as flammability, maximum operating temperature, electrical tracking, heat deflection, and direct support of live electrical parts.Design

A board designed in 1967; the sweeping curves in the traces are evidence of freehand design using adhesive tape

Modern PCBs are designed with dedicated layout software, generally in the following steps:

- Schematic capture through an electronic design automation (EDA) tool.

- Card dimensions and template are decided based on required circuitry and case of the PCB.

- The positions of the components and heat sinks are determined.

- Layer stack of the PCB is decided, with one to tens of layers depending on complexity. Ground and power planes are decided. A power plane is the counterpart to a ground plane and behaves as an AC signal ground while providing DC power to the circuits mounted on the PCB. Signal interconnections are traced on signal planes. Signal planes can be on the outer as well as inner layers. For optimal EMI performance high frequency signals are routed in internal layers between power or ground planes.

- Line impedance is determined using dielectric layer thickness, routing copper thickness and trace-width. Trace separation is also taken into account in case of differential signals. Microstrip, stripline or dual stripline can be used to route signals.

- Components are placed. Thermal considerations and geometry are taken into account. Vias and lands are marked.

- Signal traces are routed. Electronic design automation tools usually create clearances and connections in power and ground planes automatically.

- Gerber files are generated for manufacturing.

Manufacturing

PCB manufacturing consists of many steps.PCB CAM