Earthquake Engineering

Earthquake engineering is the design, development, and production of earthquake-resistant

structures. In many parts of the world, the designs of most buildings do not need to consider

the stresses of the ground shaking. However, buildings in areas prone to earthquakes need

to be designed so that their structures can withstand this unique kind of stress. Earthquake

engineers have developed a number of design strategies that help minimize the effects of

the earth shaking. These strategies include strong and light building skeletons, solid bases,

and bracing.

Engineers often use models to test designs on a small and manageable scale. In the

field of earthquake engineering, engineers use a shake table in order to model how their

earthquake resistant designs respond to vigorous shaking.The building is said to be safe in the event of natural disasters such as earthquakes, tsunamis, etc. are not experiencing collapsing or collapsed. Here I will discuss why a building should take into account the seismic force, let us consider what the sense of the earthquake. What the earthquake. ?? Earthquake rocks slab that is shifting earth that cause the ground above her moves in a way that can mobilize all the existing buildings on it. While a working system of buildings / earthquake resistant buildings d say whether the building is earthquake resistant because it can withstand earthquake loads by strengthening its structure is by way shear wall or by other means in order to minimize the earthquake is by the use of dampers. This tool is typically used in high-rise buildings or bridges. The purpose of the damper is to reduce the sway of a building / buildings caused by the earthquake or wind. The use of this damper is already used in Japan, such as the earthquakes in Japan some time ago. Damage to the size of structural components and non-structure due to ground movement does not only depend on the characteristics of the earthquake alone. Here are some of the main factors that affect damage to buildings caused by the earthquake: 1. Characteristics of the earthquake that occurred Acceleration peak ground surface seismic Long Duration Frequency earthquake fault 2. Characteristics of the location where the building will be erected Distance buildings to the epicenter of the geological structure of the building to the epicenter Type subsoil location building land location time natural shakes buildings 3. Characteristics of natural shakes time structure of the building structure damping (damping) of the building structure detailing terms and concepts are planned. The main factor of one (1) and two (2) above is a natural occurrence that must be taken into account its impact on the buildings planned, but the factors which the third (3) the properties of the dynamic of the building that can be altered or engineered such that the effect of the quake on the buildings planned can be minimized. So it's a difficult thing to avoid damage to buildings caused by the earthquake, when used in conventional planning, because it depends on the strength of structural components themselves, as well as post-elastic response behavior. Here are some examples of buildings that were damaged by the earthquake that occurred tectonic field on September 30, 2009 when a magnitude 7.6 on the Richter scale. The size of the damage to buildings in the city is mainly due to factors related to the structural characteristics of detailing and structural design concepts philosophy strong column-weak beam is not implemented.

Along with the development of technology in planning earthquake-resistant building, have developed an alternative design approach to reduce the risk of damage to buildings caused by the earthquake, and is able to maintain the integrity of structural components and non-structural seismic strong. This design approach is not the way to strengthen the structure of the building, but it is by reducing the seismic forces that work on the building or add to a system on a structure devoted to absorb most of the seismic energy that went into the building and only a small portion (the rest) will be borne by the component structure the building itself. One concept planning approach that has been used by many people is to use structural control devices such as base isolation system or the use of passive energy dissipation. Here are some types of buildings often use the system in order to control structural damage to buildings in the event of a strong earthquake can be minimized and do not disturb the operation of the building. Building Facility related emergency (hospitals, power plants, telecommunications, etc.) Building with components or materials at high risk for living beings (nuclear facilities, chemicals, etc.) building into contact with the (mall, apartments, office , schools, etc.) building related to the national defense building that has components and electronic equipment that is expensive building / museum / monument relating to the history by implementing control systems on the structure of the expected performance of the building can be entered at the level of operational performance. STRUCTURAL CONTROL SYSTEMS (STRUCTURAL CONTROL DEVICES) There are some structural response control systems due to seismic forces where these systems can be classified into three (3) major groups namely: Semi active active-control systems, control systems and passive base isolation system as in Figure 3. System this has been widely used Country - Countries that have a high risk of earthquakes such as Japan, Italy, USA, New Zealand, Portugal, Iran, Indonesia, Turkey, China, and Taiwan. Although the use of the system is still limited, seismic isolation systems and energy dissipator passive or a combination of structural control system is the most widely applied in buildings in the world to control the response of buildings in the quake. Structural passive control system does not require electrical energy (power) to generate control forces on the structure. In passive systems control forces generated by the system itself, which arises because of the relative motion of the dots themselves part of the structure, while the active control systems require external energy to drive the actuator to control the desired style for output structure. To measure the response of the structure needed a sensor that is connected to the computer. The sensor sends information about the structure of the response to the computer and the computer determines the desired force actuator based on such information. Excess active control system is generating respons appropriate structure, while the drawback is its high cost because it requires power from the outside is quite large.

SYSTEM ISOLATION BASE (BASE Isolation SYSTEM) The main principle of how the base isolators types of elastomeric bearings (HDRB or LRB) is to extend the time vibrate naturally structure outside of the frequency of the dominant quake to 2.5 or 3 times from the time of the vibrating structure without insulator (fixed base structures) and has damping between 10 s / d 20%. Consequently earthquake forces transmitted to the structure becomes smaller. While on friction pendulum systemh (FPS), parameters that affect the magnitude of the reduction of seismic forces working on the structure is the coefficient of friction and a radius of curvature of the concave surface of the sliding plane FPS system. Besides, the unique features of this system is a vibrating structure does not depend on the mass of the building but it depends on the radius of curvature and the acceleration of gravity of the FPS system. Dissipation of energy generated by friction on the surface of PTPE material (Teflon) while the restoring force generated by a spring made of polyurethane. To carry the vertical force and rotation that occurs is provided bearing called Polytron disk (Figure 5). The advantages of this system is to have a large enough damping can reach up to 60% of critical damping.

above is a theory that takes into account / minimize seismic forces on buildings.

EARTHQUAKE RESISTANT BUILDING

What it earthquake resistant buildings? Why should buildings earthquake resistant? What are the basic principles of earthquake resistant buildings?

There is a slight error in our common picture, because many thought that the building should be 'anti' earthquake, not 'hold' earthquake. So what's the difference?

Buildings erected on the land would have been affected by the vibrations of the soil itself. This means that the building is certainly exposed to vibration, whether it's an earthquake or other vibration. Therefore, the building is not 'anti' earthquake, but it should be 'resistant' earthquake.

Building understandingThe building is a physical manifestation in the form of man-made structures comprising started the foundation, walls up to the roof permanently and made in one place. The building can also be called a building, ie all facilities, infrastructure or infrastructure in human culture in building a civilization.

Purpose Building ManufactureThe purpose of the building is to know clearly how to plan, carry out the manufacture of the building so that the building is strong, durable, healthy and comfortable when used.

understanding EarthquakeAn earthquake is a vibration caused by the movement of tectonic plates, mountain or irregular movement and cause damage.- Earthquake, is the movement of rock layers are derived from the earth or under the earth's surface..- Earthquake Volcanic (Volcano), is an earth tremors caused by the volcanic magma activity, which occurs usually before the volcano erupted.- Earthquake Tectonics, is the vibration caused by the activities of the earth's shifting plates suddenly and have the power from small to very large.- Earthquake Ruins, was the earth tremors caused by the collapse of the earth or landslides, usually occurs in areas limestone soils or mining areas.- Earthquake-made, is the vibration of the earth caused by the activities of humans, such as dynamite blasting, nuclear or other explosive devices that can cause vibrations in the earth.

Characteristics of Earthquake ShocksAt the building site, the earthquake will cause the soil under the building and surrounding shaken and moved irregularly. Ground acceleration occurs in three-dimensional form combinations of vibration frequency of 0.5 Hertz and 50 Hertz.If the building rigid (fixed) to the ground (can not be shifted) inertial forces hold ground acceleration will work on each structural element of a building during an earthquake occurs. The magnitude of the forces of inertia depends on the weight of the building. The more light means less inertia forces working on the structure.Basic Principles of Earthquake Resistant BuildingsThe basic principles of earthquake resistant building is a building that survived the collapse caused earth tremors (earthquakes), and has the flexibility to help reduce vibration.- Designed and calculated- The combination of load and structure analysis- The use of lightweight material- Placement of the mass of the structure of separate but interacting

1. Basic Principles of Structural RigidityThe principle is intended to make the structural stiffness of the main structure of a building more solid to shocks. For example, the reinforcement in the concrete structure of the building will help reduce vibration well. Stiffness can avoid the possibility of the concrete structure of the building will collapse when the earthquake struck.2. Principle of FlexibilityIn addition to the movement of the earth, the building itself is actually sustains the movements on the structure itself on a small scale. By using the principle relationship pedestal roll on the load. Roll on building relationships is loading on building a relationship that can move on a small scale to reduce vibration.

How Earthquake Resistant Buildings?The definition of earthquake resistant buildings are buildings where:1. earthquake rocked lightly, do not damage anything2. moderate earthquake rocked, only non-structural damage3. earthquake rocked large, suffered structural damage but remained standing and did not collapse.

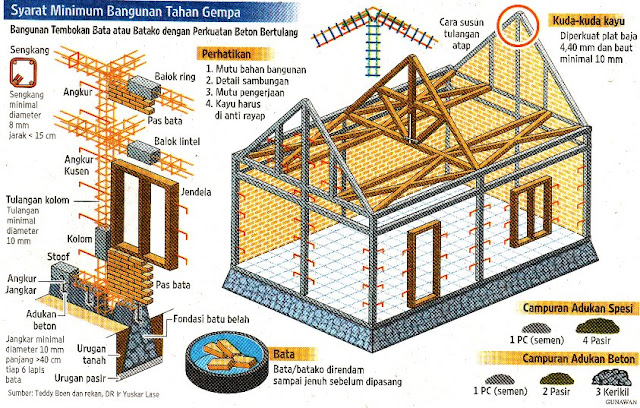

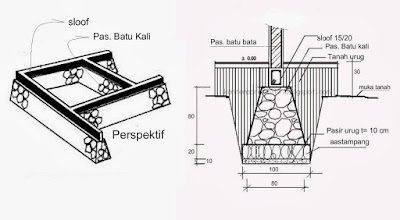

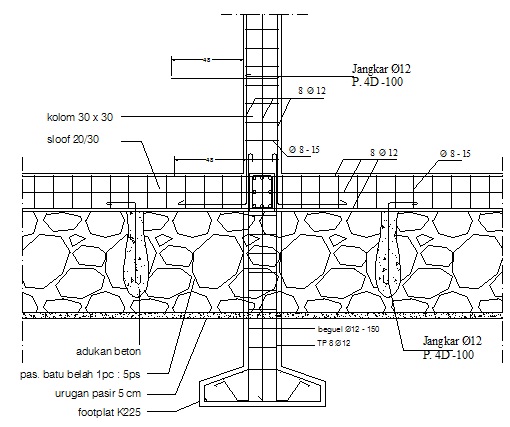

Important elements of Earthquake Resistant Structures1. FoundationsThe foundation is a structure of the bottom of the building that serves to distribute the load of the structure above the ground. To that should be the foundation placed on hard ground.Each building foundations need to be planned based on the type, strength and carrying capacity of the land where the establishment. For stable ground and has a good carrying capacity, then the foundation will also need a simple construction. However, if the land is unstable with poor carrying capacity, then the structure of the foundation used to be more complex.The vibration caused by the movement of the earth as much as possible tempered first by the foundation, because the structure is in direct contact with the ground.In addition, the foundation also must be able to withstand the load, including:- Expenses Horizontal or shear loads- Cost of living, such as building its own weight, the burden, the burden of water- Style or sliding earth quake- Lift the water- Moment and torque

continuous foundation stone

foundation scribble or foundation parallel bus

2. Concrete

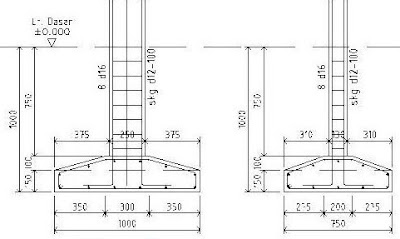

Here consists of reinforced concrete structures concrete sloof , pole / concrete columns and concrete ring balk. Concrete used for the reinforced concrete structure is to use a ratio of 1 cement: 2 sand: 3 Gravel (1 Pc: Ps 2: 3 Kr). The water used is 1/2 of the weight of cement (FAS 0.5), and the quality that can be achieved from this comparison was 150 kg / m2.

The use of tools such as Molen or vibrator is strongly recommended to produce concrete with high quality.

quality of concrete cement sand gravel

quality of concrete

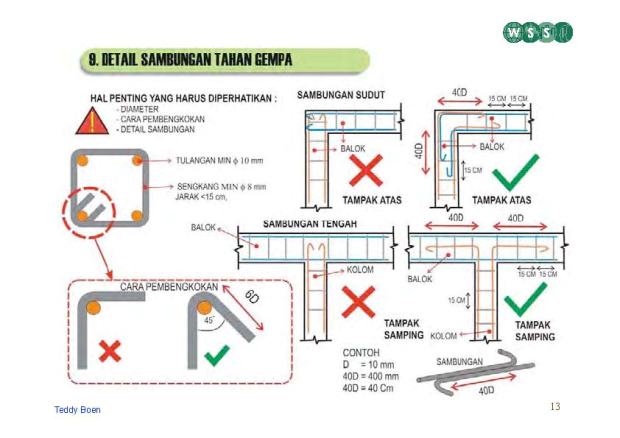

3. Concrete Association

Concrete reinforcement plays an important role in the concept of earthquake resistant buildings. Workmanship and quality of the concrete reinforcement should be kept. In the general population, mostly artisan considers trivial point of this work and less heed to the values of bond strength reinforcement.

Bonding concrete reinforcement consists of:

- Sloof concrete,

- Columns of concrete,

- Ring concrete balk

bone bonding in concrete

earthquake resistant connection details

earthquake resistant reinforcement connection details

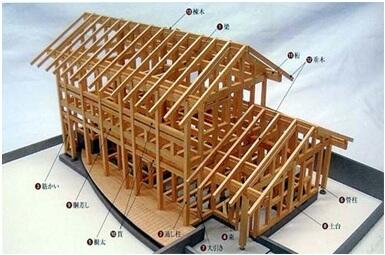

4. Frame Roof

Lightweight material for the roof structure is usually used as wood with simple bonding connection method. To strengthen the relationship between the rod and maintain stability, the relationship between the rods forming a triangle. The relationship between horses to one another using a rod stiffeners.

detail roof

Characteristics of earthquake resistant building construction, among others:1. Plan a simple and symmetricalResearch on the damage caused by the earthquake showed the importance of making simple buildings and elements of the containment structure symmetrical horizontal force. Such structures can withstand earthquake forces better because of the lack of effect of torque and power more evenly.

2. The construction materials as possibleOften, on the implementation of certain development using heavy building materials. But if possible, you should wear lightweight building materials. This is because the magnitude of the earthquake inertial load is proportional to the weight of building materials.For example, the roof cover over the framework of the wooden horses produce horizontal loads of 3x earthquake loads generated by closing the tin roof. Similarly, the pair brick generate load 15x earthquake load generated by a wooden wall.

3. The load restraint system is goodIn order for a building to withstand earthquakes, seismic inertial forces must be transmitted from each structural element to the main structure of the horizontal force and then move these forces to the foundation and soil.

X . I

construction of earthquake-resistant houses

Indeed, the construction of earthquake-resistant houses are relatively expensive and not necessarily we were able to make it happen but we can try to be able to manipulate in order to be more economical with less does not detract from the principle of the construction of earthquake-resistant homes that may be we try to apply.

Basic Principles of earthquake resistant house construction

Soften the impact of the earthquake

The use of wood materials

Wood has a tensile strength

System disassembly (knock down)

More precise workmanship

Planning in manufacturing

Planning to use the principle of the module, module length of 910 - 1000 cm

foundation work on earthquake resistant houses

construction beams on the ground floor of earthquake resistant houses

workmanship beams and columns in the structure earthquake resistant houses

Work on the roof of the structure of the house arrest of earthquake

X . III

Earthquake-resistant Foundations and Materials

If a building's foundation sits on soft or filled-in soil, the whole building may fail in an earthquake regardless of the advanced engineering techniques employed. Assuming, however, that the soil beneath a structure is firm and solid, engineers can greatly improve how the building-foundation system will respond to seismic waves. For example, earthquakes often knock buildings from their foundations. One solution involves tying the foundation to the building so the whole structure moves as a unit.

Another solution -- known as base isolation -- involves floating a building above its foundation on a system of bearings, springs or padded cylinders. Engineers use a variety of bearing pad designs, but they often choose lead-rubber bearings, which contain a solid lead core wrapped in alternating layers of rubber and steel. The lead core makes the bearing stiff and strong in the vertical direction, while the rubber and steel bands make the bearing flexible in the horizontal direction. Bearings attach to the building and foundation via steel plates and then, when an earthquake hits, allow the foundation to move without moving the structure above it. As a result, the building's horizontal acceleration is reduced and suffers far less deformation and damage.

Even with a base-isolation system in place, a building still receives a certain amount of vibrational energy during an earthquake. The building itself can dissipate, or damp, this energy to some extent, although its capacity to do this is directly related to the ductility of the material used in the construction. Ductility refers to the ability of the material to undergo large plastic deformations. Brick and concrete buildings have low ductility and therefore absorb very little energy. This makes them especially vulnerable in even minor earthquakes. Buildings constructed of steel-reinforced concrete, on the other hand, perform much better because the embedded steel increases the ductility of the material. And buildings made of structural steel -- steel components that come in a variety of preformed shapes, such as beams, angles and plates -- offer the highest ductility, allowing buildings to bend considerably without breaking.

Ideally, engineers don't have to rely solely on a structure's inherent ability to dissipate energy. In increasingly more earthquake-resistant buildings, designers are installing damping systems. Active mass damping, for example, relies on a heavy mass mounted to the top of a building and connected to viscous dampers that act like shock absorbers . When the building begins to oscillate, the mass moves in the opposite direction, which reduces the amplitude of mechanical vibrations. It's also possible to use smaller damping devices in a building's brace system.

Even with extensive testing on laboratory shake tables, any seismic engineering design concept remains a prototype until it experiences an actual earthquake. Only then can the larger scientific community evaluate its performance and use what it learns to drive innovation. In the next section, we'll examine some of those innovations, as well as what the future may hold for seismic engineering.

How Earthquake-resistant Buildings Work ?

Future Earthquake Resistant Construction

The purpose of earthquake resistant buildings is to preserve life. That means a building that did not collapse and allow occupants to escape was considered a success - even if it ends up being demolished. But what if a building can be deformed during the earthquake, and then return to its original form? many scientists are working together to develop innovative technology known as rocking frame, which consists of three basic components - steel frame, steel cables and steel fuse. Here's how it works: When an earthquake occurs, rock steel frame up and down to their hearts content. All energy will be directed downward to fit that houses several fuses tooth like. Teeth gnashing fuse together and may even fail, but the frame itself remains intact. Once the shaking has stopped, the steel wires in the frame attractive building returned to an upright position. Workers then check the fuse and replace the broken one. The result is a building that can be occupied again quickly after the earthquake.

X . IV

Futuristic Construction Technologies

In the beginning, there was mud. Human habitation of the earliest built no more than brick-and-thatched mud baked in the sun. man was the first to experiment with concrete, mixing limestone and volcanic rock to build a magnificent structure.

For centuries, engineers and architects have found a new way to build creations always higher, stronger and more beautiful to use materials that change the game like steel beams, foundation and earthquake resistant glass curtain wall.

But what does the future hold for the construction technology? Will there come a day when construction crews noisy replaced by a herd of autonomous nanobots? Cracks in concrete foundations will one day miraculously heal themselves, or gas stations replaced with electric cars running on the road of self charging?

let us see and learn 10 of the most interesting innovations construction of the future. Some even used today.

1. Self-healing Concrete

Concrete is a construction material that is most widely used in the world. In fact, it is the second most consumed substance on Earth after water. Think of all the concrete houses, office buildings, churches and bridges are built every year. Concrete is cheap and widely adaptable, but also vulnerable to cracks and breakage under pressure as extreme heat and cold.

In the past, the only way to repair cracked concrete is to patch, strengthen it, or knock it down and start from scratch. But not anymore. In

2010, a graduate student and professor of chemical engineering at the

University of Rhode Island created a new type of "smart" concrete

"heals" itself cracking. Mix concrete embedded with tiny capsules of sodium silicate. When a crack forms, the capsules rupture and release the healing agent like gel that hardens to fill the void.This is not the only method of self-healing concrete. Other researchers have used bacteria or embedded glass capillaries or polymer micro capsules to achieve the same result. However, Rhode Island researchers believe their method is the most cost-effective.

Extend real life can have huge environmental benefits. production of concrete in the world today accounts for 5 percent of global carbon dioxide emissions. smart concrete structure will not only make us safer, but also reduce greenhouse gases.

2. Carbon Nanotubes

A nanometer is one-billionth of a meter. It was impossibly small. A sheet of paper is 100,000 nanometers. Your fingernails grow about 1 nanometer per second. Even a strand of your DNA is 2.5 nanometers wide. For building materials in scale "nano" would have seemed impossible,

but using cutting-edge techniques such as electron-beam lithography,

scientists and engineers have managed to create carbon tubes with walls

that only 1 nanometer thick.

When larger particles are divided into portions getting smaller, the proportion of surface area to mass increases. The

carbon nanotube has the highest ratio of strength-to-weight of matter

on Earth and can be drawn one million times longer than their thickness.

Carbon

nanotubes are so light and strong that they can be incorporated into

other building materials such as metal, concrete, wood and glass to add

density and tensile strength. Engineers

even experimenting with nano sensors that can monitor the pressure in

the building materials and identify potential fractures or cracks before

they happen

3. Transparent Aluminum

Transparent aluminum could be used to construct towering glass-walled skyscrapers that required less internal support

For

decades, the chemical engineer dreaming of a material that combines the

strength and durability of metal with a purity of crystal-clear glass. Such a "clear metal" can be used to build a glass-walled skyscrapers that requires less internal support. military buildings can safely install a thin transparent metal shutters withstand the highest caliber artillery fire. And to think you could build a giant aquarium with this!

Back

in the 1980s, scientists began experimenting with novel types of

ceramic made of a mixture of aluminum powder, oxygen and nitrogen. A ceramic is a hard, crystalline material is usually made by the process of heating and cooling. In this case, aluminum powder were placed under great pressure, heated

for days at 2000 degrees C (3632 degrees F) and finally polished to

produce a very clear material, such as glass with the strength of

aluminum.

Known

as transparent aluminum, or Alon, space age materials are already used

by the military for making armored window and optical lenses.

4. Permeable concentrate

During a heavy storm, sheets of rainwater pour down on roadways, sidewalks and parking lots, scouring up surface debris and pollutants and washing potentially toxic chemicals like gasoline directly into sewers and streams. The U.S. Environmental Protection Agency (EPA) identifies storm water runoff in paved urban areas as a major source of water pollution.

Nature has its own way of filtering out toxins from rainwater. Soil is a magnificent filter for metals and other inorganic materials. As rainwater passes down through soil levels, microorganisms and plant roots absorb excess chemicals. Knowing this, engineers have created a new type of permeable concrete that allows rainwater to pass right through pavement and let nature do its work.

Permeable or pervious concrete is made with larger grains of rock and sand, leaving between 15 and 35 percent of open space in the pavement . Slabs of permeable concrete are laid atop gravel or another porous base material that lets rainwater settle to the soil substrate beneath. Permeable concrete is an excellent replacement for asphalt in parking lots. Not only does it significantly decrease runoff, but also the lighter color of concrete reflects sunlight and stays cooler in the summer.

5. Aerogel Insulation

A carbon sponge made of aerogel rests on this cherry blossom. While it is lighter than helium, it can absorb oil 250-900 times its own mass

If Michelangelo's famous marble statue of David was made of aerogel, it would weigh only 4 pounds (2 kilograms)! Aerogel is one of the least dense substances on Earth, a foam-like solid material that holds its shape despite being almost as light as air. Some types have densities just three times heavier than air, but typically aerogels are 15 times heavier than air .

You might think of gel as a wet substance, such as hair gel. But aerogel is made by removing the liquid from a gel. All that's left is the silica structure — which is 90 to 99 percent air. Aerogel is almost weightless, but can be spun out into thin sheets of aerogel fabric. In construction projects, aerogel fabric demonstrates "super-insulating" properties. Its porous structure makes it difficult for heat to pass through. In tests, aerogel fabric had two to four times the insulating power of traditional fiberglass or foam insulation . Once the price comes down, it could be widely used in construction.

6. Temperature-Reactive Tiles

This table changes color when something warm rests on it, thanks to a temperature-reactive surface

If you were alive in 1991 and lived aboveground, odds are good that you owned a Hypercolor T-shirt. By some scientific miracle — a miracle called thermochromic dye — the folks at Hypercolor made T-shirts that changed color with your body temperature. The commercials made it look super cool and sexy; your girlfriend could put her hot hands on your chest and leave a glowing mark. But in reality the hottest parts of your body are usually your armpits. Glowing armpits = not super sexy.

Today, a company called Moving Color manufactures glass decorative tiles coated with thermochromic paint that "come alive" with changing surface temperatures. At room temperature, the tiles are a glossy black, but when you touch the tiles — or hit them with direct light or warm water — the colors transform like the Northern Lights into iridescent blues, pinks and greens. The coolest application has to be the color-shifting shower. The good news for Moving Color is that houses don't have armpits.

6 . Robo ( Ringing on Boat ) Swarm Construction

Kirstin Petersen, an academic fellow in artificial intelligence at Harvard University, demonstrates robots inspired by termites at the American Association for the Advancement of Science meeting in Chicago in 2014.

One of nature's most ingenious builders is the humble termite. With a brain the size of a grain of sand, it works alongside hundreds of thousands of mound-mates to build colossal and complex mud structures. Termites captured the attention of Harvard robotics researchers because the insects don't take orders from some central termite architect. Each termite works alone according to genetically programmed rules of behavior. Together, as a swarm of single-minded individuals, they create monumental works of mud.

Inspired by termites, researchers at Harvard's Self-organizing Systems Research Group have built small construction robotics programmed to work together as a swarm. The four-wheeled robots can build brick-like walls by lifting each brick, climbing the wall and laying the brick in an open spot. They have sensors to detect the presence of other robo's and rules for getting out of each other's way. Like termites, no one is "controlling" them, but they are programmed to collectively build a specific design.

Imagine the applications: Swarming robots building levee walls along a dangerously flooded coastline; thousands of tiny robo's constructing a space station on Mars; or deep underwater gas pipelines being assembled by swimming swarms of bots. A similar experiment used a swarm of autonomous flying robots to build an artfully undulating brick tower .

7 . 3-D Printed Houses

shows the 3D-printed walls for houses his company is building in Shanghai, China. His company plans to build 10 of these in a day.

3-D printing has finally gone mainstream. Makerbot is selling nifty (and just about affordable) desktop machines that can print out fully rendered 3-D plastic toys, jewelry, machine parts and artificial limbs. But what if you want to print something bigger than a shoebox? Could you actually build a 3-D printer large enough to print out a plastic house?

The answer is "yes." A Dutch architecture firm has launched an ambitious public art project to build a 3-D printed house. But first, they had to build one of the world's largest 3-D printers, called the Kamermaker or "room maker." Using the same plastic source material as small-scale 3-D printers, the Kamermaker can print out large LEGO-like plastic components that will be assembled into individual rooms of the house. The rooms will then lock together — again, think LEGO — with the printed exteriors of the home designed to look like a traditional Dutch canal house.

Meanwhile, a Chinese construction company is building houses using a giant 3-D printer that sprays layers of cement and construction waste to assemble the homes. The company says the houses will cost less than $5,000 each, and it can produce up to 10 of them in a day .

8 . Smart Roads

No need for a solar-paneled car if we come up with roads that can wire memory flyer provide power to an electric car.

Google is hogging all of the limelight with its self-driving car, but what good are smart cars if they still have to drive on "dumb" roads?

One of the most exciting new ideas is a roadway that acts as a charger for electric vehicles. A New Zealand company has already built a large "power pad" that can wirelessly charge a parked electric car . The next step is to embed the wireless charging technology into actual road surfacing so electric vehicles can recharge on the move. No more refueling stations!

Other intriguing ideas that may come true one day include road surfaces that absorb sunlight to generate electricity, or — even cooler — embedding the road with piezoelectric crystals that capture the vibrations of passing cars and convert them into usable energy

9 . Building With CO2

The hard shell of the abalone inspired MIT researchers to isolate the enzyme abalone use to mineralize C02 in order to build their shells. One day, we might be able to make carbon bricks from C02

Carbon dioxide (CO2) spewed from power plants and automobiles is the single largest source of man-made greenhouse gas. Every year, we pump more than 30 billion metric tons (33 billion tons) of CO2 into the atmosphere where it speeds the damaging effects of global warming . While the energy sector experiments with trapping or "sequestering" CO2 emissions underground, a team of researchers at Massachusetts Institute of Technology (MIT) has successfully used genetically modified yeast to convert CO2 gas into solid, carbon-based building materials.

Like the Harvard termite team, the MIT researchers were also inspired by nature, this time the abalone. Like other crustaceans, abalone can convert ocean-borne CO2 and minerals into calcium carbonate to build their rock-hard shells. The researchers isolated the enzyme that abalone use to mineralize the CO2 and engineered a batch of yeast to produce it. A beaker full of genetically modified yeast can produce 2 pounds (1 kilogram) of solid carbonate from only 1 pound (0.5 kilograms) of C02 . Imagine how many carbon bricks they could make with 30 billion metric tons of CO2.

10 . green structural engineering marvels

There's something at once exhilarating and terrifying about watching a swarm of autonomous flying robo's build something beautiful, or a self-driving robo's car seamlessly pull up to the Taco Bell drive-thru. We are creating machines whose artificial intelligence will soon rival our own "organic" intelligence. In 99 percent of the cases, this will invariably be a good thing, making roadways safer — the Google cars have yet to have an accident or get a ticket — and automating tasks that used to require hundreds of hours of dangerous human labor. But if Hollywood has taught us anything, it's that intelligent machines will eventually rebel against us and harvest our organs for battery power. I just hope that our race for scientific progress is held in check by a strong ethical "off" switch. Just to be safe, I unplug all of my "smart" appliances at night.

FUTURE HOME TECHNOLOGY

Talking about future home technologies often conjures images of super-high-tech architecture and interfaces.

Talking about future home technologies often conjures images of super-high-tech architecture and interfaces. Home-automation systems like this one, shown in New York in November 2000, have been around for years.

Home-automation systems like this one, shown in New York in November 2000, have been around for years.Imagine coming home after work and pushing one button that adjusts the lighting for your entire house. The lights go on in the kitchen and living room, maybe your bedroom and select hallways, and the drapes lower throughout the house. Then the exterior lights begin to blaze. Actually, let's go one step better. You've got a control panel in your home, much like your programmable thermostat. You program in your daytime and nighttime lighting preferences, plus those for the weekend, and voilà -- no need to mess with your lights again .

You may be thinking, "Of course I'd have to mess with them again. What if I wanted different lighting because I was reading, or snuggling with a date?" No worries. The system would be so smart, and so all-encompassing, that you could pre-program settings for romance, reading, dinner parties and more .

Various advanced lighting systems are currently available, although they're not widely used because they're an added expense. In the future, though, the hope is they'll be standard features in homes. And why not? Much like the programmable thermostat mentioned earlier, controlled lighting saves energy and money. It's also a great safety and security feature

Tracking energy use is becoming more popular and will get easier as technology improves. Power Tracking

Tracking energy use is becoming more popular and will get easier as technology improves. Power TrackingDid you ever wonder why we've long had smart technology in our cars, but not our homes? Think about it. If you're low on gas, your car tells you. If your tire pressure is low, your car tells you. If you're short on oil, need to check your engine or are out of windshield wiper fluid, your car tells you. All of this information helps keep your car healthy, and you safe. It also saves you money by taking preventive measures and avoiding costly repairs. But what does your home and its major appliances tell you? Nothing. Powerhouse Dynamics, for one, wants to change this.

The Maine-based company has unveiled the Total Home Energy Management program, which monitors a home's energy use, energy cost and carbon footprint every single minute. Thanks to its detailed tracking, the system can tell you when your energy use spikes and why, allowing you to moderate consumption. It also monitors your appliances, letting you know when maintenance is needed so you can avoid pricey repairs, and even cluing you in when an appliance is so old and energy-inefficient that it's cheaper to chuck it and buy a new one. And new features are constantly being added as the company identifies and addresses the needs of its customers . For example, when the defrost cycle in a customer's refrigerator wasn't working properly, the system was modified to provide an alert

Although there are robots in the home today, they don't look much like the ones seen in sci-fi shows

Although there are robots in the home today, they don't look much like the ones seen in sci-fi shows  Home Security Through Facial Recognition Software

Home Security Through Facial Recognition Software

Good day. I was impressed with your article. Thanks for sharing.

BalasHapusseismic cable

seismic sensor supplier