Purification techniques in various substances and atoms are categorized in the field of electronics, namely the process of filtering a signal into a signal that we want to select and purify both sound and image and text and animation according to their original form and have the same and noble value

XO___XO Electronic filter

Electronic filters are circuits which perform signal processing functions, specifically to remove unwanted frequency components from the signal, to enhance wanted ones, or both. Electronic filters can be:

- passive or active

- analog or digital

- high-pass, low-pass, band-pass, band-stop (band-rejection; notch), or all-pass.

- discrete-time (sampled) or continuous-time

- linear or non-linear

- infinite impulse response (IIR type) or finite impulse response (FIR type)

The most common types of electronic filters are linear filters, regardless of other aspects of their design. See the article on linear filters for details on their design and analysis

he oldest forms of electronic filters are passive analog linear filters, constructed using only resistors and capacitors or resistors and inductors. These are known as RC and RL single-pole filters respectively. However, these simple filters have very limited uses. Multipole LC filters provide greater control of response form, bandwidth and transition bands. The first of these filters was the constant k filter, invented by George Campbell in 1910. Campbell's filter was a ladder network based on transmission line theory. Together with improved filters by Otto Zobel and others, these filters are known as image parameter filters. A major step forward was taken by Wilhelm Cauer who founded the field of network synthesis around the time of World War II. Cauer's theory allowed filters to be constructed that precisely followed some prescribed frequency function.

Classification by technology

Passive filters

Passive implementations of linear filters are based on combinations of resistors (R), inductors (L) and capacitors (C). These types are collectively known as passive filters, because they do not depend upon an external power supply and/or they do not contain active components such as transistors.

Inductors block high-frequency signals and conduct low-frequency signals, while capacitors do the reverse. A filter in which the signal passes through an inductor, or in which a capacitor provides a path to ground, presents less attenuation to low-frequency signals than high-frequency signals and is therefore a low-pass filter. If the signal passes through a capacitor, or has a path to ground through an inductor, then the filter presents less attenuation to high-frequency signals than low-frequency signals and therefore is a high-pass filter. Resistors on their own have no frequency-selective properties, but are added to inductors and capacitors to determine the time-constants of the circuit, and therefore the frequencies to which it responds.

The inductors and capacitors are the reactive elements of the filter. The number of elements determines the order of the filter. In this context, an LC tuned circuit being used in a band-pass or band-stop filter is considered a single element even though it consists of two components.

At high frequencies (above about 100 megahertz), sometimes the inductors consist of single loops or strips of sheet metal, and the capacitors consist of adjacent strips of metal. These inductive or capacitive pieces of metal are called stubs.

Single element types

The simplest passive filters, RC and RL filters, include only one reactive element, except hybrid LC filter which is characterized by inductance and capacitance integrated in one element.

L filter

An L filter consists of two reactive elements, one in series and one in parallel.

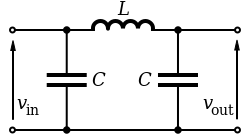

T and π filters

Three-element filters can have a 'T' or 'π' topology and in either geometries, a low-pass, high-pass, band-pass, or band-stop characteristic is possible. The components can be chosen symmetric or not, depending on the required frequency characteristics. The high-pass T filter in the illustration, has a very low impedance at high frequencies, and a very high impedance at low frequencies. That means that it can be inserted in a transmission line, resulting in the high frequencies being passed and low frequencies being reflected. Likewise, for the illustrated low-pass π filter, the circuit can be connected to a transmission line, transmitting low frequencies and reflecting high frequencies. Using m-derived filter sections with correct termination impedances, the input impedance can be reasonably constant in the pass band.

Multiple element types[

Multiple element filters are usually constructed as a ladder network. These can be seen as a continuation of the L,T and π designs of filters. More elements are needed when it is desired to improve some parameter of the filter such as stop-band rejection or slope of transition from pass-band to stop-band.

Active filters

Active filters are implemented using a combination of passive and active (amplifying) components, and require an outside power source. Operational amplifiers are frequently used in active filter designs. These can have high Q factor, and can achieve resonancewithout the use of inductors. However, their upper frequency limit is limited by the bandwidth of the amplifiers.

Other filter technologies

There are many filter technologies other than lumped component electronics. These include digital filters, crystal filters, mechanical filters, surface acoustic wave (SAW) filters, bulk acoustic wave (BAW) filters, garnet filters, and atomic filters (used in atomic clocks).

The transfer function

The transfer function of a filter is the ratio of the output signal to that of the input signal as a function of the complex frequency :

with .

The transfer function of all linear time-invariant filters, when constructed of discrete components, will be the ratio of two polynomials in , i.e. a rational function of . The order of the transfer function will be the highest power of encountered in either the numerator or the denominator.

Classification by topology

Electronic filters can be classified by the technology used to implement them. Filters using passive filter and active filter technology can be further classified by the particular electronic filter topology used to implement them.

Any given filter transfer function may be implemented in any electronic filter topology.

Some common circuit topologies are:

- Cauer topology – passive

- Sallen–Key topology – active

- Multiple feedback topology – active

- State variable topology – active

- Biquadratic topology – active

Classification by design methodology

| Linear analog electronic filters |

|---|

Historically, linear analog filter design has evolved through three major approaches. The oldest designs are simple circuits where the main design criterion was the Q factor of the circuit. This reflected the radio receiver application of filtering as Q was a measure of the frequency selectivity of a tuning circuit. From the 1920s filters began to be designed from the image point of view, mostly being driven by the requirements of telecommunications. After World War II the dominant methodology was network synthesis. The higher mathematics used originally required extensive tables of polynomial coefficient values to be published but modern computer resources have made that unnecessary.[3]

Direct circuit analysis[edit]

Low order filters can be designed by directly applying basic circuit laws such as Kirchhoff's laws to obtain the transfer function. This kind of analysis is usually only carried out for simple filters of 1st or 2nd order.

Image impedance analysis

This approach analyses the filter sections from the point of view of the filter being in an infinite chain of identical sections. It has the advantages of simplicity of approach and the ability to easily extend to higher orders. It has the disadvantage that accuracy of predicted responses relies on filter terminations in the image impedance, which is usually not the case.[4]

Network synthesis

The network synthesis approach starts with a required transfer function and then expresses that as a polynomial equation of the input impedance of the filter. The actual element values of the filter are obtained by continued-fraction or partial-fraction expansions of this polynomial. Unlike the image method, there is no need for impedance matching networks at the terminations as the effects of the terminating resistors are included in the analysis from the start.[4]

Here is an image comparing Butterworth, Chebyshev, and elliptic filters. The filters in this illustration are all fifth-order low-pass filters. The particular implementation – analog or digital, passive or active – makes no difference; their output would be the same.

As is clear from the image, elliptic filters are sharper than all the others, but they show ripples on the whole bandwidth.

Purification for Electronics Applications

Nanochem Gas Purifiers for Electronics Applications such as fabrication of Si-based logic and memory integrated circuits, LEDs, and Flat Panel Displays.

Nanochem UHP Gas Purification.

Learn more about Nanochem capabilities - get the Nanochem Purifier OverviewBrochure.

Go to the Nanochem Product Data page on this website to learn more about Nanochem:

- types of gas purification media

- choices for purifier hardware configurations

Gas Purification Optimized for Semiconductor Fabrication Applications.

Nanochem® Gas Purifiers enable the "extreme purification" of gases used in wafer and semiconductor fabrication, including the removal of dopants and volatile metals.

"Live gas" testing is done to ensure that Nanochem® gas purifiers meet or exceed performance specifications in the specific gas for which they are marketed.

Nanochem® purifiers remove:

- moisture (water)

- hydrocarbons

- halocarbons

- carbon dioxide

- oxygen

- dopants

- volatile metals

- more

XO___XO XI PING How Is Gold Purified?

Initial Processing of DifferentTyes of Ore

If the gold is a low grade ore, then it is broken up into chunks that are then put in carefully lined pads and treated with a dilute cyanide solution, which dissolves the gold. For high grade ore, the metal is sent to a grinding mill and made into a powder. Refractory ore contains carbon and is heated to over 1000 degrees F, which removes sulfide and carbon. The resulting oxide ore is directed to the leaching circuit. Sulfide refractory ore that contains no carbon is oxidized in an autoclave to free gold from sulfide minerals, then it is sent to the leaching circuit.

Further Refining

At this point, treated high grade ore is leached with cyanide and gold is collected onto activated carbon with the cyanide solution being recycled. The gold-carbon mixture is put in a vessel where the gold is removed chemically. The carbon is then recycled. The gold is then extracted from the solution by electrolysis or chemical substitution.

Purifying the Gold

At this point, the gold is melted into dore bars composed of 90 percent gold. The bars are then sent to an external refinery to make them 999.9 parts per thousand pure gold.

Other Means of Refining Gold

According to Hoover and Strong, a refiner and manufacturer of precious metals, they produce 98 percent pure gold using the Miller process. After a sample of treated impure gold has been tested in a lab for purity, the gold is melted in a furnace, then chlorine is bubbled through the liquid. The chlorine attaches to elements in the gold that then become solid and move toward the top of the furnace. They are skimmed off. Electrolysis is ultimately used to purify the gold.

Gold Refining Techniques

Gold refining, or parting, is used to separate gold from impurities and other metals, such as silver. Gold and silver, which are often extracted from the same ores, are chemically similar, making them difficult to separate. Before the advent of processes to separate silver and gold, a gold-and-silver alloy called electrum was frequently used. Technological advances have yielded improved techniques for refining gold. Removing as many impurities as possible from gold adds to its value, both in its raw form and in fine jewelry.

Miller Process

Used to refine gold on an industrial scale, the Miller Process, invented by Francis Bowyer Miller, is capable of refining gold to 99.95% purity. This technique includes passing chlorine gas through melted, unrefined gold, causing silver and other base metals to turn solid and float to the top from where they are skimmed off. The result is 98% pure gold, which is then electrolytically refined to remove platinum and palladium.

Wohlwill Process

Another large-scale gold refining technique, the Wohlwill Process refines gold to 99.999% purity — the highest purity possible. Developed by Emil Wohlwill in 1987, this electrochemical process uses a 95% pure gold bar as an anode and small sheets of pure, 24-karat gold as the cathode. A current is passed through the system, which uses chloroauric acid as an electrolyte; the pure gold collects on the cathode, which can then be melted down or processed.

Cupellation

A process that has been around since at least the Early Bronze Age, cupellation involves treating ores under high temperatures to separate noble metals, such as gold and silver, from base metals. Base metals, such as copper, zinc and lead, will oxidize whereas noble metals do not. Cupellation involves melting ore at temperatures in excess of 960 degrees Celsius; at this temperature the base metals oxidize while silver and gold remain on top of the mixture.

Do It Yourself

It is possible to refine gold without the use of large-scale, expensive chemical procedures. The process involves first adding nitric acid to gold, then adding hydrochloric or muriatic acid. After allowing this mixture to sit, it is filtered to remove contaminants, then treated to neutralize the acids in the solution. The result will be what looks like mud at the bottom of the container; this "mud" is actually gold. Rinse the muddy chunks three or four times with water, than treat with aqueous ammonia. After white vapors form, rinse the gold again with water and allow it to dry.

The value of gold depends in part on its purity. There are several useful methods to purify gold, including the Wohlwill process, the Miller process, cupellation and acid treatment.

The Wohlwill Process

In 1874, Dr. Emil Wohlwill of the Norddeutsche Affinerie in Hamburg, Germany, developed a method to purify gold through electrolysis. The unpurified gold ore is fashioned into a 100-ounce anode, whereas pure gold strips make up the cathode. The electrolyte solution is a mix of gold chloride and hydrochloric acid. When an electric current passes from the anode to the cathode through the electrolyte, the gold at the anode dissolves and collects at the cathode. The refinery melts the cathode and casts it into bars of at least 99.5 percent purity.

The Miller Process

Dr. F. B. Miller of the Sidney Mint created a process to purify gold using chlorine, which forms chlorides with silver and other ore impurities but leaves gold unaffected. The refiner places the ore in clay pots, heats the vessels in a furnace and pumps chlorine gas into each pot. After cooking for a few hours, the refiner retrieves the pots and skims off the molten chlorides, leaving behind gold with a purity of 99.6 to 99.7 percent. The Miller process replaced the Wohlwill process for most of the industrial refining of gold ore.

Cupellation Method

The cupellation method is appropriate for separating gold from small amounts of ore. The refiner grinds the ore into a fine powder and mixes it with lead oxide, a flux made of sand or borax, and an organic reducing agent such as graphite or flour. When the mix is heated in a crucible, the lead oxide reduces to lead, into which the gold dissolves to form a heavy molten phase. The refiner drains the phase from the bottom of the first crucible and places it into a second, porous one. When heated, the lead melts, oxidizes and sinks into the crucible walls, leaving behind gold and other noble metals such as silver and platinum. Other methods, such as solvent extraction with butyl diglyme, then separate and purify the gold.

Acid Treatment

The acid mixture aqua regia, or royal water, dissolves gold and is used to purify scrap alloy containing gold. Aqua regia is a mix of three parts hydrochloric acid to one part nitric acid. The dissolved scrap gold forms gold chloride. The chlorides of silver and platinum may also be present. The refiner filters away the undissolved material and then separates the dissolved gold from the other dissolved precious metals using butyl diglyme. This clear, odorless liquid can hold dissolved gold chloride but rejects the other noble metals. The butyl diglyme sits atop the aqua regia, much like vinegar separates from oil, and can be skimmed away to yield gold of 99.9 percent purity.

How to Purify Radioactive Materials

The production of everyday used materials such as oil and gas results in the buildup of radioactive materials in high concentrations. As a result of the commonality of this occurrence, a solution has been presented as to rid the world of this toxic waste. Purifying these radioactive materials with the use of various methods allows the pure substance to be reused and prevents the depletion of resources.

Introduction

Before we can understand how to purify these substances, it is important to understand the chemistry involved within to get a deeper understanding. Radioactivity was first discovered by Henri Becquerel in 1896 when he considered that the phosphorescent materials could be related to the glow emitted by X-rays. Rutherford further enhanced this discovery with his gold foil experiment to class the particles emitted by radioactive materials into classes based on their ability to penetrate through materials. Alpha particles are larger in size and therefore the least harmful because they cannot pass through something as thin as a sheet of paper. Through analyzing radioactive decay, it can be determined that alpha particles are positive. Beta particles are larger, carry a negative charge, and require a more dense substance to hinder their path. Gamma rays are neutral and by far the most dangerous of the three. These rays cannot be easily deflected and can even go through concrete. The term radioactive is defined as an unstable particle that releases subatomic particles. Examples include carbon-14, radium, uranium. Usually isotopes of elements have enough instability to fit this definition. Although these rays have a positive effect on some fields such as medicine in terms of x-rays, caution is used to prevent bodily damage. Scientists working with these substances wear protective gear as well as gadgets that records their exposure to the substance.

Methods of Purification

The most common method of purification of radioactive materials in very minute quantities is distillation. However, radioactive materials occur in large quantities and pose a bigger question. Rather than mass purify radioactive materials, they are currently placed deep underground until radioactive decay keeps it from being harmful.

Electro filtration method: Separation of liquid and solid phases to extract the pure substance with the use of electrodes

Filtration through a substance that reduces the radioactive material in question and then using a substance that will bind this reduced radioactive material will allow it to be separated from the remaining solution. This method has recently acquired a patent and is still undergoing experimental procedures but remains effective.

Purification of Radioactive Water

In nature water generally contains a plethora of impurities. These impurities can include small microbes to something as dangerous as radioactive substances. Methods such as boiling, Chlorination (use of household chlorine bleach), and purification tablets remove microorganisms. More rigorous modes of purification are used to rid the water of other wastes including radioactive materials. Groundwater is a common example in which radium, a radioactive element, is mixed with the water. This way produces a black sludge of radioactive water which is unhealthy for consumer usage. The radium can be removed through ion exchange or the conditioning of water. Other unnatural occurances of radioactive materials require more meticulous methods. Distillation removed salts, heavy metals, and radioactive fallout (since water itself cannot become radioactive, the radioactive components are referred to as radioactive fallout). Filtering the water will also remove the radioactive fallout.

Problems

- What are way in which to purify water that contains radium?

- What does the term radioactive mean?

- Define the different kinds of emissions and their range of harmfulness.

- What does distillation do that chlorination cannot achieve?

- Why is it important to purify radioactive materials?

The Many Uses of Nuclear Technology

- The first power station to produce electricity by using heat from the splitting of uranium atoms began operating in the 1950s. Today most people are aware of the important contribution nuclear energy makes in providing a significant proportion of clean electricity.

- The applications of nuclear technology outside of civil electricity production in power plants are less well-known.

- Radioisotopes, nuclear power process heat and non-stationary power reactors have essential uses across multiple sectors, including consumer products, food and agriculture, industry, medicine and scientific research, transport, and water resources and the environment.

Radioisotopes

Isotopes are variants of a given chemical element that have nuclei with the same number of protons, but different numbers of neutrons. Some isotopes are referred to as 'stable' as they are unchanging over time. Others are 'unstable' or radioactive since their nuclei change over time through the loss of alpha and beta particles. The attributes of naturally decaying atoms, known as ‘radioisotopes’, give such atoms several applications across many aspects of modern day life.

The first practical application of a radioisotope was made by a Hungarian man named George de Hevesy in 1911. At the time de Hevesy was a young student working in Manchester, studying naturally radioactive materials. Not having much money he lived in modest accommodation and ate his meals with his landlady. He began to suspect that some of the meals that appeared regularly might be made from leftovers from the preceding days or even weeks, but he could never be sure. To try and confirm his suspicions de Hevesy put a small amount of radioactive material into the remains of a meal. Several days later, when the same dish was served again, he used a simple radiation detection instrument – a gold leaf electroscope – to check if the food was radioactive. It was, and de Hevesy's suspicions were confirmed.

History has forgotten the landlady, but George de Hevesy went on to win the Nobel prize in 1943 and the Atoms for Peace award in 1959. His was the first use of radioactive tracers – now routine in environmental science.

Supply of radioisotopes

The main isotope suppliers are Mallinckrodt Pharmaceuticals (Ireland), MDS Nordion (Canada), IRE (Europe), NTP (South Africa), Isotop-NIIAR (Russia), and ANSTO (Australia).

Most medical radioisotopes made in nuclear reactors are sourced from relatively few research reactors, including:

- HFR at Petten in Netherlands (supplied via IRE and Mallinckrodt).

- BR-2 at Mol in Belgium (supplied via IRE and Mallinckrodt).

- Maria in Poland (supplied via Mallinckrodt).

- Orphee at Saclay in France (supplied via IRE).

- FRJ-2/FRM-2 at Julich in Germany (supplied via IRE).

- LWR-15 at Rez in Czech Republic.

- HFETR at Chengdu in China.

- Safari in South Africa (supplied from NTP).

- OPAL in Australia (supplied from ANSTO to domestic market, exports from 2016).

- ETRR-2 in Egypt (forthcoming: supplied to domestic market).

- Dimitrovgrad in Russia (Isotop-NIIAR).

- NRU at Chalk River in Canada (supplied via MDS Nordion) ceased production in October 2016, though the capacity will remain on standby until the reactor closes in March 2018.

Of fission radioisotopes, the vast majority of demand is for of Mo-99 (for Tc-99m), and the world market is some $550 million per year. About 40% of it is supplied by MDS Nordion, 25% from Mallinckrodt (formerly Covidien), 17% from IRE, and 10% from NTP. Over half of the Mo-99 has been made in two reactors: NRU in Canada (30-40% but ceased production in October 2016) and HFR in the Netherlands (30%). The rest is from BR-2 in Belgium (10%), Maria in Poland (5%), Safari-1 in South Africa (10-15%), Opal in Australia (increasing to 20% from mid-2016), and until the end of 2015, Osiris in France (5%). Output from each varies due to maintenance schedules.

Russia is keen to increase its share of world supply, and in 2012 some 66% of its radioisotope production was exported. For I-131, 75% is from IRE, 25% from NTP.

World demand for Mo-99 was 23,000 six-day TBq/yr* in 2012, but has apparently dropped back to about 19,500 since. Mo-99 is mostly produced by fission of U-235 targets in a nuclear research reactor, much of this (75% in 2016) using high-enriched uranium (HEU) targets. The targets are then processed to separate the Mo-99 and also to recover I-131. OPAL, Safari, and increasingly other reactors such as Maria use low-enriched uranium (LEU) targets, which adds about 20% to production costs. However, in medical imaging, the cost of Mo-99 itself is small relative to hospital costs. Mo-99 can also be made by bombarding Mo-98 with neutrons in a reactor. However, this activation Mo-99 has relatively low specific activity, with a maximum of 74 GBq/g (depending on the neutron flux available in the reactor), compared with 185 TBq/g or more for conventional fission-produced Mo-99.

* 23,000 six-day TBq is on the basis of activity at six days from production reference point, i.e. (given a 66-hour half-life) 22% of around 104,000 TBq. This is still about two days from the end of irradiation, so some 170,000 TBq must be made in the reactor to allow for cooling, processing, and decay en route to the users.

See also information paper on Research Reactors.

Agriculture

As well as directly improving food production, agriculture needs to be sustainable over the longer term. The FAO works with the IAEA on programs to improve food sustainability assisted by nuclear and related biotechnologies.The Food and Agriculture Organization (FAO) of the United Nations (UN) estimates that about 795 million people (one in nine) were suffering from chronic undernourishment in 2014-16. Radioisotopes and radiation used in food and agriculture are helping to reduce these figures.

Plant mutation breeding

Plant mutation breeding is the process of exposing the seeds or cuttings of a given plant to radiation, such as gamma rays, to cause mutations. The irradiated material is then cultivated to generate a plantlet. Plantlets are selected and multiplied if they show desired traits. A process of marker-assisted selection (or molecular-marker assisted breeding) is used to identify desirable traits based on genes. The use of radiation essentially enhances the natural process of spontaneous genetic mutation, significantly shortening the time it takes.

Countries that have utilised plant mutation breeding have frequently realised great socio-economic benefits. In Bangladesh, new varieties of rice produced through mutation breeding have increased crops three-fold in the last few decades. During a period of rapid population growth, the use of nuclear techniques has enabled Bangladesh and large parts of Asia in general, to achieve food security and improved nutrition.

Fertilisers

Fertilisers are expensive and if not properly used can damage the environment. It is important that as much used fertilizer as possible is “fixed” in the plant matter and that a minimum is lost to the environment. 'Labelling' fertilizers with a particular isotope (e.g. nitrogen-15) provides a means of ascertaining how much has been taken up by the plants, allowing for better management of fertilizer use.

Insect control

Estimates of crop losses to insects vary, but are usually significant. Despite the widespread use of insecticides, losses are likely to be of the order of 10% globally, and often notably higher in developing countries. One approach to reducing insect depradation in agriculture is to use genetically-modified crops, so that much less insecticide is needed. Another approach is to disable the insects.

Radiation is used to control insect populations via the Sterile Insect Technique (SIT). SIT involves rearing large populations of insects that are sterilised through irradiation (gamma or X-rays), and introducing them into natural populations. The sterile insects remain sexually competitive, but cannot produce offspring. The SIT technique is environmentally-friendly, and has proved an effective means of pest management even where mass application of pesticides had failed. The International Plant Protection Convention recognises the benefits of SIT, and categorises the insects as beneficial organisms.

SIT was first developed in the USA and has been used successfully for more than 60 years. At present, SIT is applied across six continents. Since its introduction, SIT has successfully controlled the populations of a number of high profile insects, including mosquitoes, moths, screwworm, tsetse fly, and various fruit flies (Mediterranean fruit fly, Mexican fruit fly, oriental fruit fly, and melon fly).

The most recent high-profile application of SIT has been in the fight against the deadly Zika virus in Brazil and the broader Latin America and Caribbean region (see also Insect control within the section on Medicine below).

Three UN organizations – the IAEA, the FAO, the World Health Organization (WHO) – with the governments concerned, are promoting new SIT programs in many countries.

Consumer products

One of the most common uses of radioisotopes today is in household smoke detectors. These contain a small amount of americium-241 which is a decay product of plutonium-241 originating in nuclear reactors. The Am-241 emits alpha particles which ionise the air and allow a current between two electrodes. If smoke enters the detector it absorbs the alpha particles and interrupts the current, setting off the alarm.The function of many common consumer products is dependent on the use of small amounts of radioactive material. Smoke detectors, watches & clocks, and non-stick materials, among others, all utilise the natural properties of radioisotopes in their design.

Food

Some 25-30% of food harvested is lost as a result of spoilage before it can be consumed. This problem is particularly prevalent in hot, humid countries.Food irradiation

Food irradiation is the process of exposing foodstuffs to gamma rays to kill bacteria that can cause food-borne disease, and to increase shelf life. In all parts of the world there is growing use of irradiation technology to preserve food. More than 60 countries worldwide have introduced regulations allowing the use of irradiation for food products.

In addition to inhibiting spoilage, irradiation can delay ripening of fruits and vegetables to give them greater shelf life, and it also helps to control pests. Its ability to control pests and reduce required quarantine periods has been the principal factor behind many countries adopting food irradiation practices.

Industry

See also information paper on Radioisotopes in Industry.

Industrial racers

Radioisotopes are used by manufacturers as tracers to monitor fluid flow and filtration, detect leaks, and gauge engine wear and corrosion of process equipment. Small concentrations of short-lived isotopes can be detected whilst no residues remain in the environment. By adding small amounts of radioactive substances to materials used in various processes it is possible to study the mixing and flow rates of a wide range of materials, including liquids, powders and gases, and to locate leaks.

Inspection and instrumentation

Radioactive materials are used to inspect metal parts and the integrity of welds across a range of industries. For example, new oil and gas pipeline systems are checked by placing the radioactive source inside the pipe and the film outside the welds.

Gauges containing radioactive (usually gamma) sources are in wide use in all industries where levels of gases, liquids, and solids must be checked. They measure the amount of radiation from a source which has been absorbed in materials. These gauges are most useful where heat, pressure, or corrosive substances, such as molten glass or molten metal, make it impossible or difficult to use direct contact gauges.

The ability to use radioisotopes to accurately measure thickness is widely utilised in the production of sheet materials, including metal, textiles, paper, plastics, and others. Density gauges are used where automatic control of a liquid, powder, or solid is important, for example in detergent manufacture.

Carbon dating

Analysing the relative abundance of particular naturally-occurring radioisotopes is of vital importance in determining the age of rocks and other materials that are of interest to geologists, anthropologists, hydrologists, and archaeologists, among others.

Desalination

See also information paper on Nuclear Desalination.

Potable water is a major priority in sustainable development. Where it cannot be obtained from streams and aquifers, desalination of seawater, mineralised groundwater, or urban waste water is required. Most desalination today uses fossil fuels and thus contributes to increased levels of greenhouse gases. The feasibility of integrated nuclear desalination plants has been proven with over 150 reactor-years of experience, chiefly in Kazakhstan, India, and Japan. Large-scale deployment of nuclear desalination on a commercial basis with reactors built primarily for that purpose will depend on economic factors

Medicine

Many people are aware of the wide use of radiation and radioisotopes in medicine particularly for diagnosis (identification) and therapy (treatment) of various medical conditions. In developed countries about one person in 50 uses diagnostic nuclear medicine each year, and the frequency of therapy with radioisotopes is about one-tenth of this.

Diagnosis

Diagnostic techniques in nuclear medicine use radiopharmaceuticals (or radiotracers) which emit gamma rays from within the body. These tracers are generally short-lived isotopes linked to chemical compounds which permit specific physiological processes to be scrutinised.

Dependent on the type of examination, radiotracers are either injected into the body, swallowed, or inhaled in gaseous form. The emissions from the radiotracers are detected by the imaging device, which provides pictures and molecular information. The superimposition of nuclear medicine images with computed tomography (CT) or magnetic resonance imaging (MRI) scans can provide comprehensive views to physicians to aid diagnosis.

An advantage of nuclear over X-ray techniques is that both bone and soft tissue can be imaged very successfully.

The most widely used diagnostic radioisotope is technetium-99m, with a half-life of six hours, and which gives the patient a very low radiation dose. Such isotopes are ideal for tracing many bodily processes with the minimum of discomfort for the patient. They are widely used to indicate tumours and to study the heart, lungs, liver, kidneys, blood circulation and volume, and bone structure.

Therapy

Nuclear medicine is also used for therapeutic purposes. Most commonly, radioactive iodine (I-131) is used in small amounts to treat cancer and other conditions affecting the thyroid gland.

The uses of radioisotopes in therapy are comparatively few, but important. Cancerous growths are sensitive to damage by radiation, which may be external (using a gamma beam from a cobalt-60 source), or internal (using a small gamma or beta radiation source). Short-range radiotherapy is known as brachytherapy, and this is becoming the main means of treatment. Many therapeutic procedures are palliative, usually to relieve pain.

A new field is targeted alpha therapy (TAT), especially for the control of dispersed cancers. The short range of very energetic alpha emissions in tissue means that a large fraction of that radiative energy goes into the targeted cancer cells once a carrier, such as a monoclonal antibody, has taken the alpha-emitting radionuclide to exactly the right places.

Sterilisation

Hospitals use gamma radiation to sterilise medical products and supplies such as syringes, gloves, clothing, and instruments that would otherwise be damaged by heat sterilisation.

Many medical products today are sterilised by gamma rays from a cobalt-60 source, a technique which generally is much cheaper and more effective than steam heat sterilisation. The disposable syringe is an example of a product sterilised by gamma rays. Because it is a 'cold' process, radiation can be used to sterilise a range of heat-sensitive items such as powders, ointments, and solutions, as well as biological preparations such as bone, nerve, skin, etc, used in tissue grafts.

The benefit to humanity of sterilisation by radiation is tremendous. It is safer and cheaper because it can be done after the item is packaged. The sterile shelf life of the item is then practically indefinite provided the package is not broken open. Apart from syringes, medical products sterilised by radiation include cotton wool, burn dressings, surgical gloves, heart valves, bandages, plastic and rubber sheets, and surgical instruments.

Insect control

In addition to agricultural pest control (see Agriculture section above), SIT has found important applications in the fight against disease-carrying insects. The most recent high-profile application of SIT has been in the fight against the deadly Zika virus in Brazil and the broader Latin America and Caribbean region. Following its outbreak, impacted countries requested urgent support from the IAEA to help develop the established technique to suppress populations of disease-carrying mosquitoes. The IAEA responded by providing expert guidance, extensive training, and by facilitating the transfer of gamma cell irradiators to Brazil.

Source: IAEA

Transport

Nuclear-powered ships

Nuclear power is particularly suitable for vessels which need to be at sea for long periods without refuelling, or for powerful submarine propulsion. The majority of the approximately 140 ships powered by small nuclear reactors are submarines, but they range from icebreakers to aircraft carriers.

See also information paper on Nuclear-Powered Ships.

Nuclear reactors for space

Radioisotope thermal generators (RTGs) are used in space missions. The heat generated by the decay of a radioactive source, often plutionium-238, is used to generate electricity. The Voyager space probes, the Cassini mission to Saturn, the Galileo mission to Jupiter, and the New Horizons mission to Pluto are all powered by RTGs. The Spirit and Opportunity Mars rovers have used a mix of solar panels for electricity and RTGs for heat. The latest Mars rover, Curiosity, is much bigger and uses RTGs for heat and electricity as solar panels would not be able to supply enough electricity.

See also information paper on Nuclear Reactors for Space.

Hydrogen, electricity and cars

In the future, electricity or heat from nuclear power plants could be used to make hydrogen. Hydrogen can be used in fuel cells to power cars, or can be burned to provide heat in place of gas without producing emissions that would cause climate change.

See also information paper on Transport and the Hydrogen Economy.

Water resources and the environment

Environmental tracers

Radioisotopes play an important role in detecting and analysing pollutants. Nuclear techniques have been applied to a range of pollution problems including smog formation, sulphur dioxide contamination of the atmosphere, sewage dispersal from ocean outfalls, and oil spills.

Water resources

Adequate potable water is essential for life. Yet in many parts of the world fresh water has always been scarce and in others it is becoming so.

Isotope hydrology techniques enable accurate tracing and measurement of the extent of underground water resources. Such techniques provide important analytical tools in the management and conservation of existing supplies of water and in the identification of new sources. They provide answers to questions about origin, age, and distribution of groundwater, as well as the interconnections between ground and surface water, and aquifer recharge systems. The results permit planning and sustainable management of these water resources. For surface waters they can give information about leakages through dams and irrigation channels, the dynamics of lakes and reservoirs, flow rates, river discharges, and sedimentation rates. Neutron probes can measure soil moisture very accurately, enabling better management of land affected by salinity, particularly in respect to irrigation.

The Concept Electronic Water Purification System

Description

It is one of characteristics of water molecular that it acts as a perfect semi-conductor when it’s in a purest condition, without no other solvents like salt, organics. Depending on the impurities within water, it is capable of insulating or conducting electricity, making it an incredibly valuable resource in almost any large-scale electrical system. In order to precisely control the different mineral, ion, and gas impurities in water for its use as a semiconductor, ConHoo has developed a set of water processes to meet the need for electronic use.

ConHoo is very expert at designing electronic water purification system, completing a lot of cases worldwide. The mature process for small to large range 1st RO+2nd RO+EDI, producing ultrapure water for use, with resistivity up to 17.0 M?·cm.

Ultrapure water system process of electronic industry:

A 2nd RO is designed to remove 99 percent salt from the raw water, EDI remove almost every possible mineral left, permeate achieve ultrapure condition for use in semi-conductor production. EDI has exceptionally strict requirements on the feed water, with conductivity under 10us/cm. then usually a second level RO is designed to work with EDI.

RO membranes also have strict demand on its feed water quality, SDI, residual chlorine, turbidity, etc. in order to protect RO membranes, a reasonable pretreatment system and an assisting dosing system must be devised to work along. The pretreatment system always consists of multimedia filter, activated carbon filter, ultrafiltration, these physical filters clear out big particles, bacteria, organic macromolecular.

Process Details

The complete membrane method water treatment technology is effective, safe, stable, environmental protective, thus becoming more and more popular worldwide in industry water treatment. The most common process is listed below.

| Step | Process | Usage |

|---|---|---|

| 1 | Multimedia filter | Sediment particles |

| 2 | 100-micro filtration | Particles |

| 3 | Ultrafiltration | Particles, some bacteria |

| 4 | 5-micro filtration | Particles >1 µ |

| 5 | Reverse osmosis (1st pass) | TDS down to 5 ppm |

| 6 | 1-micro filtration | Bacteria |

| 7 | Reverse osmosis (2nd pass) | TDS down to 1.3 ppm |

| 8 | EDI | Residual salt, organics |

According to the information customer provided we help design the tailored water purification system for customers, taking consideration of invest, space, product quality, etc. Conhoo provide quality assurance in all our products and services by successfully competing other players in the water purification field. Until today, Conhoo has provided service for over one hundred customers, in Asia, Africa, and many other places on earth.

Tidak ada komentar:

Posting Komentar