Amplifier damping factor: More is better! (….or is it?)

Damping Factor

Amplifier damping factor: More is better! (….or is it?)

Ever have one of your friendly amplifier reps walk in your office to

present their new mondo-gazillion-watt beast and point out the damping

factor spec of greater than a bazillion? Why, gee-whiz! That’s, like, 10

times more than the other guy! It must be awesome! Right? Well, as we

have seen before, it depends on how you are going to use it. Let’s start

with defining damping factor and see what it means to us.

Definition

Amplifier damping factor (DF)is defined as “the ratio of the load

impedance (loudspeaker plus wire resistance) to the amplifier internal

output impedance.” This basically indicates the amplifier’s ability to

control overshoot of the loudspeaker, i.e., to stop the cone from

moving. It is most evident at frequencies below 150 Hz or so where the

size and weight of the cones become significant. A system where the

damping factor of the entire loudspeaker/wire/amplifier circuit is very

low will exhibit poor definition in the low frequency range. Low

frequency transients such as kick drum hits will sound “muddy” instead

of that crisp “punch” we would ideally want from the system.

The formula for calculating damping factor is

Where:

Z L = The impedance of the loudspeaker(s)

Z AMP = The output impedance of the amplifier

R W = The resistance of the wire times 2 for the total loop resistance.

Very few amplifier spec sheets state the output impedance, but you

can generally call the manufacturer for this spec or you can calculate

it by dividing the minimum rated load impedance by the damping factor

rating. For example, if we are using amplifier with a damping factor

rating of 400 and it requires a minimum load of 2 Ohms, then its output

impedance would be calculated as being 0.005 Ohms.

For example…

So let’s look at several examples and figure out what we can control

in the design of our system to achieve the best results. Say we have two

8 ohm subwoofers connected to an amplifier with a damping factor of 400

with 100’ of 12 ga. wire with a resistance of 0.00159 Ohms/ft times

100’ gives us a total resistance of 0.159 Ohms. Plugging the numbers

into our formula, we get:

In this case, our system damping factor is just 12. Most experts

agree that a reasonable minimum target DF for a live sound reinforcement

system would be 20, so we need to consider changing something to get

this up.

The critical element in this definition is the “loudspeaker plus wire resistance”

part. In this case, the resistance in 100’ of 12 ga. wire with a 4 Ohm

load results in around 0.7 dB of loss, much greater than the maximum

target of 0.4 dB of loss, so let’s try bigger wire. 10 ga. wire has a

resistance of .000999 Ohms/ft times 100’ equals .0999 Ohms and will get

us to the 0.4 dB target. What will it do for DF?

Ok, now we’re pretty close to the 20 we were looking for. Notice that

the loudspeaker impedance can also give us a big change. The higher the

circuit impedance, the less loss we have due to wire resistance. What

if we change our wiring so we have one 8 Ohm loudspeaker connected

instead of two? Going back to our 12 ga. wire, we calculate:

Even better! In fact, if you run the numbers a few times, you will

see that in a system with some significant length of wire, we will find

that damping factor will generally be 20 or higher as long as our total

wire loss is 0.4 dB or less.

What if we have a self-powered subwoofer? In this case, our

loudspeaker wire is probably around 14 ga. and since the amplifier is in

the loudspeaker enclosure, it is probably less than a couple feet long.

Assuming the manufacturer is connecting two 8 ohm loudspeakers to the

amplifier, and 14 ga. wire has a resistance of .00256 Ohms/ft times 2’

equals 0.00506 Ohms of resistance, and our amplifier has a damping

factor spec of 400, what do we get?

Wow! Now that’s a significant difference! Kind of supports the idea

of using self-powered subwoofers, or at least putting the subwoofer amps

as close as possible to the subs.

Amplifier DF Ratings

So we’ve looked at the differences in the size and length of our wire

and the differences in hanging one loudspeaker on the line vs. two to

change the impedance of the line. What if we choose an amplifier with a

higher damping factor spec., say 3000? That’s a big difference, so we

should see a much higher damping factor in our circuit, right? Assuming

this amplifier can drive a minimum 2 Ohm load, we find the output

impedance would be 0.001 Ohms. Plugging the numbers into our single

loudspeaker with 12 ga. wire system, we get:

Hmmmm, not such a big deal. That higher amplifier damping factor only

improved our system damping factor by 0.31 over the amplifier with a DF

spec of only 400.

What if we use the amplifier with the 3000 DF spec in our self-powered sub with 2’ of 14 ga. wire?

Remember our calculation using the 400 DF amplifier was 264.55, so

now we start to see when the amplifier spec becomes significant.

Essentially, in sound reinforcement systems where we have some

significant length of wire between the amplifier and the loudspeaker,

the amplifier DF spec has little affect on the performance of the

system.

In Summary…

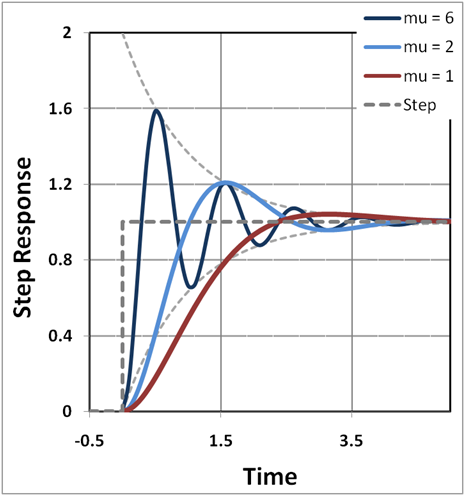

So what have we learned? In live sound reinforcement systems, damping

factor is really driven by the length and size of our wire and the

impedance of the loudspeakers we connect at the other end. Since damping

factor mostly affects low frequency, we should endeavor to keep our

subwoofer loudspeaker lines as short as possible and/or use larger gauge

wire. We should keep the impedance of the connected load as high as

possible by connecting only one transducer per wire instead of two.

So is more amplifier damping factor better? As one of my colleagues

recently said, “Sure! If the loudspeaker terminals are welded to the

amplifier output terminals!” Well, maybe he overstated it a little bit,

but yes, as long as the loudspeaker wire is really short, then by all

means!

Damping Factor

Technically, the damping factor of a system refers to the ratio of

nominal loudspeaker impedance to the total impedance driving it

(amplifier and speaker cable). In practice, damping is the ability of

the amplifier to control speaker motion once signal has stopped. A high

damping factor means that the amplifier’s impedance can absorb the

electricity generated by speaker coil motion, stopping the speaker’s

vibration.

Other points:

- Damping varies with frequency. Some manufacturers publish a damping curve for their amps.

- The

effects of damping are most apparent at low frequencies, in the range

of the woofer’s resonance. Well damped speakers sound “tighter” in the

low end. Low damping factors result in mushy or indistinct bass.

- Speakers

connected in series or parallel will experience the same damping factor

from the amp. Impedance determines damping factor, not speaker wiring.

- Higher impedance speakers increase system damping factor.

- The

damping factors you see published as amp specs are for the amp only,

not referenced to an entire system. Higher is better, and you’ll often

see quite high numbers, 200, 300, even 3000 or higher.

- System damping factors over 10 are generally acceptable. The higher the better.

- For

the tweaky among you, here’s how to calculate a system’s damping

factor: First, calculate the output impedance of the amp into, say, an 8

ohm speaker (use the nominal impedance of whatever speaker you are

using for your own calculations), and a 100 foot 12 gauge speaker cable.

Let’s also say we have an amp with a published damping factor of 3000.

Since damping factor is the ratio of speaker impedance to amp output

impedance, you can work backwards, dividing 8 by 3000, giving us .0027

ohms amp output impedance. You must also consider the impedance of the

speaker cable; 12 gauge wire is in the range of .0016 ohms/foot (cable

catalogs sometimes publish this spec). For a 50 foot speaker cable,

you’ve got 100 “feet” of impedance (50′ out, 50′ back) giving a total

cable impedance of around .16 ohms (note this is much higher than the

amp’s impedance – one reason larger speaker wire is better for long

runs!). This makes the total output impedance .1627 – pretty low. The

system damping factor will then be 8 ohms divided by .1627, resulting in

a very good score of 49.

output resistance

and damping factor

|

Output

Resistance

Dynamc

Output Resistance

Damping

Factor

Internal

Resistance

different

names for the same

Internal

resistance and source voltage determine the efficiency of a

voltage source. On the basis the example of a battery, the

influence to Hifi amplifier technology is to be exlained.

|

|

Introduction

Every battery has an internal resistance.

|

|

Why?

|

|

|

|

Fig.

1 the Ohm's law applied by the example 1.5 V of a Mignon

battery. Load e.g. 10 ohms of constant of source tension (open circuit

voltage) of 1.5 V.

|

|

|

If

we attach now a very large load (very small resistance 0.01 ohms) at

the battery, then we expect a large current. The small battery cannot

supply the large current. The Ohm's law applies nevertheless also to

batteries? Naturally, it applies also to batteries as to all voltage

supplies. What happened?

|

|

The

actual maximum current is smaller than expected, i.e. it must be

positioned still another resistance in series to the load. Yes, that

is output resistance. Output resistance determines the maximally

possible current. The maximally possible current is called short

circiut current.

|

|

The

effective resistance is the sum of load resistance and internal

resistance.

Internal resistance has

chemical causes and additionally Ohm's resistances inside the battery.

With the transformer it is the Ohm's resistance of the copper coil and

the saturation of the magnetic core. Each voltage supply could supply

its specific physical causes only a limited current.

|

|

Fig.

2 of R internal resistance limits the maximum current of a

voltage supply. Simplified said the more largely a battery, the

smaller the internal resistance. A car battery has a small internal

resistance. An electronic Piezo lighter has a very high voltage, but

an extremely large internal resistance and therefore only very small

rivers flowing. A power station generator generates also relatively

high voltages in combination with a very low internal resistance, thus

it can make very high power available.

|

Equivalent

circiut diagram

|

|

|

Fig.

3 shows the battery, internal resistance Ri, the source

voltage U and the load resistance RL - here a lamp. Drawn in also the

current I, which is equivalent large by all elements of the

equivalent circuit diagram.

The

short circiut current of a circuit can be determined with high

impedance sources, in which this are short circuit and which the

current is measured. Ri = U/I short-circuit. For low impedance sources

this method is not only inaccurate, but also lethal (spark, burns),

inaccurately and mostly also harmful for the source. E.G. with a car

battery this should be never tried, the developing currents, amounts

of heat and health risks (sparks and burns) is enormous.

In

order to measure the internal resistance of a low impedance source,

first a measurement of the source voltage without load can take place.

In the second measurement the source is loaded, with a load, which

corresponds to a usual operating condition.

|

|

Fig.

4 output resistance can be computed in this way simply.

First a measurement of the source voltage without attached load.

Afterwards with a normal load. The delta of the two voltages divided

by the current calculates the internal resistance.

|

Static

Output Resistance

A

static internal resistance meant, the resistance is constant for all

load conditions. This condition does not occur in nature, a

dependence on the load is always available, sometimes more, sometimes

less. For many voltage supplies, e.g. batteries may be spoken of a

static internal resistance, which remains constant in many operating

points. With voltage supplies, which are not regulated, a

"static" internal resistance can be defined

Dynamic

Output Resistance and Amplifier

Here

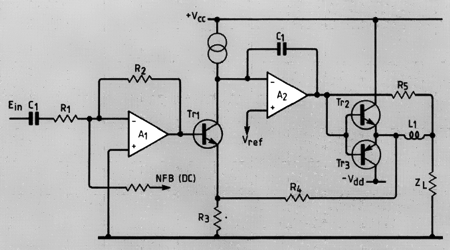

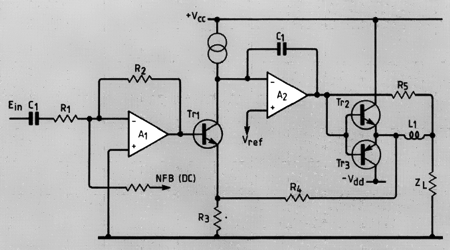

it acts over an amplifier with negative feedback

Output

resistance in the case of negative feedback under closed loop

conditions.

A

regulation is based on the principle of the negative feedback and a

much higher open loop gain than a closed loop gain. Also a Hifi

amplifier has an output resistance. Since a closed loop is present, I

speak now of a dynamic output resistance. Dynamically therefore, the

amplifier tries to regulate the output voltage, since it accomplishes

continuously an actual value with desired value comparison. In other

words, an amplifier is a DC source voltage with a very fast adjustable

internal resistance. Since a constant continuous (following the

signal) dynamic adjustment of internal resistance happens here, I call

this internal resistance: dynamic internal resistance in the

respective operating point. The measurement of dynamic internal

resistance effected as in fig. 4 described, as signal source is set an

alternating voltage on the amplifier. Dynamic internal resistance has

validity for this operating point only.

In

a coordinate system output resistance is represented as y axis and as

x axis e.g. the pertinent operating point (e.g. the respective output

voltage). Still the first derivative could be formed by this function,

in order to meet further statements.

In

electronics and audio world many names were found for output

resistance.

Damping

Factor definition

In

principle all listed designations describe dynamic internal resistance

in the unit ohm. A privileged position assumes thereby the damping

factor, it into relation to loudspeaker impedance (4 ohms or 8 ohms)

is set, the unit shortens itself ohms. The damping factor corresponds

therefore also to output resistance, only in transformed way of

writing.

|

Fig.

5 shows the mathematical definition of the damping

factor. Quotient of attached loudspeaker impedance and output

resistance in the respective operating point of the hifi

amplifier. The damping factor is not a constant size, as it is

often written. It stands in dependence to variable internal

resistance and loudspeaker impedance. From technical view the

indication of a damping factor is meaningful only if the

boundary conditions of the measurement are indicated.

-

with which frequency dynamic output

resistance was measured.

-

with which amplitude dynamic output

resistance was measured

-

with which load impedance dynamic

output resistance was measured

|

|

It

would result in for example at all no sense, it would be even

wrong to determine a very good dynamic internal resistance

during small load and to calculate a quotient with 4 ohms, in

order to receive a good damping factor. Very meaningfully it

is to be measured output resistance with that load, for which

also the damping factor is indicated later. Without data of

the boundary conditions the indication of a damping factor

from technical view is not sufficient.

|

The

output resistance and the open

loop of an amplifier depends essentially on the

frequency, temperature and the load. It lets general say, a very low

dynamic output resistance is a good condition for a low distortion

factor. Dynamic output resistance depends to 100% on the open

loop. If a dynamic output resistance rises during very high load

conditions, then the cause lies in the fact that in this operating

condition the open loop was drastically reduced.

The

dynamic output resistance is a "regulatedoutput resistance"

and can take thereby very small values. Of course only validity for

the range of the still adjustable load. Thus it is clear why also a

small operational amplifier can have a small output resistance.

|

Fig.

6 shows a somewhat unusual model for further

discussion for a common used amplifier type.

To

see: two source voltages, with in each case an adjustable

output resistance. Now if a positive input signal applies

against the automatic controller (control Amp), then upper

resistance is setted to a very high impedance value, so that

only very small current can flow by the upper source. At the

same time to it from the automatic controller the lower

resistance reduced to the desired current by the loudspeaker

flows so long. More exactly said, until the desired voltage at

the output adjusts itself. For negative voltages conditions

are changed.

The

feedback line is a part of constant control (regulation)

whether two resistances were setted also correctly. And

the more precisely control happens, the more highly is the

open loop.

If

the desired voltage is zero V, then both resistances are

adjusted to the same value during same source voltage. However

to which value? Good question - until the desired idle current

of the output stage is reached.

The

transistors in the amplifier takes over the role of adjustable

internal resistances.

|

Large

amplifiers small output resistance? - small amplifier large output

resistance?

A

large hifi amplifier - that means not that dynamic internal resistance

is automatically very small. No, a very well made small amplifier can

be quite better than a less well developed large amplifier. The

substantial difference is: the small amplifier cannot follow with

rising load any longer, its dynamic output resistance rises strongly.

While with the large one only with larger load dynamic output

resistance rises somewhat.

Effects

on a bad amping factor

Keep

in mind, an indication of a damping factor is technically only

meaningfully under indication boundary condition only if for the DUT's

the damping factors are present, which were measured under similar

boundary conditions, then becomes a number comparison possible.

Effects on bad damping factor are, the output signal correspond less

to the input signal. The effects are linear

and also nonlinear

distortions.

Also

a loudspeaker can generate voltages. An amplifier with low dynamic

output resistance can compensate these disturbances better than one

with a high damping factor. Loudspeakers generate inadvertent voltages

to their connectors, similarly like the function mode of a microphone.

The amplifier must reject these. A measure for it like generated

disturbances being suppressed, is e.g. the load Rejection Ratio.

Damping factors affect the sound, loudspeaker manufacturer have

thereby experience.

A

relatively linear controlled system reduces also the effect of the

generation of nonlinear distortions. With which we concerned at the

open loop amplifier without feedback. An open loop amplifier meant,

the amplifier does not have an overall negativefeedback of the output

signal. Only individual amplifier stages using negative feedback, e.g.

through emitter resistances or through cathode resistances with a tube

amplifier.

A

feedback free amplifier works in a steered mode and not as regulation.

During directly comparable achievement of both amplifiers types, the

steered type has a higher output resistance than the regulated

amplifier. The developer of a steered only amplifier directs his

special attention to linearize his circuit. This method helps to keep

distortions low.

|

IMPEDANCE IN AUDIO TECHNOLOGY

WHEN FOUR OHMS IS NOT FOUR OHMS

There is an enclosure in our product line that we have been

making for twenty years called, the FH-1 low frequency enclosure.

We use a four ohm loudspeaker in this enclosure; however, as

long as the enclosure is operated above its cut-off frequency

of 60 Hz, the actual load impedance that the power amplifier

sees is nominally eight ohms. Likewise, we use a four ohm loudspeaker

in the Mid bass horn of HDH-4 and HDH-1 speaker enclosures.

As long as these horns are operated above their cut-off frequency

of 300 Hz, the midbass of the enclosure will exhibit an eight

ohm load to the amplifier.

The mechanical loading of the loudspeaker by the horn makes

an impedance transformation so the amplifier sees a load impedance

of 8 ohms within the horns operating bandpass. I mention the

horn's operating bandpass because if you operate any horn below

its cut-off (-3 dB down point on the low frequency portion

of its response curve), the driver reverts back to its original

lower impedance. As long as you send horn loaded enclosure

frequencies that are above the cut-off, the system will offer

a higher load impedance to the power amplifier.

The DC resistance of the loudspeakers discussed above is 3.2

to 3.8 ohms. Mounting the loudspeaker on a horn doesn't change

the DC resistance, but a power amplifier driving that horn

will see a load impedance that is more than twice that of the

nominal four ohm impedance of the individual speaker. Hopefully

some of us now understand how a four ohm loudspeaker can become

an 8 ohm loudspeaker system when mounted on a properly designed

horn.

I had mentioned earlier a situation I discovered in Africa

where a technician had a basic understanding of impedance,

but he didn't understand how horn loading can change the impedance

of a loudspeaker. We used to have a low frequency enclosure

called the FH-2. This enclosure had two four ohm loudspeakers

wired in parallel within a folded horn. Since each of the loudspeakers

was loaded by the horn, the individual loudspeakers were mechanically

raised to eight ohms. Therefore, in parallel the two equivalent

eight ohm speakers offered a four ohm load to the amplifier

when operated in its designated bandpass 60 Hz - 400 Hz.

The technician thought he was correct and that perhaps the

manufacturer had goofed. So he wired what he thought were two

four ohm loudspeakers in series, thinking that he then had

an eight ohm load for the power amplifier. However, since these

were horn-loaded speakers, he actually changed a four ohm enclosure

into a sixteen ohm enclosure. He changed them from two horn-loaded

eight ohm speakers that were mixed in parallel to two eight

ohm loudspeakers wired in series that now offered a sixteen

ohm load for his CS-800 amplifier. So instead of the CS-800

producing 400 watts into 4 ohms (200 to each speaker), it produced

only 100 Watts (50 watts to each speaker). Now not only did

he have a 6 dB loss in SPL, he totally destroyed the damping

or control capability of the power amplifier by reducing his

potential damping factor from a rating of 200 to that of 0.5.

More on Damping Factor later.

Perhaps now that you have further insight into complex impedance,

you may also agree that when misinformed people try to "out

think" the manufacturer of a loudspeaker system, they

more often than not have their own foot crushed by the wheel

that they are trying to reinvent.

I mentioned that loudspeakers should not be wired in series

for sound reinforcement applications. And it was all right

to wire them in parallel, but that they should each have their

own pair of speaker cable leads and be wired in parallel at

the output terminals of the power amplifier. This is the professional

way of wiring loudspeakers in parallel. All loudspeakers generate

a back voltage due to the motion of the voice coil within the

magnetic field of the voice coil gap. This is referred to as

a Back-EMF or backward-electro-motive-force.

Sir Issac Newton said that for every action there is an equal

and opposite reaction. If you would take a fifteen inch Black

Widow loudspeaker and hook its terminal up to the input of

an oscilloscope and slap the cone abruptly with the palm of

your hand, you could cause a voltage to be displayed on the

scope greater that 80 volts peak to peak, 40 volts peak, or

about 28 volts RMS.

If two loudspeakers are wired in parallel within an enclosure

at a distance from the power amplifier, each speaker creates

a back-EMF that causes low frequency cancellation as these

voltages are out of phase with the incoming signal. When the

two loudspeakers are wired in parallel at the output terminals

of the power amplifier, the very low internal output impedance

(source impedance) of the amplifier (typically 0.02 ohms) acts

as a shunt or near short circuit to the back-EMF voltages.

ARE YOU READY FOR MORE?

I mentioned Damping Factor earlier and I wanted to

wait until I discussed Source Impedance before I covered it

more thoroughly.

SOURCE IMPEDANCE

Up until now I have been talking about the impedances

offered by the loudspeaker load on the amplifier. The loudspeaker

load impedance is often referred to as the output impedance

of the amplifier; however, it is more correct to call this

the amplifier load impedance. This is because amplifiers have

an internal output or "source impedance."

The ratio of the source impedance to the load impedance is

the amplifier's Damping Factor rating number. The damping Factor

number can be obtained by dividing the loudspeaker load impedance

by the internal output or source impedance of the power amp.

A typical power amplifier source impedance is 0.02 ohms. If

I were to divide an 8 ohm speaker load by 0.02 ohms, I would

have a Damping Factor number of 400.

As you can see the impedance of the load affects the damping

factor of the amplifier. The same amplifier would have a damping

factor of 200 into a four ohm load (4 / 0.02 = 200).

The damping factor is the ability of the amplifier to control

the loudspeaker load. Another word for control is regulation.

The control of the load is a function of the ability of the

power amplifier's regulation of the load. If you have a precise

millivolt scale on a digital voltmeter, you can calculate the

percentage of regulation by measuring the output voltage of

the amplifier without a load (open circuit), then place the

load resistance value on the amplifiers output and measure

the voltage. It will have dropped a very small amount.

If you then take the No Load Voltage and subtract the Full

Load Voltage from it, and then divide that number by the Full

Load Voltage, you will have calculated that amplifier's percentage

of regulation. If you now take the reciprocal of that percentage

of regulation, you will have the Damping Factor rating number

of that amplifier into that load value.

NLv - FLv / FLv = % Regulation

1 / % Regulation = Damping Factor

or DF = 1 / (NLv - FLv / Flv)

Note: You can't really measure Damping Factor at full power

because that amplifier will not be able to maintain its regulation,

but as an example let's say you are measuring a CS-800X into

an eight ohm load with 6 dB of head room. Your open circuit

(NL) voltage is measured at 20 volts, you place an eight ohm

load in the circuit (you better use a dummy load or a speaker

will be awfully loud), then you measure a (FL) voltage of 19.95

volts, your math would now be:

20 - 19.95 = 0.05 / 19.95 = 0.0025

% of Regulation would be .25%

The reciprocal of 0.0025 = 1 / 0.0025 = 400

DF = 400

Source Impedance (Z source) would then be calculated from an

inversion of the previous formula for damping factor (DF =

Z Load / Z Source) would now become:

Z Load / DF = Z Source or

8 / 400 = 0.02 ohm Source Impedance

This, ladies and gentlemen is what damping factor is all about.

Remember the resistance of the load affects the amplifier's

ability to control its load. We have all heard that the professional

method of loudspeaker cable connections in audio is use to

a heavy gauge cable and the shortest possible cable run. Losses

in loudspeaker cable runs are due to the friction, or heat,

caused by the high level of electron current flow. Most manufacturers

provide an American Wire Gauge (AWG) ## 18 in a 25 foot length

as a standard loudspeaker cord. But the electrons flow back

and forth in a 50 foot circuit. The speaker wire itself opposes

current flow because it has a resistance value.

Let's use an example of an 8 ohm loudspeaker connected directly

to the output terminals of a power amplifier:

102 � 8 = 100 � 8 = 12.5 watts

Now let us suppose we are practicing very poor audio

and have a loudspeaker connected at the end of 153.6 ft of

## 18 gauge copper wire. AWG ## 18 wire has a resistance of 6.51

ohms per 1000 ft (1000 / 6.51 = 153.60), which means that 153.6

ft of ## 18 copper wire will have a resistance of 1 ohm. Since

a loudspeaker wire has two conductors, there would actually

be 2 ohms of resistance in series with an 8 ohm speaker connected

via 153.6 ft of two conductor AWG ## 18 copper wire. Now our

power amplifier looks out at the load and sees the 2 ohms of

wire resistance, in series with 8 ohm loudspeaker impedances.

So the load is now actually 10 ohms instead of 8 ohms.

102 � 10 = 100 � 10 = 10 watts

102 � 10 = 100 � 10 = 10 watts

At first glance you may say that you are only losing

2.5 watts (which is a 20 percent power loss). However, you

are actually losing 36% power. Of the 10 watts now produced

by the amplifier, 2 watts is dissipated in the wire, while

only 8 watts gets to the loudspeaker.

If you think this is not cool, let's examine what this would

do to the amplifier's ability to control or dampen the loudspeaker

load. The loudspeaker actually sees the 2 ohms of wire resistance

in series with the amplifier's internal output or source impedance.

So instead of a Damping Factor of 400, you would have:

DF = Load Z / Source Z

DF = 8 ohm / (.02 + 2 ohm) = 8 / 2.02 = 3.96 DF

We started out with a potential damping factor of 400 and because

of our poor choice of 153.6 ft of wire, we have destroyed the

amplifier's ability to dampen or control the loudspeaker load.

Can you see now why those who know, employ the professional

method of putting the power amplifier as close to the loudspeaker

system as possible and then use the heaviest gauge wire that

will fit the loudspeaker connector. If you haven't been doing

this, you need to start, as you are no longer ignorant regarding

the importance of damping factor.

Before I give up on damping factor, I would like to make one

more point. In the above example I stated that the source impedance

of a CS-800X was .02 ohms; therefore, the DF was 400 when driving

an 8 ohm load. Well, I don't usually promote products in a

paper intended to educate the customer, but I just must make

an exception. Beginning with our recently introduced power

amplifier model CS-800S, we have included circuitry (patent

applied for) that automatically maintains a high damping factor.

This is really an ingenious and simple circuit that our chief

of analog engineering, Jack Sondermeyer, came up with.

There is a circuit that measures the small change in output

voltage when the load impedance changes, and through a feedback

network, the circuitry maintains a constant output voltage

as the voltage neither increases or decreases with a change

in load impedance. You can almost think of it as a negative

source impedance so the Damping Factor remains high. It is

still affected by the resistance in the wire, so you still

would be wise to practice the professional method of short

runs and heavy duty loudspeaker wire. The CS-800S amplifiers

coming off of our production line at Peavey consistently spec

out at greater than 2000 DF, and that is only because that

is the highest number our system can measure.

WE ARE NOT DONE YET!

This paper is on Impedance, and in the course of this

paper's unfolding I segued into source impedance and used it

as a means of explaining damping factor. Source impedance also

applies when you are interfacing components within the audio

system. With loudspeakers, we are trying to match the loudspeaker

load impedance to the output of the power amplifier to obtain

maximum power. When we are only trying to transfer signal from

one device to another within the audio chain, we are not trying

to accomplish any work, so we are not trying to produce significant

levels of current. We are just trying to pass or transfer the

audio signal. There is, of course, current flow, of course,

current flow, as electrons are moving back and forth, but the

intention is to pass the signal as a voltage and not produce

high levels of current and power. However, each signal processor

in front of the power amplifier sees the input impedance of

the next device as a load on its output.

Years ago, during the Jurassic period of audio, they attempted

to transfer audio signal into 600 ohm loads. This is no longer

valid today. The typical input impedance of a modern power

amplifier is 20,000 ohm or 20 k. However, the internal output

impedance (Source Z) of audio devices can be anywhere from

50 ohms to 2,000 ohms. In order to transfer the signal without

introducing major deviations in level and frequency response,

the Source Z to Load Z should have a ratio of 10:1; some people

accept 7:1, but I hold to the 10:1 ratio.

The source impedance is often overlooked by the non-technician

sound system operator. Ignorance may be bliss, but getting

bitten on the behind is not pleasant. There are many signal

processors, equalizers, and crossovers that do an adequate

job in certain applications, but these same devices can cause

many problems when the source-to-load impedance becomes reduced.

The best and first example I am going to use is in interfacing

a number of power amplifiers in larger systems. There is a

limit to how many power amplifier inputs can be paralleled.

The limit is determined by the source impedance of the mixer

output, the equalizer, or the electronic crossover.

Using the math associated with Ohm's Law, we can calculate

what the load impedance will be when we parallel power amplifier

inputs. Two 20,000 ohm inputs in parallel becomes a 10,000

ohm load to the signal source. Dividing the input Z by the

number of amplifiers whose inputs are in parallel will give

the resultant load Z that the signal source sees. Thus ten

power amplifiers with their inputs in parallel would be 20,000

ohms divided by 10, or 2,000 ohms.

This means that if the internal output or source impedance

of the signal source were 200 ohms, we could successfully transfer

the electrical audio signal with no problems. But if the Source

Z were 330 ohms we would be below the stated 10:1 Z ratio.

In large scale professional audio it is very important to consider

the capability of products to drive long lines and/or loads

that represent multiple impedances in parallel. There are many

mixers, equalizers, and crossovers that are priced economically,

and they work fine in certain simple applications. These products

can present problems in large systems, however.

If you want to know how many power amplifiers can be driven

by a signal source, multiply the internal output impedance

of the source by 10, and divide the result into the source

impedance of the power amplifiers. For instance, in our product

line we have two series of graphic equalizers, the EQ series

and the Q series. The EQ series exhibits a 75 ohm source impedance

while the less expensive Q series has a 330 ohm source impedance.

75 x 10 = 75020,000 / 750 = 26

330 x 10 = 3,33020,000 / 3,330 = 6

You can now see that a Peavey EQ-31 can drive 26 CS amplifiers

with their inputs in parallel, while the Q series could only

drive 6. Thus, in applications such as small systems, the Q

series could do a fine job, but there is a limit and now you

know the boundaries.

I know of one mixer manufacturer that has a source impedance

in their mixer's channel inserts of 1,000 ohms. This is not

a real problem if you come out of the mixer with a five to

eight foot shielded signal patch cable to interface some processor.

But there are many users of this product that have them in

studios where the inserts are permanently wired through lengthy

cable that is run beneath the floor across the studio to a

patch bay. They don't realize that the mixer channel is now

rolling off the high frequencies significantly because of the

capacitance of the cables and the high source impedance.

The cable itself becomes a low pass filter. The amount of high

frequency roll-off is determined by the value of the source

impedance. You can find the point where the frequency begins

to roll off by taking reciprocal (1/X) of the source impedance

(R) times the capacitance (C) in the cables, 1 / (R x C). Let's

say, for example, that the cable is long enough to offer 0.2

mfd of capacitance (a microfarad is mathematically 0.000,001

farad).

1 / 100 x 0.000,000,2 = 1 / 0.000,02 = 50,000 Hz or 50 kHz

1 / 1,000 x 0.000,000,2 = 1 / 0.000,2 = 5,000 Hz

The signal processor hooked up to the mixer with an insert

with a 100 ohm source impedance would pass signals out to 50

kHz, while the mixer with the 1,000 ohm source impedance in

its insert would have significant roll-off above 5 kHz.

We have come to the end of this lengthy paper on Impedance.

I believe we have pretty much thoroughly covered the subject.

Some of the things I just shared with you took me fifteen years

or more to understand as I now do. I don't know about you,

but I am still learning. If you are learning, you are growing.

When you stop growing you cease to produce quality.

Below, you�ll find a chart relating source-to-load impedances

and the number of amplifiers that can be driven with the inputs

wired in parallel. There is also a chart on loudspeaker wire.

| SOURCE

Z |

LOAD

IMPEDANCE |

| (in ohms) |

1 K ohm |

2 K ohm |

10 K ohm |

20 K ohm |

| 75 |

1 |

2 |

13 |

26 |

| 100 |

1 |

2 |

10 |

20 |

| 330 |

0 |

0 |

3 |

6 |

| 1000 |

0 |

0 |

1 |

2 |

| 2000 |

0 |

0 |

0 |

1 |

| Copper

Wire Guage |

| AWG## |

Dia

mils |

Dia

mm |

Cir

mils |

Square

inches |

Sq

mm |

Meter/

ohm |

Feet/

ohm |

Audio

amps |

Max

pwr |

Length

DF<50 |

| 22 |

25.35 |

0.6438 |

642.4 |

0.000504 |

0.33 |

18.52 |

60.75 |

3 |

|

|

| 18 |

40.30 |

1.024 |

1624 |

0.001276 |

0.82 |

46.8 |

153.6 |

5 |

150W |

10 Ft |

| 16 |

50.82 |

1.291 |

2583 |

0.002028 |

1.31 |

74.47 |

244.26 |

7 |

280W |

15 Ft |

| 14 |

64.08 |

1.628 |

4107 |

0.003226 |

2.08 |

118.4 |

388.35 |

9 |

400W |

25 Ft |

| 12 |

80.81 |

2.053 |

6530 |

0.005129 |

3.31 |

188.3 |

617.7 |

12 |

800W |

40 Ft |

| 0 |

101.9 |

2.588 |

10380 |

0.008155 |

5.26 |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | |