X . I

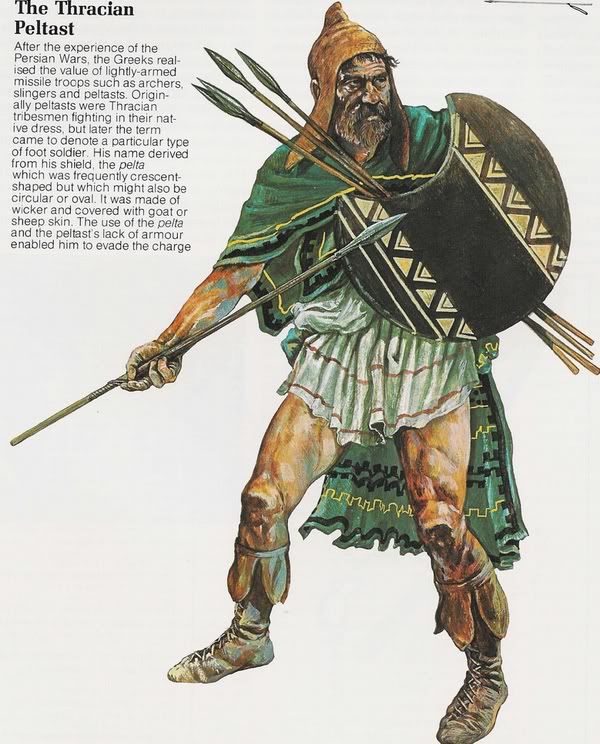

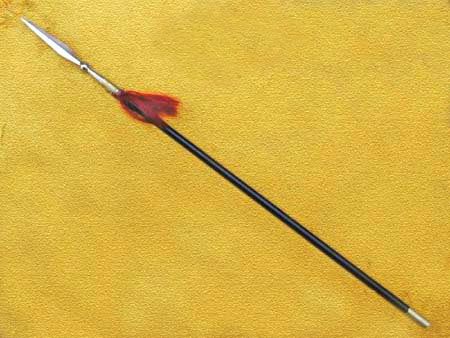

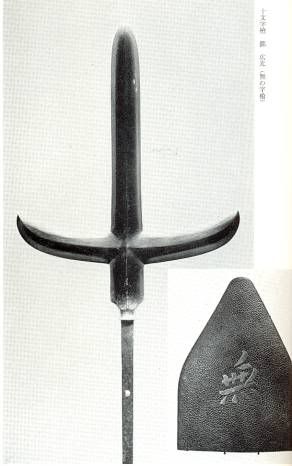

Design Eye Spear and Arrow Wood

in us making spears and arrows from wood to hunt various animals from fish, Couscous, Wild Boar, birds, lizards and so on. Shape spearheads and arrowheads of wood in different designs as needed to hunt certain species of animals. How can it be?

in us making spears and arrows from wood to hunt various animals from fish, Couscous, Wild Boar, birds, lizards and so on. Shape spearheads and arrowheads of wood in different designs as needed to hunt certain species of animals. How can it be?

example example :

Edge Spear and Arrow attributed quarry type:

Carving shaft white accented with lime, a tiny dot on the end designed bamboo, used for hunting wild boar

Scallop shells of tiny fastened with straps on the shaft also used for hunting wild boar

Spearhead-shaped three sharp branches and bending used for hunting birds, which form almost the same but bigger and stronger used for fishing

Arrowheads from bone made a pointed and sharp for the war and for hunting various kinds of animals

The tip of bamboo with small bones attached, used for hunting lizards and birds

![[Detail of 9 arrowheads from the upper Sepik River area, ESP, PNG: 54k]](http://www.art-pacific.com/images/arrowhds.gif)

Jagged ends of wood used for hunting lizards and birds

Jagged ends of wood used for hunting lizards and birds

Black jagged end of the timber used for hunting lizards and birds

Two ends of bamboo inscribed with tiny pieces of colored yarn store wrapped around the shaft used to hunt wild boar

Spear guns in use as a weapon to kill game animals and are also used as tools or weapons of war.

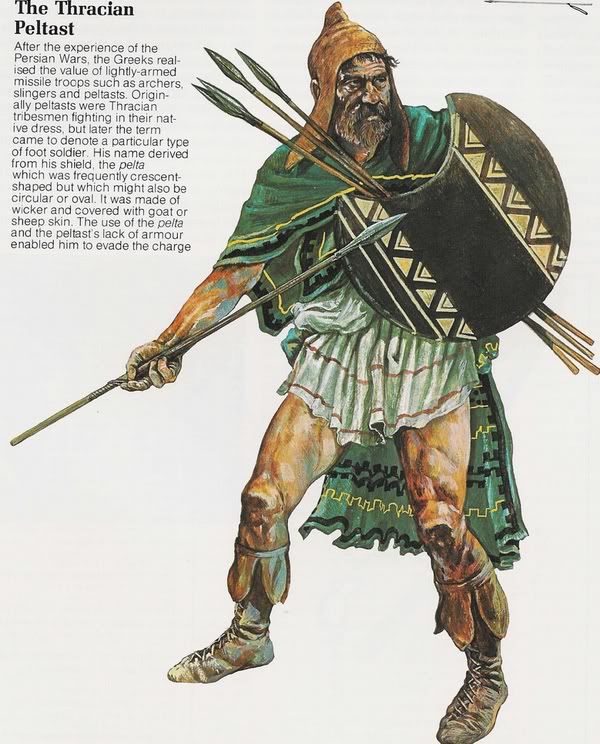

Various models, shapes and materials scattered earth spear. Starting from Europe, Asia, Africa, America.

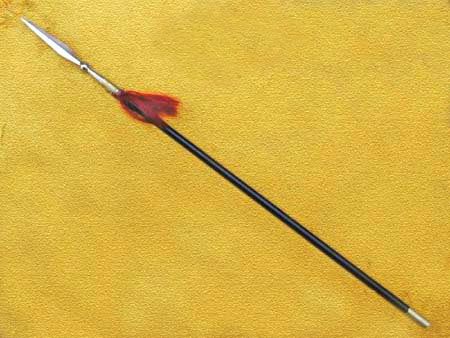

spear guns can be divided into two of the ways of use. The first spears are made and designed and used in a way thrown. Usually spear page. used for hunting game animals. The eye's spear is usually not large, but thin, flat and tapered. Left and right side spear is not so sharp as a knife. The desired effect of the spear page. is lightweight, easy to throw and can easily penetrate the target as the bodies of animals and so on.

Spear mostly made of iron "Prestige" is a mixture of two or more different metal materials and in forging tens, or even hundreds of times. wooden spears made of ironwood made circular with a diameter of no more than 1 inch. At the lower end of the lance also made tapered. The spear can be easily plug the ground.

In addition there is also a hunting spear to spear a bigger wooden handle. This is usually used to fight .

Here is a list of the names of the spear ( not yet translated ) across the world :

Boar spear

Here is a list of the names of the spear ( not yet translated ) across the world :

Boar spear

* Bohemian ear spoon

* Dung

* Falarica

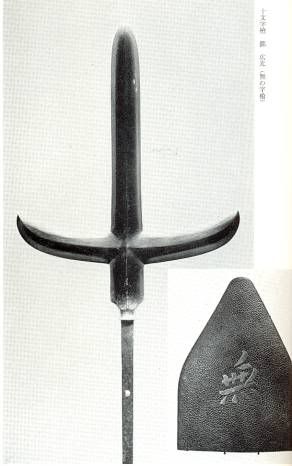

* Trisula / Trident

* Hasta

* Jousting lance

* Lance

* Magari yari

* Ox tongue

* Pike

* Qi膩ng

* Sarissa

* Spontoon

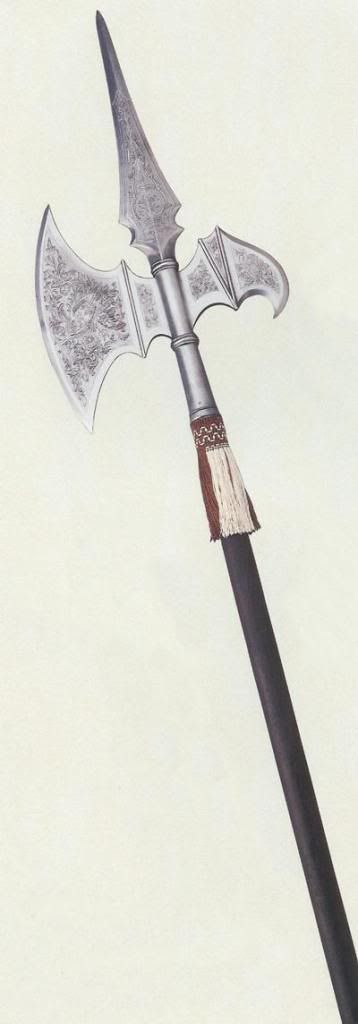

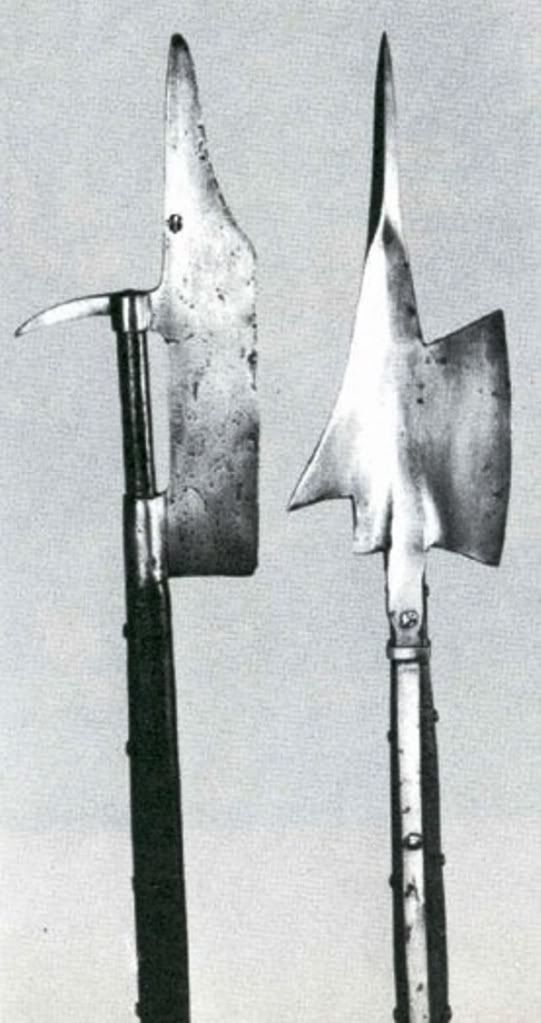

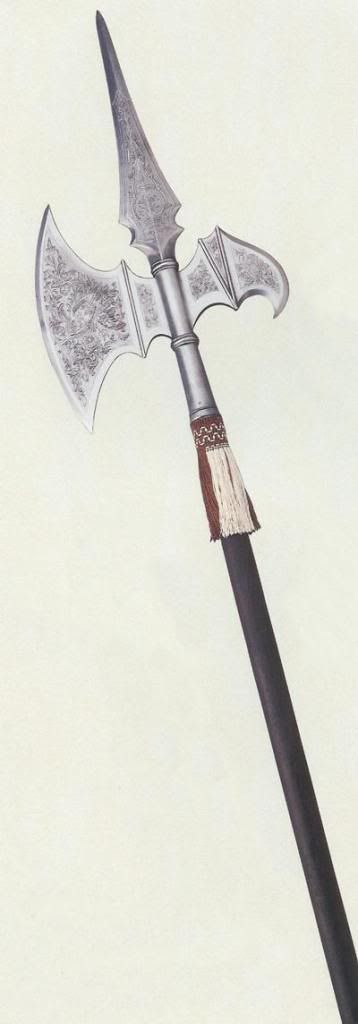

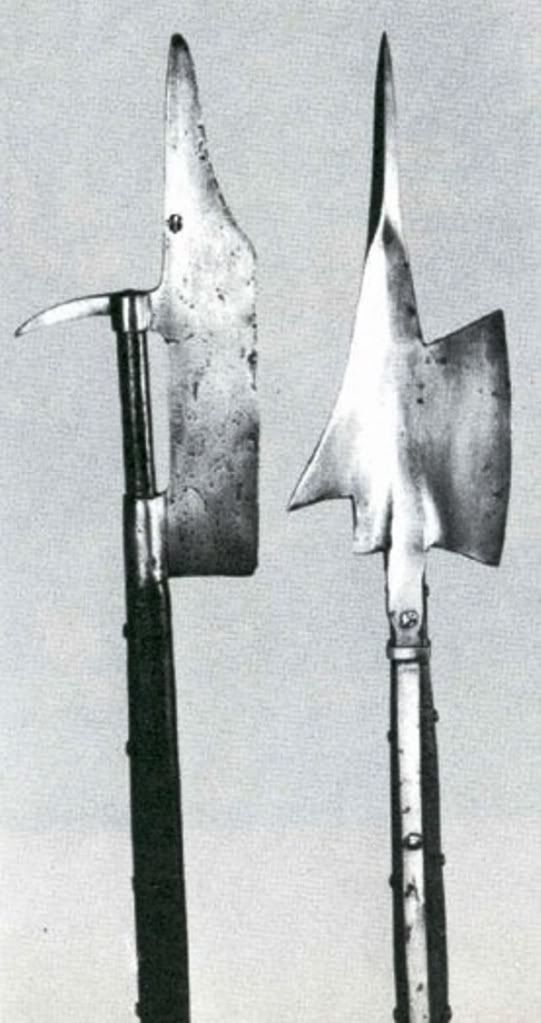

* Halberd

* Voulge

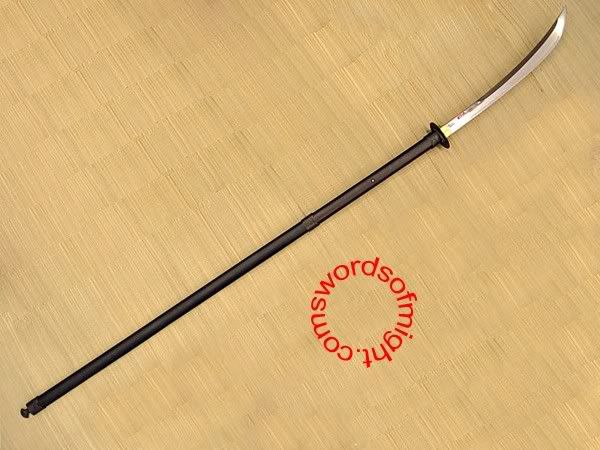

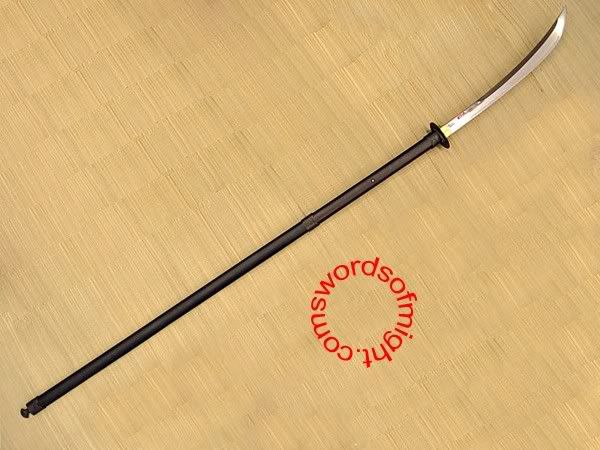

* Naginata

Spear / javelin is thrown

Spear / javelin is thrown

Spear / javelin is thrown in common with a spear shape not thrown, but the difference is how to use that to throw it. Therefore, javelin usually lighter or at least lighter than the spear.

Here are the names that are usually thrown spear in its use:

* Angon

* Assegai

* Budiak

* Fal-feg

* Jarid

* Kamayari

* Jumonji Yari

*

Ancient Weapon Katar

Survival Spear Fishing

Survival Spear Fishing

Bamboo spear to spear fish. The material should not be out of bamboo but from wood can.

X . II

Tools weapon cleaver

how to manufacture a machete acquired from various sources :

1. Iron or steel, as the main ingredients to make a machete.2. Paron hammered as the base, in the form of iron weighing approximately 50-60 kg.3. Puputan / funnel used to create wind that is necessary to maintain the coals, works the same way as wind pumps. It is made of boards long enough.4. The claw is used to clamp or take a machete material is still in a state of smoldering. This tool resembles a pair of pliers.5. Chisel used to divide and cut the material to be used as a dagger. This tool is made of steel.6. Hammer, used for diluting flattened or iron and one of her again for clicking pounding chisel.7. Files, used to smooth the dagger that is perfect nearing completion.8. regulator embers, as the name suggests is used to ferret-Orek embers. This tool is made of steel whose length is approximately 50 cm section

curved edges, while the other end of a handle made of wood.9. tubs, used to cool the saber by dipping iron or steel that is being worked on becomes a machete. This tool is made from former roar of the cut, with a height of approximately 50 cm.10. Sweep stick, used to clean hammered (coaster) of iron or steel debris.11. Charcoal, serve as fuel.12. Stone sharpening, is used to soften and simultaneously to make into a sharp machete.13. Kliwaan / forgings are used to straighten the cleaver blade.14. Sweep the fire is used to rake or collect the scattered charcoal.Manufacture tablets machete was not easy, but it is quite complicated.

First of all the iron is heated for approximately 10 minutes on a fire until flushed, lifted with tweezers, then forged plated or dipped into a bath of water. The second phase will be the cutting iron machete. The third stage of cleavage, but the iron scrap was preheated to a new burning cleaved by putting on a new anvil then split with a chisel. The fourth stage of the formation of a machete while preheated while flaked. The fifth stage, smoothing with a file on a device called a trowel. The sixth stage, gilding by immersion into a water bath in order. The seventh stage, rubbing eyes sharpening with a machete on the whetstone to be sharp. Eighth stage, a kind of ring ooze manufacture pointless to strengthen the grip. Usually made of iron with iron straight way and then burned as a ring-shaped circular. The last stage, the manufacture of the handle and a sheathed dagger made of wood.

the materials used are selected from iron or steel quality steel such as a car or on a car

there are other ways of making a machete

Machete in its manufacture through a long process and complicated. There are at least fourteen tooling used for the manufacture of knives, namely:

1. marquetry or anvil as the base hammered, such as iron, weighing 60-75 kg. The shape varies exist in the form of the letter "T".2.

trowel used to clamp or grip the dagger that was still in a state of

semi-finished, especially if it will be smoothed with a file. The shape resembles a wrench but large in size.3. Pungsong used to create wind that is necessary to maintain the coals, works the same way as wind pumps. It is made of boards long enough.4. tongs or tweezers used to clamp or take a machete material is still in a state of smoldering. This tool resembles a pliers, but his hold up to 50 cm long.5. Chisel used to divide and cut the material to be used as a dagger. This tool is made of steel.6.

hammer, shaped like the letter "T" by their usefulness divided into three

namely the hammer used to make / separating metal that is not

necessary. It weighs 1.5 kg and only craftsman uses. The second and third equal weighing 3 kg, equally used for the

conductor, but uses different, one is used for diluting the flattened or

iron / steel and the other one for chisel.

7. Files, used to smooth the dagger that is perfect nearing completion. This tool is made of steel (bodice) and wood (by the stem).8. Regulatory embers, as the name suggests is used to ferret Orek embers. This tool is made of steel whose length 50 cm sections curved edges, while the other end of a handle made of wood.9. tubs, used to cool the candidate cleaver by dipping iron or steel that is being worked on becomes a machete. This tool is made from former roar of the cut, with a height of approximately 50 cm.10. Sweep stick, used to clean hammered (coaster) of iron or steel debris. These utensils made of palm leaves (leaf) taken sweep stick, then tied into one.11. Charcoal, serve as fuel. Charcoal is made of trees.12. Stone sharpening, is used to soften and simultaneously to make into a sharp machete.13. Kliwaan / forgings used to straighten the cleaver blade. This tool is made of as (steel round and long).14. Sweep the fire, used to sweep or collect charcoal strewn across the kitchen. This

tool resembles a common tool used for whitewashing the walls, the edges

are made of tree roots, while the handle is made of iron

pipes.

Its

manufacture is quite complicated, first, of iron or steel is heated for

approximately 10 minutes on pungsong up flushed, lifted with tweezers,

then plated into a tub of water. The second stage of cutting iron or steel that will be used as a machete. The

third stage of cleavage, but the iron scrap was preheated to a new

burning cleaved by putting on a new placemat and then split with a steel

chisel. The fourth stage of the formation of a machete while preheated while flaked. The fifth stage, smoothing with a file on a device called a trowel. The sixth stage, gilding by immersion into a water bath in order (the "old" = elders) quality is good. The seventh stage, rubbing eyes sharpening with a machete on the whetstone to be sharp. Eighth stage, a kind of ring ooze manufacture pointless to strengthen the handle (upstream). Usually made of iron with iron straight way and then burned as a ring-shaped circular. Phase ninth (last), manufacture and handles made of wood.

X . I

a glimpse of the lights

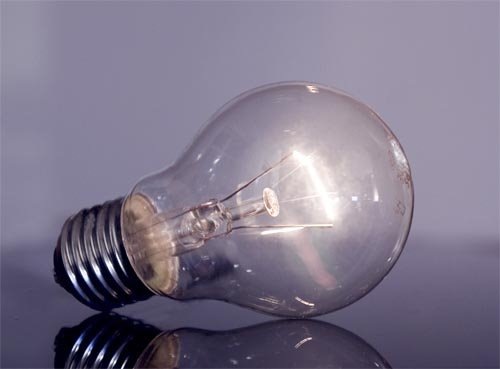

Speaking of lights, you've seen the light. Many companies around the world who create and produce light. The lamp is an object that shone commonly used in the homes, buildings and thoroughfares, electric lights are used to illuminate the dark or at night. There are also many forms, types, characteristics of the lamp. no electric lights that emit white light, and there are also electric lamps that emit yellow light dim. Many electric lights electronics sold in stores, because the function and role is very important. The lamps have some form of some small, medium, and even some that are very large. Here is a definition of what the electric lights and also the definition of the types of electric lights:

Speaking of lights, you've seen the light. Many companies around the world who create and produce light. The lamp is an object that shone commonly used in the homes, buildings and thoroughfares, electric lights are used to illuminate the dark or at night. There are also many forms, types, characteristics of the lamp. no electric lights that emit white light, and there are also electric lamps that emit yellow light dim. Many electric lights electronics sold in stores, because the function and role is very important. The lamps have some form of some small, medium, and even some that are very large. Here is a definition of what the electric lights and also the definition of the types of electric lights:

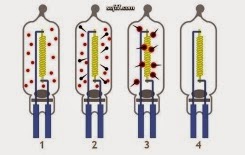

Petromax Light

petromax working principle is "gas flame (Flame from Gas) which heats a material that is incandescent in 1885. In the blue flame of a "Bunsen burner" she heats a cloth to shine six times brighter than the fire itself. The cloth suspended above the burner / burners, the only source of heat, in the form which inspired the name "coat" (ie, a robe). The coat is composed of loosely woven cotton soaked in a liquid solution of thorium and cerium nitrate.

petromax working principle is "gas flame (Flame from Gas) which heats a material that is incandescent in 1885. In the blue flame of a "Bunsen burner" she heats a cloth to shine six times brighter than the fire itself. The cloth suspended above the burner / burners, the only source of heat, in the form which inspired the name "coat" (ie, a robe). The coat is composed of loosely woven cotton soaked in a liquid solution of thorium and cerium nitrate.

After burning a "coat" the first time, the cotton on fire, leaving the skeleton rigid and brittle than thorium and cerium oxide, usually we call "petromax shirt". This oxide emits light when heated to very high temperatures - the principle of incandescent lamps. The newly discovered principle is very revolutionary, especially in the implementation of street lighting, and quickly spread throughout the industrialized world.

Soon, the idea of using liquid fuel for lighting explored. At the end of the 19th century, alcohol-fueled incandescent lamps and kerosene have been developed. This

liquid-fueled lamps use pressure to push the fuel to the "burner", and

the heat from the burner is used to vaporize the liquid fuel. Thus often called "pressure lamp / lantern".

One

of the first and most successful lanterns / pressure kerosene lanterns

made from baker was created in 1910 by Max Graetz - so that it becomes

the name PETROMAX (Petro and Max) - became world famous. Lamp pumped (The kerosene lantern), and a smaller cousin Geniol

lantern, remains popular to this day, both in the private sector and for

professional applications.

Principle kerosene lantern that acts as a small gas plant. The fuel tank is pressurized to about 2 atmospheres (2 bar or 30 psi) with air made with a hand pump. This pressure is used to force the liquid into vapor kerosene. Initially, vaporizers should be preheated so that the change of kerosene into gas before lighting materials / petromax shirt. This

preheating can be achieved by burning alcohol is poured into a cup

preheating located at the base of the vaporiser or under shirts. Once

in operation, the heat of the flames blue (wrapped in a t-shirt) is

used to convert petroleum liquid to a gas / vapor rising through the

vaporizer. Kerosene

liquid into vapor at temperatures around 250 ° C (480 ° F), about half

way to the top of a vaporizer - see illustration. Kerosene vapors proceed through vaporizer circular, and a rise in

temperature, until it comes out of a small hole in the end of the

vaporizer near the speed of sound (1000 ft / sec.).

After

the steam out of kerosene began to spread and mix with the air in the

room was a small square on the side of the lamp pumped. steam mixing kerosene with air resulting kerosene lamp hissing sound when used.Kerosene vapor and air moves into the tube in which both are mixed in a rotating flow (turbulent). This

ensures complete combustion and out of the ceramic nozzles, producing

heat and flame blue shirts were clean and burn petromax .

X . II

Explanation Electric Lamps & Lighting Electrical Types

Understanding Electric Lamps

Understanding Electric Lamps

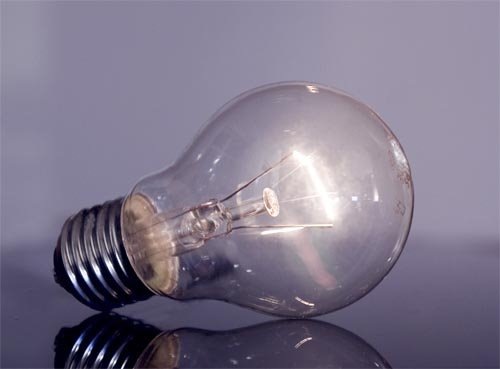

Electric lamp is a device that can produce light when an electric current is applied. The electrical current can be derived power is electricity generated by power plants centralized (Centrally Generated Electric Power) as Genset or electricity generated by batteries and accumulators.

symbol Lights

Types of Electric Lamps

Types of Electric Lamps

Along with the development of technology, Light Electric also has undergone various improvements and progress. Technology

Electric Lamp Incandescent Lamp not only invented by Thomas Alva Edison

alone but is already composed of various types and technologies. Basically, Electric Lamps can be categorized into three types:

Incandescent Lamp (Incandescent Lamps), Gas-discharge Lamp (Gas

Discharge Lamp) and Light Emitting Diode (LED lights).

A. Incandescent Lamp (Incandescent Lamp)

Incandescent

lamps also called Incandescent Lamp is a type of electrical lamp which

produces light by heating the wire filament inside a glass bulb filled

with a gas such as nitrogen, argon, krypton, or hydrogen. We can find a wide selection of Glow Lamp in electrical voltage is line voltage range from 1.5V to 300V.

Incandescent

lamps that can work on DC and AC current flow is widely used in lamps

Luminaries Road, lights Home and Office, Car Lighting, Lamps and

Lighting Decoration Flash. Incandescent lamps in general can only last about 1000 hours and require more electrical energy compared with other lamp types.

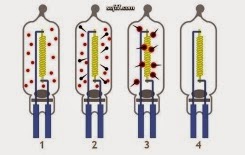

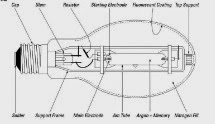

B. Gas Discharge Lamps (Gas Discharge Lamp)

Gas discharge lamps produce light by sending an electrical discharge through the ionized gas, for example in plasma. The nature of gas discharge is highly dependent on the frequency or modulation of the electric current. Typically, this lamp lights using noble gases (argon, neon, krypton, and xenon) or a mixture of these gases. Most of these lamps also contain additional ingredients, such as mercury, sodium, and / or metal halide.

C. The LED (Light Emitting Diode)

LED lights are electronic components that can emit monochromatic light when a given voltage is developed. LED is a family of diodes made of semiconductor materials. Colors light emitted by LEDs depends on the type of semiconductor material he used. LEDs also emit infrared light that is not visible to the eye as often

encountered in Remote Control Remote Control TV or other electronic

devices.

LED shape similar to a bulb (light bulb) are small and can be paired easily into a variety of electronic devices. Unlike the Glow Lamp, LED does not require burning filament that does not cause heat producing lightLED symbol .

X . III

Lamp Types

Based lamp types are divided into several groups, among others:

Based lamp types are divided into several groups, among others:

1. Incandescent Lamp (Incandescent Lamps)

2. Halogen lamps

3. Fluorescent Lamp (Lamp TL)

4. Mercury Lamps

5. Low Pressure Sodium Lamps (SOX)

6. High Pressure Sodium Lamps (SON)

7. LED Lights

Incandenscent lamp (Incandescent Lamps)

characteristics

This type of lamp is commonly referred incandenscent incandescent lamps, incandescent bulbs will emit light when electric current passes through a wire filament incandescent lamp and then heating the filaments. Manufacture of incandescent lamps is also based on several factors, namely the temperature of the filament, the gas mixture is loaded, efficacy (im / W), and the life of the lamp.

Prisoners tungsten filament will be higher if the temperature rises, so the rise in voltage will result in up to prisoners will also be a slight increase in the current flowing. Prisoners filaments approximately one-quarter of the state twelve normal temperature in a cold state. One to note the characteristics of incandescent lamps are the effects of changes in voltage to the lamp.

Work principle

The working principle of the incandescent lamp is a way to connect electrical short in the filament of carbon (C) resulting in short-circuit current to the resulting hot embossing. Heated made up to a certain temperature to give off light,

halogen light

halogen light

mercury light

Kerosene lamp, also called oil lamp has a unique shape. Therefore, these lights also can sometimes be used as a wedding gift or birthday present.

Kerosene lamp, also called oil lamp has a unique shape. Therefore, these lights also can sometimes be used as a wedding gift or birthday present.

Let modifications kerosene lamp into the lamp without the need for kerosene present again.

Tools :

• LED color free @ 1 piece

• Cable small size (yellow and black) @ 1 m

• Batteries buttons (CR2032) @ 1 piece

• The adhesive / tape @ 1 piece

• Fill blackhousing @ 4 pieces

• Header / fishbone @ 2 pieces

• fuel hose / shrink tube @ 1 m

How to modification without lamp pumped into oil again:

How to modification without lamp pumped into oil again:

1. Prepare the tool above tools, such as the image above.

2. Cut into 4 pieces black housing contents and unplug the iron content of the header like this:

3. Take the lamp pumped, and then remove all the parts be as shown below.

3. Take the lamp pumped, and then remove all the parts be as shown below.

4. Remove the rope axis by turning the lever to the left.

5. Cut the yellow and black wires with a length of about 15 cm, then peel each end of the cable.

6. Cable ends are peeled and then put on the content of the black housing and sheathed with the fuel hose was cut sufficiently.

7. Take the LED, then pair foot long LED (+) on the cable of yellow and short legs (-) on the black wire.

8. Pull the LED so that its position had a meeting with the hole axis. Attach the end of black housing empty the contents of the header, so that later can be connected to the battery.

8. Pull the LED so that its position had a meeting with the hole axis. Attach the end of black housing empty the contents of the header, so that later can be connected to the battery.

9. Adhere the end of the cable to the battery latch (CR2032), this time I used a medical plaster, you should use black duct tape or clear. So it becomes like this:

10. Now try to test whether the LED is lit, if lit then the result will be like this:

10. Now try to test whether the LED is lit, if lit then the result will be like this:

11. Attach the parts of a lamp pumped to be like this:

![[Detail of 9 arrowheads from the upper Sepik River area, ESP, PNG: 54k]](http://www.art-pacific.com/images/arrowhds.gif)