Cara kerja gardan

Fungsi utama gardan adalah membedakan putaran roda kiri dan kanan pada

saat mobil sedang membelok.Hal itu dimaksudkan agar mobil dapat

membelok dengan baik tanpa membuat kedua ban menjadi slip atau

tergelincir. Untuk mempelajari cara kerja gardan berikut ini ,

sebaiknya Anda baca terlebih dahulu postingan saya tentang

mengenal gardan . Adapun cara kerja gardan adalah sebagai berikut :

Pada saat mobil berjalan lurus :

Pada saat mobil berjalan lurus keadaan kedua ban roda kiri dan kanan

sama - sama dalam kecepatan putaran yang sama.Dan juga beban yang

ditanggung roda kiri dan roda kanan adalah sama. Sehingga urutan

perpindahan putaran dari as kopel akan diteruskan untuk memutar drive

pinion . Drive pinion akan memutar ring gear , dan ring gear bersama -

sama dengan differential case akan berputar. Dengan berputarnya

differential case , maka pinion gear akan terbawa berputar bersama

dengan differential case karena antara differential case dan pinion gear

dihubungkan dengan pinion shaft. Karena beban antara roda kiri dan

roda kanan adalah sama saat jalan lurus , maka pinion gear akan membawa

side gear kanan dan side gear kiri untuk berputar dalam satu kesatuan.

Jadi dalam keadaan jalan lurus sebenarnya pinion gear tidak berputar ,

pinion gear hanaya membawa side gear untuk berputar bersama - sama

dengan differential case dalam kecepatan putaran yang sama. Bila

differential case berputar satu kali , maka side gear juga berputar

satu kali juga , demikian seterusnya dalam keadaan lurus. Putaran side

gear ini kemudian akan diteruskan untuk menggerakkan as roda dan

kemudian menggerakkan roda.

Pada saat kendaraan membelok :

Pada saat mobil sedang membelok beban yang ditanggung pada roda bagian

dalam adalah lebih besar daripada beban yang ditanggung roda bagian luar

. Misalkan sebuah mobil sedang belok ke kiri, maka beban pada roda

kiri akan lebih besar daripada beban roda kanan. Dengan demikian urutan

perpindahan tenaganya adalah sebagai berikut ; P:utaran dari as kopel

akan diteruskan untuk memutar drive pinion . Drive pinion akan memutar

ring gear . Dengan berputarnya ring gear maka differential case akan

terbawa juga untuk berputar. Karena beban roda kiri lebih besar dari

roda kanan saat belok ke kiri , maka side gear sebelah kiri akan memberi

perlawanan terhadap pinion gear untuk tidak berputar . Gaya perlawanan

dari side gear kiri ini akan membuat pinion gear menjadi berputar

mengitari side gear kiri. Dengan berputarnya pininon gear , maka side

gear kanan akan diputar oleh pinion gear. Sehingga side gear kanan akan

berputar lebih cepat dari side gear kiri. Gerakan side gear ini akan

diteruskan ke as roda kemudian ke roda. Untuk roda kanan akan berputar

lebih cepat daripada roda kiri karena side gear kanan berputar lebih

cepat.

Penggerak Sudut

1. Bagian – bagian poros penggerak aksel

1. Rumah Penggerak Aksel

2. Gigi Pinion

3. Gigi Korona

4. Gigi Kerucut Samping/Matahari

5. Rumah Differensial

6. Poros Gigi Kerucut Antara

7. Gigi Kerucut Antara/Planet

8. Mounting Rumah Penggerak aksel

9. Tutup Debu

10. Poros Aksel

11. Penghubung Bola/Penghubung CV

12. Bantalan Rumah Diferensial

13. Bantalan Poros Pinion

14. Sil Oli

2. Penggunaan :

Kendaraan dengan motor memanjang, untuk meneruskan putaran ke roda-roda

diperlukan penggerak sudut. Karena arah putaran motor berbeda dengan

arah putaran roda – roda

3. Fungsi : • Merubah arah putaran dari arah putaran mesin ke kanan ( a ) menjadi arah putaran maju ( b ) ke roda – roda

4. Jenis Penggerak Sudut

Pada saat sekarang penggerak aksel hanya menggunakan penggerak sudut

roda korona. Tetapi pada sistem lama, misalnya merek PEUGEOT menggunakan

penggerak roda cacing.

Perbandingan gigi pada : • Sedan station antara 3,5 : 1 s/d 4,5 : 1

• Truk antara 5 : 1 s/d 12 : 1

Jenis biasa :

Sumbu poros pinion segaris dengan aksis roda korona Konstruksi ini hanya digunakan pada truk

Kerugian :

• Suara tidak halus

• Gaya pada gigi besar ( Konstruksi Berat )

Jenis biasa :

Sumbu poros pinion segaris dengan aksis roda korona Konstruksi ini hanya digunakan pada truk

Kerugian :

• Suara tidak halus

• Gaya pada gigi besar ( Konstruksi Berat )

Jenis Hypoid

Sumbu poros pinion tidak segaris dengan aksis roda korona

Konstruksi ini : Digunakan pada sedan, station dan truk

Keuntungan :

• Suara halus

• Permukaan gigi yang memindahkan gaya lebih besar

• Poros penggerak ( Gardan ) lebih rendah

Kerugian :

• Perlu oli khusus GL 4 atau GL 5

• Gesekan antara gigi lebih besar

5. Bentuk Gigi

Dari bentuk giginya, roda korona ada 2 macam

• Klingenberg

• Gleason

Klingenberg

Klingenberg

• Tebal puncak gigi bagian dalam dan bagian luar sama (A=B)

• Disebut gigi spiral karena bentuk gigi sebagian dari busur spiral

• Kebanyakan digunakan pada mobil Eropa dan Jepang

Gleason

Gleason

• Tebal puncak gigi bagian dalam dan bagian luar tidak sama (a?b)

• Disebut gigi lingkar karena bentuk – bentuk gigi sebagian dari busur lingkaran

• Kebanyakan digunakan pada mobil Amerika

6. Penyetelan Penggerak Aksel

1. Tinggi pinion

Untuk mendapatkan posisi gigi pinion yang tepat terhadap gigi roda korona

2. Pre – load pinion

Agar keausan bantalan tidak menyebabkan kebebasan bantalan

3. Celah bebas gigi roda korona ( Back Lash )

Roda korona dapat berputar dengan baik/halus dan tidak menimbulkan suara persentuhan gigi atau suara dengung

4. Pre – load bantalan rumah diferensial ( Keseluruhan )

Agar keausan bantalan tidak menimbulkan kebebasan bantalan / gerak aksial roda korona

5. Memeriksa Persinggungan gigi

Untuk menempatkan posisi permukaan kontak gigi pinion dan roda korona

benar ( di tengah – tengah ) sehinggga suara halus dan keausan merata

7. Bentuk Rumah Aksel ( Penggerak Aksel )

Dari bentuk rumah penggerak aksel dapat dibedakan tiga macam :

• Aksel Banjo

• Aksel Spicer

• Aksel Terompet

7.1. Aksel Banjo

Rumah bantalan lebih kuat menahan gaya ke samping / aksial roda korona

kurang kuat, biasa digunakan pada kendaraan sedan, Station dan Jep

7.2. Aksel Spicer

Rumah bantalan lebih kuat menahan gaya ke samping / aksial roda korona jenis ini sering digunakan pada jeep dan truk

7.4. Aksel Terompet

Rumah bantalan merupakan satu kesatuan yang kokoh dengan rumah aksel,

jenis ini paling kuat menahan gaya ke samping / aksial roda korona

biasanya digunakan pada jenis kendaraaan berat

Jarang lagi digunakan pada kendaraan, karena :

• Konstruksi rumit

• Penyetelan sulit

• Harga mahal

Jenis Tapak Ban Mobil

Asimetris

Unidirectional/ satu arah

Tapak ban searah ini sangat mudah dikenali yakni pada corak/ kembang

bagian tengah seperti membentuk huruf v, tapak ban tipe searah ini

memiliki kemampuan membuang air yang cukup bagus karena bisa dibuang ke

dua arah (sisi luar dan dalam). Ban ini hanya optimal digunakan searah

jadi tipe unidirectional jarang digunakan untuk ban offroad. Huruf v

seperti anak panah menunjukkan arah maju (putaran kedepan) jadi

hati-hati saat memasang ban tipe searah ini karena kesalahan dalan

rotasi bisa sangat jelek performanya, biasanya pada dinding ban juga ada

tanda panah yang menunjukkan arah rotasi ban.

Ban tipe ini biasanya tersedia untuk tipe di atas 15 inch, nyaman untuk jalan aspal untuk kecepatan dan performa yang tinggi

Tapak Ban Eco

Ban eco dikembangkan oleh produsen ban untuk menghasilkan ban yang

ringan dan tidak terlalu mencengkeram pada aspal, ban eco memiliki alur

yang sederhana dengan lebar tapak ban yang relatif kecil untuk

meminimalkan hambatan akibat gesekan dengan aspal. Ban eco ini sangat

baik untuk mobil hemat BBM karena menunjang performa penghematan

konsumsi BBM, kurang cocok dipakai pada mobil-mobil SUV karena daya

cengkeram ke permukaan jalan kecil (mudah slip)

Ban Alur Lebar

Ban yang menggunakan alur lebar ini biasanya memiliki ketebalan tapak

yang tinggi, ban offroad banyak memakai tipe ini (beralur lebar),

kelebihan ban dengan alur lebar adalah sangat mumpuni dalam membuang air

yang meskipun hujan lebat ban ini mampu membuang air dengan sempurna

dan masih mencengkeram aspal dengan baik. Cocok untuk medan-medan

ekstrim seperti jalan licin, berair, berpasir dan lain sebagainya.

Kelemahan ban alur lebar ini adalah tidak cocok digunakan untuk

kecepatan tinggi pada jalan aspal karena selain getaran yang ditimbulkan

terasa sampak dalam kabin, suara yang ditimbulkan juga sangat berisik

pada kecepatan tinggi.

Ban Slick

Ban Semi Slick

Differential (mechanical device)

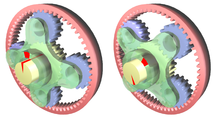

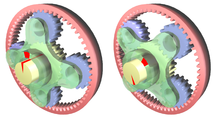

A spur gear differential constructed by engaging the planet gears of two

co-axial epicyclic gear trains. The casing is the carrier for this

planetary gear train. A differential is a particular type of simple planetary gear train

that has the property that the angular velocity of its carrier is the

average of the angular velocities of its sun and annular gears. This is

accomplished by packaging the gear train so it has a fixed carrier train ratio R = -1,

which means the gears corresponding to the sun and annular gears are

the same size. This can be done by engaging the planet gears of two

identical and coaxial epicyclic gear trains to form a spur gear differential. Another approach is to use bevel gears for the sun and annular gears and a bevel gear as the planet, which is known as a bevel gear differential.

Overview

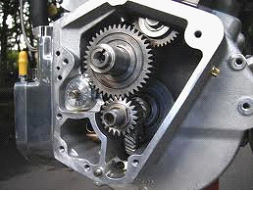

Automotive differential: The drive gear 2 is mounted on the carrier 5

which supports the planetary bevel gears 4 which engage the driven bevel

gears 3 attached to the axles 1.

ZF Differential. The drive shaft enters from the front and the driven axles run left and right.

In

automobiles

and other wheeled vehicles, the differential allows the outer drive

wheel to rotate faster than the inner drive wheel during a turn. This is

necessary when the vehicle turns, making the wheel that is traveling

around the outside of the turning curve roll farther and faster than the

other. The average of the rotational speed of the two driving wheels

equals the input rotational speed of the drive shaft. An increase in the

speed of one wheel is balanced by a decrease in the speed of the other.

When used in this way, a differential couples the input shaft (or prop shaft) to the

pinion, which in turn runs on the

crown

wheel of the differential. This also works as reduction gearing to give

the ratio. On rear wheel drive vehicles the differential may connect to

half-shafts inside an axle casing or drive shafts that connect to the

rear driving wheels. Front wheel drive vehicles tend to have the pinion

on the end of the main-shaft of the gearbox and the differential is

enclosed in the same casing as the gearbox. They have individual

drive-shafts to each wheel. Older 4x4 vehicles and tractors usually have

a solid front axle, the modern way can be a separate differential and

drive shaft arrangement for the front.

A differential consists of one input, the drive shaft, and two

outputs which are the two drive wheels, however the rotation of the

drive wheels are coupled by their connection to the roadway. Under

normal conditions, with small tyre slip, the ratio of the speeds of the

two driving wheels is defined by the ratio of the radii of the paths

around which the two wheels are rolling, which in turn is determined by

the track-width of the vehicle (the distance between the driving wheels)

and the radius of the turn.

Non-automotive uses of differentials include performing

analog arithmetic.

Two of the differential's three shafts are made to rotate through

angles that represent (are proportional to) two numbers, and the angle

of the third shaft's rotation represents the sum or difference of the

two input numbers. The earliest known use of a differential gear is in

the

Antikythera Mechanism,

circa 80 BCE, which used a differential gear to control a small sphere

representing the moon from the difference between the sun and moon

position pointers. The ball was painted black and white in hemispheres,

and graphically showed the phase of the moon at a particular point in

time.

[1] See also the Chinese

South-pointing chariot. An

equation clock

that used a differential for addition was made in 1720. In the 20th

Century, large assemblies of many differentials were used as

analog computers,

calculating, for example, the direction in which a gun should be aimed.

However, the development of electronic digital computers has made these

uses of differentials obsolete. Military uses may still exist. See

Electromagnetic pulse. Practically all the differentials that are now made are used in automobiles and similar vehicles.

Epicyclic gearing

is used here to apportion torque asymmetrically. The input shaft is the

green hollow one, the yellow is the low torque output, and the pink is

the high torque output. The force applied in the yellow and the pink

gears is the same, but since the arm of the pink one is 2× to 3× as big,

the torque will be 2× to 3× as high.

Epicyclic differential

Epicyclic gearing

is used here to apportion torque asymmetrically. The input shaft is the

green hollow one, the yellow is the low torque output, and the pink is

the high torque output. The force applied in the yellow and the pink

gears is the same, but since the arm of the pink one is 2× to 3× as big,

the torque will be 2× to 3× as high.

An epicyclic differential can use

epicyclic gearing to split and apportion

torque asymmetrically between the front and rear axles. An epicyclic differential is at the heart of the

Toyota Prius

automotive drive train, where it interconnects the engine,

motor-generators, and the drive wheels (which have a second differential

for splitting torque as usual). It has the advantage of being

relatively compact along the length of its axis (that is, the sun gear

shaft).

Epicyclic gears are also called planetary gears because the axes of

the planet gears revolve around the common axis of the sun and ring

gears that they mesh with and roll between. In the image, the yellow

shaft carries the sun gear which is almost hidden. The blue gears are

called planet gears and the pink gear is the ring gear or annulus.

Ring gears are also used in

starter motors.

Spur-gear differential

This is another type of differential that was used in some early automobiles, more recently the

Oldsmobile Toronado, as well as other non-automotive applications. It consists of

spur gears only.

A spur-gear differential has two equal-sized spur gears, one for each half-shaft, with a space between them. Instead of the

Bevel gear,

also known as a miter gear, assembly (the "spider") at the centre of

the differential, there is a rotating carrier on the same axis as the

two shafts. Torque from a

prime mover or

transmission, such as the drive shaft of a car, rotates this carrier.

Mounted in this carrier are one or more pairs of identical pinions,

generally longer than their diameters, and typically smaller than the

spur gears on the individual half-shafts. Each pinion pair rotates

freely on pins supported by the carrier. Furthermore, the pinion pairs

are displaced axially, such that they mesh only for the part of their

length between the two spur gears, and rotate in opposite directions.

The remaining length of a given pinion meshes with the nearer spur gear

on its axle. Therefore, each pinion couples that spur gear to the other

pinion, and in turn, the other spur gear, so that when the drive shaft

rotates the carrier, its relationship to the gears for the individual

wheel axles is the same as that in a bevel-gear differential.

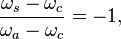

A spur gear differential is constructed from two identical coaxial

epicyclic gear trains assembled with a single carrier such that their

planet gears are engaged. This forms a

planetary gear train with a fixed carrier train ratio

R = -1.

In this case, the fundamental formula for the planetary gear train yields,

or

Thus, the angular velocity of the carrier of a spur gear differential

is the average of the angular velocities of the sun and annular gears.

In discussing the spur gear differential, the use of the term

annular gear

is a convenient way to distinguish the sun gears of the two epicyclic

gear trains. The second sun gear serves the same purpose as the annular

gear of a simple planetary gear train, but clearly does not have the

internal gear mate that is typical of an annular gear.

Planetary differential used to drive a

chart recorder

circa 1961. The motors drive the sun and annular gears, while the

output is taken from the planet gear carrier. This gives 3 different

speeds depending on which motors are on.

Non-automotive applications

Differential used to control the take-up

reel of a

paper tape reader made by

Tally circa 1962. The bevel gears spin freely on their shafts, unless a

brake shoe stops the left gear. This causes the planet gear to drive the output shaft at half the speed of the driven gear on the right.

Planetary differential used to drive a

chart recorder

circa 1961. The motors drive the sun and annular gears, while the

output is taken from the planet gear carrier. This gives 3 different

speeds depending on which motors are on.

Chinese

south-pointing chariots

may also have been very early applications of differentials. The

chariot had a pointer which constantly pointed to the south, no matter

how the chariot turned as it travelled. It could therefore be used as a

type of

compass.

It is widely thought that a differential mechanism responded to any

difference between the speeds of rotation of the two wheels of the

chariot, and turned the pointer appropriately. However, the mechanism

was not precise enough, and, after a few miles of travel, the dial could

have very well been pointing in the complete opposite direction.

The earliest definitely verified use of a differential was in a clock

made by Joseph Williamson in 1720. It employed a differential to add

the

Equation of Time to

local mean time, as determined by the clock mechanism, to produce

solar time, which would have been the same as the reading of a

sundial.

During the 18th Century, sundials were considered to show the "correct"

time, so an ordinary clock would frequently have to be readjusted, even

if it worked perfectly, because of seasonal variations in the Equation

of Time. Williamson's and other

equation clocks

showed sundial time without needing readjustment. Nowadays, we consider

clocks to be "correct" and sundials usually incorrect, so many sundials

carry instructions about how to use their readings to obtain clock

time.

In the first half of the twentieth century, mechanical

analog computers, called

differential analyzers, were constructed that used differential gear trains to perform

addition and

subtraction. The U.S. Navy Mk.1 gun fire control computer used about 160 differentials of the bevel-gear type.

A differential gear train can be used to allow a difference between two input axles.

Mills

often used such gears to apply torque in the required axis.

Differentials are also used in this way in watchmaking to link two

separate regulating systems with the aim of averaging out errors.

Greubel Forsey use a differential to link two double

tourbillon systems in their Quadruple Differential Tourbillon.

Functional description

Input torque is applied to the ring gear (blue), which turns the entire

carrier (blue). The carrier is connected to both sun gears (red and

yellow) only through the planet gear (green). Torque is transmitted to

the sun gears through the planet gear. The planet gear revolves around

the axis of the carrier, driving the sun gears. If the resistance at

both wheels is equal, the planet gear revolves without spinning about

its own axis, and both wheels turn at the same rate.

If the left sun gear (red) encounters resistance, the planet gear

(green) spins as well as revolving, allowing the left sun gear to slow

down, with an equal speeding up of the right sun gear (yellow).

The following description of a differential applies to a

"traditional" rear-wheel-drive car or truck with an "open" or limited

slip differential combined with a reduction gearset using bevel gears

(these are not strictly necessary – see

spur-gear differential):

Thus, for example, if the car is making a turn to the right, the main

crown wheel may make 10 full rotations. During that time, the left

wheel will make more rotations because it has further to travel, and the

right wheel will make fewer rotations as it has less distance to

travel. The sun gears (which drive the axle half-shafts) will rotate in

opposite directions relative to the ring gear by, say, 2 full turns each

(4 full turns relative to each other), resulting in the left wheel

making 12 rotations, and the right wheel making 8 rotations.

The rotation of the crown wheel gear is always the average of the

rotations of the side sun gears. This is why, if the driven roadwheels

are lifted clear of the ground with the engine off, and the drive shaft

is held (say leaving the transmission 'in gear', preventing the ring

gear from turning inside the differential), manually rotating one driven

roadwheel causes the opposite roadwheel to rotate in the opposite

direction by the same amount.

When the vehicle is traveling in a straight line, there will be no

differential movement of the planetary system of gears other than the

minute movements necessary to compensate for slight differences in wheel

diameter, undulations in the road (which make for a longer or shorter

wheel path), etc.

Automobiles without differentials

Although most automobiles in the developed world use differentials there are a few that do not. Several different types exist:

- Race cars and trucks in certain classes. Drag racing is done in a straight line (and often on a prepared surface), which obviates the need for a differential. A spool

is used to make a solid connection between both drive wheels, which is

simpler and less likely to break under very heavy acceleration. Racing

on dirt or mud tracks also allows the use of spools, because the loose

surface gives way while cornering. NASCAR

mandates the use of spools in their cars, which does cause axle

wind-up, and degrades handling in turns. Other forms of racing without

differentials includes tractor pulling, mud bogging and other 4x4 motorsports where differential action is not needed.

- Vehicles with a single driving wheel. Besides motorcycles, which are

generally not classified as automobiles, this group includes most

three-wheeled cars. These were quite common in Europe in the mid-20th

Century, but have now become rare there. They are still common in some

areas of the developing world, such as India. Some early four-wheeled

cars also had only one driving wheel to avoid the need for a

differential. However, this arrangement led to many problems. The system

was unbalanced, the driving wheel would easily spin, etc.. Because of

these problems, few such vehicles were made.

- Vehicles using two freewheels.

A freewheel, as used on a pedal bicycle for example, allows a road

wheel to rotate faster than the mechanism that drives it, allowing a

cyclist to stop pedalling while going downhill. Some early automobiles

had the engine driving two freewheels, one for each driving road wheel.

When the vehicle turned, the engine would continue to drive the wheel on

the inside of the curve, but the wheel on the outside was permitted to

rotate faster by its freewheel. Thus, while turning, the vehicle had

only one driving wheel. Driving in reverse is also impossible as is

engine braking due to the freewheels.

- Vehicles with continuously variable transmissions, such as the DAF Daffodil. The Daffodil, and other similar vehicles which were made until the 1970s by the Dutch company DAF,

had a type of transmission that used an arrangement of belts and

pulleys to provide an infinite number of gear ratios. The engine drove

two separate transmissions which ran the two driving wheels. When the

vehicle turned, the two wheels could rotate at different speeds, making

the two transmissions shift to different gear ratios, thus functionally

substituting for a differential. The slower moving wheel received more

driving torque than the faster one, so the system had limited-slip

characteristics. The duplication also provided redundancy. If one belt

broke, the vehicle could still be driven.

- Light vehicles with closely spaced rear wheels, such as the Isetta and Opperman Unicar, or very low mass vehicles.

- Vehicles with separate motors for the driving wheels. Electric cars

can have a separate motor for each driving wheel, eliminating the need

for a differential, but usually with some form of gearing at each motor

to get the large wheel torques necessary. A multi-motor electric vehicle

such as the Dual Motor Tesla Model S

can electronically control the power distribution between the motors on

a millisecond scale, in this case acting as a centre differential where

open differentials are still employed left-to-right.

Automatic lockers

Automatic lockers lock and unlock automatically with no direct input

from the driver. Some automatic locking differential designs ensure that

engine power is always transmitted to both wheels, regardless of

traction conditions, and will "unlock" only when one wheel is required

to spin faster than the other during cornering. These would be more

correctly termed "automatic unlocking" differentials, because their

at-rest position is locked. They will never allow either wheel to spin

slower than the

differential carrier

or axle as a whole, but will permit a wheel to be over-driven faster

than the carrier speed. The most common example of this type would be

the famous "Detroit Locker," also known as the "Detroit No-Spin," which

replaces the entire differential carrier assembly. Others, sometimes

referred to as "

lunchbox lockers,"

employ the stock differential carrier and replace only the internal

spider gears and shafts with interlocking plates. Both types of

automatic lockers will allow for a degree of differential wheel speed

while turning corners in conditions of equal traction, but will

otherwise lock both axle shafts together when traction conditions demand

it.

- Pros: Automatic action, no driver interaction necessary, no stopping

for (dis-) engagement necessary, continuous driving even in unforeseen

road condition changes

- Cons: Increased tire wear and noticeable impact on driving behavior.

During cornering, which half-axle is uncoupled is dependent on torque

direction applied by the drivelive. When the torque direction is

reversed, the speed of the driveline is suddenly forced to change from

the inner to outer axle, accompanied by tire chirping and a large jerk.

During cornering, the automatic locker is characterized by heavy

understeer which transitions instantly to power oversteer when traction

is exceeded.

Some other automatic lockers operate as an open differential until

wheel slip is encountered and then they lock up. This style generally

uses an internal governor to monitor vehicle speed and wheel slip. An

example of this is the

Eaton Automatic Locking Differential (ALD), or

Eaton Automatic Differential Lock (ADL), developed by the

Eaton Corporation and introduced in 1973 for

GM's

Rounded-Line C/K Series pickups and utilities.

The Eaton ADL is sometimes incorrectly called the "Gov-Lok", despite

neither GM nor Eaton ever calling it by that name. "Gov-Lok" is rather

an

unofficial name of unknown origin

that gained popularity over the years. Both Eaton and GM do not know

where the name came from, and Eaton has made several unsuccessful

attempts in the past to debunk the Gov-Lok name.

An updated version of the old Eaton ADL design is still available from Eaton, now known as the

Eaton mLocker mechanical differential lock.

Some other automatic lockers operate as an open differential until

high torque is applied and then they lock up. This style generally uses

internal gears systems with very high friction. An example of this is

the ZF "sliding pins and cams" available for use in early Volkswagens.

Selectable lockers

Selectable lockers allow the driver to lock and unlock the

differential at will from the driver's seat. This can be accomplished

many ways.

- Compressed air (pneumatics).

- Cable operated mechanism as is employed on the "Ox Locker."

- Electronic solenoids and (electromagnetics)

like Eaton's "ELocker." However, OEMs are beginning to offer electronic

lockers as well. Nissan Corporation's electric locker can be found as

optional equipment on the Frontier (Navara) & Xterra.

- Pros: Allows the differential to perform as an "open" differential

for improved driveability, maneuverability, provides full locking

capability when it is desirable or needed

- Cons: Mechanically complex with more parts to fail. Some lockers

require vehicle to stop for engagement. Needs human interaction and

forward-thinking regarding upcoming terrain. Unskilled drivers often put

massive stress on driveline components when leaving the differential in

locked operation on terrain not requiring a locker.

Spool

A spool is a device that connects the two axles directly to the ring

gear. There is no differentiation side to side, so a vehicle equipped

with a spool will bark tires in turns and may become unmanageable in wet

or snowy weather. Spools are usually reserved for competition vehicles

not driven on the street.

Mini-spool uses the stock carrier and replaces only the internal

components of the differential, similar in installation to the lunchbox

locker. A full spool replaces the entire carrier assembly with a single

machined piece. A full spool is perhaps the strongest means of locking

an axle, but has no ability to differentiate wheel speeds whatsoever,

putting high stress on all affected driveline components.

The internal spider gears of an open differential can also be welded

together to create a locked axle; this method is not recommended as the

welding process seriously compromises the metallurgical composition of

the welded components, and can lead to failure of the unit under stress.

If it is desirable to have a spooled axle, the better option is to

install either a mini-spool or a full spool.

Disadvantages

Because they do not operate as smoothly as standard differentials,

automatic locking differentials are often responsible for increased tire

wear. Some older automatic locking differentials are known for making a

clicking or banging noise when locking and unlocking as the vehicle

negotiates turns. This is annoying to many drivers. Also, automatic

locking differentials will affect the ability of a vehicle to steer,

particularly if a locker is located in the front axle. Aside from tire

scuffing while turning any degree on high friction (low slip) surfaces,

locked axles provoke understeer and, if used on the front axle, will

increase steering forces required to turn the vehicle. Furthermore,

automatically locking differentials can cause a loss of control on ice

where an open differential would allow one wheel to spin and the other

to hold,

while not transferring power. An example of this would

be a vehicle parked sideways on a slippery grade. When both wheels spin,

the vehicle will break traction and slide down the grade.

Alternatives

Limited slip differentials

are considered a compromise between a standard differential and a

locking differential because they operate more smoothly, and they do

direct some extra torque to the wheel with the most traction compared to

a standard differential, but they are not capable of 100% lockup.

Traction control systems

are also used in many modern vehicles either in addition or as a

replacement of locking differentials. One example is that offered by

Volkswagen under the name of

electronic differential lock

(EDL). This EDL is not in fact a differential lock, but operates at

each wheel. Sensors monitor wheel speeds, and if one is rotating more

than 100 RPM more than the other (i.e. slipping) the EDL system

momentarily brakes it. This transfers more power to the other wheel,

but still employs the

open differential, which is the same as on cars without the EDL option. Electronic traction control systems may be integrated with

anti-lock braking

systems, which have a similar action on braking and use some similar

components. Such systems are used for example on the most recent

Nissan Pathfinder,

Land Rover Defender,

Land Rover Freelander, the

McLaren P1 and the

McLaren 650s.

Applications

- Race cars

often use locking differentials in order to maintain traction during

high speed maneuvers or when accelerating at extreme rates.

Additionally, vehicle dynamics are made more predictable when there is a

loss of traction, as the driver knows that neither wheel will suddenly

sap power if it encounters a low-friction surface.

- Some utility vehicles such as tow trucks, forklifts, tractors, and heavy equipment

use locking differentials to maintain traction, especially when driving

on soft, muddy, or uneven surfaces. Lockers are common in agricultural

equipment and military trucks. On some farm tractors, there is a pedal

that can be stepped on with the operator's heel to lock the differential

as needed.

- Differential locking can also be used in the sport of drifting as an alternative to a limited slip differential.

- Four-wheel drive vehicles that drive off-road

often use a locking differential to keep from getting stuck when

driving on loose, muddy, or rocky terrain. Locking differentials are

considered essential equipment for serious off-road driving. Many such

vehicles have a locking differential on the central differential

(between the front and rear axles), rear differential and front

differential; or any combination of any of the three. Differential locks

are also used on some "non-utility" four-wheel-drive vehicles (such as

the Mitsubishi Shogun)

to compensate for a relative lack of axle articulation (vertical wheel

movement). High amounts of articulation are desirable for off-road

driving, to allow the wheels to maintain ground contact over uneven

surfaces, but this can lead to excessive body-roll at high speeds on the

road, as well as vague steering. Such 4x4s often have suspension

systems designed as a compromise between articulation and handling. If

articulation is limited, one wheel on an axle may be lifted off the

ground by rough terrain, thus losing all traction to all wheels (all

power goes to the lifted wheel, which spins freely). A rear locking

differential is often supplied to make up for this compromise – if a

wheel is lifted off the ground, the locking differential can be brought

into play, driving the wheel that remains on the ground.

Example usage: On many vehicles (Construction Standard)

Example usage: On many vehicles (Construction Standard) Example usage: VW bug (old), bis Mb and othersimage

Example usage: VW bug (old), bis Mb and othersimage B. Driving Wheels Home

B. Driving Wheels Home

Example usage: on most vehicles

Example usage: on most vehicles In the four-wheel drive system can be distinguished:

In the four-wheel drive system can be distinguished:

PRINSIP KERJA TRANSMISI MANUAL

PRINSIP KERJA TRANSMISI MANUAL

Planetary differential used to drive a

Planetary differential used to drive a