Electronics

Capacitors are widely used in electronic circuits for blocking direct current while allowing alternating current to pass. In analog filter networks, they smooth the output of power supplies. In resonant circuits they tune radios to particular frequencies. In electric power transmission systems they stabilize voltage and power flow .

Specific orbital energy

In the gravitational two-body problem, the specific orbital energy (or vis-viva energy) of two orbiting bodies is the constant sum of their mutual potential energy () and their total kinetic energy (), divided by the reduced mass. According to the orbital energy conservation equation (also referred to as vis-viva equation), it does not vary with time:

where

- is the relative orbital speed;

- is the orbital distance between the bodies;

- is the sum of the standard gravitational parameters of the bodies;

- is the specific relative angular momentum in the sense of relative angular momentum divided by the reduced mass;

- is the orbital eccentricity;

- is the semi-major axis.

It is expressed in J/kg = m2·s−2 or MJ/kg = km2·s−2. For an elliptic orbit the specific orbital energy is the negative of the additional energy required to accelerate a mass of one kilogram to escape velocity (parabolic orbit). For a hyperbolic orbit, it is equal to the excess energy compared to that of a parabolic orbit. In this case the specific orbital energy is also referred to as characteristic energy.

Equation forms for different orbits

For an elliptic orbit, the specific orbital energy equation, when combined with conservation of specific angular momentum at one of the orbit's apsides, simplifies to:

where

- is the standard gravitational parameter;

- is semi-major axis of the orbit.

Proof:

-

- For an elliptic orbit with specific angular momentum h given by

-

- we use the general form of the specific orbital energy equation,

-

- with the relation that the relative velocity at periapsis is

-

- Thus our specific orbital energy equation becomes

-

- and finally with the last simplification we obtain:

For a parabolic orbit this equation simplifies to

For a hyperbolic trajectory this specific orbital energy is either given by

or the same as for an ellipse, depending on the convention for the sign of a.

In this case the specific orbital energy is also referred to as characteristic energy (or ) and is equal to the excess specific energy compared to that for a parabolic orbit.

It is related to the hyperbolic excess velocity (the orbital velocity at infinity) by

It is relevant for interplanetary missions.

Thus, if orbital position vector () and orbital velocity vector () are known at one position, and is known, then the energy can be computed and from that, for any other position, the orbital speed.

Rate of change

For an elliptic orbit the rate of change of the specific orbital energy with respect to a change in the semi-major axis is

where

- is the standard gravitational parameter;

- is semi-major axis of the orbit.

In the case of circular orbits, this rate is one half of the gravity at the orbit. This corresponds to the fact that for such orbits the total energy is one half of the potential energy, because the kinetic energy is minus one half of the potential energy.

Additional energy

If the central body has radius R, then the additional energy of an elliptic orbit compared to being stationary at the surface is

- For the Earth and a just little more than this is ; the quantity is the height the ellipse extends above the surface, plus the periapsis distance (the distance the ellipse extends beyond the center of the Earth); the latter times g is the kinetic energy of the horizontal component of the velocity.

Examples

ISS

The International Space Station has an orbital period of 91.74 minutes (5.5 ks), hence the semi-major axis is 6,738 km.

The energy is −29.6 MJ/kg: the potential energy is −59.2 MJ/kg, and the kinetic energy 29.6 MJ/kg. Compare with the potential energy at the surface, which is −62.6 MJ/kg. The extra potential energy is 3.4 MJ/kg, the total extra energy is 33.0 MJ/kg. The average speed is 7.7 km/s, the net delta-v to reach this orbit is 8.1 km/s (the actual delta-v is typically 1.5–2 km/s more for atmospheric drag and gravity drag).

The increase per meter would be 4.4 J/kg; this rate corresponds to one half of the local gravity of 8.8 m/s².

For an altitude of 100 km (radius is 6471 km):

The energy is −30.8 MJ/kg: the potential energy is −61.6 MJ/kg, and the kinetic energy 30.8 MJ/kg. Compare with the potential energy at the surface, which is −62.6 MJ/kg. The extra potential energy is 1.0 MJ/kg, the total extra energy is 31.8 MJ/kg.

The increase per meter would be 4.8 J/kg; this rate corresponds to one half of the local gravity of 9.5 m/s². The speed is 7.8 km/s, the net delta-v to reach this orbit is 8.0 km/s.

Taking into account the rotation of the Earth, the delta-v is up to 0.46 km/s less (starting at the equator and going east) or more (if going west).

Voyager 1

For Voyager 1, with respect to the Sun:

- = 132,712,440,018 km3s−2 is the standard gravitational parameter of the Sun

- r = 17 billion kilometers

- v = 17.1 km/s

Hence:

- 146 km2s−2 − 8 km2s−2 = 138 km2s−2

Thus the hyperbolic excess velocity (the theoretical orbital velocity at infinity) is given by

- 16.6 km/s

However, Voyager 1 does not have enough velocity to leave the Milky Way. The computed speed applies far away from the Sun, but at such a position that the potential energy with respect to the Milky Way as a whole has changed negligibly, and only if there is no strong interaction with celestial bodies other than the Sun.

Applying thrust

Assume:

- a is the acceleration due to thrust (the time-rate at which delta-v is spent)

- g is the gravitational field strength

- v is the velocity of the rocket

Then the time-rate of change of the specific energy of the rocket is : an amount for the kinetic energy and an amount for the potential energy.

The change of the specific energy of the rocket per unit change of delta-v is

which is |v| times the cosine of the angle between v and a.

Thus, when applying delta-v to increase specific orbital energy, this is done most efficiently if a is applied in the direction of v, and when |v| is large. If the angle between v and g is obtuse, for example in a launch and in a transfer to a higher orbit, this means applying the delta-v as early as possible and at full capacity. See also gravity drag. When passing by a celestial body it means applying thrust when nearest to the body. When gradually making an elliptic orbit larger, it means applying thrust each time when near the periapsis.

When applying delta-v to decrease specific orbital energy, this is done most efficiently if a is applied in the direction opposite to that of v, and again when |v| is large. If the angle between v and g is acute, for example in a landing (on a celestial body without atmosphere) and in a transfer to a circular orbit around a celestial body when arriving from outside, this means applying the delta-v as late as possible. When passing by a planet it means applying thrust when nearest to the planet. When gradually making an elliptic orbit smaller, it means applying thrust each time when near the periapsis.

If a is in the direction of v:

Tangential velocities at altitude

| Orbit | Center-to-center distance | Altitude above the Earth's surface | Speed | Orbital period | Specific orbital energy |

|---|---|---|---|---|---|

| Standing on Earth's surface at the equator (for comparison – not an orbit) | 6,378 km | 0 km | 465.1 m/s (1,674 km/h or 1,040 mph) | 23 h 56 min | −62.6 MJ/kg |

| Orbiting at Earth's surface (equator) | 6,378 km | 0 km | 7.9 km/s (28,440 km/h or 17,672 mph) | 1 h 24 min 18 sec | −31.2 MJ/kg |

| Low Earth orbit | 6,600–8,400 km | 200–2,000 km | circular orbit: 7.8–6.9 km/s (17,450–14,430 mph) respectively elliptic orbit: 6.5–8.2 km/s respectively | 1 h 29 min – 2 h 8 min | −29.8 MJ/kg |

| Molniya orbit | 6,900–46,300 km | 500–39,900 km | 1.5–10.0 km/s (3,335–22,370 mph) respectively | 11 h 58 min | −4.7 MJ/kg |

| Geostationary | 42,000 km | 35,786 km | 3.1 km/s (6,935 mph) | 23 h 56 min | −4.6 MJ/kg |

| Orbit of the Moon | 363,000–406,000 km | 357,000–399,000 km | 0.97–1.08 km/s (2,170–2,416 mph) respectively | 27.3 days | −0.5 MJ/kg |

Energy storage is the capture of energy produced at one time for use at a later time. A device that stores energy is sometimes called an accumulator or battery. Energy comes in multiple forms including radiation, chemical, gravitational potential, electrical potential, electricity, elevated temperature, latent heat and kinetic. Energy storage involves converting energy from forms that are difficult to store to more conveniently or economically store able forms. Bulk energy storage is currently dominated by hydroelectric dams, both conventional as well as pumped.

Some technologies provide short-term energy storage, while others can endure for much longer.

A wind-up clock stores potential energy (in this case mechanical, in the spring tension), a rechargeable battery stores readily convertible chemical energy to operate a mobile phone, and a hydroelectric dam stores energy in a reservoir as gravitational potential energy. Fossil fuels such as coal and gasoline store ancient energy derived from sunlight by organisms that later died, became buried and over time were then converted into these fuels. Food (which is made by the same process as fossil fuels) is a form of energy stored in chemical form.

Ice storage tanks store ice frozen by cheaper energy at night to meet peak daytime demand for cooling. The energy isn't stored directly, but the work-product of consuming energy (pumping away heat) is stored, having the equivalent effect on daytime consumption.

Flow battery

A flow battery operates by passing a solution over a membrane where ions are exchanged to charge/discharge the cell. Cell voltage is chemically determined by the Nernst equation and ranges, in practical applications, from 1.0 to 2.2 V. Its storage capacity is a function of the volume of the tanks holding the solution.

A flow battery is technically akin both to a fuel cell and an electrochemical accumulator cell. Commercial applications are for long half-cycle storage such as backup grid power.

Supercapacitor

Supercapacitors, also called electric double-layer capacitors (EDLC) or ultracapacitors, are generic terms for a family of electrochemical capacitors . that do not have conventional solid dielectrics. Capacitance is determined by two storage principles, double-layer capacitance and pseudocapacitance.

Supercapacitors bridge the gap between conventional capacitors and rechargeable batteries. They store the most energy per unit volume or mass (energy density) among capacitors. They support up to 10,000 farads/1.2 volt, up to 10,000 times that of electrolytic capacitors, but deliver or accept less than half as much power per unit time (power density).

While supercapacitors have specific energy and energy densities that are approximately 10% of batteries, their power density is generally 10 to 100 times greater. This results in much shorter charge/discharge cycles. Additionally, they will tolerate many more charge and discharge cycles than batteries.

Supercapacitors support a broad spectrum of applications, including:

- Low supply current for memory backup in static random-access memory (SRAM)

- Power for cars, buses, trains, cranes and elevators, including energy recovery from braking, short-term energy storage and burst-mode power delivery

UltraBattery

The UltraBattery is a hybrid lead-acid cell and carbon-based ultracapacitor (or supercapacitor) invented by Australia’s national research body, the Commonwealth Scientific and Industrial Research Organisation (CSIRO). The lead-acid cell and ultracapacitor share the sulfuric acid electrolyte and both are packaged into the same physical unit. The UltraBattery can be manufactured with similar physical and electrical characteristics to conventional lead-acid batteries making it possible to cost-effectively replace many lead-acid applications.

The UltraBattery tolerates high charge and discharge levels and endures large numbers of cycles, outperforming previous lead-acid cells by more than an order of magnitude. In hybrid-electric vehicle tests, millions of cycles have been achieved. The Ultra Battery is also highly tolerant to the effects of sulfation compared with traditional lead-acid cells. This means it can operate continuously in partial state of charge whereas traditional lead-acid batteries are generally held at full charge between discharge events. It is generally electrically inefficient to fully charge a lead-acid battery so by decreasing time spent in the top region of charge the Ultra Battery achieves high efficiencies, typically between 85 and 95% DC-DC.

The Ultra Battery can work across a wide range of applications. The constant cycling and fast charging and discharging necessary for applications such as grid regulation and leveling and electric vehicles can damage chemical batteries, but are well handled by the ultra capacitive qualities of Ultra Battery technology. The technology has been installed in Australia and the US on the megawatt scale, performing frequency regulation and renewable smoothing applications .

Electrical methods

Capacitor

A capacitor (originally known as a 'condenser') is a passive two-terminal electrical component used to store energy electrostatically. Practical capacitors vary widely, but all contain at least two electrical conductors (plates) separated by a dielectric (i.e., insulator). A capacitor can store electric energy when disconnected from its charging circuit, so it can be used like a temporary battery, or like other types of rechargeable energy storage system.[62] Capacitors are commonly used in electronic devices to maintain power supply while batteries change. (This prevents loss of information in volatile memory.) Conventional capacitors provide less than 360 joules per kilogram, while a conventional alkaline battery has a density of 590 kJ/kg.

Capacitors store energy in an electrostatic field between their plates. Given a potential difference across the conductors (e.g., when a capacitor is attached across a battery), an electric field develops across the dielectric, causing positive charge (+Q) to collect on one plate and negative charge (-Q) to collect on the other plate. If a battery is attached to a capacitor for a sufficient amount of time, no current can flow through the capacitor. However, if an accelerating or alternating voltage is applied across the leads of the capacitor, a displacement current can flow. Besides capacitor plates, charge can also be stored in a dielectric layer.

Capacitance is greater given a narrower separation between conductors and when the conductors have a larger surface area. In practice, the dielectric between the plates emits a small amount of leakage current and has an electric field strength limit, known as the breakdown voltage. However, the effect of recovery of a dielectric after a high-voltage breakdown holds promise for a new generation of self-healing capacitors. The conductors and leads introduce undesired inductance and resistance.

Research is assessing the quantum effects of nanoscale capacitors for digital quantum batteries.

Superconducting magnetics

Superconducting magnetic energy storage (SMES) systems store energy in a magnetic field created by the flow of direct current in a superconducting coil that has been cooled to a temperature below its superconducting critical temperature. A typical SMES system includes a superconducting coil, power conditioning system and refrigerator. Once the superconducting coil is charged, the current does not decay and the magnetic energy can be stored indefinitely.

The stored energy can be released to the network by discharging the coil. The associated inverter/rectifier accounts for about 2–3% energy loss in each direction. SMES loses the least amount of electricity in the energy storage process compared to other methods of storing energy. SMES systems offer round-trip efficiency greater than 95%.

Due to the energy requirements of refrigeration and the cost of superconducting wire, SMES is used for short duration storage such as improving power quality. It also has applications in grid balancing.[69]

Interseasonal thermal storage

Seasonal thermal energy storage (STES) allows heat or cold to be used months after it was collected from waste energy or natural sources. The material can be stored in contained aquifers, clusters of boreholes in geological substrates such as sand or crystalline bedrock, in lined pits filled with gravel and water, or water-filled mines.

Flow Battery Energy Storage (FBES)

A flow battery stores energy in two soluble redox couples contained in external liquid electrolyte tanks. These electrolytes can be pumped from the tanks to the cell stack which consists of two electrolyte flow compartments separated by ion selective membranes. The operation is based on reduction-oxidation reactions of the electrolyte solutions. During the charging phase, one electrolyte is oxidized at the anode and another electrolyte is reduced at the cathode, and the electrical energy is converted to the electrolyte chemical energy. The above process is reversed during the discharging phase.

Flow batteries can be classified into the categories of redox flow batteries and hybrid flow batteries, depending on whether all electroactive components can be dissolved in the electrolyte. Fig. * shows a schematic diagram of a vanadium redox flow battery system. A crucial advantage of FBES is that the power of a FBES system is independent of its storage capacity. The power of the FBES system is determined by the size of the electrodes and the number of cells in the stack; whereas the storage capacity is determined by the concentration and the amount of electrolyte . Also, the very small self-discharge is an inherent strength of the FBES system due to the electrolytes being stored in separate sealed tanks . Drawbacks of flow batteries include low performance resulting from non-uniform pressure drops and the reactant mass transfer limitation, relatively high manufacturing costs and more complicated system requirements compared to traditional batteries

Capacitor and supercapacitor

A capacitor is composed of at least two electrical conductors (normally made of metal foils) separated by a thin layer of insulator (normally made of ceramic, glass or a plastic film). When a capacitor is charged, energy is stored in the dielectric material in an electrostatic field . Its maximum operating voltage is dependent on the breakdown characteristics of the dielectric material. Capacitors are appropriate for storing small quantities of electrical energy and conducting a varying voltage; they have a higher power density and shorter charging time compared to conventional batteries . However, they have limited capacity, relatively low energy density and high energy dissipation due to the high self-discharge losses . According to these characteristics, capacitors can be used for some power quality applications, such as high voltage power correction, smoothing the output of power supplies, bridging and energy recovery in mass transit systems.

Supercapacitors, also named electric double-layer capacitors or ultra capacitors, contain two conductor electrodes, an electrolyte and a porous membrane separator. Due to their structures, supercapacitors can have both the characteristics of traditional capacitors and electrochemical batteries. The energy is stored in the form of static charge on the surfaces between the electrolyte and the two conductor electrodes. The super capacitors with high-performance are based on nano materials to increase electrode surface area for enhancing the capacitance.

Superconducting Magnetic Energy Storage (SMES)

A typical SMES system is composed of three main components which include: a superconducting coil unit, a power conditioning subsystem, and a refrigeration and vacuum subsystem . The SMES system stores electrical energy in the magnetic field generated by the Direct Current (DC) in the superconducting coil which has been cryogenically cooled to a temperature below its superconducting critical temperature. In general, when current passes through a coil, the electrical energy will be dissipated as heat due to the resistance of the wire; however, if the coil is made from a superconducting material, such as mercury or vanadium, under its superconducting state (normally at a very low temperature), zero resistance occurs and the electrical energy can be stored with almost no losses. One commonly used superconducting material is Niobium–Titanium which has a superconducting critical temperature of 9.2 K . In the discharging phase, the SMES system can release the stored electrical energy back to the Alternating Current (AC) system, by a connected power converter module. The magnitude of stored energy is determined by the self-inductance of coil and the current flowing through it . A simplified structure of a SMES system is illustrated in

Superconducting coils can be classified into two groups: Low Temperature Superconducting (LTS) coils, working at ∼5 K, and High Temperature Superconducting (HTS) coils, working at ∼70 K . The LTS-SMES technology is more mature and commercially available while the HTS-SMES is currently in the development stage. SMES devices in the range of 0.1–10 MW have been used commercially; while SMES systems with 100 MW h could be available in the next decade.

The features of SMES include relatively high power density (up to ∼4000 W/L), fast response time (millisecond level), very quick full discharge time (less than 1 min), high cycle efficiency (∼95–98%) and long lifetime (up to ∼30 years) . In contrast to rechargeable batteries, SMES devices are capable of discharging near to the totality of the stored energy with little degradation after thousands of full cycles. The drawbacks are that they have high capital cost (up to 10,000 $/kW h, 7200 $/kW), high daily self-discharge (10–15%) and a negative environmental impact due to the strong magnetic field . Moreover, the coil is sensitive to small temperature variations which can cause the loss of energy. From the above, SMES is suitable for short-term storage in power and energy system applications and it is expected to have an important role in the increased use of intermittent renewable energy .

Recently, considerable research and development effort has been made: (1) to reduce the costs of superconducting coils and related refrigeration systems; (2) to develop HTS coil materials which are less cryogenically sensitive . Since 2011, Super Power Inc., in partnership with ABB Inc., Brookhaven national laboratory and the Texas center for superconductivity at the University of Houston has been developing an advanced SMES demonstrator 20 kW ultra-high field SMES system with a capacity up to 2 MJ . This demonstration project aims to pave the way of grid-scale SMES technology for the U.S. electric grid operation and for the integration of renewable sources. The University of Bath in the UK continuously focus on SMES technology development and a relevant on-going project funded by the UK EPSRC aims to investigate HTS-SMES as part of hybrid EES systems for renewable energy micro-grids .

3.8. Solar fuels

Solar fuel is a relatively new technology to EES. Approaches to produce solar fuels include: (1) natural photosynthesis; (2) artificial photosynthesis; (3) thermochemical approaches . A number of fuels can be produced by solar energy, such as solar hydrogen, carbon-based fuels, and solar chemical heat pipe . These fuels can be stored and subsequently provide the basis for later electricity generation.

For the first two approaches to produce solar fuels, solar energy is captured via photosynthesis and then stored in chemical bonds, i.e., the sunlight is used to convert water and/or carbon dioxide into oxygen and other materials shows a comparison of natural and artificial photosynthesis. The artificial system for water-splitting catalysts generally relies on scarce elements, e.g., Ruthenium (Ru), Palladium (Pd) and Rhenium (Re) . For example, sunlight can be captured by Ruthenium (Ru) as a catalyst, and electrons moves from the donor (marked as “D”) to the acceptor .

The thermochemical approach uses thermal processes for solar fuels production, which involve the generation of very high temperatures in a closed environment to split water into its constituent parts . Thus this method is more dependent on strong sunlight compared to the other two . After the solar radiant energy is concentrated by heliostats, an endothermic chemical transformation is carried out in a reaction vessel. The reaction produces hydrogen and/or carbon monoxide and/or other materials .

Solar fuel technology is currently at the development stage. The power rating of solar fuels is potentially up to 20 MW and the specific energy estimate is from 800 W h/kg to 100,000 W h/kg . The storage duration can range from a few hours to several months . One drawback of artificial photosynthesis is that the water-splitting catalysts normally depend on scarce, expensive elements . Another disadvantage is that solar fuel facilities need a large area to place devices to concentrate sunlight, especially when using the thermochemical approach to produce solar fuels.

Research in solar fuels has recently undergone substantial advances, making it possible for it to become cost-effective for utility EES applications in the near future. There are on-going research projects in the U.S., the Netherlands, South Korea, Singapore, Japan and China. In the US, there are several organizations focusing on this area, such as Energy Innovation Hub at DoE, the MIT spin-out Sun Catalytix and the Princeton University spin-out Liquid Light. The “Towards BioSolar Cells” research programme has focused on increasing the photosynthetic efficiency and creating solar collectors . Concerning the issue of the reliance on scarce and expensive elements, one important breakthrough in the development of using earth-abundant, relatively cheap catalysts (e.g. cobalt and phosphate) and silicon-based semiconductors for the water-splitting process has been recently reported by the Nocera’s team from MIT . Asia’s pioneering solar fuel research laboratory at Nanyang Technological University of Singapore has also made effort on the investigation of affordable approaches to extract large amounts of hydrogen from water using sunlight for engineering applications

Hydrogen storage and fuel cell

Hydrogen energy storage systems use two separate processes for storing energy and producing electricity . The use of a water electrolysis unit is a common way to produce hydrogen which can be stored in high pressure containers and/or transmitted by pipelines for later use When using the stored hydrogen for electricity generation, the fuel cell (also known as regenerative fuel cell) is adopted, which is the key technology in hydrogen EES.

Fuel cells can convert chemical energy in hydrogen (or hydrogen-rich fuel) and oxygen (from air) to electricity . The overall reaction is: 2H2 + O2 → 2H2O + energy . Electrical and heat energy are released during the process . Depending on the choice of fuel and electrolyte, there are six major groups of fuel cells, which are: Alkaline Fuel Cell (AFC), Phosphoric Acid Fuel Cell (PAFC), Solid Oxide Fuel Cell (SOFC), Molten Carbonate Fuel Cell (MCFC), Proton Exchange Membrane Fuel Cell (PEMFC) and Direct Methanol Fuel Cell (DMFC)

In general, the electricity generation by using fuel cells is quieter, produces less pollution and is more efficient than the fossil fuel combustion approach . Other features include easy scaling (potential from 1 kW to hundreds of MW) and compact design . Fuel cell systems combined with hydrogen production and storage can provide stationary or distributed power (primary electrical power, heating/cooling or backup power) and transportation power (potentially replacing fossil fuels for vehicles) . Such hydrogen EES systems can offer capacity and power independence in energy production, storage and usage, due to the separate processes. It should be noted that the disposal of exhaust fuel cells must consider degradation and recycling while toxic metals are used as electrodes or catalysts. Many of the relevant aspects and approaches have been under investigation , . For instance, palladium in catalysts of fuel cells can be reprocessed into other products in theory .

Currently, hydrogen EES with fuel cell technology is in the development and demonstration stage. Stationary power applications are relatively mature. In 2012 nearly 80% of total investment in the global fuel cell industry was made by the U.S. companies . Cost reduction and durability verification/improvement are essential to deploy this technology in large-scale EES applications . Some research or demonstration projects are in place and on-going across the world. The world’s first utility-scale test of a stand-alone renewable energy system integrated with hydrogen storage and fuel cells was installed in Norway, which delivered power with required quality and high reliability . One of the world’s largest biogas fuel cell power plants was launched in 2012 in California (2.8 MW), which converts biogas into electricity and usable high-quality heat . In 2013, the US Naval Air Warfare Center Weapons Division in California successfully tested a novel 5 kW trailer-mounted regenerative fuel cell system to use solar power to produce hydrogen with fuel cells . Since 2013, McPhy and Enertrag AG in Germany have worked jointly to develop economic wind-hydrogen solutions for EES and for transportation fuel cell applications . Currently, the on-going hydrogen storage and fuel cell relevant projects include IdealHy (the Netherlands), RE4CELL (Spain), Sapphire (Norway), SmartCat (France), etc.

XO__XO XXX components of electronics components switch mode power supply

Critical Components Behind Switch-mode Power Supplies ( Power Semiconductor )

passive components in the input circuit of a power supply is to protect the electronic device from overcurrent and overvoltage and ensure electromagnetic compatibility—especially important considerations in today’s portable applications where long battery life is a necessity. The choice of the components used in switch-mode power supplies (SMPS) is extremely important, as their impact on performance is often not considered. These components—such as resistors, capacitors and inductors—are called upon to deal with heat, size, output power and device price tag.

Switch-mode power supplies switch on and off at high frequency, providing electric energy transfer from capacitors and inductors. SMPS are smaller and feature a lighter package and reduced manufacturing costs.

While there are many components involved in SMPS, a handful of critical devices include:

1. Capacitors

Capacitors perform energy storage, filtering, compensation and soft-start programming. The overriding loss for capacitors in SMPS applications is based on effective series resistance (ESR). ESR results from the physical construction of a capacitor, the resistance of internal interconnects, and even the behavior of the material used as an insulator between capacitor plates. Many capacitors are particularly sensitive to heat and a function of ESR is to dissipate heat in the presence of a current flow into or out of a capacitor. The ESR of a capacitor is typically the most important specification when selecting capacitors for SMPS applications—even more important than the component’s basic capacitance rating.

Capacitors represent the key components of the DC link. They smooth the rectifier ripple voltage and stabilize the DC link voltage. While all rectifiers produce an output voltage that has ripple superimposed on the DC, it varies in magnitude, waveform and frequency depending on the rectifiers. The downside of ripple includes possible reduced productivity or process equipment life, interference with process instrumentation, and electromagnetic coupling with nearby structures, resulting in heating of the structures and increased losses.

DC link capacitors expose the rectifier and power line to extremely high input currents at the moment of turn-on, potentially destroying the rectifier diode or causing the power fuse to blow. This can be avoided by using negative temperature coefficient (NTC) thermistors as inrush current limiters (ICL), for a gentle power up. When NTC ICLs are sufficiently heated by the current flow, their resistance drops to a negligible value. The B57*S series of EPCOS NTC thermistors offers a corresponding ICL for each required current strength.

EPCOS aluminum electrolytic capacitors are particularly suitable for this job based on their high CV value; they allow today’s compact power supplies to be easily implemented. The capacitors are distinguished by a very high ripple current capability, combined with low ESR and ESL values, leading to lower intrinsic heating. Depending on the required output and voltage of the link circuit, radial versions or snap-in types with two or four pins are used. The capacitors cover a voltage range from 10 V DC to 600 V DC and maximum temperatures of 85° C to 140° C.

In two EPCOS aluminum electrolytic capacitors with screw terminals (B43700* and B43720*), the permissible rated voltage increased from 550 V DC to 600 V DC. Covering a capacitance range from 680 µF to 6800 µF, the highly compact components are designed for temperatures up to 85° C. A new snap-in series (B43541*) for temperatures up to 85° C, offers a rated voltage of 600 V DC instead of the previous 550 V DC, and features capacitance values of between 47 µF and 270 µF.

Among the newcomers to the range are types with a higher-rated voltage for temperatures up to 105° C. Screw-terminal types are rated at 500 V DC instead of the previous 450 V DC, and the rating of the snap-in types increased from 500 V DC to 550 V DC. The benefit to developers is that they need to connect fewer series capacitors in the link circuit, which reduces costs and mounting space.

Alternatively, EPCOS MKP film capacitors can also be used to stabilize the DC link. The B3267* high-power series and the B3277* high-density series are designed for voltages from 450 V DC to 1300 V DC and cover a capacitance range from 0.47 µF to 110 µF. As with all EPCOS film capacitors, they are distinguished by a very long operating life and are self-healing. Dielectric breakdowns caused by over-voltages lead to local vaporization of the metallization, yet the capacitor remains fully functional.

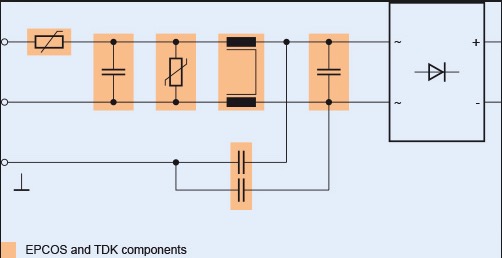

EPCOS and TDK components in the input circuit of a power supply protect the electronic device against overcurrent and overvoltage, assuring EMC.

EPCOS and TDK components in the input circuit of a power supply protect the electronic device against overcurrent and overvoltage, assuring EMC.

2. PTC Thermistors

In comparison to the NTC thermistors previously mentioned, positive temperature coefficient (PTC) thermistors provide protection from current surges, such as those that occur as a result of a short circuit. At excessive currents, these components heat up and acquire a high resistance. As with ICLs, they are inserted directly into the current path of the power input. The B5910*J series spans commonly used current levels and are available in leaded or packaged versions.

3. Varistors

Varistors (variable resistors), commonly referred to as Metal Oxide Varistors (MOVs), are ceramic-based components used to protect susceptible circuitry against damaging overvoltage conditions. Varistors are voltage-dependent resistors whose resistance decreases with increasing voltage. Connected in parallel with the electronic device, or circuit that is to be protected, a varistor forms a low-resistance shunt when voltage increases. Common overvoltage sources include lightning, inductive load switching and electrostatic discharge (ESD).

EPCOS offers an extensive range of varistors including leaded and SMD equivalents, ThermoFuse types and Multilayer SMDs.

- Leaded and SMD equivalents span voltages ranging from 11 to 1000 Vac, surge current ratings from 100A thru 100kA, energy ratings from .3 thru 6000 joules, as well as new125° high-temperature types

- ThermoFuse varistors range from 130 to 1000 Vac and surge current ratings to 10,000A . A varistor disc in the series with a thermally coupled fuse is packaged in a plastic housing. If the varistor overheats, the thermal fuse activates, disconnecting the varistor from the circuit.

- Multilayer SMD types in case sizes 0201 thru 2220 feature voltages ranging from 4 thru 60 Vac with surge current ratings up to 1200A

4. EMC and Transient Protection

The ability of a system to function in an electromagnetic environment without introducing electromagnetic disturbances that may interfere with other electrical products in the same environment is called electromagnetic compatibility (EMC). EMC and transient protection is delivered via a broad range of EPCOS X- and Y-capacitors and common-mode chokes. For example, the electromagnetic interference (EMI) capacitors of the B3292*, B3202*, B3291* and B81123 series are designed for voltages of 250 V AC to 350 V AC.

In addition, EPCOS also offers a broad range of double, triple and quadruple common-mode chokes with the B827* series, with voltages that extend from 250 V AC to 690 V AC and permissible current-handling capacities from 0.25A to 200A.

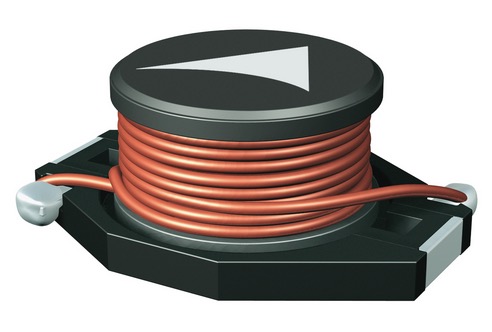

5. High-performance and Compact Inductors

Inductors are magnetic energy-storage elements that consist of a wire coil wound around a ferromagnetic core. Current that flows through the inductor induces a magnetic field in the core. This field is the mechanism for energy storage. Current in an inductor cannot change instantaneously; when a voltage is applied across an inductor, the current will ramp.

When the switch closes, the full voltage appears across the inductor. When the switch is open, the current in the inductor will ramp down at the same rate and a large voltage is generated as the magnetic field collapses. The magnetic field is the energy-storage mechanism.

Two main core materials are used in inductors for SMPS—powdered iron and solid ferrite. A powdered iron core has air gaps within the material, giving a soft saturation curve. These are for applications that need large, instantaneous current. In comparison, ferrite core inductors saturate faster but are lower cost and have lower core losses.

To reach various voltage levels at the SMPS output, MOSFET-switched power transformers of the EPCOS B78* series are required. They are offered in the most varied core shapes, as well as in SMD or plated through hole (PTH) versions. Despite their compact dimensions, outputs of up to 200 W can be realized per transformer. Versions with several outputs are available. The new chokes and transformers of the EPCOS e-mobility platform represent a special highlight. They were developed specifically for on-board chargers and are characterized, apart from their compact dimensions, especially by low losses.

Power inductors are used in SMPS applications with high requirements for temperature range and reliability.

Power inductors are used in SMPS applications with high requirements for temperature range and reliability.

To smooth the output voltages after rectification, EPCOS SMT inductors must be present in the current path; the EPCOS series B8246*, B8247* or B8255* are suitable for this purpose. The range covers types with current-handling capabilities from 0.11 A to 71 A in shielded and unshielded versions. Thanks to the flat-wire helical windings of the high-current versions, this produces a very high copper fill factor so that these components have a low space requirement despite their high performance. TDK inductors are ideal for this purpose. Single-ended aluminum electrolytic capacitors of the B41* series or film capacitors are recommended for smoothing the voltage path.

EPCOS current sensors are indispensable for exact regulation of SMPS. The B82801* series specifically targets this purpose. The sensors are available with transformation ratios of 1:20 to 1:125 and designed for currents from 7 to 40 A.

SMPS can be used in computers, instrumentation, laser and medical applications. They are ideal for use across a wide range of power classes from a few watts when charging a phone, to kilowatts in high-performance industrial power supplies. Design engineers must carefully select such critical components in order to deliver higher performance and greater reliability to the end design.

Components of SWITCH MODE POWER SUPPLY (SMPS) Most of the components used in SWITCH MODE POWER SUPPLY (SMPS) can be easily identified. However, some components are difficult to identify. Some components are designed especially for a particular model. The different components of SWITCH MODE POWER SUPPLY (SMPS) are:

Most of the components used in SWITCH MODE POWER SUPPLY (SMPS) can be easily identified. However, some components are difficult to identify. Some components are designed especially for a particular model. The different components of SWITCH MODE POWER SUPPLY (SMPS) are:

Switch Mode (chopper) Transistors and other Semiconductors.

A transistor is small and fast semiconductor used for amplification and voltage stabilization.

Bipolar Power Transistors (often BU or 2SC/2SD numbers.) High voltage power transistors, which are used as the main switch mode transistor.

Diodes and Rectifiers - AC line rectifier uses a combination of 2 or 4 diodes. High efficiency diodes are used to rectify output voltages. These diodes look like normal axial lead diodes. They can be combined in pairs inside TO220 type packages. To troubleshoot SWITCH MODE POWER SUPPLY (SMPS) problems, test for shorted and open junctions.

Capacitors (filter and bypass) in an SWITCH MODE POWER SUPPLY (SMPS)

Filter Capacitors - Used to filter the rectified AC line input voltage and various outputs of the power supply.

Bypass Capacitors - These are green colored, high quality plastic dipped or rectangular molded capacitors part of RFI filter. They are placed at output section and seldom fail.

Resistors - Test for proper value with the help of multimeter. While measuring the resistor in-circuit, if the value is higher than normal value, then resistor is bad.

Startup Resistors - They are high value (100K) medium wattage resistors. Test for open circuit results in dead supply without blown fuses or fusable resistors.

Pixabay

Flameproof or Fusable Resistors - They are rectangular ceramic blocks which are blue or gray in color. They function as fuses; hence they cannot be replaced with higher wattage types. Test for open circuits.

WTC Resistors (thermistors) - Negative Temperature Coefficient resistors act as inrush surge limiters. There may be one or two of these in series with the AC input. These often look like fat black disk capacitors.

Transformers and Inductors required in a SWITCH MODE POWER SUPPLY (SMPS)

High Frequency Transformers - They consist of the switch Mode power transformer and feedback transformer. They provide line isolation and generate multiple output voltage. They rarely cause problems and can be tested for open circuit. Some supplies use small Transformers for feedback instead of optoisolators. Optoisolator is used to isolate the input line with the rest of the section.

Inductors - Output inductors rarely fail and they can be tested for open circuit. Replace the faulty inductor if found.

Coupled Inductors - They are used as a part of Pi type RFI filter which is placed in the AC input circuit. The windings of inductor are in series with AC line. They look like small transformer. They are very reliable and help to reduce noise and spikes. They can be tested for open circuit.

Reliable protection and stabilization

TDK offers developers of power supplies one-stop shopping for passive components: The extremely broad range, especially of EPCOS components, covers all types of powerful DC link capacitors. They are complemented by an extensive range of transformers, chokes, protection devices and EMC components, and more.

Very few electrical devices are still powered by AC voltage from the power line. Whether in communications and information technology, consumer electronics, industrial electronics or lighting, power supplies are omnipresent in a large variety of topologies.

Power supply technology encompasses converters for photovoltaic and wind power plants and frequency converters for industrial drives as well as switch-mode power supplies in a very wide range of power classes. The latter extends from a few watts for mobile phone chargers up to the kilowatt range for high-performance industrial power supplies. Figure 1 shows a typical layout of the input circuit of switch-mode power supplies (SMPS) with all passive components upstream of the rectifier.

| Figure 1: Input circuit layout of a switch-mode power supply | |

|

Safe from current surges

DC link capacitors expose the rectifier and power line to extremely high input currents at the moment of turn-on. In extreme cases, this can lead to the destruction of the rectifier diode or cause the power fuse to blow.

This can be avoided by the use of NTC thermistors as inrush current limiters (ICL), which ensure a gentle power-up. These thermistors have a relatively high resistance at the moment of turn-on and thus limit the inrush current. Only when they have been sufficiently heated by the current flow does their resistance drop to a negligible value. The B57*S series of EPCOS NTC thermistors offers a corresponding ICL for every required current strength.

During operation, PTC thermistors assure protection from current surges, such as during a short circuit. At excessive currents, these components heat up and acquire a high resistance. Just like the ICLs, they are inserted directly into the current path of the power input. The B5910*J series covers the commonly used current levels. These components are available in leaded or packaged versions. Figure 2 shows NTC and PTC thermistors for overcurrent protection and a varistor of the ETFV series, a component that combines multiple protection functions.

| Figure 2: Ceramic protection devices | |

|

Decentralized power generation, especially via wind power and solar plants, increases the risk of voltage fluctuations and dangerous overvoltages. Safe operation of power supplies can be assured by using the EPCOS varistors which make TDK the world market leader in overvoltage protection devices. These ceramic components are continuously being further developed and improved. Thus, types that can handle multiple high-voltage pulses are now available. The varistors of the ETFV series feature a special highlight (Figure 2 right). They are equipped with an integrated thermal fuse that disconnects the component in the event of overload. These components also offer a monitor output via which a malfunction can be signaled. Thanks to their heat resistance and flame-retardant design, these varistors satisfy UL 94 V-0 specifications. Moreover, they are qualified to UL 1449 3rd edition, UL 60691 and IEC 6 0950-1 Annex Q. The ETFV varistors can be connected via circuit board clamps, which significantly simplifies maintenance. In addition to many variants of monolithic varistors with diverse connection configurations and power ratings, SMD multilayer varistors are also very well suited to protect the control electronics of power supplies.

EMC – an absolute must

For EMC and transient protection, EPCOS offers one of the broadest ranges of X- and Y-capacitors and common-mode chokes worldwide. The EMI capacitors of the B3292*, B3202*, B3291* and B81123 series are designed for voltages of 250 V AC to 330 V AC. These components have the corresponding approvals to UL1414, UL1283, CSA C22.2 and EN 60384-14.

EPCOS offers a wide range of double, triple and quad common-mode chokes with the B827* series. Their voltages extend from 250 V AC to 690 V AC, and their permissible current handling capacities from 0.25 A to 200 A.

To achieve maximum efficiency with a simultaneously low power-line load via a large conduction angle, a PFC boost stage is connected immediately after the rectifier. EPCOS inductors are ideally suited for this purpose. They offer a wide range of current capabilities and are available as both leaded and SMD components.

| Figure 3: EPCOS EMC components for power supplies | |

|

| Figure 4: Circuit diagram of an SMPS with DC link circuit, converter and output filtering | |

|

Capacitors for the DC link

The key components of the DC link are the capacitors. They smooth the rectifier ripple voltage and thus stabilize the DC link voltage. EPCOS aluminum electrolytic capacitors are suitable for this purpose. With their high CV values, they allow highly compact power supplies to be implemented. EPCOS aluminum electrolytic capacitors are distinguished by a very high ripple current capability and low ESR and ESL values, leading to lower intrinsic heating. Depending on the required output and voltage of the link circuit, radial versions or snap-in types with 2 or 4 pins are used here. The capacitors cover a voltage range from 10 V DC to 600 V DC and are designed for maximum temperatures of 85 °C to 140 °C.

In two newly developed series of EPCOS aluminum electrolytic capacitors with screw terminals (B43700* and B43720*), the permissible rated voltage has now been increased from 550 V DC to 600 V DC (Figure 5). These capacitors cover a capacitance range from 1200 µF to 6800 µF. They are designed for temperatures of up to 85 °C and are also highly compact. A new snap-in series (B43541*) for temperatures of up to 85 °C also offers a rated voltage of 600 V DC instead of the previous 550 V DC, and it has capacitance values of between 47 µF and 330 µF. Among the newcomers to the range are types with a higher rated voltage for temperatures of up to 105 °C. The screw terminal types are now rated at 500 V DC instead of the previous 450 V DC, and the rating of the snap-in types has been increased from 500 V DC to 550 V DC. Thanks to these significant voltage increases, developers need to connect fewer series capacitors in the link circuit, which reduces costs and requires less mounting space.

Alternatively, EPCOS MKP film capacitors can also be used to stabilize the DC link. The B3267* (High Power) or B3277* (High Density) series are suitable for this purpose. They are designed for voltages from 450 V DC to 1300 V DC and cover a capacitance range from 0.47 µF to 110 µF. Like all EPCOS film capacitors, they are distinguished by a very long operating life. They are also self-healing, meaning that dielectric breakdowns caused by over-voltages lead to local vaporization of the metalization, so that the capacitor nevertheless remains fully functional.

| Figure 5: EPCOS aluminum electrolytic capacitor for 600 V | ||

|

High-performance and compact inductors

To reach various voltage levels at the SMPS output, MOSFET-switched power transformers of the EPCOS B78* series are required. They are offered in the most varied core shapes as well as in SMD or PTH versions. Despite their compact dimensions, outputs of up to 200 W can be realized per transformer. Versions with several outputs are available. The new chokes and transformers of the EPCOS e-mobility platform represent a special highlight. They were developed specifically for on-board chargers and are characterized, apart from their compact dimensions, especially by low losses.

To reach various voltage levels at the SMPS output, MOSFET-switched power transformers of the EPCOS B78* series are required. They are offered in the most varied core shapes as well as in SMD or PTH versions. Despite their compact dimensions, outputs of up to 200 W can be realized per transformer. Versions with several outputs are available. The new chokes and transformers of the EPCOS e-mobility platform represent a special highlight. They were developed specifically for on-board chargers and are characterized, apart from their compact dimensions, especially by low losses.

To smooth the output voltages derived in this way after rectification, EPCOS SMT inductors must be present in the current path; the EPCOS series B8246*, B8247* or B8255* are suitable for this purpose. The range covers types with current handling capabilities from 0.11 A to 71 A in shielded and unshielded versions. Thanks to the flat-wire helical windings of the high-current versions, this produces a very high copper fill factor, so that these components have a low space requirement despite their high performance. TDK inductors are ideal for this purpose. Single-ended aluminum electrolytic capacitors of the B41* series or film capacitors are recommended for smoothing the voltage path.

EPCOS current sensors are indispensable for exact regulation of the SMPS. The B82801* series was developed for this purpose. These sensors are available with transformation ratios of 1:20 to 1:125 and are designed for currents from 7 A to 40 A.

| Table: EPCOS and TDK components for power supplies | |

|

Introduction to SMPS (Switched Mode Power Supply)

Switched Mode Power Supply uses a switching regulator to convert electric power efficiently. SMPS transfers electric power from a source ( AC mains) to the load by converting the characteristics of current and voltage. SMPS always provide a well regulated power to the load irrespective of the input variations. SMPS incorporates a Pass transistor that switches very fast typically at 50Hz and 1 MHz between the on and off states to minimize the energy waste. SMPS regulates the output power by varying the on to off time using minimum voltage so that efficiency is very high compared to the linear power supply.

What is inside a SMPS?

Block diagram of SMPS

The SMPS essentially has

1. Input rectifier

2. Inverter

3. Voltage converter

4. Output regulator

Input rectifier

The AC input from mains is first rectified in the SMPS using a rectifier to convert it into DC. The rectifier consisting of a full wave diode bridge or module that produces an unregulated DC voltage to the Smoothing capacitor. The input AC passing into the rectifier has AC voltage pulses that may reduce the power factor. So control techniques are used to force the average input current to follow the sine wave.

Inverter

This stage converts the rectified DC into AC using a power oscillator. The power oscillator has a small output transformer with a few windings at the frequency 20-100 kHz. Switching is controlled by a MOSFET amplifier. The output AC voltage is usually isolated optically from the input AC by using an Optocoupler IC for safety reasons.

Components of SMPS Contd..

Voltage converter

This stage has a high frequency transformer and the inverted AC drives its primary windings. This creates the up and down voltage at the output. If DC is required, the output AC is converted to DC using a rectifier circuit using Silicon diodes or Schottky diodes (fast recovery and minimum loss of current and low forward voltage drop) . The rectified output DC is then filtered using the filter section consisting of inductors andcapacitors. Some non isolated SMPS contains an inductor instead of the transformer and the circuit act as boost converter or buck converter. In high voltage SMPS,Capacitor-Diode multiplier is used instead of inductors or transformer.

Output regulator

The output stage always monitors the output voltage by comparing with a reference voltage using a feedback system. For safety reasons, the output stage is isolated by an optoisolator as seen in the SMPS of computers. In some SMPS, Open loop regulation is used without feedback circuit and constant voltage is fed to the transformer input.

The feedback circuit needs power to run before it can generate power, so an additional non-switching power-supply for stand-by is added.

SMPS Mobile Charger

Added advantages of SMPS over the conventional linear power regulators are:

1. Light weight since the transformer is too small and it it operates at high frequency of 50Hz-1MHz.

2. Output voltage is well regulated and controlled by duty cycle and there is little resistive loss since the transistor fully on or off during switching.

3. Greater efficiency since the switching transistor dissipates very little heat. The SMPS can fail and can cause very high output voltage that destroys the equipment.

Trouble shooting

Breakdown of SMPS can cause the PC either restarts automatically or shutdown instantly. Confirm the SMPS complaint as follows:

1. Confirm whether the power cord is tight in the socket of SMPS and is connected well in the UPS.

2. Remove the 4 pin connector and connect a 10 Ohms 10 Watt resistor across the yellow (+ 12V) and black (Gnd) pins of the connector.

1. Connect the power code to UPS and connect the 24 pin cord to the Mother board

1. Short the pin 16 (Green) with the adjacent black pin (pin17) using a short wire.

2. If the Fan runs normally, SMPS is working normally.

3. If not, unplug the fan and check it with 12 volt supply. If the fan is OK, then the check the voltage at the output pins of the connecter. Voltage levels in the 24 pin connector are shown below.

Pin No

|

Wire Color

|

Output

|

1

|

Orange

|

+3.3 V

|

2

|

Orange

|

+3.3 V

|

3

|

Black

|

GND

|

4

|

Red

|

+5 V

|

5

|

Black

|

GND

|

6

|

Red

|

+5 V

|

7

|

Black

|

GND

|

8

|

Gray

| |

9

|

Purple

|

+5 V Standby

|

10

|

Yellow

|

+12 V

|

11

|

Yellow

|

+12 V

|

12

|

Orange

|

+3.3 V

|

13

|

Orange

|

+3.3 V

|

14

|

Blue

|

-12 V

|

15

|

Black

|

GND

|

16

|

Green

| |

17

|

Black

|

GND

|

18

|

Black

|

GND

|

19

|

Black

|

GND

|

20

|

White

|

-5 V

|

21

|

Red

|

+5 V

|

22

|

Red

|

+5 V

|

23

|

Red

|

+5 V

|

24

|

Black

|

GND

|

If the voltage in the pins is not as specified, replace the SMPS before powering the PC again.

XO___XO XXX 10001 + 10 Switched Mode Power Supply uses a switching regulator to convert electric power efficiently. SMPS transfers electric power from a source ( AC mains) to the load by converting the characteristics of current and voltage. SMPS always provide a well regulated power to the load irrespective of the input variations. SMPS incorporates a Pass transistor that switches very fast typically at 50Hz and 1 MHz between the on and off states to minimize the energy waste. SMPS regulates the output power by varying the on to off time using minimum voltage so that efficiency is very high compared to the linear power supply.

What is inside a SMPS?

Block diagram of SMPS

The SMPS essentially has

1. Input rectifier

2. Inverter

3. Voltage converter

4. Output regulator

Input rectifier

The AC input from mains is first rectified in the SMPS using a rectifier to convert it into DC. The rectifier consisting of a full wave diode bridge or module that produces an unregulated DC voltage to the Smoothing capacitor. The input AC passing into the rectifier has AC voltage pulses that may reduce the power factor. So control techniques are used to force the average input current to follow the sine wave.

Inverter

This stage converts the rectified DC into AC using a power oscillator. The power oscillator has a small output transformer with a few windings at the frequency 20-100 kHz. Switching is controlled by a MOSFET amplifier. The output AC voltage is usually isolated optically from the input AC by using an Optocoupler IC for safety reasons.

Components of SMPS Contd..

Voltage converter

This stage has a high frequency transformer and the inverted AC drives its primary windings. This creates the up and down voltage at the output. If DC is required, the output AC is converted to DC using a rectifier circuit using Silicon diodes or Schottky diodes (fast recovery and minimum loss of current and low forward voltage drop) . The rectified output DC is then filtered using the filter section consisting of inductors andcapacitors. Some non isolated SMPS contains an inductor instead of the transformer and the circuit act as boost converter or buck converter. In high voltage SMPS,Capacitor-Diode multiplier is used instead of inductors or transformer.

Output regulator

The output stage always monitors the output voltage by comparing with a reference voltage using a feedback system. For safety reasons, the output stage is isolated by an optoisolator as seen in the SMPS of computers. In some SMPS, Open loop regulation is used without feedback circuit and constant voltage is fed to the transformer input.

The feedback circuit needs power to run before it can generate power, so an additional non-switching power-supply for stand-by is added.

SMPS Mobile Charger

Added advantages of SMPS over the conventional linear power regulators are:

1. Light weight since the transformer is too small and it it operates at high frequency of 50Hz-1MHz.

2. Output voltage is well regulated and controlled by duty cycle and there is little resistive loss since the transistor fully on or off during switching.

3. Greater efficiency since the switching transistor dissipates very little heat. The SMPS can fail and can cause very high output voltage that destroys the equipment.

Trouble shooting

Breakdown of SMPS can cause the PC either restarts automatically or shutdown instantly. Confirm the SMPS complaint as follows:

1. Confirm whether the power cord is tight in the socket of SMPS and is connected well in the UPS.

2. Remove the 4 pin connector and connect a 10 Ohms 10 Watt resistor across the yellow (+ 12V) and black (Gnd) pins of the connector.

1. Connect the power code to UPS and connect the 24 pin cord to the Mother board

1. Short the pin 16 (Green) with the adjacent black pin (pin17) using a short wire.

2. If the Fan runs normally, SMPS is working normally.

3. If not, unplug the fan and check it with 12 volt supply. If the fan is OK, then the check the voltage at the output pins of the connecter. Voltage levels in the 24 pin connector are shown below.

Pin No

|

Wire Color

|

Output

|

1

|

Orange

|

+3.3 V

|

2

|

Orange

|

+3.3 V

|

3

|

Black

|

GND

|

4

|

Red

|

+5 V

|

5

|

Black

|

GND

|

6

|

Red

|

+5 V

|

7

|

Black

|

GND

|

8

|

Gray

| |

9

|

Purple

|

+5 V Standby

|

10

|

Yellow

|

+12 V

|

11

|

Yellow

|

+12 V

|

12

|

Orange

|

+3.3 V

|

13

|

Orange

|

+3.3 V

|

14

|

Blue

|

-12 V

|

15

|

Black

|

GND

|

16

|

Green

| |

17

|

Black

|

GND

|

18

|

Black

|

GND

|

19

|

Black

|

GND

|

20

|

White

|

-5 V

|

21

|

Red

|

+5 V

|

22

|

Red

|

+5 V

|

23

|

Red

|

+5 V

|

24

|

Black

|

GND

|

XO__XO XXX 10001 + 10 Surface-mount technology

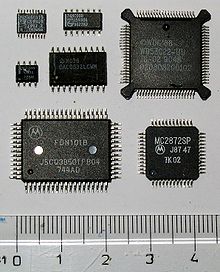

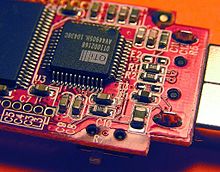

Surface-mount technology (SMT) is a method for producing electronic circuits in which the components are mounted or placed directly onto the surface of printed circuit boards (PCBs). An electronic device so made is called a surface-mount device (SMD). In industry, it has largely replaced the through-hole technology construction method of fitting components with wire leads into holes in the circuit board. Both technologies can be used on the same board, with the through-hole technology used for components not suitable for surface mounting such as large transformers and heat-sinked power semiconductors.

By employing SMT, the production process speeds up, but the risk of defects also increase due to component miniaturization and to the denser packing of boards. In those conditions, detection of failures has become critical for any SMT manufacturing process.

An SMT component is usually smaller than its through-hole counterpart because it has either smaller leads or no leads at all. It may have short pins or leads of various styles, flat contacts, a matrix of solder balls (BGAs), or terminations on the body of the component.

Surface-mount technology was developed in the 1960s and became widely used in the mid 1980s. By the late 1990s, the great majority of high-tech electronic printed circuit assemblies were dominated by surface mount devices. Much of the pioneering work in this technology was done by IBM. The design approach first demonstrated by IBM in 1960 in a small-scale computer was later applied in the Launch Vehicle Digital Computer used in the Instrument Unit that guided all Saturn IB and Saturn V vehicles. Components were mechanically redesigned to have small metal tabs or end caps that could be directly soldered to the surface of the PCB. Components became much smaller and component placement on both sides of a board became far more common with surface mounting than through-hole mounting, allowing much higher circuit densities and smaller circuit boards and, in turn, machines or subassemblies containing the boards.

Often only the solder joints hold the parts to the board; in rare cases parts on the bottom or "second" side of the board may be secured with a dot of adhesive to keep components from dropping off inside reflow ovens if the part has a large size or weight. Adhesive is sometimes used to hold SMT components on the bottom side of a board if a wave soldering process is used to solder both SMT and through-hole components simultaneously. Alternatively, SMT and through-hole components can be soldered on the same side of a board without adhesive if the SMT parts are first reflow-soldered, then a selective solder mask is used to prevent the solder holding those parts in place from reflowing and the parts floating away during wave soldering. Surface mounting lends itself well to a high degree of automation, reducing labor cost and greatly increasing production rates.

Conversely, SMT does not lend itself well to manual or low-automation fabrication, which is more economical and faster for one-off prototyping and small-scale production, and this is one reason why many through-hole components are still manufactured. Some SMDs can be soldered with a temperature-controlled manual soldering iron, but unfortunately, those that are very small or have too fine a lead pitch are impossible to manually solder without expensive hot-air solder reflow equipment . SMDs can be one-quarter to one-tenth the size and weight, and one-half to one-quarter the cost of equivalent through-hole parts, but on the other hand, the costs of a certain SMT part and of an equivalent through-hole part may be quite similar, though rarely is the SMT part more expensive.

Common abbreviations

Different terms describe the components, technique, and machines used in manufacturing. These terms are listed in the following table:

| SMp term | Expanded form |

|---|---|

| SMD | Surface-mount devices (active, passive and electromechanical components) |

| SMT | Surface-mount technology (assembling and mounting technology) |

| SMA | Surface-mount assembly (module assembled with SMT) |

| SMC | Surface-mount components (components for SMT) |

| SMP | Surface-mount packages (SMD case forms) |

| SME | Surface-mount equipment (SMT assembling machines) |

Assembly techniques

Where components are to be placed, the printed circuit board normally has flat, usually tin-lead, silver, or gold plated copper pads without holes, called solder pads. Solder paste, a sticky mixture of flux and tiny solder particles, is first applied to all the solder pads with a stainless steel or nickel stencil using a screen printing process. It can also be applied by a jet-printing mechanism, similar to an inkjet printer. After pasting, the boards then proceed to the pick-and-place machines, where they are placed on a conveyor belt. The components to be placed on the boards are usually delivered to the production line in either paper/plastic tapes wound on reels or plastic tubes. Some large integrated circuits are delivered in static-free trays. Numerical control pick-and-place machines remove the parts from the tapes, tubes or trays and place them on the PCB.[3]

The boards are then conveyed into the reflow soldering oven. They first enter a pre-heat zone, where the temperature of the board and all the components is gradually, uniformly raised. The boards then enter a zone where the temperature is high enough to melt the solder particles in the solder paste, bonding the component leads to the pads on the circuit board. The surface tension of the molten solder helps keep the components in place, and if the solder pad geometries are correctly designed, surface tension automatically aligns the components on their pads.

There are a number of techniques for reflowing solder. One is to use infrared lamps; this is called infrared reflow. Another is to use a hot gas convection. Another technology which is becoming popular again is special fluorocarbon liquids with high boiling points which use a method called vapor phase reflow. Due to environmental concerns, this method was falling out of favor until lead-free legislation was introduced which requires tighter controls on soldering. At the end of 2008, convection soldering was the most popular reflow technology using either standard air or nitrogen gas. Each method has its advantages and disadvantages. With infrared reflow, the board designer must lay the board out so that short components don't fall into the shadows of tall components. Component location is less restricted if the designer knows that vapor phase reflow or convection soldering will be used in production. Following reflow soldering, certain irregular or heat-sensitive components may be installed and soldered by hand, or in large-scale automation, by focused infrared beam (FIB) or localized convection equipment.

If the circuit board is double-sided then this printing, placement, reflow process may be repeated using either solder paste or glue to hold the components in place. If a wave soldering process is used, then the parts must be glued to the board prior to processing to prevent them from floating off when the solder paste holding them in place is melted.

After soldering, the boards may be washed to remove flux residues and any stray solder balls that could short out closely spaced component leads. Rosin flux is removed with fluorocarbon solvents, high flash point hydrocarbon solvents, or low flash solvents e.g. limonene (derived from orange peels) which require extra rinsing or drying cycles. Water-soluble fluxes are removed with deionized water and detergent, followed by an air blast to quickly remove residual water. However, most electronic assemblies are made using a "No-Clean" process where the flux residues are designed to be left on the circuit board, since they are considered harmless. This saves the cost of cleaning, speeds up the manufacturing process, and reduces waste. However, it is generally suggested to wash the assembly, even when a "No-Clean" process is used, when the application uses very high frequency clock signals (in excess of 1 GHz). Another reason to remove no-clean residues is to improve adhesion of conformal coatings and underfill materials.[4] Regardless of cleaning or not those PCBs, current industry trend suggests to carefully review a PCB assembly process where "No-Clean" is applied, since flux residues trapped under components and RF shields may affect surface insulation resistance (SIR), especially on high component density boards.[5]

Certain manufacturing standards, such as those written by the IPC - Association Connecting Electronics Industries require cleaning regardless of the solder flux type used to ensure a thoroughly clean board. Proper cleaning removes all traces of solder flux, as well as dirt and other contaminants that may be invisible to the naked eye. No-Clean or other soldering processes may leave "white residues" that, according to IPC, are acceptable "provided that these residues have been qualified and documented as benign".[6]However, while shops conforming to IPC standard are expected to adhere to the Association's rules on board condition, not all manufacturing facilities apply IPC standard, nor are they required to do so. Additionally, in some applications, such as low-end electronics, such stringent manufacturing methods are excessive both in expense and time required.

Finally, the boards are visually inspected for missing or misaligned components and solder bridging. If needed, they are sent to a rework station where a human operator repairs any errors. They are then usually sent to the testing stations (in-circuit testing and/or functional testing) to verify that they operate correctly. Automated Optical Inspection (AOI) systems are commonly used in PCB manufacturing. This technology has proven highly efficient for process improvements and quality achievements.

Advantages

The main advantages of SMT over the older through-hole technique are:

- Smaller components. As of 2017 smallest component is metric 0201 measuring 0.25mm × 0.125mm

- Much higher component density (components per unit area) and many more connections per component.

- Components can be placed on both sides of the circuit board.

- Higher density of connections because holes do not block routing space on inner layers, nor on back-side layers if components are mounted on only one side of the PCB.

- Small errors in component placement are corrected automatically as the surface tension of molten solder pulls components into alignment with solder pads. (On the other hand, through-hole components cannot be slightly misaligned, because once the leads are through the holes, the components are fully aligned and cannot move laterally out of alignment.)

- Better mechanical performance under shock and vibration conditions (partly due to lower mass, and partly due to less cantilevering)

- Lower resistance and inductance at the connection; consequently, fewer unwanted RF signal effects and better and more predictable high-frequency performance.

- Better EMC performance (lower radiated emissions) due to the smaller radiation loop area (because of the smaller package) and the lesser lead inductance.[8]

- Fewer holes need to be drilled. (Drilling PCBs is time-consuming and expensive.)

- Lower initial cost and time of setting up for mass production, using automated equipment.

- Simpler and faster automated assembly. Some placement machines are capable of placing more than 136,000 components per hour.

- Many SMT parts cost less than equivalent through-hole parts.

- A surface mount package is favored where a low profile package is required or the space available to mount the package is limited. As electronic devices become more complex and available space is reduced, the desirability of a surface mount package increases. Concurrently, as the device complexity increases, the heat generated by operation increases. If the heat is not removed, the temperature of the device rises shortening the operational life. It is therefore highly desirable to develop surface mount packages having high thermal conductivity.

Disadvantages

- SMT is unsuitable for large, high-power, or high-voltage parts, for example in power circuitry. It is common to combine SMT and through-hole construction, with transformers, heat-sinked power semiconductors, physically large capacitors, fuses, connectors, and so on mounted on one side of the PCB through holes.

- SMT is unsuitable as the sole attachment method for components that are subject to frequent mechanical stress, such as connectors that are used to interface with external devices that are frequently attached and detached.

- SMDs' solder connections may be damaged by potting compounds going through thermal cycling.

- Manual prototype assembly or component-level repair is more difficult and requires skilled operators and more expensive tools, due to the small sizes and lead spacings of many SMDs.[10] Handling of small SMT components can be difficult, requiring tweezers, unlike nearly all through-hole components. Whereas through-hole components will stay in place (under gravitational force) once inserted and can be mechanically secured prior to soldering by bending out two leads on the solder side of the board, SMDs are easily moved out of place by a touch of a soldering iron. Without expert skill, when manually soldering or desoldering a component, it is easy to accidentally reflow the solder of an adjacent SMT component and unintentionally displace it, something that is almost impossible to do with through-hole components.