x ample : Pickling is the first step in the production process of cold-rolled strip. First, the coils from the hot strip mill are welded into endless strips. In the continuous pickling line the scale that forms on the hot strip during hot rolling is rinsed with hydrochloric acid. This creates a bare metallic strip surface.

To ensure an uninterrupted pickling process, the continuous pickling line features a strip accumulator, also called a looper. The strip is accumulated to avoid unintentional standstill or operational stops, for coil welding.

X . I

Kinds of Sensors

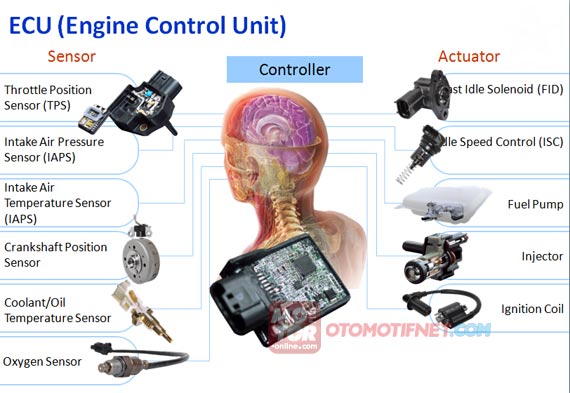

Sensors are tools that can be used to detect something (such as: temperature, speed, distance etc.) and often serve to measure the magnitude (amount) of something. The sensor is a type of transducer (converting power into another power) such as changing mechanical, magnetic, heat, chemical and light variations into voltage and electric current. Sensors are usually categorized by the meter and play an important role in the control of modern manufacturing processes. The sensors provide the eye, ears, nose and tongue of the tongue and become the microprocessor's brain of industrial automation systems. So the sensor is very important in the manufacture of automation tools such as in the field of industry, and others.

x ample sensor function picture :

Here are the various Sensors and their Functions and Implementation:

Sensors On Electronic Fuel Injection

1. Light sensorLight Sensor

Light sensors, as the name suggests, are used against objects that have shapes of color or light, which are converted into different power.The light sensor consists of 3 kinds of categories:· Photovoltaic, the working procedure of this sensor that is, convert direct light energy into electrical energy, in the presence of irradiation of light will cause the movement of electrons and generate voltage.· Photoconductive this sensor provides a change of resistance (resistance) in the cells. Principle of work, the higher the intensity of light received the sensor, the smaller the value of the resistance.· Photoelectric, work-principle sensor based on reflection due to change of position / distance of a light source (infrared or laser) or its reflecting target, consisting of the light source and receiver pair.Here are some examples of light sensors:

A. LDR (Light Dependent Resistor)This sensor serves to convert the intensity of light into electrical resistance. The working principle of LDR (Light Dependent Resistors) is, the higher the intensity of light that concerns the surface of LDR (Light Dependent Resistor), the greater the electrical resistance generated, and vice versa. This sensor can be implemented in the manufacture of automatic lights. Lights that automatically live at night, and die during the day. Lights live because the light intensity read by the sensor is very minimal, and vice versa.

B. PhotodiodeThis photodiode serves to change the intensity of light into diode conductivity. A photodiode similar to the diode in general, the difference in this photodiode is the fitting of a lens focusing lens to focus the falling beam at the "p n" encounter.

B. PhotodiodeThis photodiode serves to change the intensity of light into diode conductivity. A photodiode similar to the diode in general, the difference in this photodiode is the fitting of a lens focusing lens to focus the falling beam at the "p n" encounter.

Working principle: The light emitting energy falling at the "p n" encounter causes an electron to move to a higher energy level. The electrons move out of the band's valence leaving the hole generating a free electron pair and a hole. know about this one robot, Line Follower or more details Line Tracer. The Photodiode sensor is used to accept the color difference input from the line object reflected by the LED light beam, so that Line Tracer can proceed precisely over the line.

C. Phototransistor

Serves to change the intensity of light into the conductivity of the transistor. The phototransistor is similar to the transistor in general. The difference lies in, phototransistor mounted a lens focusing lens on the base foot to focus the falling light at meeting "p n".

2. Pressure Sensor

Pressure SensorThis sensor pressure sensor has a transducer that measures wire strain, which converts mechanical voltage into electrical signals. The basis of its sensing on changes in transducer resistance (transducer) is changed due to changes in length and area of its cross section. Examples of products that use Pressure sensors, such as: A tool for automatic detection of adult blood pressure. The device is performed with a cuff attached to the patient's arm, then pumped up to a certain pressure which is then just done a blood pressure measurement.

3. Proximity Sensor

Proximity SensorThe proximity sensor or so-called "proximity sensor" is a sensor capable of detecting the presence of nearby objects without direct physical contact. Usually this sensor consists of a solid-state electronics instrument wrapped tightly to protect from the effects of vibration, fluid, chemicals, and corrosive excessive. Proximity sensors can be applied to sensing conditions on objects that are considered too small or soft to drive a mechanical switch. Example of utilization of Proximity sensor is on Smartphone which in its application using Air Gesture technique. Where users can do access management to the smartphone without making physical contact to the smartphone screen.

Pressure SensorThis sensor pressure sensor has a transducer that measures wire strain, which converts mechanical voltage into electrical signals. The basis of its sensing on changes in transducer resistance (transducer) is changed due to changes in length and area of its cross section. Examples of products that use Pressure sensors, such as: A tool for automatic detection of adult blood pressure. The device is performed with a cuff attached to the patient's arm, then pumped up to a certain pressure which is then just done a blood pressure measurement.

3. Proximity Sensor

Proximity SensorThe proximity sensor or so-called "proximity sensor" is a sensor capable of detecting the presence of nearby objects without direct physical contact. Usually this sensor consists of a solid-state electronics instrument wrapped tightly to protect from the effects of vibration, fluid, chemicals, and corrosive excessive. Proximity sensors can be applied to sensing conditions on objects that are considered too small or soft to drive a mechanical switch. Example of utilization of Proximity sensor is on Smartphone which in its application using Air Gesture technique. Where users can do access management to the smartphone without making physical contact to the smartphone screen.

4. Ultrasonic Sensor

Ultrasonic Sensor

Ultrasonic sensors work on the principle of the reflection of sound waves, where these sensors produce sound waves which then capture them back with time difference as the basis for their sensing. The time difference between the sound waves emitted by the re-capture of the sound waves is directly proportional to the distance or height of the object that reflects it. Types of objects that can be sensed include: solid objects, liquid, granules and textiles. Many products are on processing using Ultrasonic sensors.

5. Speed Sensor (RPM)

Speed Sensor (RPM)The process of sensing the speed sensor is the reverse process of a motor, in which a rotating axis on a generator will produce a voltage proportional to the speed of the rotation of the object. Rotation speed is often measured using sensors that sense magnetic pulses (induces) that arise when a magnetic field occurs. For example on speedometer. The tool measures the speed of motor speed in kilometers per hour.

6. Magnet Sensor

Magnet Sensor

Magnet sensor or also called magnetic relay, is a tool that will be affected by magnetic field and will give change condition at output. Like a switch two conditions (on / off) is driven by the presence of magnetic field around it. Usually this sensor is packaged in a vacuum packing and free of dust, moisture, smoke or steam. Implementation of this tool such as, Computer-based magnetic field measurements consist of magnetic field sensor UGN3503, Op-Amp LM358 and ADC 0804. The working principle of the tool is closer to the magnet on the sensor. The sensor output of the voltage will be amplified by the op-amp to be processed by the ADC. Next the voltage is converted by ADC into digital data, then processed by computer with visual basic program and the result is displayed on PC.

Magnet Sensor

Magnet sensor or also called magnetic relay, is a tool that will be affected by magnetic field and will give change condition at output. Like a switch two conditions (on / off) is driven by the presence of magnetic field around it. Usually this sensor is packaged in a vacuum packing and free of dust, moisture, smoke or steam. Implementation of this tool such as, Computer-based magnetic field measurements consist of magnetic field sensor UGN3503, Op-Amp LM358 and ADC 0804. The working principle of the tool is closer to the magnet on the sensor. The sensor output of the voltage will be amplified by the op-amp to be processed by the ADC. Next the voltage is converted by ADC into digital data, then processed by computer with visual basic program and the result is displayed on PC.

7. Sensor Encoder (Encoder)

Encoding Sensor

Encoding Sensor

Encoder (Encoder) is used to convert linear or spin movements into digital signals, where the rotating sensor monitors the rotary motion of a device. This sensor usually consists of 2 layers of encoding type, namely; First, an additional rotary encoder (which transmits a certain amount of pulses for each round) that will generate a square wave on the object being rotated. Second, the absolute coding (which completes certain binary codes for each corner position) has the same way of working with the exceptions, the more or more density of the resulting square wave pulse in order to form an encoding in a particular arrangement. Examples of implementation of this sensor can be made into a system that can calculate the strength of earthquakes by using incremental rotary encoder sensor and processed by microcontroller...

8. Temperature SensorTemperature Sensor

As the name suggests, this sensor is certainly used to detect the temperature. There are 4 main types of commonly used temperature sensors, namely thermocouple (T / C) resistance temperature detector (RTD), thermistor and IC sensor. The thermocouple is essentially composed of a pair of hot and cold transducers which are connected together and melted together, in which there is a distinction arising between the joint and the reference line acting as a reference. Resistance Temperature Detector (RTD) has a basic principle in electrical resistance of metals that vary in proportion to temperature. The comparison of these variations is precision with a high degree of consistency / stability on detection of detainees. Platinum is a material that is often used because it has temperature resistance, linier , stability and reproducibility. Thermistors are heat-sensitive resistors that usually have a negative temperature coefficient, because when the temperature increases the resistance decreases or vice versa. This type is very sensitive with a 5% resistance per C so it can detect small temperature changes. While the IC Sensor is a temperature sensor with integrated circuit that uses chip silicon for weakness sensing . It has a very linear output voltage and current configuration. Usually this sensor is mostly installed on the smoke detector tool used to track the fire.

9. Flow Meter Sensor

Sensor Flow MeterFlow Meter is a sensor used to determine the flow of a material both solid and liquid. In the Industrial World there are various types of Sensor Flow this. For Yang Liquid usually use Turbine type, Electromagnetic, venture meter and others. As for Solid material is usually used from a combination of some instrument equipment used as Flow Meter, for example Weigh Feeder .

10. Flame sensor

Flame Sensor

This flame sensor can detect a flame with a wavelength of 760 nm ~ 1100 nm. In many robot matches, the detection of flame becomes one of the common rules of the race that never lags. Therefore this sensor is very useful, which you can make 'eye' for the robot to be able to detect the source of the flame, or looking for the ball. Suitable for use on fire-fighting robot and soccer robot.

This flame sensor has a reading angle of 60 degrees, and operates at a temperature of 25 -85 degrees Celsius. And of course for your attention, that the distance between the sensor and the detected object should not be too close, to avoid sensor damage.

X . II

Sensors and Transducers

But in order for an electronic circuit or system to perform any useful task or function it needs to be able to communicate with the “real world” whether this is by reading an input signal from an “ON/OFF” switch or by activating some form of output device to illuminate a single light.

In other words, an Electronic System or circuit must be able to “do” something and Sensors and Transducers are the perfect components for doing this.

Related Products: Ambient Light Sensor | Temperature and Humidity Sensors

The word “Transducer” is the collective term used for both Sensors which can be used to sense a wide range of different energy forms such as movement, electrical signals, radiant energy, thermal or magnetic energy etc , and Actuators which can be used to switch voltages or currents.

There are many different types of sensors and transducers, both analogue and digital and input and output available to choose from. The type of input or output transducer being used, really depends upon the type of signal or process being “Sensed” or “Controlled” but we can define a sensor and transducers as devices that converts one physical quantity into another.

Devices which perform an “Input” function are commonly called Sensors because they “sense” a physical change in some characteristic that changes in response to some excitation, for example heat or force and covert that into an electrical signal. Devices which perform an “Output” function are generally called Actuators and are used to control some external device, for example movement or sound.

Electrical Transducers are used to convert energy of one kind into energy of another kind, so for example, a microphone (input device) converts sound waves into electrical signals for the amplifier to amplify (a process), and a loudspeaker (output device) converts these electrical signals back into sound waves and an example of this type of simple Input / Output (I/O) system is given below.

There are many different types of sensors and transducers available in the marketplace, and the choice of which one to use really depends upon the quantity being measured or controlled, with the more common types given in the table below.

There are many different types of sensors and transducers available in the marketplace, and the choice of which one to use really depends upon the quantity being measured or controlled, with the more common types given in the table below.

Input type transducers or sensors, produce a voltage or signal output response which is proportional to the change in the quantity that they are measuring (the stimulus). The type or amount of the output signal depends upon the type of sensor being used. But generally, all types of sensors can be classed as two kinds, either Passive Sensors or Active Sensors.

Generally, active sensors require an external power supply to operate, called an excitation signal which is used by the sensor to produce the output signal. Active sensors are self-generating devices because their own properties change in response to an external effect producing for example, an output voltage of 1 to 10v DC or an output current such as 4 to 20mA DC. Active sensors can also produce signal amplification.

A good example of an active sensor is an LVDT sensor or a strain gauge. Strain gauges are pressure-sensitive resistive bridge networks that are external biased (excitation signal) in such a way as to produce an output voltage in proportion to the amount of force and/or strain being applied to the sensor.

Unlike an active sensor, a passive sensor does not need any additional power source or excitation voltage. Instead a passive sensor generates an output signal in response to some external stimulus. For example, a thermocouple which generates its own voltage output when exposed to heat. Then passive sensors are direct sensors which change their physical properties, such as resistance, capacitance or inductance etc.

But as well as analogue sensors, Digital Sensors produce a discrete output representing a binary number or digit such as a logic level “0” or a logic level “1”.

Analogue sensors tend to produce output signals that are changing smoothly and continuously over time. These signals tend to be very small in value from a few mico-volts (uV) to several milli-volts (mV), so some form of amplification is required.

Analogue sensors tend to produce output signals that are changing smoothly and continuously over time. These signals tend to be very small in value from a few mico-volts (uV) to several milli-volts (mV), so some form of amplification is required.

Then circuits which measure analogue signals usually have a slow response and/or low accuracy. Also analogue signals can be easily converted into digital type signals for use in micro-controller systems by the use of analogue-to-digital converters, or ADC’s.

In our simple example above, the speed of the rotating shaft is measured by using a digital LED/Opto-detector sensor. The disc which is fixed to a rotating shaft (for example, from a motor or robot wheels), has a number of transparent slots within its design. As the disc rotates with the speed of the shaft, each slot passes by the sensor in turn producing an output pulse representing a logic “1” or logic “0” level.

In our simple example above, the speed of the rotating shaft is measured by using a digital LED/Opto-detector sensor. The disc which is fixed to a rotating shaft (for example, from a motor or robot wheels), has a number of transparent slots within its design. As the disc rotates with the speed of the shaft, each slot passes by the sensor in turn producing an output pulse representing a logic “1” or logic “0” level.

These pulses are sent to a register of counter and finally to an output display to show the speed or revolutions of the shaft. By increasing the number of slots or “windows” within the disc more output pulses can be produced for each revolution of the shaft. The advantage of this is that a greater resolution and accuracy is achieved as fractions of a revolution can be detected. Then this type of sensor arrangement could also be used for positional control with one of the discs slots representing a reference position.

Compared to analogue signals, digital signals or quantities have very high accuracies and can be both measured and “sampled” at a very high clock speed. The accuracy of the digital signal is proportional to the number of bits used to represent the measured quantity. For example, using a processor of 8 bits, will produce an accuracy of 0.390% (1 part in 256). While using a processor of 16 bits gives an accuracy of 0.0015%, (1 part in 65,536) or 260 times more accurate. This accuracy can be maintained as digital quantities are manipulated and processed very rapidly, millions of times faster than analogue signals.

In most cases, sensors and more specifically analogue sensors generally require an external power supply and some form of additional amplification or filtering of the signal in order to produce a suitable electrical signal which is capable of being measured or used. One very good way of achieving both amplification and filtering within a single circuit is to use Operational Amplifiers as seen before.

The very small analogue signal voltages produced by a sensor such as a few milli-volts or even pico-volts can be amplified many times over by a simple op-amp circuit to produce a much larger voltage signal of say 5v or 5mA that can then be used as an input signal to a microprocessor or analogue-to-digital based system.

Therefore, to provide any useful signal a sensors output signal has to be amplified with an amplifier that has a voltage gain up to 10,000 and a current gain up to 1,000,000 with the amplification of the signal being linear with the output signal being an exact reproduction of the input, just changed in amplitude.

Then amplification is part of signal conditioning. So when using analogue sensors, generally some form of amplification (Gain), impedance matching, isolation between the input and output or perhaps filtering (frequency selection) may be required before the signal can be used and this is conveniently performed by Operational Amplifiers.

Also, when measuring very small physical changes the output signal of a sensor can become “contaminated” with unwanted signals or voltages that prevent the actual signal required from being measured correctly. These unwanted signals are called “Noise“. This Noise or Interference can be either greatly reduced or even eliminated by using signal conditioning or filtering techniques as we discussed in the Active Filter tutorial.

By using either a Low Pass, or a High Pass or even Band Pass filter the “bandwidth” of the noise can be reduced to leave just the output signal required. For example, many types of inputs from switches, keyboards or manual controls are not capable of changing state rapidly and so low-pass filter can be used. When the interference is at a particular frequency, for example mains frequency, narrow band reject or Notch filters can be used to produce frequency selective filters.

Were some random noise still remains after filtering it may be necessary to take several samples and then average them to give the final value so increasing the signal-to-noise ratio. Either way, both amplification and filtering play an important role in interfacing both sensors and transducers to microprocessor and electronics based systems in “real world” conditions.

Were some random noise still remains after filtering it may be necessary to take several samples and then average them to give the final value so increasing the signal-to-noise ratio. Either way, both amplification and filtering play an important role in interfacing both sensors and transducers to microprocessor and electronics based systems in “real world” conditions.

In the next tutorial about Sensors, we will look at Positional Sensors which measure the position and/or displacement of physical objects meaning the movement from one position to another for a specific distance or angle.

In other words, an Electronic System or circuit must be able to “do” something and Sensors and Transducers are the perfect components for doing this.

Related Products: Ambient Light Sensor | Temperature and Humidity Sensors

The word “Transducer” is the collective term used for both Sensors which can be used to sense a wide range of different energy forms such as movement, electrical signals, radiant energy, thermal or magnetic energy etc , and Actuators which can be used to switch voltages or currents.

There are many different types of sensors and transducers, both analogue and digital and input and output available to choose from. The type of input or output transducer being used, really depends upon the type of signal or process being “Sensed” or “Controlled” but we can define a sensor and transducers as devices that converts one physical quantity into another.

Devices which perform an “Input” function are commonly called Sensors because they “sense” a physical change in some characteristic that changes in response to some excitation, for example heat or force and covert that into an electrical signal. Devices which perform an “Output” function are generally called Actuators and are used to control some external device, for example movement or sound.

Electrical Transducers are used to convert energy of one kind into energy of another kind, so for example, a microphone (input device) converts sound waves into electrical signals for the amplifier to amplify (a process), and a loudspeaker (output device) converts these electrical signals back into sound waves and an example of this type of simple Input / Output (I/O) system is given below.

Simple Input / Output System using Sound Transducers

Common Sensors and Transducers

| Quantity being Measured | Input Device (Sensor) | Output Device (Actuator) |

| Light Level | Light Dependant Resistor (LDR) Photodiode Photo-transistor Solar Cell | Lights & Lamps LED’s & Displays Fibre Optics |

| Temperature | Thermocouple Thermistor Thermostat Resistive Temperature Detectors | Heater Fan |

| Force/Pressure | Strain Gauge Pressure Switch Load Cells | Lifts & Jacks Electromagnet Vibration |

| Position | Potentiometer Encoders Reflective/Slotted Opto-switch LVDT | Motor Solenoid Panel Meters |

| Speed | Tacho-generator Reflective/Slotted Opto-coupler Doppler Effect Sensors | AC and DC Motors Stepper Motor Brake |

| Sound | Carbon Microphone Piezo-electric Crystal | Bell Buzzer Loudspeaker |

Generally, active sensors require an external power supply to operate, called an excitation signal which is used by the sensor to produce the output signal. Active sensors are self-generating devices because their own properties change in response to an external effect producing for example, an output voltage of 1 to 10v DC or an output current such as 4 to 20mA DC. Active sensors can also produce signal amplification.

A good example of an active sensor is an LVDT sensor or a strain gauge. Strain gauges are pressure-sensitive resistive bridge networks that are external biased (excitation signal) in such a way as to produce an output voltage in proportion to the amount of force and/or strain being applied to the sensor.

Unlike an active sensor, a passive sensor does not need any additional power source or excitation voltage. Instead a passive sensor generates an output signal in response to some external stimulus. For example, a thermocouple which generates its own voltage output when exposed to heat. Then passive sensors are direct sensors which change their physical properties, such as resistance, capacitance or inductance etc.

But as well as analogue sensors, Digital Sensors produce a discrete output representing a binary number or digit such as a logic level “0” or a logic level “1”.

Analogue and Digital Sensors

Analogue Sensors

Analogue Sensors produce a continuous output signal or voltage which is generally proportional to the quantity being measured. Physical quantities such as Temperature, Speed, Pressure, Displacement, Strain etc are all analogue quantities as they tend to be continuous in nature. For example, the temperature of a liquid can be measured using a thermometer or thermocouple which continuously responds to temperature changes as the liquid is heated up or cooled down.Thermocouple used to produce an Analogue Signal

Then circuits which measure analogue signals usually have a slow response and/or low accuracy. Also analogue signals can be easily converted into digital type signals for use in micro-controller systems by the use of analogue-to-digital converters, or ADC’s.

Digital Sensors

As its name implies, Digital Sensors produce a discrete digital output signals or voltages that are a digital representation of the quantity being measured. Digital sensors produce a Binary output signal in the form of a logic “1” or a logic “0”, (“ON” or “OFF”). This means then that a digital signal only produces discrete (non-continuous) values which may be outputted as a single “bit”, (serial transmission) or by combining the bits to produce a single “byte” output (parallel transmission).Light Sensor used to produce an Digital Signal

These pulses are sent to a register of counter and finally to an output display to show the speed or revolutions of the shaft. By increasing the number of slots or “windows” within the disc more output pulses can be produced for each revolution of the shaft. The advantage of this is that a greater resolution and accuracy is achieved as fractions of a revolution can be detected. Then this type of sensor arrangement could also be used for positional control with one of the discs slots representing a reference position.

Compared to analogue signals, digital signals or quantities have very high accuracies and can be both measured and “sampled” at a very high clock speed. The accuracy of the digital signal is proportional to the number of bits used to represent the measured quantity. For example, using a processor of 8 bits, will produce an accuracy of 0.390% (1 part in 256). While using a processor of 16 bits gives an accuracy of 0.0015%, (1 part in 65,536) or 260 times more accurate. This accuracy can be maintained as digital quantities are manipulated and processed very rapidly, millions of times faster than analogue signals.

In most cases, sensors and more specifically analogue sensors generally require an external power supply and some form of additional amplification or filtering of the signal in order to produce a suitable electrical signal which is capable of being measured or used. One very good way of achieving both amplification and filtering within a single circuit is to use Operational Amplifiers as seen before.

Signal Conditioning of Sensors

As we saw in the Operational Amplifier tutorial, op-amps can be used to provide amplification of signals when connected in either inverting or non-inverting configurations.The very small analogue signal voltages produced by a sensor such as a few milli-volts or even pico-volts can be amplified many times over by a simple op-amp circuit to produce a much larger voltage signal of say 5v or 5mA that can then be used as an input signal to a microprocessor or analogue-to-digital based system.

Therefore, to provide any useful signal a sensors output signal has to be amplified with an amplifier that has a voltage gain up to 10,000 and a current gain up to 1,000,000 with the amplification of the signal being linear with the output signal being an exact reproduction of the input, just changed in amplitude.

Then amplification is part of signal conditioning. So when using analogue sensors, generally some form of amplification (Gain), impedance matching, isolation between the input and output or perhaps filtering (frequency selection) may be required before the signal can be used and this is conveniently performed by Operational Amplifiers.

Also, when measuring very small physical changes the output signal of a sensor can become “contaminated” with unwanted signals or voltages that prevent the actual signal required from being measured correctly. These unwanted signals are called “Noise“. This Noise or Interference can be either greatly reduced or even eliminated by using signal conditioning or filtering techniques as we discussed in the Active Filter tutorial.

By using either a Low Pass, or a High Pass or even Band Pass filter the “bandwidth” of the noise can be reduced to leave just the output signal required. For example, many types of inputs from switches, keyboards or manual controls are not capable of changing state rapidly and so low-pass filter can be used. When the interference is at a particular frequency, for example mains frequency, narrow band reject or Notch filters can be used to produce frequency selective filters.

Typical Op-amp Filters

In the next tutorial about Sensors, we will look at Positional Sensors which measure the position and/or displacement of physical objects meaning the movement from one position to another for a specific distance or angle.

As their name implies, Position Sensors detect the position of something which means that they are referenced either to or from some fixed point or position. These types of sensors provide a “positional” feedback.

One method of determining a position, is to use either “distance”, which could be the distance between two points such as the distance travelled or moved away from some fixed point, or by “rotation” (angular movement). For example, the rotation of a robots wheel to determine its distance travelled along the ground. Either way, Position Sensors can detect the movement of an object in a straight line using Linear Sensors or by its angular movement using Rotational Sensors.

Potentiometer

Potentiometers come in a wide range of designs and sizes such as the commonly available round rotational type or the longer and flat linear slider types. When used as a position sensor the moveable object is connected directly to the rotational shaft or slider of the potentiometer.

A DC reference voltage is applied across the two outer fixed connections forming the resistive element. The output voltage signal is taken from the wiper terminal of the sliding contact as shown below.

This configuration produces a potential or voltage divider type circuit output which is proportional to the shaft position. Then for example, if you apply a voltage of say 10v across the resistive element of the potentiometer the maximum output voltage would be equal to the supply voltage at 10 volts, with the minimum output voltage equal to 0 volts. Then the potentiometer wiper will vary the output signal from 0 to 10 volts, with 5 volts indicating that the wiper or slider is at its half-way or center position.

The output signal (Vout) from the potentiometer is taken from the centre wiper connection as it moves along the resistive track, and is proportional to the angular position of the shaft.

The output signal (Vout) from the potentiometer is taken from the centre wiper connection as it moves along the resistive track, and is proportional to the angular position of the shaft.

While resistive potentiometer position sensors have many advantages: low cost, low tech, easy to use etc, as a position sensor they also have many disadvantages: wear due to moving parts, low accuracy, low repeatability, and limited frequency response.

While resistive potentiometer position sensors have many advantages: low cost, low tech, easy to use etc, as a position sensor they also have many disadvantages: wear due to moving parts, low accuracy, low repeatability, and limited frequency response.

But there is one main disadvantage of using the potentiometer as a positional sensor. The range of movement of its wiper or slider (and hence the output signal obtained) is limited to the physical size of the potentiometer being used.

For example a single turn rotational potentiometer generally only has a fixed mechanical rotation of between 0o and about 240 to 330o maximum. However, multi-turn pots of up to 3600o (10 x 360o) of mechanical rotation are also available.

Most types of potentiometers use carbon film for their resistive track, but these types are electrically noisy (the crackle on a radio volume control), and also have a short mechanical life.

Wire-wound pots also known as rheostats, in the form of either a straight wire or wound coil resistive wire can also be used, but wire wound pots suffer from resolution problems as their wiper jumps from one wire segment to the next producing a logarithmic (LOG) output resulting in errors in the output signal. These too suffer from electrical noise.

For high precision low noise applications conductive plastic resistance element type polymer film or cermet type potentiometers are now available. These pots have a smooth low friction electrically linear (LIN) resistive track giving them a low noise, long life and excellent resolution and are available as both multi-turn and single turn devices. Typical applications for this type of high accuracy position sensor is in computer game joysticks, steering wheels, industrial and robot applications.

It basically consists of three coils wound on a hollow tube former, one forming the primary coil and the other two coils forming identical secondaries connected electrically together in series but 180o out of phase either side of the primary coil.

A moveable soft iron ferromagnetic core (sometimes called an “armature”) which is connected to the object being measured, slides or moves up and down inside the tubular body of the LVDT.

A small AC reference voltage called the “excitation signal” (2 – 20V rms, 2 – 20kHz) is applied to the primary winding which in turn induces an EMF signal into the two adjacent secondary windings (transformer principles).

If the soft iron magnetic core armature is exactly in the centre of the tube and the windings, “null position”, the two induced emf’s in the two secondary windings cancel each other out as they are 180o out of phase, so the resultant output voltage is zero. As the core is displaced slightly to one side or the other from this null or zero position, the induced voltage in one of the secondaries will be become greater than that of the other secondary and an output will be produced.

The polarity of the output signal depends upon the direction and displacement of the moving core. The greater the movement of the soft iron core from its central null position the greater will be the resulting output signal. The result is a differential voltage output which varies linearly with the cores position. Therefore, the output signal from this type of position sensor has both an amplitude that is a linear function of the cores displacement and a polarity that indicates direction of movement.

The phase of the output signal can be compared to the primary coil excitation phase enabling suitable electronic circuits such as the AD592 LVDT Sensor Amplifier to know which half of the coil the magnetic core is in and thereby know the direction of travel.

When the armature is moved from one end to the other through the centre position the output voltages changes from maximum to zero and back to maximum again but in the process changes its phase angle by 180 deg’s. This enables the LVDT to produce an output AC signal whose magnitude represents the amount of movement from the centre position and whose phase angle represents the direction of movement of the core.

When the armature is moved from one end to the other through the centre position the output voltages changes from maximum to zero and back to maximum again but in the process changes its phase angle by 180 deg’s. This enables the LVDT to produce an output AC signal whose magnitude represents the amount of movement from the centre position and whose phase angle represents the direction of movement of the core.

A typical application of a linear variable differential transformer (LVDT) sensor would be as a pressure transducer, were the pressure being measured pushes against a diaphragm to produce a force. The force is then converted into a readable voltage signal by the sensor.

Advantages of the linear variable differential transformer, or LVDT compared to a resistive potentiometer are that its linearity, that is its voltage output to displacement is excellent, very good accuracy, good resolution, high sensitivity as well as frictionless operation. They are also sealed for use in hostile environments.

Proximity sensors, are non-contact position sensors that use a magnetic field for detection with the simplest magnetic sensor being the reed switch. In an inductive sensor, a coil is wound around an iron core within an electromagnetic field to form an inductive loop.

When a ferromagnetic material is placed within the eddy current field generated around the inductive sensor, such as a ferromagnetic metal plate or metal screw, the inductance of the coil changes significantly. The proximity sensors detection circuit detects this change producing an output voltage. Therefore, inductive proximity sensors operate under the electrical principle of Faraday’s Law of inductance.

An inductive proximity sensor has four main components; The oscillator which produces the electromagnetic field, the coil which generates the magnetic field, the detection circuit which detects any change in the field when an object enters it and the output circuit which produces the output signal, either with normally closed (NC) or normally open (NO) contacts.

An inductive proximity sensor has four main components; The oscillator which produces the electromagnetic field, the coil which generates the magnetic field, the detection circuit which detects any change in the field when an object enters it and the output circuit which produces the output signal, either with normally closed (NC) or normally open (NO) contacts.

Inductive proximity sensors allow for the detection of metallic objects in front of the sensor head without any physical contact of the object itself being detected. This makes them ideal for use in dirty or wet environments. The “sensing” range of proximity sensors is very small, typically 0.1mm to 12mm.

Proximity Sensor

As well as industrial applications, inductive proximity sensors are also commonly used to control the flow of traffic by changing of traffic lights at junctions and cross roads. Rectangular inductive loops of wire are buried into the tarmac road surface.

When a car or other road vehicle passes over this inductive loop, the metallic body of the vehicle changes the loops inductance and activates the sensor thereby alerting the traffic lights controller that there is a vehicle waiting.

One main disadvantage of these types of position sensors is that they are “Omni-directional”, that is they will sense a metallic object either above, below or to the side of it. Also, they do not detect non-metallic objects although Capacitive Proximity Sensors and Ultrasonic Proximity Sensors are available. Other commonly available magnetic positional sensors include: reed switches, Hall Effect Sensors and variable reluctance sensors.

All optical encoders work on the same basic principle. Light from an LED or infra-red light source is passed through a rotating high-resolution encoded disk that contains the required code patterns, either binary, grey code or BCD. Photo detectors scan the disk as it rotates and an electronic circuit processes the information into a digital form as a stream of binary output pulses that are fed to counters or controllers which determine the actual angular position of the shaft.

There are two basic types of rotary optical encoders, Incremental Encoders and Absolute Position Encoders.

Encoder Disk

Incremental Encoders, also known as quadrature encoders or relative rotary encoder, are the simplest of the two position sensors. Their output is a series of square wave pulses generated by a photocell arrangement as the coded disk, with evenly spaced transparent and dark lines called segments on its surface, moves or rotates past the light source. The encoder produces a stream of square wave pulses which, when counted, indicates the angular position of the rotating shaft.

Incremental encoders have two separate outputs called “quadrature outputs”. These two outputs are displaced at 90o out of phase from each other with the direction of rotation of the shaft being determined from the output sequence.

The number of transparent and dark segments or slots on the disk determines the resolution of the device and increasing the number of lines in the pattern increases the resolution per degree of rotation. Typical encoded discs have a resolution of up to 256 pulses or 8-bits per rotation.

The simplest incremental encoder is called a tachometer. It has one single square wave output and is often used in unidirectional applications where basic position or speed information only is required. The “Quadrature” or “Sine wave” encoder is the more common and has two output square waves commonly called channel A and channel B. This device uses two photo detectors, slightly offset from each other by 90o thereby producing two separate sine and cosine output signals.

By using the Arc Tangent mathematical function the angle of the shaft in radians can be calculated. Generally, the optical disk used in rotary position encoders is circular, then the resolution of the output will be given as: θ = 360/n, where n equals the number of segments on coded disk.

By using the Arc Tangent mathematical function the angle of the shaft in radians can be calculated. Generally, the optical disk used in rotary position encoders is circular, then the resolution of the output will be given as: θ = 360/n, where n equals the number of segments on coded disk.

Then for example, the number of segments required to give an incremental encoder a resolution of 1o will be: 1o = 360/n, therefore, n = 360 windows, etc. Also the direction of rotation is determined by noting which channel produces an output first, either channel A or channel B giving two directions of rotation, A leads B or B leads A. This arrangement is shown below.

One main disadvantage of incremental encoders when used as a position sensor, is that they require external counters to determine the absolute angle of the shaft within a given rotation. If the power is momentarily shut off, or if the encoder misses a pulse due to noise or a dirty disc, the resulting angular information will produce an error. One way of overcoming this disadvantage is to use absolute position encoders.

One main disadvantage of incremental encoders when used as a position sensor, is that they require external counters to determine the absolute angle of the shaft within a given rotation. If the power is momentarily shut off, or if the encoder misses a pulse due to noise or a dirty disc, the resulting angular information will produce an error. One way of overcoming this disadvantage is to use absolute position encoders.

One main advantage of an absolute encoder is its non-volatile memory which retains the exact position of the encoder without the need to return to a “home” position if the power fails. Most rotary encoders are defined as “single-turn” devices, but absolute multi-turn devices are available, which obtain feedback over several revolutions by adding extra code disks.

One main advantage of an absolute encoder is its non-volatile memory which retains the exact position of the encoder without the need to return to a “home” position if the power fails. Most rotary encoders are defined as “single-turn” devices, but absolute multi-turn devices are available, which obtain feedback over several revolutions by adding extra code disks.

Typical application of absolute position encoders are in computer hard drives and CD/DVD drives were the absolute position of the drives read/write heads are monitored or in printers/plotters to accurately position the printing heads over the paper.

In this tutorial about Position Sensors, we have looked at several examples of sensors that can be used to measure the position or presence of objects. In the next tutorial we will look at sensors that are used to measure temperature such as thermistors, thermostats and thermocouples, and as such are known commonly as Temperature Sensors.

Temperature Sensors

These types of temperature sensor vary from simple ON/OFF thermostatic devices which control a domestic hot water heating system to highly sensitive semiconductor types that can control complex process control furnace plants.

We remember from our school science classes that the movement of molecules and atoms produces heat (kinetic energy) and the greater the movement, the more heat that is generated. Temperature Sensors measure the amount of heat energy or even coldness that is generated by an object or system, allowing us to “sense” or detect any physical change to that temperature producing either an analogue or digital output.

There are many different types of Temperature Sensor available and all have different characteristics depending upon their actual application. A temperature sensor consists of two basic physical types:

The bi-metallic strip can be used itself as an electrical switch or as a mechanical way of operating an electrical switch in thermostatic controls and are used extensively to control hot water heating elements in boilers, furnaces, hot water storage tanks as well as in vehicle radiator cooling systems.

The thermostat consists of two thermally different metals stuck together back to back. When it is cold the contacts are closed and current passes through the thermostat. When it gets hot, one metal expands more than the other and the bonded bi-metallic strip bends up (or down) opening the contacts preventing the current from flowing.

The thermostat consists of two thermally different metals stuck together back to back. When it is cold the contacts are closed and current passes through the thermostat. When it gets hot, one metal expands more than the other and the bonded bi-metallic strip bends up (or down) opening the contacts preventing the current from flowing.

On/Off Thermostat

There are two main types of bi-metallic strips based mainly upon their movement when subjected to temperature changes. There are the “snap-action” types that produce an instantaneous “ON/OFF” or “OFF/ON” type action on the electrical contacts at a set temperature point, and the slower “creep-action” types that gradually change their position as the temperature changes.

Snap-action type thermostats are commonly used in our homes for controlling the temperature set point of ovens, irons, immersion hot water tanks and they can also be found on walls to control the domestic heating system.

Creeper types generally consist of a bi-metallic coil or spiral that slowly unwinds or coils-up as the temperature changes. Generally, creeper type bi-metallic strips are more sensitive to temperature changes than the standard snap ON/OFF types as the strip is longer and thinner making them ideal for use in temperature gauges and dials etc.

Although very cheap and are available over a wide operating range, one main disadvantage of the standard snap-action type thermostats when used as a temperature sensor, is that they have a large hysteresis range from when the electrical contacts open until when they close again. For example, it may be set to 20oC but may not open until 22oC or close again until 18oC.

So the range of temperature swing can be quite high. Commercially available bi-metallic thermostats for home use do have temperature adjustment screws that allow for a more precise desired temperature set-point and hysteresis level to be pre-set.

Thermistor

Thermistors are generally made from ceramic materials such as oxides of nickel, manganese or cobalt coated in glass which makes them easily damaged. Their main advantage over snap-action types is their speed of response to any changes in temperature, accuracy and repeatability.

Most types of thermistor’s have a Negative Temperature Coefficient of resistance or (NTC), that is their resistance value goes DOWN with an increase in the temperature, and of course there are some which have a Positive Temperature Coefficient, (PTC), in that their resistance value goes UP with an increase in temperature.

Thermistors are constructed from a ceramic type semiconductor material using metal oxide technology such as manganese, cobalt and nickel, etc. The semiconductor material is generally formed into small pressed discs or balls which are hermetically sealed to give a relatively fast response to any changes in temperature.

Thermistors are rated by their resistive value at room temperature (usually at 25oC), their time constant (the time to react to the temperature change) and their power rating with respect to the current flowing through them. Like resistors, thermistors are available with resistance values at room temperature from 10’s of MΩ down to just a few Ohms, but for sensing purposes those types with values in the kilo-ohms are generally used.

Thermistors are passive resistive devices which means we need to pass a current through it to produce a measurable voltage output. Then thermistors are generally connected in series with a suitable biasing resistor to form a potential divider network and the choice of resistor gives a voltage output at some pre-determined temperature point or value for example:

By changing the fixed resistor value of R2 (in our example 1kΩ) to a potentiometer or preset, a voltage output can be obtained at a predetermined temperature set point for example, 5v output at 60oC and by varying the potentiometer a particular output voltage level can be obtained over a wider temperature range.

By changing the fixed resistor value of R2 (in our example 1kΩ) to a potentiometer or preset, a voltage output can be obtained at a predetermined temperature set point for example, 5v output at 60oC and by varying the potentiometer a particular output voltage level can be obtained over a wider temperature range.

It needs to be noted however, that thermistor’s are non-linear devices and their standard resistance values at room temperature is different between different thermistor’s, which is due mainly to the semiconductor materials they are made from. The Thermistor, have an exponential change with temperature and therefore have a Beta temperature constant ( β ) which can be used to calculate its resistance for any given temperature point.

However, when used with a series resistor such as in a voltage divider network or Whetstone Bridge type arrangement, the current obtained in response to a voltage applied to the divider/bridge network is linear with temperature. Then, the output voltage across the resistor becomes linear with temperature.

A Resistive RTD

Resistive temperature detectors have positive temperature coefficients (PTC) but unlike the thermistor their output is extremely linear producing very accurate measurements of temperature.

However, they have very poor thermal sensitivity, that is a change in temperature only produces a very small output change for example, 1Ω/oC.

The more common types of RTD’s are made from platinum and are called Platinum Resistance Thermometer or PRT‘s with the most commonly available of them all the Pt100 sensor, which has a standard resistance value of 100Ω at 0oC. The downside is that Platinum is expensive and one of the main disadvantages of this type of device is its cost.

Like the thermistor, RTD’s are passive resistive devices and by passing a constant current through the temperature sensor it is possible to obtain an output voltage that increases linearly with temperature. A typical RTD has a base resistance of about 100Ω at 0oC, increasing to about 140Ω at 100oC with an operating temperature range of between -200 to +600oC.

Because the RTD is a resistive device, we need to pass a current through them and monitor the resulting voltage. However, any variation in resistance due to self heat of the resistive wires as the current flows through it, I2R , (Ohms Law) causes an error in the readings. To avoid this, the RTD is usually connected into a Whetstone Bridge network which has additional connecting wires for lead-compensation and/or connection to a constant current source.

Thermocouples are thermoelectric sensors that basically consists of two junctions of dissimilar metals, such as copper and constantan that are welded or crimped together. One junction is kept at a constant temperature called the reference (Cold) junction, while the other the measuring (Hot) junction. When the two junctions are at different temperatures, a voltage is developed across the junction which is used to measure the temperature sensor as shown below.

The operating principal of a thermocouple is very simple and basic. When fused together the junction of the two dissimilar metals such as copper and constantan produces a “thermo-electric” effect which gives a constant potential difference of only a few millivolts (mV) between them. The voltage difference between the two junctions is called the “Seebeck effect” as a temperature gradient is generated along the conducting wires producing an emf. Then the output voltage from a thermocouple is a function of the temperature changes.

The operating principal of a thermocouple is very simple and basic. When fused together the junction of the two dissimilar metals such as copper and constantan produces a “thermo-electric” effect which gives a constant potential difference of only a few millivolts (mV) between them. The voltage difference between the two junctions is called the “Seebeck effect” as a temperature gradient is generated along the conducting wires producing an emf. Then the output voltage from a thermocouple is a function of the temperature changes.

If both the junctions are at the same temperature the potential difference across the two junctions is zero in other words, no voltage output as V1 = V2. However, when the junctions are connected within a circuit and are both at different temperatures a voltage output will be detected relative to the difference in temperature between the two junctions, V1 – V2. This difference in voltage will increase with temperature until the junctions peak voltage level is reached and this is determined by the characteristics of the two dissimilar metals used.

Thermocouples can be made from a variety of different materials enabling extreme temperatures of

between -200oC to over +2000oC to be measured. With such a large choice of materials and temperature range, internationally recognised standards have been developed complete with thermocouple colour codes to allow the user to choose the correct thermocouple sensor for a particular application. The British colour code for standard thermocouples is given below.

The three most common thermocouple materials used above for general temperature measurement are Iron-Constantan (Type J), Copper-Constantan (Type T), and Nickel-Chromium (Type K). The output voltage from a thermocouple is very small, only a few millivolts (mV) for a 10oC change in temperature difference and because of this small voltage output some form of amplification is generally required.

The type of amplifier, either discrete or in the form of an Operational Amplifier needs to be carefully selected, because good drift stability is required to prevent recalibration of the thermocouple at frequent intervals. This makes the chopper and instrumentation type of amplifier preferable for most temperature sensing applications.

The type of amplifier, either discrete or in the form of an Operational Amplifier needs to be carefully selected, because good drift stability is required to prevent recalibration of the thermocouple at frequent intervals. This makes the chopper and instrumentation type of amplifier preferable for most temperature sensing applications.

Other Temperature Sensor Types not mentioned here include, Semiconductor Junction Sensors, Infra-red and Thermal Radiation Sensors, Medical type Thermometers, Indicators and Colour Changing Inks or Dyes.

In this tutorial about “Temperature Sensor Types”, we have looked at several examples of sensors that can be used to measure changes in temperature. In the next tutorial we will look at sensors that are used to measure light quantity, such as Photodiodes, Phototransistors, Photovoltaic Cells and the Light Dependent Resistor.

The light sensor is a passive devices that convert this “light energy” whether visible or in the infra-red parts of the spectrum into an electrical signal output. Light sensors are more commonly known as “Photoelectric Devices” or “Photo Sensors” because the convert light energy (photons) into electricity (electrons).

Photoelectric devices can be grouped into two main categories, those which generate electricity when illuminated, such as Photo-voltaics or Photo-emissives etc, and those which change their electrical properties in some way such as Photo-resistors or Photo-conductors. This leads to the following classification of devices.

Photoresistors are Semiconductor devices that use light energy to control the flow of electrons, and hence the current flowing through them. The commonly used Photoconductive Cell is called the Light Dependent Resistor or LDR.

Typical LDR

As its name implies, the Light Dependent Resistor (LDR) is made from a piece of exposed semiconductor material such as cadmium sulphide that changes its electrical resistance from several thousand Ohms in the dark to only a few hundred Ohms when light falls upon it by creating hole-electron pairs in the material.

The net effect is an improvement in its conductivity with a decrease in resistance for an increase in illumination. Also, photoresistive cells have a long response time requiring many seconds to respond to a change in the light intensity.

Materials used as the semiconductor substrate include, lead sulphide (PbS), lead selenide (PbSe), indium antimonide (InSb) which detect light in the infra-red range with the most commonly used of all photoresistive light sensors being Cadmium Sulphide (Cds).

Cadmium sulphide is used in the manufacture of photoconductive cells because its spectral response curve closely matches that of the human eye and can even be controlled using a simple torch as a light source. Typically then, it has a peak sensitivity wavelength (λp) of about 560nm to 600nm in the visible spectral range.

The most commonly used photoresistive light sensor is the ORP12 Cadmium Sulphide photoconductive cell. This light dependent resistor has a spectral response of about 610nm in the yellow to orange region of light. The resistance of the cell when unilluminated (dark resistance) is very high at about 10MΩ’s which falls to about 100Ω’s when fully illuminated (lit resistance).

The most commonly used photoresistive light sensor is the ORP12 Cadmium Sulphide photoconductive cell. This light dependent resistor has a spectral response of about 610nm in the yellow to orange region of light. The resistance of the cell when unilluminated (dark resistance) is very high at about 10MΩ’s which falls to about 100Ω’s when fully illuminated (lit resistance).

To increase the dark resistance and therefore reduce the dark current, the resistive path forms a zigzag pattern across the ceramic substrate. The CdS photocell is a very low cost device often used in auto dimming, darkness or twilight detection for turning the street lights “ON” and “OFF”, and for photographic exposure meter type applications.

Connecting a light dependant resistor in series with a standard resistor like this across a single DC supply voltage has one major advantage, a different voltage will appear at their junction for different levels of light.

Connecting a light dependant resistor in series with a standard resistor like this across a single DC supply voltage has one major advantage, a different voltage will appear at their junction for different levels of light.

The amount of voltage drop across series resistor, R2 is determined by the resistive value of the light dependant resistor, RLDR. This ability to generate different voltages produces a very handy circuit called a “Potential Divider” or Voltage Divider Network.

As we know, the current through a series circuit is common and as the LDR changes its resistive value due to the light intensity, the voltage present at VOUT will be determined by the voltage divider formula. An LDR’s resistance, RLDR can vary from about 100Ω’s in the sun light, to over 10MΩ’s in absolute darkness with this variation of resistance being converted into a voltage variation at VOUT as shown.

One simple use of a Light Dependent Resistor, is as a light sensitive switch as shown below.

LDR Switch

This basic light sensor circuit is of a relay output light activated switch. A potential divider circuit is formed between the photoresistor, LDR and the resistor R1. When no light is present ie in darkness, the resistance of the LDR is very high in the Megaohms (MΩ’s) range so zero base bias is applied to the transistor TR1 and the relay is de-energised or “OFF”.

As the light level increases the resistance of the LDR starts to decrease causing the base bias voltage at V1 to rise. At some point determined by the potential divider network formed with resistor R1, the base bias voltage is high enough to turn the transistor TR1 “ON” and thus activate the relay which in turn is used to control some external circuitry. As the light level falls back to darkness again the resistance of the LDR increases causing the base voltage of the transistor to decrease, turning the transistor and relay “OFF” at a fixed light level determined again by the potential divider network.

By replacing the fixed resistor R1 with a potentiometer VR1, the point at which the relay turns “ON” or “OFF” can be pre-set to a particular light level. This type of simple circuit shown above has a fairly low sensitivity and its switching point may not be consistent due to variations in either temperature or the supply voltage. A more sensitive precision light activated circuit can be easily made by incorporating the LDR into a “Wheatstone Bridge” arrangement and replacing the transistor with an Operational Amplifier as shown.

In this basic dark sensing circuit, the light dependent resistor LDR1 and the potentiometer VR1 form one adjustable arm of a simple resistance bridge network, also known commonly as a Wheatstone bridge, while the two fixed resistors R1 and R2 form the other arm. Both sides of the bridge form potential divider networks across the supply voltage whose outputs V1 and V2 are connected to the non-inverting and inverting voltage inputs respectively of the operational amplifier.

In this basic dark sensing circuit, the light dependent resistor LDR1 and the potentiometer VR1 form one adjustable arm of a simple resistance bridge network, also known commonly as a Wheatstone bridge, while the two fixed resistors R1 and R2 form the other arm. Both sides of the bridge form potential divider networks across the supply voltage whose outputs V1 and V2 are connected to the non-inverting and inverting voltage inputs respectively of the operational amplifier.

The operational amplifier is configured as a Differential Amplifier also known as a voltage comparator with feedback whose output voltage condition is determined by the difference between the two input signals or voltages, V1 and V2. The resistor combination R1 and R2 form a fixed voltage reference at input V2, set by the ratio of the two resistors. The LDR – VR1 combination provides a variable voltage input V1 proportional to the light level being detected by the photoresistor.

As with the previous circuit the output from the operational amplifier is used to control a relay, which is protected by a free wheel diode, D1. When the light level sensed by the LDR and its output voltage falls below the reference voltage set at V2 the output from the op-amp changes state activating the relay and switching the connected load.

Likewise as the light level increases the output will switch back turning “OFF” the relay. The hysteresis of the two switching points is set by the feedback resistor Rf can be chosen to give any suitable voltage gain of the amplifier.

The operation of this type of light sensor circuit can also be reversed to switch the relay “ON” when the light level exceeds the reference voltage level and vice versa by reversing the positions of the light sensor LDR and the potentiometer VR1. The potentiometer can be used to “pre-set” the switching point of the differential amplifier to any particular light level making it ideal as a simple light sensor project circuit.

Photo-diode

The construction of the Photodiode light sensor is similar to that of a conventional PN-junction diode except that the diodes outer casing is either transparent or has a clear lens to focus the light onto the PN junction for increased sensitivity. The junction will respond to light particularly longer wavelengths such as red and infra-red rather than visible light.

This characteristic can be a problem for diodes with transparent or glass bead bodies such as the 1N4148 signal diode. LED’s can also be used as photodiodes as they can both emit and detect light from their junction. All PN-junctions are light sensitive and can be used in a photo-conductive unbiased voltage mode with the PN-junction of the photodiode always “Reverse Biased” so that only the diodes leakage or dark current can flow.

The current-voltage characteristic (I/V Curves) of a photodiode with no light on its junction (dark mode) is very similar to a normal signal or rectifying diode. When the photodiode is forward biased, there is an exponential increase in the current, the same as for a normal diode. When a reverse bias is applied, a small reverse saturation current appears which causes an increase of the depletion region, which is the sensitive part of the junction. Photodiodes can also be connected in a current mode using a fixed bias voltage across the junction. The current mode is very linear over a wide range.

When used as a light sensor, a photodiodes dark current (0 lux) is about 10uA for geranium and 1uA for silicon type diodes. When light falls upon the junction more hole/electron pairs are formed and the leakage current increases. This leakage current increases as the illumination of the junction increases.

When used as a light sensor, a photodiodes dark current (0 lux) is about 10uA for geranium and 1uA for silicon type diodes. When light falls upon the junction more hole/electron pairs are formed and the leakage current increases. This leakage current increases as the illumination of the junction increases.

Thus, the photodiodes current is directly proportional to light intensity falling onto the PN-junction. One main advantage of photodiodes when used as light sensors is their fast response to changes in the light levels, but one disadvantage of this type of photodevice is the relatively small current flow even when fully lit.

The following circuit shows a photo-current-to-voltage converter circuit using an operational amplifier as the amplifying device. The output voltage (Vout) is given as Vout = Ip × Rf and which is proportional to the light intensity characteristics of the photodiode.

This type of circuit also utilizes the characteristics of an operational amplifier with two input terminals at about zero voltage to operate the photodiode without bias. This zero-bias op-amp configuration gives a high impedance loading to the photodiode resulting in less influence by dark current and a wider linear range of the photocurrent relative to the radiant light intensity. Capacitor Cf is used to prevent oscillation or gain peaking and to set the output bandwidth (1/2πRC).

Photodiodes are very versatile light sensors that can turn its current flow both “ON” and “OFF” in nanoseconds and are commonly used in cameras, light meters, CD and DVD-ROM drives, TV remote controls, scanners, fax machines and copiers etc, and when integrated into operational amplifier circuits as infrared spectrum detectors for fibre optic communications, burglar alarm motion detection circuits and numerous imaging, laser scanning and positioning systems etc.

Photodiodes are very versatile light sensors that can turn its current flow both “ON” and “OFF” in nanoseconds and are commonly used in cameras, light meters, CD and DVD-ROM drives, TV remote controls, scanners, fax machines and copiers etc, and when integrated into operational amplifier circuits as infrared spectrum detectors for fibre optic communications, burglar alarm motion detection circuits and numerous imaging, laser scanning and positioning systems etc.

Photo-transistor

An alternative photo-junction device to the photodiode is the Phototransistor which is basically a photodiode with amplification. The Phototransistor light sensor has its collector-base PN-junction reverse biased exposing it to the radiant light source.

Phototransistors operate the same as the photodiode except that they can provide current gain and are much more sensitive than the photodiode with currents are 50 to 100 times greater than that of the standard photodiode and any normal transistor can be easily converted into a phototransistor light sensor by connecting a photodiode between the collector and base.

Phototransistors consist mainly of a bipolar NPN Transistor with its large base region electrically unconnected, although some phototransistors allow a base connection to control the sensitivity, and which uses photons of light to generate a base current which in turn causes a collector to emitter current to flow. Most phototransistors are NPN types whose outer casing is either transparent or has a clear lens to focus the light onto the base junction for increased sensitivity.

In the NPN transistor the collector is biased positively with respect to the emitter so that the base/collector junction is reverse biased. therefore, with no light on the junction normal leakage or dark current flows which is very small. When light falls on the base more electron/hole pairs are formed in this region and the current produced by this action is amplified by the transistor.

In the NPN transistor the collector is biased positively with respect to the emitter so that the base/collector junction is reverse biased. therefore, with no light on the junction normal leakage or dark current flows which is very small. When light falls on the base more electron/hole pairs are formed in this region and the current produced by this action is amplified by the transistor.

Usually the sensitivity of a phototransistor is a function of the DC current gain of the transistor. Therefore, the overall sensitivity is a function of collector current and can be controlled by connecting a resistance between the base and the emitter but for very high sensitivity optocoupler type applications, Darlington phototransistors are generally used.

Photo-darlington

Photodarlington transistors use a second bipolar NPN transistor to provide additional amplification or when higher sensitivity of a photodetector is required due to low light levels or selective sensitivity, but its response is slower than that of an ordinary NPN phototransistor.

Photo darlington devices consist of a normal phototransistor whose emitter output is coupled to the base of a larger bipolar NPN transistor. Because a darlington transistor configuration gives a current gain equal to a product of the current gains of two individual transistors, a photodarlington device produces a very sensitive detector.

Typical applications of Phototransistors light sensors are in opto-isolators, slotted opto switches, light beam sensors, fibre optics and TV type remote controls, etc. Infrared filters are sometimes required when detecting visible light.

Another type of photojunction semiconductor light sensor worth a mention is the Photo-thyristor. This is a light activated thyristor or Silicon Controlled Rectifier, SCR that can be used as a light activated switch in AC applications. However their sensitivity is usually very low compared to equivalent photodiodes or phototransistors.

To help increase their sensitivity to light, photo-thyristors are made thinner around the gate junction. The downside to this process is that it limits the amount of anode current that they can switch. Then for higher current AC applications they are used as pilot devices in opto-couplers to switch larger more conventional thyristors.

However, unlike the other photo devices we have looked at above which use light intensity even from a torch to operate, photovoltaic solar cells work best using the suns radiant energy.

Solar cells are used in many different types of applications to offer an alternative power source from conventional batteries, such as in calculators, satellites and now in homes offering a form of renewable power.

Photovoltaic Cell

Photovoltaic cells are made from single crystal silicon PN junctions, the same as photodiodes with a very large light sensitive region but are used without the reverse bias. They have the same characteristics as a very large photodiode when in the dark.

When illuminated the light energy causes electrons to flow through the PN junction and an individual solar cell can generate an open circuit voltage of about 0.58v (580mV). Solar cells have a “Positive” and a “Negative” side just like a battery.

Individual solar cells can be connected together in series to form solar panels which increases the output voltage or connected together in parallel to increase the available current. Commercially available solar panels are rated in Watts, which is the product of the output voltage and current (Volts times Amps) when fully lit.

The amount of available current from a solar cell depends upon the light intensity, the size of the cell and its efficiency which is generally very low at around 15 to 20%. To increase the overall efficiency of the cell commercially available solar cells use polycrystalline silicon or amorphous silicon, which have no crystalline structure, and can generate currents of between 20 to 40mA per cm2.

The amount of available current from a solar cell depends upon the light intensity, the size of the cell and its efficiency which is generally very low at around 15 to 20%. To increase the overall efficiency of the cell commercially available solar cells use polycrystalline silicon or amorphous silicon, which have no crystalline structure, and can generate currents of between 20 to 40mA per cm2.

Other materials used in the construction of photovoltaic cells include Gallium Arsenide, Copper Indium Diselenide and Cadmium Telluride. These different materials each have a different spectrum band response, and so can be “tuned” to produce an output voltage at different wavelengths of light.

In this tutorial about Light Sensors, we have looked at several examples of devices that are classed as Light Sensors. This includes those with and those without PN-junctions that can be used to measure the intensity of light.

In the next tutorial we will look at output devices called Actuators. Actuators convert an electrical signal into a corresponding physical quantity such as movement, force, or sound. One such commonly used output device is the Electromagnetic Relay.