Instrumentation, Control and Electronics

Some agencies combine Instrumentation and Electronics, partly choose or combine it with Full Control. Actually, in which the position and slices to all three?

INSTRUMENTATION

Nothing defines Instrumentation as Art and Science of Measurement and Control / Control.

Others define Instrumentation as making instrument or measuring devices, since the instrument is a tool to measure or regulate Physical variables such as flow (flow), temperature (temperature), ketingggian fluid (level), pressure (pressure), etc. Instrumentation tools often involve control systems and electronics. Process control is one of Instrumentation applications.

Instrumentation can also meant the tools to measure or control one variable, either the remote control or automatically, for example: Valve, Analyzer, Smoke Detector, solenoids, regulators, circuit breakers, and relays.

In addition to control, instrumentation often also involves signal processing and transmission of signals or data. Shipping and controls can use System PLC, DCS, SCADA, or instrumentation-based Computer Control. Control Instrumentation role in dalampengumpulan information, alteration of data / information / parameters.

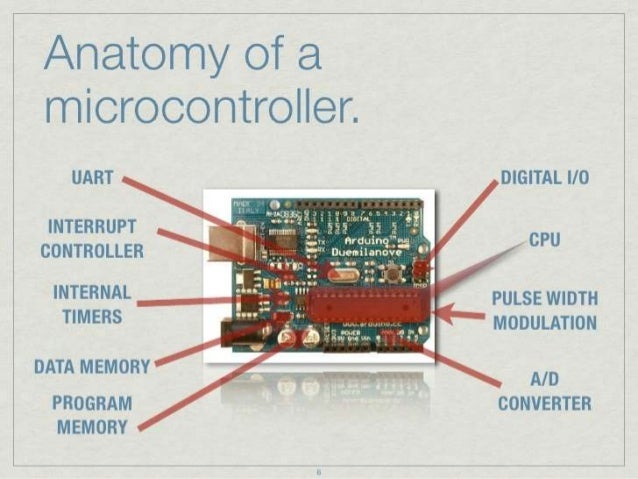

instrumentation engineeringIs a field that focuses on the principles and operation of the measuring instrument for designing automated systems in the domain of Electrical Engineering, Process, Pneumatic etc. Instrument Engineer usually work in the industry with the field work associated with process automation, such as the Chemical Industry, Manufacturing with the task to improve the productivity, reliability, security, optimization and stability of the system. To control parameters in a process or system, use tools such as microcontroller, microprocessor, PLC etc.

Instrumentation technicianAssignment to repair and perform maintenance tools and instrumentation systems.

CONTROL

There are two divisions in the field of control, the classic and modern are all applicable for Mechanical Control (Control Engineering).cat: Here sometimes used the term controls and sometimes control.

control TheoryScope: single-input and single-output (SISO) system design.System analysis :> Time domain: the differential equation> Complex-s domain: the Laplace transform (converted into the frequency domain)> All systems are assumed to be of the order of 2 or have a single variable, Order larger and multivariable in heed> Controller is designed with you estimate, because it requires onsite tuning> More easily implemented physically, because it is preferred in the industry.> Example: PID controllers.

modern controlScope: complex s or frequency-domain, multi-input and multi-output (MIMO)System analysis:> System symbolized by the collection of first order differential equations defined by state variables.> Overcoming the limitations of classical Controls on designing more complex such as controls on fighter aircraft.> Example: Nonlinear Control, Multivariable Control, Adaptive Control and Robust> People: Rudolf E. Kalman and Aleksandr Lyapunov

Mechanical and Control SystemsMechanical control is a field of engineering that focuses on modeling a variety of dynamic systems (eg mechanical systems) and design a controller that can control the system as desired.

Although the controller should not be electrically, but many who already consider Mechanical control is part of the Electrical Engineering.Electrical or Electronic circuits, DSP, microcontroller, PLC, etc., all can be used to implement control systems.

control engineers use many techniques feedback when designing control systems, particularly with a PID controller. But it could also without using a feedback technique is often called Loop Control.

Control Engineering Education at the University.At many universities, Mechanical control is taught in the Department of Electrical Engineering, Mechanical Engineering, Mechatronics Engineering, Aerospace Engineering, Automotive Engineering and Chemical Engineering (control process).Because now there are many implementations with a Computer and Systems terntanam (FPGA, microcontroller, microprocessor), it can also be taught in the Department of Computer Science, Information Technology or Information Engineering.Applications can control techniques in Science, Management, Finance, or even psychology (human behavior).

Course on Techniques such control> Linear Control (Analysis on Time & Frequency / complek-S domain) -> requires background Mathematics and strong Laplace transform (called Classical Control Theory).> Digital control and Nonlinear Control -> Z transformation requires basic knowledge and algebra.

ELECTRONICS

Electronics Engineering is a field that uses knowledge of the behavior of electrons to develop components, firmware device, system, or Electronic Equipment.

Electronics Engineering requires a strong mathematical basis, while the Electronics Engineering curriculum in general consist of:

Semiconductor physics

basic Electronics

Electronic circuit

devais Microelectronics

Analog circuit

Digital circuit

Analog IC Design

Digital IC Design

Integrated circuit technology

Semiconductor fabrication

Power electronics

electronics Telecommunications

Electronic instrumentation

Signals and Systems

Embedded systems

microcontroller

Computer Aided Electronics

conclusions:>> Instrumentation can be attached to control or Electronics.>> "Instrumentation and Control" is broader in scope, not only of Electronic instrumentation but also to other non-electronic fields, such as process control and control in the industry.>> "Electronic Instrumentation" or "Electronic Instrumentation" is referring to the use of Electronic Instrumentation.>> Instrumentation get into minor of Electronics, Electronic Instrumentation and vice versa can be entered as minor Instrumentation Engineering.>> Instrumentation requires control and electronics as well as other fields such as Science / Computer Engineering or Computer Science / Information Technology, for Instrumentation Engineering is a multidisciplinary field.

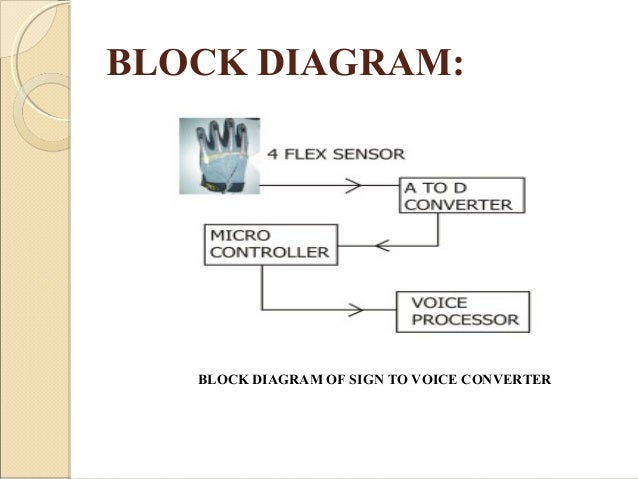

If likened chart Instrumentation (Electronic) was SENSOR-SIGNAL PROCESSING / CONDITIONING SIGNAL-ACTUATORthenSENSOR: Physical touch with nature, convert one form of energy into electrical energy, large overlaps with PhysicsSIGNAL PROCESSING / CONDITIONING: when the amount of used electric then bersingggungan with Electrical Engineering / Electrical EngineeringACTUATOR: changing the electrical magnitude into the magnitude Mechanically, requires knowledge of Mechanical Engineering.

If it involves controlling it requires CONTROL TECHNIQUES

X . I

About Process Instrumentation System

Today many modern instrumentation system is easily available and we find, especially leading to increased industrial productivity and production quality. Some applications only use instrumentation systems created or designed specifically for a process, and other applications using a more complex system. Of course some aspects affecting the design of the system being designed, among other things is the cost (budget), the complexity of processes, and other factors.

Real instrumentation development began in the 1980s, where many large companies started to invest for the procurement of hardware and software, the demand for increasingly extended to enterprise and industrial manufacturing. Such conditions require researchers continue to conduct testing and development to the flexibility of the system, which is certainly related to the instrumentation system.

The emergence AMRF (Automated Manufacturing Research Facility) enables cooperation between industry and government, in shifting its development effort is to change the instrumentation system into a general concept for broader implementation.

Although the instrumentation system is ready for use at all continuous production processes, but broadly categorized into two types: process instrumentation and automation. The development of instrumentation can not be released simply by development komputisasi, komputisasi have a significant role in this regard.

In an industrial systems, the computer is the core of the DDC (Direct Digital Control) or means of digital control directly, DCS (Distribution Control System), supervisory control, control systems hybrid system and SCADA (Supervisory Control And Data Acquisition), as well as systems such simple single loop controllers.

In SCADA, enabling communication through remote devices that are in the area by far (in the area) using techniques such as communication via microwave transmission signal and telemetry. Instrumentation system is the heart of a variety of operating systems, including remote air, satellite control, transportation systems and fully automatic vehicle directly can be monitored from the control center.

Progress instrumentation system is also a part of several related applications, such as the concept in CAD (Computer Aided Design), CAE (Computer Aided Engineering), CAM (Computer Aided Manufacturing), CIM (Computer Integrated Manufacturing), JIT (Just In Time), FMS (Flexible Manufacturing System).

X . II

Instruments and Process Instrumentation System

a. Consideration Process Instrumentation System

Instrumentation systems are designed using the factor - the following factors into consideration:

User requirements and specifications,

Functional design specifications,

Design a complete system and its structure,

Test specification (code on integrated testing),

Warranty and other support to training,

Health and safety.

b. Function Process Instrumentation System

The main function of the instrumentation system are:

Math On-Line, to establish monitoring and control process. Variables that can not be measured directly but can be measured using other measurable variables.

Determining set-point and set limits on the variable and the signal representing the variable.

Selecting variables and perform operations programmed to control and take decisions in accordance purposes.

Logical and conditional.

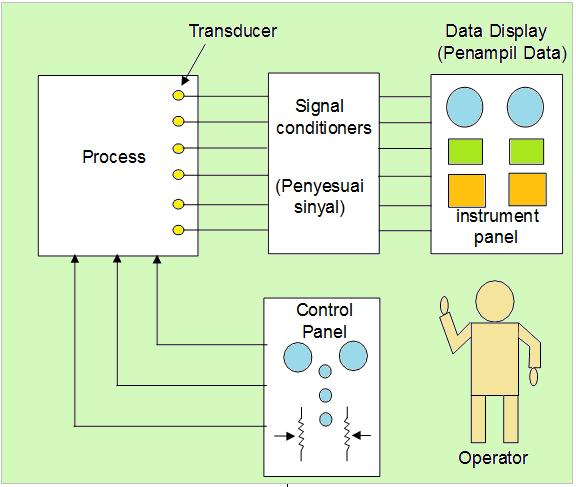

Block Diagram Typical Process Instrumentation System Digital :

understanding instruments

The instrument is a monitoring tool as well as measuring physical variables, physical parameters are referred to as measurrands. The main components of the instrument consists of sensors and transducers. Part sensor generates a signal response of physical variables, the types of signal processing depending on the information needed.

Many types of sensors and transducers that can be selected to meet the measurement requirements. For example is there are many different sensor and transducer types are available for use in position sensing motion, including capacitive sensors, inductive sensors, and optical sensors.

Measurements can be either static measurement and dynamic measurement. Static measurements eg fixed dimensions and weight, this simple measurement because of a physical quantity being measured does not change over time. While the dynamic measurement is a measurement on which media stable and transient behavior of physical variables, this should be analyzed and adapted to the dynamic behavior of the instrument.

Discussion of the sensor and transducer is very spacious

Process Instrumentation System Large

In most modern instrumentation systems based on digital technique, involves a series of: digital systems, computers, microprocessors and IC (Integrated Circuit), more or less the same in every application.

What are the advantages in the use of digital instrumentation systems? obviously with the digital system will increase the sensitivity, the system's flexibility, ease of information transmission, and much more.

Instrumentation systems can be divided into several main sections, namely: Sensing (sensing) instrument controllers, the device interface (interface), input and output facilities, communication devices, the main equipment of information processing and human-machine interface applications.

In large instrumentation systems computer control system located centrally, diditribusikan or hierarchical and network together using one of the available technology.

In a centralized control system, all information collected on a central computer is the implementation of the decision maker. Examples of centralized computer control system, for example: MD 85 or PCS 8000. This is not like a computer running software control, but is designed and manufactured for specific applications.

Modern industrial instrumentation systems such as DCS has three main components, namely:

The main lines of data, this section handle the flow of information Atar devices / components.

Operator station, as control of the desired command.

Microprocessor-based controller, serves as an effective process control and can be configured as multi-loop or single-loop.

The database system is stored and process information to be displayed. For example: Display can be organized into groups: detail, trend or display a warning alarm. The operator can handle the number of loops (up to 10,000). however, DCS has limitations in areas such as the use of orientation, communication, capacity, sequencing, speed, and reliability.

Some of these problems can be eliminated by increasing the main lines of communication, use microprocessors that are more reliable, the use of database management more effective, improvements to the programming language, add data storage capacity and the addition of other devices.

There are so many digital devices are on general sale, such as TDC (of Honeywell) and series TOSDIC (from Toshiba). Multi-task functions centralized computer system is divided among the number of independent processes. Spatial distribution This module allows the use of the main line data.

Hierarchical process control system in Instrumentation Systems

Hierarchical control system is a combination of centralized control systems and distributed systems. So have two computers, as the first computer to control in situ process, while the second computer as the processing of all plant. In this system, all computers work together through communication network LAN (Local Area Network) or WAN (Wide Area Network).

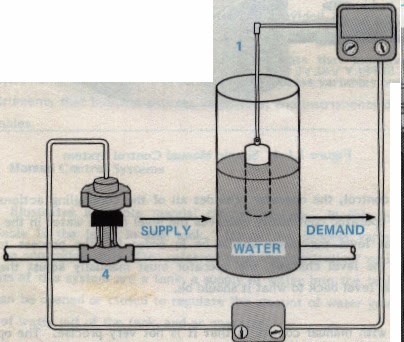

Automation

Understanding correctly and carefully studying the control systems are essential to modern instrumentation systems. In this system the process is monitored continuously, the data obtained from the sensing and actuator in operation during the process.

Data is collected, processed and then the implementation of process control. Therefore most of the modern process control based on the measurement and control of process variables, information transmission, signal adjustment, and decision making.

The present is more sophisticated measuring devices for monitoring process variables, also including the types of computers, microprocessors and microcontrollers used in information gathering, decision-making and implementing decisions.

The control function is not limited to the software on the computer, but covers the entire loop in a variety of instruments and equipment elements. Instrumentation is part of a process involving the measurement options.

Advances in sensor technology to produce a number of gauges which can be used in a broader process / large and complex. This device includes an electromechanical sensor which has a high sensitivity, optical scanners, machine monitoring devices, and others. In all these applications to choose a method of reliable and effective in measuring critical process variables, making further decisions regarding the overall system can be taken.

In automation, the characteristics of the signal conversion and transmission process can affect the overall accuracy of the system, because of the possibility of damages and disruption. Losses can occur due to disturbances in the power supply or mechanical disturbances, noise, cable management, and other factors. Due need special attention in selecting communications technology and equipment.

The process of digital systems, Microprocessors and Computer

The use of microprocessors and computers in instrumentation systems can be categorized as follows:

Data Handling (data handling), consisting of data acquisition, signal conditioning, information extraction and data compression, interpretation, recording, storage, and communications.

Control instrumentation (Instrumentation Control), consisting of ON / OFF control sensors, actuators, system resources, and control processes.

Human-machine Interface (interface), one of the important role of the computer systems in instrumentation systems is to provide the operator to display information ergonomic controls.

Experiment and procedural development, involves commissioning, testing, and prototyping systems generally targeted.

Reporting and documentation, involves recording data and keep records of operational procedures.

This above is important to understand the basic order of the computer to put it right as a function in the system instrumentation.

Microprocessors are integrated circuits whose function is to handle and process the binary data, that is to say, a general purpose microprocessor is used as the CPU (Central Processing Unit) in the computer.

Which are often used include: Intel, Zilog, AMD, Motorola, NEC, IBM, Fujitsu, Sony, Texas Instruments, Hitachi. Instead microprocessors that have built-in memory and interface circuitry is referred to as a microcontroller, because the microcontroller is small, simple, low price, and ready to be used in many applications in automation and instrumentation. One is Motorola MC68HC11 microcontroller and the PIC microcontroll

Data Handling (data handling), consisting of data acquisition, signal conditioning, information extraction and data compression, interpretation, recording, storage, and communications.

Control instrumentation (Instrumentation Control), consisting of ON / OFF control sensors, actuators, system resources, and control processes.

Human-machine Interface (interface), one of the important role of the computer systems in instrumentation systems is to provide the operator to display information ergonomic controls.

Experiment and procedural development, involves commissioning, testing, and prototyping systems generally targeted.

Reporting and documentation, involves recording data and keep records of operational procedures.

This above is important to understand the basic order of the computer to put it right as a function in the system instrumentation.

Microprocessors are integrated circuits whose function is to handle and process the binary data, that is to say, a general purpose microprocessor is used as the CPU (Central Processing Unit) in the computer.

Which are often used include: Intel, Zilog, AMD, Motorola, NEC, IBM, Fujitsu, Sony, Texas Instruments, Hitachi. Instead microprocessors that have built-in memory and interface circuitry is referred to as a microcontroller, because the microcontroller is small, simple, low price, and ready to be used in many applications in automation and instrumentation. One is Motorola MC68HC11 microcontroller and the PIC microcontroll

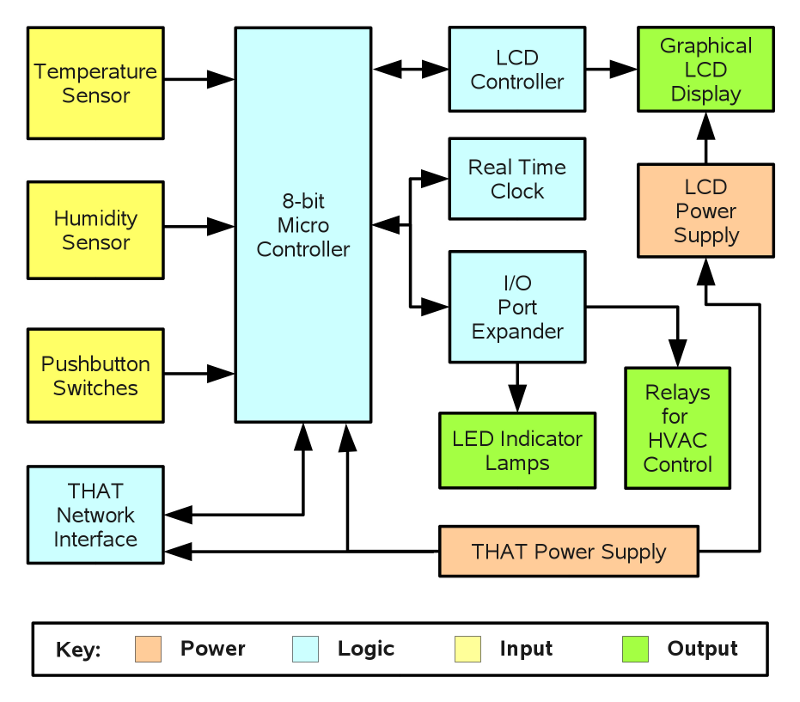

Microcontroller and Computer Basic Shapes

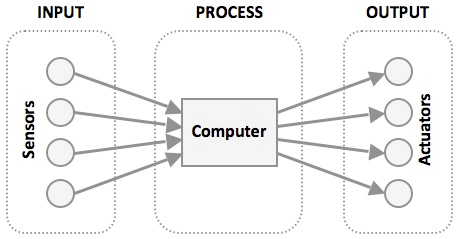

Microcontroller and computers are widely used in instrumentation systems, has an important role in data acquisition, data processing and control. A typical computer-based instrumentation system consists of sub-systems such as the following picture:

Microcontroller and computers are widely used in instrumentation systems, has an important role in data acquisition, data processing and control. A typical computer-based instrumentation system consists of sub-systems such as the following picture:

Microcontroller and computers in general use in the instrumentation system can be divided into two types, namely: an embedded controller and a dedicated computer.

Process Block Diagram Computer

Process Instrumentation System Block Diagram

X . III

Understanding Instrumentation System

Instrumentation system is a basic necessity in building a system

process production equipment, various types of information from the

instrumentation system ensures completeness of data on production, so

they can know how the maximum efficiency, production costs can be

reduced and the most important is the quality of production at the end

of a process system.

Information obtained from instrumentation systems are diverse, it is in accordance with the needs of the data reporting system, perhaps using direct measurement methods. But the system of the production process is very complex, direct measurement is impractical, changing to an indirect measurement may be applied. In this way monitoring of the quantity measured by the required results.

Indirect monitoring mostly using electronic methods, keep in mind that the electronic method has the advantages of high speed, simple application and processing, as well as easy integration with the computer system.

Information obtained from instrumentation systems are diverse, it is in accordance with the needs of the data reporting system, perhaps using direct measurement methods. But the system of the production process is very complex, direct measurement is impractical, changing to an indirect measurement may be applied. In this way monitoring of the quantity measured by the required results.

Indirect monitoring mostly using electronic methods, keep in mind that the electronic method has the advantages of high speed, simple application and processing, as well as easy integration with the computer system.

The information he is not necessarily a direct result of the measurement value, meaning the value of being air-variation connected to the other parameters. A new problem and it needs a method appropriate scale. Thus, the instrument may be used individually in other applications.Classification System Instrumentation

On the application of measurement in the industry, using the measurement of physical variables to determine the unit streams in the dynamic unit. With so instrumentation can be classified as follows:I. Flow (Flow) or per-variable

Variable flow can be measured from a point in space. Measurement of flow variable can be applied to measurement:

Power

momentum

Flow

Cost

Current

Volume

II. Trans-variable

Trans-variables requires a reference point and the point of measurement, several measurements using this method include:

displacement,

The velocity (speed)

Pressure (Pressure)

Temperature (Temperature)

Level (Altitude)

Voltage (voltage).

Type Instrumentation System

Instrumentation systems based on industrial applications, an outline of the instrumentation system is divided into two. That is :

Automated Systems. Systems that operate without operator assistance.

System Manual / Analog. The system operates with the assistance of an operator.

When viewed from the display, system design, instrumentation can be divided into two, namely:

Kind of self-operated

Type of power operated

To be sure whatever type of instrument applied. Requires some basic block as a function. Block will be incorporated as a combination that is useful to assist in changing the measurement system (conversion) process conditions become suitable conditions. Block - This block is referred to as a functional unit that exist on all systems instrumentation.

Classification System Instrumentation

I. Analog Instrumentation SystemAnalog Instrumentation SystemsAnalog Instrumentation Systems

Analog instrumentation system is divided into three functional units, namely:a. Primary section (transducer)

Sensing section receives the value measured and converted into electrical signals, there are various kinds of electrical signals are used, namely: voltage, current, change in resistance, inductance, capacitance.

So transducer is equipment that converts the value received from the sensing (sensors) into an electrical signal.b. Secondary Section (Signal Processing)

After changing the value sensing transducer into electrical signals, and then put into a unit called as part of signal processing (signal processing).

The function of this unit is to strengthen the output transducers are still weak later in the filter to be changed into a form acceptable by the output unit.

Devices on the secondary section include: amplifiers, filters, analog to digital converters and so on.c. The last section (final)

The final part shows the value of the unit (output unit). The signals received from the secondary unit or signal processing on the input of the unit to enter the finals and show value. This unit could be a CRO, digital computers and so on.II. Digital Instrumentation SystemDigital Instrumentation SystemDigital Instrumentation System

In the digital instrumentation systems also use parts - parts of the analog system. The basic operation is also included handling analog signals, make measurements, convert and handle digital data. Programming and control.

Digital Instrumentation System

Analog instrumentation system is divided into three functional units, namely:a. Primary section (transducer)

Sensing section receives the value measured and converted into electrical signals, there are various kinds of electrical signals are used, namely: voltage, current, change in resistance, inductance, capacitance.

So transducer is equipment that converts the value received from the sensing (sensors) into an electrical signal.b. Secondary Section (Signal Processing)

After changing the value sensing transducer into electrical signals, and then put into a unit called as part of signal processing (signal processing).

The function of this unit is to strengthen the output transducers are still weak later in the filter to be changed into a form acceptable by the output unit.

Devices on the secondary section include: amplifiers, filters, analog to digital converters and so on.c. The last section (final)

The final part shows the value of the unit (output unit). The signals received from the secondary unit or signal processing on the input of the unit to enter the finals and show value. This unit could be a CRO, digital computers and so on.II. Digital Instrumentation SystemDigital Instrumentation SystemDigital Instrumentation System

In the digital instrumentation systems also use parts - parts of the analog system. The basic operation is also included handling analog signals, make measurements, convert and handle digital data. Programming and control.

Digital Instrumentation System

a. transducers

All physical input parameters, such as temperature, pressure, displacement, velocity, acceleration is converted into an electrical signal proportional.b. Adjustment Unit Signals (Signal Condition Unit)

This unit works the same as signal processing in the analog system, covering all parts of the calibration circuit balancing.c. Scanner / Multiplexer

Some of the analog signal received by the device is fully provided for measuring instruments.d. Signal converter (signal converter)

This device is used to convert analog signals into signals that can be received in the analog to digital. (Analog to digital converter).e. Analog to Digital Converter (Analog to Digital Converter)

These devices convert analog signals to digital signals proportional. The output of this device is inserted into the digital display.

All physical input parameters, such as temperature, pressure, displacement, velocity, acceleration is converted into an electrical signal proportional.b. Adjustment Unit Signals (Signal Condition Unit)

This unit works the same as signal processing in the analog system, covering all parts of the calibration circuit balancing.c. Scanner / Multiplexer

Some of the analog signal received by the device is fully provided for measuring instruments.d. Signal converter (signal converter)

This device is used to convert analog signals into signals that can be received in the analog to digital. (Analog to digital converter).e. Analog to Digital Converter (Analog to Digital Converter)

These devices convert analog signals to digital signals proportional. The output of this device is inserted into the digital display.

f. Hardware Help

All system programming and digital data processing functions performed by this unit requires no additional equipment, may be a computer or a device other instruments. Some of the functions include linearzing and comparison limit.

g. Digital Recorders (Digital Recorder)

Some systems use a CRO or a computer for digital recording.

examples of instruments and control mechanisms for measuring the human body using a computer

X . IIII

Automated Control System On Electronic Products

Automatic control system is a technology that connects the mechanical system, electronics, and electricity in the information system that serves as the controller or controllers.Automatic Control SystemsAutomatic Control SystemsDefinition of Automatic Control Systems

Electronics products that use the automatic control system is a tool that can work in accordance with the will of its users. For example, the rice cooker can exchange system of human labor become automatic working tools that are practical and easier for users.

A program instructions contained in a control system which executes an instruction and automate the process of moving the command requires energi.Dalam processes and operate programs and control systems.

Control systems use sensors that give information as input to the brain giving the orders, in order to provide the action that is output. The sensor reader process, an element of the control system.

Feedback is outside stimuli are applied to a control system to get a particular response of the regulatory system. Feedback is also called the expected output response.

Examples of Automatic Control Systems On Electronic ProductsI. On Industrial and Household

Electronics product with an automatic control system almost all of its products are household electronics. One of them, namely the automatic lights. Lamp will automatically work with sensor control.

Television with remote control which have automated systems, refrigerators, washing machines, DVD players, and more furniture household electronics that implement automatic control system.II. In the Robo

Lots of robots produced to help people complete the work or in their duties, the robot's control system can use automated means and teleoperasi. Sensors on the robot can be programmed in order to move on the orders it receives.III. On Information Technology

In the field of communication, ranging from old school phone to the latest gadgets surely have automation systems on switching. This switch serves as a regulator of signal, storage number, LAN, and so forth.IIII. On Transportation

In the field of transport automated control system has long been used to auto pilot, air ticket booking system, and auto machinist on electric trains.IIIII. On Service Industry

It's getting a lot of people are familiar with automated technology for the service industry, such as the information on health care, banking and the financial services the other . the start of government, weather forecasts, and so forth.

X . IIIIII

Understanding of Electronics

Understanding of Electronics

About electronics is the study of weak current electrical system is controlled by several components, the division of duties according to their respective functions.

The current flowing in an electronic circuit called electrons or can call electrically charged particles.

Science electronics basically directly related to physics, in the manufacture of components or systems continued development of these components, become more energy efficient, more simple, more multi-use, and other advantages -kelebihan certainly more to follow the progress of time.

As for the shape of the design and manufacturing of its electronic

circuit is part of the science of electrical engineering, further

categorized into computer engineering, electronic instrumentation

techniques.In

day to day life will never be separated from the gear perkakas-

electronics, has become a familiar part of life and even the direction

of the trend. For example: radio, television, computer, digital camera, mobile

phones, PDAs and others were certainly very numerous to mention.

Until this era of modernization, the science of electronics is the leading actor in all aspects of advances in technology, there is no limit anymore between science electronics and various other techniques. A basic requirement to include electronics applications in other fields.Progress on the implementation of its electronics more towards simplify all aspects of life, tend to indulge in a positive or negative sense.Improved communication, advances in automation, transportation progress, and progress - progress that others did not escape the role of the science of electronics.At the Electronic Arts again divided into several areas of science such as: Introduction to Electronics Components, Electronics scheme, use of the means of measuring electronics, Electronics Assembly, etc.And distribution to the general field can be divided (wider) as follows:

The housing Electronics (Electronics commonly in use by the general kalayak),

Electronics Building (electronics that application in buildings of the building),

Electronics Industry (electronics for industry or factories as support automation for example),

Electronic Communication (Implementation in the field of communications, the data transfer etc.),

Progress of Science of Electronics developed rapidly in the last twenty years, especially in the field of communications and automation (robotisasi). So that raises a lot of business potential opportunities in the field of electronics. An overwhelming influence on all aspects of daily life - today.

Until this era of modernization, the science of electronics is the leading actor in all aspects of advances in technology, there is no limit anymore between science electronics and various other techniques. A basic requirement to include electronics applications in other fields.Progress on the implementation of its electronics more towards simplify all aspects of life, tend to indulge in a positive or negative sense.Improved communication, advances in automation, transportation progress, and progress - progress that others did not escape the role of the science of electronics.At the Electronic Arts again divided into several areas of science such as: Introduction to Electronics Components, Electronics scheme, use of the means of measuring electronics, Electronics Assembly, etc.And distribution to the general field can be divided (wider) as follows:

The housing Electronics (Electronics commonly in use by the general kalayak),

Electronics Building (electronics that application in buildings of the building),

Electronics Industry (electronics for industry or factories as support automation for example),

Electronic Communication (Implementation in the field of communications, the data transfer etc.),

Progress of Science of Electronics developed rapidly in the last twenty years, especially in the field of communications and automation (robotisasi). So that raises a lot of business potential opportunities in the field of electronics. An overwhelming influence on all aspects of daily life - today.

Instrumentation electronics (Electronic Instrumentation)

Today measuring tools mechanical and electrical tools mostly done

using electronic instrumentation (electronic instrumentation), are no

longer using measurement devices fashioned as a few years ago.Instrumentation electronics (Electronic Instrumentation)

Most of the tools of measurement used in the present is the result of a merger between a mechanical device and some electronic detection element (electronic sensing element).

Some technicians / experts instrumentation using the latest tools for special calibration work though some still use basic electronic instrument, the readings are still calculated manually by the user.

It is important to know some tools or measurement devices common basic instrument in use and train familiarize themselves in various activities of measurement instrumentation.

There are a wide variety of measurement instrumentation tools are sold in the market at this time. However, some of the most important tool and that must be recognized is the main inter alia as follows:1. Multimeter,2. Frequency Counter (Frequency Counters),3. Oscilloscop,4. Recorder Line Graph (Strip Chart Recorders),5. Function Generator (Function Generators),6. Spectrum Analyzers.

Most of the tools of measurement used in the present is the result of a merger between a mechanical device and some electronic detection element (electronic sensing element).

Some technicians / experts instrumentation using the latest tools for special calibration work though some still use basic electronic instrument, the readings are still calculated manually by the user.

It is important to know some tools or measurement devices common basic instrument in use and train familiarize themselves in various activities of measurement instrumentation.

There are a wide variety of measurement instrumentation tools are sold in the market at this time. However, some of the most important tool and that must be recognized is the main inter alia as follows:1. Multimeter,2. Frequency Counter (Frequency Counters),3. Oscilloscop,4. Recorder Line Graph (Strip Chart Recorders),5. Function Generator (Function Generators),6. Spectrum Analyzers.

X . IIIIIII

Transmitting Electrical Energy Without Wires

In a technology event, initiated by Intel (Intel Developer Forum, or IDF), Chief Technology, Justin Rattner, a simple technology demonstrator transmitting cordless power does this by turning on the light, with less than one meter without using a cable. And since then, the opportunity - the next opportunity intel shows that this technology can be continuously developed, such as on an intel opportunity to demonstrate the operation of the netbook without using a battery or even operate the speakers without the use of cables, just by changing the sound signal so electrical signals.Working Principle Power Without Wires

Basically how electricity works without wires (wireless) is almost the same as when we yell to wear glasses. In which the vibration of the vocal cords flowing out through the air, then the air space to be absorbed into the glass so it would vibrate.

The basic principle of cordless power transfer is very closely linked to the phenomenon of resonance. A receiver can capture energy from the magnetic field due to the coil, and radiated through the same frequency from a transmitter. To obtain optimal impedance, the cable reels used on both the sides.

In the wireless power technology is broadly consists of four main components, namely the circuit for the transmitter (electric), for emitting antenna / transmitter or transmitter, an antenna for a receiver or receiver and a set of receivers.

Proof of cordless power if the technology is safe, is when ever tested-kan a transfer electricity through the water in the aquarium, and the results without any fish injured or react abnormally. And if we think the layman, the water is a good conductor. It should, in theory, an electric current flowing in the transmitting antenna is enough to make the fish in the aquarium electrocuted to death. But the fact it, not that that happened.

Transmitting Electrical Energy Without Wires

In a technology event, initiated by Intel (Intel Developer Forum, or IDF), Chief Technology, Justin Rattner, a simple technology demonstrator transmitting cordless power does this by turning on the light, with less than one meter without using a cable. And since then, the opportunity - the next opportunity intel shows that this technology can be continuously developed, such as on an intel opportunity to demonstrate the operation of the netbook without using a battery or even operate the speakers without the use of cables, just by changing the sound signal so electrical signals.Working Principle Power Without Wires

Basically how electricity works without wires (wireless) is almost the same as when we yell to wear glasses. In which the vibration of the vocal cords flowing out through the air, then the air space to be absorbed into the glass so it would vibrate.

The basic principle of cordless power transfer is very closely linked to the phenomenon of resonance. A receiver can capture energy from the magnetic field due to the coil, and radiated through the same frequency from a transmitter. To obtain optimal impedance, the cable reels used on both the sides.

In the wireless power technology is broadly consists of four main components, namely the circuit for the transmitter (electric), for emitting antenna / transmitter or transmitter, an antenna for a receiver or receiver and a set of receivers.

Proof of cordless power if the technology is safe, is when ever tested-kan a transfer electricity through the water in the aquarium, and the results without any fish injured or react abnormally. And if we think the layman, the water is a good conductor. It should, in theory, an electric current flowing in the transmitting antenna is enough to make the fish in the aquarium electrocuted to death. But the fact it, not that that happened.

History of Electrical Invention Without Wires

The basic idea or main pioneers of this technology is Nikola Tesla. Croatia brilliant scientist who may not be widely known by the public. But unfortunately in January 1943 Scientists have died, and with it the discovery also participated buried without ter-publication and further developed. For research laboratory where he, along with a note or data- data have been burned. Many are recognizing when tesla is one brilliant scientist. But unfortunately because of these findings contrast with the capitalist powers at the time, the name was isolated and drowned among other scientists.

Because as we all know, if the time was the invention of cordless power Tesla is successful, then the capitalist circles (employers' and large plants as well as the cable industry) would go bankrupt, and thousands of workers will lose their jobs threatened.

And even at the time of Thomas Edison continue to make statements about his anxiety about the dangers of wireless power Tesla's invention. It is understandable if Thomas did that, because he supported industrial entrepreneurs who have capital, waiting for the various inventions may be unable to compete when it comes to wireless technology invention Tesla recognized and developed on a massive scale.

Thankful nowadays wireless power transfer technology that has been pioneered Tesla has begun in use, and continues to be developed. As an example now widely circulated baterry charging the wireless phone, and maybe next time we could really home free of wires, or even, electric car charging can be done without the slightest baterry and wires .

The basic idea or main pioneers of this technology is Nikola Tesla. Croatia brilliant scientist who may not be widely known by the public. But unfortunately in January 1943 Scientists have died, and with it the discovery also participated buried without ter-publication and further developed. For research laboratory where he, along with a note or data- data have been burned. Many are recognizing when tesla is one brilliant scientist. But unfortunately because of these findings contrast with the capitalist powers at the time, the name was isolated and drowned among other scientists.

Because as we all know, if the time was the invention of cordless power Tesla is successful, then the capitalist circles (employers' and large plants as well as the cable industry) would go bankrupt, and thousands of workers will lose their jobs threatened.

And even at the time of Thomas Edison continue to make statements about his anxiety about the dangers of wireless power Tesla's invention. It is understandable if Thomas did that, because he supported industrial entrepreneurs who have capital, waiting for the various inventions may be unable to compete when it comes to wireless technology invention Tesla recognized and developed on a massive scale.

Thankful nowadays wireless power transfer technology that has been pioneered Tesla has begun in use, and continues to be developed. As an example now widely circulated baterry charging the wireless phone, and maybe next time we could really home free of wires, or even, electric car charging can be done without the slightest baterry and wires .

Cordless Power Transfer

Have you ever imagined, all electrical installations in your home system using wireless or cordless electric installation, with no milling or cable attached to the wall at all. Similar to a bluetooth or wireless technology that has been applied to various electronic devices today.

And I think it is not impossible, because recently from a reliable source said, there have been studies or rather the researchers have developed and are testing this technology in the electrical circuit. And if it has been 100% successful and started to distribute in bulk, then no doubt your house will completely sterile of cabling system as it is now.