In the electronics industry we know a lot of electronic products on the consumer market, including:

1. LED television

2. DVD Player

3. Microwave

4. Washing machine

5. Refrigerator

6. Rice cooker

7. Ac (Air Conditioner)

8. Digital camera

Diagram Production processes in industries that produce electronic products usually follow the pattern:

1. IQC Process (Incoming Process): checking FIFO system raw materials

2. production process up to assembly

3. packing process

4. Warehousing process

5. Psychometric processes: testing the performance of electronic equipment

6. the process of checking each production process

7. Outgoing process, namely checking the final results that have been stored in the warehouse.

and then the knowledge that must be understood by each production operator and good supervisor staff, line leader and manager as well as general manager in the electronics industry are knowledge and skills regarding electronic circuits and their placement, namely:

1. measure solder and soldering on PCB board (Printed Circuit Board)

2. PCB Matrix

3. Flip Flop (Memory) circuit

4. LED circuit

5. SMD (Surface Mount Device) Components

6. Jumper wire

7. welding

8. installation of components and rules

9. Electronic arts and design

10 Knowledge of electronic circuits

from some information about the electronics industry above, one of them is the washing machine that we will discuss below both in terms of instruments and controls as well as functions and production processes.

Best regards

Signature __ Gen. Mac Tech

some examples of assembly in the electronics equipment industry :

Through the use of the high-tech equipment, the production processes are fully automated, and the quality of transactions is assured at every stage applying electronic monitoring systems

PRODUCTION OF AIR CONDITIONERS

At the beginning of 2014 the production of heat exchangers and evaporators for air-conditioners was organized. The high-speed stamping presses with corresponding accessories were installed. The site is equipped with two lines for cutting and shaping of 0.105 mm thick aluminum foil. The design of the cut foil is elaborated taking into account the climate of Central Asia and the conditions of high dustiness in order to ensure its long service as well as for prevention purposes.

Upgraded quality control was achieved by application of modern equipment of ULVAC (Japan) and Inficon (Germany) that detects any gas escape in the radiator and refrigerant in the air conditioner. There is also a laboratory and climatic chambers for complete scan of the modes and parameters of the air conditioner.

In the 4th quarter of 2014 it is planned to start the production of split air conditioners based on ozone friendly refrigerant R 410 a. Besides, in the second quarter of 2015 the devices with inverter compressors with variable speeds will be manufactured.

PRODUCTION OF REFRIGERATORS

The production of the internal chambers and door panels for refrigerators and deep-freezers by ARTEL is carried out in the special thermo vacuum forming machine (TVFM) by the famous Italian manufacturer COMI, which can quickly produce an item of any form or size characterised by high quality and attractive design.

The automatic line for sidebars formation automatically download, pierce, bend, form and cut metal panels.

ARTEL uses the most modern technologies to install the control panels. The equipment for preparation and installation of control panels in the refrigerator body and doors is manufactured by Canon (Italy) and provides automatic replacement of forms and automatic filling of raw material in the system. As well as the ability to simultaneously fill in 4 models of refrigerator.

During the assembling of the fridge units on the production line the compressor by EMBRACO is installed - the world leader of the production of hermetic compressors.

The advantages of the EMBRACO compressor:

- High performance and reliability.

- Stable operation during electricity alterations from 155-160 V to 245-250 V.

- Lifetime without breakdowns of more than 10 years.

- Economical power consumption. Class A + power consumption.

- Low noise and vibration.

- Small weight and dimensions compared to other compressors of the same power level.

Preliminary automatic vacuum refrigeration of the referegirating unit is carried out by the vacuum pump ULVAC VD-301 (Japan). Ultimate refrigerant filling is produced on Italian equipment GALILEO, which is furnished with an automatic alarm for gas leak measurement. Ultrasonic welding of KOBRA (Germany) is used for soldering after refilling the refrigerant. The leak detectors Inficon ECOTEC 300 (Germany) perform automatically control of refrigerant R600a leaks at the final stage.

There is a total stage by stage control of each device realised on the refrigerators assembly line.

PRODUCTION OF GAS STOVES AND ELECTRIC MINI OVENS

The production site includes: spiral, compressing installation and assembling lines of gas stoves and mini ovens with accessories and testing devices.

To paint the metal parts of stoves, as well as to enamel the working surfaces of stoves and mini ovens the equipment by leading manufacturers is used:

- painting assembly-line that allows to realize 5-stage chemical cleaning of metal products in automatic mode, to avoid products corrosion and to improve the adhesion of the paint layer.

- enamelling line, that includes automated cameras for the application of enamels and drying oven

Strength of welded joints, as well as spot welding is guaranteed by application of the equipment by Turkish company KAYSAN.

PRODUCTION OF TELEVISION SETS

New production line has a number of structural improvements, which make manufacture of televisions much more economical and easier from a technological point of view. The line meets all the rules and requirements of modern production lines. The process consists of pre-assembly process – preparation of main issues consisting of LED panels, speakers, metal frames for fastening of boards and panels, test line and packaging.

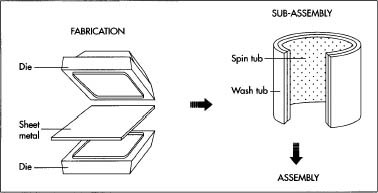

PRODUCTION OF WASHING MACHINES

The production of semi-automatic washing machines with an outstanding modern design and high security was launched in 2012.

They are manufactured of impact-resistant plastic that do not corrode, are equipped with press chamber locks, preventing possible injuries.

- The semi-automatic washing machines are ideal for locations where there is no hot water and central water supply.

- Almost any laundry detergent can be used, even the most simple and affordable one.

- Energy consumption is 6-10 times more cost-effective during medium washing cycle.

PRODUCTION OF PHONES

The production facilities consist of 4 lines, adapted for the assembly process and packaging, a line for manufacturing thermoplastic plastic phone frames, a large laboratory area and paint shop, designed to paint the middle and back parts of the phone frame.

Assembly tables are covered with an antistatic coating, all work on the assembly line are realized in gloves.

Broadband radio communication tester R&SCMW 500 serves for analyzing control signals of the receiver-transmitters in the cellular phones and allows you to check the power of the radio unit and to speed up the scan time.

After carrying out assembly operations the cell phones are delivered to a specially equipped testing laboratory. Each phone is checked separately, and runs two control stages performed by experts of the plant.

LABORATORY

ARTEL tests its products under controlled conditions before releasing them on the market. The tests allow you to determine the reliability of products in various situations.

Environmental test laboratory is a necessary component of an industrial complex, providing complete product testing for the ability to operate in any circumstances, when the failures of technology are possible followed by conditions resulting in emergency situations. Simulation of the external climatic conditions is achieved by various combinations of values of temperature, pressure, humidity.

There are laboratories created and climatic chambers equipped at each production line to fully validate the parameters of electrical engineering.

Here is a partial list of tests that are conducted in laboratories and climatic chambers:

Production of refrigerator

- check for refrigerant leaks

- check for electrical safety.

Functional testing:

- temperature rise test

- control of the average temperature of the freezer and refrigeration chambers.

- test on energy consumption:

- test to obtain food in refrigerators ice

- test of moisture deposition.

Production of air conditioner

- test on cooling/heating capacity, equipment that does not have analogues in Central Asia

- workability of high and low voltage

- the speed of the airflow

- workability at low and high temperature conditions

- calculation of EFFICIENCY of the product.

Production of mobile phones

- Broadband radio communication tester by German manufacturer ROHDE @SCWARZ serves for analyzing control signals of cell phone reception-transmitters, allows you to check the power of the radio unit.

- color control box TILOT60 to check colors for matching in different lighting specters;

- audio signal generator TH 1312-20 to test the speakers;

- electrical safety tester GPI 735A for checking charge at high voltage;

- microphone tester AWA-6063B;

- hyperbaric chamber (temperature and humidity chamber) MHU-408L;

- sound level tester TES-135 OA – device to measure the sound level.

SHOP FOR INJECTION MOLDING

Automatic molding machines (AMM) is an equipment for casting plastic parts under pressure.

Nowadays, ARTEL production base includes a wide range of the automatic molding machines by the world famous company of Haitian – one of the world leaders in quality and sales.

ARTEL uses full range of AMM Haitian SATURN and Haitian MARS that are equipped with components by famous European manufactures, that allows to produce high quality equipment. AMM of this type have energy-saving resources and are controlled by a mini processor, all processes are taking place following a special program, which has a positive effect on the quality of the products and performance of the enterprise.

High repeatability precision of injection-molding process is guaranteed by the computer control system of Austrian company KEBA. Alarm display indicates errors during operation and provides comprehensive information about problems.

The biggest machine has the force of a closure of the 21000 Kn and injection capacity of 9683 CC, that allows to produce large-scale products weighing up to 7 kg, with the exact dimension geometry. The smallest machine has the force of a closure of 1600 Kn and injection capacity of 320 CC, that allows to produce minor devices of high quality.

PLATE BENDING PRESSES AND METAL CUTTING LINES

There is a a large shop of plate bending presses by SIMPAC (Korea) at ARTEL production facilities. Eccentric presses are designed for cutting operations, embossing, pressing on progressive plates of the parts for air conditioners, gas stoves and mini ovens. Hydraulic presses with a force of 200, 250, 350 and 450 tons are designed for accurate deep drawing of sheet metal. The execution within the range of nominal force from 10 to 450 tons and dimensions of cabinets from 620 x 405 mm to 2 800 x 1 300 mm are also available.

Automated lines for length and cross cutting of Turkish manufacturer AGMLINE, occupying a leading position in the world in production of this equipment, are used for cutting parts for gas stoves and mini ovens.

Slitting line is designed for cutting of a rolled sheet metal into strips with simultaneous formation of strips into individual rolls. Cutup lines for rolled material are intended for cross cutting of wide rolls of sheet metal into sheets. Cutting of the plate with thickness from 0.5 mm to 4 mm is performed simultaneously with the installation of reinforcement rollers.

The guillotine shears to cut metal by BAYRA and BAYKAL are also used in this area. They consist of a machine designed for cutting sheet and strip metal with thickness from 0.5 mm to 4 mm.

Washing machine

A washing machine (laundry machine, clothes washer, or washer) is a device used to wash laundry. The term is mostly applied to machines that use water as opposed to dry cleaning (which uses alternative cleaning fluids, and is performed by specialist businesses) or ultrasonic cleaners. The user adds laundry detergent which is sold in liquid or powder form to the wash water.

A typical front-loader washing machine

Washing by hand

Laundering by hand involves soaking, beating, scrubbing, and rinsing dirty textiles. Before indoor plumbing, the washerwoman (laundress) or housewife also had to carry all the water used for washing, boiling, and rinsing the laundry; according to an 1886 calculation, women fetched water eight to ten times every day from a pump, well, or spring.[1] Water for the laundry would be hand carried, heated on a fire for washing, then poured into the tub. That made the warm soapy water precious; it would be reused, first to wash the least soiled clothing, then to wash progressively dirtier laundry.

Removal of soap and water from the clothing after washing was a separate process. First, soap would be rinsed out with clear water. After rinsing, the soaking wet clothing would be formed into a roll and twisted by hand to extract water. The entire process often occupied an entire day of hard work, plus drying and ironing.

It is also often used in washbasins.

Washing by machine

Clothes washer technology developed as a way to reduce the manual labor spent, providing an open basin or sealed container with paddles or fingers to automatically agitate the clothing. The earliest machines were hand-operated and constructed from wood, while later machines made of metal permitted a fire to burn below the washtub, keeping the water warm throughout the day's washing.

The earliest special-purpose mechanical washing device was the washboard, invented in 1797 by Nathaniel Briggs of New Hampshire.

By the mid-1850s steam-driven commercial laundry machinery were on sale in the UK and US.[4] Technological advances in machinery for commercial and institutional washers proceeded faster than domestic washer design for several decades, especially in the UK. In the United States there was more emphasis on developing machines for washing at home, though machines for commercial laundry services were widely used in the late 19th and early 20th centuries.[5] The rotary washing machine was patented by Hamilton Smith in 1858.[3] As electricity was not commonly available until at least 1930, some early washing machines were operated by a low-speed, single-cylinder hit-and-miss gasoline engine.

Wringing by machine

After the items were washed and rinsed, water had to be removed by twisting. To help reduce this labor, the wringer/mangle machine was developed. As implied by the term "mangle," these early machines were quite dangerous, especially if powered and not hand-driven. A user's fingers, hand, arm, or hair could become entangled in the laundry being squeezed, resulting in horrific injuries; unwary bystanders, such as children, could also be caught and hurt. Safer mechanisms were developed over time, and the more hazardous designs were eventually outlawed.

The mangle used two rollers under spring tension to squeeze water out of clothing and household linen. Each laundry item would be fed through the wringer separately. The first wringers were hand-cranked, but were eventually included as a powered attachment above the washer tub. The wringer would be swung over the wash tub so that extracted wash water would fall back into the tub to be reused for the next load.

The modern process of water removal by spinning did not come into use until electric motors were developed. Spinning requires a constant high-speed power source, and was originally done in a separate device known as an "extractor". A load of washed laundry would be transferred from the wash tub to the extractor basket, and the water spun out in a separate operation. These early extractors were often dangerous to use, since unevenly distributed loads would cause the machine to shake violently. Many efforts were made to counteract the shaking of unstable loads, such as mounting the spinning basket on a free-floating shock-absorbing frame to absorb minor imbalances, and a bump switch to detect severe movement and stop the machine so that the load could be manually redistributed.

Combined processes

What is now referred to as an automatic washer was at one time referred to as a "washer/extractor", which combined the features of these two devices into a single machine, plus the ability to fill and drain water by itself. It is possible to take this a step further, and to also merge the automatic washing machine and clothes dryer into a single device, called a combo washer dryer.

Flash Black

Early machines

The first English patent under the category of Washing machines was issued in 1691.[8] A drawing of an early washing machine appeared in the January 1752 issue of The Gentleman's Magazine, a British publication. Jacob Christian Schäffer's washing machine design was published 1767 in Germany.[9] In 1782, Henry Sidgier issued a British patent for a rotating drum washer, and in the 1790s Edward Beetham sold numerous "patent washing mills" in England.[10] One of the first innovations in washing machine technology was the use of enclosed containers or basins that had grooves, fingers, or paddles to help with the scrubbing and rubbing of the clothes. The person using the washer would use a stick to press and rotate the clothes along the textured sides of the basin or container, agitating the clothes to remove dirt and mud.[11] This crude agitator technology was hand-powered, but still more effective than actually hand-washing the clothes.

More advancements were made to washing machine technology in the form of the rotative drum design. Basically, these early design patents consisted of a drum washer that was hand-cranked to make the wooden drums rotate. While the technology was simple enough, it was a milestone in the history of washing machines, as it introduced the idea of "powered" washing drums. As metal drums started to replace the traditional wooden drums, it allowed for the drum to turn above an open fire or an enclosed fire chamber, raising the water temperature for more effective washes.

It would not be until the 19th century when steam power would be used in washing machine designs.[12]

In 1862, a patented "compound rotary washing machine, with rollers for wringing or mangling" by Richard Lansdale of Pendleton, Manchester, was shown at the 1862 London Exhibition.

The first United States Patent titled "Clothes Washing" was granted to Nathaniel Briggs of New Hampshire in 1797. Because of the Patent Office fire in 1836, no description of the device survives. Invention of a washing machine is also attributed to Watervliet Shaker Village, as a patent was issued to an Amos Larcom of Watervliet, New York, in 1829, but it is not certain that Larcom was a Shaker.[14] A device that combined a washing machine with a wringer mechanism did not appear until 1843, when Canadian John E. Turnbull of Saint John, New Brunswick patented a "Clothes Washer With Wringer Rolls."[15] During the 1850s, Nicholas Bennett from the Mount Lebanon Shaker Society at New Lebanon, New York, invented a "wash mill", but in 1858 he assigned the patent to David Parker of the Canterbury Shaker Village, where it was registered as the "Improved Washing Machine".[16][17]

Margaret Colvin invented the Triumph Rotary Washer, which was exhibited in the Women's Pavilion at the Centennial International Exhibition of 1876 in Philadelphia. At the same Exhibition, the Shakers won a gold medal for their machine.

Electric washing machines were advertised and discussed in newspapers as early as 1904.[20] Alva J. Fisher has been incorrectly credited with the invention of the electric washer. The US Patent Office shows at least one patent issued before Fisher's US patent number 966677 (e.g. Woodrow's US patent number 921195). The "inventor" of the electric washing machine remains unknown.

US electric washing machine sales reached 913,000 units in 1928. However, high unemployment rates in the Depression years reduced sales; by 1932 the number of units shipped was down to about 600,000.

It is presumed that the first laundromat opened in Fort Worth, Texas in 1934.It was run by Andrew Clein. Patrons used coin-in-the-slot facilities to rent washing machines. The term "laundromat" can be found in newspapers as early as 1884 and they were widespread during the Depression. England established public wash rooms for laundry along with bath houses throughout the 19th century.

Washer design improved during the 1930s. The mechanism was now enclosed within a cabinet, and more attention was paid to electrical and mechanical safety. Spin dryers were introduced to replace the dangerous power mangle/wringers of the day.

By 1940, 60% of the 25,000,000 wired homes in the United States had an electric washing machine. Many of these machines featured a power wringer, although built-in spin dryers were not uncommon.

Automatic machines

Bendix Home Appliances, a subsidiary of Avco, introduced the first domestic automatic washing machine in 1937,[23] having applied for a patent in the same year.[24] Avco had licensed the name from Bendix Corporation, an otherwise unrelated company. In appearance and mechanical detail, this first machine was not unlike the front loading automatic washers produced today. Although it included many of today's basic features, the machine lacked any drum suspension and therefore had to be anchored to the floor to prevent "walking". Because of the components required, the machine was also very expensive. For instance, the Bendix Home Laundry Service Manual (published November 1, 1946) shows that the drum speed change was facilitated by a 2-speed gearbox built to a heavy duty standard (not unlike a car automatic gearbox, albeit at a smaller size). The timer was also probably fairly costly, because miniature electric motors were expensive to produce.

Early automatic washing machines were usually connected to a water supply via temporary slip-on connectors to sink taps. Later, permanent connections to both the hot and cold water supplies became the norm, as dedicated laundry water hookups became common. Most modern front-loading European machines now only have a cold water connection (called "cold fill") and rely completely on internal electric heaters to raise the water temperature.

Many of the early automatic machines had coin-in-the-slot facilities and were installed in the basement laundry rooms of apartment houses.

In early automatic washing machines, any changes in impeller/drum speed were achieved by mechanical means or by a rheostat on the motor power supply. However, since the 1970s electronic control of motor speed has become a common feature on the more expensive models.

Modern washers

Over time manufacturers of automatic washers have gone to great lengths to reduce cost. For instance, expensive gearboxes are no longer required, since motor speed can be controlled electronically. Some models can be controlled via WiFi.

Even on some expensive washers, the outer drum of front loading machines is often made of plastic. This makes changing the main bearings difficult, as the plastic drum usually cannot be separated into two halves to enable the inner drum to be removed to gain access to the bearing.

Some manufacturers have taken steps to reduce vibration emanating from their washers, by means of reducing or controlling motor speeds, using hydraulic suspensions instead of spring suspensions, and having freely moving steel balls contained inside a ring mounted on both the front and back sides of the drum in order to counter the weight of the clothes and reduce vibration.

Some machines, since 1998 now use a direct drive motor, a low aspect ratio device, where the stator assembly is attached to the rear of the outer drum, whilst the co-axial rotor is mounted on the shaft of the inner drum.[31] Direct drive eliminates the need for a pulley, belt and belt tensioner. It was invented by LG Electronics in 1998 and patents granted in the US in 2010. Since, other manufacturers have followed suit. Some washing machines with this type of motor come with 10 or even 20 year warranties, but only for the motor itself.

Some other washing machines include water jets (also known as water sprays and water showers) and steam nozzle that claim to sanitize clothes and help reduce washing times and remove soil from the clothes. Water jets get their water from the bottom of the drum, thus recirculating the water in the washer. Others have special drums with holes that will fill with water from the bottom of the tub and redeposit the water on top of the clothes. Some drums have elements with the shape of waves, pyramids, hexagons or diamonds. Some include titanium or ceramic heating elements that claim to eliminate calcium build up in the element.[36] They can heat water up to 95 °C. Some high end models have lights built into the washer itself to light up the drum,[29] and others have soap dispensers where the user just fills a tank] with detergent and softener and the washing machine automatically doses the detergent and softener[39] and sometimes picks the most appropiate wash cycle.[40] In some models, the tanks come pre filled and are installed and replaced with new tanks, also pre filled or refilled by the user, in a dedicated compartment on the bottom of the machine.[41] Some have support for single use capsules containing enough laundry additives for one load. The capsules are installed in the detergent compartment.[42] Many dilute the detergent before it comes in contact with the clothes, some by means of mixing the soap and water with air to make foam,[48] which is then introduced into the drum. Some have pulsators that are mounted on a plate on the bottom of the drum instead of an agitator. The plate spins, and the pulsators generate waves that help shake the soil out of the clothes. Many also include mechanisms to prevent or remove undissolved detergent residue on the detergent dispenser.] Some manufacturers like LG Electronics and Samsung Electronics have introduced functions on their washers that allow users to troubleshoot common problems with their washers without having to contact technical support. LG's approach involves a phone receiving signals through sound tones, while Samsung's approach involves having the user take a photo of the washer's time display with his or her phone. In both methods, the problem and steps to resolve it are displayed on the phone itself.

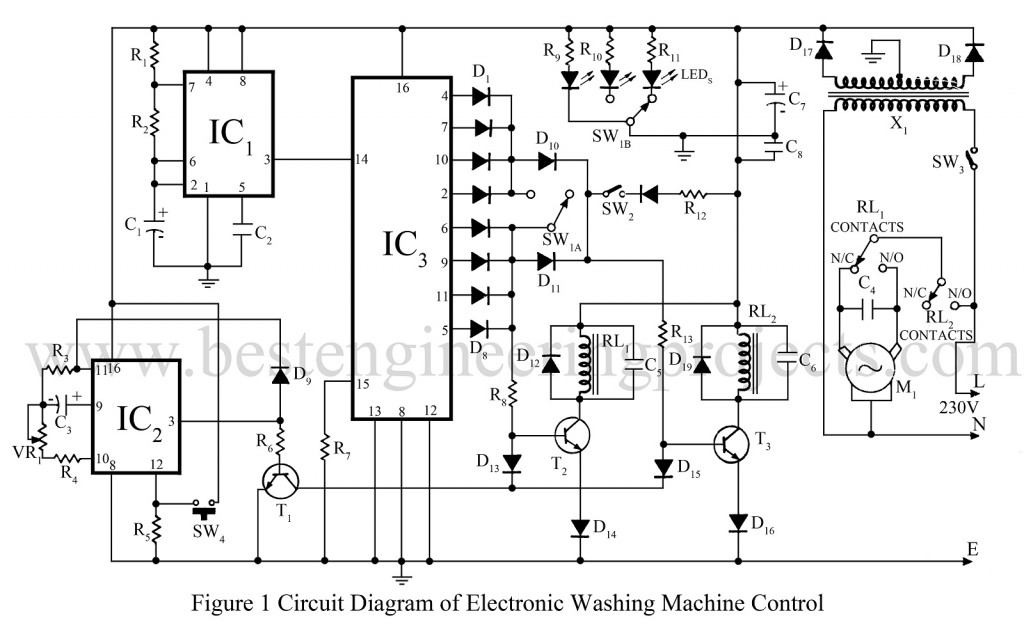

In the early 1990s, upmarket machines incorporated microcontrollers for the timing process. These proved reliable and cost-effective, so many cheaper machines now also incorporate microcontrollers rather than electromechanical timers. Since the 2010s, some machines have touch panel displays, full color or color displays, or touch sensitive control panels. (see Color depth)[58]

In 1994, Staber Industries released the System 2000 washing machine, which is the only top-loading, horizontal-axis washer to be manufactured in the United States. The hexagonal tub spins like a front-loading machine, using only about one third as much water as conventional top-loaders. This factor has led to an Energy Star rating for its high efficiency. This type of horizontal axis washer and dryer (with a circular drum) is often used in Europe, where space is limited, as they can be as thin as 40 cm in width.

In 1998, New Zealand-based company Fisher & Paykel introduced its SmartDrive washing machine line in the US. This washing machine uses a computer-controlled system to determine certain factors such as load size and automatically adjusts the wash cycle to match. It also used a mixed system of washing, first with the "Eco-Active" wash, using a low level of recirculated water being sprayed on the load followed by a more traditional style wash. The SmartDrive also included direct drive brushless DC electric motor, which simplified the bowl and agitator drive by doing away with the need for a gearbox system.

In 2000, the British inventor James Dyson launched the CR01 ContraRotator, a type of washing machine with two cylinders rotating in opposite directions. It was claimed that this design reduced the wash time and produced cleaner washing than a single cylinder machine. In 2004 there was the launch of the CR02, which was the first washing machine to gain the British Allergy Foundation Seal of Approval. However, neither of the ContraRotator machines are now in production as they were too expensive to manufacture. They were discontinued in 2005.

In 2001, Whirlpool Corporation introduced the Calypso, the first vertical-axis high efficiency washing machine to be top-loading. A washplate in the bottom of the tub nutated (a special wobbling motion) to bounce, shake, and toss the laundry around. Simultaneously, water containing detergent was sprayed on to the laundry. The machine proved to be good at cleaning, but gained a bad reputation due to frequent breakdowns and destruction of laundry. The washer was recalled with a class-action lawsuit and pulled off the market.

In 2003, Maytag introduced their top-loading Neptune washer. Instead of an agitator, the machine had two washplates, perpendicular to each other and at a 45 degree angle from the bottom of the tub. The machine would fill with only a small amount of water and the two washplates would tumble the load within it, mimicking the action of a front-loading washer in a vertical axis design.

In 2006, Sanyo introduced the first drum type washing machine with "Air Wash" function. It also reused and disinfected rinse water.[71][72] This washing machine uses only 50 L (11.0 imp gal; 13.2 US gal) of water in the recycle mode.

In 2008, the University of Leeds created a concept washing machine that uses only a cup (less than 300 ml) of water and 20 kg of re-usable plastic beads to carry out a full wash.[73] The machine leaves clothes virtually dry, and uses less than 2 % of the water and energy otherwise used by a conventional machine. As such, it could save billions of liters of water each year. The concept is being developed as the Xeros Washing Machine.

Approximately in 2012, eco indicators were introduced, capable of predicting the energy demand based on the customer settings in terms of program and temperature.[74]

Features available in most modern consumer washing machines:

- Delayed execution: a timer to delay the start of the laundry cycle

- Predefined programs for different laundry types

- Rotation speed settings

- Variable temperatures, including cold wash

Additionally some of the modern machines feature:

- Child lock

- Steam

- Time remaining indication

Around 2015 and 2017, some manufacturers](namely Samsung and LG Electronics) offered washers and dryers that either have a top loading washer and dryer built on top of a front loading washer and dryer respectively (in Samsung washers and dryers) or offer users an optional top loading washer that can be installed under a washer or dryer (for LG washers and dryers) Both manufacturers have also introduced front loading washers allowing users to add items after a wash cycle has started, and has also introduced top loading washers with a built in sink] and a detergent dispenser that claims to leave no residue on the dispenser itself. In IFA 2017,] Samsung released the QDrive, a front loading washer similar to the Dyson ContraRotator but instead of 2 counterrotating drums, the QDrive has a single drum with a counterrotating impeller mounted on the back of the drum. Samsung claims this technique reduces cycle times by half and energy consumption by 20%.

Types

Top-loading

This design places the clothes in a vertically mounted perforated basket that is contained within a water-retaining tub, with a finned water-pumping agitator in the center of the bottom of the basket. Clothes are loaded through the top of the machine, which is usually but not always covered with a hinged door.

During the wash cycle, the outer tub is filled with water sufficient to fully immerse and suspend the clothing freely in the basket. The movement of the agitator pushes water outward between the paddles towards the edge of the tub. The water then moves outward, up the sides of the basket, towards the center, and then down towards the agitator to repeat the process, in a circulation pattern similar to the shape of a torus. The agitator direction is periodically reversed, because continuous motion in one direction would just lead to the water spinning around the basket with the agitator rather than the water being pumped in the torus-shaped motion. Some washers supplement the water-pumping action of the agitator with a large rotating screw on the shaft above the agitator, to help move water downwards in the center of the basket.

Since the agitator and the drum are separate and distinct in a top-loading washing machine, the mechanism of a top-loader is inherently more complicated than a front-loading machine. Manufacturers have devised several ways to control the motion of the agitator during wash and rinse separately from the high speed rotation of the drum required for the spin cycle.

While a top-loading washing machine could use a universal motor or DC brushless motor, it is conventional for top-loading washing machines to use more expensive, heavy, and more electrically efficient and reliable induction motors. The action of a front-loading washing machine is better suited to a motor capable of reversing direction with every reversal of the wash basket; a universal motor is noisier, less efficient, doesn't last as long, but is better suited to the task of reversing direction every few seconds.

An alternative to the oscillating agitator design is the impeller type washtub pioneered by Hoover on its long running Hoovermatic series of top loading machines. Here, an impeller (trademarked by Hoover as a "Pulsator") mounted on the side of the tub spins in a constant direction, and creates a fast moving current of water in the tub which drags the clothes through the water along a toroidal path. The impeller design has the advantage of its mechanical simplicity - a single speed motor with belt drive is all that is required to drive the Pulsator with no need for gearboxes or complex electrical controls, but has the disadvantage of lower load capacity in relation to tub size. Hoovermatic machines were made mostly in twin tub format for the European market - (where they competed with Hotpoint's Supermatic line which used the oscillating agitator design) until the early 1990s. Some industrial garment testing machines still use the Hoover wash action.

The many different ways different manufacturers have solved the same problem over the years is a good example of many different ways to solve the same engineering problem with different goals, different manufacturing capabilities and expertise, and different patent encumbrances.

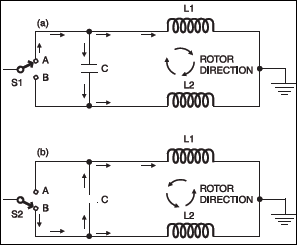

Reversible motor

In most current top-loading washers, if the motor spins in one direction, the gearbox drives the agitator; if the motor spins the other way, the gearbox locks the agitator and spins the basket and agitator together. Similarly, if the pump motor rotates one way it recirculates the sudsy water; in the other direction it pumps water from the machine during the spin cycle. Mechanically, this system is very simple.

Mode-changing transmission

In some top loaders, the motor runs only in one direction. During agitation, the transmission converts the rotation into the alternating motion driving the agitator. During the spin cycle, the timer turns on a solenoid which engages a clutch locking the motor's rotation to the wash basket, providing a spin cycle. General Electric's very popular line of Filter-Flo (seen to the right) used a variant of this design where the motor reversed only to pump water out of the machine. The same clutch which allows the heavy tub full of wet clothes to "slip" as it comes up to the motor's speed, is also allowed to "slip" during agitation to engage a Gentle Cycle for delicate clothes.

Whirlpool (Kenmore) created a popular design demonstrating the complex mechanisms which could be used to produce different motions from a single motor with the so-called "wig wag" mechanism, which was used for decades until modern controls rendered it obsolete. In the Whirlpool mechanism, a protruding moving piece oscillates in time with the agitation motion. Two solenoids are mounted to this protruding moving piece, with wires attaching them to the timer. During the cycle, the motor operates continuously, and the solenoids on the "wig wag" engage agitation or spin. Despite the wires controlling the solenoids being subject to abrasion and broken connections due to their constant motion and the solenoids operating in a damp environment where corrosion could damage them, these machines were surprisingly reliable.

Reversible motor with mode-changing transmission

Some top-loaders, especially compact apartment-sized washers, use a hybrid mechanism. The motor reverses direction every few seconds, often with a pause between direction changes, to perform the agitation. Spin cycle is accomplished by engaging a clutch in the transmission. A separate motorized pump is generally used to drain this style of machine. These machines could easily be implemented with universal motors or more modern DC brushless motors, but older ones tend to use a capacitor-start induction motor with a pause between reversals of agitation.

Top-load advantages

The top-loader's spin cycle between washing and rinsing allows an extremely simple passive fabric softener dispenser, which operates through centrifugal force and gravity. Fabric softener, vinegar, or any other liquid rinse agent, is placed in a cup at the top of the agitator. It "rides along" during the wash cycle. When the spin cycle is engaged, the fabric softener is pulled up by a tapered cup and centrifugal force, where it collects in the top of the spinning agitator. Once the spin cycle is completed, centrifugal force no longer suspends the fabric softener and it falls through the center of the agitator to join the rinse water coming into the tub. The same objective must be accomplished by a solenoid valve or a pump, and associated timer controls and wiring, on a front loader.

A lint trap can also be built into the center of the agitator,[83] or on the drum's walls, passively collecting lint from water forced through the agitator. Front-loaders tend to require separate pumps and plumbing to provide lint filters which are often mounted behind covers on the bottom of the machine.

Another advantage to the top loading design is the reliance on gravity to contain the water, rather than potentially trouble-prone or short-lived front door seals. Top loaders may require less periodic maintenance, since there is no need to clean a door seal or bellows, although a plastic tub may still require a periodic "maintenance wash" cycle (described below).

As with front-loading washers, clothing should not be packed tightly into a top-loading washer. Although wet fabric usually fits into a smaller space than dry fabric, a dense wad of fabric can restrict water circulation, resulting in poor soap distribution and incomplete rinsing. Extremely overloaded top-loading washers can either jam the motion of the agitator, overloading or damaging the motor or gearbox, burning drive belts, or tearing fabrics - many Whirlpool/Kenmore machines even have a mechanical "fuse" designed to break before the expensive motor is damaged. Extreme overloading can also push fabrics into the small gap between the underside of the agitator and the bottom of the wash basket, resulting in fabrics wrapped around the agitator shaft, possibly requiring agitator removal to unjam.

Some top-loading machines use mechanisms very similar to front-loading drum machines, and are described below.

Front-loading

The front-loading or horizontal-axis clothes washer is the dominant design in Europe. In the U.S. and elsewhere, most "high-end" washing machines are of this type. In addition, most commercial and industrial clothes washers around the world are of the horizontal-axis design.

This layout mounts the inner basket and outer tub horizontally, and loading is through a door at the front of the machine. The door often but not always contains a transparent window. Agitation is supplied by the back-and-forth rotation of the cylinder and by gravity. The clothes are lifted up by paddles on the inside wall of the drum and then dropped. This motion flexes the weave of the fabric and forces water and detergent solution through the clothes load. Because the wash action does not require the clothing be freely suspended in water, only enough water is needed to moisten the fabric. Because less water is required, front-loaders typically use less soap, and the repeated dropping and folding action of the tumbling can easily produce large amounts of foam or suds.

Front-loaders control water usage through the surface tension of water, and the capillary wicking action this creates in the fabric weave. A front-loader washer always fills to the same low water level, but a large pile of dry clothing standing in water will soak up the moisture, causing the water level to drop. The washer then refills to maintain the original water level. Because it takes time for this water absorption to occur with a motionless pile of fabric, nearly all front-loaders begin the washing process by slowly tumbling the clothing under the stream of water entering and filling the drum, to rapidly saturate the clothes with water.

Front-loading washers are mechanically simple compared to top-loaders, with the main motor (a universal motor or variable-frequency drive motor) normally being connected to the drum via a grooved pulley belt and large pulley wheel, without the need for a gearbox, clutch or crank. But front-load washers suffer from their own technical problems, due to the drum lying sideways. For example, a top loading washer keeps water inside the tub merely through the force of gravity pulling down on the water, while a front-loader must tightly seal the door shut with a gasket to prevent water dripping onto the floor during the wash cycle. This access door is locked shut during the entire wash cycle, since opening the door with the machine in use could result in water gushing out onto the floor. For front-loaders without viewing windows on the door, it is possible to accidentally pinch fabric between the door and the drum, resulting in tearing and damage to the pinched clothing during tumbling and spinning.

Nearly all front-loader washers for the consumer market also use a folded flexible bellows assembly around the door opening, to keep clothing contained inside the basket during the tumbling wash cycle. If this bellows assembly were not used, small articles of clothing such as socks could slip out of the wash basket near the door, and fall down the narrow slot between the outer tub and basket, plugging the drain and possibly jamming rotation of the inner basket. Retrieving lost items from between the outer tub and inner basket can require complete disassembly of the front of the washer and pulling out the entire inner wash basket. Commercial and industrial front-loaders used by businesses (described below) usually do not use the bellows, and instead require all small objects to be placed in a mesh bag to prevent loss near the basket opening.

The bellows assembly around the door is a potential source of problems for the consumer front-loader. The bellows has a large number of flexible folds to permit the tub to move separately from the door during the high speed extraction cycle. On many machines, these folds can collect lint, dirt, and moisture, resulting in mold and mildew growth, and a foul odor. Some front-loading washer operating instructions say the bellows should be wiped down monthly with a strong bleach solution, while others offer a special "freshening" cycle where the machine is run empty with a strong dosing of bleach.

The inherent mechanical weak spot of the front loader design is the cantilevered mounting of the inner drum within the outer tub. The drum bearing has to support the entire weight of the drum, the laundry, and the dynamic loads created by the sloshing of the water and of the imbalance of the load during the spin cycle. The drum bearing eventually wears out, and usually requires extensive dismantling of the machine to replace, which often results in the machine being written off due to the failure of a relatively inexpensive component that is labor-intensive to renew. Some manufacturers have compounded this problem by "overmolding" the drum bearing into the outer tub to reduce manufacturing costs, but this makes the bearing impossible to renew without replacing the entire outer tub - which usually forces owners to scrap the entire machine - this may be viewed as an implementation of built-in obsolescence.

Compared to top-loading washers, clothing can be packed more tightly in a front loader, up to the full drum volume if using a cottons wash cycle. This is because wet cloth usually fits into a smaller space than dry cloth, and front loaders are able to self-regulate the water needed to achieve correct washing and rinsing. Extreme overloading of front-loading washers pushes fabrics towards the small gap between the loading door and the front of the wash basket, potentially resulting in fabrics lost between the basket and outer tub, and in severe cases, tearing of clothing and jamming the motion of the basket.

Variant and hybrid designs

There are many variations of the two general designs. Top-loading machines in Asia use impellers instead of agitators. Impellers are similar to agitators except that they do not have the center post extending up in the middle of the wash tub basket.

Some machines which actually load from the top are otherwise much more similar to front-loading horizontal-axis drum machines. They have a drum rotating around a horizontal axis, as a front-loader, but there is no front door; instead there is a liftable lid which provides access to the drum, which has a hatch which can be latched shut. Clothes are loaded, the hatch and lid are closed, and the machine operates and spins just like a front-loader. These machines are narrower but usually taller than front-loaders, usually have a lower capacity, and are intended for use where only a narrow space is available, as is sometimes the case in Europe. They have incidental advantages: they can be loaded without bending down; they do not require a perishable rubber bellows seal; and instead of the drum having a single bearing on one side, it has a pair of symmetrical bearings, one on each side, avoiding asymmetrical bearing loading and potentially increasing life. This type of washing machine is popular in Europe, where space is limited, as a washer can be as thin as 40 cm in width, and a full washer and dryer installation can be as thin as 80 cm in width.

There are also combo washer dryer machines that combine washing cycles and a full drying cycle in the same drum, eliminating the need to transfer wet clothes from a washer to a dryer machine. In principle, these machines are convenient for overnight cleaning (the combined cycle is considerably longer), but the effective capacity for cleaning larger batches of laundry is drastically reduced. The drying process tends to use much more energy than using two separate devices, because a combo washer dryer not only must dry the clothing, but also needs to dry out the wash chamber itself. These machines are used more in Europe, because they can be fitted into small spaces, and many can be operated without dedicated utility connections. In these machines, the washer and dryer functions often have different capacities, with the dryer usually having the lowest capacity. These machines should not be confused with a dryer on top of a washer installation, or with a laundry center, which is a one piece appliance offering a compromise between a washer-dryer combo and a full washer to the side of the dryer installation or a dryer on top of a washer installation. Laundry centers usually have the dryer on top of the washer, with the controls for both machines being on a single control panel. Often, the controls are simpler than the controls on a washer-dryer combo or a dedicated washer and dryer. on

True front-loaders, and top-loading machines with horizontal-axis drum as described above, can be compared with top-loaders on a number of aspects:

- Efficient cleaning: Front-loaders usually use less energy, water, and detergent compared to the best top-loaders.[90] "High Efficiency" washers use 20% to 60% of the detergent, water and energy of "standard" washers. They usually take somewhat longer (20–110 minutes) to wash a load, but are often computer controlled with additional sensors, to adapt the wash cycle to the needs of each load. As this technology improves, the human interface will also improve, to make it easier to understand and control the many different cleaning options.

- Water usage: Front-loaders usually use less water than top-loading residential clothes washers. Estimates are that front-loaders use from one third[91] to one half[92] as much water as top-loaders.

- Spin-dry effectiveness: Front-loaders (and European horizontal axis top loaders) offer much higher maximum spin speeds of up to 2000 RPM, although home machines tend to be in the 1000 to 1400 RPM range, while top-loaders (with agitators) do not exceed 1140 RPM. High-efficiency top-loaders with a wash plate (instead of an agitator) can spin up to 1100 RPM, as their center of gravity is lower. Higher spin speeds, along with the diameter of the drum, determine the g-force, and a higher g-force removes more residual water, making clothes dry faster. This also reduces energy consumption if clothes are dried in a clothes dryer.

- Cycle length: Top-loaders have tended to have shorter cycle times, in part because their design has traditionally emphasized simplicity and speed of operation more than resource conservation.

- Wear and abrasion: Top-loaders require an agitator or impeller mechanism to force enough water through clothes to clean them effectively, which greatly increases mechanical wear and tear on fabrics. Front-loaders use paddles in the drum to repeatedly pick up and drop clothes into water for cleaning; this gentler action causes less wear. The amount of clothes wear can be roughly gauged by the amount of accumulation in a clothes dryer lint filter, since the lint largely consists of stray fibers detached from textiles during washing and drying.

- Difficult items: Top-loaders may have trouble cleaning large items, such as sleeping bags or pillows, which tend to float on top of the wash water rather than circulate within it. In addition, vigorous top-loader agitator motions may damage delicate fabrics.

- Noise: Front-loaders tend to operate more quietly than top-loaders because the door seal helps contain noise, and because there is less of a tendency to imbalance. Top-loaders usually need a mechanical transmission (due to agitators, see above), which can generate more noise than the rubber belt or direct drive found in most front loaders.

- Compactness: True front-loading machines may be installed underneath counter-height work surfaces. A front-loading washing machine, in a fully fitted kitchen, may even be disguised as a kitchen cabinet. These models can also be convenient in homes with limited floor area, since the clothes dryer may be installed directly above the washer ("stacked" configuration).

- Water leakage: Top-loading machines are less prone to leakage, because simple gravity can reliably keep water from spilling out the loading door on top. True front-loading machines require a flexible seal or gasket on the front door, and the front door must be locked during operation to prevent opening, lest large amounts of water spill out. This seal may leak and require replacement. However, many current front-loaders use so little water that they can be stopped mid-cycle for addition or removal of laundry, while keeping the water level in the horizontal tub below the door level. Best practice installations of either type of machine will include a floor drain or an overflow catch tray with a drain connection, since neither design is immune to leakage or a solenoid valve getting stuck in the open position.

- Maintenance and reliability: Top-loading washers are more tolerant of maintenance neglect, and may not need a regular "freshening" cycle to clean door seals and bellows. During the spin cycle, a top-loading tub is free to move about inside the cabinet of the machine, using only a lip around the top of the inner basket and outer tub to keep the spinning water and clothing from spraying out over the edge. Therefore, the potentially problematic door-sealing and door-locking mechanisms used by true front-loaders are not needed. On the other hand, top-loaders use mechanical gearboxes that are more vulnerable to wear than simpler front-load motor drives.

- Accessibility and ergonomics: Front-loaders are more convenient for very short people and those with paraplegia, as the controls are front-mounted and the horizontal drum eliminates the need for standing or climbing. Risers, also referred to as pedestals, often with storage drawers underneath, can be used to raise the door of a true front-loader closer to the user's level.

- Initial cost: In countries where top-loaders are popular, front-loaders tend to be more expensive to buy than top-loaders, though their lower operating costs can ultimately lead to lower total cost of ownership, especially if energy, detergent, or water are expensive. On the other hand, in countries with a large front-loader user base, top-loaders are usually seen as alternatives and more expensive than basic off-brand front loaders, although without many differences in total cost of ownership apart from design-originated ones. In addition, manufacturers have tended to include more advanced features such as internal water heating, automatic dirt sensors, and high-speed emptying on front-loaders, although some of these features could be implemented on top-loaders.

Wash cycles

The earliest washing machines simply carried out a washing action when loaded with clothes and soap, filled with hot water, and started. Over time machines became more and more automated, first with very complex electromechanical controllers, then fully electronic controllers; users put clothes into the machine, select a suitable program via a switch, start the machine, and come back to remove clean and slightly damp clothes at the end of the cycle. The controller starts and stops many different processes including pumps and valves to fill and empty the drum with water, heating, and rotating at different speeds, with different combinations of settings for different fabrics.

Washing

Many front loading machines have internal electrical heating elements to heat the wash water, to near boiling if desired. The rate of chemical cleaning action of the detergent and other laundry chemicals increases greatly with temperature, in accordance with the Arrhenius equation. Washing machines with internal heaters can use special detergents formulated to release different chemical ingredients at different temperatures, allowing different type of stains and soils to be cleaned from the clothes as the wash water is heated up by the electrical heater.

However, higher-temperature washing uses more energy, and many fabrics and elastics are damaged at higher temperatures. Temperatures exceeding 40 °C (104 °F) have the undesirable effect of inactivating the enzymes when using biological detergent.

Many machines are cold-fill, connected to cold water only, which they heat to operating temperature. Where water can be heated more cheaply or with less carbon dioxide emission than by electricity, cold-fill operation is inefficient.

Front loaders need to use low-sudsing detergents because the tumbling action of the drum folds air into the clothes load that can cause over-sudsing and overflows. However, due to efficient use of water and detergent, the sudsing issue with front-loaders can be controlled by simply using less detergent, without lessening cleaning action.

Rinsing

Washing machines perform several rinses after the main wash to remove most of the detergent. Modern washing machines use less water due to environmental concerns; however, this has led to the problem of poor rinsing on many washing machines on the market,[93] which can be a problem to people who are sensitive to detergents. The Allergy UK website suggests re-running the rinse cycle, or rerunning the entire wash cycle without detergent.[94]

In response to complaints, many washing machines allow the user to select additional rinse cycles, at the expense of higher water usage and longer cycle time.

Spinning

Higher spin speeds, along with larger tub diameters, remove more water, leading to faster drying. If a heated clothes-dryer is used after the wash and spin, energy use is reduced if more water has been removed from clothes. However, faster spinning can crease clothes more. Also, mechanical wear on bearings increases rapidly with rotational speed, reducing life. Early machines would spin at only 300 rpm and, because of lack of any mechanical suspension, would often shake and vibrate.

In 1976, most front loading washing machines spun at around 700 rpm, or less.

Separate spin-driers, without washing functionality, are available for specialized applications. For example, a small high-speed centrifuge machine may be provided in locker rooms of communal swimming pools to allow wet swimsuits to be substantially dried to a slightly damp condition after daily use.

Maintenance wash

Many home washing machines use a plastic, rather than metal, outer shell to contain the wash water; residue can build up on the plastic tub over time. Some manufacturers advise users to perform a regular maintenance or "freshening" wash to clean the inside of the washing machine of any mold, bacteria, encrusted detergent, and unspecified dirt more effectively than with a normal wash.

A maintenance wash is performed without any laundry, on the hottest wash program if there is a heater,[95] adding substances such as white vinegar, 100 grams of citric acid, a detergent with bleaching properties, or a proprietary washing machine cleaner. The first injection of water goes into the sump[96] so the machine can be allowed to fill for about 30 seconds before adding cleaning substances.

Efficiency and standards

Capacity and cost are both considerations when purchasing a washing machine. All else being equal, a machine of higher capacity will cost more to buy, but will be more convenient if large amounts of laundry must be cleaned. Fewer runs of a machine of larger capacity may have lower running costs and better energy and water efficiency than frequent use of a smaller machine, particularly for large families. Running a large machine with small loads is wasteful.

For many years energy and water efficiency were not regulated, and little attention was paid to them. From the last part of the twentieth century increasing attention was paid to efficiency, with regulations enforcing some standards, and efficiency being a selling point, both to save on running costs and to reduce carbon dioxide emissions associated with energy generation, and waste of water.

As energy and water efficiency were regulated, and a selling point, but effectiveness of rinsing was not, manufacturers tended to reduce the degree of rinsing after washing, saving water and motor energy. This had the side-effect of leaving more detergent residue in clothes. Insufficient rinsing can leave enough detergent in clothes to affect people with allergies or sensitivity.[93]

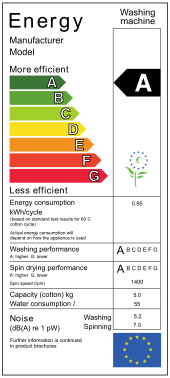

Europe

Washing machines display an EU Energy Label with grades for energy efficiency, washing performance and spin efficiency. Grades for energy efficiency run from A+++ to G (best to worst), providing a simple method for judging running costs. Washing performance and spin efficiency are graded in the range A to G. However, all machines for sale must have washing performance A, such that manufacturers cannot compromise washing performance in order to improve the energy efficiency. This labeling has had the desired effect of driving customers toward more efficient washing machines and away from less efficient ones.

The TopTenEU and other national TopTen European organizations provide independent recommendations for high efficient washing machines.

According to newer regulations, each washing machine is equipped with a waste water filter. There are two reasons for that. On one hand it has to be ensured that no hazardous chemical substances are disposed of improperly through the waste water channel; on the other hand it must also be ensured that in case of a backwards shear in the waste water channel that is possible in case of technical problems, the feces and other waste could not enter the washing machine.[16]

United States

Top-loading and front-loading clothes washers are covered by a single Federal Standard regulating energy consumption. The old Federal Standard applicable until January 1, 2011 included no restriction on water consumption; washer manufacturers faced no legal restriction on how much unheated rinse water could be used.[98] Energy consumption for clothes washers is quantified using the energy factor.

But after new mandatory Federal Standards were introduced, many US washers were manufactured to be more energy- and water-efficient than required by the federal standard, or even certified by the more stringent Energy Star standard.] Manufacturers were found to be motivated to exceed mandatory standards by a program of direct-to-manufacturer tax credits.

In North America, the Energy Star program compares and lists energy efficient clothes washers. Certified Energy Star units can be compared by their Modified Energy Factor (MEF) and Water Factor (WF) coefficients.

The MEF tells us how many cubic feet of clothes are washed per kWh (kilowatt hour) and is closely related to the configuration of the washer (top-loading, front-loading), its spin speed and the temperatures and the amount of water used in the rinse and wash cycles.

Energy Star residential clothes washers have a MEF of at least 2.0 (the higher the better), but the best machines may reach 3.5. Energy Star washers have also a WF of less than 6.0 (the lower the better)

A commercial washing machine is intended for more frequent use than a consumer washing machine. Durability and functionality is more important than style; most commercial washers are bulky and heavy, often with more expensive stainless steel construction to minimize corrosion in a constantly moist environment. They are built with large easy-to-open service covers, and washers are designed not to require access to the underside for service. Often commercial washers are installed in long rows with a wide access passageway behind all the machines to allow maintenance without moving the heavy machines.

Laundromat machines

Many commercial washers are built for use by the general public, and are installed in publicly accessible laundromats or laundrettes, operated by money accepting devices or card readers. The features of a commercial laundromat washer are more limited than a consumer washer, usually offering just two or three basic wash programs and an option to choose wash cycle temperatures.

The common front-loading commercial washing machine also differs from consumer models in its expulsion of wash and rinse water. While the consumer models pump used washer water out, allowing the waste line to be located above the washer, front loading commercial machines generally use only gravity to expel used water. A drain in the rear, at the bottom of the machine opens at the appointed time during the cycle and water flows out. This creates the need for a drainage trough behind machines, which leads to a filter and drain. The trough is usually part of a cement platform built for the purpose of raising the machines to a convenient height, and can be seen behind washers at most laundromats.

Most laundromat machines are horizontal-axis front-loading models, because of their lower operating costs (notably lower consumption of expensive hot water).

Industrial washers

By contrast, commercial washers for internal business operations (still often referred to as "washer/extractor" machines) may include features absent from domestic machines. Many commercial washers offer an option for automatic injection of five or more different chemical types, so that the operator does not have to deal with constantly measuring out soap products and fabric softeners for each load by hand. Instead, a precise metering system draws the detergents and wash additives directly from large liquid-chemical storage barrels and injects them as needed into the various wash and rinse cycles. Some computer-controlled commercial washers offer the operator control over the various wash and rinse cycles, allowing the operator to program custom washing cycles.

Most large-scale industrial washers are horizontal-axis machines, but may have front-, side-, or top-load doors. Some industrial clothes washers can batch-process up to 800 pounds (360 kg) of textiles at once, and can be used for extremely machine-abusive washing tasks such as stone washing or fabric bleaching and dyeing.

An industrial washer can be mounted on heavy-duty shock absorbers and attached to a concrete floor, so that it can extract water from even the most severely out-of-balance and heavy wash loads. Noise and vibration is not as unacceptable as in a domestic machine. It may be mounted on hydraulic cylinders, permitting the entire washer to be lifted and tilted so that fabrics can be automatically dumped from the wash drum onto a conveyor belt once the cycle is complete.

One special type of continuous-processing washer is known as the tunnel washer. This specialized high-capacity machine does not have a drum where everything being washed undergoes distinct wash and rinse cycles, but moves the laundry slowly and continuously through a long, large-diameter horizontal-axis rotating tube in the manner of an assembly line, with different processes at different positions.

Social impact

The historically laborious process of washing clothes (a task which often had a whole day set aside to perform) has at times been labelled 'woman's work'. The spread of the washing machine has been seen to be a force behind the improvement of women's position in society. In 2009 the Italian newspaper L'Osservatore Romano published a controversial article on International Women's Day arguing that the washing machine had done more for the liberation of women than the contraceptive pill and abortion rights.[103] A study from Université de Montréal, Canada presented a similar point of view, adding fridges as well.[104] The following year, Swedish statistician Hans Rosling suggested that the positive effect the washing machine had on the liberation of women, makes it "the greatest invention of the industrial revolution".[105] It has been argued that washing machines are an example of labour saving technology, which does not decrease employment because households can internalize the gains of the innovation.[106] Historian Frances Finnegan credits the rise of this technology in helping undercut the economic viability of the Magdalene Asylums in Ireland, later revealed to be inhumanly abusive prisons for women, by supplanting their laundry businesses and prompting the eventual closure of the institutions as a whole.[107]

Before the advent of the washing machine, laundry was done first at watercourses and then in public washhouses known as lavoirs. Camille Paglia and others argue that the washing machine led to a type of social isolation of women,[108] as a communal activity became a solitary one.

In India, dhobis, a caste group specialized in washing clothes, are slowly adapting to modern technology, but even with access to washing machines, many still handwash garments as well.[109] Since most modern homes are equipped with a washing machine, many Indians have dispensed with the services of the dhobiwallahs.

Environmental impact

Due to the increasing cost of repairs relative to the price of a washing machine, there has been a major increase in the number of defective washing machines being discarded, to the detriment of the environment. The cost of repair and the expected life of the machine may make the purchase of a new machine seem like the better option.

Different washing machine models vary widely in their use of water, detergent, and energy. The energy required for heating is large compared to that used by lighting, electric motors, and electronic devices. Because of their use of hot water, washing machines are among the largest consumers of energy in a typical modern home

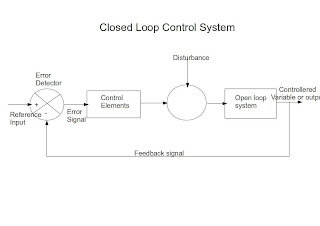

The washing machine program

All the important parts of the clothes washer are electrically controlled, including the inner drum, the valves, the pump, and the heating element. The programmer is like the conductor of an orchestra, switching these things on and off in a sensible sequence that goes something like this:

- You put your clothes in the machine and detergent either in the machine itself or in a tray up above.

- You set the program you want and switch on the power.

- The programmer opens the water valves so hot and cold water enter the machine and fill up the outer and inner drums. The water usually enters at the top and trickles down through the detergent tray, washing any soap there into the machine.

- The programmer switches off the water valves.

- The thermostat measures the temperature of the incoming water. If it's too cold, the programmer switches on the heating element. This works just like an electric kettle or water boiler.

- When the water is hot enough, the programmer makes the inner drum rotate back and forth, sloshing the clothes through the soapy water.

- The detergent pulls the dirt from your clothes and traps it in the water.

- The programmer opens a valve so the water drains from both drums. Then it switches on the pump to help empty the water away.

- The programmer opens the water valves again so clean water enters the drums.

- The programmer makes the inner drum rotate back and forth so the clean water rinses the clothes. It empties both drums and repeats this process several times to get rid of all the soap.

- When the clothes are rinsed, the programmer makes the inner drum rotate at really high speed—around 80 mph (130 km/h). The clothes are flung against the outside edge of the inner drum, but the water they contain is small enough to pass through the drum's tiny holes into the outer drum. Spinning gets your clothes dry using the same idea as a centrifuge.

- The pump removes any remaining water from the outer drum and the wash cycle comes to an end.

- You take your clothes out and marvel at how clean they are!

- But there's still the problem of drying your wet clothes to figure out.

The two drums are the most important parts of a clothes washer, but there are lots of other interesting bits too. There's a thermostat (thermometer mechanism) to test the temperature of the incoming water and a heating element that warms it up to the required temperature. There's also an electrically operated pump that removes water from the drum when the wash is over. There's a mechanical or electronic control mechanism called a programmer, which makes the various parts of the clothes washer go through a series of steps to wash, rinse, and spin your clothes. There are two pipes that let clean hot and cold water into the machine and a third pipe that lets the dirty water out again. All these pipes have valves on them (like little doors across them that open and shut when necessary).

Your machine doesn't know what you put into it and can't automatically tell how carefully to wash something like a delicate woollen jumper—because it doesn't know that's what it's got to do! The only things under its control are the amount and temperature of the water, the speed of the spin, the number of times the drum oscillates, the number of rinses, and so on. No-one wants to wash clothes in a scientific way: "I think I need 5.42 litres of water at exactly 42°C, I'll need to wash for exactly 34 minutes, and I'll need 200 spin revolutions when I'm done." That would give us literally an infinite number of possibilities, which is too much like hard work. Recognizing this, machine engineers try to make life easy by offering a few preset programs: each one uses a slightly different combination of these variables so it washes safely within the tolerance of different fabrics.

Why does that matter? All fabrics are different. A fabric like wool is immensely strong but has two big drawbacks (from the point of getting it clean): it's extremely hygroscopic (absorbs huge amounts of water) and loses its elasticity as the temperature increases. So if you're designing a washing machine to wash woollens, that's your starting point: don't allow the wool to become too hot (because the fibers will degrade and stretch too much) and don't agitate it excessively because it will stretch and not return to shape. With sturdier fabrics like denim, you can afford to bash them about in the drum much more—indeed, you must do so, because you need the agitation to get the detergent deep into the fibers and break up the dirt (and, of course, clothes made from denim are more likely to get dirtier than more delicate fabrics such as cashmere jumpers, which people treat more carefully).

Each program you find marked on a clothes washing machine is a best guess by the engineers as to how much agitation a particular garment/fabric is likely to need and how much it can put up with without getting damaged. If you were handwashing in a sink, you'd make those judgements instinctively, balancing the need to get your garment clean with the need to protect it from damage. While your brain/hands would do that without thinking, the washing machine does it with a certain wash temperature, so many agitations, so many spins, and a certain spin speed.

What's the difference between a front-loader and a top-loader?

The washing process is slightly different in front- and top-loading machines, so let's now look at each of these in a bit more detail:

In a front-loading clothes washer...

- There's a fixed outer drum (blue) and a rotating inner drum (red) with small holes around its edge. The drums are mounted on a horizontal axis.

- The inner drum is held to the frame of the machine by heavy-duty springs. That's because, when the clothes spin, they can make the drum shake violently; the springs help to absorb the vibrations.

- Hot and cold water enter through the detergent tray at the top.

- The inner drum turns back and forth. The plastic paddles on the inside (shown here by gray triangles) help to slosh the clothes through the detergent and water held by the outer drum.

- An electric motor turns the inner drum, typically using a long rubber belt (yellow).

- A heating element heats the water as necessary.

- When the wash cycle is finished, the pump sucks the water away.

- The water empties down a tube to the drain.

In a toploader...

- You lift the lid on top and drop your clothes in from above. We're looking here from one side.

- Just like in a front-loading machine, there's an outer drum (blue) and an inner drum with holes in it (red), but they're mounted about a vertical axis.

- Hot and cold water enter through pipes near the top, passing through the detergent tray and flushing the detergent into the machine.

- During the wash cycle, a large plastic agitator (green) turns around, moving your clothes through the water. Both drums remain stationary.

- The agitator is powered by an electric motor using a rubber belt.

- During the spin cycle, the same electric motor turns the inner drum (red) at high speed, throwing water through its holes into the outer drum.

- When the wash is finished, the pump drains the water from the outer drum.

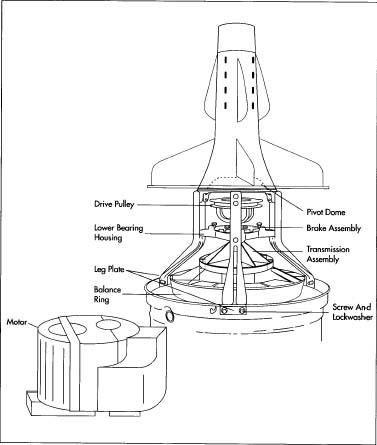

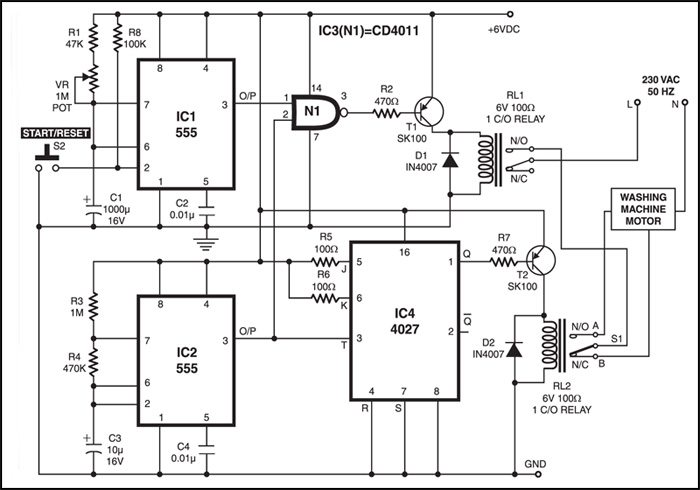

XO___XO Washing Machine

Mechanical washing machines appeared in the early 1800s, although they were all hand-powered. Early models cleaned clothes by rubbing them, while later models cleaned clothes by moving them through water. Steam-powered commercial washers appeared in the 1850s, but home washing machines remained entirely hand-powered until the early 1900s, when several companies started making electric machines. The Automatic Electric Washer Company and Hurley Machine Corporation both began selling electric washers in 1907, while Maytag offered an electric wringer washer in 1911. In 1947, Bendix offered the first fully automatic washing machine, and by 1953 spin-dry machines overtook the wringer types in popularity.

The last wringer washer manufactured in the United States was made in June of 1990 at Speed Queen's plant in Ripon, Wisconsin. The major U.S. manufacturers today are General Electric, Maytag (Montgomery Ward), Speed Queen (Amana and Montgomery Ward), Whirlpool (Kenmore), and White Consolidated (Frigidaire and Westinghouse).

Many models with many varying features are now available; however, with a few exceptions, only the controls are different. The only difference between the washer in your home and the top-load washers in the laundromat is the ruggedness of construction.