Bypassing the Transistor Paradigm

Current computer technology is based on solid state transistors, in which binary information is carried by switching current between "on" and "off" states. When these devices are shrunk to the molecular scale, they run up against fundamental physical limits, most importantly regarding energy dissipation; as a result, superdense transistor devices would melt as soon as they were switched on. In this Perspective,we discusses the advantages of an alternative route to molecular electronics, quantum-dot cellular automata , which store binary information in a charge configuration instead of a current switch.

How Electronic Components Work

Electronic gadgets have become an integral part of our lives. They have made our lives more comfortable and convenient. From aviation to medical and healthcare industries, electronic gadgets have a wide range of applications in the modern world. In fact, the electronics revolution and the computer revolution go hand in hand.

Most gadgets have tiny electronic circuits that can control machines and process information. Simply put, electronic circuits are the lifelines of various electrical appliances. This guide explains in detail about common electronic components used in electronic circuits and how they work.

In this article I will provide an overview on electronic circuits. Then I will provide more information on 7 different types of components. For each type I'll discuss the composition, how it works, and the function & significance of the component.

Electronic Circuit Overview

An electronic circuit is a structure that directs and controls electric current to perform various functions including signal amplification, computation, and data transfer. It comprises several different components such as resistors, transistors, capacitors, inductors, and diodes. Conductive wires or traces are used to connect the components to each other. However, a circuit is complete only if it starts and ends at the same point, forming a loop.

The Elements of an Electronic Circuit

The complexity and the number of components in an electronic circuit may change depending on its application. However, the simplest circuit consists of three elements, including a conducting path, a voltage source, and a load.

Element 1: Conducting Path

The electric current flows through the conducting path. Though copper wires are used in simple circuits, they are rapidly being replaced by conductive traces. Conductive traces are nothing but copper sheets laminated onto a non-conductive substrate. They are often used in small and complex circuits such as Printed Circuit Boards (PCB).

Element 2: Voltage Source

The primary function of a circuit is to allow electric current to pass through it safely. So, the first key element is the voltage source. It is a two-terminal device such as a battery, generators or power systems that provide a potential difference (voltage) between two points in the circuit so that current can flow through it.

Element 3: Load

A load is an element in the circuit that consumes power to perform a particular function. A light bulb is the simplest load. Complex circuits, however, have different loads such as resistors, capacitors, transistors, and transistors.

Electronic Circuit Facts

Fact 1: Open Circuit

As mentioned before, a circuit must always form a loop to allow the current to flow through it. However, when it comes to an open circuit, the current can’t flow as one or more components are disconnected either intentionally (by using a switch) or accidentally (broken parts). In other words, any circuit that does not form a loop is an open circuit.

Fact 2: Closed Circuit

A closed circuit is one that forms a loop without any interruptions. Thus, it is the exact opposite of an open circuit. However, a complete circuit that doesn’t perform any function is still a closed circuit. For example, a circuit connected to a dead battery may not perform any work, but it is still a closed circuit.

Fact 3: Short Circuit

In the case of short-circuit, a low-resistance connection forms between two points in an electric circuit. As a result, the current tends to flow through this newly formed connection rather than along the intended path. For example, if there is a direct connection between the battery’s negative and positive terminal, the current will flow through it rather than passing through the circuit.

However, short circuits usually lead to serious accidents as the current can flow at dangerously high levels. Hence, a short circuit can damage electronic equipment, cause batteries to explode, and even start a fire in commercial and residential buildings.

Fact 4: Printed Circuit Boards (PCBs)

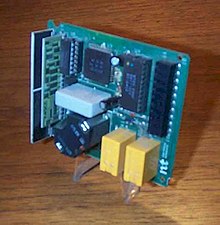

Most electronic appliances require complex electronic circuits. That’s why designers have to arrange tiny electronic components on a circuit board. It comprises a plastic board with connecting copper tracks on one side and lots of holes to affix the components. When the layout of a circuit board is printed chemically onto a plastic board, it is called a printed circuit board or PCB.

Fact 5: Integrated Circuits (ICs)

Though PCBs can offer a lot of advantages, most modern instruments such as computers and mobiles require complex circuits, having thousands and even millions of components. That’s where integrated circuits come in. They are the tiny electronic circuits that can fit inside a small silicon chip. Jack Kilby invented the first integrated circuit in 1958 at Texas Instruments. The sole purpose of ICs is to increase the efficiency of the electronic devices, while reducing their size and manufacturing cost. Over the years, integrated circuits have become increasingly sophisticated as technology continues to evolve. That’s why personal computers, laptops, mobiles phones, and other consumer electronics are getting cheaper and better by the day.

Electronic Components

Thanks to modern technology, electronic circuit building process has been completely automated, especially for building ICs and PCBs. The number and arrangement of components in a circuit may vary depending on its complexity. However, it is built using a small number of standard components.

The following components are used to construct electronic circuits.

Component 1: Capacitor

Capacitors are widely used to build different types of electronic circuits. A capacitor is a passive two-terminal electrical component that can store energy in an electric field electrostatically. In simple terms, it works as a small rechargeable battery that stores electricity. However, unlike a battery, it can charge and discharge in the split of a second.

A. Composition

Capacitors come in all shapes and sizes, but they usually have the same primary components. There are two electrical conductors or plates separated by a dielectric or insulator stacked between them. Plates are composed of conducting material such as thin films of metal or aluminum foil. A dielectric, on the other hand, is a non-conducting material such as glass, ceramic, plastic film, air, paper, or mica. You can insert the two electrical connections protruding from the plates to fix the capacitor in a circuit.

B. How Does It Work?

When you apply a voltage over the two plates or connect them to a source, an electric field develops across the insulator, causing one plate to accumulate positive charge while negative charge gets collected on the other. The capacitor continues to hold its charge even if you disconnect it from the source. The moment you connect it to a load, the stored energy will flow from the capacitor to the load.

Capacitance is the amount of energy stored in a capacitor. The higher the capacitance, the more energy it can store. You can increase the capacitance by moving the plates closer to each other or increasing their size. Alternatively, you can also enhance the insulation qualities to increase the capacitance.

C. Function and Significance

Though capacitors look like batteries, they can perform different types of functions in a circuit such as blocking direct current while allowing alternating current to pass or smooth the output from a power supply. They are also used in electric power transmission systems to stabilize voltage and power flow. One of the most significant functions of a capacitor in the AC systems is power factor correction, without which you can’t provide sufficient amount of starting torque to single phase motors.

Filters Capacitor Applications

If you are using a microcontroller in a circuit to run a specific program, you don’t want its voltage to drop as that will reset the controller. That’s why designers use a capacitor. It can supply the microcontroller with the necessary power for a split second to avoid a restart. In other words, it filters out the noise on the power line and stabilizes the power supply.

Hold-Up Capacitor Applications

Unlike a battery, a capacitor releases its charge rapidly. That’s why it is used to provide power to a circuit for a short while. Your camera batteries charge the capacitor attached to the flash gun. When you take a flash photograph, the capacitor releases its charge in a split second to generate a flash of light.

Timer Capacitor Applications

In a resonant or time-dependent circuit, capacitors are used along with a resistor or inductor as a timing element. The time required to charge and discharge a capacitor determines the operation of the circuit.

Component 2: Resistor

A resistor is a passive two-terminal electrical device that resists the flow of current. It is probably the simplest element in an electronic circuit. It is also one of the most common components as resistance is an inherent element of nearly all electronic circuits. They are usually color-coded.

A. Composition

A resistor is not a fancy device at all because resistance is a natural property possessed by almost all conductors. So, a capacitor consists of a copper wire wrapped around an insulating material such as a ceramic rod. The number of turns and the thinness of copper wire are directly proportional to the resistance. The higher the number of turns and thinner the wire, the higher the resistance.

You can also find resistors made of a spiral pattern of a carbon film. Hence, the name carbon film resistors. They are designed for lower-power circuits because carbon film resistors are not as precise as their wire-wound counterparts. However, they are cheaper than wired resistors. Wire terminals are attached to the both ends. As resistors are blind to the polarity in a circuit, the current can flow through in either direction. So, there is no need to worry about attaching them in a forward or a backward direction.

B. How Does It Work?

A resistor may not look like much. One may think it doesn’t do anything except consume power. However, it performs a vital function: controlling the voltage and the current in your circuit. In other words, resistors give you control over the design of your circuit.

When electric current starts flowing through a wire, all the electrons start moving in the same direction. It’s just like water flowing through a pipe. Less amount of water will flow through a thin pipe because there is less room for its movement.

Similarly, when the current passes through a thin wire in a resistor, it becomes progressively harder for the electrons to wiggle through it. In short, the number of electrons flowing through a resistor goes down as the length and thinness of the wire increases.

C. Function and Significance

Resistors have plenty of applications, but the three most common ones are managing current flow, dividing voltage, and resistor-capacitor networks.

Limiting the Flow of Current

If you don’t add resistors to a circuit, the current will flow at dangerously high levels. It can overheat other components and possibly damage them. For example, if you connect an LED directly to a battery, it would still work. However, after some time the LED will heat up like a fireball. It will eventually burn as LEDs are less tolerant to heat.

But, if you introduce a resistor in the circuit, it will reduce the flow of current to an optimal level. Thus, you can keep the LED on longer without overheating it.

Dividing Voltage

Resistors are also used to reduce the voltage to the desired level. Sometimes, a particular part of a circuit such as a microcontroller may need a lower voltage than the circuit itself. This is where a resistor comes in.

Let’s say your circuit runs off of a 12V battery. However, the microcontroller needs only a 6V supply. So, to divide the voltage in half, all you have to do is place two resistors of equal resistance value in series. The wire in between the two resistors will have halved the voltage of your circuit where the microcontroller can be attached. Using appropriate resistors, you can lower the voltage within the circuit to any level.

Resistor-Capacitor Networks

Resistors are also used in combination with capacitors to build ICs that contain resistor-capacitor arrays in a single chip. They are also known as RC filters or RC networks. They are often used to suppress electromagnetic Interference (EMI) or Radio Frequency Interference (RFI) in various instruments, including input/output ports of computers and laptops, Local Area Networks (LANs), and Wide Area Networks (WANs), among others. They are also used in machine tools, switchgears, motor controllers, automated equipment, industrial appliances, elevators, and escalators.

Component 3: Diode

A diode is a two-terminal device that allows electric current to flow in only one direction. Thus, it is the electronic equivalent of a check valve or a one-way street. It is commonly used to convert an Alternating Current (AC) into a Direct Current (DC). It is made either of a semiconductor material (semiconductor diode) or vacuum tube (vacuum tube diode). Today, however, most diodes are made from semiconductor material, particularly silicon.

A. Composition

As mentioned earlier, there are two types of diodes: vacuum diodes and semiconductor diodes. A vacuum diode consists of two electrodes (cathode and anode) placed inside a sealed vacuum glass tube. A semiconductor diode comprises p-type and n-type semiconductors. It is, therefore, known as a p-n junction diode. It is usually made of silicon, but you can also use germanium or selenium.

B. How Does It Work?

Vacuum Diode

When the cathode is heated by a filament, an invisible cloud of electrons, called space charge, forms in the vacuum. Though electrons are emitted from the cathode, the negative space charge repels them. As electrons can’t reach the anode, no current flows through the circuit. However, when the anode is made positive, the space charge vanishes. As a result, current starts flowing from the cathode to the anode. Thus, electric current within the diode flows only from the cathode to the anode and never from the anode to the cathode.

P-N Junction Diode

A p-n junction diode comprises p-type and n-type semiconductors of silicon. The p-type semiconductor is usually doped with boron, leaving holes (positive charge) in it. The n-type semiconductor, on the other hand, is doped with antimony, adding a few extra electrons (negative charge) in it. So, electric current can flow through both semiconductors.

When you put p-type and n-type blocks together, the extra electrons from the n-type combine with the holes in the p-type, creating a depletion zone without any free electrons or holes. In short, current can no longer pass through the diode.

When you connect the battery’s negative terminal to the n-type silicon and the positive terminal to p-type (forward-bias), current starts to flow as electrons and holes can now move across the junction. However, if you reverse the terminals (reverse-bias), no current flows through the diode because holes and electrons are pushed away from each other, widening the depletion zone. So, just like a vacuum diode, a junction diode can also allow current to pass in one direction only.

C. Function and Significance

Though diodes are one of the simplest components in an electronic circuit, they have unique applications across industries.

AC to DC Conversion

The most common and important application of a diode is the rectification of AC power to DC power. Usually, a half-wave (single diode) or a full-wave (four diodes) rectifier is used to convert AC power into DC power, particularly in household power supply. When you pass AC power supply through a diode, only half the AC waveform passes through it. As this voltage pulse is used to charge the capacitor, it produces steady and continuous DC currents without any ripples. Different combinations of diodes and capacitors are also used to build various types of voltage multipliers to multiply a small AC voltage into high DC outputs.

Bypass Diodes

Bypass diodes are often used to protect solar panels. When the current from the rest of the cells passes through a damaged or dusty solar cell, it causes overheating. As a result, the overall output power decreases, creating hot spots. The diodes are connected parallel to the solar cells to protect them against this overheating problem. This simple arrangement limits the voltage across the bad solar cell while allowing the current to pass through undamaged cells to the external circuit.

Voltage Spike Protection

When the power supply is suddenly interrupted, it produces a high voltage in most inductive loads. This unexpected voltage spike can damage the loads. However, you can protect expensive equipment by connecting a diode across the inductive loads. Depending on the type of security, these diodes are known by many names including snubber diode, flyback diode, suppression diode, and freewheeling diode, among others.

Signal Demodulation

They are also used in the process of signal modulation because diodes can remove the negative element of an AC signal efficiently. The diode rectifies the carrier wave, turning it into DC. The audio signal is retrieved from the carrier wave, a process called audio-frequency modulation. You can hear the audio after some filtering and amplification. Hence, diodes are commonly found in radios to extract the signal from the carrier wave.

Reverse Current Protection

Reversing polarities of a DC supply or incorrectly connecting the battery can cause a substantial current to flow through a circuit. Such a reverse connection can damage the connected load. That’s why a protective diode is connected in series with the positive side of the battery terminal. The diode becomes forward-biased in the case of correct polarity and the current flows through the circuit. However, in the event of a wrong connection, it becomes reverse-biased, blocking the current. Thus, it can protect your equipment from potential damage.

Component 4: Transistor

One of the most crucial components of an electronic circuit, transistors have revolutionized the field of electronics. These tiny semiconductor devices with three terminals have been around for more than five decades now. They are often used as amplifiers and switching devices. You can think of them as relays without any moving parts because they can turn something ‘on’ or ‘off’ without any movement.

A. Composition

In the beginning, Germanium was used to build transistors which were extremely temperature-sensitive. Today, however, they are made from Silicon, a semiconductor material found in the sand because Silicon transistors are much more temperature-tolerant and cheaper to manufacture. There are two different types of Bipolar Junction Transistors (BJT), NPN and PNP. Each transistor has three pins called Base (b), collector (c), and emitter (e). NPN and PNP refer to the layers of semiconductor material used to make the transistor.

B. How Does It Work?

When you sandwich a p-type silicon slab between two n-type bars, you get an NPN transistor. The emitter is attached to one n-type, while the collector is attached to the other. The base is attached to the p-type. The surplus holes in the p-type silicon act as barriers, blocking the flow of the current. However, if you apply a positive voltage to the base and the collector and negatively charge the emitter, electrons start flowing from the emitter to the collector.

The arrangement and number of p-type and n-type blocks remain inverted in a PNP transistor. In this type of transistor, one n-type is sandwiched between two p-type blocks. As voltage allocation is different, a PNP transistor works differently. An NPN transistor requires a positive voltage to the base, while a PNP requires a negative voltage. In short, the current must flow away from the base to turn a PNP transistor on.

C. Function and Significance

Transistors function as both, switches and amplifiers in most electronic circuits. Designers often use a transistor as a switch because unlike a simple switch, it can turn a small current into a much larger one. Though you can use a simple switch in an ordinary circuit, an advanced circuit may need varying amounts of currents at different stages.

Transistors in Hearing Aids

One of the most well-known applications of transistors is the hearing aid. Usually, a small microphone in the hearing aid picks up the sound waves, converting them into fluctuating electrical pulses or currents. When these currents pass through a transistor, they are amplified. The amplified pulses then pass through a speaker, converting them into sound waves once again. Thus, you can hear a substantially louder version of the surrounding noise.

Transistors in Computers and Calculators

We all know that computers store and process information using the binary language of “zero” and “one.” However, most people don’t know that transistors play a critical role in making something called logic gates, which are the backbones of computer programs. Transistors are often hooked up with logic gates to build a unique piece of an arrangement called a flip-flop. In this system, the transistor remains ‘on’ even if you remove the base current. It now flips on or off whenever new current passes through it. Thus, a transistor can store a zero when it’s off or a one when it’s on, which is the working principle of computers.

Darlington Transistors

A Darlington transistor is made of two PNP or NPN polar junction transistors placed together. It is named after its inventor Sidney Darlington. The sole purpose of a Darlington transistor is to deliver a high current gain from a low base current. You can find these transistors in instruments that require a high current gain at a low frequency such as power regulators, display drivers, motor controllers, light and touch sensors, alarm systems, and audio amplifiers.

IGBT and MOSFET Transistors

The Insulated-Gate Bipolar Transistor (IGBT) transistors are often used as amplifiers and switches in various instruments including electric cars, trains, refrigerators, air-conditioners, and even stereo systems. On the other hand, Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFET) are commonly used in integrated circuits to control a device’s power levels or for storing data.

Component 5: Inductor

An inductor, also known as a reactor, is a passive component of a circuit having two terminals. This device stores energy in its magnetic field, returning it to the circuit whenever required. It was discovered that when two inductors are placed side by side without touching, the magnetic field created by the first inductor affects the second inductor. It was a crucial breakthrough that led to the invention of the first transformers.

A. Composition

It is probably the simplest component, comprising just a coil of copper wire. The inductance is directly proportional to the number of turns in the coil. Sometimes, however, the coil is wound around a ferromagnetic material such as iron, laminated iron, and powdered iron to increase the inductance. The shape of this core can also increase the inductance. Toroidal (donut-shaped) cores provide better inductance compared to solenoidal (rod-shaped) cores for the same number of turns. Unfortunately, it is difficult to join inductors in an integrated circuit, so they are usually replaced by resistors.

B. How Does It Work?

Whenever the current passes through a wire, it creates a magnetic field. However, the unique shape of the inductor leads to the creation of a much stronger magnetic field. This powerful magnetic field, in turn, resists alternating current, but it lets direct current flow through it. This magnetic field also stores energy.

Take a simple circuit comprising a battery, a switch, and a bulb. The bulb will glow brightly the moment you turn the switch on. Add an inductor to this circuit. As soon you turn the switch on, the bulb changes from bright to dim. On the other hand, when the switch is turned off, it becomes very bright, just for a fraction of a second before turning off completely.

As you turn the switch on, the inductor starts using the electricity to create a magnetic field, temporarily blocking the current flow. But, only DC current passes through the inductor as soon as the magnetic field is complete. That’s why the bulb changes from bright to dim. All this time, the inductor stores some electrical energy in the form of magnetic field. So, when you turn the switch off, the magnetic field keeps the current in the coil steady. Thus, the bulb burns brightly for a while before turning off.

C. Function and Significance

Though inductors are useful, it is difficult to incorporate them into electronic circuits due to their size. As they are bulkier compared to other components, they add a lot of weight and occupy plenty of space. Hence they are usually replaced by resistors in integrated circuits (ICs). Still, inductors have a wide range of industrial applications.

Filters in Tuned Circuits

One of the most common applications of inductors is to select the desired frequency in tuned circuits. They are used extensively with capacitors and resistors, either in parallel or series, to create filters. The impedance of an inductor increases as the frequency of signal increases. Thus, a stand-alone inductor can only act as a low-pass filter. However, when you combine it with a capacitor, you can create a notched filter because the impedance of a capacitor decreases as the frequency of signal increase. So, you can use different combinations of capacitors, inductors, and resistors to create various types of filters. They are found in most electronics including televisions, desktop computers, and radios.

Inductors as Chokes

If an alternate current flows through an inductor, it creates an opposite current flow. Thus, it can convert an AC supply into a DC. In other words, it chokes the AC supply but allows the DC to pass through it, hence the name ‘choke.’ Usually, they are found in power supply circuits that need to convert AC supply to DC supply.

Ferrite Beads

A ferrite bead or ferrite choke is used to suppress high-frequency noise in electronic circuits. Some of the common uses of ferrite beads include computer cables, television cables, and mobile charge cables. These cables can, sometimes, act as antennas, interloping with audio and video output of your television and computer. So, inductors are used in ferrite beads to reduce such radio frequency interference.

Inductors in Proximity Sensors

Most proximity sensors work on the principle of inductance. An inductive proximity sensor comprises four parts including an inductor or coil, an oscillator, a detection circuit and an output circuit. The oscillator generates a fluctuating magnetic field. Whenever an object comes into the proximity of this magnetic field, eddy currents start to build up, reducing the sensor’s magnetic field.

The detection circuit determines the strength of the sensor, while output circuit triggers the appropriate response. Inductive proximity sensors, also called contactless sensors, are cherished for their reliability. They are used at traffic lights to detect the traffic density and also as parking sensors in cars and trucks.

Induction Motors

An induction motor is probably the most common example of the application of inductors. Usually, in an induction motor, inductors are placed in a fixed position. In other words, they are not allowed to align with the nearby magnetic field. An AC power supply is used to create a rotating magnetic field which then rotates the shaft. The power input controls the speed of rotation. Hence, inductions motors are often used in fixed speed applications. The induction motors are very reliable and robust because there is no direct contact between the motor and the rotor.

Transformers

As mentioned earlier, the discovery of inductors led to the invention of transformers, one of the fundamental components of power transmission systems. You can create a transformer by combining the inductors of a shared magnetic field. They are usually used to increase or decrease voltages of the power lines to the desired level.

Energy Storage

Just like a capacitor, an inductor can also store energy. However, unlike a capacitor, it can store energy for a limited time. As the energy is stored in a magnetic field, it collapses as soon as the power supply is removed. Still, inductors function as reliable energy storage device in switch mode power supply such as desktop computers.

Component 6: Relay

A relay is an electromagnetic switch that can open and close circuits electromechanically or electronically. You need a relatively small current to operate a relay. Usually, they are used to regulate low currents in a control circuit. However, you can also use relays to control high electric currents. A relay is the electrical equivalent of a lever. You can switch it on with a small current to turn on (or leverage) another circuit using large current. Relays are either electromechanical relays or solid-state relays.

A. Composition

An Electromechanical Relay (EMR) comprises a frame, coil, armature, spring, and contacts. The frame supports various parts of the relay. The armature is the moving part of a relay switch. A coil (mostly copper wire), wound around a metal rod generates a magnetic field that moves the armature. Contacts are the conducting parts that open and close the circuit.

A Solid-State Relay (SSR) consists of an input circuit, a control circuit, and an output circuit. The input circuit is the equivalent of a coil in an electromechanical relay. The control circuit acts as a coupling device between input and output circuits, while the output circuit performs the same function as the contacts in an EMR. Solid-state relays are becoming increasingly popular as they are cheaper, faster, and reliable compared to electromechanical relays.

B. How Does It Work?

Whether you are using an electromechanical relay or a solid-state relay, it is either a Normally Closed (NC) or a Normally Opened (NO) relay. In case of an NC relay, the contacts remain closed when there is no power supply. However, in a NO relay, the contacts remain open when there is no power supply. In short, whenever current flows through a relay, the contacts will either open or close shut.

In an EMR, power supply energizes the relay coil, creating a magnetic field. The magnetic coil attracts a ferrous plate mounted on the armature. When the current stops, the armature is released into its resting position by spring action. An EMR can also have single or multiple contacts within a single package. If a circuit uses only one contact, it is called a Single Break (SB) circuit. A Double Break Circuit (DB), on the other hand, comes with tow contacts. Usually, single break relays are used to control low power devices such as indicator lamps, while double break contacts are used to regulate high-power devices such as solenoids.

When it comes to operating an SSR, you need to apply a voltage higher than the specified pickup voltage of the relay to activate the input circuit. You have to apply a voltage less than the stipulated minimum dropout voltage of the relay to deactivate the input circuit. Control circuit transfers the signal from the input circuit to the output circuit. The output circuit switches on the load or performs the desired action.

C. Function and Significance

As they can control a high current circuit by a low current signal, most control processes use relays as the primary protection and switching devices. They can also detect fault and irregularities occurring in the power distribution systems. Typical applications include telecommunication, automobiles, traffic control systems, home appliances, and computers among others.

Protective Relays

Protective relays are used to trip or isolate a circuit if any irregularities are detected. Sometimes, they can also set off alarms when a fault is detected. Types of protection relays depend on their function. For example, an overcurrent relay is designed to identify the current exceeding a predetermined value. When such current is detected, the relay operates tripping a circuit breaker to protect the equipment from potential damage.

A distance relay or impedance relay, on the other hand, can detect abnormalities in the ratio of current and voltage rather than monitoring their magnitude independently. It swarms into action when the V/I ratio falls below a predetermined value. Usually, protective relays are used to protect equipment such as motors, generators, and transformers, and so on.

Automatic Reclosing Relay

An automatic reclosing relay is designed to cause multiple reclosures of a circuit breaker that is already tripped by a protective relaying. For example, when there is a sudden voltage drop, the electrical circuit in your home may experience several brief power outages. These outages occur because a reclosing relay is trying to switch on the protective relay automatically. If it succeeds the power supply will be restored. If not, there will be a complete blackout.

Thermal Relays

The thermal effect of electrical energy is the working principle of a thermal relay. In short, it can detect the rise the ambient temperature and switch on or off a circuit accordingly. It consists of a bimetallic strip which heats up if an overcurrent passes through it. The heated strip bends and closes the No contact, tripping the circuit breaker. The most common application of thermal relay is overload protection of electric motor.

Component 7. Quartz Crystal

Quartz crystals have several applications in the electronics industry. However, they are mostly used as resonators in electronic circuits. Quartz is a naturally occurring form of silicon. However, it is now produced synthetically to meet the growing demand. It exhibits the piezoelectric effect. If you apply physical pressure on one side, the resulting vibrations generate an AC voltage across the crystal. Quartz crystal resonators are available in many sizes according to the required applications.

A. Composition

As mentioned earlier, quartz crystals are either synthetically manufactured or occur naturally. They are often used to make crystal oscillators to create an electrical signal with a precise frequency. Usually, the shape of quartz crystals is hexagonal with pyramids at ends. However, for practical purposes, they are cut into rectangular slabs. The most common types of cutting formats include X cut, Y cut, and AT cut. This slab is placed between two metal plates called holding plates. The outer shape of a quartz crystal or crystal oscillator can be cylindrical, rectangular or square.

B. How Does It Work?

If you apply an alternating voltage to a crystal, it causes mechanical vibrations. The cut and the size of the quartz crystal determine the resonant frequency of these vibrations or oscillations. Thus, it generates a constant signal. Quartz oscillators are cheap and easy to manufacture synthetically. They are available in the range from a few KHz to a few MHz. As they have a higher quality factor or Q factor, crystal oscillators are remarkably stable with respect to time and temperature.

C. Function and Significance

The exceptionally high Q factor enables you to use quartz crystals and the resonant element in oscillators as well as filters in electronic circuits. You can find this highly reliable component in radio frequency applications, as oscillator clock circuits in microprocessor boards, and as a timing element in digital watches as well.

Quartz Watches

The problem with traditional coil spring watches is that you have to keep winding the coil periodically. Pendulum watches, on the other hand, depend on the force of gravity. Thus, they tell time differently at different sea levels and altitudes due to changes in the gravitational force. The performance of quartz watches, however, is not affected by any of these factors. Quartz watches are battery-powered. Usually, a tiny crystal of quartz regulates the gears that control the second, the minute, and the hour hands. As quartz watches use very little energy, the battery can often last longer.

Filters

You can also use quartz crystals in an electronic circuit as filters. They are often used to filter out unwanted signals in radios and microcontrollers. Most basic filters consist of a single quartz crystal. However, advanced filters may comprise more than one crystal to match the performance requirements. These quartz crystal filters are far superior to the ones manufactured using LC components.

Conclusion

From communicating with your loved ones living across continents to making a hot cup of coffee, electronic gadgets touch almost every aspect of our lives. However, what makes these electronic gadgets finish seemingly time-consuming tasks in just a few minutes? Tiny electronic circuits are the foundation of all electronic equipment.

Bypass Caps: Decouple Your Way to Cleaner Power

In modern electronics it is rare to encounter electronics with few active components. Increasing IC counts in circuits introduces interesting design challenges. In this post we will discuss bypass capacitors and their role in preventing noise and voltage glitches on power supply rails.

All ICs need power which for most applications is supplied from a single voltage regulator. Powering multiple chips from a single regulator is not as simple as dropping your chips on a PCB and connecting them to the power supply. ICs do not present a constant load on the power supply, instead they have varying loads depending on their function. Since the voltage regulator’s job is to keep its output voltage constant, variations in the load will represent themselves as changing current.

Lets take a look at some hypothetical (and highly exaggerated) examples of different chips and the current waveforms they demand from the power supply.

Figure 1: Hypothetical current waveforms for various integrated circuits

LED Driver: Differing current levels when IC Turns on LEDs

Microcontroller: Current spikes corresponding to the clock frequency

Opamp: Current is proportional to the load it drives

It is not uncommon for a circuit to have a single voltage regulator supplying the example chips above and more. As the complexity of a circuit increases, so does the complexity of the load presented on the power supply.

THE PROBLEM:

So what happens when we connect all of these chips to the same power supply? Lets take a look at a theoretical PCB to find out.

Figure 2: Example PCB

This example PCB shows a voltage regulator which supplies power to the the three chips mentioned above. Power traces are shown in green stemming from the voltage regulator. (All other traces are not shown for clarity).

In any circuit there will inevitably be some distance between the voltage regulator and the chips that it provides power to. In an ideal world, the copper traces that span the distance between the regulator and ICs would have no impedance and act as a short circuit. In reality, all traces will exhibit some non-zero impedance and will have an impact on the trace voltage when current flows through them.

Considering the current waveforms presented above, as they pass through the impedance of the traces they induce voltage spikes or noise (remember ohm’s law?). This noise is not due to the voltage regulator or the traces picking up stray electromagnetic waves in the environment, but simply due to the chips pulling the current they need to operate – something that they are supposed to do!

To make matters worse, the way traces are routed on the PCB can compound the issue. On our example pcb, the current that supplies all three ICs is forced to pass through a single trace before splitting into individual traces to the chips. Because the current for all three chips pass through this one segment, the induced noise on this trace is the sum of the induced voltages. The voltage noise that is induced on the trace is then at risk of being coupled into our ICs and potentially anything further down the line.

Figure 3: Example PCB – All IC current flowing through one trace

In this example with only three chips and it is easy to see how this can become an issue. Imagine what would happen if we had more chips pulling more complex current waveforms? It is certainly possible for the induced noise on a power supply line to become large enough to compromise the performance of some if not all of the ICs connected to the supply or the components that are connected themselves to the ICs.

THE SOLUTION:

Luckily, the solution to this problem is both cheap and simple. By placing a low impedance path connected to the traces that feed power to the ICs we can create a filter that “bypasses” or “decouples” noise on the supply line. The easiest way to accomplish this is to add a capacitor across the power supply + and – lines. These capacitors are typically called bypass capacitors for reasons that will become clear soon.

Below is an image of a schematic showing a bypass capacitor connected across the power supply lines near an IC.

Figure 4: Schematic representation of bypass cap

Let’s take a look at the effects of a bypass capacitor on the transient current flowing into this IC.

Figure 5: Current loop with and without bypass cap

The image on the left shows the flow of current in a circuit that has no bypass cap on the IC. Any transient spikes in current will be subjected to any impedance on the traces and can cause problematic voltage droops or noise.

The image on the right shows the same circuit with a bypass capacitor installed across the power supply lines near the IC. Since the capacitor has the ability to source large currents quickly, the transients can be supplied directly from the capacitor instead of having to be sourced from the power supply. This can be seen with the current loop on the right in red. The addition of this capacitor helps “bypass” the transient current spikes from the voltage regulator and helps keep the voltage on the traces steady by sourcing the quick current transients.

By acting as a local transient current source, the capacitor prevents noise and voltage glitches from being coupled into other ICs that are connected on the power supply traces. Because of this, the capacitors are often called “decoupling capacitors” in addition to the name “bypass capacitor” since they decouple the current demands of one component in the circuit from the rest of the circuit.

It is important to note that the names “decoupling capacitor” and “bypass capacitor” were given to describe the function of the capacitors in the circuit and not a specific part. There are no capacitors that are specifically called decoupling caps or bypass caps as any cap can perform the function although some caps are more suited to the job than others as we will explore later.

LAYOUT CONSIDERATIONS:

Bypass caps should always be placed as close to the power pins as possible. Since the intent of the cap is to provide as low of an impedance path as possible and to decouple the current path for transients, keeping the traces from the cap to the IC short is very important. Every power pin on an IC should be bypassed with its own unique cap.

Figure 6: Example bypass cap layout

BYPASS CAP VALUE AND SIZE:

Considering the impedance of the traces on the PCB, the input impedance of the IC, and the operating frequency of the IC, an optimal value of bypass capacitor does exist but going through the rigors of calculating the value is rarely useful or necessary. In many cases the datasheet for an IC will give a recommended value for the capacitor. If no value is suggested, 0.1uF (100nF) is widely accepted as a standard go-to value. For most designs, a standard ceramic 0402, 0603, or 0805 package size will typically work well as a bypass cap.

RECAP

Bypass capacitors are an absolute must to avoid issues with noise on power supply traces and cross talk between devices on a PCB. Every IC in your designs should have bypass caps placed close to their power pins to provide low impedance paths for reducing the impact of current transients.

XO ___XO Control systems

Introduction

An instrumented control system is an electrical, electronic, or programmable electronic system (E/E/PES) which may perform some or all of the following functions:

- Monitoring, recording and logging of plant status and process parameters;

- Provision of operator information regarding the plant status and process parameters;

- Provision of operator controls to affect changes to the plant status;

- Automatic process control and batch/sequence control during start-up, normal operation, shutdown, and disturbance. i.e. control within normal operating limits;

- Detection of onset of hazard and automatic hazard termination (i.e. control within safe operating limits), or mitigation;

- Prevention of automatic or manual control actions which might initiate a hazard.

These functions are normally provided by, alarm, protection (trip, interlocks and emergency shutdown), and process control systems.

These engineered systems are individually and collectively described as control systems, and may be independent, or share elements such as the human interface, plant interface, logic, utilities, environment and management systems.

The human interface may comprise a number of input and output components, such as controls, keyboard, mouse, indicators, annunciators, graphic terminals, mimics, audible alarms, and charts.

The plant interface comprises inputs (sensors), outputs (actuators), and communications (wiring, fibre optic, analogue/digital signals, pneumatics, fieldbus, signal conditioning, barriers, and trip amplifiers).

The logic elements may be distributed, and linked by communications, or marshalled together and may be in the form of relays, discrete controllers or logic (electronic, programmable or pneumatic), distributed control systems (DCS), supervisory control and data acquisition (SCADA), computers (including PCs), or programmable logic controllers (PLC). The logic elements may perform continuous control functions, or batch or change of state (e.g. start-up/shut-down) sequences. It should also be noted that logic functions may be distributed to be undertaken within smart sensors or actuators.

Utilities are the power supplies and physical elements required for the systems, such as electricity and instrument air.

Environment is the physical accommodation and surroundings in which the control systems (including the operator) are required to work, including physical accommodation or routings, environmental conditions (humidity, temperature, flammable atmospheres), and external influences such as electromagnetic radiation and hazards which might affect the operation of the control system during normal or abnormal conditions such as fire, explosion, chemical attack etc.

Modern instrumented control systems are generally electrical, electronic or programmable electronic systems (E/E/PES), but some purely pneumatic systems may still be in operation.

Safety related systems

A control system or device is deemed to be safety related if it provides functions which significantly reduce the risk of a hazard, and in combination with other risk reduction measures, reduces the overall risk to a tolerable level, or if it is required to function to maintain or achieve a safe state for the equipment under control (EUC).

These functions are known as the safety functions of the system or device and are the ability to prevent initiation of a hazard or detect the onset of a hazard, and to take the necessary actions to terminate the hazardous event, achieve a safe state, or mitigate the consequences of a hazard.

All elements of the system which are required to perform the safety function, including utilities, are safety related, and should be considered part of the safety related system.

Safety related control systems may operate in low demand mode, where they are required to carry out their safety function occasionally (not more than once/year) or in high demand (more than once/year) or continuous mode where failure to perform the required safety function will result in an unsafe state or place a demand on another protective system. The likelihood of failure of a low demand system is expressed as probability of failure on demand, and as failure rate per hour for high/continuous demand systems.

Safety related control systems operating in continuous or high demand mode where the E/E/PES is the primary risk reduction measure have been known as HIPS (high integrity protective systems). However, use of such systems does not circumvent the need for a hierarchical approach to risk reduction measures such as inherent safety, and careful consideration of prevention of common mode failures by use of diverse technology and functionality (such as relief valves), independent utilities and maintenance and test procedures, physical separation, and external risk reduction (such as bunds). Measures should favour simple technological solutions rather than complex ones. The lowest failure rate which can be claimed for high integrity systems operating in continuous or high demand mode is 10-9 dangerous failures per hour.

It should be noted that control systems for equipment under control which are not safety related as defined above may also contribute to safety and should be properly designed, operated and maintained. Where their failure can raise the demand rate on the safety related system, and hence increase the overall probability of failure of the safety related system to perform its safety function, then the failure rates and failure modes of the non-safety systems should have been considered in the design, and they should be independent and separate from the safety related system.

A control system operating in continuous or high demand mode, for which a failure rate of less than 10-5/hr is claimed in order to demonstrate a tolerable risk, provides safety functions, and is safety related.

In some circumstances, the safety function may require the operator to take action, in which case, he/she is part of the safety related system and will contribute significantly to the probability of failure on demand (PFD). Typically, in a well designed system, a figure of 10-1 is assumed for the probability of an operator failing to take correct action on demand. Where exceptional care has been taken in design of human factors such as alarm management, instructions and training, and where such arrangements are monitored and reviewed, then a probability of failure on demand of not better than 10-2 may be achievable. Any supporting hardware or software, such as alarm systems, would also need the requisite integrity level).

| System | Claimed failure rate or probability of failure on demand |

|---|---|

| Non-safety related system | Not better than 10-5/hr |

| Operator action | 10-1/demand (typical)

10-2/demand (best)

|

| High integrity protective system | Not better than 10-9/hr |

System integrity

The integrity required of a safety related system depends upon the level of risk reduction claimed for the safety function to be performed.

Safety integrity is the probability that safety related system will satisfactorily perform the required safety function under all stated conditions within a stated period of time when required to do so.

Safety integrity is therefore a function of performance and availability.

Performance is the ability of the system or device to perform the required safety function in a timely manner under all relevant conditions so as to achieve the required state.

Availability is the measure of readiness of the system to perform the required safety function on demand, and is usually expressed in terms of probability of failure on demand.

Performance and availability depend on:

- Proper design or selection, installation and maintenance and testing of the plant interfaces, including sensors actuators and logic, for the required duty and full range of process and environmental conditions under which they will be required to operate, including, where necessary, any excursions beyond the safe operating limits of the plant;

- Accuracy and repeatability of the instrumentation;

- Speed of response of the system;

- Adequate margins between normal and safe operating limits and the system settings;

- Reliability;

- Survivability from the effects of the hazardous event or other external influences such as power system failure or characteristics, lightning, electromagnetic radiation (EMR), flammable, corrosive or humid atmospheres, temperature, rodent attack, vibration physical impact, and other plant hazards;

- Independence (the ability of the system to act alone, without dependence on other protective measures, control systems or common utilities or to be influenced by them.

The following measures are required to ensure adequate performance and availability of the safety related system:

- Protection against random failures by hardware reliability, fault tolerance (e.g. by redundancy) and fault detection (diagnostic coverage, and proof testing);

- Protection against systematic and common mode failures by a properly managed safety lifecycle, independence from common utilities, common management systems and other protective systems, and by diversity. The lifecycle includes hazard and risk evaluation, specification, design, validation, installation, commissioning, operation, maintenance, and modification and are detailed in BS IEC 61508.

Integrity levels

History

Historically, little industry guidance has been available for qualifying or quantifying safety integrity levels to achieve to achieve a requisite risk reduction.

Guidance related to determination of suitable integrity of programmable electronic systems in terms of configuration, reliability (quantitative and qualitative), and quality has been available in the HSE document Programmable Electronic Systems in safety related applications (PES 1 and 2) since 1987.

Additional guidance has also been available in EEMUA 160 Safety related instrument systems for the process industries.

However, most major companies will have developed internal standards which relate safety related system integrity to required risk reduction. These standards are likely to address the design process, system configuration, and demonstration that the required risk reduction has been achieved by qualitative or quantitative analysis of the failure rate of the design. They will also have procedures to ensure that the integrity is maintained during commissioning, operation, maintenance, and modification.

The latest applicable standard is BS IEC 61508 ‘Functional safety of electrical/electronic/programmable electronic safety-related systems’ which is in 7 parts. Parts 1, 3, 4, are published as British Standards, Part 5 is issued as an international IEC standard, and Parts 2, 6 and 7 remain in draft form.

Underlying philosophy

Integrity levels for safety related systems may be determined from the hazard and risk analysis of the equipment under control. A number of different methodologies are available, but the process includes identification of hazards and the mechanisms which can initiate them, risk estimation (likelihood of occurrence), and risk evaluation (overall risk based on likelihood and consequences). The risk estimation provides a measure of the risk reduction required to reduce the risk to a tolerable level.

Hazard identification results in the identification of safety functions which are required to control the risk.

The safety functions may then be allocated to a number of different systems including E/E/PES, other technology and external measures.

For each system providing a safety function, a failure rate measure can be assigned which in turn determines the integrity required of the system. alternatively, a qualitative approach (based on the likelihood and consequence of the hazard, and the frequency and level of exposure and avoidability) may be used to define the required integrity.

Safety Integrity Levels

IEC 61508 assigns four software and hardware safety integrity levels (SILs) to required measures of risk reduction. Guidance is then provided on the system configuration, level of subsystem fault tolerance and diagnostic coverage, and safety life-cycle measures required to achieve the designated hardware SIL, and the software methods and life-cycle measures required to achieve the designated software SIL. It also provides guidance on qualitative methods for establishing the SIL level required. Part 2 of the standard places architectural constraints on the hardware configuration by setting minimum fault tolerance and diagnostic coverage requirements for each element or subsystem. It should be noted that IEC 61508 limits the risk reductions which can be claimed for a safety related E/E/PES which operated in low demand mode or continuous mode to no better than 10-6 and 10-9 respectively for SIL4.

The requirement is more demanding for subsystems which do not have well defined behaviour modes or behaviour (e.g. programmable systems). The standard requires that a reliability model of the system architecture be created and the reliability predicted and compared with the target safety integrity level to confirm that the required risk reduction has been achieved.

It is necessary to demonstrate that the required level of integrity has been achieved in the design, installation, operation and maintenance of the system.

It should be noted that the integrity of a safety related system is critically dependant upon the detection and correction of dangerous failures. Where there is a low level of diagnostic coverage, as is usually the case with lower integrity systems, then the integrity is critically dependent upon the proof test interval. Where there is a high level of diagnostic coverage to automatically reveal failures on-line, for example for high demand high integrity systems, then the integrity is also heavily dependant upon the frequency of diagnostic checks, and the mean time to repair the equipment, which includes the diagnostic test interval.

SIL levels are now being quoted for proprietary subsystems (and certified by test bodies). Quoted SILs should be associated with proof test intervals, diagnostic coverage and fault tolerance criteria. They are useful for evaluation of architectural constraints, but do not eliminate the requirement to confirm that the requires safety integrity level for the safety function provided by the system has been achieved. Software includes high level user application programmes and parameter settings.

Alarm systems

Alarm systems alert operators to plant conditions, such as deviation from normal operating limits and to abnormal events, which require timely action or assessment.

Alarm systems are not normally safety related, but do have a role in enabling operators to reduce the demand on the safety related systems, thus improving overall plant safety.

However, where a risk reduction of better than 10-1 failures on demand is claimed then the alarm system, including the operator, is a safety related system which requires a suitable safety integrity level (SIL 1 or SIL 2 as defined by BS IEC61508).

EEMUA 191 ‘Alarm systems - a guide to design, management and procurement’ considers alarm settings, the human interface (alarm presentation), alarm processing and system management controls for both safety related and other alarm systems. It provides the following guidance in regard to safety related alarm systems:

- The alarm system should be designed in accordance with IEC 61508 to SIL 1 or 2, with the designated reliability;

- The alarm system should be independent from the process control system and other alarms unless it has also been designated safety related;

- The operator should have a clear written alarm response procedure for each alarm which his simple, obvious and invariant, and in which he is trained;

- The alarms should be presented in an obvious manner, distinguishable from other alarms, have the highest priority, and remain on view at all times when it is active;

- The claimed operator workload and performance should be stated and verified.

Alarms which are not designated as safety should be carefully designed to ensure that they fulfil their role in reducing demands on safety related systems.

For all alarms, regardless of their safety designation, attention is required to ensure that under abnormal condition such as severe disturbance, onset of hazard, or emergency situations, the alarm system is remains effective given the limitations of human response. The extent to which the alarm system survives common cause failures, such as a power loss, should also be adequately defined.

Further guidance is available in EEMUA 191 ‘Alarm systems - a guide to design, management and procurement’, and CHID circular CC/Tech/Safety/9.

Alarm settings

The type of alarm and its setting should be established so as to enable the operator to make the necessary assessment and take the required timely action. Settings should be documented and controlled in accordance with the alarm system management controls.

Human interface (alarm presentation)

The human interface should be suitable. Alarms may be presented either on annunciator panel, individual indicators, VDU screen, or programmable display device.

Alarms lists should be carefully designed to ensure that high priority alarms are readily identified, that low priority alarms are not overlooked, and that the list remains readable even during times of high alarm activity or with repeat alarms.

Alarms should be prioritised in terms of which alarms require the most urgent operator attention.

Alarms should be presented within the operators field of view, and use consistent presentation style (colour, flash rate, naming convention).

Each alarm should provide sufficient operator information for the alarm condition, plant affected, action required, alarm priority, time of alarm and alarm status to be readily identified.

The visual display device may be augmented by audible warnings which should at a level considerably higher than the ambient noise at the signal frequency. Where there are multiple audible warnings, they should be designed so that they are readily distinguished from each other and from emergency alarm systems. They should be designed to avoid distraction of the operator in high operator workload situations. Where both constant frequency and variable frequency (including pulsed or intermittent) signals are used, then the later should denote a higher level of danger or a more urgent need for intervention.

Alarm processing

The alarms should be processed in such a manner as to avoid operator overload at all times (alarm floods). The alarm processing should ensure that fleeting or repeating alarms do not result in operator overload even under the most severe conditions. A number of alarm processing techniques include filtering, deadband, debounce timers, and shelving, are described in EEMUA 191 ‘Alarm systems - a guide to design, management and procurement’.

The presentation of alarms should not exceed that which the operator is capable of acting upon, or alternatively the alarms should be prioritised and presented in such a way that the operator may deal with the most important alarms without distraction of the others. Applicable alarm processing techniques include grouping and first-up alarms, eclipsing of lower grade alarms (e.g. suppression high alarm when the high-high activates) suppression of out of service plant alarms, suppression of selected alarms during certain operating modes, automatic alarm load shedding and shelving.

Care should be taken in the use of shelving or suppression to ensure that controls exist to ensure that alarms are returned to an active state when they are relevant to plant operation.

Alarm system management procedures

Management systems should be in place to ensure that the alarm system is operated, maintained and modified in a controlled manner. Alarm response procedures should be available, and alarm parameters should be documented.

The performance of the alarms system should be assessed and monitored to ensure that it is effective during normal and abnormal plant conditions. The monitoring should include evaluation of the alarm presentation rate, operator acceptance and response times, operator workload, standing alarm count and duration, repeat or nuisance alarms, and operator views of operability of the system. Monitoring may be achieved by regular and systematic auditing.

Matters which are not worthy of operator attention should not be alarmed.

Logging may be a suitable alternative for engineering or discrepancy events to prevent unnecessary standing alarms. A system for assessing the significance of such logged events to ensure timely intervention by maintenance personnel may be required.

Protection systems (Trips and Interlocks)

Protective tripping systems provide a defence against excursions beyond the safe operating limits by detecting a excursions beyond set points related to the safe operating limits (i.e. the onset of a hazard) and taking timely action to maintain or restore the equipment under control to a safe state. Trips should not be self resetting unless adequate justification has been made. Protective interlocks prevent those control actions which might initiate a hazard from being undertaken by an operator or process control system, and are by nature self-resetting.

Protection systems should indicate that a demand to perform a safety function has been made and that the necessary actions have been performed.

Independence

Protective systems should be sufficiently independent of the control system or other protective systems (electrical/electronic or programmable). Where there is an interface between systems (e.g. for indication, monitoring or shared components) or shared utilities (e.g. power), environment (e.g. accommodation, wiring routes) or management systems (maintenance procedures, personnel), then the method of achieving independence should be defined, and common cause failures adequately considered.

Measures to defend against common mode failures due to environmental interactions may include physical separation or segregation of system elements (sensors, wiring, logic, actuators or utilities) of different protective systems.

Independence will also be required for protection against systematic and common mode faults. Measures may include use of diverse technology for different protective systems. Where more than one E/E/PES protective system is used to provide the required risk reduction for a safety function, then adequate independence should be achieved by diverse technology, construction, manufacturer or software as necessary to achieve the requires safety integrity level.

Dependence on utilities

The action required from the protective system depend upon the nature of the process. The actions may be passive in nature, such as simple isolation of plant or removal of power, or they may be active in that continued or positive action is required to maintain or restore a safe state, for example by injection of inhibitor into the process, or provision of emergency cooling.

Active protective measures have a high dependence upon utilities, and may be particularly vulnerable to common mode failures. The scope of the protective system therefore includes all utilities upon which it depends, and they should have an integrity consistent and contributory to that of the remainder of the system.

Measures taken to defend against common mode failure of utilities will be commensurate with the level of safety integrity required, but may include standby or uninterruptable/reservoir supplies for electricity, air, cooling water, or other utilities essential for performance of the safety function. Such measures should themselves be of sufficient integrity.

Survivability and external influences

The protective system should be adequately protected against environmental influences, the effects of the hazard against which it is protecting, and other hazards which may be present. Environmental influences include power system failure or characteristics, lightning (BS 6651), electromagnetic radiation (EMR) (BS 6667, IEC 61000), flammable atmospheres (BS 5345, BS EN 60079, BS 6467, BS 7535, BS EN 50281), corrosive or humid atmospheres, ingress of water or dust (BS EN 60529), temperature, rodent attack, chemical attack, vibration physical impact, and other plant hazards.

Degradation of protection against environmental influences during maintenance and testing should have been considered and appropriate measures taken. e.g. Use of radios by maintenance personnel may be prohibited during testing of a protective system with the cabinet door open where the cabinet provides protection against EMR.

Protection against random hardware faults

The architecture of the protective system should be designed to protect against random hardware failure. It should be demonstrated that the required reliability has been achieved commensurate with the require integrity level. Defensive measures may include high reliability elements, automatic diagnostic features to reveal faults, and redundancy of elements (e.g. 2 out of 3 voting for sensors) to provide fault tolerance.

Protection common mode failures

Diversity of elements is not effective for protection against random hardware faults, but is useful in defence against common mode failures within a protective system.

Protection systematic failures

Protection against systematic hardware and software failures may be achieved by appropriate safety lifecycles (see IEC 61508, Out of Control).

Sensing

Sensors include their connection to the process, both of which should be adequately reliable. A measure of their reliability is used in confirming the integrity level of the protective system. This measure should take into account the proportion of failures of the sensor and its process connection which are failures to danger.

Dangerous failures can be minimised by a number of measures such as:

- Use of measurement which is as direct as possible, (e.g. pneumercators provide an inferred level measurement but actually measure back pressure against a head and are sensitive to changes in density due to temperature variations within the process, and to balance gas flow, upon which they are dependant);

- Control of isolation or bleed valves to prevent uncoupling from the process between proof tests or monitoring such that their operation causes a trip;

- Use of good engineering practice and well proven techniques for process connections and sample lines to prevent blockage, hydraulic locking, sensing delays etc.;

- Use of analogue devices (transmitters) rather than digital (switches);

- Use of positively actuated switches operating in a positive mode together with idle current (de-energise to trip);

- Appropriate measures to protect against the effects of the process on the process connection or sensor, such as vibration, corrosion, and erosion;

- Monitoring of protective system process variable measurement (PV) and comparison against the equivalent control system PV either by the operator or the control system.

Guidance on process connection is provided in BS 6739 British Standard Code of practice for instrumentation in process control systems: Installation design and practice.

Proof testing procedures should clearly set out how sensors are reinstated and how such reinstatement is verified after proof testing.

Maintenance procedures should define how sensors/transmitters are calibrated with traceability back to national reference standards by use of calibrated test equipment.

Other matters which will need to have been considered are:

- Cross sensitivities of analysers to other fluids which might be present in the process;

- Reliability of sampling systems;

- Protection against systematic failures on programmable sensors/analysers. The measures taken will depend on the level of variability and track record of the software. ‘Smart’ transmitters with limited variability software which are extensively proven in use may require no additional measures other than those related to control of operation, maintenance, and modification, whereas bespoke software for an on-line analyser may require a defence in depth against systematic failures (BS IEC 61508 Part 3);

- Signal conditioning (e.g. filtering) and which may affect the sensor response times;

- Degradation of measurement signals (distance between sensor and transmitter may be important);

- Accuracy, repeatability, hysteresis and common mode effects (e.g. effects of gauge pressure or temperature on differential pressure measurement);

- Integrity of process connections and sensors for containment (sample or impulse lines, instrument pockets are often a weak link in process containment measures).

Use of ‘SMART’ instruments requires adequate diagnostic coverage and fault tolerance (see architectural constraints in IEC 61508 Part 2), and measures to protect against systematic failures (software design/integration, inadvertent re-ranging during maintenance). Measures may include use of equipment in non-smart mode (analogue signal output, no remote setting) and equipment of stable design for which there is an extensive record of reliability under similar circumstances.

Actuators and signal conversion

Actuators are the final control elements or systems and include contactors and the electrical apparatus under control, valves (control and isolation), including pilots valves, valve actuators and positioners, power supplies and utilities which are required for the actuator to perform its safety function, all of which should be adequately reliable. A measure of their reliability is used in confirming the integrity level of the protective system. This measure should take into account the proportion of failures of the actuator under the relevant process conditions which are failures to danger.

Actuators are frequently the most unreliable part of the tripping process.

Dangerous failures can be minimised by a number of measures such as:

- Use of ‘fail-safe’ principles so that the actuator takes up the tripped state on loss of signal or power (electricity, air etc.). e.g. held open, spring return actuator;

- Provision of uninterruptable or reservoir supplies of sufficient capacity for essential power;

- Failure detection and performance monitoring (end of travel switches, time to operate, brake performance, shaft speed, torque etc.) during operation;

- Actuator exercising or partial stroke shutoff simulation during normal operation to reveal failures or degradation in performance. Note this is not proof testing but may reduce probability of failure by improved diagnostic coverage (IEC 61508);

- Overrating of equipment.

Other matters which should have been considered are:

- Valves should be properly selected for their duty, and it should not be assumed that a control valve can satisfactorily perform isolation functions;

- Actuators may also include programmable control elements (e.g. SMART instruments) particularly within positioners and variable speed drives and motor control centres. Modern motor control centres may use programmable digital addressing. This introduces a significant risk of introduction of systematic failure and failure modes which cannot be readily predicted. Such an arrangement should be treated with caution. It is normally reasonably practicable for trip signal to act directly upon the final contactor;

- Potential for failure due to hydraulic locking between valves (e.g. trace heated lines between redundant shutoff valves).

Logic systems

Commonly, the logic systems for protective systems are electronic, but programmable and other technology systems (magnetic or fluidic/pneumatic) have been used.

The architecture of the logic system will be determined by the hardware fault tolerance requirements, for example dual redundant channels. Where a high level of integrity for the system is required (SIL3 or SIL4) then diverse hardware between channels may be employed. This should not be confused with diversity of independent protective systems.

Logic systems are likely to incorporate provisions for fault alarms and overrides, for which there should be suitable management control arrangements. They may also provide monitoring of input and output signal lines for detection of wiring (open circuit, short circuit) and sensors/actuators (stuck-at, out of range). Such monitoring may initiate an alarm, a trip action or, in a voting arrangement, disable the faulty element.

Software based systems should be adequately protected against systematic failures, for example by an appropriate hardware and software safety lifecycles, and suitable techniques and quality systems. Guidance is available in BS IEC 61508 Part 3, PES Parts 1 & 2, EEMUA 160, Out of Control, and IGasE SR15 - Programmable equipment in safety related applications.

Wiring and communications (signal transmission)