A sentence and sentence sentence from me and the nuclear family regarding

e - ASASS in industrial products both services and manufacturing on maintenance

measurable

A service and manufacturing industry is now entering the production stage using automatic start and stop system electronic machine system, thereby reducing the limited ability of human resources in terms of skills and attitudes that can lead to errors of work and may result in failed production or errors in quantities that significantly create both material and mental and spiritual harm to many conditions and places. a production must surely pay attention to: 1. man --- 2. e - ASASS (electronic Automatic start and stop system) --- 3. supplying in and out of production materials --- 4. good medium to good industrial workings; correct ; efficient and effective ---

5. working capital both in the form of money and skills and the most important knowledge for the survival of the company goes on, especially the attitude in the development of research and development. every industry that produces products in the form of services and manufactures for now now features a close loop method in terms of answer back electronics method with high quality audio and video feedback display and accurate and effective data information delivery. in the method of production and distribution of goods and services on this earth many use the concept of 4P STP namely: place, production, promotion, price generated by SWOT system ( strengthness ; Weakness ; Opportunities and Threatness ) with STP object (segmentation - targeting - positioning). the production of goods and services in the world of the earth today embraces the order case means a goods and services produced by the service industry and manufacturing if there is orders from customers only on the case of certain goods and services produced without orders are usually goods and services in the main needs for life on earth this. the product life cycle of a production of goods and services continues to compete according to the development of the era in the current zero era (the era of electronics efficiency system). many examples of product developments are constantly competing and turning cooler and more comfortable for life as examples of products for the administration of accounting and accounting when used to use office stationery like chalk - then now markers and pens and pencils - and then developments manual and electronic typewriters - then the development of PC keyboards and PCs - and the development of notebooks and laptops. the development of the method of buying and selling transactions on this earth used to be a day-to-day exchange of goods without regard to the value of the product - now using currency exchange instruments and demand deposits - then now using the means of exchange transactions with debit and credit cards on automatic teller machines machine - the latest now using electronic money transactions (e - money). so the flash up life cycle products on this earth are mutually sustainable development that is full of coolness and safety on each product in the sense of giving more coolness and comfort to life on earth at this time. perhaps I will illustrate some of the development of service and manufacturing industries that developed in the era of e - ASASS. where an industrial e - ASASS embraces the principle of 1. molding with electronics power 2. pour material on mold or molding called tempering process 3. the process of smoothing and stabilizing a product usually using vibration process or vibrator with electronics power 4. cooling process or wholeness shape of a product so it is stronger and sturdier and bending to the last 5. packing process or wrapping the product to be more attractive and has added value, 6. the process of product delivery both goods and services electronically can on-line also to 7. feedback products from the service and manufacturing industries by electronic data processing which is conditioned between buyer and supplier and consumer to be better, correct, efficient and effective which will give advantage and accuracy of data for all side of life on earth. for that in the future we will continue to develop e - ASSAS so that all products both services and manufactures become more qualified and more beautiful and measurable both from product care and measurement. I will explain some of the following types of industries and their application to life on this earth .

XXX . ____ . 10001 + 10 Chocolate industry

chocolate moulding machine electronically

Technical know-how, project engineering and supply of production lines and machines and free tooling (including controls), in whole or in accordance with additional customer specific requirements or also belong to the core of work system in the division Chocolate and Confectionary.

The new INFINITY Series chocolate tempering machines are fitted with a custom-designed chocolate pump, instead of an auger or wheel. The INFINITY X2 has a 20kg tank capacity but it can be operated with as little as 3 kgs of chocolate. It is a table-top machine with a footprint of 600 x 600mm. Chocolate is manually tempered using seed.

Tempering Method

First melt your chocolate to 45˚c. If you’re starting from solid callets, this will take approximately 3 hours and so is often done overnight. You then have two choices for how to temper your chocolate:

Method 1 – Set the temperature as required and add more solid chocolate callets (seed) equivalent to 20-30% of the melted chocolate in your tank. Your chocolate will be tempered in approximately 30 minutes, OR

Method 2 – Allow the melted chocolate to cool to 34-35˚c, then add 2-3kgs of seed or 1% of Mycryo (pre-crystallised cocoa butter). Your chocolate will be tempered in 5-10 minutes.

Once tempered, your chocolate will remain tempered for up to 8 hours in the INFINITY X2 without the need for any extra stirring or heat. By comparison, a typical 8kg or 15kg wheel moulding machine will only keep your chocolate tempered for a maximum of 1 hour unattended in perfect conditions.

Other features include:

- Foot-pedal operated dosing system (with optional timer control)

- Variable flow rate and interchangeable nozzles

- Dual agitation for efficient seed tempering with no dead spots

- Cover totally encloses chocolate to protect it from contamination

- Vibrating table attachment (optional)

- Depositing head (optional)

Chocotemper-Top is an innovative table top chocolate tempering machine with a 12 pound capacity, making it ideal for candy stores, pastry shops, ice-cream parlors and restaurants.

Although it has a small size, it has similar performance and capabilities of much larger tempering machines, and obtains a continually fluid chocolate with perfect crystallization.

Features:

Features:

• 5.5kg / 12.13 pound Capacity

• Advanced "touch screen" technology, ensures easy operation and consistent results.

• Stainless steel construction, ensures years of operation with an eye-catching design.

• Stainless steel construction, ensures years of operation with an eye-catching design.

• Stainless steel auger. Removable for cleaning.

• Foot Petal activates chocolate flow through nozzle.

• Night mode, keeps chocolate melted overnight and then tempered in the morning.

• Cleaning process for easy hygienic operation.

• Heat is maintained through heating elements surrounding both the melting tank and auger.

• Cooling is achieved through an internal refrigeration unit.

Chocolate Tempering Operation:

Input chocolate melting temperature and temper temperature into the machine.

After 5 minutes the tank mixing blade starts rotation and the chocolate begins melting.

When the chocolate is fully melted approximately 45 minutes, the auger rotation begins and the chocolate flows from the upper nozzle at 36°C (97F degrees).

After 80 minutes the chocolate reaches 45°C (113F degrees).

After 100 minutes the chocolate reaches 47/48°C (117-119F degrees).

Temper now begins and the chocolate is cooled to 31°C (88F degrees).

Total time is approximately 120 minutes.

• Night mode, keeps chocolate melted overnight and then tempered in the morning.

• Cleaning process for easy hygienic operation.

• Heat is maintained through heating elements surrounding both the melting tank and auger.

• Cooling is achieved through an internal refrigeration unit.

Chocolate Tempering Operation:

Input chocolate melting temperature and temper temperature into the machine.

After 5 minutes the tank mixing blade starts rotation and the chocolate begins melting.

When the chocolate is fully melted approximately 45 minutes, the auger rotation begins and the chocolate flows from the upper nozzle at 36°C (97F degrees).

After 80 minutes the chocolate reaches 45°C (113F degrees).

After 100 minutes the chocolate reaches 47/48°C (117-119F degrees).

Temper now begins and the chocolate is cooled to 31°C (88F degrees).

Total time is approximately 120 minutes.

* For even faster operation, the chocolate can be melted separately and added to the machine for tempering.

Specifications:

Bowl Capacity: 12.13 pounds (5.5kg)

Electrical: 240V, 50/60hz, CE certified. Professional electrical installation maybe required.

Specifications:

Bowl Capacity: 12.13 pounds (5.5kg)

Electrical: 240V, 50/60hz, CE certified. Professional electrical installation maybe required.

Weight: 115 pounds

Dimension: 19" x 18" x 24.5"

Dimension: 19" x 18" x 24.5"

Chocolate Moulding Plant

Aasted moulding plant was configured for regular

Mini bar production

Utilises 280mm x 620mm x 35mm moulds at 25 to 30 moulds per minute.

This line is in its order of production is as follows:

Mould turnover section.

Servo controlled Aasted Mikroverk chocolate depositor (Single shot).

Allen Bradley Panelview touch screen controls for depositor.

Carle & Montanari digital depositor controller.

Crowder section.

Shell licking roller assembly.

Mould shaker segment.

Final cooler section with blowers.

Refrigeration plant.

Bar demoulder segment.

Overhead mould return conveyor.

Allen Bradley motor control panels.

Allen Bradley Panelview touch screen controls for moulding plant.

Automatic Chocolate Molding Line (Automatic one-shot)

Automatic molding line different types of chocolate a length of 62 meters on the quad open format

Preparation for Filling and Emptying molds automatically

Preparation for Filling and Emptying molds automatically

Composed of the following units:

- Mold loading unit

- Mould heating

- 1st filling depositor

- Vibration unit

- 1st pre-cooling to set the shell thickness.

- Chocolate Shell moulding Line

- Chocolate Shell Making Unit

- crisped rice , filling unit (two pieces)

- Robot feed all the nuts

- 2nd filling depositor (for cream and jelly)

- Vibration unit

- the 3rd cooling cream and jelly

- Heating unit , shell ends

- 3rd filling depositor for closure

- Vibration unit

- Rectification unit

- 4th cooling, for the final product

- Empty molds return to the conveyor (62 m)

- Marshmallow Cuisine (1 team)

- Touch screen, PLC control

- Length: 62 m. (47 m Shell, 16 meter tunnel)

Process Flowchart

Main Components and Its Functions

※ Sugar Grinding Machine: To grind the granulated sugar tin to powder and improve the efficiency of fine grinding without dust.

※ Chocolate Conche Machine: To conche and refine chocolate paste and suitable for refining jam, peanut butter or other liquid and pastes.

※ Delivery Pump 1: To pump and convey the chocolate paste and other paste products.

※ Heat Holding Pump: It is special storage device for refined or ball ground chocolate pastes with electric heating and automatic temperature control. It enables the chocolate paste kept at a rated temperature. Through heat preservation and stirring, it will lower down the moisture content of the chocolate and improve its liquidity to have a longer shelf life and better taste.

※ Delivery Pump 2: To pump and convey the chocolate paste and other paste products.

※ Tempering Machine: It is essential machine to produce natural cocoa butter chocolate. This device sets a special procedure as per the forming rule of the chocolate paste crystals at different temperatures to strictly and automatically control the required chocolate paste temperature at each production process. This step ensures the quality of the chocolate with stronger fragrance and better taste.

※ Chocolate Forming Machine With Cooling Tunnel: This machine is a special equipment for casting and forming the chocolate at a rational amount. It can be used to produce sole-flavor, double-flavor, center filling, crushed nut filling and mixed paste chocolates. This device has full functions of molds baking, casting, molds vibrating and conveying. It is adopted with PLC Man-Machine operation interface and can easily change the molds in variety.

※ Packing Machine: To pack the finished chocolates into different styles for storage or marketing sales.

Chocolate Samples

Multifunctional Stereo Decorating Chocolate Forming

Cooling tunnel for the ending process of chocolate

XXX . ____ . 10001 + 10 . ___ . XO noodle industry printing machine electronically

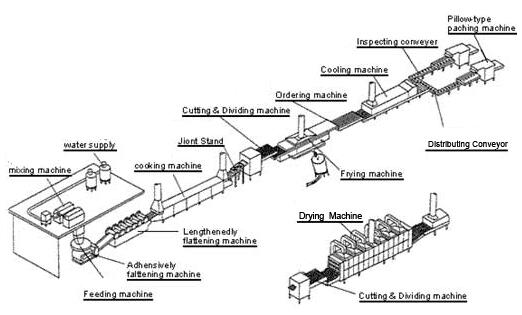

Step by step process of Instant Noodles Manufacturing

Noodle is a widely popular food item, with a distinct and delicious taste. However, the process that goes into making instant noodles is not that easy. In here, we will see the process of instant noodles manufacturing.

Step by Step process

- Knead and Mix: As a first step, the wheat flour and water goes into the mixing machine in the noodles manufacturing process. Here, dough is kneaded with about 0.3 to 0.4kg water at a temperature of 20 to 30 degree Celsius, thus providing the dough with textiform tissue generating elastic feature for the noodles.

- Creating noodle belt: Then the dough goes into two rotating rollers wherein two noodles belt is bought together as one belt, helping to distribute the noodles evenly. The dough is also left for a specific time to mature.

- Rolling: With the help of pressing rollers, the 10mm thick noodles is flattened repeatedly using four rollers and finally becomes thin at 1mm thickness.

- Slitter: To add to the noodles manufacturing process, these noodles is then put into the slitter, where with the help of roller blades these instant noodles are made even thinner and wavy.

- Steamer: Then is the pregelatinization process in the steamer, where the instant noodles is steamed for one to five minutes.

- Dipping bath: Then the steamed noodles are dipped in seasoning.

- Feeder: Then it is cut as long as 40-70cm then moulded using a round- or square- shaped metal mould serving

- Dehydration process: Most of the noodles are dehydrated either by oil frying or air drying, thus giving rise to fried or non-fried noodles. There are also the steamed noodles that are known as Raw-type instant noodles.

- Cooler: Following the dehydration in the noodles manufacturing process, the noodles that are at 100 degree Celsius is cooled with air.

- Check weight and detect metal: In case any metal is detected in the noodles or if the weight is beyond the preset range, the product is then discarded.

- Packing: The ready instant noodles are then put into firm bags or containers as required along with the garnish and seasonings and then sealed with aluminium foils.

Noodles manufacturing at home

In the same way, noodles can also be made at home. For noodles manufacturing at home knead the dough with flour, eggs and water and then you can roll out the pasta or noodles with help of pasta machine or hand.

The manufacturing process of instant noodles

Instant Noodles: Processing, Quality, and Nutritional Aspects

Noodles are one of the staple foods consumed in many Asian countries. Instant noodles have become internationally recognized food, and worldwide consumption is on the rise. The properties of instant noodles like taste, nutrition, convenience, safety, longer shelf-life, and reasonable price have made them popular. Quality factors important for instant noodles are color, flavor, and texture, cooking quality, rehydration rates during final preparation, and the presence or absence of rancid taste after extended storage. Microstructure of dough and noodles has been studied to understand the influence of ingredients and processing variables on the noodle quality by employing scanning electron microscopy. Applications of newer techniques like confocal laser scanning microscopy and epifluorescence light microscopy employed to understand the micro structure changes in dough and noodles have also been discussed. Sincere efforts of researchers are underway to improve the formulation, extend the shelf life, and promote universal fortification of instant noodles. Accordingly, many researchers are exploring the potential of noodle fortification as an effective public health intervention and improve its nutritional properties. This review focuses on the functionality of ingredients, unit operations involved, quality criteria for evaluation, recent trends in fortification, and current knowledge in relation to instant noodles.

The Noodle Process

we are engaging in integrated risk management from raw materials procurement to production and distribution and strengthening safety measures.

Clean, Efficient and Fast

Non fried instant noodle machine or baked instant ramen noodle processing line adopts advanced technology, high degree of automation, with reasonable layout and easy maintenance. The produced instant noodle is of high quality and good taste.

This non-fried instant noodles plant uses automatically temperature control, which ensures the original color of the noodle flavor and nutritional composition. Is ideal equipment for non-fried instant noodle production.

Application:

Whole production line to make the instant noodles. Welcome to our company, we will take you around our production department, and check the machines.

Features:

The Production flow chart: wheat flour, dressing mixer →curing machine →Composite continuous rolling→steamed noodles → frame cutting→folding → cooling → packing

Introduction:

According to the desired production capacity, the plant can produce 60,80,100 or 120,200 thousand packs of instant noodles every shift . Using the advanced technology for nutrient and instant foodstuff complete lines,the plant is innovative with advanced structure,excellent performance and reliable quality that provide an ideal choice for the investor in foodstuff industry.

Automatic Fried instant noodle processing line is the production of new generation which developed by our company based on similar productions from overseas and domestic market. It has high technology,compact structure,original design and stable performance.

Introduction (application)

Instant noodles production line is used to fully automatically produce ripple-type instant noodles with high automatically, easy operation, moderate output, good energy conservation and small floor space.

Technological Process

Raw Materials Configuration→ Mixing→ Pressing & Shaping→ Cooking→ Cutting→ Frying→ Cooling & Oil Filtering

Characteristics

- The size of instant noodles can be adjusted according to users’ requirement.

- Pressing & shaping machine, cutting machine and frying machine are all frequency control.

- Rolling pressing design make the noodles more springy.

- Adopt good quality and food-grade stainless steel, which is longer service life and neatness.

- Longer frying length to ensure good cooking and better taste of instant noodles.

- Cooling conveyor is special designed with oil filtering function.

- High automation and accurate control system to save labor cost and improve the quality of final products.

Workers:

Normally 1-2 operators are sufficient for production.

Noodles made

How to make noodles

Noodles are a basic staple of Asian and European cuisines. Chinese noodles may be boiled in soups, stir-fried as chow foon, or deep fried into crunchy strips for chow mein and other dishes. Italian cooking is renowned for noodles such as spaghetti, fettuccine, linguine, and capellini among many other shapes of pasta like lasagna, ravioli, rotini, gemelli, and mostaccioli.

Cutting pasta by hand

Japanese noodle varieties include ramen, soba, somen, hiyamugi, kishimen, and udon. Noodles are a favorite food throughout the world because of their simplicity, versatility, organoleptic appeal, and satiety.

Noodles and spaghetti consist basically of flour and water.

Ingredients:

Ingredients:

- 2 cups flour

- 1/2 cup water

Egg noodles are made by using two eggs plus enough water to make 1/2 cup instead of the plain water. For pasta made by hand, Italian recipes recommend using one egg for every 100 grams of pasta flour. Since one cup of flour weighs approximately 160 grams, this corresponds to three eggs for two cups of flour. This makes a soft dough which is easy to work by hand, and which gets stiffer as additional flour is introduced from the flour used for dusting the work surfaces where the dough is rolled.

For machine rolling, a stiff but pliable dough is prepared from flour and water. Knead the dough thoroughly, cover with plastic, and allow it to rest for 20 minutes. The resting time allows the flour to absorb water uniformly and makes the dough more pliable and easier to handle. Flatten the dough with a rolling pin and make a sheet one millimeter thick (the thickness of a U.S. penny). Dust with flour to prevent sticking, as necessary. Roll the sheet into a log, and cut slices of the width desired for the noodles. Pasta rolling pins, illustrated below, can also be used to manually cut the dough into noodles.

A pasta machine , such as the one illustrated below, can be used to roll and cut the dough evenly. When using this type of pasta machine, the dough must not be too wet, otherwise it will stick in the machine. Once you have rolled the sheets, it may be necessary to let them air dry for about 10 minutes to be able to cut them properly. The drying time will vary depending on the humidity of the air and the amount of moisture in the dough. If the dough is too moist, the noodles will tend to clump together. The noodles may be air dried by draping them on plastic coat hangers or a Pasta Drying Rack

, such as the one illustrated below, can be used to roll and cut the dough evenly. When using this type of pasta machine, the dough must not be too wet, otherwise it will stick in the machine. Once you have rolled the sheets, it may be necessary to let them air dry for about 10 minutes to be able to cut them properly. The drying time will vary depending on the humidity of the air and the amount of moisture in the dough. If the dough is too moist, the noodles will tend to clump together. The noodles may be air dried by draping them on plastic coat hangers or a Pasta Drying Rack for several hours, or they may be refrigerated for use at a later time.

for several hours, or they may be refrigerated for use at a later time.

Flour for noodles and pasta

Italians like their pasta "al dente", which is slightly chewy rather than pasty. Good quality Italian pasta is made from semolina flour that is ground from the hard durum winter wheat berry. The firmness of the pasta made from semolina is due to the high level of gluten protein in the flour, approximately 13 percent, and the fact that semolina is coarsely ground, rather than finely ground. Although good noodles can be made with bread flour or unbleached white flour, they are not as chewy as the noodles made from semolina.

Italians like their pasta "al dente", which is slightly chewy rather than pasty. Good quality Italian pasta is made from semolina flour that is ground from the hard durum winter wheat berry. The firmness of the pasta made from semolina is due to the high level of gluten protein in the flour, approximately 13 percent, and the fact that semolina is coarsely ground, rather than finely ground. Although good noodles can be made with bread flour or unbleached white flour, they are not as chewy as the noodles made from semolina.

Pasta of different colors may be obtained by adding pureed colorful vegetables to the dough. Spinach produces a green pasta. Beets produce a red pasta. Additional flour may be needed to compensate for the water content of the vegetables. Click here for multi-color pasta and striped pasta recipes.

Japanese soba noodles are made from wheat and buckwheat flour, whereas hiyamugi, kishimen, and udon noodles are made from high-gluten wheat flour (udon ko) similar to bread flour. Asian cooking uses several types of semi-transparent noodles with a high starch content. Rice vermicelli, also known as rice noodles or rice sticks, are thin noodles made from rice flour. Cellophane noodles or bean threads are usually made from mung bean starch.

The Extrusion Method

Pasta can also be made by extrusion, which consists of forcing the dough through dies with holes of various shapes. Most commercial pasta is made by this method. Extrusion machines produce a continuous stream of pasta that must be cut off to the desired length as the pasta shape emerges from the machine. Machines such as a stand mixer with the Food Grinder Attachment

with the Food Grinder Attachment can be converted to extrude pasta at home with Pasta Maker Plates

can be converted to extrude pasta at home with Pasta Maker Plates . The dough for extruders has to be slightly softer than the dough for the roller machines to decrease the pressure needed to produce the pasta and keep the machine from overheating. The KitchenAid Stand Mixer also has a Pasta Roller Attachment

. The dough for extruders has to be slightly softer than the dough for the roller machines to decrease the pressure needed to produce the pasta and keep the machine from overheating. The KitchenAid Stand Mixer also has a Pasta Roller Attachment .

.

Pasta can also be made by extrusion, which consists of forcing the dough through dies with holes of various shapes. Most commercial pasta is made by this method. Extrusion machines produce a continuous stream of pasta that must be cut off to the desired length as the pasta shape emerges from the machine. Machines such as a stand mixer

Extrusion dies and pasta shapes

Spaetzle noodles

Spätzle or spaetzle are egg noodles of soft texture made by extrusion. Spaetzle are found in the cuisine of Germany and regions of neighboring Austria and Switzerland. This type of pasta is also called Spätzli or Chnöpfli in Switzerland. A typical recipe consists of 1 cup all-purpose flour, 1 teaspoon salt, 1/2 teaspoon ground pepper, 1/2 teaspoon ground nutmeg, 2 large eggs, 1/4 cup milk, and 3 tablespoons unsalted butter.

In a large bowl, combine the flour, salt, pepper, and nutmeg. In another mixing bowl, whisk the eggs and milk together. Pour the egg-milk mixture in the center of the dry ingredients and combine well. The dough should be smooth and thick. Let the dough rest for 10 to 15 minutes. Bring 3 quarts of salted water to a boil in a large pot, then reduce to a simmer. To form the spaetzle, place a spaetzle maker or a colander with large holes over the boiling water and push the dough through the holes with a spatula or spoon. Do this in batches, and cook for 3 to 4 minutes or until the spaetzle float to the surface. Stir gently to prevent sticking. Rinse the cooked spaetzle in cool water. Melt the butter in a large skillet over medium heat, add the spaetzle and toss until it is coated with butter. Serve, and sprinkle with chopped chives or grated cheese.

Chinese Noodles

A bowl containing 4,000-year old millet noodles was found in a Chinese archeological site. The Chinese have a long history of making noodles using several techniques. One of them is to dip a chopstick into a batter of flour and water. The batter has to be thick enough to adhere to the chopstick, but light enough to come off when the chopstick is flicked unto a pot of boiling water. The noodles formed by this technique are not uniform in size or shape. Similarly, knife-shaved noodles , also known as hand-sliced noodles, are made by shaping a two-kilogram piece of dough into a log, and shaving off strips of dough using quick slicing motions with a sharp cleaver into a pot of boiling water.

A bowl containing 4,000-year old millet noodles was found in a Chinese archeological site. The Chinese have a long history of making noodles using several techniques. One of them is to dip a chopstick into a batter of flour and water. The batter has to be thick enough to adhere to the chopstick, but light enough to come off when the chopstick is flicked unto a pot of boiling water. The noodles formed by this technique are not uniform in size or shape. Similarly, knife-shaved noodles , also known as hand-sliced noodles, are made by shaping a two-kilogram piece of dough into a log, and shaving off strips of dough using quick slicing motions with a sharp cleaver into a pot of boiling water.

The Chinese also make hand-pulled noodles using a flexible dough that can be stretched easily. This is done by increasing the amount of water in the dough (approximately 1 cup of water for every 2 cups of flour). Cover the dough with plastic and allow it to rest at room temperature for at least 60 minutes to relax the gluten. The dough is stretched until it looks like a long, thick rope. The rope is folded in half, twisted, and stretched back to its original length approximately ten times. The twisting is done by holding one end of the rope in each hand while the center hangs down under the force of gravity and flinging one side against the other in a circular motion. The rope is twisted first to the right, stretched, folded in half, and then twisted to the left, stretched, and folded in half again. This process creates a structure of dough fibers oriented along the length of the dough rope that is necessary for being able to pull the noodles. Next, the rope of dough is placed on a countertop covered with plenty of flour, and the noodles are made by pulling the dough, resting it briefly on the floured countertop, grabbing the two ends with one hand, while holding the middle with the other hand. This process is repeated until the noodles are of the appropriate thickness. Each time, the noodles are rolled on the countertop covered with flour to keep them from sticking, and the number of noodles doubles.

The following recipe was documented to work well for pulled noodles.[2] Measure the ingredients carefully using a digital scale. Mix the dry ingredients, and stir in the water and the vegetable oil. Once the dough has formed, put the dough on a flat table and knead it with your hands. The dough has to be kneaded and stretched until the gluten structure breaks down and no lumps are visible when the dough is stretched. This requires about 20 minutes. A stand mixer set at medium speed can do the job in about 15 minutes. The amount of flour and water may need to be adjusted to get the proper consistency. The dough is ready for pulling when it feels like clay, and it does not tear when you try to stretch it. Pulling noodles is definitely an art that requires lots of practice!

Luke Rymarz's Recipe for Hand-Pulled Noodles

- 156 grams cake flour

- 25 grams all purpose flour

- 110 grams warm water

- 2 grams salt

- 1 gram baking soda

- 6 grams vegetable oil

To cook the noodles, drop them into boiling water and boil for approximately 10 minutes. Pasta should be cooked in plenty of water. Add the pasta only when the water is boiling vigorously, and stir immediately. Different shapes and kinds of pasta take different times to cook, generally in the range of 2 to 13 minutes. Toward the end of the cooking time, test the pasta to make sure that it is firm and chewy, but not hard or doughy (undercooked) or mushy (overcooked). Drain the noodles using a colander and serve them topped with your favorite spaghetti sauce, beef Stroganoff, or chicken cacciatore. You can also make noodle soup by adding the boiled noodles to a well-seasoned chicken soup.

Noodle soup with chicken, baby bok choi, and green onions

You don't have to go to China to see how hand-pulled noodles are made. Come to the corner of 6th street and H street in Washington, D.C. The Chinatown Express restaurant has a store-front window where you can see the chef pulling noodles for lunch and supper. You may order the noodles stir-fried with your choice of meat, seafood, or vegetables, or in a soup with a variety of garnishes.

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

UP _ TO EDP AND e- Money FOR e - ASASS ON INDUSTRY SERVICE AND MAINTENANCE SO DO

MANUFACTURE

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++