.motor or actuator device in electronics is a tool that converts electrical energy into mechanical energy (Potential energy and Kinetic Energy) energy change is useful to move some tools and materials output and its usefulness for our environment as well as in daily life such as: water pump, DVD, rotating tape, turning the pool, moving the arm of the robot arm, pulling the pulley, moving the conveyor and staircase, lifting the elevator, aircraft propeller, fan, out door air conditioning, moving the car fan and the wheels of the motor and the car , as a tool for moving ships and motorboats, moving gun cartridges or pistols so glimpse of the usefulness of the motor and its functions.

XXX . XXX DC motor

A DC motor is any of a class of rotary electrical machines that converts direct current electrical energy into mechanical energy. The most common types rely on the forces produced by magnetic fields. Nearly all types of DC motors have some internal mechanism, either electro mechanical or electronic, to periodically change the direction of current flow in part of the motor.

DC motors were the first type widely used, since they could be powered from existing direct-current lighting power distribution systems. A DC motor's speed can be controlled over a wide range, using either a variable supply voltage or by changing the strength of current in its field windings. Small DC motors are used in tools, toys, and appliances. The universal motor can operate on direct current but is a lightweight motor used for portable power tools and appliances. Larger DC motors are used in propulsion of electric vehicles, elevator and hoists, or in drives for steel rolling mills. The advent of power electronics has made replacement of DC motors with AC motors possible in many applications.

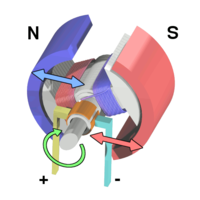

Workings of a brushed electric motor with a two-pole rotor (armature) and permanent magnet stator. "N" and "S" designate polarities on the inside axis faces of the magnets; the outside faces have opposite polarities. The + and - signs show where the DC current is applied to the commutator which supplies current to the armature coils .

Workings of a brushed electric motor with a two-pole rotor (armature) and permanent magnet stator. "N" and "S" designate polarities on the inside axis faces of the magnets; the outside faces have opposite polarities. The + and - signs show where the DC current is applied to the commutator which supplies current to the armature coils . Electromagnetic motors

A coil of wire with a current running through it generates an electromagnetic field aligned with the center of the coil. The direction and magnitude of the magnetic field produced by the coil can be changed with the direction and magnitude of the current flowing through it.

A simple DC motor has a stationary set of magnets in the stator and an armature with one or more windings of insulated wire wrapped around a soft iron core that concentrates the magnetic field. The windings usually have multiple turns around the core, and in large motors there can be several parallel current paths. The ends of the wire winding are connected to a commutator. The commutator allows each armature coil to be energized in turn and connects the rotating coils with the external power supply through brushes. (Brushless DC motors have electronics that switch the DC current to each coil on and off and have no brushes.)

The total amount of current sent to the coil, the coil's size and what it's wrapped around dictate the strength of the electromagnetic field created.

The sequence of turning a particular coil on or off dictates what direction the effective electromagnetic fields are pointed. By turning on and off coils in sequence a rotating magnetic field can be created. These rotating magnetic fields interact with the magnetic fields of the magnets (permanent or electromagnets) in the stationary part of the motor (stator) to create a force on the armature which causes it to rotate. In some DC motor designs the stator fields use electromagnets to create their magnetic fields which allow greater control over the motor.

At high power levels, DC motors are almost always cooled using forced air.

Different number of stator and armature fields as well as how they are connected provide different inherent speed/torque regulation characteristics. The speed of a DC motor can be controlled by changing the voltage applied to the armature. The introduction of variable resistance in the armature circuit or field circuit allowed speed control. Modern DC motors are often controlled by power electronics systems which adjust the voltage by "chopping" the DC current into on and off cycles which have an effective lower voltage.

Since the series-wound DC motor develops its highest torque at low speed, it is often used in traction applications such as electric locomotives, and trams. The DC motor was the mainstay of electric traction drives on both electric and diesel-electric locomotives, street-cars/trams and diesel electric drilling rigs for many years. The introduction of DC motors and an electrical grid system to run machinery starting in the 1870s started a new second Industrial Revolution. DC motors can operate directly from rechargeable batteries, providing the motive power for the first electric vehicles and today's hybrid cars and electric cars as well as driving a host of cordless tools. Today DC motors are still found in applications as small as toys and disk drives, or in large sizes to operate steel rolling mills and paper machines. Large DC motors with separately excited fields were generally used with winder drives for mine hoists, for high torque as well as smooth speed control using thyristor drives. These are now replaced with large AC motors with variable frequency drives.

If external mechanical power is applied to a DC motor it acts as a DC generator, a dynamo. This feature is used to slow down and recharge batteries on hybrid car and electric cars or to return electricity back to the electric grid used on a street car or electric powered train line when they slow down. This process is called regenerative braking on hybrid and electric cars. In diesel electric locomotives they also use their DC motors as generators to slow down but dissipate the energy in resistor stacks. Newer designs are adding large battery packs to recapture some of this energy.

Brushed

The brushed DC electric motor generates torque directly from DC power supplied to the motor by using internal commutation, stationary magnets (permanent or electromagnets), and rotating electromagnets.

Advantages of a brushed DC motor include low initial cost, high reliability, and simple control of motor speed. Disadvantages are high maintenance and low life-span for high intensity uses. Maintenance involves regularly replacing the carbon brushes and springs which carry the electric current, as well as cleaning or replacing the commutator. These components are necessary for transferring electrical power from outside the motor to the spinning wire windings of the rotor inside the motor.

Brushes are usually made of graphite or carbon, sometimes with added dispersed copper to improve conductivity. In use, the soft brush material wears to fit the diameter of the commutator, and continues to wear. A brush holder has a spring to maintain pressure on the brush as it shortens. For brushes intended to carry more than an ampere or two, a flying lead will be molded into the brush and connected to the motor terminals. Very small brushes may rely on sliding contact with a metal brush holder to carry current into the brush, or may rely on a contact spring pressing on the end of the brush. Very small short-lived motors, such as are used in toys, may be made of a folded strip of metal that contacts the commutator.

Brushless

Typical brushless DC motors use one or more permanent magnets in the rotor and electromagnets on the motor housing for the stator. A motor controller converts DC to AC. This design is mechanically simpler than that of brushed motors because it eliminates the complication of transferring power from outside the motor to the spinning rotor. The motor controller can sense the rotor's position via Hall effect sensors or similar devices and can precisely control the timing, phase, etc., of the current in the rotor coils to optimize torque, conserve power, regulate speed, and even apply some braking. Advantages of brushless motors include long life span, little or no maintenance, and high efficiency. Disadvantages include high initial cost, and more complicated motor speed controllers. Some such brushless motors are sometimes referred to as "synchronous motors" although they have no external power supply to be synchronized with, as would be the case with normal AC synchronous motors.

Uncommutated

Other types of DC motors require no commutation.

- Homopolar motor – A homopolar motor has a magnetic field along the axis of rotation and an electric current that at some point is not parallel to the magnetic field. The name homopolar refers to the absence of polarity change. Homopolar motors necessarily have a single-turn coil, which limits them to very low voltages. This has restricted the practical application of this type of motor.

- Ball bearing motor – A ball bearing motor is an unusual electric motor that consists of two ball bearing-type bearings, with the inner races mounted on a common conductive shaft, and the outer races connected to a high current, low voltage power supply. An alternative construction fits the outer races inside a metal tube, while the inner races are mounted on a shaft with a non-conductive section (e.g. two sleeves on an insulating rod). This method has the advantage that the tube will act as a flywheel. The direction of rotation is determined by the initial spin which is usually required to get it going.

Permanent magnet stators

A PM motor does not have a field winding on the stator frame, instead relying on PMs to provide the magnetic field against which the rotor field interacts to produce torque. Compensating windings in series with the armature may be used on large motors to improve commutation under load. Because this field is fixed, it cannot be adjusted for speed control. PM fields (stators) are convenient in miniature motors to eliminate the power consumption of the field winding. Most larger DC motors are of the "dynamo" type, which have stator windings. Historically, PMs could not be made to retain high flux if they were disassembled; field windings were more practical to obtain the needed amount of flux. However, large PMs are costly, as well as dangerous and difficult to assemble; this favors wound fields for large machines.

To minimize overall weight and size, miniature PM motors may use high energy magnets made with neodymium or other strategic elements; most such are neodymium-iron-boron alloy. With their higher flux density, electric machines with high-energy PMs are at least competitive with all optimally designed singly fed synchronous and induction electric machines. Miniature motors resemble the structure in the illustration, except that they have at least three rotor poles (to ensure starting, regardless of rotor position) and their outer housing is a steel tube that magnetically links the exteriors of the curved field magnets.

Wound stators

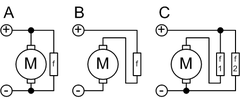

There are three types of electrical connections between the stator and rotor possible for DC electric motors: series, shunt/parallel and compound (various blends of series and shunt/parallel) and each has unique speed/torque characteristics appropriate for different loading torque profiles/signatures.

Series connection

A series DC motor connects the armature and field windings in series with a common D.C. power source. The motor speed varies as a non-linear function of load torque and armature current; current is common to both the stator and rotor yielding current squared (I^2) behavior. A series motor has very high starting torque and is commonly used for starting high inertia loads, such as trains, elevators or hoists. This speed/torque characteristic is useful in applications such as dragline excavators, where the digging tool moves rapidly when unloaded but slowly when carrying a heavy load.

A series motor should never be started at no load. With no mechanical load on the series motor, the current is low, the counter-Electro motive force produced by the field winding is weak, and so the armature must turn faster to produce sufficient counter-EMF to balance the supply voltage. The motor can be damaged by overspeed. This is called a runaway condition.

Series motors called universal motors can be used on alternating current. Since the armature voltage and the field direction reverse at the same time, torque continues to be produced in the same direction. However they run at a lower speed with lower torque on AC supply when compared to DC due to reactance voltage drop in AC which is not present in DC. Since the speed is not related to the line frequency, universal motors can develop higher-than-synchronous speeds, making them lighter than induction motors of the same rated mechanical output. This is a valuable characteristic for hand-held power tools. Universal motors for commercial utility are usually of small capacity, not more than about 1 kW output. However, much larger universal motors were used for electric locomotives, fed by special low-frequency traction power networks to avoid problems with commutation under heavy and varying loads.

Shunt connection

A shunt DC motor connects the armature and field windings in parallel or shunt with a common D.C. power source. This type of motor has good speed regulation even as the load varies, but does not have the starting torque of a series DC motor. It is typically used for industrial, adjustable speed applications, such as machine tools, winding/unwinding machines and tensioners.

Compound connection

A compound DC motor connects the armature and fields windings in a shunt and a series combination to give it characteristics of both a shunt and a series DC motor. This motor is used when both a high starting torque and good speed regulation is needed. The motor can be connected in two arrangements: cumulatively or differentially. Cumulative compound motors connect the series field to aid the shunt field, which provides higher starting torque but less speed regulation. Differential compound DC motors have good speed regulation and are typically operated at constant speed.

A brushed DC motor is an internally commutated electric motor designed to be run from a direct current power source. Brushed motors were the first commercially important application of electric power to driving mechanical energy, and DC distribution systems were used for more than 100 years to operate motors in commercial and industrial buildings. Brushed DC motors can be varied in speed by changing the operating voltage or the strength of the magnetic field. Depending on the connections of the field to the power supply, the speed and torque characteristics of a brushed motor can be altered to provide steady speed or speed inversely proportional to the mechanical load. Brushed motors continue to be used for electrical propulsion, cranes, paper machines and steel rolling mills. Since the brushes wear down and require replacement, brushless DC motors using power electronic devices have displaced brushed motors from many applications.

Simple two-pole DC motor

The following graphics illustrate a simple, two-pole, brushed, DC motor.

When a current passes through the coil wound around a soft iron core, the side of the positive pole is acted upon by an upwards force, while the other side is acted upon by a downward force. According to Fleming's left hand rule, the forces cause a turning effect on the coil, making it rotate. To make the motor rotate in a constant direction, "direct current" commutators make the current reverse in direction every half a cycle (in a two-pole motor) thus causing the motor to continue to rotate in the same direction.

A problem with the motor shown above is that when the plane of the coil is parallel to the magnetic field—i.e. when the rotor poles are 90 degrees from the stator poles—the torque is zero. In the pictures above, this occurs when the core of the coil is horizontal—the position it is just about to reach in the last picture on the right. The motor would not be able to start in this position. However, once it was started, it would continue to rotate through this position by momentum.

There is a second problem with this simple pole design. At the zero-torque position, both commutator brushes are touching (bridging) both commutator plates, resulting in a short-circuit. The power leads are shorted together through the commutator plates, and the coil is also short-circuited through both brushes (the coil is shorted twice, once through each brush independently). Note that this problem is independent of the non-starting problem above; even if there were a high current in the coil at this position, there would still be zero torque. The problem here is that this short uselessly consumes power without producing any motion (nor even any coil current.) In a low-current battery-powered demonstration this short-circuiting is generally not considered harmful. However, if a two-pole motor were designed to do actual work with several hundred watts of power output, this shorting could result in severe commutator overheating, brush damage, and potential welding of the brushes—if they were metallic—to the commutator. Carbon brushes, which are often used, would not weld. In any case, a short like this is very wasteful, drains batteries rapidly and, at a minimum, requires power supply components to be designed to much higher standards than would be needed just to run the motor without the shorting.

One simple solution is to put a gap between the commutator plates which is wider than the ends of the brushes. This increases the zero-torque range of angular positions but eliminates the shorting problem; if the motor is started spinning by an outside force it will continue spinning. With this modification, it can also be effectively turned off simply by stalling (stopping) it in a position in the zero-torque (i.e. commutator non-contacting) angle range. This design is sometimes seen in home built hobby motors, e.g. for science fairs and such designs can be found in some published science project books. A clear downside of this simple solution is that the motor now coasts through a substantial arc of rotation twice per revolution and the torque is pulsed. This may work for electric fans or to keep a flywheel spinning but there are many applications, even where starting and stopping are not necessary, for which it is completely inadequate, such as driving the capstan of a tape transport, or any instance where to speed up and slow down often and quickly is a requirement. Another disadvantage is that, since the coils have a measure of self inductance, current flowing in them cannot suddenly stop. The current attempts to jump the opening gap between the commutator segment and the brush, causing arcing.

Even for fans and flywheels, the clear weaknesses remaining in this design—especially that it is not self-starting from all positions—make it impractical for working use, especially considering the better alternatives that exist. Unlike the demonstration motor above, DC motors are commonly designed with more than two poles, are able to start from any position, and do not have any position where current can flow without producing electromotive power by passing through some coil. Many common small brushed DC motors used in toys and small consumer appliances, the simplest mass-produced DC motors to be found, have three-pole armatures. The brushes can now bridge two adjacent commutator segments without causing a short circuit. These three-pole armatures also have the advantage that current from the brushes either flows through two coils in series or through just one coil. Starting with the current in an individual coil at half its nominal value (as a result of flowing through two coils in series), it rises to its nominal value and then falls to half this value. The sequence then continues with current in the reverse direction. This results in a closer step-wise approximation to the ideal sinusoidal coil current, producing a more even torque than the two-pole motor where the current in each coil is closer to a square wave. Since current changes are half those of a comparable two-pole motor, arcing at the brushes is consequently less.

If the shaft of a DC motor is turned by an external force, the motor will act like a generator and produce an Electromotive force (EMF). During normal operation, the spinning of the motor produces a voltage, known as the counter-EMF (CEMF) or back EMF, because it opposes the applied voltage on the motor. The back EMF is the reason that the motor when free-running does not appear to have the same low electrical resistance as the wire contained in its winding. This is the same EMF that is produced when the motor is used as a generator (for example when an electrical load, such as a light bulb, is placed across the terminals of the motor and the motor shaft is driven with an external torque). Therefore, the total voltage drop across a motor consists of the CEMF voltage drop, and the parasitic voltage drop resulting from the internal resistance of the armature's windings. The current through a motor is given by the following equation:

The mechanical power produced by the motor is given by:

As an unloaded DC motor spins, it generates a backwards-flowing electromotive force that resists the current being applied to the motor. The current through the motor drops as the rotational speed increases, and a free-spinning motor has very little current. It is only when a load is applied to the motor that slows the rotor that the current draw through the motor increases.

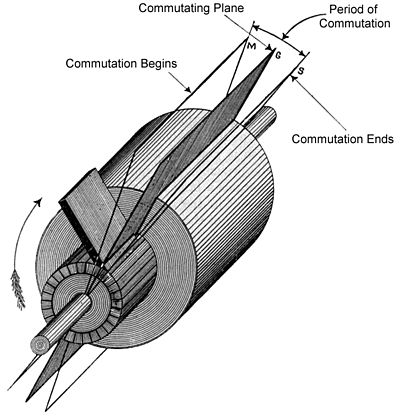

The commutating plane

In a dynamo, a plane through the centers of the contact areas where a pair of brushes touch the commutator and parallel to the axis of rotation of the armature is referred to as the commutating plane. In this diagram the commutating plane is shown for just one of the brushes, assuming the other brush made contact on the other side of the commutator with radial symmetry, 180 degrees from the brush shown.

|

Compensation for stator field distortion

In a real dynamo, the field is never perfectly uniform. Instead, as the rotor spins it induces field effects which drag and distort the magnetic lines of the outer non-rotating stator.

The faster the rotor spins, the further the degree of field distortion. Because the dynamo operates most efficiently with the rotor field at right angles to the stator field, it is necessary to either retard or advance the brush position to put the rotor's field into the correct position to be at a right angle to the distorted field.

These field effects are reversed when the direction of spin is reversed. It is therefore difficult to build an efficient reversible commutated dynamo, since for highest field strength it is necessary to move the brushes to the opposite side of the normal neutral plane.

The effect can be considered to be somewhat similar to timing advance in an internal combustion engine. Generally a dynamo that has been designed to run at a certain fixed speed will have its brushes permanently fixed to align the field for highest efficiency at that speed.

Motor design variations

DC motors

Brushed DC motors are constructed with wound rotors and either wound or permanent-magnet stators.

Wound stators

The field coils have traditionally existed in four basic formats: separately excited (sepex), series-wound, shunt-wound, and a combination of the latter two; compound-wound.

In a series wound motor, the field coils are connected electrically in series with the armature coils (via the brushes). In a shunt wound motor, the field coils are connected in parallel, or "shunted" to the armature coils. In a separately excited (sepex) motor the field coils are supplied from an independent source, such as a motor-generator and the field current is unaffected by changes in the armature current. The sepex system was sometimes used in DC traction motors to facilitate control of wheelslip.

Permanent-magnet motors

Permanent-magnet types have some performance advantages over direct-current, excited, synchronous types, and have become predominant in fractional horsepower applications. They are smaller, lighter, more efficient and reliable than other singly-fed electric machines.

Originally all large industrial DC motors used wound field or rotor magnets. Permanent magnets have traditionally only been useful on small motors because it was difficult to find a material capable of retaining a high-strength field. Only recently have advances in materials technology allowed the creation of high-intensity permanent magnets, such as neodymium magnets, allowing the development of compact, high-power motors without the extra real-estate of field coils and excitation means. But as these high performance permanent magnets become more applied in electric motor or generator systems, other problems are realized (see Permanent magnet synchronous generator).

Axial field motors

Traditionally, the field has been applied radially—in and away from the rotation axis of the motor. However some designs have the field flowing along the axis of the motor, with the rotor cutting the field lines as it rotates. This allows for much stronger magnetic fields, particularly if halbach arrays are employed. This, in turn, gives power to the motor at lower speeds. However, the focused flux density cannot rise about the limited residual flux density of the permanent magnet despite high coercivity and like all electric machines, the flux density of magnetic core saturation is the design constraint.

Speed control

Generally, the rotational speed of a DC motor is proportional to the EMF in its coil (= the voltage applied to it minus voltage lost on its resistance), and the torque is proportional to the current. Speed control can be achieved by variable battery tappings, variable supply voltage, resistors or electronic controls. A simulation example can be found here[3] and [4]. The direction of a wound field DC motor can be changed by reversing either the field or armature connections but not both. This is commonly done with a special set of contactors (direction contactors). The effective voltage can be varied by inserting a series resistor or by an electronically controlled switching device made of thyristors, transistors, or, formerly, mercury arc rectifiers.

Series-parallel

Series-parallel control was the standard method of controlling railway traction motors before the advent of power electronics. An electric locomotive or train would typically have four motors which could be grouped in three different ways:

- All four in series (each motor receives one quarter of the line voltage)

- Two parallel groups of two in series (each motor receives half the line voltage)

- All four in parallel (each motor receives the full line voltage)

This provided three running speeds with minimal resistance losses. For starting and acceleration, additional control was provided by resistances. This system has been superseded by electronic control systems.

Field weakening

The speed of a DC motor can be increased by field weakening. Reducing the field strength is done by inserting resistance in series with a shunt field, or inserting resistances around a series-connected field winding, to reduce current in the field winding. When the field is weakened, the back-emf reduces, so a larger current flows through the armature winding and this increases the speed. Field weakening is not used on its own but in combination with other methods, such as series-parallel control.

Chopper

In a circuit known as a chopper, the average voltage applied to the motor is varied by switching the supply voltage very rapidly. As the "on" to "off" ratio is varied to alter the average applied voltage, the speed of the motor varies. The percentage "on" time multiplied by the supply voltage gives the average voltage applied to the motor. Therefore, with a 100 V supply and a 25% "on" time, the average voltage at the motor will be 25 V. During the "off" time, the armature's inductance causes the current to continue through a diode called a "flyback diode", in parallel with the motor. At this point in the cycle, the supply current will be zero, and therefore the average motor current will always be higher than the supply current unless the percentage "on" time is 100%. At 100% "on" time, the supply and motor current are equal. The rapid switching wastes less energy than series resistors. This method is also called pulse-width modulation (PWM) and is often controlled by a microprocessor. An output filter is sometimes installed to smooth the average voltage applied to the motor and reduce motor noise.

Since the series-wound DC motor develops its highest torque at low speed, it is often used in traction applications such as electric locomotives, and trams. Another application is starter motors for petrol and small diesel engines. Series motors must never be used in applications where the drive can fail (such as belt drives). As the motor accelerates, the armature (and hence field) current reduces. The reduction in field causes the motor to speed up until it destroys itself. This can also be a problem with railway motors in the event of a loss of adhesion since, unless quickly brought under control, the motors can reach speeds far higher than they would do under normal circumstances. This can not only cause problems for the motors themselves and the gears, but due to the differential speed between the rails and the wheels it can also cause serious damage to the rails and wheel treads as they heat and cool rapidly. Field weakening is used in some electronic controls to increase the top speed of an electric vehicle. The simplest form uses a contactor and field-weakening resistor; the electronic control monitors the motor current and switches the field weakening resistor into circuit when the motor current reduces below a preset value (this will be when the motor is at its full design speed). Once the resistor is in circuit, the motor will increase speed above its normal speed at its rated voltage. When motor current increases, the control will disconnect the resistor and low speed torque is made available.

Ward Leonard

A Ward Leonard control is usually used for controlling a shunt or compound wound DC motor, and developed as a method of providing a speed-controlled motor from an AC supply, though it is not without its advantages in DC schemes. The AC supply is used to drive an AC motor, usually an induction motor that drives a DC generator or dynamo. The DC output from the armature is directly connected to the armature of the DC motor (sometimes but not always of identical construction). The shunt field windings of both DC machines are independently excited through variable resistors. Extremely good speed control from standstill to full speed, and consistent torque, can be obtained by varying the generator and/or motor field current. This method of control was the de facto method from its development until it was superseded by solid state thyristor systems. It found service in almost any environment where good speed control was required, from passenger lifts through to large mine pit head winding gear and even industrial process machinery and electric cranes. Its principal disadvantage was that three machines were required to implement a scheme (five in very large installations, as the DC machines were often duplicated and controlled by a tandem variable resistor). In many applications, the motor-generator set was often left permanently running, to avoid the delays that would otherwise be caused by starting it up as required. Although electronic (thyristor) controllers have replaced most small to medium Ward-Leonard systems, some very large ones (thousands of horsepower) remain in service. The field currents are much lower than the armature currents, allowing a moderate sized thyristor unit to control a much larger motor than it could control directly. For example, in one installation, a 300 amp thyristor unit controls the field of the generator. The generator output current is in excess of 15,000 amperes, which would be prohibitively expensive (and inefficient) to control directly with thyristors.

Torque and speed of a DC motor

A DC motor's speed and torque characteristics vary according to three different magnetization sources, separately excited field, self-excited field or permanent-field, which are used selectively to control the motor over the mechanical load's range. Self-excited field motors can be series, shunt, or compound wound connected to the armature.

Basic properties

Define

- Eb, induced or counter EMF (V)

- Ia, armature current (A)

- kb, counter EMF equation constant

- kn, speed equation constant

- kT, torque equation constant

- n, armature frequency (rpm)

- Rm, motor resistance (Ω)

- T, motor torque (Nm)

- Vm, motor input voltage (V)

- Φ, machine's total flux (Wb)

Counter EMF equation

The DC motor's counter emf is proportional to the product of the machine's total flux strength and armature speed:

- Eb = kb Φ n

Voltage balance equation

The DC motor's input voltage must overcome the counter emf as well as the voltage drop created by the armature current across the motor resistance, that is, the combined resistance across the brushes, armature winding and series field winding, if any:

- Vm = Eb + Rm Ia

Torque equation

The DC motor's torque is proportional to the product of the armature current and the machine's total flux strength:

where

- kT = kb2π

Speed equation

Since

- n = Ebkb Φ and

- Vm = Eb + Rm Ia

where

- kn = 1kb

Torque and speed characteristics

Shunt wound motor

With the shunt wound motor's high-resistance field winding connected in parallel with the armature, Vm, Rm and Ø are constant such that the no load to full load speed regulation is seldom more than 5%.[15] Speed control is achieved three ways:

- Varying the field voltage

- Field weakening

- Variable resistance in the field circuit.

Series wound motor

The series motor responds to increased load by slowing down; the current increases and the torque rises in proportional to the square of the current since the same current flows in both the armature and the field windings. If the motor is stalled, the current is limited only by the total resistance of the windings and the torque can be very high, but there is a danger of the windings becoming overheated. Series wound motors were widely used as traction motors in rail transport[17] of every kind, but are being phased out in favour of power inverter-fed AC induction motors. The counter emf aids the armature resistance to limit the current through the armature. When power is first applied to a motor, the armature does not rotate, the counter emf is zero and the only factor limiting the armature current is the armature resistance.[18] As the prospective current through the armature is very large, the need arises for an additional resistance in series with the armature to limit the current until the motor rotation can build up the counter emf. As the motor rotation builds up, the resistance is gradually cut out.

The series wound DC motor's most notable characteristic is that it is almost entirely dependent on the torque required to drive the load. This suits large inertial loads as motor accelerates from maximum torque, torque reducing gradually as load increases.

As the series motor's speed can be dangerously high, series motors are often geared or direct-connected to the load.

Permanent magnet motor

A permanent magnet DC motor is characterized by a linear relationship between stall torque when the torque is maximum with the shaft at standstill and no load speed with no applied shaft torque and maximum output speed . There is a quadratic power relationship between these two speed-axis points.

Protection

To extend a DC motor’s service life, protective devices and motor controllers are used to protect it from mechanical damage, excessive moisture, high dielectric stress and high temperature or thermal overloading.[22] These protective devices sense motor fault conditions[23] and either annunciate an alarm to notify the operator or automatically de-energize the motor when a faulty condition occurs. For overloaded conditions, motors are protected with thermal overload relays. Bi-metal thermal overload protectors are embedded in the motor's windings and made from two dissimilar metals. They are designed such that the bimetallic strips will bend in opposite directions when a temperature set point is reached to open the control circuit and de-energize the motor. Heaters are external thermal overload protectors connected in series with the motor’s windings and mounted in the motor contactor. Solder pot heaters melt in an overload condition, which cause the motor control circuit to de-energize the motor. Bimetallic heaters function the same way as embedded bimetallic protectors. Fuses and circuit breakers are overcurrent or short circuit protectors. Ground fault relays also provide overcurrent protection. They monitor the electric current between the motor’s windings and earth system ground. In motor-generators, reverse current relays prevent the battery from discharging and motorizing the generator. Since D.C. motor field loss can cause a hazardous runaway or overspeed condition, loss of field relays[24] are connected in parallel with the motor’s field to sense field current. When the field current decreases below a set point, the relay will deenergize the motor’s armature. A locked rotor condition prevents a motor from accelerating after its starting sequence has been initiated. Distance relays protect motors from locked-rotor faults. Undervoltage motor protection is typically incorporated into motor controllers or starters. In addition, motors can be protected from overvoltages or surges with isolation transformers, power conditioning equipment, MOVs, arresters and harmonic filters. Environmental conditions, such as dust, explosive vapors, water, and high ambient temperatures, can adversely affect the operation of a DC motor. To protect a motor from these environmental conditions, the National Electrical Manufacturers Association (NEMA) and the International Electrotechnical Commission (IEC) have standardized motor enclosure designs based upon the environmental protection they provide from contaminants. Modern software can also be used in the design stage, such as Motor-CAD, to help increase the thermal efficiency of a motor.

DC motor starters

The counter-emf aids the armature resistance to limit the current through the armature. When power is first applied to a motor, the armature does not rotate. At that instant the counter-emf is zero and the only factor limiting the armature current is the armature resistance and inductance. Usually the armature resistance of a motor is less than 1 Ω; therefore the current through the armature would be very large when the power is applied. This current can make an excessive voltage drop affecting other equipment in the circuit and even trip overload protective devices.

Therefore, the need arises for an additional resistance in series with the armature to limit the current until the motor rotation can build up the counter-emf. As the motor rotation builds up, the resistance is gradually cut out.

Manual-starting rheostat

When electrical and DC motor technology was first developed, much of the equipment was constantly tended by an operator trained in the management of motor systems. The very first motor management systems were almost completely manual, with an attendant starting and stopping the motors, cleaning the equipment, repairing any mechanical failures, and so forth.

The first DC motor-starters were also completely manual, as shown in this image. Normally it took the operator about ten seconds to slowly advance the rheostat across the contacts to gradually increase input power up to operating speed. There were two different classes of these rheostats, one used for starting only, and one for starting and speed regulation. The starting rheostat was less expensive, but had smaller resistance elements that would burn out if required to run a motor at a constant reduced speed.

This starter includes a no-voltage magnetic holding feature, which causes the rheostat to spring to the off position if power is lost, so that the motor does not later attempt to restart in the full-voltage position. It also has overcurrent protection that trips the lever to the off position if excessive current over a set amount is detected.

Three-point starter

The incoming power is indicated as L1 and L2. The components within the broken lines form the three-point starter. As the name implies there are only three connections to the starter. The connections to the armature are indicated as A1 and A2. The ends of the field (excitement) coil are indicated as F1 and F2. In order to control the speed, a field rheostat is connected in series with the shunt field. One side of the line is connected to the arm of the starter (represented by an arrow in the diagram). The arm is spring-loaded so, it will return to the "Off" position when not held at any other position.

- On the first step of the arm, full line voltage is applied across the shunt field. Since the field rheostat is normally set to minimum resistance, the speed of the motor will not be excessive; additionally, the motor will develop a large starting torque.

- The starter also connects an electromagnet in series with the shunt field. It will hold the arm in position when the arm makes contact with the magnet.

- Meanwhile, that voltage is applied to the shunt field, and the starting resistance limits the current to the armature.

- As the motor picks up speed counter-emf is built up; the arm is moved slowly to short.

Four-point starter

The four-point starter eliminates the drawback of the three-point starter. In addition to the same three points that were in use with the three-point starter, the other side of the line, L1, is the fourth point brought to the starter when the arm is moved from the "Off" position. The coil of the holding magnet is connected across the line. The holding magnet and starting resistors function identical as in the three-point starter.

- The possibility of accidentally opening the field circuit is quite remote. The four-point starter provides the no-voltage protection to the motor. If the power fails, the motor is disconnected from the line.

AP Monitor

Advanced process monitor (APMonitor), is a modeling language for differential algebraic (DAE) equations. It is a free web-service for solving representations of physical systems in the form of implicit DAE models. APMonitor is suited for large-scale problems and allows solutions of linear programming, integer programming, nonlinear programming, nonlinear mixed integer programming, dynamic simulation, moving horizon estimation, and nonlinear model predictive control.[4] APMonitor does not solve the problems directly, but calls nonlinear programming solvers such as APOPT, BPOPT, IPOPT, MINOS, and SNOPT. The APMonitor API provides exact first and second derivatives of continuous functions to the solvers through automatic differentiation and in sparse matrix form.

Programming Language Integration

Julia, MATLAB, Python are mathematical programming languages that have AP Monitor integration through web-service APIs. The interfaces are built-in optimization toolboxes or modules to both load and process solutions of optimization problems. AP Monitor is an object-oriented modeling language and optimization suite that relies on programming languages to load, run, and retrieve solutions. AP Monitor models and data are compiled at run-time and translated into objects that are solved by an optimization engine such as APOPT or IPOPT. The optimization engine is not specified by AP Monitor, allowing several different optimization engines to be switched out. The simulation or optimization mode is also configurable to reconfigure the model for dynamic simulation, nonlinear model predictive control, moving horizon estimation or general problems in mathematical optimization.

As a first step in solving the problem, a mathematical model is expressed in terms of variables and equations such as the Hock & Schittkowski Benchmark Problem #71[5] used to test the performance of nonlinear programming solvers. This particular optimization problem has an objective function and subject to the inequality constraint and equality constraint . The four variables must be between a lower bound of 1 and an upper bound of 5. The initial guess values are . This mathematical model is translated into the APMonitor modeling language in the following text file.

! file saved as hs71.apm

Variables

x1 = 1, >=1, <=5

x2 = 5, >=1, <=5

x3 = 5, >=1, <=5

x4 = 1, >=1, <=5

End Variables

Equations

minimize x1*x4*(x1+x2+x3) + x3

x1*x2*x3*x4 > 25

x1^2 + x2^2 + x3^2 + x4^2 = 40

End Equations

The problem is then solved in Python by first installing the APMonitor package with pip install APMonitor or from the following Python code.

# Install APMonitor

import pip

pip.main(['install','APMonitor'])

Installing a Python is only required once for any module. Once the APMonitor package is installed, it is imported and the apm_solve function solves the optimization problem. The solution is returned to the programming language for further processing and analysis.

# Python example for solving an optimization problem

from APMonitor import *

# Solve optimization problem

sol = apm_solve('hs71',3)

# Access solution

x1 = sol['x1']

x2 = sol['x2']

Similar interfaces are available for MATLAB and Julia with minor differences from the above syntax. Extending the capability of a modeling language is important because significant pre- or post-processing of data or solutions is often required when solving complex optimization, dynamic simulation, estimation, or control problems.

High Index DAEs

The highest order of a derivative that is necessary to return a DAE to ODE form is called the differentiation index. A standard way for dealing with high-index DAEs is to differentiate the equations to put them in index-1 DAE or ODE form (see Pantelides algorithm). However, this approach can cause a number of undesirable numerical issues such as instability. While the syntax is similar to other modeling languages such as gProms, APMonitor solves DAEs of any index without rearrangement or differentiation. As an example, an index-3 DAE is shown below for the pendulum motion equations and lower index rearrangements can return this system of equations to ODE form

Pendulum motion (index-3 DAE form)

Model pendulum

Parameters

m = 1

g = 9.81

s = 1

End Parameters

Variables

x = 0

y = -s

v = 1

w = 0

lam = m*(1+s*g)/2*s^2

End Variables

Equations

x^2 + y^2 = s^2

$x = v

$y = w

m*$v = -2*x*lam

m*$w = -m*g - 2*y*lam

End Equations

End Model

Applications in APMonitor Modeling Language

Many physical systems are naturally expressed by differential algebraic equation. Some of these include:

- cell cultures

- chemical reactors

- cogeneration (power and heat)

- distillation columns

- drilling automation

- friction stir welding

- hydrate formation in deep-sea pipelines

- infectious disease spread

- oscillators

- severe slugging control

- solar thermal energy production

- solid oxide fuel cells

- space shuttle launch simulation

- Unmanned Aerial Vehicles (UAVs)

Models for a direct current (DC) motor and blood glucose response of an insulin dependent patient are listed below. They are representative of differential and algebraic equations encountered in many branches of science and engineering.

Direct current (DC) motor

Parameters

! motor parameters (dc motor)

v = 36 ! input voltage to the motor (volts)

rm = 0.1 ! motor resistance (ohms)

lm = 0.01 ! motor inductance (henrys)

kb = 6.5e-4 ! back emf constant (volt·s/rad)

kt = 0.1 ! torque constant (N·m/a)

jm = 1.0e-4 ! rotor inertia (kg m²)

bm = 1.0e-5 ! mechanical damping (linear model of friction: bm * dth)

! load parameters

jl = 1000*jm ! load inertia (1000 times the rotor)

bl = 1.0e-3 ! load damping (friction)

k = 1.0e2 ! spring constant for motor shaft to load

b = 0.1 ! spring damping for motor shaft to load

End Parameters

Variables

i = 0 ! motor electric current (amperes)

dth_m = 0 ! rotor angular velocity sometimes called omega (radians/sec)

th_m = 0 ! rotor angle, theta (radians)

dth_l = 0 ! wheel angular velocity (rad/s)

th_l = 0 ! wheel angle (radians)

End Variables

Equations

lm*$i - v = -rm*i - kb *$th_m

jm*$dth_m = kt*i - (bm+b)*$th_m - k*th_m + b *$th_l + k*th_l

jl*$dth_l = b *$th_m + k*th_m - (b+bl)*$th_l - k*th_l

dth_m = $th_m

dth_l = $th_l

End Equations

Blood glucose response of an insulin dependent patient

! Model source:

! A. Roy and R.S. Parker. “Dynamic Modeling of Free Fatty

! Acids, Glucose, and Insulin: An Extended Minimal Model,”

! Diabetes Technology and Therapeutics 8(6), 617-626, 2006.

Parameters

p1 = 0.068 ! 1/min

p2 = 0.037 ! 1/min

p3 = 0.000012 ! 1/min

p4 = 1.3 ! mL/(min·µU)

p5 = 0.000568 ! 1/mL

p6 = 0.00006 ! 1/(min·µmol)

p7 = 0.03 ! 1/min

p8 = 4.5 ! mL/(min·µU)

k1 = 0.02 ! 1/min

k2 = 0.03 ! 1/min

pF2 = 0.17 ! 1/min

pF3 = 0.00001 ! 1/min

n = 0.142 ! 1/min

VolG = 117 ! dL

VolF = 11.7 ! L

! basal parameters for Type-I diabetic

Ib = 0 ! Insulin (µU/mL)

Xb = 0 ! Remote insulin (µU/mL)

Gb = 98 ! Blood Glucose (mg/dL)

Yb = 0 ! Insulin for Lipogenesis (µU/mL)

Fb = 380 ! Plasma Free Fatty Acid (µmol/L)

Zb = 380 ! Remote Free Fatty Acid (µmol/L)

! insulin infusion rate

u1 = 3 ! µU/min

! glucose uptake rate

u2 = 300 ! mg/min

! external lipid infusion

u3 = 0 ! mg/min

End parameters

Intermediates

p9 = 0.00021 * exp(-0.0055*G) ! dL/(min*mg)

End Intermediates

Variables

I = Ib

X = Xb

G = Gb

Y = Yb

F = Fb

Z = Zb

End variables

Equations

! Insulin dynamics

$I = -n*I + p5*u1

! Remote insulin compartment dynamics

$X = -p2*X + p3*I

! Glucose dynamics

$G = -p1*G - p4*X*G + p6*G*Z + p1*Gb - p6*Gb*Zb + u2/VolG

! Insulin dynamics for lipogenesis

$Y = -pF2*Y + pF3*I

! Plasma-free fatty acid (FFA) dynamics

$F = -p7*(F-Fb) - p8*Y*F + p9 * (F*G-Fb*Gb) + u3/VolF

! Remote FFA dynamics

$Z = -k2*(Z-Zb) + k1*(F-Fb)

End Equations

Modelica is an object-oriented, declarative, multi-domain modeling language for component-oriented modeling of complex systems, e.g., systems containing mechanical, electrical, electronic, hydraulic, thermal, control, electric power or process-oriented subcomponents. The free Modelica language is developed by the non-profit Modelica Association. The Modelica Association also develops the free Modelica Standard Library. that contains about 1360 generic model components and 1280 functions in various domains, as of version 3.2.1

While Modelica resembles object-oriented programming languages, such as C++ or Java, it differs in two important respects. First, Modelica is a modeling language rather than a conventional programming language. Modelica classes are not compiled in the usual sense, but they are translated into objects which are then exercised by a simulation engine. The simulation engine is not specified by the language, although certain required capabilities are outlined.

Second, although classes may contain algorithmic components similar to statements or blocks in programming languages, their primary content is a set of equations. In contrast to a typical assignment statement, such as

x := 2 + y;

where the left-hand side of the statement is assigned a value calculated from the expression on the right-hand side, an equation may have expressions on both its right- and left-hand sides, for example,

x + y = 3 * z;

Equations do not describe assignment but equality. In Modelica terms, equations have no pre-defined causality. The simulation engine may (and usually must) manipulate the equations symbolically to determine their order of execution and which components in the equation are inputs and which are outputs.

The Modelica design effort was initiated in September 1996 by Hilding Elmqvist. The goal was to develop an object-oriented language for modeling of technical systems in order to reuse and exchange dynamic system models in a standardized format. Modelica 1.0 is based on the PhD thesis[4] of Hilding Elmqvist and on the experience with the modeling languages Allan,[5] Dymola, NMF[6] ObjectMath,[7] Omola,[8]SIDOPS+,[9] and Smile.[10] Hilding Elmqvist is the key architect of Modelica, but many other people have contributed as well (see appendix E).[1] In September 1997, version 1.0 of the Modelica specification was released which was the basis for a prototype implementation within the commercial Dymola software system. In year 2000, the non-profit Modelica Association was formed to manage the continually evolving Modelica language and the development of the free Modelica Standard Library. In the same year, the usage of Modelica in industrial applications started.

This table presents the timeline of the Modelica specification

| Release | Release Date | Highlights |

|---|---|---|

| 1.0 | 1997, September | First version to model continuous dynamic systems. |

| 1.1 | 1998, December | Language elements to model discrete systems (pre, when) |

| 1.2 | 1999, June | Interface to C and Fortran, inner/outer for global variables, refined semantics of event handling |

| 1.3 | 1999, December | Improved semantics for inner/outer connections, protected elements, array expressions. |

| 1.4 | 2000, December | Removed declare-before-use rule, refined package concept, refined when-clause |

| 2.0 | 2002, July | Initialization of models, standardization of graphical appearance, functions with mixed positional and named arguments, record constructor, enumerations |

| 2.1 | 2004, March | Overdetermined connector to model 3-dim. mechanical systems, enhanced redeclaration of submodels, array and array indices of enumerations |

| 2.2 | 2005, February | Expandable connector to model signal buses, conditional component declarations, arrays with dynamic size changes in functions |

| 3.0 | 2007, September | Clean-up version: specification newly written, type system and graphical appearance refined, language flaws fixed, balanced model concept to detect model errors in a much better way |

| 3.1 | 2009, May | Stream connector to handle bi-directional flow of fluid, operator overloading, mapping model parts to execution environments (for use in embedded systems) |

| 3.2 | 2010, March | Improved initialization with homotopy method, functions as formal inputs to functions, Unicode support, access control to protect IP, improved support of object libraries |

| 3.3 | 2012, May | Added language elements to describe periodic and non-periodic synchronous controllers based on clocked equations, as well as synchronous state machines. |

| 3.4 | 2017, April | Automatic conversion of models. Many minor improvements |

Implementations

Commercial front-ends for Modelica include AMESim from the French company Imagine SA (now part of Siemens PLM Software), Dymola from the Swedish company Dynasim AB (now part of Dassault Systemes), CyModelica[12] from the American company CyDesign Labs now ESI Group, Wolfram SystemModeler (formerly MathModelica) from the Swedish company Wolfram MathCore AB (now part of Wolfram Research), SimulationX from the German company ESI ITI GmbH, MapleSim from the Canadian company Maplesoft,[13] and CATIA Systems [14][15] from Dassault Systemes (CATIA is one of the major CAD systems).

JModelica.org is an extensible Modelica-based open source platform for optimization, simulation and analysis of complex dynamic systems. The main objective of the project is to create an industrially viable open source platform for simulation optimization of Modelica models, while offering a flexible platform serving as a virtual lab for algorithm development and research.

Openmodelica is an open-source Modelica-based modeling and simulation environment intended for industrial and academic usage. Its long-term development is supported by a non-profit organization – the Open Source Modelica Consortium (OSMC). The goal with the OpenModelica effort is to create a comprehensive Open Source Modelica modeling, compilation and simulation environment based on free software distributed in binary and source code form for research, teaching, and industrial usage.

The free simulation environment Scicos uses a subset of Modelica for component modeling. Support for a larger part of the Modelica language is currently under development. Nevertheless, there is still some incompatibility and diverging interpretation between all the different tools concerning the Modelica language

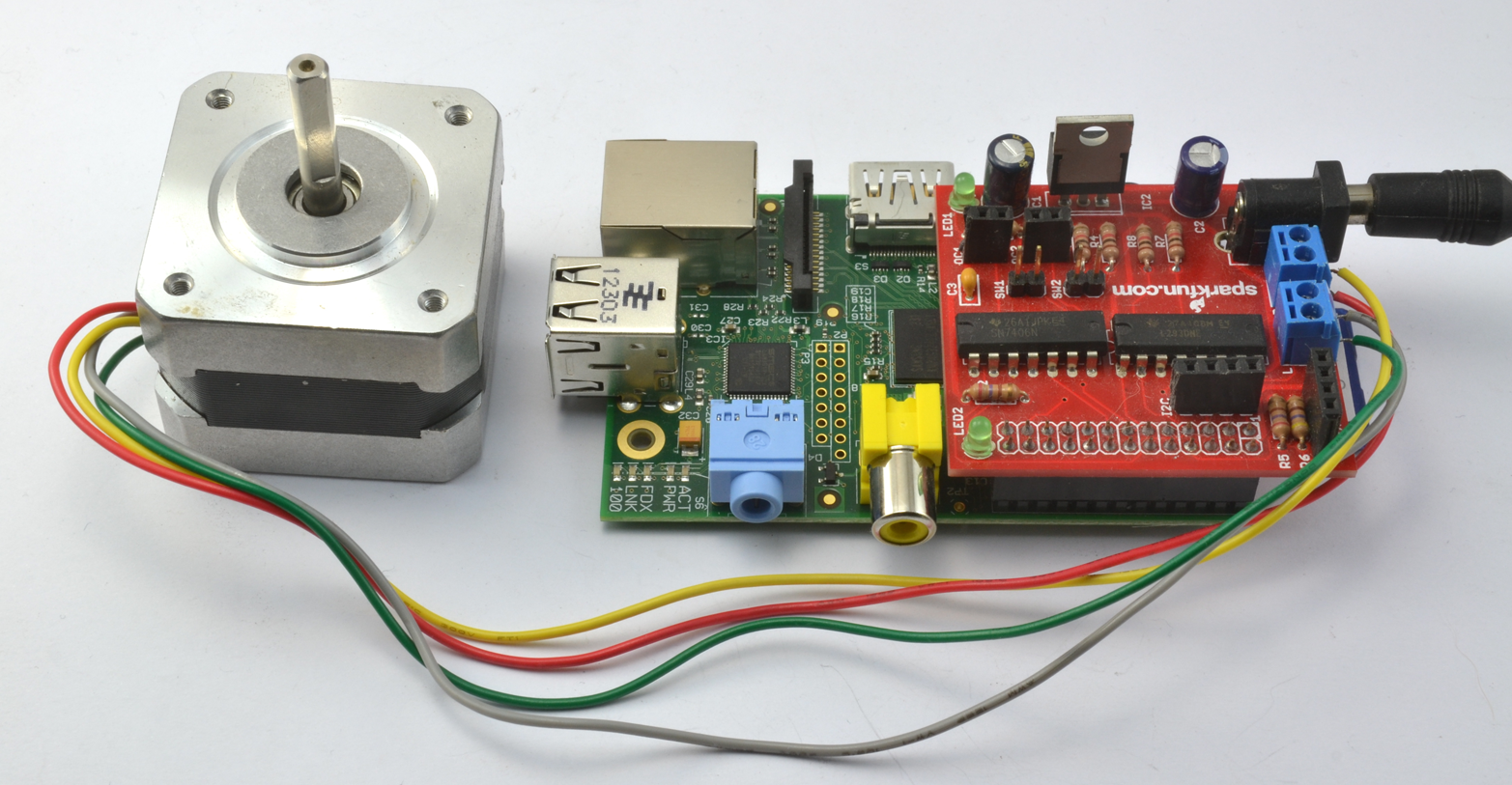

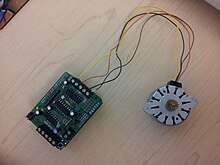

XXX . XXX 4%zero Stepper motor

A stepper motor or step motor or stepping motor is a brush less DC electric motor that divides a full rotation into a number of equal steps. The motor's position can then be commanded to move and hold at one of these steps without any position sensor for feedback (an open-loop controller), as long as the motor is carefully sized to the application in respect to torque and speed.

Switched reluctance motors are very large stepping motors with a reduced pole count, and generally are closed-loop commutated.

Frame 1: The top electromagnet (1) is turned on, attracting the nearest teeth of the gear-shaped iron rotor. With the teeth aligned to electromagnet 1, they will be slightly offset from right electromagnet (2).

Frame 2: The top electromagnet (1) is turned off, and the right electromagnet (2) is energized, pulling the teeth into alignment with it. This results in a rotation of 3.6° in this example.

Frame 3: The bottom electromagnet (3) is energized; another 3.6° rotation occurs.

Frame 4: The left electromagnet (4) is energized, rotating again by 3.6°. When the top electromagnet (1) is again enabled, the rotor will have rotated by one tooth position; since there are 25 teeth, it will take 100 steps to make a full rotation in this example.

Fundamentals of operation

Brushed DC motors rotate continuously when DC voltage is applied to their terminals. The stepper motor is known by its property to convert a train of input pulses (typically square wave pulses) into a precisely defined increment in the shaft position. Each pulse moves the shaft through a fixed angle.

Stepper motors effectively have multiple "toothed" electromagnets arranged around a central gear-shaped piece of iron. The electromagnets are energized by an external driver circuit or a micro controller. To make the motor shaft turn, first, one electromagnet is given power, which magnetically attracts the gear's teeth. When the gear's teeth are aligned to the first electromagnet, they are slightly offset from the next electromagnet. This means that when the next electromagnet is turned on and the first is turned off, the gear rotates slightly to align with the next one. From there the process is repeated. Each of those rotations is called a "step", with an integer number of steps making a full rotation. In that way, the motor can be turned by a precise angle.

The circular arrangement of electromagnets is divided into groups, each group called a phase, and there is an equal number of electromagnets per group. The number of groups is chosen by the designer of the stepper motor. The electromagnets of each group are interleaved with the electromagnets of other groups to form a uniform pattern of arrangement. For example, if the stepper motor has two groups identified as A or B, and ten electromagnets in total, then the grouping pattern would be ABABABABAB.

Electromagnets within the same group are all energized together. Because of this, stepper motors with more phases typically have more wires (or leads) to control the motor.

Types

There are three main types of stepper motors:

Permanent magnet motors use a permanent magnet (PM) in the rotor and operate on the attraction or repulsion between the rotor PM and the stator electromagnets. Variable reluctance (VR) motors have a plain iron rotor and operate based on the principle that minimum reluctance occurs with minimum gap, hence the rotor points are attracted toward the stator magnet poles.

Two-phase stepper motors

There are two basic winding arrangements for the electromagnetic coils in a two phase stepper motor: bipolar and unipolar.

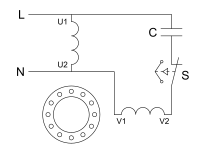

Unipolar motors

A unipolar stepper motor has one winding with center tap per phase. Each section of windings is switched on for each direction of magnetic field. Since in this arrangement a magnetic pole can be reversed without switching the direction of current, the commutation circuit can be made very simple (e.g., a single transistor) for each winding. Typically, given a phase, the center tap of each winding is made common: giving three leads per phase and six leads for a typical two phase motor. Often, these two phase commons are internally joined, so the motor has only five leads.

A micro controller or stepper motor controller can be used to activate the drive transistors in the right order, and this ease of operation makes unipolar motors popular with hobbyists; they are probably the cheapest way to get precise angular movements.

For the experimenter, the windings can be identified by touching the terminal wires together in PM motors. If the terminals of a coil are connected, the shaft becomes harder to turn. One way to distinguish the center tap (common wire) from a coil-end wire is by measuring the resistance. Resistance between common wire and coil-end wire is always half of the resistance between coil-end wires. This is because there is twice the length of coil between the ends and only half from center (common wire) to the end. A quick way to determine if the stepper motor is working is to short circuit every two pairs and try turning the shaft. Whenever a higher than normal resistance is felt, it indicates that the circuit to the particular winding is closed and that the phase is working.

Bipolar motors

Bipolar motors have a single winding per phase. The current in a winding needs to be reversed in order to reverse a magnetic pole, so the driving circuit must be more complicated, typically with an H-bridge arrangement (however there are several off-the-shelf driver chips available to make this a simple affair). There are two leads per phase, none are common.

Static friction effects using an H-bridge have been observed with certain drive topologies.[2]

Dithering the stepper signal at a higher frequency than the motor can respond to will reduce this "static friction" effect.

Because windings are better utilized, they are more powerful than a unipolar motor of the same weight. This is due to the physical space occupied by the windings. A unipolar motor has twice the amount of wire in the same space, but only half used at any point in time, hence is 50% efficient (or approximately 70% of the torque output available). Though a bipolar stepper motor is more complicated to drive, the abundance of driver chips means this is much less difficult to achieve.

An 8-lead stepper is wound like a unipolar stepper, but the leads are not joined to common internally to the motor. This kind of motor can be wired in several configurations:

- Unipolar.

- Bipolar with series windings. This gives higher inductance but lower current per winding.

- Bipolar with parallel windings. This requires higher current but can perform better as the winding inductance is reduced.

- Bipolar with a single winding per phase. This method will run the motor on only half the available windings, which will reduce the available low speed torque but require less current

Higher-phase count stepper motors

Multi-phase stepper motors with many phases tend to have much lower levels of vibration. While they are more expensive, they do have a higher power density and with the appropriate drive electronics are often better suited to the application

Stepper motor driver circuits

Stepper motor performance is strongly dependent on the driver circuit. Torque curves may be extended to greater speeds if the stator poles can be reversed more quickly, the limiting factor being a combination of the winding inductance. To overcome the inductance and switch the windings quickly, one must increase the drive voltage. This leads further to the necessity of limiting the current that these high voltages may otherwise induce.

An additional limitation, often comparable to the effects of inductance, is the back-EMF of the motor. As the motor's rotor turns, a sinusoidal voltage is generated proportional to the speed (step rate). This AC voltage is subtracted from the voltage waveform available to induce a change in the current.

L/R driver circuits

L/R driver circuits are also referred to as constant voltage drives because a constant positive or negative voltage is applied to each winding to set the step positions. However, it is winding current, not voltage that applies torque to the stepper motor shaft. The current I in each winding is related to the applied voltage V by the winding inductance L and the winding resistance R. The resistance R determines the maximum current according to Ohm's law I=V/R. The inductance L determines the maximum rate of change of the current in the winding according to the formula for an inductor dI/dt = V/L. Thus when controlled by an L/R drive, the maximum speed of a stepper motor is limited by its inductance since at some speed, the voltage U will be changing faster than the current I can keep up. In simple terms the rate of change of current is L / R (e.g. a 10 mH inductance with 2 ohms resistance will take 5 ms to reach approx 2/3 of maximum torque or around 24 ms to reach 99% of max torque). To obtain high torque at high speeds requires a large drive voltage with a low resistance and low inductance.

With an L/R drive it is possible to control a low voltage resistive motor with a higher voltage drive simply by adding an external resistor in series with each winding. This will waste power in the resistors, and generate heat. It is therefore considered a low performing option, albeit simple and cheap.

Modern voltage-mode drivers overcome some of these limitations by approximating a sinusoidal voltage waveform to the motor phases. The amplitude of the voltage waveform is set up to increase with step rate. If properly tuned, this compensates the effects of inductance and back-EMF, allowing decent performance relative to current-mode drivers, but at the expense of design effort (tuning procedures) that are simpler for current-mode drivers.

Chopper drive circuits

Chopper drive circuits are referred to as constant current drives because they generate a somewhat constant current in each winding rather than applying a constant voltage. On each new step, a very high voltage is applied to the winding initially. This causes the current in the winding to rise quickly since dI/dt = V/L where V is very large. The current in each winding is monitored by the controller, usually by measuring the voltage across a small sense resistor in series with each winding. When the current exceeds a specified current limit, the voltage is turned off or "chopped", typically using power transistors. When the winding current drops below the specified limit, the voltage is turned on again. In this way, the current is held relatively constant for a particular step position. This requires additional electronics to sense winding currents, and control the switching, but it allows stepper motors to be driven with higher torque at higher speeds than L/R drives. Integrated electronics for this purpose are widely available.

Phase current wave forms

A stepper motor is a poly phase AC synchronous motor (see Theory below), and it is ideally driven by sinusoidal current. A full-step waveform is a gross approximation of a sinusoidal , and is the reason why the motor exhibits so much vibration. Various drive techniques have been developed to better approximate a sinusoidal drive waveform: these are half stepping and micro stepping.

Wave drive (one phase on)

In this drive method only a single phase is activated at a time. It has the same number of steps as the full-step drive, but the motor will have significantly less than rated torque. It is rarely used. The animated figure shown above is a wave drive motor. In the animation, rotor has 25 teeth and it takes 4 steps to rotate by one tooth position. So there will be 25×4 = 100 steps per full rotation and each step will be 360/100 = 3.6 degrees.

Full-step drive (two phases on)

This is the usual method for full-step driving the motor. Two phases are always on so the motor will provide its maximum rated torque. As soon as one phase is turned off, another one is turned on. Wave drive and single phase full step are both one and the same, with same number of steps but difference in torque.

Half-stepping

When half-stepping, the drive alternates between two phases on and a single phase on. This increases the angular resolution. The motor also has less torque (approx 70%) at the full-step position (where only a single phase is on). This may be mitigated by increasing the current in the active winding to compensate. The advantage of half stepping is that the drive electronics need not change to support it. In animated figure shown above, if we change it to half-stepping, then it will take 8 steps to rotate by 1 teeth position. So there will be 25×8 = 200 steps per full rotation and each step will be 360/200 = 1.8°. Its angle per step is half of the full step.

Microstepping

What is commonly referred to as microstepping is often sine–cosine microstepping in which the winding current approximates a sinusoidal AC waveform. Sine–cosine microstepping is the most common form, but other waveforms can be used. Regardless of the waveform used, as the microsteps become smaller, motor operation becomes more smooth, thereby greatly reducing resonance in any parts the motor may be connected to, as well as the motor itself. Resolution will be limited by the mechanical stiction, backlash, and other sources of error between the motor and the end device. Gear reducers may be used to increase resolution of positioning.

Step size repeatability is an important step motor feature and a fundamental reason for their use in positioning.

Example: many modern hybrid step motors are rated such that the travel of every full step (example 1.8 degrees per full step or 200 full steps per revolution) will be within 3% or 5% of the travel of every other full step, as long as the motor is operated within its specified operating ranges. Several manufacturers show that their motors can easily maintain the 3% or 5% equality of step travel size as step size is reduced from full stepping down to 1/10 stepping. Then, as the microstepping divisor number grows, step size repeatability degrades. At large step size reductions it is possible to issue many microstep commands before any motion occurs at all and then the motion can be a "jump" to a new position.

Theory

A step motor can be viewed as a synchronous AC motor with the number of poles (on both rotor and stator) increased, taking care that they have no common denominator. Additionally, soft magnetic material with many teeth on the rotor and stator cheaply multiplies the number of poles (reluctance motor). Modern steppers are of hybrid design, having both permanent magnets and soft iron cores.

To achieve full rated torque, the coils in a stepper motor must reach their full rated current during each step. Winding inductance and counter-EMF generated by a moving rotor tend to resist changes in drive current, so that as the motor speeds up, less and less time is spent at full current — thus reducing motor torque. As speeds further increase, the current will not reach the rated value, and eventually the motor will cease to produce torque.

Pull-in torque

This is the measure of the torque produced by a stepper motor when it is operated without an acceleration state. At low speeds the stepper motor can synchronize itself with an applied step frequency, and this pull-in torque must overcome friction and inertia. It is important to make sure that the load on the motor is frictional rather than inertial as the friction reduces any unwanted oscillations.

The pull-in curve defines an area called the start/stop region. Into this region, the motor can be started/stopped instantaneously with a load applied and without loss of synchronism.

The pull-in curve defines an area called the start/stop region. Into this region, the motor can be started/stopped instantaneously with a load applied and without loss of synchronism.

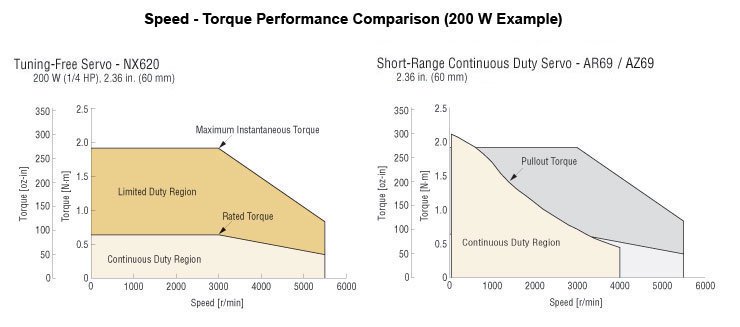

Pull-out torque

The stepper motor pull-out torque is measured by accelerating the motor to the desired speed and then increasing the torque loading until the motor stalls or misses steps. This measurement is taken across a wide range of speeds and the results are used to generate the stepper motor's dynamic performance curve. As noted below this curve is affected by drive voltage, drive current and current switching techniques. A designer may include a safety factor between the rated torque and the estimated full load torque required for the application.

Detent torque

Synchronous electric motors using permanent magnets have a resonant position holding torque (called detent torque or cogging, and sometimes included in the specifications) when not driven electrically. Soft iron reluctance cores do not exhibit this behavior.

Ringing and resonance

When the motor moves a single step it overshoots the final resting point and oscillates round this point as it comes to rest. This undesirable ringing is experienced as motor vibration and is more pronounced in unloaded motors. An unloaded or under loaded motor may, and often will, stall if the vibration experienced is enough to cause loss of synchronisation.

Stepper motors have a natural frequency of operation. When the excitation frequency matches this resonance the ringing is more pronounced, steps may be missed, and stalling is more likely. Motor resonance frequency can be calculated from the formula:

Mh Holding torque N·m

p Number of pole pairs

Jr Rotor inertia kg·m²

p Number of pole pairs

Jr Rotor inertia kg·m²

Stepper motor ratings and specifications

Stepper motors' nameplates typically give only the winding current and occasionally the voltage and winding resistance. The rated voltage will produce the rated winding current at DC: but this is mostly a meaningless rating, as all modern drivers are current limiting and the drive voltages greatly exceed the motor rated voltage.

Data sheets from the manufacturer often indicate Inductance. Back-EMF is equally relevant, but seldom listed (it is straightforward to measure with an oscilloscope). These figures can be helpful for more in-depth electronics design, when deviating from standard supply voltages, adapting third party driver electronics, or gaining insight when choosing between motor models with otherwise similar size, voltage, and torque specifications.

A stepper's low speed torque will vary directly with current. How quickly the torque falls off at faster speeds depends on the winding inductance and the drive circuitry it is attached to, especially the driving voltage.

Steppers should be sized according to published torque curve, which is specified by the manufacturer at particular drive voltages or using their own drive circuitry. Dips in the torque curve suggest possible resonances, whose impact on the application should be understood by designers.

Step motors adapted to harsh environments are often referred to as IP65 rated.

The US National Electrical Manufacturers Association (NEMA) standardises various aspects of stepper motors. They are typically referred with NEMA DD, where DD is the diameter of the faceplate in inches × 10 (e.g., NEMA 17 has diameter of 1.7 inches). There are further specifiers to describe stepper motors, and such details may be found in the ICS 16-2001 standard (section 4.3.1.1).

Applications

Computer controlled stepper motors are a type of motion-control positioning system. They are typically digitally controlled as part of an open loop system for use in holding or positioning applications.

In the field of lasers and optics they are frequently used in precision positioning equipment such as linear actuators, linear stages, rotation stages, goniometers, and mirror mounts. Other uses are in packaging machinery, and positioning of valve pilot stages for fluid control systems.

Commercially, stepper motors are used in floppy disk drives, flatbed scanners, computer printers, plotters, slot machines, image scanners, compact disc drives, intelligent lighting, camera lenses, CNC machines and, more recently, in 3D printers.

Stepper motor system

A stepper motor system consists of three basic elements, often combined with some type of user interface (host computer, PLC or dumb terminal):

- Indexers

- The indexer (or controller) is a microprocessor capable of generating step pulses and direction signals for the driver. In addition, the indexer is typically required to perform many other sophisticated command functions.