an ordinary weapon is used for a wide range of interests both for the special and military interests of every weapon useful and in the form of various materials there are mechanical as well as laser weapons that are now frequently used; the world of armaments is now so well developed in form, usability, work function and manual and automated although in practice weapons have organic and non organic weapons beyond this we only describe the function of weapons work specifically.

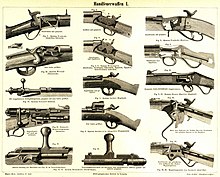

XXX . XXX Mechanic Gun Weapon

How Revolvers Work

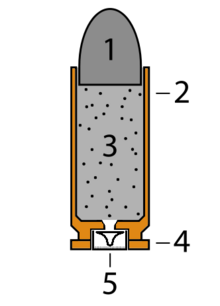

The first revolvers used gunpowder, balls and caps like the earlier percussion-cap pistols. The shooter would load each of the six chambers in the cylinder with gunpowder and a projectile, and place separate percussion caps on corresponding nipples. While the loading procedure was tedious, a shooter could have six rounds fully prepared ahead of time.

In the 1870s, these models were replaced by revolvers that used bullet cartridges instead of gunpowder and caps. Cartridges are a combination of a projectile (the bullet), a propellant (gunpowder, for example) and a primer (the explosive cap), all contained in one metal package.

In a modern revolver, cartridges are loaded into six chambers, each of which can be positioned in front of the gun's barrel. A spring-loaded hammer is positioned on the other side of the cylinder, in line with the barrel. The basic idea of the gun is to cock the hammer back, line up a new cartridge in between the hammer and the barrel and then release the hammer by pulling a trigger. The spring throws the hammer forward so it hits the primer. The primer explodes, igniting the propellant, which drives the bullet down the barrel.

The inside of the barrel is lined with spiraling grooves, which spin the bullet to give it stability. A longer barrel improves stability, since it spins the bullet for longer. Extending the barrel also increases the speed of the bullet, since the gas pressure accelerates the bullet for a longer period of time.

In early revolvers, a shooter had to pull the hammer back before each shot and then pull the trigger to release the hammer. In modern revolvers, simply pulling the trigger will force the hammer backward and then release it.

The sequence of events in each shot is very simple:

- The trigger lever pushes the hammer backward.

- As it moves backward, the hammer compresses a metal spring in the gun stock (the handle). The diagram above shows a coiled spring; uncoiled tension springs are also used in revolvers.

- At the same time, a pawl attached to the trigger pushes on a ratchet to rotate the cylinder. This positions the next breech chamber in front of the gun barrel.

- Another pawl lodges in a small depression on the cylinder. This stops the cylinder in a particular position so it is perfectly lined up with the barrel.

- When the trigger lever is pushed all the way back, it releases the hammer.

- The compressed spring drives the hammer forward. The firing pin on the hammer extends through the body of the gun and hits the primer. The primer explodes, igniting the propellant.

- The propellant burns, releasing a large volume of gas. The gas pressure drives the bullet down the barrel. The gas pressure also causes the cartridge case to expand, temporarily sealing the breech. All of the expanding gas pushes forward rather than backward.

- To reload the gun, the shooter swings the cylinder out and pushes on the ejector rod to operate the extractor in the middle of the cylinder. The extractor grabs the base of the spent shells and removes them from the cylinders.

- To reload, the shooter can place individual cartridges into the chambers or load six at once with a speed loader (basically, a small metal holder with cartridges secured in the right position).

In double-action revolvers, the shooter can either pull the trigger to cock and fire or pull the hammer back ahead of time. The advantage of cocking the hammer first is that the trigger moves more easily when it is time to fire.

Obviously, a revolver is easier to use than a flintlock or a percussion-cap weapon. A shooter can load six shots at a time and only needs to pull the trigger to fire. But revolvers seem very limited next to newer technologies: The shooter must pull the trigger for every shot and stop to reload regularly. On the battlefield, the revolver can't possibly stand up to modern automatic weapons.

The enduring popularity of revolvers is due to the simplicity of their design. Everything fits together so well that the guns very rarely jam. And since they are made with a relatively small number of parts, they are relatively inexpensive to manufacture. For the home defender and criminals alike, it is an ideal, affordable weapon.

To understand how a revolver works, it helps to know something about guns in general. Almost every gun is based on the same simple concept: You apply explosive pressure behind a projectile to launch it down a barrel. The earliest and simplest application of this idea is the cannon.

A cannon is just a metal tube with a closed end and an open end. The closed end has a small fuse hole. To load the cannon, you pour in gunpowder (a mixture of charcoal, sulfur and potassium nitrate), and then drop in a cannonball. The gunpowder and cannonball sit in the breech, the rear part of the bore (the open space in the cannon). To prepare for a shot, you run a fuse (a length of flammable material) through the hole so it reaches down to the gunpowder. To fire the cannon, you light the fuse. The flame travels along the fuse and finally reaches the gunpowder.

When you ignite gunpowder, it burns rapidly, producing a lot of hot gas in the process. The hot gas applies much greater pressure on the powder side of the cannonball than the air in the atmosphere applies on the other side. This propels the cannonball out of the gun at high speed.

The first handheld guns were essentially miniature cannons; you loaded some gunpowder and a steel ball and lit a fuse. Eventually, this technology gave way to trigger-activated weapons, such as the flintlock gun and the percussion cap.

©HOWSTUFFWORKS

Flintlock guns ignited gun powder by producing a tiny spark, while percussion caps used mercuric fulminate, an explosive compound you could ignite with a sharp blow. To load a percussion-cap gun, you poured gunpowder into the breech, stuffed a ball in on top of it, and placed a mercuric fulminate cap on top of a small nipple. To fire the gun, you cocked a hammer all the way back and pulled the gun's trigger. The trigger released the hammer, which swung forward onto the explosive cap. The cap ignited, shooting a small flame down a tube to the gunpowder. The gunpowder exploded, launching the ball out of the barrel. (Check out How Flintlock Guns Work for more information on these weapons.)

In the 1800s, the percussion-cap gun slowly gave way to the revolver, which only had to be reloaded every five or six shots instead of after each shot. In the next section, we'll see how this system works.

How Flintlock Guns Work

If you have ever studied American history, you are sure to have heard about the flintlock. The flintlock mechanism was the first reliable and relatively inexpensive system for firing a gun, and was hugely popular in colonial America. It was first developed in the mid-1500s and spread until, by 1660, the English Army adopted the flintlock system for its "Brown Bess" guns. The Brown Bess became famous because of its widespread use during the American Revolution. The flintlock remained popular until the mid-1800s, when it was replaced by the percussion-cap lock. By the time of the civil war, nearly all guns manufactured used the percussion cap. That means that the flintlock, as a technology, lasted about 300 years!

The flintlock gun and the flintlock itself are fascinating devices. There are at least four things that make them so interesting:

- Next to the pendulum clock, the flintlock gun was probably the most technologically advanced device that anyone commonly owned at the time.

- The flintlock is incredibly important historically. Colonial America depended on it for food, protection and warfare.

- The flintlock itself is amazing from a mechanical standpoint.

- The flintlock is the foundation of all modern guns. If you want to understand how modern guns work, you get the best view by understanding the flintlock. A flintlock gun is the simplest reliable gun possible, and it can teach you a great deal about the technology behind guns in general.

How Pendulum Clocks Work

Have you ever looked inside a grandfather clock or a small mechanical alarm clock, seen all the gears and springs and thought, "Wow -- that's complicated!"? While clocks normally are fairly complicated, they do not have to be confusing or mysterious. In fact, as you learn how a clock works, you can see how clock designers faced and solved a number of interesting problems to create accurate timekeeping devices. In this article, we'll help you understand what makes clocks tick, so the next time you look inside one you can make sense of what's happening.

Pendulum clocks have been used to keep time since 1656, and they have not changed dramatically since then. Pendulum clocks were the first clocks made to have any sort of accuracy. When you look at a pendulum clock from the outside, you notice several different parts that are important to the mechanism of all pendulum clocks:

- There is the face of the clock, with its hour and minute hand (and sometimes even a "moon phase" dial).

- There are one or more weights (or, if the clock is more modern, a keyhole used to wind a spring inside the clock -- we will stick with weight-driven clocks in this article).

- And, of course, there is the pendulum itself.

In most wall clocks that use a pendulum, the pendulum swings once per second. In small cuckoo clocks the pendulum might swing twice a second. In large grandfather clocks, the pendulum swings once every two seconds. So, how do these parts work together to keep the clock ticking and the time accurate? Let's take a look at the weight, first.

The idea behind the weight is to act as an energy storage device so that the clock can run for relatively long periods of time unattended. When you "wind" a weight-driven clock, you pull on a cord that lifts the weight. That gives the weight "potential energy" in the Earth's gravitational field. As we will see in a moment, the clock uses that potential energy as the weight falls to drive the clock's mechanism.

So let's say that we wanted to use a falling weight to create the simplest possible clock -- a clock that has just a second hand on it. We want the second hand on this simple clock to work like a normal second hand on any clock, making one complete revolution every 60 seconds. We might try to do that, as shown in the figure on the right, simply by attaching the weight's cord to a drum and then attaching a second hand to the drum as well. This, of course, would not work. In this simple mechanism, releasing the weight would cause it to fall as fast as it could, spinning the drum at about 1,000 rpm until the weight clattered on the floor.

Still, it's headed in the right direction. Let's say we put some kind of friction device on the drum -- some sort of brake pad or something that would slow the drum down. This might work. We would certainly be able to devise some scheme based on friction to get the second hand to make approximately one revolution per minute. But it would only be approximate. As the temperature and the humidity in the air changed, the friction in the device would change. Thus our second hand would not keep very good time.

So, back in the 1600s, people who wanted to create accurate clocks were trying to solve the problem of how to cause the second hand to make exactly one revolution per minute. The Dutch astronomer Christiaan Huygens is credited with first suggesting the use of a pendulum. Pendulums are useful because they have an extremely interesting property: The period (the amount of time it takes for a pendulum to go back and forth once) of a pendulum's swing is related only to the length of the pendulum and the force of gravity. Since gravity is constant at any given spot on the planet, the only thing that affects the period of a pendulum is the length of the pendulum. The amount of weight does not matter. Nor does the length of the arc that the pendulum swings through. Only the length of the pendulum matters.

As we stated on the previous page, the only thing affecting the period of a pendulum is the length of that pendulum. You can prove this fact to yourself by performing the following experiment. For this experiment you will need:

- A weight

- A string

- A table

- A watch with a second hand (or a numeric seconds display on a digital watch)

For the weight you can use anything. In a pinch, a coffee mug or a book will do -- it doesn't really matter. Tie the string to the weight. Then suspend your pendulum over the edge of the table so that the length of the pendulum is about 2 feet, as shown here:

Now pull the weight back about a foot and let your pendulum start swinging. Time it for 30 or 60 seconds and count how many times it swings back and forth. Remember that number. Now stop the pendulum and restart it, but this time pull it back only 6 inches initially so it is swinging through a much smaller arc. Count the number of swings again through the same 30- or 60-second time period. What you will find is that the number you get is the same as the first number you counted. In other words, the angle of the arc through which the pendulum swings does not affect the pendulum's period. Only the length of the pendulum's string matters. If you play around with the length of your pendulum you will find that you can adjust it so that it swings back and forth exactly 60 times in one minute.

(Note: If you want to be exactly accurate about the pendulum period, see this interesting article.)

Once someone noticed this fact about pendulums, it was realized that you could use the phenomenon to create an accurate clock. The figure below shows how you can create a clock's escapement using a pendulum.

In an escapement there is a gear with teeth of some special shape. There is also a pendulum, and attached to the pendulum is some sort of device to engage the teeth of the gear. The basic idea that is being demonstrated in the figure is that, for each swing of the pendulum back and forth, one tooth of the gear is allowed to "escape."

This content is not compatible on this device.

For example, if the pendulum is swinging toward the left and passes through the center position as shown in the figure on the right, then as the pendulum continues toward the left the left-hand stop attached to the pendulum will release its tooth. The gear will then advance one-half tooth's-width forward and hit the right-hand stop. In advancing forward and running into the stop, the gear will make a sound... "tick" or "tock" being the most common. That is where the ticking sound of a clock or watch comes from!

One thing to keep in mind is that pendulums will not swing forever. Therefore, one additional job of the escapement gear is to impart just enough energy into the pendulum to overcome friction and allow it to keep swinging. To accomplish this task, the anchor (the name given to the gizmo attached to the pendulum to release the escapement gear one tooth at a time) and the teeth on the escapement gear are specially shaped. The gear's teeth escape properly, and the pendulum is given a nudge in the right direction by the anchor each time through a swing. The nudge is the boost of energy that the pendulum needs to overcome friction, so it keeps swinging.

So, let's say that you create an escapement. If you gave the escapement gear 60 teeth and attached this gear directly to the weight drum we discussed above, and if you then used a pendulum with a period of one second, you would have successfully created a clock in which the second hand turns at the rate of one revolution per minute. By adjusting the pendulum's length very carefully we could create a clock with very high accuracy.

However, while accurate, this clock would have two problems that would make it less-than-useful:

- Most people want a clock to have hour and minute hands as well.

- You would have to wind the clock about every 20 minutes. Because the drum makes one revolution every minute, the weight would unwind to the floor very quickly. Most people would not like a clock that had to be rewound every 20 minutes!

So, what does it take to solve the winding problem?

The problem of having to rewind every 20 minutes is easy to solve. As discussed in How Gear Ratios Work, you can create a high-ratio gear train that causes the drum to make perhaps one turn every six to 12 hours. This would give you a clock that you only had to rewind once a week or so. The gear ratio between the weight drum and the escapement gear might be something like 500:1, as shown in the diagram below:

In this diagram the escapement gear has 120 teeth, the pendulum has a period of half a second and the second hand is connected directly to the escapement gear. Each gear in the weight's gear train has an 8:1 ratio, so the full train's ratio is 492:1.

You can see that if you let the escapement gear itself drive another gear train with a ratio of 60:1, then you can attach the minute hand to the last gear in that train. A final train with a ratio of 12:1 would handle the hour hand. Presto! You have a clock.

Now this clock is nice, but it has two problems:

- The hour, minute and second hands are on different axes. That problem is generally solved by using tubular shafts on the gears and then arranging the gear trains so that the gears driving the hour, minute and second hands share the same axis. The tubular gear shafts are aligned one inside the other. Look closely at any clock face and you can see this arrangement.

- Because all of these gears are connected directly together, there is no easy way to rewind or set the clock. That is often handled by having a gear that can be slipped out of the train. When you pull on the stem of a wristwatch to set the watch, that is essentially what you are doing. In the figure above, you might imagine temporarily removing the small black gear to either wind or set the clock.

You can see that, even though all the gears in a clock make it look complicated, what a pendulum clock is doing is really pretty simple. There are five basic parts:

- Weight or spring - This provides the energy to turn the hands of the clock.

- Weight gear train - A high-ratio gear train gears the weight drum way up so that you don't have to rewind the clock very often.

- Escapement - Made up of the pendulum, the anchor and the escapement gear, the escapement precisely regulates the speed at which the weight's energy is released.

- Hand gear train - The train gears things down so the minute and hour hands turn at the right rates.

- Setting mechanism - This somehow disengages, slips or ratchets the gear train so the clock can be rewound and set.

Once you understand these pieces, clocks are a piece of cake!

Here's a set of questions from readers:

- Watches obviously do not use pendulums, so how do they keep time? A pendulum is one periodic mechanical system with a precise period. There are other mechanical systems that have the same feature. For example, a weight bouncing on a spring has a precise period. Another example is a wheel with a spring on its axle. In this case, the spring causes the wheel to rotate back and forth on its axis. Most mechanical watches use the wheel/spring arrangement.

- What is the difference between a weight-driven and a spring-driven clock? Nothing, really. Both a weight and a spring store energy. In a spring-driven clock you wind the spring and it unwinds into the same sort of gear train found on a weight-driven clock.

- What can you do to make a clock more accurate? the discusses the creation of extremely accurate mechanical clocks to find a ship's longitude. Creating accurate mechanical clocks that can live on a ship (unlike a pendulum clock...) was a real challenge!

- How does the moon phase dial on a grandfather clock work? The moon phase dial works just like the hands of the clock do. The minute hand on a clock moves at the rate of one revolution every hour. The hour hand moves at one revolution every 12 hours. The moon phase dial moves at a rate of one revolution every 56 days or so. The moon's cycle is 28 days, and the moon phase dial generally has two moons painted on it.

XXX . XXX 4%zero Revolution in Time keeping on function to trigger gun

Accurate Mechanical Clocks

In 1656, Christiaan Huygens, a Dutch scientist, made the first pendulum clock, regulated by a mechanism with a "natural" period of oscillation. (Galileo Galilei is credited with inventing the pendulum-clock concept, and he studied the motion of the pendulum as early as 1582. He even sketched out a design for a pendulum clock, but he never actually constructed one before his death in 1642.) Huygens' early pendulum clock had an error of less than 1 minute a day, the first time such accuracy had been achieved. His later refinements reduced his clock's error to less than 10 seconds a day.

Around 1675, Huygens developed the balance wheel and spring assembly, still found in some of today's wristwatches. This improvement allowed portable 17th century watches to keep time to 10 minutes a day. And in London in 1671, William Clement began building clocks with the new "anchor" or "recoil" escapement, a substantial improvement over the verge because it interferes less with the motion of the pendulum.

In 1721, George Graham improved the pendulum clock's accuracy to 1 second per day by compensating for changes in the pendulum's length due to temperature variations. John Harrison, a carpenter and self-taught clock-maker, refined Graham's temperature compensation techniques and developed new methods for reducing friction. By 1761, he had built a marine chronometer with a spring and balance wheel escapement that won the British government's 1714 prize (worth more than $10,000,000 in today's currency) for a means of determining longitude to within one-half degree after a voyage to the West Indies. It kept time on board a rolling ship to about one-fifth of a second a day, nearly as well as a pendulum clock could do on land, and 10 times better than required to win the prize.

Over the next century, refinements led in 1889 to Siegmund Riefler's clock with a nearly free pendulum, which attained an accuracy of a hundredth of a second a day and became the standard in many astronomical observatories. A true free-pendulum principle was introduced by R.J. Rudd about 1898, stimulating development of several free-pendulum clocks. One of the most famous, the W.H. Shortt clock, was demonstrated in 1921. The Shortt clock almost immediately replaced Riefler's clock as a supreme timekeeper in many observatories. This clock contained two pendulums, one a slave and the other a master. The slave pendulum gave the master pendulum the gentle pushes needed to maintain its motion, and also drove the clock's hands. This allowed the master pendulum to remain free from mechanical tasks that would disturb its regularity.

Quartz Clocks

The performance of the Shortt clock was overtaken as quartz crystal oscillators and clocks, developed in the 1920s and onward, eventually improved timekeeping performance far beyond that achieved using pendulum and balance-wheel escapements.

Quartz clock operation is based on the piezoelectric property of quartz crystals. If you apply an electric field to the crystal, it changes its shape, and if you squeeze it or bend it, it generates an electric field. When put in a suitable electronic circuit, this interaction between mechanical stress and electric field causes the crystal to vibrate and generate an electric signal of relatively constant frequency that can be used to operate an electronic clock display.

Quartz crystal clocks were better because they had no gears or escapements to disturb their regular frequency. Even so, they still relied on a mechanical vibration whose frequency depended critically on the crystal's size, shape and temperature. Thus, no two crystals can be exactly alike, with just the same frequency. Such quartz clocks and watches continue to dominate the market in numbers because their performance is excellent for their price. But the timekeeping performance of quartz clocks has been substantially surpassed by atomic clocks.

Scientists had long realized that atoms (and molecules) have resonances; each chemical element and compound absorbs and emits electromagnetic radiation at its own characteristic frequencies. These resonances are inherently stable over time and space. An atom of hydrogen or cesium here today is (so far as we know) exactly like one a million years ago or in another galaxy. Thus atoms constitute a potential "pendulum" with a reproducible rate that can form the basis for more accurate clocks.

The development of radar and extremely high frequency radio communications in the 1930s and 1940s made possible the generation of the kind of electromagnetic waves (microwaves) needed to interact with atoms. Research aimed at developing an atomic clock focused first on microwave resonances in the ammonia molecule. In 1949, NIST built the first atomic clock, which was based on ammonia. However, its performance wasn't much better than the existing standards, and attention shifted almost immediately to more promising atomic-beam devices based on cesium.

The first practical cesium atomic frequency standard was built at the National Physical Laboratory in England in 1955, and in collaboration with the U.S. Naval Observatory (USNO), the frequency of the cesium reference was established or measured relative to astronomical time. While NIST was the first to start working on a cesium standard, it wasn't until several years later that NIST completed its first cesium atomic beam device, and soon after a second NIST unit was built for comparison testing. By 1960, cesium standards had been refined enough to be incorporated into the official timekeeping system of NIST. Standards of this sort were also developed at a number of other national standards laboratories, leading to wide acceptance of this new timekeeping technology.

The cesium atom's natural frequency was formally recognized as the new international unit of time in 1967: the second was defined as exactly 9,192,631,770 oscillations or cycles of the cesium atom's resonant frequency, replacing the old second that was defined in terms of the Earth's motions. The second quickly became the physical quantity most accurately measured by scientists. As of January, 2002, NIST's latest primary cesium standard was capable of keeping time to about 30 billionths of a second per year. Called NIST-F1, it is the 8th of a series of cesium clocks built by NIST and NIST's first to operate on the "fountain" principle.

Other kinds of atomic clocks have also been developed for various applications; those based on hydrogen offer exceptional stability, for example, and those based on microwave absorption in rubidium vapor are more compact, lower in cost, and require less power.

Much of modern life has come to depend on precise time. The day is long past when we could get by with a timepiece accurate to the nearest quarter-hour. Transportation, communication, financial transactions, manufacturing, electric power and many other technologies have become dependent on accurate clocks. Scientific research and the demands of modern technology continue to drive our search for ever more accurate clocks. The next generation of time standards is presently under development at NIST, USNO, in France, in Germany, and other laboratories around the world.

As we continue our "Walk Through Time," we will see how agencies such as the National Institute of Standards and Technology, the U.S. Naval Observatory, and the International Bureau of Weights and Measures in Paris assist the world in maintaining a single, uniform time system.

Broadcast frequencies are 2.5 MHz (megahertz), 5 MHz, 10 MHz, and 15 MHz for both stations, plus 20 MHz on WWV. The signal includes UTC time in both voice and coded form; standard carrier frequencies, time intervals and audio tones; information about Atlantic or Pacific storms; geophysical alert data related to radio propagation conditions; and other public service announcements. Accuracies of one millisecond (one thousandth of a second) can be obtained from these broadcasts if one corrects for the distance from the stations (near Ft. Collins, Colorado, and Kauai, Hawaii) to the receiver. The telephone services provide time signals accurate to 30 milliseconds or better, which is the maximum delay in cross-country telephone lines.

In 1956, low-frequency station WWVB, which offers greater accuracy than WWV or WWVH, began broadcasting at 60 kilohertz. The broadcast power for WWVB was increased in 1999 from about 10 kilowatts to 50 kilowatts, providing much improved signal strength and coverage to most of the North American continent. This has stimulated commercial development of a wide range of inexpensive radio-controlled clocks and watches for general consumer use.

Time signals are an important byproduct of the Global Positioning System (GPS), and indeed this has become the premier satellite source for time signals. The time scale operated by the USNO serves as reference for GPS, but it is important to note that the time scales of NIST and USNO are highly coordinated (that is, synchronized to well within 100 nanoseconds, or 100 billionths of a second). Thus, signals provided by either NIST or USNO can be considered as traceable to both institutions. The agreements and coordination of time between these two institutions are important to the country, since they simplify the process of achieving legal traceability when regulations require it.

NIST also offers an Internet Time Service (ITS) and an Automated Computer Time Service (ACTS) that allow setting of computer and other clocks through the Internet or over standard commercial telephone lines. Free software for using these services on several types of popular computers can be downloaded there.

XXX . XXX 4%zero null 0 1 2 Automated Computer Time Service (ACTS)

The Automated Computer Time Service (ACTS) has been provided since 1988 for users who need to synchronize computer clocks to the correct time. ACTS only works with analog modems that use ordinary telephone lines. Digital modems, such as Digital Subscriber Line (DSL), cable and wireless modems, cannot synchronize using ACTS. For computers with Internet access, the Internet Time Service should be used to synchronize to NIST.

Software

Using ACTS requires only a computer, a modem, and some simple software. When a computer connects to ACTS by telephone, it receives an ASCII time code. The information in the time code is then used to set the computer's clock.

ACTS works at speeds up to 9600 baud with 8 data bits, 1 stop bit, and no parity. To receive the full time code, you must connect at a speed of at least 1200 baud. The full time code is transmitted every second and contains more information than the 300 baud time code, which is transmitted every 2 seconds.

The full time code looks like this:

JJJJJ YR-MO-DA HH:MM:SS TT L DUT1 msADV UTC(NIST) OTM

where:

JJJJJ is the Modified Julian Date (MJD). The MJD has a starting point of midnight on November 17, 1858. You can obtain the MJD by subtracting exactly 2 400 000.5 days from the Julian Date, which is an integer day number obtained by counting days from the starting point of noon on 1 January 4713 B.C. (Julian Day zero).

YR-MO-DA is the date. It shows the last two digits of the year, the month, and the current day of month.

HH:MM:SS is the time in hours, minutes, and seconds. The time is always sent as Coordinated Universal Time (UTC). An offset needs to be applied to UTC to obtain local time. For example, Mountain Time in the U. S. is 7 hours behind UTC during Standard Time, and 6 hours behind UTC during Daylight Saving Time.

TT is a two digit code (00 to 99) that indicates whether the United States is on Standard Time (ST) or Daylight Saving Time (DST). It also indicates when ST or DST is approaching. This code is set to 00 when ST is in effect, or to 50 when DST is in effect. On the day of the transition from DST to ST, the code is set to 01. On the day of the transition from ST to DST, the code is set to 51. The client software is responsible for implementing the change at 2 a.m. on the day of the transition. Prior to the transition, the code is decremented as the transition day approaches. For example, November is the month of the transition (in the United States) from DST to ST. On November 1, the number changes from 50 to the actual number of days until the time change. It will decrement by 1 every day, and reach 01 on the day of the transition. It will be set to 00 the day after the transition, and will remain there until March 1, when the countdown for the ST to DST transition begins.

L is a one-digit code that indicates whether a leap second will be added or subtracted at midnight on the last day of the current month. If the code is 0, no leap second will occur this month. If the code is 1, a positive leap second will be added at the end of the month. This means that the last minute of the month will contain 61 seconds instead of 60. If the code is 2, a second will be deleted on the last day of the month. Leap seconds occur at a rate of about one per year. They are used to correct for irregularity in the earth's rotation.

DUT1 is a correction factor for converting UTC to an older form of universal time. It is always a number ranging from -0.8 to +0.8 seconds. This number is added to UTC to obtain UT1.

msADV is a five-digit code that displays the number of milliseconds that NIST advances the time code. It is originally set to 45.0 milliseconds. If you return the on-time marker (OTM) three consecutive times, it will change to reflect the actual one way line delay.

The label UTC(NIST) indicates that you are receiving Coordinated Universal Time (UTC) from the National Institute of Standards and Technology (NIST).

OTM (on-time marker) is an asterisk (*). The time values sent by the time code refer to the arrival time of the OTM. In other words, if the time code says it is 12:45:45, this means it is 12:45:45 when the OTM arrives.

Since the OTM is delayed as it travels from NIST to your computer, ACTS sends it out 45 milliseconds early. This always removes some of the delay. Better results are possible if the user's software returns the OTM to ACTS after it is received. Each time the OTM is returned, ACTS measures the amount of time it took for the OTM to go from ACTS to the user and back to ACTS. This quantity (the round-trip path delay) is divided by two to get the one-way path delay. ACTS then advances the OTM by the one-way path delay and the OTM changes from an asterisk to a pound sign (#). When the # sign appears, the time code is synchronized within a few milliseconds of UTC(NIST).

The ACTS system in Colorado has 8 phone lines and receives an average of about 2,000 telephone calls per day. It can be reached by dialing (303) 494-4774.

The ACTS system in Hawaii has 2 phone lines and receives about one hundred calls per day. It can be reached by dialing (808) 335-4721.

NIST Debuts Dual Atomic Clock — and a New Stability Record

What could be better than a world-leading atomic clock? Two clocks in one.

Physicists at the National Institute of Standards and Technology (NIST) have combined two experimental atomic clocks based on ytterbium atoms to set yet another world record for clock stability. Stability can be thought of as how precisely the duration of each clock tick matches every other tick that comes before and after.

This extraordinary stability makes the ytterbium lattice clock a more powerful tool for precision tests such as whether the “fundamental constants” of nature are really constant, and searches for the elusive dark matter purported to make up much of the universe. The experiment demonstrating the double-clock design is reported in Nature Photonics.

“We eliminated a critical type of noise in the clock’s operation, effectively making the clock signal stronger,” NIST physicist Andrew Ludlow said. “This means we can reach a clock instability of 1.5 parts in a quintillion (1 followed by 18 zeros) in just a few thousand seconds. While this only slightly beats the record level of clock stability we demonstrated a few years ago, we get there 10 times faster.”

NIST atomic clocks routinely perform at very high levels, but scientists continually tweak them to reduce slight imperfections. The new double-clock design eliminates a small but significant distortion in the laser frequency that probes and synchronizes with the atoms. The more stable the clock, the better its measurement power.

The new ytterbium lattice ‘double clock’ is the most stable clock in the world, although another NIST atomic clock, based on strontium and located at JILA, holds the world record for precision. Precision refers to how closely the clock tunes itself to the natural frequency at which the atoms oscillate between two electronic energy levels.

Both the ytterbium and strontium clocks tick at optical frequencies, much higher than the microwave frequencies of cesium atomic clocks used as time standards. An optical atomic clock operates by tuning the frequency of a laser to resonate with the frequency of the atoms’ transition between two energy states. This atomic ticking is transferred to the laser for use as a timekeeping tool. Any noise or uncertainty affecting this process disturbs the laser frequency and, thus, the timekeeping precision.

Optical atomic clocks typically alternate laser probing of the atoms with periods of “dead time” during which the atoms are prepared and measured. During dead times, certain laser frequency fluctuations are not properly observed or compensated for in the laser tuning process. The resulting noise effects (first observed in the 1990s by G.J. Dick, then of the California Institute of Technology) has, until now, limited clock stability and precision.

NIST’s new double-clock design has zero dead time—and is, therefore, nicknamed the ZDT clock—and virtually no dead-time noise, because it probes atoms continuously by switching back and forth from one atomic ensemble to the other. The two ensembles of 5,000 and 10,000 ytterbium atoms, respectively, are each trapped in a grid of laser light called an optical lattice and probed by a shared laser.

Measurements of the responses of the two atom ensembles are combined to produce a single, combined correction to the laser frequency. These measurements and corrections are made twice as fast as in a single clock. Because there is no dead-time noise, the new clock attains record stability levels 10 times faster than before. Crucially, the performance is now limited by the atomic system of the clock rather than the laser, a long-sought goal in physics that Ludlow calls a “dream” for future applications.

This approach can ultimately reduce atomic clock size and complexity, so the apparatus could be made portable enough to use outside the laboratory. The physical package is currently larger than a single clock, but eventually both atomic systems could share a single vacuum apparatus and simpler laser systems, thus reducing the overall size, Ludlow said. Portable optical atomic clocks could be distributed around the world for relativistic geodesy (gravity-based measurements of the shape of the Earth) or carried on spacecraft for tests of general relativity.

Next-Generation Atomic Clocks

This photo shows about 1 million ytterbium atoms illuminated by a blue laser in an experimental atomic clock that holds the atoms in a lattice made of intersecting laser beams. The photo was taken with a digital camera through the window of a vacuum chamber. NIST is studying the possible use of ytterbium atoms in next-generation atomic clocks based on optical frequencies, which could be more stable and accurate than today's best time standards, which are based on microwave frequencies.

An experimental atomic clock based on ytterbium atoms is about four times more accurate than it was several years ago, giving it a precision comparable to that of the NIST-F1 cesium fountain clock, the nation's civilian time standard, scientists at the National Institute of Standards and Technology (NIST) report in Physical Review Letters.*

NIST scientists evaluated the clock by measuring the natural frequency of ytterbium, carefully accounting for all possible deviations such as those caused by collisions between the atoms, and by using NIST-F1 as a "ruler" for comparison. The results were good enough to indicate that the ytterbium clock is competitive in some respects with NIST-F1, which has been improving steadily and now keeps time to within 1 second in about 100 million years. (Because the international definition of the second is based on the cesium atom, technically no clock can be more accurate than cesium standards such as NIST-F1.) More importantly, the improved ytterbium clock gives the time standards community more options in the ongoing development and comparisons of next-generation clocks, says NIST physicist Chris Oates, an author of the new paper.

The NIST ytterbium clock is based on about 30,000 heavy metal atoms that are cooled to 15 microkelvins (close to absolute zero) and trapped in a column of several hundred pancake-shaped wells—an "optical lattice"—made of laser light. A laser that "ticks" 518 trillion times per second induces a transition between two energy levels in the atoms. The clock's enhanced performance was made possible by improvements in the apparatus and a switch to a different form of ytterbium whose nucleus is slightly magnetic due its "spin-one half" angular momentum. This atom is less susceptible to key errors than the "spin-zero" form of ytterbium used previously.

NIST scientists are developing five versions of next-generation atomic clocks, each using a different atom and offering different advantages. The experimental clocks all operate at optical (visible light) frequencies, which are higher than the microwave frequencies used in NIST-F1, and thus can divide time into smaller units, thereby yielding more stable clocks. Additionally, optical clocks could one day lead to time standards up to 100 times more accurate than today's microwave clocks.

The best optical clocks are currently based on single ions (electrically charged atoms), such as the NIST "logic clock" using an aluminum ionic . But lattice clocks have the potential for higher stability because they simultaneously average signals from tens of thousands of atoms. Ongoing comparisons of the ytterbium clock to that of the strontium lattice clock located nearby at JILA, a joint institute of NIST and the University of Colorado at Boulder, should help enable worldwide tests of optical clock performance with extremely high precision. JILA is At this point it is far from clear which atom and clock design will be selected by research groups around the world as a future time and frequency standard.

Advances in atomic clock performance support development of technologies such as high data rate telecommunications and the Global Positioning System (GPS). Optical clocks are already providing record measurements of possible changes in the fundamental "constants" of nature, a line of inquiry that has huge implications for cosmology and tests of the laws of physics, such as Einstein's theories of special and general relativity. Next-generation clocks might lead to new types of gravity sensors for exploring underground natural resources and fundamental studies of the Earth. Other possible applications may include ultra-precise autonomous navigation, such as landing planes by GPS.

XXX . XXX 4%zero null 0 1 2 3 Stun Gun Circuit

This stun gun delivers 50.000 Volts and produces high voltage pulses discrupting muscles and nervous system, leaving anyone who touches it in a state of menthal confusion.

This stun gun is powered by a 9V battery. The transformer steps up the voltage to about 1800V (but with very low current). A 555 timer IC is used to generate a high-frequency output. A 1 MEG variable resistor can also be used at the output to drop the voltage, but this is optional. If you build this circuit, be careful, as it outputs a high voltage. Touching the output leads will induce a painful shock.

Stun gun is an electronic device that is officially used as a weapon for law enforcement in developed countries. Another word of this tool is called an electric shock weapon. The designed tool is not lethal but bsa cripples humans in seconds. The principle of this tool utilizes the doubling of voltage that reaches 800 KV (800 thousand volt) DC with low current.

This tool is intentionally designed to a minimum physically possible with the purpose of mobility and results are beyond doubt. Power supplied by 3-6 volt DC battery then raised with high frequency switching process.

Simple stun gun uses I C 555 as switching

The above circuit consists of one component oscillation tool , transistor amplifier and step-up transformer. oscillation tool to trigger transistor to produce voltage shaped wave box. So the process of moving electrical energy from the primary coil to the secondary coil can occur. Probably the reader remembers that the transformer or transformer can not be driven by DC voltage (mostly using AC), with this switching the DC voltage is changed as AC but has no negative peak (-V).

A simple stun gun uses a transistor as a switching

The above series is similar to the first one. The fundamental difference in this circuit is added switching using TRIAC, while the oscillator uses resistor and capacitor components (RC). To be understood as a child of engineering, this circuit has negative (-) and positive (+) outputs mounted on two electrodes with a certain distance (ex: 5 cm). In the theory of insulating material, the strong air insulation between the electrode gap is + 30 KV / cm, above that voltage the air is no longer able to withstand. Output voltage generated stun gun is around 25 KV - 800 KV, so that when activated there corona phenomena between two electrodes caused by ionization of electrical charges. Because it exceeds its voltage gradient (+ 30KV) there arises a fire jump.

XXX . XXX 4%zero null 0 1 2 3 4 Electronic firing

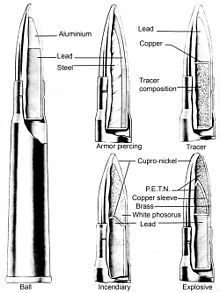

Electronic firing refers to the use of an electric current to fire a cartridge, instead of a percussion cap.

In modern firearm designs, a firing pin and percussion cap are used to ignite the propellant in the cartridge which propels the bullet forward. The firing pin must travel a short distance, creating a short delay between the user pulling the trigger and the weapon firing, which generally decreases accuracy.

In an electronic-fired firearm, however, an electric current is used instead to ignite the propellant, which fires the cartridge.

Electrically primed small arms cartridges retain the primer which functions in the same way as a conventional primer. Rather than being struck by a firing pin or equivalent mechanical means, a small electric current serves to detonate the primer which provides the thermal impulse necessary to ignite the propellant which then deflagrates, producing pressure.

Firearm

A firearm is a portable gun (a barreled ranged weapon) that inflicts damage on targets by launching one or more projectiles driven by rapidly expanding high-pressure gas produced by exothermic combustion (deflagration) of propellant within an ammunition cartridge. If gas pressurization is not achieved via propellant combustion but through mechanical gas compression, then the gun is technically an air gun, not a firearm.[4]

The first primitive firearms originated in 10th-century China when bamboo tubes containing gunpowder and pellet projectiles was mounted on spears into the one-person-portable fire lance,[5], which was later used as a shock weapon to good effect in the Siege of De'an. In 13th century, the Chinese invented the metal-barrelled hand cannon, widely considered to be the true ancestor of all firearms. The technology gradually spread through the rest of East Asia, South Asia, the Middle East, and Europe. Older firearms typically used black powder as a propellant, but modern firearms use smokeless powder or other propellants. Most modern firearms (with the notable exception of smoothbore shotguns) have rifled barrels to impart spin to the projectile for improved flight stability.

Modern firearms can be described by their caliber (i.e. their bore diameter; this is given in millimeters or inches e.g. 7.5 mm, .357 in.) or in the case of shotguns their gauge (e.g. 12 ga.); by the type of action employed (muzzle, breech, lever, bolt, pump, revolver, semi-automatic, automatic etc.) together with the usual means of deportment (hand-held or mechanical mounting). Further classification may make reference to the type of barrel used (rifled) and to the barrel length (24 inch), to the firing mechanism (e.g. matchlock, wheellock, flintlock, percussion lock), to the design's primary intended use (e.g. hunting rifle), or to the commonly accepted name for a particular variation (e.g. Gatling gun).

Shooters aim firearms at their targets with hand-eye coordination, using either iron sights or optical sights. The accurate range of pistols generally does not exceed 110 yards (100 m), while most rifles are accurate to 550 yards (500 m) using iron sights, or to longer ranges using optical sights (firearm rounds may be dangerous or lethal well beyond their accurate range; the minimum distance for safety is much greater than specified range). Purpose-built sniper rifles and anti-materiel rifles are accurate to ranges of more than 2,200 yards (2,000 m).

A US Navy sailor fires a firearm at a target

Types of firearms

Firearms include a variety of ranged weapons and there is no agreed upon definition. Many soldiers consider a firearm to be any ranged weapon that uses gunpowder or a derivative as a propellant.

Configuration

Handguns

The smallest of all firearms is the handgun. There are two common types of handguns: revolvers and semi-automatic pistols. Revolvers have a number of firing chambers or "charge holes" in a revolving cylinder; each chamber in the cylinder is loaded with a single cartridge or charge. Semi-automatic pistols have a single fixed firing chamber machined into the rear of the barrel, and a magazine so they can be used to fire more than one round. Each press of the trigger fires a cartridge, using the energy of the cartridge to activate the mechanism so that the next cartridge may be fired immediately. This is opposed to "double-action" revolvers which accomplish the same end using a mechanical action linked to the trigger pull.

Prior to the 19th century, virtually all handguns were single-shot muzzleloaders.[citation needed] With the invention of the revolver in 1818, handguns capable of holding multiple rounds became popular. Certain designs of auto-loading pistol appeared beginning in the 1870s and had largely supplanted revolvers in military applications by the end of World War I. By the end of the 20th century, most handguns carried regularly by military, police and civilians were semi-automatic, although revolvers were still widely used. Generally speaking, military and police forces use semi-automatic pistols due to their high magazine capacities and ability to rapidly reload by simply removing the empty magazine and inserting a loaded one. Revolvers are very common among handgun hunters because revolver cartridges are usually more powerful than similar caliber semi-automatic pistol cartridges (which are designed for self-defense) and the strength, simplicity and durability of the revolver design is well-suited to outdoor use. Revolvers, especially in .22 LR and 38 Special/357 Magnum, are also common concealed weapons in jurisdictions allowing this practice because their simple mechanics make them smaller than many autoloaders while remaining reliable. Both designs are common among civilian gun owners, depending on the owner's intention (self-defense, hunting, target shooting, competitions, collecting, etc.).

Long guns

A long gun is generally any firearm that is larger than a handgun and is designed to be held and fired with both hands, either from the hip or the shoulder. Long guns typically have a barrel between 10 and 30 inches (there are restrictions on minimum barrel length in many jurisdictions; maximum barrel length is usually a matter of practicality), that along with the receiver and trigger group is mounted into a wood, plastic, metal or composite stock, composed of one or more pieces that form a foregrip, rear grip, and optionally (but typically) a shoulder mount called the butt. Early long arms, from the Renaissance up to the mid-19th century, were generally smoothbore firearms that fired one or more ball shot, called muskets.

Rifles and shotguns

Most modern long guns are either rifles or shotguns. Both are the successors of the musket, diverging from their parent weapon in distinct ways. A rifle is so named for the spiral fluting (rifling) machined into the inner surface of its barrel, which imparts a self-stabilizing spin to the single bullets it fires. Shotguns are predominantly smoothbore firearms designed to fire a number of shot; pellet sizes commonly ranging between 2 mm #9 birdshot and 8.4 mm #00 (double-aught) buckshot. Shotguns are also capable of firing single slugs, or specialty (often "less lethal") rounds such as bean bags, tear gas or breaching rounds. Rifles have a very small impact area but a long range and high accuracy. Shotguns have a large impact area with considerably less range and accuracy. However, the larger impact area can compensate for reduced accuracy, since shot spreads during flight; consequently, in hunting, shotguns are generally used for flying game.

Rifles and shotguns are commonly used for hunting and often to defend a home or place of business. Usually, large game are hunted with rifles (although shotguns can be used, particularly with slugs), while birds are hunted with shotguns. Shotguns are sometimes preferred for defending a home or business due to their wide impact area, multiple wound tracks (when using buckshot), shorter range, and reduced penetration of walls (when using lighter shot), which significantly reduces the likelihood of unintended harm, although the handgun is also common.

There are a variety of types of rifles and shotguns based on the method they are reloaded. Bolt-action and lever-action rifles are manually operated. Manipulation of the bolt or the lever causes the spent cartridge to be removed, the firing mechanism recocked, and a fresh cartridge inserted. These two types of action are almost exclusively used by rifles. Slide-action (commonly called 'pump-action') rifles and shotguns are manually cycled by shuttling the foregrip of the firearm back and forth. This type of action is typically used by shotguns, but several major manufacturers make rifles that use this action.

Both rifles and shotguns also come in break-action varieties that do not have any kind of reloading mechanism at all but must be hand-loaded after each shot. Both rifles and shotguns come in single- and double-barreled varieties; however due to the expense and difficulty of manufacturing, double-barreled rifles are rare. Double-barreled rifles are typically intended for African big-game hunts where the animals are dangerous, ranges are short, and speed is of the essence. Very large and powerful calibers are normal for these firearms.

Rifles have been in nationally featured marksmanship events in Europe and the United States since at least the 18th century, when rifles were first becoming widely available. One of the earliest purely "American" rifle-shooting competitions took place in 1775, when Daniel Morgan was recruiting sharpshooters in Virginia for the impending American Revolutionary War. In some countries, rifle marksmanship is still a matter of national pride. Some specialized rifles in the larger calibers are claimed to have an accurate range of up to about 1 mile (1,600 m), although most have considerably less. In the second half of the 20th century, competitive shotgun sports became perhaps even more popular than riflery, largely due to the motion and immediate feedback in activities such as skeet, trap and sporting clays.

In military use, bolt-action rifles with high-power scopes are common as sniper rifles, however by the Korean War the traditional bolt-action and semi-automatic rifles used by infantrymen had been supplemented by select-fire designs known as "automatic rifles".

Carbines

A carbine is a firearm similar to a rifle in form and intended usage, but generally shorter or smaller than the typical "full-size" hunting or battle rifle of similar time period, and sometimes using a smaller or less-powerful cartridge. Carbines were and are typically used by members of the military in roles that are expected to engage in combat, but where a full-size rifle would be an impediment to the primary duties of that soldier (vehicle drivers, field commanders and support staff, airborne troops, engineers, etc.). Carbines are also common in law enforcement and among civilian owners where similar size, space and/or power concerns may exist. Carbines, like rifles, can be single-shot, repeating-action, semi-automatic or select-fire/fully automatic, generally depending on the time period and intended market. Common historical examples include the Winchester Model 1892, Lee–Enfield "Jungle Carbine", SKS, M1 carbine (no relation to the larger M1 Garand) and M4 carbine (a more compact variant of the current M16 rifle). Modern U.S. civilian carbines include compact customizations of the AR-15, Ruger Mini-14, Beretta Cx4 Storm, Kel-Tec SUB-2000, bolt-action rifles generally falling under the specifications of a scout rifle, and aftermarket conversion kits for popular pistols including the M1911 and Glock models.

Machine guns

A machine gun is a fully automatic emplaceable weapon, most often separated from other classes of automatic weapon by the use of belt-fed ammunition (though some designs employ drum, pan or hopper magazines), generally in a rifle-inspired caliber ranging between 5.56×45mm NATO (.223 Remington) for a light machine gun to as large as .50 BMG or even larger for crewed or aircraft weapons. Although not widely fielded until World War I, early machine guns were being used by militaries in the second half of the 19th century. Notables in the U.S. arsenal during the 20th century included the M2 Browning .50 caliber heavy machine gun and M1919 Browning .30 caliber medium machine gun, and the M60 7.62×51mm NATO general-purpose machine gun which came into use around the Vietnam War. Machine guns of this type were originally defensive firearms crewed by at least two men, mainly because of the difficulties involved in moving and placing them, their ammunition, and their tripod. In contrast, modern light machine guns such as the FN Minimi are often wielded by a single infantryman. They provide a large ammunition capacity and a high rate of fire, and are typically used to give suppressing fire during infantry movement. Accuracy on machine guns varies based on a wide number of factors from design to manufacturing tolerances, most of which have been improved over time. Machine guns are often mounted on vehicles or helicopters, and have been used since World War I as offensive firearms in fighter aircraft and tanks (e.g. for air combat or suppressing fire for ground troop support).

The definition of machine gun is different in U.S. law. The National Firearms Act and Firearm Owners Protection Act define a "machine gun" in the United States code Title 26, Subtitle E, Chapter 53, Subchapter B, Part 1, § 5845 as: "... any firearm which shoots ... automatically more than one shot, without manual reloading, by a single function of the trigger". "Machine gun" is therefore largely synonymous with "automatic weapon" in the U.S. civilian parlance, covering all automatic firearms.

Submachine guns

A submachine gun is a magazine-fed firearm, usually smaller than other automatic firearms, that fires pistol-caliber ammunition; for this reason certain submachine guns can also be referred to as machine pistols, especially when referring to handgun-sized designs such as the Škorpion vz. 61 and Glock 18. Well-known examples are the Israeli Uzi and Heckler & Koch MP5 which use the 9×19mm Parabellum cartridge, and the American Thompson submachine gun which fires .45 ACP. Because of their small size and limited projectile penetration compared to high-power rifle rounds, submachine guns are commonly favored by military, paramilitary and police forces for close-quarters engagements such as inside buildings, in urban areas or in trench complexes.

Submachine guns were originally about the size of carbines. Because they fire pistol ammunition, they have limited long-range use, but in close combat can be used in fully automatic in a controllable manner due to the lighter recoil of the pistol ammunition. They are also extremely inexpensive and simple to build in time of war, enabling a nation to quickly arm its military. In the latter half of the 20th century, submachine guns were being miniaturized to the point of being only slightly larger than some large handguns. The most widely used submachine gun at the end of the 20th century was the Heckler & Koch MP5. The MP5 is actually designated as a "machine pistol" by Heckler & Koch (MP5 stands for Maschinenpistole 5, or Machine Pistol 5), although some reserve this designation for even smaller submachine guns such as the MAC-10 and Glock 18, which are about the size and shape of pistols.

Automatic rifles

An automatic rifle is a magazine-fed firearm, wielded by a single infantryman, that is chambered for rifle cartridges and capable of automatic fire. The M1918 Browning Automatic Rifle was the first U.S. infantry weapon of this type, and was generally used for suppressive or support fire in the role now usually filled by the light machine gun. Other early automatic rifles include the Fedorov Avtomat and the Huot Automatic Rifle. Later, German forces fielded the Sturmgewehr 44 during World War II, a light automatic rifle firing a reduced power "intermediate cartridge". This design was to become the basis for the "assault rifle" subclass of automatic weapons, as contrasted with "battle rifles", which generally fire a traditional "full-power" rifle cartridge.

Assault rifles

In World War II, Germany introduced the StG 44, and brought to the forefront of firearm technology what eventually became the class of firearm most widely adopted by the military, the assault rifle. An assault rifle is usually slightly smaller than a battle rifle such as the Karabiner 98k, but the chief differences defining an assault rifle are select-fire capability and the use of a rifle round of lesser power, known as an intermediate cartridge. This reduces recoil allowing for controllable bursts at short range like a submachine gun, while retaining rifle-like accuracy at medium ranges. Generally, assault rifles have mechanisms that allow the user to select between single shots, fully automatic bursts, or fully automatic fire.

Soviet engineer Mikhail Kalashnikov quickly adapted the German concept, using a less-powerful 7.62×39mm cartridge derived from the standard 7.62×54mmR Russian battle rifle round, to produce the AK-47, which has become the world's most widely used assault rifle. Soon after World War II, the Automatic Kalashnikov AK-47 assault rifle began to be fielded by the Soviet Union and its allies in the Eastern Bloc, as well as by nations such as China, North Korea, and North Vietnam.

In the United States, the assault rifle design was later in coming; the replacement for the M1 Garand of WWII was another John Garand design chambered for the new 7.62×51mm NATO cartridge; the select-fire M14, which was used by the U.S. military until the 1960s. The significant recoil of the M14 when fired in full-automatic mode was seen as a problem as it reduced accuracy, and in the 1960s it was replaced by Eugene Stoner's AR-15, which also marked a switch from the powerful .30 caliber cartridges used by the U.S. military up until early in the Vietnam War to the much less powerful but far lighter and light recoiling .223 caliber (5.56mm) intermediate cartridge. The military later designated the AR-15 as the "M16". The civilian version of the M16 continues to be known as the AR-15 and looks exactly like the military version, although to conform to B.A.T.F.E. regulations in the U.S., it lacks the mechanism that permits fully automatic fire.

Variants of both of the M16 and AK-47 are still in wide international use today, though other automatic rifle designs have since been introduced. A smaller version of the M16A2, the M4 carbine, is widely used by U.S. and NATO tank and vehicle crews, airbornes, support staff, and in other scenarios where space is limited. The IMI Galil, an Israeli-designed weapon based on the action of the AK-47, is in use by Israel, Italy, Burma, the Philippines, Peru, and Colombia. Swiss Arms of Switzerland produces the SIG SG 550 assault rifle used by France, Chile, and Spain among others, and Steyr Mannlicher produces the AUG, a bullpup rifle in use in Austria, Australia, New Zealand, Ireland, and Saudi Arabia among other nations.

Modern designs call for compact weapons retaining firepower. The bullpup design, by mounting the magazine behind the trigger, unifies the accuracy and firepower of the traditional assault rifle with the compact size of the submachine gun (though submachine guns are still used); examples are the French FAMAS and the British SA80.

Personal defense weapons

A recently developed class of firearm is the personal defense weapon or PDW, which is in simplest terms a submachine gun designed to fire ammunitions with ballistic performance similar to rifle cartridges. While a submachine gun is desirable for its compact size and ammunition capacity, its pistol cartridges lack the penetrating capability of a rifle round. Conversely, rifle bullets can pierce light armor and are easier to shoot accurately, but even a carbine such as the Colt M4 is larger and/or longer than a submachine gun, making it harder to maneuver in close quarters. The solution many firearms manufacturers have presented is a weapon resembling a submachine gun in size and general configuration, but which fires a higher-powered armor-penetrating round (often specially designed for the weapon), thus combining the advantages of a carbine and submachine gun. This also earned the PDWs an infrequently used nickname — the submachine carbines. The FN P90 and Heckler & Koch MP7 are most famous examples of PDWs.

Function

Firearms are also categorized by their functioning cycle or "action" which describes its loading, firing, and unloading cycle.

Manual

The earliest evolution of the firearm, there are many types of manual action firearms. These can be divided into two basic categories: single shot and repeating.

A single shot firearm can only be fired once per equipped barrel before it must be reloaded or charged via an external mechanism or series of steps. A repeating firearm can be fired multiple times, but can only be fired once with each subsequent pull of the trigger. Between trigger pulls, the firearm's action must be reloaded or charged via an internal mechanism.

Semi-automatic

A semi-automatic, self-loading, or "auto loader" firearm is one that performs all steps necessary to prepare it for firing again after a single discharge, until cartridges are no longer available in the weapon's feed device or magazine. Auto loaders fire one shot with each pull of the trigger. Some people confuse the term with "fully automatic" firearms. (See next.) While some semi-automatic rifles may resemble military-style firearms, they are not properly classified "Assault Weapons" which refers to those that continue to fire until the finger no longer depressed the trigger.

Automatic

An automatic firearm, or "fully automatic", "fully auto", or "full auto", is generally defined as one that continues to load and fire cartridges from its magazine as long as the trigger is depressed (and until the magazine is depleted of available ammunition. The first weapon generally considered in this category is the Gatling gun, originally a carriage-mounted, crank-operated firearm with multiple rotating barrels that was fielded in the American Civil War. The modern trigger-actuated machine gun began with various designs developed in the late 19th century and fielded in World War I, such as the Maxim gun, Lewis Gun, and MG 08 "Spandau". Most automatic weapons are classed as long guns (as the ammunition used is of similar type as for rifles, and the recoil of the weapon's rapid fire is better controlled with two hands), but handgun-sized automatic weapons also exist, generally in the "sub machine gun" or "machine pistol" class.

Selective fire

Selective fire, or "select fire", means the capability of a weapon's fire control to be adjusted in either semi-automatic or fully automatic firing modes. The modes are chosen by means of a selector, which varies depending on the weapon's design. Some selective-fire weapons have burst fire mechanisms built in to limit the maximum number of shots fired in fully automatic mode, with most common limits being two or three rounds per trigger pull. The presence of selective-fire modes on firearms allows more efficient use of ammunition for specific tactical needs, either precision-aimed or suppressive fire. This capability is most commonly found on military weapons of the 20th and 21st centuries, most notably the assault rifles.

History

The earliest depiction of a firearm is a sculpture from a cave in Sichuan, China. The sculpture dates to the 12th century and is of a figure carrying a vase-shaped bombard, with flames and a cannonball coming out of it.[7]:31–32 The oldest surviving gun, a hand cannon made of bronze, has been dated to 1288 because it was discovered at a site in modern-day Acheng District, Heilongjiang, China, where the Yuan Shi records that battles were fought at that time.[8] The firearm had a 6.9 inch barrel of a 1-inch diameter, a 2.6 inch chamber for the gunpowder and a socket for the firearm's handle. It is 13.4 inches long and 7.8 pounds without the handle, which would have been made of wood.[7]:32

The Europeans and Arabs (first Mamluks) obtained firearms in the 14th century.[7]:1 The Koreans adopted firearms from the Chinese in the 14th century. The Turks, Iranians, (first Aq Qoyunlu and Safavids), and Indians (first Mughals) all got them no later than the 15th century. In each case directly or indirectly from the Europeans. The Japanese did not acquire firearms until the 16th century, and then from the Portuguese rather than the Chinese.[7]:31–32

The development behind firearms accelerated during the 19th and 20th centuries. Breech-loading became more or less a universal standard for the reloading of most hand-held firearms and continues to be so with some notable exceptions (such as mortars). Instead of loading individual rounds into weapons, magazines holding multiple munitions were adopted—these aided rapid reloading. Automatic and semi-automatic firing mechanisms meant that a single soldier could fire many more rounds in a minute than a vintage weapon could fire over the course of a battle. Polymers and alloys in firearm construction made weaponry progressively lighter and thus easier to deploy. Ammunition changed over the centuries from simple metallic ball-shaped projectiles that rattled down the barrel to bullets and cartridges manufactured to high precision. Especially in the past century has particular attention been devoted to accuracy and sighting to make firearms altogether far more accurate than ever before. More than any single factor though, firearms have proliferated due to the advent of mass production—enabling arms manufacturers to produce large quantities of weaponry to a consistent standard.

The force of a projectile is related to the kinetic energy imparted to it, given by the formula where is the mass and is the velocity of the projectile.

Generally, kinetic energy can be enhanced in two ways:

- By increasing the mass of the bullet, either by increasing caliber (and thus size and weight), or by using denser materials like uranium or tungsten.

- By increasing the projectile's velocity, through better or larger propellant charges, through better manufacturing tolerances and materials in bullet and barrel, or through longer barrels.

Velocities of bullets increased with the use of a "jacket" of a metal such as copper or copper alloys that covered a lead core and allowed the bullet to glide down the barrel more easily than exposed lead. Such bullets are designated as "full metal jacket" (FMJ). Such FMJ bullets are less likely to fragment on impact and are more likely to traverse through a target while imparting less energy. Hence, FMJ bullets impart less tissue damage than non-jacketed bullets that expand. (Dougherty and Eidt, 2009) This led to their adoption for military use by countries adhering to the Hague Convention in 1899.

That said, the basic principle behind firearm operation remains unchanged to this day. A musket of several centuries ago is still similar in principle to a modern-day assault rifle—using the expansion of gases to propel projectiles over long distances—albeit less accurately and rapidly.

Evolution

Early models

Fire lances

The Chinese fire lance was the direct predecessor to the modern concept of the firearm. It was not a gun itself, but an addition to the soldiers' spears. Originally it consisted of paper or bamboo barrels that would have incendiary gunpowder within it, that could be lit one time and would project flames at the enemy. Sometimes the Chinese troops would place small projectiles within the barrel that would also be projected when the gunpowder was lit, but most of the explosive force would create flames. Later, the barrel was changed to be made of metal, so that a more explosive gunpowder could be used and put more force into the propulsion of the projectile.[7]:31–32

Hand cannons

The original predecessor of all firearms, the Chinese fire lance and hand cannon were loaded with gunpowder and the shot (initially lead shot, later replaced by cast iron through the muzzle, while a fuse was placed at the rear. This fuse was lit, causing the gunpowder to ignite and propel the cannonball. In military use, the standard hand cannon was tremendously powerful, while also being somewhat useless[citation needed] due to relative inability of the gunner to aim the weapon, or control the ballistic properties of the projectile. Recoil could be absorbed by bracing the barrel against the ground using a wooden support, the forerunner of the stock. Neither the amount of gunpowder, nor the consistency in projectile dimensions were controlled, with resulting inaccuracy in firing due to windage, and due to the difference in diameter between the bore and the shot. The hand cannons were replaced by lighter carriage-mounted artillery pieces, and ultimately the arquebus.

Muskets

Muzzle-loading muskets (smooth-bored long guns) were among the first firearms developed. The firearm was loaded through the muzzle with gunpowder, optionally some wadding and then a bullet (usually a solid lead ball, but musketeers could shoot stones when they ran out of bullets). Greatly improved muzzleloaders (usually rifled instead of smooth-bored) are manufactured today and have many enthusiasts, many of whom hunt large and small game with their guns. Muzzleloaders have to be manually reloaded after each shot; a skilled archer could fire multiple arrows faster than most early muskets could be reloaded and fired, although by the mid-18th century, when muzzleloaders became the standard small armament of the military, a well-drilled soldier could fire six rounds in a minute using prepared cartridges in his musket. Before then, effectiveness of muzzleloaders was hindered by both the low reloading speed and, before the firing mechanism was perfected, the very high risk posed by the firearm to the person attempting to fire it.

One interesting solution to the reloading problem was the "Roman Candle Gun" with superposed loads. This was a muzzleloader in which multiple charges and balls were loaded one on top of the other, with a small hole in each ball to allow the subsequent charge to be ignited after the one ahead of it was ignited. It was neither a very reliable nor popular firearm, but it enabled a form of "automatic" fire long before the advent of the machine gun.

Loading techniques

Most early firearms were muzzle-loading. This form of loading has several disadvantages, such as a slow rate of fire and having to expose oneself to enemy fire to reload as the weapon had to be pointed upright so the powder could be poured through the muzzle into the breech followed by the ramming the projectile into the breech. As effective methods of sealing the breech were developed through the development of sturdy, weatherproof, self-contained metallic cartridges, muzzle-loaders were replaced by single-shot breech loaders. Eventually single-shot weapons were replaced by the following repeater type weapons.

Internal magazines