Power supply

A power supply is an electronic device that supplies electric energy to an electrical load. The primary function of a power supply is to convert one form of electrical energy to another. As a result, power supplies are sometimes referred to as electric power converters. Some power supplies are discrete, stand-alone devices, whereas others are built into larger devices along with their loads. Examples of the latter include power supplies found in desktop computers and consumer electronics devices.

Every power supply must obtain the energy it supplies to its load, as well as any energy it consumes while performing that task, from an energy source. Depending on its design, a power supply may obtain energy from various types of energy sources, including electrical energy transmission systems, energy storage devices such as a batteries and fuel cells, electromechanical systems such as generators and alternators, solar power converters, or another power supply.

All power supplies have a power input, which receives energy from the energy source, and a power output that delivers energy to the load. In most power supplies the power input and output consist of electrical connectors or hardwired circuit connections, though some power supplies employ wireless energy transfer in lieu of galvanic connections for the power input or output. Some power supplies have other types of inputs and outputs as well, for functions such as external monitoring and control.

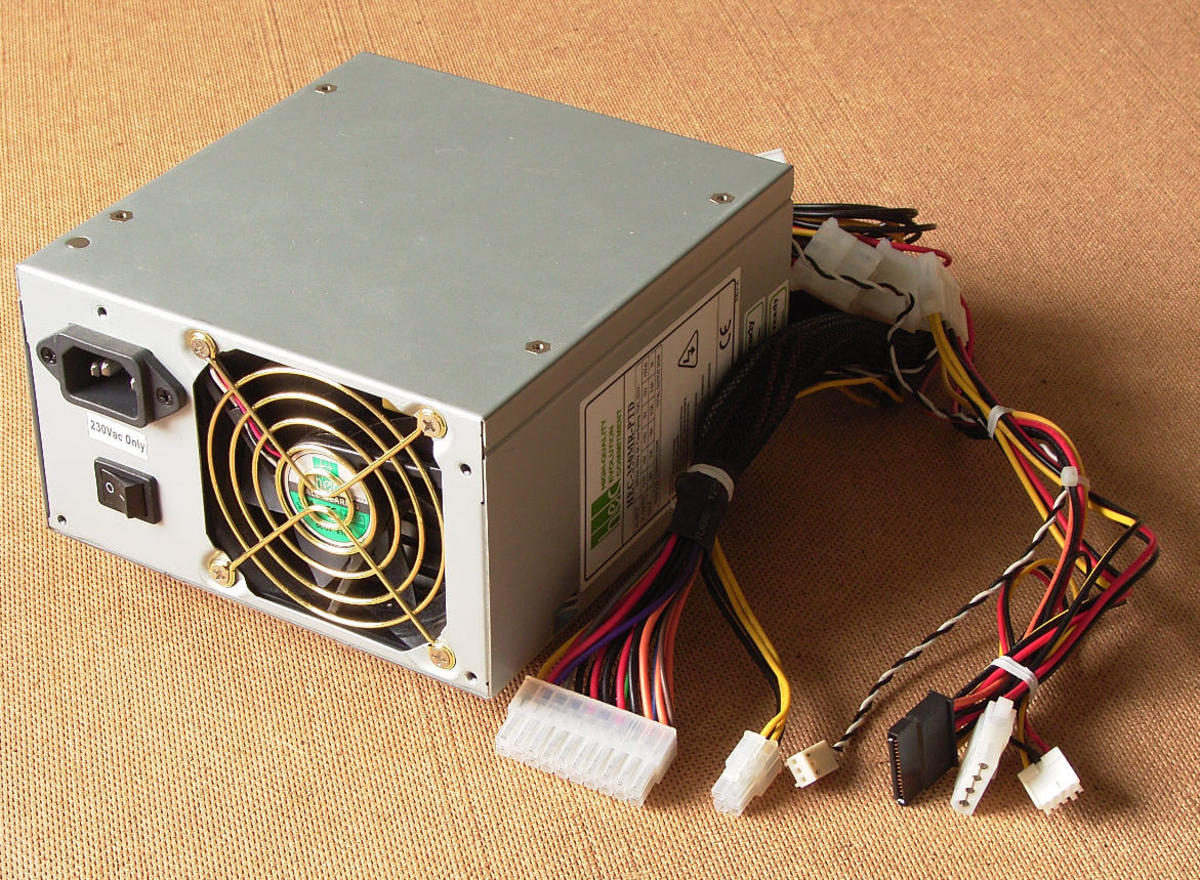

A simple desktop power supply with power output connector seen at lower-left and power input connector (not shown) located at the rear

General classification

Functional

Power supplies are categorized in various ways, including by functional features. For example, a regulated power supply is one that maintains constant output voltage or current despite variations in load current or input voltage. Conversely, the output of an unregulated power supply can change significantly when its input voltage or load current changes. Adjustable power supplies allow the output voltage or current to be programmed by mechanical controls (e.g., knobs on the power supply front panel), or by means of a control input, or both. An adjustable regulated power supply is one that is both adjustable and regulated. An isolated power supply has a power output that is electrically independent of its power input; this is in contrast to other power supplies that share a common connection between power input and output.Mechanical

Power supplies are packaged in different ways and classified accordingly. A bench power supply is a stand-alone desktop unit used in applications such as circuit test and development. Open frame power supplies have only a partial mechanical enclosure, sometimes consisting of only a mounting base; these are typically built into machinery or other equipment. Rack mount power supplies are designed to be secured into standard electronic equipment racks. An integrated power supply is one that shares a common printed circuit board with its load.Power conversion method

Power supplies can be broadly divided into linear and switching types. Linear power converters process the input power directly, with all active power conversion components operating in their linear operating regions. In switching power converters, the input power is converted to AC or to DC pulses before processing, by components that operate predominantly in non-linear modes (e.g., transistors that spend most of their time in cutoff or saturation). Power is "lost" (converted to heat) when components operate in their linear regions and, consequently, switching converters are usually more efficient than linear converters because their components spend less time in linear operating regions.Types

DC power supply

A DC power supply is one that supplies a constant DC voltage to its load. Depending on its design, a DC power supply may be powered from a DC source or from an AC source such as the power mains.AC-to-DC supply

The filter removes most, but not all of the AC voltage variations; the remaining AC voltage is known as ripple. The electric load's tolerance of ripple dictates the minimum amount of filtering that must be provided by a power supply. In some applications, high ripple is tolerated and therefore no filtering is required. For example, in some battery charging applications it is possible to implement a mains-powered DC power supply with nothing more than a transformer and a single rectifier diode, with a resistor in series with the output to limit charging current.

Linear regulator

The function of a linear voltage regulator is to convert a varying DC voltage to a constant, often specific, lower DC voltage. In addition, they often provide a current limiting function to protect the power supply and load from overcurrent (excessive, potentially destructive current).A constant output voltage is required in many power supply applications, but the voltage provided by many energy sources will vary with changes in load impedance. Furthermore, when an unregulated DC power supply is the energy source, its output voltage will also vary with changing input voltage. To circumvent this, some power supplies use a linear voltage regulator to maintain the output voltage at a steady value, independent of fluctuations in input voltage and load impedance. Linear regulators can also reduce the magnitude of ripple and noise on the output voltage.

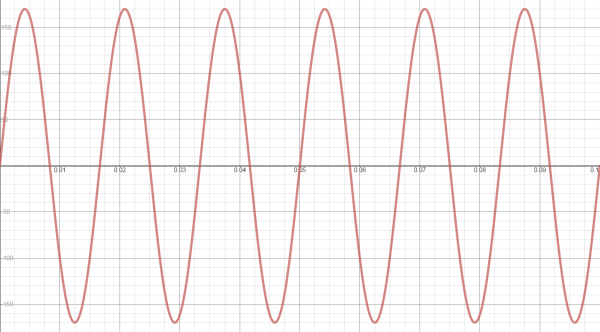

AC power supplies

An AC power supply typically takes the voltage from a wall outlet (mains supply) and lowers it to the desired voltage. Some filtering may take place as well.In modern use, AC power supplies can be divided into single phase and three phase systems. "The primary difference between single phase and three phase AC power is the constancy of delivery." [1] AC power Supplies can also be used to change the frequency as well as the voltage, they are often used by manufacturers to check the suitability of their products for use in other countries. 230V 50 Hz or 115 60 Hz or even 400 Hz for avionics testing.

Switched-mode power supply

In a switched-mode power supply (SMPS), the AC mains input is directly rectified and then filtered to obtain a DC voltage. The resulting DC voltage is then switched on and off at a high frequency by electronic switching circuitry, thus producing an AC current that will pass through a high-frequency transformer or inductor. Switching occurs at a very high frequency (typically 10 kHz — 1 MHz), thereby enabling the use of transformers and filter capacitors that are much smaller, lighter, and less expensive than those found in linear power supplies operating at mains frequency. After the inductor or transformer secondary, the high frequency AC is rectified and filtered to produce the DC output voltage. If the SMPS uses an adequately insulated high-frequency transformer, the output will be electrically isolated from the mains; this feature is often essential for safety.Switched-mode power supplies are usually regulated, and to keep the output voltage constant, the power supply employs a feedback controller that monitors current drawn by the load. The switching duty cycle increases as power output requirements increase.

SMPSs often include safety features such as current limiting or a crowbar circuit to help protect the device and the user from harm.[2] In the event that an abnormal high-current power draw is detected, the switched-mode supply can assume this is a direct short and will shut itself down before damage is done. PC power supplies often provide a power good signal to the motherboard; the absence of this signal prevents operation when abnormal supply voltages are present.

Some SMPSs have an absolute limit on their minimum current output.[3] They are only able to output above a certain power level and cannot function below that point. In a no-load condition the frequency of the power slicing circuit increases to great speed, causing the isolated transformer to act as a Tesla coil, causing damage due to the resulting very high voltage power spikes. Switched-mode supplies with protection circuits may briefly turn on but then shut down when no load has been detected. A very small low-power dummy load such as a ceramic power resistor or 10-watt light bulb can be attached to the supply to allow it to run with no primary load attached.

The switch-mode power supplies used in computers have historically had low power factors and have also been significant sources of line interference (due to induced power line harmonics and transients). In simple switch-mode power supplies, the input stage may distort the line voltage waveform, which can adversely affect other loads (and result in poor power quality for other utility customers), and cause unnecessary heating in wires and distribution equipment. Furthermore, customers incur higher electric bills when operating lower power factor loads. To circumvent these problems, some computer switch-mode power supplies perform power factor correction, and may employ input filters or additional switching stages to reduce line interference.

Programmable power supply

A programmable power supply is one that allows remote control of its operation through an analog input or digital interface such as RS232 or GPIB. Controlled properties may include voltage, current, and in the case of AC output power supplies, frequency. They are used in a wide variety of applications, including automated equipment testing, crystal growth monitoring, semiconductor fabrication, and x-ray generators.Programmable power supplies typically employ an integral microcomputer to control and monitor power supply operation. Power supplies equipped with a computer interface may use proprietary communication protocols or standard protocols and device control languages such as SCPI.

Uninterruptible power supply

An uninterruptible power supply (UPS) takes its power from two or more sources simultaneously. It is usually powered directly from the AC mains, while simultaneously charging a storage battery. Should there be a dropout or failure of the mains, the battery instantly takes over so that the load never experiences an interruption. In a computer installation, this gives the operators time to shut down the system in an orderly way. Other UPS schemes may use an internal combustion engine or turbine to continuously supply power to a system in parallel with power coming from the AC. The engine-driven generators would normally be idling, but could come to full power in a matter of a few seconds in order to keep vital equipment running without interruption. Such a scheme might be found in hospitals or telephone central offices.High voltage power supply

A high voltage power supply is one that outputs hundreds or thousands of volts. A special output connector is used that prevents arcing, insulation breakdown and accidental human contact. Federal Standard connectors are typically used for applications above 20 kV, though other types of connectors (e.g., SHV connector) may be used at lower voltages. Some high voltage power supplies provide an analog input that can be used to control the output voltage. High voltage power supplies are commonly used to accelerate and manipulate electron and ion beams in equipment such as x-ray generators, electron microscopes, and focused ion beam columns, and in a variety of other applications, including electrophoresis and electrostatics.High voltage power supplies typically apply the bulk of their input energy to a power inverter, which in turn drives a voltage multiplier or a high turns ratio, high voltage transformer, or both (usually a transformer followed by a multiplier) to produce high voltage. The high voltage is passed out of the power supply through the special connector, and is also applied to a voltage divider that converts it to a low voltage metering signal compatible with low voltage circuitry. The metering signal is used by a closed-loop controller that regulates the high voltage by controlling inverter input power, and it may also be conveyed out of the power supply to allow external circuitry to monitor the high voltage output.

Specification

The suitability of a particular power supply for an application is determined by various attributes of the power supply, which are typically listed in the power supply's specification. Commonly specified attributes for a power supply include:- Input voltage type (AC or DC) and range

- Efficiency of power conversion

- The amount of voltage and current it can supply to its load

- How stable its output voltage or current is under varying line and load conditions

- How long it can supply energy without refueling or recharging (applies to power supplies that employ portable energy sources)

- Operating and storage temperature ranges

Power supply applications

Power supplies are a fundamental component of many electronic devices and therefore used in a diverse range of applications. This list is a small sample of the many applications of power supplies.Computer power supply

A modern computer power supply is a switch-mode power supply that converts AC power from the mains supply, to several DC voltages. Switch-mode supplies replaced linear supplies due to cost, weight, and size improvement. The diverse collection of output voltages also have widely varying current draw requirements.Electric Vehicle power supply

Electric vehicles are those which rely on energy created through electricity generation. A power supply unit is part of the necessary design to convert high voltage vehicle battery power.[4]Welding power supply

Arc welding uses electricity to melt the surfaces of the metals in order to join them together through coalescence. The electricity is provided by a welding power supply, and can either be AC or DC. Arc welding typically requires high currents typically between 100 and 350 amperes. Some types of welding can use as few as 10 amperes, while some applications of spot welding employ currents as high as 60,000 amperes for an extremely short time. Older welding power supplies consisted of transformers or engines driving generators. More recent supplies use semiconductors and microprocessors reducing their size and weight.Aircraft power supply

Both commercial and military avionic systems require either a DC-DC or AC/DC power supply to convert energy into usable voltage.AC adapter

An AC adapter is a power supply built into an AC mains power plug. AC adapters are also known by various other names such as "plug pack" or "plug-in adapter", or by slang terms such as "wall wart". AC adapters typically have a single AC or DC output that is conveyed over a hardwired cable to a connector, but some adapters have multiple outputs that may be conveyed over one or more cables. "Universal" AC adapters have interchangeable input connectors to accommodate different AC mains voltages.Adapters with AC outputs may consist only of a passive transformer (plus a few diodes in DC-output adapters), or they may employ switch-mode circuitry. AC adapters consume power (and produce electric and magnetic fields) even when not connected to a load; for this reason they are sometimes known as "electricity vampires", and may be plugged into power strips to allow them to be conveniently turned on and off.

Overload protection

Power supplies often have protection from short circuit or overload that could damage the supply or cause a fire. Fuses and circuit breakers are two commonly used mechanisms for overload protection.[5]A fuse contains a short piece of wire which melts if too much current flows. This effectively disconnects the power supply from its load, and the equipment stops working until the problem that caused the overload is identified and the fuse is replaced. Some power supplies use a very thin wire link soldered in place as a fuse. Fuses in power supply units may be replaceable by the end user, but fuses in consumer equipment may require tools to access and change.

A circuit breaker contains an element that heats, bends and triggers a spring which shuts the circuit down. Once the element cools, and the problem is identified the breaker can be reset and the power restored.

Some PSUs use a thermal cutout buried in the transformer rather than a fuse. The advantage is it allows greater current to be drawn for limited time than the unit can supply continuously. Some such cutouts are self resetting, some are single use only.

Current limiting

Some supplies use current limiting instead of cutting off power if overloaded. The two types of current limiting used are electronic limiting and impedance limiting. The former is common on lab bench PSUs, the latter is common on supplies of less than 3 watts output.A foldback current limiter reduces the output current to much less than the maximum non-fault current.

Terminology

- SCP - Short circuit protection

- OPP - Overpower (overload) protection

- OCP - Overcurrent protection

- OTP - Overtemperature protection

- OVP - Overvoltage protection

- UVP - Undervoltage protection

- UPS - Uninterruptable Power Supply

- PSU - Power Supply Unit

- SMPSU - Switch-Mode Power Supply Unit

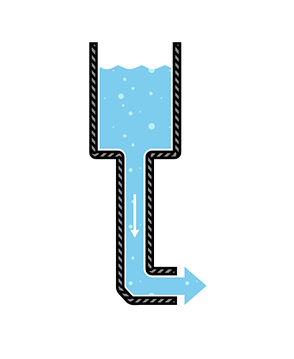

X . I Direct current (DC)

Direct current (DC) is the unidirectional flow of electric charge. A battery is a good example of a DC power supply. Direct current may flow in a conductor such as a wire, but can also flow through semiconductors, insulators, or even through a vacuum as in electron or ion beams. The electric current flows in a constant direction, distinguishing it from alternating current (AC). A term formerly used for this type of current was galvanic current.[1]

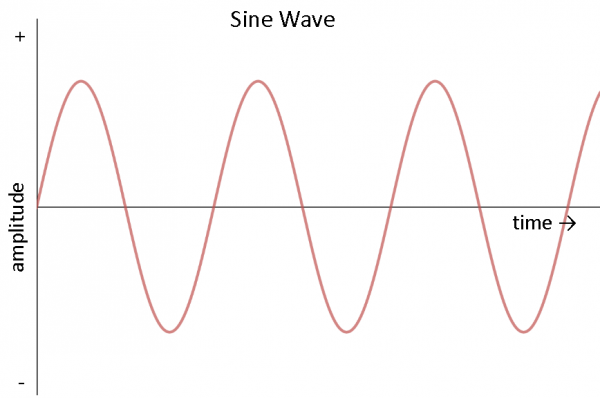

The abbreviations AC and DC are often used to mean simply alternating and direct, as when they modify current or voltage.[2][3]

Direct current may be obtained from an alternating current supply by use of a rectifier, which contains electronic elements (usually) or electromechanical elements (historically) that allow current to flow only in one direction. Direct current may be converted into alternating current with an inverter or a motor-generator set.

Direct current is used to charge batteries and as power supply for electronic systems. Very large quantities of direct-current power are used in production of aluminum and other electrochemical processes. It is also used for some railways, especially in urban areas. High-voltage direct current is used to transmit large amounts of power from remote generation sites or to interconnect alternating current power grids.

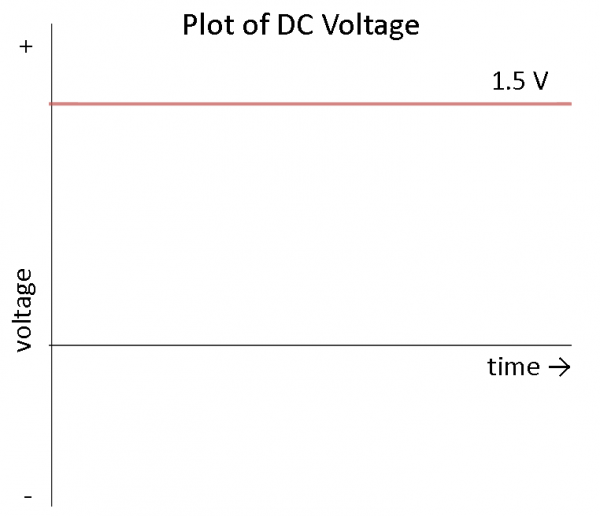

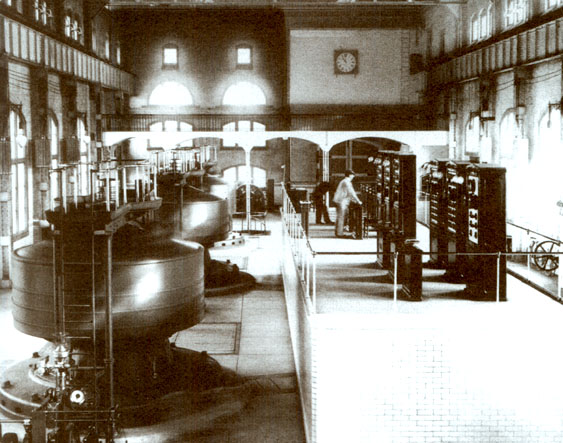

Direct Current (red line). The vertical axis shows current or voltage and the horizontal 't' axis measures time and shows the zero value.

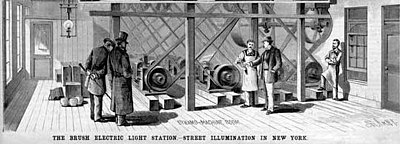

History of electric power transmission

Brush Electric Company's central power plant with dynamos generating direct current to power arc lamps for public lighting in New York. Beginning operation in December 1880 at 133 West Twenty-Fifth Street, the high voltages it operated at allowed it to power a 2-mile (3.2 km) long circuit.[4]

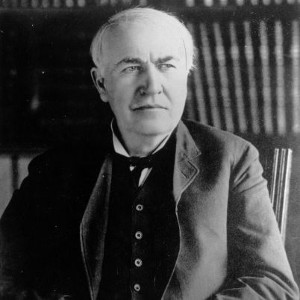

The late 1870s and early 1880s saw electricity starting to be generated at power stations. These were initially set up to power arc lighting (a popular type of street lighting) running on very high voltage (usually higher than 3000 volt) direct current or alternating current.[8] This was followed by the wide spread use of low voltage direct current for indoor electric lighting in business and homes after inventor Thomas Edison launched his incandescent bulb based electric "utility" in 1882. Because of the significant advantages of alternating current over direct current in using transformers to raise and lower voltages to allow much longer transmission distances, direct current was replaced over the next few decades by alternating current in power delivery. In the mid-1950s, high-voltage direct current transmission was developed, and is now an option instead of long-distance high voltage alternating current systems. For long distance underseas cables (e.g. between countries, such as NorNed), this DC option is the only technically feasible option. For applications requiring direct current, such as third rail power systems, alternating current is distributed to a substation, which utilizes a rectifier to convert the power to direct current.

Various definitions[edit]

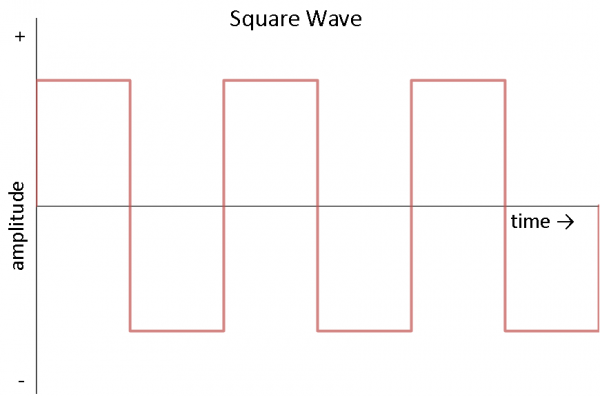

The term DC is used to refer to power systems that use only one polarity of voltage or current, and to refer to the constant, zero-frequency, or slowly varying local mean value of a voltage or current.[9] For example, the voltage across a DC voltage source is constant as is the current through a DC current source. The DC solution of an electric circuit is the solution where all voltages and currents are constant. It can be shown that any stationary voltage or current waveform can be decomposed into a sum of a DC component and a zero-mean time-varying component; the DC component is defined to be the expected value, or the average value of the voltage or current over all time.Although DC stands for "direct current", DC often refers to "constant polarity". Under this definition, DC voltages can vary in time, as seen in the raw output of a rectifier or the fluctuating voice signal on a telephone line.

Some forms of DC (such as that produced by a voltage regulator) have almost no variations in voltage, but may still have variations in output power and current.

In regard to radio frequency applications, DC commonly denotes a frequency of 0 Hz. An example of this is the phrase "DC to daylight", meaning a radio system which can receive or transmit in a frequency range from 0 Hz to some higher frequency. Most radio systems do not provide DC coverage.

Circuits

A direct current circuit is an electrical circuit that consists of any combination of constant voltage sources, constant current sources, and resistors. In this case, the circuit voltages and currents are independent of time. A particular circuit voltage or current does not depend on the past value of any circuit voltage or current. This implies that the system of equations that represent a DC circuit do not involve integrals or derivatives with respect to time.If a capacitor or inductor is added to a DC circuit, the resulting circuit is not, strictly speaking, a DC circuit. However, most such circuits have a DC solution. This solution gives the circuit voltages and currents when the circuit is in DC steady state. Such a circuit is represented by a system of differential equations. The solution to these equations usually contain a time varying or transient part as well as constant or steady state part. It is this steady state part that is the DC solution. There are some circuits that do not have a DC solution. Two simple examples are a constant current source connected to a capacitor and a constant voltage source connected to an inductor.

In electronics, it is common to refer to a circuit that is powered by a DC voltage source such as a battery or the output of a DC power supply as a DC circuit even though what is meant is that the circuit is DC powered.

Domestic

Most electronic circuits require a DC power supply.

Domestic DC installations usually have different types of sockets, connectors, switches, and fixtures from those suitable for alternating current. This is mostly due to the lower voltages used, resulting in higher currents to produce the same amount of power.

It is usually important with a DC appliance to observe polarity, unless the device has a diode bridge to correct for this.

Automotive

Most automotive applications use DC. The alternator is an AC device which uses a rectifier to produce DC. Usually 12 V DC are used, but a few have a 6 V (e.g. classic VW Beetle) or a 42 V electrical system.Telecommunication

Through the use of a DC-DC converter, higher DC voltages such as 48 V to 72 V DC can be stepped down to 36 V, 24 V, 18 V, 12 V, or 5 V to supply different loads. In a telecommunications system operating at 48 V DC, it is generally more efficient to step voltage down to 12 V to 24 V DC with a DC-DC converter and power equipment loads directly at their native DC input voltages, versus operating a 48 V DC to 120 V AC inverter to provide power to equipment.Many telephones connect to a twisted pair of wires, and use a bias tee to internally separate the AC component of the voltage between the two wires (the audio signal) from the DC component of the voltage between the two wires (used to power the phone).

Telephone exchange communication equipment, such as DSLAMs, uses standard −48 V DC power supply. The negative polarity is achieved by grounding the positive terminal of power supply system and the battery bank. This is done to prevent electrolysis depositions.

High-voltage power transmission

High-voltage direct current (HVDC) electric power transmission systems use DC for the bulk transmission of electrical power, in contrast with the more common alternating current systems. For long-distance transmission, HVDC systems may be less expensive and suffer lower electrical losses.Other

Applications using fuel cells (mixing hydrogen and oxygen together with a catalyst to produce electricity and water as byproducts) also produce only DC.Light aircraft electrical systems are typically 12 V or 20 V DC.

DC/DC Power Supplies

A DC-to-DC converter is a class of power supply which converts a source of direct current (DC) from one voltage level to another. They can essentially step-up, step-down or invert a DC voltage. Future Electronics is proud to offer a wide range of DC/DC Converter Power Suppliers including: Bias Power, SL Power (Condor), Cosel, Friwo, Mean Well, Murata Power Solutions, Power One, Recom Power, Vicor and Wall Industries.Choosing the Right DC to DC Power Supply:

When you are looking for the right DC to DC power supply, with FutureElectronics.com parametric search, no matter the application (or need, such as open frame or encapsulated) , you can filter the results by various attributes: by Type (Open Frame or Encapsulated), by form factor (1/4 Brick, ½ Brick 1/8 Brick), by Isolation (Isolated, Non-Isolated), by Number of Outputs (Single or Dual), by Output Voltage (1 W, 2 W, 3 W, 5 W,10 W,15 W, 20 W, 30 W, 50 W), by Input Voltage (-15 V / 15 V, -12 V / 12 V, -5 V / 5 V, 3.3 V, 5 V, 5.5 V, 12 V,15 V, 24 V) and by Package Style (DIP-24, DIP-6, SIP-3, SIP-4, SIP-7, SIP-8).Applications for DC/DC Converter Power Supplies:

DC to DC converters are important in portable electronic devices such as cellular phones and laptop computers, which are supplied with power primarily from batteries. Portable devices often contain several sub-circuits, each with its own voltage level requirement, different from that supplied by a battery or an external supply. A DC to DC converter offers a method to increase voltage from a partially lowered battery voltage, thereby saving space instead of using multiple batteries to accomplish the same thing.Other power supply applications and uses include: low noise amplifiers, signal processing, data acquisition - including sensors, automatic test equipment, laboratory test equipment, control circuits. In short, Future Electronics has the right DC DC power supply solution for your needs.

DC to DC Converters in R&D Quantities or Production Ready Packaging

A power supply is an electronic circuit that converts an ac voltage to dc voltage. It is basically consisting of the following elements: transformer, rectifier, filter and regulator circuits. Power supply units (PSU) are used in computers, amateur radio transmitters and receivers, and all other electronic equipment that use dc voltage as an input. Uninterruptible power supply is a must for computers which holds volatile data from time to time. This prevents corruption of data due to power failure and low voltage.

Transformer

The transformer is a static device that transfers electrical energy from the primary winding to the secondary winding without affecting the frequency. It is used to step-up or step-down the ac voltage level and isolates the remainder of the electronic system from the ac power.

The primary winding of the transformer is connected to an ac voltage source that produces alternating current while the secondary is connected to a load. The primary and secondary windings are not physically connected to each other but due to electromagnetic induction following Faraday's law, there is an induced voltage in the secondary winding. There are three main functions of transformers namely: stepping the voltage up, stepping the voltage down and providing isolation between the primary and secondary circuits.

A simple power supply used in desktop computers. This unit supplies the regulated voltage necessary for computer to operate properly. | Source

Rectifier

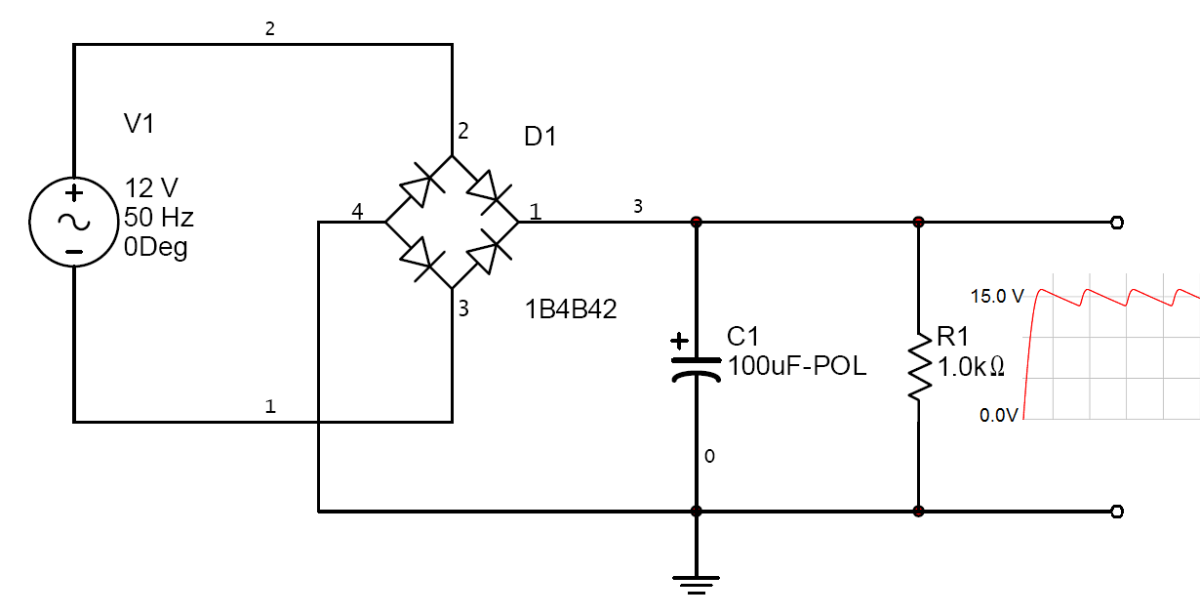

The rectifier is a device used to change the ac power into pulsating dc. The basic rectifier is the diode. This diode is a unidirectional device that operates as rectifier in the forward direction. The three basic rectifier circuits using diodes are the half-wave, full-wave center-tapped and full-wave bridge type.

Filter

The filter of the power supply is used to keep the ripple component from appearing in the output. It is designed to convert pulsating DC from rectifier circuits into a suitably smooth dc level. The two basic types of power supply filters are the capacitance filter (C-filter) and RC-filter. The C-filter is the simplest and most economical filter available. On the other hand, RC-filter is used to reduce the amount of ripple voltage across a capacitor filter. Its primary function is to pass most of the dc component while attenuating the ac component of the signal.

Ripple and Ripple factor

Ripple is the unwanted ac component of the signal after rectification. It is unwanted because it can destroy or damage the load. This is the main reason why filters are installed in power supply - to prevent high ripples. The job of the filter is to smoothen the signal and suppress the ac component or variations. Ripple factor is the ratio of the root mean square of the ripple voltage to the value of dc component at the output voltage. It is sometimes expressed in percentage or in peak-to-peak value. The ripple factor determines the effectivity of a filter being used in the circuit.

Ripple and Ripple factor

Ripple is the unwanted ac component of the signal after rectification. It is unwanted because it can destroy or damage the load. This is the main reason why filters are installed in power supply - to prevent high ripples. The job of the filter is to smoothen the signal and suppress the ac component or variations. Ripple factor is the ratio of the root mean square of the ripple voltage to the value of dc component at the output voltage. It is sometimes expressed in percentage or in peak-to-peak value. The ripple factor determines the effectivity of a filter being used in the circuit.

A sample full-wave bridge rectifier circuit with RC filter. The filter is used to reduce the ac component of the signal. | Source

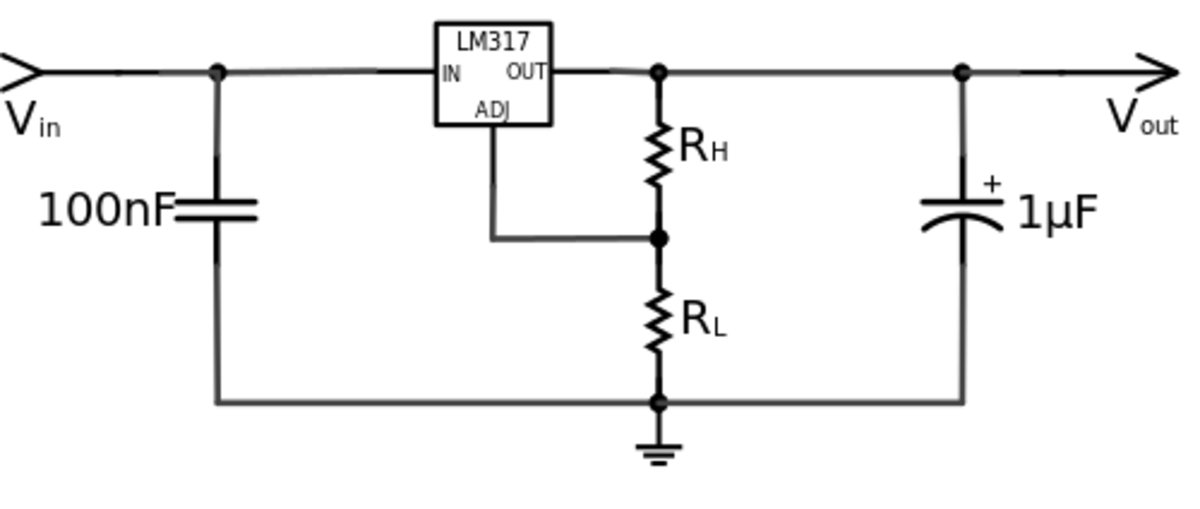

Voltage Regulators

A voltage regulator is designed to provide a very steady or well regulated dc output. It is always ideal to have a steady output voltage so that the load will operate properly. The output level is maintained regardless of the variation of the input voltage. The commonly used transistor voltage regulators are the series voltage regulator and the shunt voltage regulator.

Series voltage regulator

The series element controls the amount of the unregulated input voltage that goes to the output as a regulated output. The regulated output voltage is sampled by a circuit that provides a feedback to the comparator circuit and is compared to a reference voltage.

Shunt voltage regulator

The shunt voltage regulator provides regulation by shunting current away from the load to regulate the output voltage.

Series voltage regulator

The series element controls the amount of the unregulated input voltage that goes to the output as a regulated output. The regulated output voltage is sampled by a circuit that provides a feedback to the comparator circuit and is compared to a reference voltage.

Shunt voltage regulator

The shunt voltage regulator provides regulation by shunting current away from the load to regulate the output voltage.

A typical schematic diagram of LM317. The major component, LM317 IC is used as adjustable voltage regulator. | Source

IC Voltage Regulators

A regulator Integrated Circuit (IC) unit contains the circuitry - the reference source, comparator, amplifier, control device, and the overload protector - inside a single IC. There are also adjustable voltage regulators which allow the user to set the desired output level. Other IC regulators have fixed output values. It is said that IC regulators are superior compared to transistor voltage regulators when it comes to linearity of the output voltage.

Power supplies or power supply units, PSU, form an essential part of very many items of electronics equipment.

The most common form takes in AC power from the mains supply and delivers a DC voltage to the item requiring power.

Accordingly power supplies are widely used in a variety of forms - some large supplying high levels of current, other power supplies, much smaller providing lower levels of power.

In most power supplies there are number of different elements. These may not all be present in every design.

As a result of the different properties of each type of power supply regulator, linear regulators tend to be used in applications where very low levels of noise and ripple are required and heat dissipation may not be such a problem. Hi-fi amplifiers are one such area. Switching mode regulators are used more widely as they can be made very compact, they are very efficient and the levels of ripple, spikes and noise can normally be low enough for most applications.

When choosing any DC power supply, the specification is of key importance. A variety of DC power supply specifications will be quoted, each detailing a different element of the performance of the power supply.

For different applications, different power supply specifications will be important. However each one needs to be considered when choosing or specifying a suitable power supply.

Solar Cell, Solar Module & Solar Array Test ( DC problematic )

The goal of achieving ever increasing solar cell efficiency and reduced cost demands accurate, repeatable, fast, and reliable test results. The research, design, and development work necessary to achieving superior performing, highly manufacturable solar cells, modules and arrays requires high performance test equipment.

Producing quality solar modules and arrays in a production environment requires the characterization and sorting of solar cells. Matching the I-V performance of solar cells destined for installation in a common module or array is necessary for achieving optimum output power capability. Maximizing productivity and module or array performance means making fast, accurate and reliable measurements.

Measuring the forward I-V performance of a solar cell, module, or array involves loading the device with a constant voltage, varying the voltage in increments from zero to the device open circuit voltage (Voc), and measuring the output current. Zero volts corresponds to the maximum available short circuit current (Isc). At Voc, the measured output current of the device is zero. Measuring the reverse I-V performance of a shadowed (dark) solar device requires the application, in increments, of a reverse polarity voltage.

Power supplies or power supply units, PSU, form an essential part of very many items of electronics equipment.

The most common form takes in AC power from the mains supply and delivers a DC voltage to the item requiring power.

Accordingly power supplies are widely used in a variety of forms - some large supplying high levels of current, other power supplies, much smaller providing lower levels of power.

Power supply basics

The aim of a DC power supply is to provide the required level of DC power to the load using an AC supply at the input. Different applications require different attributes, but more often than not these days DC power supplies provide an accurate output voltage - this is regulated using electronic circuitry so that it provides a constant output voltage over a wide range of output loads.In most power supplies there are number of different elements. These may not all be present in every design.

- Input transformer: The input transformer is used to transform the incoming line voltage down to the required level for the power supply. Typically the input transformer provides a step down function. It also isolates the output circuit from the line supply.

- Rectifier: The power supply rectifier converts the incoming signal from an AC format into raw DC. Either half wave or more commonly full wave rectifiers may be used as they make use of both halves of the incoming AC signal.

- Smoothing: The raw DC from the rectifier is far from constant falling to zero when the AC waveform crossed the zero axis, and then rising to its peak. The addition of a reservoir capacitor here fills in the troughs in the waveform, enabling the next stage of the power supply to operate. Large value capacitors are normally used within this stage.

- Regulator: This stage of the power supply takes the smoothed voltage and uses a regulator circuit to provide a constant output virtually regardless of the output current and any minor fluctuations in the input level.

Power supply regulation

There are two basic forms of power supply used in electronics equipment:- Unregulated: This form of power supply was the only type used many years ago. It simply consisted of a rectifier section and this was followed by capacitor or capacitor and inductor smoothing. There was no regulation to steady the voltage. If a large current was drawn the voltage would fall as a result of the resistive losses, and also the smoothing would not be as effective and the level of hum would rise.

- Voltage regulated: As transistor circuitry became more commonplace, regulated power supplies became more common. Today they are almost universally used. They typically incorporate a voltage reference, and the output voltage is compared to this and altered accordingly by control circuitry within the regulated power supply.

- Linear regulated power supply: Linear regulated power supplies use an analogue approach. A series element - a semiconductor transistor or FET - is controlled allow the correct voltage at the output for any current within the operating range.

Note on Linear Power Supplies:

Linear power supplies are widely used for applications where low noise and ripple are required. As the name suggests, they use linear technology - typically a series linear regulator element to drop voltage. As such they dissipate power, but without any switching mode, they are able to offer high levels of performance

- Switching regulator power supply: The switching regulator format for a power supply uses a large output reservoir capacitor. A series element - a transistor or FET - is switched on and off to keep the voltage on the capacitor within the required limits.

Note on Switch Mode Power Supplies:

Switch mode power supplies and switch mode regulators have many advantages in terms of efficiency, size and weight. Their design can be more involved than might be thought at first. Yet with a good understanding, these switch mode power supplies, SMPSs, switch mode regulators and switch mode controllers can be successfully designed and built..

| Regulator type | Advantages | Disadvantages |

|---|---|---|

Linear regulator |

|

|

Switching regulator |

|

|

When choosing any DC power supply, the specification is of key importance. A variety of DC power supply specifications will be quoted, each detailing a different element of the performance of the power supply.

For different applications, different power supply specifications will be important. However each one needs to be considered when choosing or specifying a suitable power supply.

Power supply voltage and current specification

The voltage and current are the two most important parameters and will naturally be quoted in volts and amps. Sometimes the output power in watts may be quoted.Line regulation specification

Line regulation is the variation in output voltage when the input or line voltage changes. It is normally quoted in millivolts variation or as a percentage of the output voltage and should be a few millivolts (e.g. 5 mV) or around 0.01% of the maximum output voltage for most supplies for a change of line voltage anywhere within the operating range.Power supply specification for load regulation

Load regulation is the variation in output voltage for a change in the load. It is normally quoted as a in millivolts variation or as percentage of the maximum output voltage It might typically be a few millivolts (e.g. 5 mV) or 0.01% for a step load change from 0 to 100% load. It is normally quoted for a constant line voltage and steady temperature.Power supply specification for ripple and noise

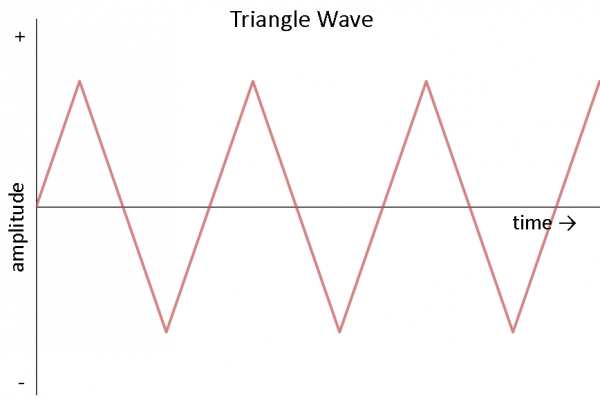

The ripple and noise on the output is combined as a single measurement. For linear supplies, ripple frequency will normally be at twice the line frequency. For switching supplies ripple and spikes will arise from the switching action of the supply. The ripple components are often given as rms figures, but for switching supplies a peak to peak measurement is more useful because it shows the extent of the spikes arising from the switching. Most good supplies should offer noise and ripple figures of better than 10 mV rms and for switching supplies figures of 50mV or less should be achievable in many cases, although very high current supplies may have slightly higher values.Power supply stability specification

Stability of the output voltage is important for some applications and is quoted for many supplies. Typically the output voltage will be measured over a period of time under constant load and input voltage and the voltage drift measured. Typically, this will be a few millivolts (e.g. five to ten) over a period of ten hours.Temperature stability specification

The temperature stability might also be important. This is measured as a percentage or absolute voltage change per degree C. Typically, this might be in the region of 0.02% / degree C or 2 mV / degree C.Power Management

- in-depth technical information and articles about all forms of power management and power sources from DC power supplies to DC-DC converters, batteries and green power sources.

DC power supplies

Battery technology

Battery technology is an area of power management electronics that is growing in importance and sophistication with the ever increasing number of battery power electronics products.Green energy

With the focus on reducing environmental effects of power management, technologies such as energy harvesting are been more widely investigated.Analysis

- Modern Power Supply System Design

- Isolation & Partial Discharge Testing of DC-DC Converters for Gate Drive Applications

- Power Density Dominates Server Design: Outlook for 2016

- Wireless Charging for the Automotive Environment

- LED Lighting Power Supplies

- Digital vs Analogue Power Supplies - Finding the right balance

- Integrated Power Considerations

- Understanding custom battery packs: options and applications

- Understanding Power Supply Reliability

- The Art of Selecting Power Supplies

Latest news

Solar Cell, Solar Module & Solar Array Test ( DC problematic )

The goal of achieving ever increasing solar cell efficiency and reduced cost demands accurate, repeatable, fast, and reliable test results. The research, design, and development work necessary to achieving superior performing, highly manufacturable solar cells, modules and arrays requires high performance test equipment.

Producing quality solar modules and arrays in a production environment requires the characterization and sorting of solar cells. Matching the I-V performance of solar cells destined for installation in a common module or array is necessary for achieving optimum output power capability. Maximizing productivity and module or array performance means making fast, accurate and reliable measurements.

Measuring the forward I-V performance of a solar cell, module, or array involves loading the device with a constant voltage, varying the voltage in increments from zero to the device open circuit voltage (Voc), and measuring the output current. Zero volts corresponds to the maximum available short circuit current (Isc). At Voc, the measured output current of the device is zero. Measuring the reverse I-V performance of a shadowed (dark) solar device requires the application, in increments, of a reverse polarity voltage.

Why do electronic circuits need their power supply to be DC, or rectified AC?

I'm pretty sure the answer to this should be obvious - even to me ...

It's been a while I've been reading and attempting to construct simple electronic circuits. The supply almost always is either through a battery/cell, or AC duly rectified to DC. I have the impression electronic circuits rarely ever work off an AC supply.

|

1.

AC flips polarity very often. Most semiconductor devices have been designed with very particular polarity conditions in mind. If one were to reverse the polarity between two inputs on many different components, you would get magic smoke coming out of it. For example take mosfet operation. An NMOS is expected to block current from drain to source until the gate is activated. If you have AC across drain to source, then it allows current to flow backwards (losing gate control). It's not impossible to design an electronic circuit with active devices around AC, but it makes it much more challenging. I should also qualify this statement: many electronics circuits do have signals with AC components to them, but they usually have a DC offset to them to prevent the polarity switching. That would be something like 5VppAC with a 2.5V DC offset would be an AC signal from 0-5 V. That remains the same polarity at all times even though it's passing an AC signal. 2.

|