X . I

Photocopy machine

Photo copy machine is one of the electronic devices that function to duplicate documents. The basic idea is a copy of the shadows, where we know if we are exposed to light then we have no idea. The image that will be transferred to pilot media and subsequent reproduction as a result of which we see everyday.

Photocopy machine

The First Office Copier who created the Canon copier. Canon Canon engine produces first graphic automatically called Copyflo. With the first office copier really produced. Twenty-two years after the electro photography ever commercial push button photocopier first time it was introduced into the world.

Canon domination later changed when new manufacturers changed what the world knew as Canon machines to copiers and it is a new beginning for the greatest marketing battle of the 20th century.

At the beginning of Ricoh were emerging as a potential competitor to Canon and develop RiCopy diazo copier. ,

Brands like Panasonic Toshiba Canon Minolta Konica and of course Sharp began to produce small office copiers are becoming a big challenge in completion for dominance in the market Canon copier business.

Today Canon continues to be one of the world leaders in the copier market along with Sharp and Konica Minolta. More recently copiers provide more than just copy. They can now print fax scan and even send an email. It has become a great way to save money on office equipment and has also provided businesses with more office space where before they would have had separate machines such as printers and scanners fax machines.

Basic Principles of Process Engineering Copy

The inventor of the copier (photocopy) Chester F. Carison, which in the experiment following a few simple process like this :

Work principle1. Lighting, a very bright light resulting from exposure lamp that illuminates a document that is placed on the glass upside down on the glass, the image on the document will then be reflected through the lens, and the lens will direct the picture tube toward the drum. Drum is a cylindrical tube of aluminum coated with selenium which is very sensitive to light.2. Figure lighter on the drum surface will cause the electrons appear and neutralize the positive ions generated by the filament (corona wire) upper drum (wire 1), so that on the surface that the light is not charged electrons, while in the darker light will produce no changes in charge, remains positively charged.3. The black powder (toner) that are negatively charged on the developer, will be attracted by the positive ions on the surface of the drum,4. The high voltage DC provided on a filament (corona wire) makes the drum is positively charged, the filament (corona wire) there are two, one are above the drum (wire 1), and under the drum (wire 2).5. A sheet of paper is passed under the drum when the drum rotates, before the paper reaches the drum in advance of paper used by the positively charged wire 2, so that the toner sticks to the paper would be attracted by very strong to the paper, because of the attraction of positive charge on the paper is stronger of the positive charge on the drum coupled with the force of gravity6. Next the paper will miss through two pressurized hot rollers, hot rollers of the two will be exhausting toner which then will stick tightly to the paper. This event will produce a copy or copies of the same image exactly like the original.7. After the toner down to the paper drum will continue to rotate until past the blade (cleaning blade) cleaning drum and then through the wire 1 (primary corona wire), so that the drum back positively charged and ready to go back illuminated continuously repeated.

Principles of How to Work Copiers

The majority of photo copy machine is currently implementing the work process as mentioned above. So on all the machines have parts which are called:1. Charging; A cylindrical tube (drum) by an electrical charge that is electrically charged wire high-called corona wire or a charge roller. Cylinder tube is coated with a material which is photo conduction. A photo of a semi-conductor conductor will be conductive when exposed to light.

2. Exposure; A tube lights blazing illuminating the original document and section / area that is white will reflect light onto the surface of the cylinder (drum). The affected part of the reflection of light will be positively charged conductive and vice versa are not affected by the reflection will remain negatively charged. The result of this lighting will be formed on the surface of the drum.

3. Developing; Section which contains toner (powder) are positively charged. When in contact with the drum and generate an image, toner (powder) will be attracted and attached to the drum is negatively charged (black areas = text / image on the original document).

4. Transfer; The results of the image formed of toner (powder) on the surface of the drum, transferred to the surface of a sheet of paper with the aid of a negative electric charge that is higher than the negative electric charge on the drum.

5. Fusing; The smelting process toner (powder) and fused on a sheet of paper with the aid of a roll (roller) which provides pressure.

Description of the parts above is the working principle is applied to the photo copy machine Digital. While in most of the photo copy machine Analog applying a positive electrical charge on the drum and negative electric charge on toner (powder).

How it Works Photocopier

The workings of the machine copies of photos (photo copy) awesome is constituted by both natural phenomena, namely:

The attraction between two materials having the opposite electrical charge current.

Some of the material will be a conductor of electric current (conductor) is better when it is exposed to light.

Charging:Electrostatic drum cylinders in the engine fed by a high-voltage wire called a corona wire (corona wire) or a charged wire. Drum has a layer of material which is photoconductive. A photoconductor is a semiconductor that can be conductive when exposed to light.

Catching material:

A bright light will illuminate the original document, and the white areas of the original document (the part that is not exposed to ink) transmit light to the surface of the photoconductive drum. Areas of the drum are exposed to light become conductive, so disposed toward the ground. The area of the drum that is not exposed to light (part article / black areas of the original document) remain negatively charged. The result is an electric latent image on the drum surface.

imaging:

Positively charged toner. When the toner spewed out into the drum to get the image, the toner interested and seep into the area - an area that is negatively charged (black areas).

displacement:

The resulting toner image on the drum surface is transferred / transferred from the drum to a sheet of paper that has a negative charge is higher than the surface of the drum.

Drying: Toner melt and stick to the paper because of the heat and pressure rollers.

how photocopiers above is an example of a copy machine with a negatively charged drum and paper, as well as positively charged toner as that contained in the digital copying machines today. Some ancient copy machines, most of which are still analog, using drum and paper is positively charged and negatively charged and toner

The above process is an example of a copier with a negatively charged drum and paper, as well as positively charged toner as found in today's digital copier. Some ancient copy machine, which is still mostly analog, using drum and paper is positively charged and negatively charged and toner.

Stages of Production Copiers

Once introduced in the 1960s by Xerox, fotokopimenjadi machine equipment well known and widely used in the world of business and government offices. As a substitute for carbon paper, mimeograph, and other reproduction machines, photocopy using electric polarization of the light sensitive material to produce a copy accurately and economically over paper documents. The birth of computers and electronic communication is slowly reducing the need for photocopying, but because it is easy to use and can reproduce copies in large quantities, then the copier is still widely used.

To produce a photocopy of the original document, the copier first create a temporary image, a kind of negative film from the original. Inside the machine there is a cylinder made of conductive metal (usually aluminum), coated with photoconductive (usually selenium). Photoconductor is a material that will hold the charge in darkness, but will disappear when illuminated light cargo. The cylindrical surface electrically in - charge / loaded, then passed over the luminous lamp image. Area of the original image on a blank white will reflect light back into the cylinder, which will free up / discharge that area. If the image is dark, the photoconductor will keep filling charge. The result is similar to the electrical map of the original image. Most copier that apply advanced technology to produce digital copies of the image and use laser to load / charge the cylinder ..The next step is to apply the toner to the cylinder electrically already in - charge in the previous step. Toner is a powder ink, and stick to the areas that were charge. Static electricity that holds the toner to the cylinder is equal to the power that makes the hair can be attached to the balloon if the hair bubble and balloon rubbed together for some time to generate an electric charge. The next step is to transfer the image to a sheet of paper, where the toner melted by heat and pressure roller, and to "remove" the former image on the cylinder by means of highlighting it with light.

Mechanical systems that exist on the copier is simple, but it seems complex. Image transfer process does not occur at the location where the original image is placed. Instead drum should be put away into the machine, so as not to hit the light, until a series of projecting mirror image of him. A photoconductor belt to move the toner and paper simultaneously. Cylinder deleted / cleared by the next series of light and made to be readyin - charge again electrically to the next image.

Types Photocopier

Types of machine Photocopy Generally based measure is a copy machine can be divided into three, namely small copy machine (portable), a photo copy machine medium (standard) and a large copy machine.

Photo copy machine small (Portable), Characteristics include: easy to carry, copying speed of 5-10 pieces per minute, with paper size A4 (210 x 297 mm)

Copier medium (standard), ± 70 kg weight machines copying speeds of 15-25 pages per minute, with a size of A3 paper (297 × 420 mm) and B4 (257 × 364 mm)

Photo copy machine large, heavy machines over 70 kg copying speed of at least 3 pieces per minute, can zoom in and out, doubling on colored paper, as well as equipped with automatic document sorting board

Applications Static electricitya. Electrostatic copying machines

Copy machine works on the principle of attractive forces between dissimilar payloads. The positive charge is given on the cylinder almumunium (Al) plated selenium (Se). The next cylinder illuminated with a projected image / text that will be in the coffee. Selenium is a photoconductor, ie materials that are insulators in the dark and be a conductor when it got light. Se part that is exposed will be conductive and will deliver electrons from Al to neutralize the positive charge in that section. Se part that does not get fixed beam of positively charged. The toner particles will stick to the positively charged layer Se. A sheet of paper was given a positive charge in the cylinder miss out on it so that the negatively charged toner particles will pull toward the positively charged paper. The pattern of the toner particles on the paper will form a shadow text / image on coffee. Toner will be attached to the paper which then is passed between rollers hot plate. This principle also applies on a laser printer.

Dangerous things on PhotocopierEach machine or other electronic device, it has many benefits and is often helping people work becomes easier. Certainly a good machine also melelui long process and can also use the chemicals or to provide treatment to the environment around the machine in order to have a good performance. It is therefore often encountered a machine that can give negative effects on the environment, such as pollution, fouling, or other effects. With the development of technology, the machine is designed as much as possible in order to minimize the impact of the pollution generated. But the methods used are often more harmful than the pollution itself, eg chemicals atupun radiation.In photocopiers there are also parts which if not used properly or the wrong treatment can lead to negative effects on the environment and human life, among others, ozone gas output when copying in progress, toner powder used1. Gas Ozone (O3)Ozone is a form of oxygen (O2) that is unstable, ozone itself is made up of three oxygen molecules which when examined had an adverse impact on human health. In nature, ozone itself is formed by the mixing of ultraviolet light by the Earth's atmosphere that forms a layer at an altitude of about 50 kilometers. Ozone is believed to be the most toxic substances and materials usual blackened.Ozone can be formed on the air due to electric currents such as lightning, and by force tinggiseperti electromagnetic radiation. Ozone is also generated from the operation of the electrical appliance with voltage (voltage) is high, such as copy machines, x-ray equipment and electric welding arc with use . In the copy machine itself, ozone is formed when inserting the tube and paper and output ± ozone is the breakdown (breakdown) of the tube material during the transfer of the image (image) and also produced by the ultra violet emissions from light photocopiers. Ozone is out of photocopiers is toxic sharp pick that can cause many problems for human health

. Health effectsAs usual ozone quickly turned back into oxygen, ozone concentrations are normal around photocopiers should not cause symptoms in employees. Range of decomposition depends on time, temperature (broken gas faster at higher temperatures) and contact with various surfaces. However, the concentration of ozone can be formed if the room has good ventilation. If the ozone concentration increased to 0.25 ppm or more, odorless gas that can cause irritation to the eyes, upper respiratory tract and lungs - lungs, throat and nose. Other symptoms are headache, shortness of breath, dizziness, fatigue, and loss of olfactory sensitivity while. In konsentrasi10 ppm can immediately endanger the lives and health. Inhalation of ozone in the long term in some ppm concentrations known to damage the lungs. Beberapaotoritas suggest that a concentration of 0.1 ppm is likely to cause kelahiranprematur and short lifespan.

tonerToner is a powder used in laser printers and photocopiers to form the printed text and images on paper. Toner in powder form used in copy machines generally dry and made from various formulas of carbon black. Generally comprises about 10% of carbon black, which is sprayed in a polyester resin polystereneacrylic sensitive or heat. Fine toner powder which can be out of mesinfotocopy, especially if the system fails toner and automatic die tool. Toner powder can also exit during maintenance or when the refilling tube.

*. Health effectsToner is a fine powder which has a negative effect on humans are quite dangerous. Fine powder such as toner extremely easy to pitch suspension in the air, so for ordinary workers generally work with copying machines are generally easily contaminated with toner which reacts with the air around the place he worked. Often toner dust can cause respiratory problems such as sneezing and coughing. For people with respiratory diseases such as asthma and bronchitis, Toner can act as an irritant which can cause or aggravate the condition irtiasiA study published in the University of Rostock in Germany is reported to have found that the microscopic particles in toners are carcinogenic, similar to asbestos. Some technicians wherewith working with printers and copiers on a daily basis were observed for several years, they showed increased lung problems

Effects Noise (Noise)Photo copy machine at high speed and has a dual function, has the potential to be more noisy. Photo machine older copies could lead to noise levels above 75 dB (A) and the machine copies of photos with a great ability to produce noise of 80 dB (A). The noise level is more appropriate for the office area should kurangdari 60 dB (A).

* .Efek HealthThe noise from the operation of the copy machine (especially persistent) can cause stress among workers and concentration problems. In the press and printing industry, noise is the main danger to workers and can cause temporary deafness and tinnitus or ear ringing

Ultra Violet LightUltraviolet radiation (often abbreviated as UV, from English: ultraviolet) radiation is electromagnetic wavelength shorter than areas with visible light, but longer than X-rays were small. The lights are fluorescent types, metalhalide or quartz is generally used in a copy machine. Lamp itself is not a danger, but the lights can cause pressure on the eye when it takes place repeatedly. So in doing the copy should always be done by lowering the engine petutup

*. Health effectsThe lights are used continuously on a copy machine may cause eye irritation and headaches after exposure, when seen in person. It can irritate and cause strain on workers

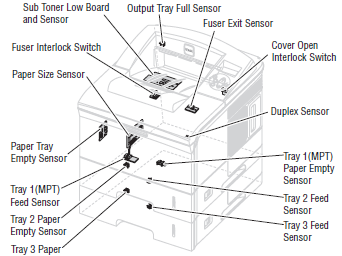

section section photocopiers

Components photocopiers

I. CCD sensor

That is the light sensor in a working camera to record images. This sensor consists of millions of tiny light sensor, a sensor for one pixel, large and small CCD is measured in units called megapixels. The bigger the more pixels, the better the results of the drawing.

II. toner container

Toner or ink powder is a powder used in laser printers and photocopiers to form the printed text and images on paper. In the early days, the powder used is ordinary carbon. However, to improve the quality of the mold, the material used is a mixture of carbon with a polymer. The particles in the ink powder melted due to the heat in the fuser (fuser), and then attached to the paper.

III. cylindrical photosensitive

IIII. roller settlers

IIIII. circumvention staining

IIIIII. cylinder rotates photos

IIIIIII. tray photocopy

IIIIIIII. paper sorting trays

IIIIIIIII. paper tray

IIIIIIIIII.casing photocopiers

X . II

Printer Copier Components

Printer

Copier

Components

As the only significant difference between the printer function and the digital copier function is the network connection source of original image to print, the components are much the same, but highly dependent on whether the printer copier uses a laser printing or inkjet printing mechanism.LASER

Laser

A light emitting laser gun is controlled by the printer electronics to fire light pulses towards mirrors, which reflect the light onto the photosensitive drum to form the image as static electricity. This is not a component that can be replaced by the consumer, but is fundamental to the laser printing process.

Photoconductive Drum

The drum is an aluminum cylinder coated with a photoconductive (light sensitive) film. The photoconductive material reacts to the light and so the image is formed on the drum as a series of active and inactive areas of static electricity on the photoconductive material. The intensity of light – perhaps by reflecting the amount of colour or grey, black or white – from the original document provides an intensity of electrical charge on the photoconductive material, which is created by the charge corona.

Charge Corona

The first of the two Corona components is the Charge Corona, which is a thin wire in a metal slide, usually part of the drum unit, with the purpose of producing an electrical charge on the Drum where the light reacts with the photoconductive film. This charge is to attract the toner to the drum, as the toner unit consists of a positively charged chemical.

Toner Unit

Toner is a powder which contains finely grounded dye coloured plastic, and this will become ink when heated. The unit also consists of something called ‘Developer’ which is a finely grounded metallic chemical with that can be electrically charged. When the electrically charged Drum rolls passed the toner unit, the developer is attracted to the drum, and carries the toner along with it onto the drum. Where there are colour toners, the collection of toner units with different colour dyes sit in parallel within proximity of the drum.

Transfer Corona

Much like the Charge Corona, the Transfer Corona is a thin wire housed in a metal slide that electrically attracts the toner from the drum onto the copy paper. At the same time this component separates the electrically charged paper away from the drum so the paper can continue to the next stage of the process.

Fuser Unit

The Fuser Unit binds the toner to the paper, consisting of two rollers, of which the upper one is heated to melt the toner plastic and releasing the ink onto the paper as the paper passes through the rollers. The upper fuser roller is heated by a temperature-controlled lamp, and is coated with a non-stick (and therefore easily cleanable) silicon coating. The lower fuser roller is not heated, and is generally just a soft silicon rubber.

Cleaning Unit

As the drum is not only charged but attracts the toner with developer material to form the copy image on the drum, the cleaning unit is designed to remove any residue of the substances that form on the drum after the Transfer Corona has transferred the necessary toner representing the image onto the paper. The cleaning unit consists of a magnetic roller and a cleaning blade. The cleaning blade is simply a silicone rubber strip attached to a metal bracket, and makes physical contact with the Drum to remove the residue.

INKJET

Ribbon

The ribbon is a piece of material that carries wiring from the electronic circuitry to the printhead which houses the ink cartridges. The electronic circuit sends information through the ribbon to control the motion of the printhead across the paper according to the image formation of the document to print.

At the same time, heat is transferred through the ribbon to the print cartridges and is only applied when ink needs to be released.

Printhead

The printhead is a casing that houses the ink cartridges, with specifically sized openings at the bottom to released the ink through, and has the ribbon attached to the back with a mechanism to transfer the signals from the control circuit which the ribbon is attached to on the other end.

The printhead sits on a horizontal pole which is placed at a particular distance above the passing paper; enough for the printhead to slide across the pole to specific positions according to where the image needs to be printed onto the paper.

Ink Cartridge

Inkjet ink cartridges are tubes containing different dye inks, but has an electronic chip to collect heat energy, which then creates and air bubble in the tube, and displaces ink which is released at an opening which sits aligned with an opening on the printhead to release into onto the paper in a controlled flow.

For colour printers, there are typically 5 cartridges, where four are the colours, black, magenta, cyan and yellow. The fifth is usually a larger cartridge with black also, dedicated to black and white printing, as it is the most common colour and thus would cause disproportionate consumption of the black coloured cartridge.

OTHER PARTS

Electronics

CCD: These components include a CCD (Charge Couple Device) which acts as a sensor to the image light from the lamp/mirror, and converts it into a series of charges that represents the formation of the image from the light. The CCD is used for the copying process, to convert a scanned image into digital data.

Electronic Control Circuit: The purpose of the control circuit will vary depending on the machine functionality. Usually a switch connected to the user control panel will activate the specific function, whether to scan, copy or print.

For the copier function, the signal is passed from the CCD to a circuit board which will have an ‘Analogue to Digital Converter’. The output of the circuit passes the signal to the printing mechanism, whether laser or inkjet.

For the printer function, the document image is sent by a network connection from the computer and the circuitry accepts the data and passes the signal on to the printing mechanism.

In the laser printing mechanism, the information is sent through a light emitting laser gun to project the image as light again onto mirrors towards the photosensitive drum.

In the inkjet printing mechanism, the information causes electronic circuitry to control heat and movement through a ribbon attached to a printhead component.

Printer Output Attachment System: For mid to high volume printers, there are often physical attachment systems, such as for the output trays. This allows systems to be customized to business and printing volume needs, but generally the attachment systems are from the same manufacturer as the copier printer for output sections to fit together.

The attachments can have many or few paper trays for multiple, high volume printing, and can and automatic stapler as one of the output catch trays.

These variables of an attachment makes mid to higher volume printing more efficient, organised and time-effective.

X . III

flashback Photocopiers

Traditional photocopiers are otherwise

known as analogue copiers, which are very different to digital copiers

now more commonly in use. Initially, analogue copiers were limited to

monochromatic (black and white) copy of a single sheet using certain

photoelectric, electrostatic and electrochemical methods.

The common method of creating a copy is

by shining a light through the original document which then generates

static electricity between a rotating drum and a powdery chemical called

‘toner’ that releases the ink. To understand more about how traditional

copiers work, click here.

The ink from the toner in a traditional

copier is of a single dark colour, producing the black and white effect

on the photo copy. To make multiple copies of an original sheet, the

processes inside the machine need to be repeated over the original

document. This makes the system slow for large volume photocopying and

replacing the toner very costly. The drum also needs to be replaced

periodically, though not as frequently as the toner, but this is also

very expensive.

Colour Photocopiers

Traditional colour

copiers require ink that can replicate the placement of colours on the

original document. Although colour toner was available quite early, the

basic mechanism of photocopying in analogue copiers was too simplistic

to make sense of colour. Therefore, the original colour copiers used a

process called Dye Sublimation.

Eventually, a mechanism to detect colour

using light allowed electrostatic technology and colour toners to be

used for colour copiers just like black and white copiers.

Colour copiers make it possible to

reprint colour photographs and graphics on normal printing paper, but

the quality can be limiting as the wet ink from the toner in analogue

copiers can cause the paper to wrinkle if the original has a high

density of colour content.

Functionality and Availability

The electrostatic mechanism in analogue

copiers only allows a copy to be made at the same scale as the original

document. This means, for example, that an A4 document will only produce

a copy of the same paper size.

Even with basic functionality, colour

copiers have higher running costs than black and white copiers, as

multiple toners are often required for the different colours and are

more expensive. However, typically colour copiers have the option to

switch to black and white, allowing you to use the analogue colour

photocopier economically.

Traditional copiers, whether black and

white or in colour, can still be purchased but are increasingly less

available. As a result, not only is it difficult to find supply of

consumables such as toner and the drum and thus also costly; but the

operating costs to replace the toner, drum and any other moving parts

prone to breakage can be expensive.

Disposing of old toner can be an environmental headache, but there are means available to recycle old toner units.

Digital photocopiers, as opposed to

traditional analogue copiers, use raster image processing (RIP)

technology to store imagery of the original document in the machine as a

set of pixilated information. With this fundamental function of

copying, digital copiers now come in many different forms and with a

range of functionality that utilizes the ability to reuse the stored

image of information.

With added functionality, such as

facsimile to send a copy to another physical location, or scanning to

send the digitally stored image to a computer terminal, digital copiers

are inherently multifunctional.

You can find information on different

types of copiers with other functionality elsewhere on this website, but

standalone digital photocopiers are available with a wide variety of

features to make photocopying efficient, cost effective and of high

quality.

Types of Digital Copiers

There are two main types of digital

copiers that use different mechanisms to process the printed copy are

Inkjet and Laser. To learn more about how digital copiers work, click

here.

Inkjet

An inkjet photocopier typically uses the

common method of scanning the original document by RIP technology using

a laser, but the inkjet technology in the digital copier is mainly for

the printing of the copy. Inkjets are cheap to maintain with fewer

moving parts involved, but the process of inkjet printing is slower than

laser printing, and the ink can often remain wet during printing if

there is a lot of colour variation in the original image. Therefore,

Inkjets are best for simple colour photocopying at low volumes.

Laser

Laser photocopiers also user the common

method of scanning the original document, but use laser printing

technology to print the copy. Laser printers are faster and of high

printing quality, as well as reliable, but as a result can be expensive;

yet they still have lower operating costs compared to an analogue

photocopier.

Benefits of Digital Copiers

QualityDigital copiers are instantly of higher quality than analogue copiers for a number of reasons. Firstly, the scanning of the original document itself uses optical technology, and the result is converted to digital information in raster form as a copy image. Secondly, the digitization of the scanned image means that most standard digital copiers allow you to change the intensity and other attributes to apply to refine the quality of the scanned copy.

By scanning and retaining a copy of the

original in memory, the features on a digital copier can be used to

adjust settings and reprint to ensure the copies cannot be distinguished

from the original. The printing mechanisms in digital copiers are also

more advanced than in analogue copiers.

Efficiency

The benefit of a digital copier is that a

single scan of a document can be used to print multiple copies, which

is extremely time-efficient and allows for high volume photocopying

without having to repeat the most important part of the process.

It also helps productivity as only the

first copy needs to be observed to ensure it is as desired, and the rest

can be left to print automatically as they are certain to be exactly

the same, while the user can do other activities to save time.

Cost Effective

Digital copiers not only have lower

operating costs than analogue copiers, but the efficiency of scanning

and digitizing the scanned image for reuse, reprinting and tuning its

visual attributes saves on paper, ink and electricity. Ink cartridges

for digital copiers are also cheaper as they are widely available.

Environmentally Friendly

Digital copiers are instantly more

environmentally friendlier than analogue copiers because they have less

consumables to dispose of. However, there are continuous environmental

benefits of digital copiers by with less energy consumption,

particularly helped by only needing to commit a scan of a document once,

which is energy intensive, no matter how many copies are required to be

printed.

Most modern digital copiers allow

different energy saving modes, including automatic or timed power shut

down, or sleep modes for a period of inactive use. The technology in

digital copiers also tends to be quieter.

Feature Rich

Even in single-purpose digital copiers,

the digital system allows there to be a whole range of features which

would not be possible in an analogue copier.

Aside from image quality adjustments and

copier preferences, you can also configure settings for the copy,

including scaling, multiple pages on a single sheet, duplex printing and

different print settings to manage large volume sets.

The number of features and the level of

sophistication can vary, and the price of the photocopier will vary

accordingly, but consumables or parts will also cost proportionately.

Many modern digital copiers also contain

a meter to monitor the usage, consumable supplies in the machine, such

as paper and ink levels. Advanced meters can also include security

measures to monitor who and when the photocopier is used.

The possibilities of features are end memory flyer .

Copier components

The paper cassette, often also called the paper tray, is the container to hold the stack of paper sheets to print on.

Paper Feed

The paper feed is a rubber piece that

takes a sheet of paper from the paper cassette and sends it into the

printer system, beginning with the registration rollers.

Registration Roller

A soft rubber roller that collects the paper and passes it towards the drum.

Exposure Lamp

The exposure lamp exists in most old and

new systems that copy an original document, and its purpose is to

supply light to the image of the original so the light reflects off a

series of lenses and optical mirrors and projects the image onto the

Drum.

Photoconductive Drum

The drum is an aluminum cylinder coated

with a photoconductive (light sensitive) film. The photoconductive

material reacts to the light and so the image is formed on the drum as a

series of active and inactive areas of static electricity on the

photoconductive material. The intensity of light – perhaps by

reflecting the amount of colour or grey, black or white – from the

original document provides an intensity of electrical charge on the

photoconductive material, which is created by the charge corona.

Charge Corona

The first of the two Corona components

is the Charge Corona, which is a thin wire in a metal slide, usually

part of the drum unit, with the purpose of producing an electrical

charge on the Drum where the light reacts with the photoconductive film.

This charge is to attract the toner to the drum, as the toner unit

consists of a positively charged chemical.

Toner Unit

Toner

is a powder which contains finely grounded dye coloured plastic, and

this will become ink when heated. The unit also consists of something

called ‘Developer’ which is a finely grounded metallic chemical with

that can be electrically charged. When the electrically charged Drum

rolls passed the toner unit, the developer is attracted to the drum, and

carries the toner along with it onto the drum. Where there are colour

toners, the collection of toner units with different colour dyes sit in

parallel within proximity of the drum.

Toner

is a powder which contains finely grounded dye coloured plastic, and

this will become ink when heated. The unit also consists of something

called ‘Developer’ which is a finely grounded metallic chemical with

that can be electrically charged. When the electrically charged Drum

rolls passed the toner unit, the developer is attracted to the drum, and

carries the toner along with it onto the drum. Where there are colour

toners, the collection of toner units with different colour dyes sit in

parallel within proximity of the drum.

Transfer Corona

Much like the Charge Corona, the

Transfer Corona is a thin wire housed in a metal slide that electrically

attracts the toner from the drum onto the copy paper. At the same time

this component separates the electrically charged paper away from the

drum so the paper can continue to the next stage of the process.

Fuser Unit

The Fuser Unit binds the toner to the

paper, consisting of two rollers, of which the upper one is heated to

melt the toner plastic and releasing the ink onto the paper as the paper

passes through the rollers. The upper fuser roller is heated by a

temperature-controlled lamp, and is coated with a non-stick (and

therefore easily cleanable) silicon coating. The lower fuser roller is

not heated, and is generally just a soft silicon rubber.

Cleaning Unit

As the drum is not only charged but

attracts the toner with developer material to form the copy image on the

drum, the cleaning unit is designed to remove any residue of the

substances that form on the drum after the Transfer Corona has

transferred the necessary toner representing the image onto th paper.

The cleaning unit consists of a magnetic roller and a cleaning blade.

The cleaning blade is simply a silicone rubber strip attached to a metal

bracket, and makes physical contact with the Drum to remove the

residue.

Paper Transport

The Paper Transport is a carriage system

that holds together the process of copying by consisting of a series of

rubber rollers and planes to facilitate the copy paper’s passage along

the process.

Paper Tray

The Paper Tray – also known as the

‘catch tray’ – is often an optional extension to the exit location for

the copy paper, allowing the paper to stack more efficiently with less

risk of paper falling off the printer exit shelf.

CCD and other Electronics

In digital copiers, there are additional

components to digitise the copied image before it is transported to the

physical copying process. These components include a CCD (Charge Couple

Device) which acts as a sensor to the image light from the lamp/mirror,

and converts it into a series of charges that represents the formation

of the image from the light.

The signal is then passed on to other

electronics on a circuit board within the copier, such as an ‘Analogue

to Digital Converter’. On the output of the circuit, the signal is

passed to a laser gun which forms the image as light again onto mirrors

towards the photosensitive drum. The purpose of the electronics is to

add a stage of refinement and flexibility to the copy.

How Photocopiers Work

Analogue photocopiers use traditional xenography processes to duplicate a document, using the process of combining static electricity with a dry plastic chemical powder called ‘toner’. This is the process by which analogue photocopying takes place:- The original is placed on a clear glass plate

- When the user initiates the process using a button, the copy paper is collected from the paper cassette using the paper feed, and inserted into the paper transport, while a fluorescent or incandescent lamp is turned on underneath the glass

- The light from the exposure lamp shining on a strip of the original image through the glass carries a reflection of the portion of image onto a mirror. In this way, the lamp is shifted along the document to light a portion of the image at a time

- The mirror is positioned to project the image light into a rotating photoconductive drum

- As the photosensitive film on the drum reacts to the light, the Charge Corona applies a negative charge to the drum to create static electricity where the light has formed an active image representation on the drum

- As the drum rotates passed the development toner unit, the toner powder consisting of negatively charged developer material is attracted to the drum surface where the image is arranged in the form of negative charge

- The toner attaches to the drum in the arrangement of the image, and is carried by the drum to where it meets the copy paper

- The Transfer Corona then separates the charges by attracting the toner away from the drum and onto the paper, forming the image on the paper as the drum rotates passed the corona.

- The drum continues to rotate on and passes a cleaning unit, which collects residue toner and developer left on the drum, and removes any residue charge from the drum to be clean for the next copy

- The paper with the toner is passed on to the Fuser Unit, which uses the heating element on the upper roller to melt the toner plastic and release the ink pigment onto the paper, and press it onto the paper.

- The paper is then transported on, and often brushed for any residue, before exiting the copier onto the paper/catch tray

Digital Photocopiers

Digital photocopiers are not so dissimilar in process to analogue

copiers when you consider the printing element of producing a copy.

However, there are commonly two types of printing mechanisms in copiers:

Inkjet and Laser.For either type, digital copiers can be considered as having a laser scanner component to copy and digitise the original, and a printer element with either of two mechanisms The scanning component is the fundamentally digital part of a digital copier, and takes the following process:

- The original document is placed on a clear glass plate

- The user can manipulate the number of copies, scale and other attributes using a digital control panel

- Once the user initiates the copying process using a start button, the copy paper is collected from the paper cassette using the paper feed and inserted into the paper transport, while a fluorescent or incandescent lamp is turned on underneath the glass

- The light from the exposure lamp shining on a strip of the original image through the glass carries a reflection of the portion of image onto a mirror. In this way, the lamp is shifted along the document to light a portion of the image at a time

- The CCD panel converts each strip of image light into a signal of information for each row of a raster

- The signal is passed through an analogue to digital converter for the Raster Image Processor (RIP), which creates a raster image copy of the original, storing it in memory

- The raster image can then undergo image processing for the attributes set by the user before initiating the copy, and any other advanced image processing such as orientation correction

After any image processing and image handling is completed, the RIP outputs the signal to the printing section of the copier.

In laser photocopiers, the signal is passed through a laser gun, which then acts as the light source to project each line of image information onto the rotating photosensitive drum to recreate the image on the drum as an arrangement of static electricity. This then follows the same printing process as an analogue photocopier. This laser-induced printing process is also similar to what happens in a laser printer.

In inkjet photocopiers, the RIP passes the signal through electrical circuitry that controls the horizontal movement of the printhead across the paper and the heat to set the ink at the positions required on each line, just like it does for inkjet printers.

X . IIII

Scanner Copier

About Scanner Copiers

Scanner Copiers are digital imaging

systems not only for physical photocopying, but also transferring and

storing a digital copy of an original document or image in a computer or

storage device for further electronic use.

Digital copiers have a physical scanning

component, but this is only to digitise the copy of the original

document within the machine’s memory, and have no network connection to a

computer.

Copiers with integrated laser scanners are connected to a local network, either with a server or directly to computers.

Regular scanner copiers exist for normal

paper documents, but exist in various forms for different types of

scanning. These can include being able to scan film material,

photographs, books, stapled documents, multiple sized and double sided

(duplex) scanning, amongst many others.

For business systems the latter three

are often the most important, particularly for high speed, high volume

scanning and copying with the need to produce copies that look as

authentic as the original document. To do this, scanner copiers not only

have built-in image correction software for high-fidelity copy

printing, but utility software for computers are available to use with

imaging systems to preview and apply further image processing and

recognition for electronic archiving and document management.

Digital scanners come in all forms and

sizes depending on the main application. For business uses, generally

scanners are needed for documents and graphics, so appropriate types of

scanners are most often combined with copiers and printers into a single

unit to be more productive, economical and environmentally-friendly.

The

traditional type of digital scanner is the Flatbed, which is the

mechanism found in the common, original photocopiers. By raising a lid,

the document can be placed on a clear glass plate, with a moving light

beneath to start the process of projecting and copying the image from

the original once the lid is placed down and the scanning/copying is

initiated by the user.

The

traditional type of digital scanner is the Flatbed, which is the

mechanism found in the common, original photocopiers. By raising a lid,

the document can be placed on a clear glass plate, with a moving light

beneath to start the process of projecting and copying the image from

the original once the lid is placed down and the scanning/copying is

initiated by the user.

The two main disadvantages of flatbed

scanners are the limited area of the glass plate, and that only one side

can be scanned at a time, making it a manual process for a double-sided

document. However, the advantage of the traditional flatbed scanner is

that the document is given a completely flat surface and straight edges

to align the document in as original form as possible. Flatbed lids also

allow you to keep the scanning component unexposed and clean.

Sheet-Feed Scanners

Sheet-Feed scanners are essentially for

fast scanning of single sheets of paper representing a document or

image. The mechanism is simply for the original sheet of paper to be

inserted into a paper feed tray – often a vertically angled stand that

allows the paper to slot into the machine.

With the paper inserted in the right

direction, the user initiates the scanning process and the scanner

machine will pull the paper in to pass it through an internal scanning

component.

The scanning component is not dissimilar

to the flatbed type of scanner, but instead of manually placing the

original onto a clear glass plate for light to pass and reflect the

image, the paper is fed passed an area that light can be projected onto

the paper and reflected onto internal sensors.

Older sheet-feed scanners were manual,

so that when the user manually inserts a sheet into the open slot of the

machine, the machines knows to begin the scanning process. Now

automatic sheet-feed scanners are designed to use a paper feed

component, which upon the user initiating the scanning process, collects

the topmost sheet of paper from the paper tray, and continues to

collect any further sheets if there is a stack.

For a more practical design, automatic

sheet-feed scanners (and scanner copiers) are build with an inclined

horizontal paper feed tray – instead of the traditional vertical design –

so that it is easier to stack papers and the automatic collection of

each sheet of paper is quicker and more efficient.

The advantages of sheet-feed scanners

(and thus also scanner copiers) mostly benefit environments in which a

large number of single sheets of documents require fast scanning or

photocopying, particularly in high volume. However, sheet-feed scanners

can often be restrictive in size

Duplex Scanners

Duplex scanners have a specific function

of scanning both sides of a document sheet. They essentially take the

form of sheet-feed scanners, but the internal mechanism is to transport

the paper through the scanning system so that each side is exposed one

after another to the light reflecting the current side of the document.

Duplex scanners are now readily

available as integrated into a copier, so that there is scope for duplex

photocopying. It makes scanning and photocopier even faster and

efficient where double-sided document information is required to be

copied or electronically stored.

As it is typically a sheet-feed

mechanism using a paper feed tray, many double-sided sheets can be

stacked and automatically copied or scanned. However, this limits the

original document to being single, independent sheets of paper, and

usually restricted in size.

Wide Format refers to the larger sizes

demanded by graphics media, such as for banners, posters and other large

size applications for copy, scanning and printing.

Wide format scanners accept original

documents from small to large sizes through a sheet-feed system, and

stored digitally on a computer or server. This is particularly useful

for large size arts and graphics, especially as flatbed scanners and

regular sheet-feed scanners are extremely limited on the size they can

scan.

When integrated with a copier, wide

format scanner copiers can take small and regular size documents for

large size copy production; but also the ability to copy large size

documents to rescale.

Scanner copiers function similarly to regular digital photocopiers, but

fundamentally include network connection capabilities to communicate

scanned between the scanner copier system and a computer or server.

How Scanner Copiers Work

Scanners and copiers are quite often integrated into a single system

now, as digital copiers already have a laser scanning component and it

is readily possible to establish network connections to a computer or

network server for communicating and storing scanned documents.The scanner component in scanner copier systems varies very little, regardless of which type of scanner. The feeding mechanism can be flatbed or sheet-feed, but the internal process of copying the image is much the same. When using the scanner component, the copy of the image is sent to a network terminal. Using the copier component sends the scanned image onto the printing process.

This is the general process of copying

using a scanner (illustrated by a flatbed

scanner):

- The original document is fed in by a sheet-feed method or placed on a clear glass plate on a flatbed

- The light from the exposure lamp shining on a strip of the original image carries a reflection of the portion of image onto a mirror. In this way, the lamp is shifted along the document to light a portion of the image at a time

- The light reflects off the mirror onto the CCD sensor panel in an organised sequence so the CCD can form

- The CCD panel converts each strip of image light into a signal of information for the rows of a raster

- The signal is passed through an analogue to digital converter for the Raster Image Processor (RIP), which creates a raster image copy of the original

X . IIIII

Printer Copiers

Printer copiers are the primitive form of multifunctional printer systems, usually consisting of all three functions of copier, scanner and printer.

The printer element requires a network connection to a terminal such as a computer or server, where the information is transferred from the terminal to the printer copier system. The scanner transfers information in the opposite direction, but more information on this is provided in the ‘Multifunctional Units’ section.

With printer copiers, the functional focus is all on the printing component: with importance given to speed, volume of printing and size.

Types of Printers

Mechanism

There are two main types of printing

mechanisms that conventional printers can be found in: the laser printer

and the inkjet printer, using quite different components and physical

printing process.

LASER: Laser printers use a laser gun to

project light representing the image of the document to print, onto a

photosensitive drum which then uses static electricity to imprint toner

ink onto paper. Laser printers are typically faster in operation and

sometimes better in quality, but relatively more expensive than inkjet

printers.

INKJET: Inkjet printers use a mechanical

system that navigates a printhead component containing ink tubes over

the paper according to the original image of the document to print. The

ink is released using heat, which is controlled by internal electronics

to correspond with when there is image information or not to print. The

process is slower than a laser printer – though this factor is improving

with modern inkjets – but their running costs are lower, especially to

replace the ink cartridges compared to laser printer toner, and the even

more expensive drum.

Colour

Just as copiers, printers can either be

monochrome (black and white) or colour printers. Black and white

printers are far less expensive, and relative to a colour printer with

the same technical specifications and capabilities, can be faster at

printing as there is less coordination required for ink colours.

This is more applicable in laser

printers where the difference is between using a single toner for black

and white printing, and multiple toners for colour printing. Inkjets

are typically found in colour as the mechanism of having a moving

printhead with all the ink colours together, is no less time consuming

if there is only one colour of ink as opposed to many tubes releasing

ink during the print process.

Volume

One of the most important attributes of

printers is the volume of production within a given period of time,

usually defined by per minute. Printers are now created especially to

cater for different levels of volume required, and can be the deciding

factor for the type of printer purchased.

The volume of printing reflects the copy

capabilities in a printer copier. The volume production per minute can

vary based on whether it a purely monochromatic printing system or in

colour. However, as a guide, these are the approximate levels of volume

printing:

Mid Volume: 30-50 pages per minute, up to approximately 30,000 per month

High Volume: 50-80 pages per minute, up to approximately 100,000 per month

Production Volume: 80-130 pages per minute, up to approximately 800,000 per month

Many mid to high volume printer copiers

can be used with an attachment that has different exit paper tray

formations to reflect printing requirements. Some have fewer trays but

of different sizes, while others have many trays to simultaneously print

multiple copies at once by increasing the number of paper exits.

However, this flexibility will entirely depend on the printer copier’s

printing capabilities and available output areas.

Size

Most conventional business printer

copiers are created to print up to A3 paper size, with exit paper trays

often for both A4 and A3 prints and copies.

Production printers can often handle

larger size prints, while Wide Format printers are primarily used for

large size printing, such as for banners and posters.

Wide format printers also tend to use

continuous roll paper to print so that any dimension can be achieved

within the limited large width of the printer copier. After printing is

complete, the machine will cut away the print from the roll of paper.

Wide format printers can be either an

analogue or digital as analogue printers can produce a higher degree of

accuracy without pixilation, and this is often more of a desirable

attribute in typical wide format printing applications, such as printing

large scale graphics, instead of attributes such as speed.

Printer Copier Components

As the only significant difference between the printer function and the digital copier function is the network connection source of original image to print, the components are much the same, but highly dependent on whether the printer copier uses a laser printing or inkjet printing mechanism.

LASERLaser

A light emitting laser gun is controlled by the printer electronics to fire light pulses towards mirrors, which reflect the light onto the photosensitive drum to form the image as static electricity. This is not a component that can be replaced by the consumer, but is fundamental to the laser printing process.

Photoconductive Drum

The drum is an aluminum cylinder coated with a photoconductive (light sensitive) film. The photoconductive material reacts to the light and so the image is formed on the drum as a series of active and inactive areas of static electricity on the photoconductive material. The intensity of light – perhaps by reflecting the amount of colour or grey, black or white – from the original document provides an intensity of electrical charge on the photoconductive material, which is created by the charge corona.

Charge Corona

The first of the two Corona components is the Charge Corona, which is a thin wire in a metal slide, usually part of the drum unit, with the purpose of producing an electrical charge on the Drum where the light reacts with the photoconductive film. This charge is to attract the toner to the drum, as the toner unit consists of a positively charged chemical.

Toner Unit

Toner is a powder which contains finely grounded dye coloured plastic, and this will become ink when heated. The unit also consists of something called ‘Developer’ which is a finely grounded metallic chemical with that can be electrically charged. When the electrically charged Drum rolls passed the toner unit, the developer is attracted to the drum, and carries the toner along with it onto the drum. Where there are colour toners, the collection of toner units with different colour dyes sit in parallel within proximity of the drum.

Transfer Corona

Much like the Charge Corona, the Transfer Corona is a thin wire housed in a metal slide that electrically attracts the toner from the drum onto the copy paper. At the same time this component separates the electrically charged paper away from the drum so the paper can continue to the next stage of the process.

Fuser Unit

The Fuser Unit binds the toner to the paper, consisting of two rollers, of which the upper one is heated to melt the toner plastic and releasing the ink onto the paper as the paper passes through the rollers. The upper fuser roller is heated by a temperature-controlled lamp, and is coated with a non-stick (and therefore easily cleanable) silicon coating. The lower fuser roller is not heated, and is generally just a soft silicon rubber.

Cleaning Unit

As the drum is not only charged but attracts the toner with developer material to form the copy image on the drum, the cleaning unit is designed to remove any residue of the substances that form on the drum after the Transfer Corona has transferred the necessary toner representing the image onto the paper. The cleaning unit consists of a magnetic roller and a cleaning blade. The cleaning blade is simply a silicone rubber strip attached to a metal bracket, and makes physical contact with the Drum to remove the residue.

INKJET

Ribbon

The ribbon is a piece of material that carries wiring from the electronic circuitry to the printhead which houses the ink cartridges. The electronic circuit sends information through the ribbon to control the motion of the printhead across the paper according to the image formation of the document to print.

At the same time, heat is transferred through the ribbon to the print cartridges and is only applied when ink needs to be released.

Printhead

The printhead is a casing that houses the ink cartridges, with specifically sized openings at the bottom to released the ink through, and has the ribbon attached to the back with a mechanism to transfer the signals from the control circuit which the ribbon is attached to on the other end.

The printhead sits on a horizontal pole which is placed at a particular distance above the passing paper; enough for the printhead to slide across the pole to specific positions according to where the image needs to be printed onto the paper.

Ink Cartridge

Inkjet ink cartridges are tubes containing different dye inks, but has an electronic chip to collect heat energy, which then creates and air bubble in the tube, and displaces ink which is released at an opening which sits aligned with an opening on the printhead to release into onto the paper in a controlled flow.

For colour printers, there are typically 5 cartridges, where four are the colours, black, magenta, cyan and yellow. The fifth is usually a larger cartridge with black also, dedicated to black and white printing, as it is the most common colour and thus would cause disproportionate consumption of the black coloured cartridge.

OTHER PARTS

Electronics

CCD: These components include a CCD (Charge Couple Device) which acts as a sensor to the image light from the lamp/mirror, and converts it into a series of charges that represents the formation of the image from the light. The CCD is used for the copying process, to convert a scanned image into digital data.

Electronic Control Circuit: The purpose of the control circuit will vary depending on the machine functionality. Usually a switch connected to the user control panel will activate the specific function, whether to scan, copy or print.

For the copier function, the signal is passed from the CCD to a circuit board which will have an ‘Analogue to Digital Converter’. The output of the circuit passes the signal to the printing mechanism, whether laser or inkjet.

For the printer function, the document image is sent by a network connection from the computer and the circuitry accepts the data and passes the signal on to the printing mechanism.

In the laser printing mechanism, the information is sent through a light emitting laser gun to project the image as light again onto mirrors towards the photosensitive drum.

In the inkjet printing mechanism, the information causes electronic circuitry to control heat and movement through a ribbon attached to a printhead component.

Printer Output Attachment System: For mid to high volume printers, there are often physical attachment systems, such as for the output trays. This allows systems to be customized to business and printing volume needs, but generally the attachment systems are from the same manufacturer as the copier printer for output sections to fit together.

The attachments can have many or few paper trays for multiple, high volume printing, and can and automatic stapler as one of the output catch trays.

These variables of an attachment makes mid to higher volume printing more efficient, organised and time-effective.

Printer

Copiers

Work

Printer copiers essentially have two elements: the scanning element of the copier, and the printing element. The copier function uses the same mechanism as the print function to print the copy, whether it uses a laser printing mechanism or an inkjet mechanism. To understand how the copier works to scan an original document and pass the image copy to the printing element of the printer copier, click here.

Here we detail how the two main printer mechanisms work.

Laser Printers

The printing mechanism inside Laser Printers is very similar to the common form of digital copier, only with a different sequence of process.

Below describes the process used for laser printing:

- When the print command is give by the user at the computer, the document to be printed is sent page by page as a series of images to the printer’s data memory

- The images are processed as rasters, and the information on the raster rows stimulate a laser to fire light towards a mirror at a given angle to represent the position on the image

- The light reflects off the mirror towards a rotating photoconductive drum

- The Charge Corona creates a charge on the drum where the drum surface is activated by light

- The image begins to form on the rotating drum as a series of negative charges

- As the drum rolls passed the toner unit, the positively charged developer material is attracted to the drum and carries toner powder onto the drum

- The toner attaches to the drum in the arrangement of the image, and is carried by the rotating drum to where it meets the print paper

- The Transfer Corona then separates the charges by attracting the toner away from the drum and onto the paper, forming the image on the paper as the drum rotates passed the corona.

- The drum continues to rotate on and passes a cleaning unit, which collects residue toner and developer left on the drum, and removes any residue charge from the drum to be clean for the next copy

- The paper with the toner is passed on to the Fuser Unit, which uses the heating element on the upper roller to melt the toner plastic and release the ink pigment onto the paper, and press it onto the paper

- The paper is then transported on, and often brushed for any residue, before exiting the printer onto the paper/catch tray.

The information transfer and printing mechanism in inkjet printers is very different to laser printers. Instead of using light and static electricity like the laser printer, the inkjet printer uses systematic mechanical movement of a container called a Printhead, holding the ink cartridges over the paper, controlled by an electronic circuit, and releases ink where necessary by heat.

Inkjet printing takes the following process:

- When the print command is give by the user at the computer, the document to be printed is sent page by page as a series of images to the printer’s data memory

- Each horizontal line of data from an image is read by electronic circuitry, which then sends signals through a ribbon to the mechanical structure of the printhead

- The signal makes the printhead move along a pole according to where the data exists on the line of image, with the paper sitting underneath

- Where there is data, the heat is transferred through the ribbon to the printhead, which contains the ink cartridges

- The heat is transferred to the appropriate colour ink tubes, and creates a bubble to displace a portion of ink

- The ink is released through an opening in the printhead as it is positioned over the paper

- In this way, each line of image data is translated through the printhead movement and positioning, and heat transfer to release the ink where appropriate as the paper passes under the printhead

- As the paper passes and is printed on, it exits the printer

X . IIIIII

Multifunctional Unit ( MFPs)

Commercially multifunctional systems are commonly also known as an ‘All-in-One’, encompassing all of the above functions.

MFPs exist in different sizes, catering different volumes and scales of digital sophistication. Since an ‘All-in-One’ requires network connection to a computer terminal as a minimum, contemporary commercial systems are usually equipped with good connectivity, such as being wireless-enabled.

Types of MFPs

Multifunctional Units integrating copier and other functions vary largely in size rather than main functionality:

Volume AIOs

All-in-One (AIO) printer copier and

scanner systems vary in size due to volume capacity, and contain

multiple trays to cater for different functionality and sizes for

copying and printing.

Medium and high volume AIOs can often

include additional functions such as automatic stapling printed and

copied documents, and directly scanning or receiving document images to

and from other printer/scanner machines on a network.

Commercial Production

Large

commercial multifunctional systems are typically used as a single

source production for high volume copying, printing and communication of

documents, which includes sophisticated queuing of multiple and

simultaneous tasks.

These systems usually have a

computer-like digital control panel for dynamic programming and

manipulation of the system. They also tend to have the capability to

coordinate with large local networks of servers, computer terminals and

other smaller imaging systems on the network.

Facsimiles

Facsimilies

Facsimiles are an earlier way of

communicating documents from one physical location to another. The

mechanism was to combine early copier technology with telephony data

transfer to create a new mode of communication of physical data.

Fax machines used to exist as a

single-function machine integrated with a telephone, and many advanced

Fax machines included a copier function which used the same mechanism as

the Fax data input (typically using the sheet-feed method).

For enterprise use, fax functionality

integrated into multifunctional copier, scanner and printer units enable

a document copy to be transferred electronically without a computer

terminal or network. The recipient can either receive the copy by their

own personal fax machine or local multifunctional system with telephony

connection.

This utilization of the facsimile

communication method by integrating it with an All-in-One, allows a

single document to be simultaneously photocopied for physical output,

scanned to digital storage, while still faxed to a different location.

Multifunctional units with scanning, copying and printing functionality

typically use the same components in mono-functional systems, but are

combined in a mechanical structure to forum an MFP system.

X . IIIIIII

Introduction connectivity

Whether it is for a home office or a large organisation, almost all copier systems with integrated print and scanning functions have the ability to connect to a network or connection terminal such as a computer or server. There are various ways to do so, most commonly by routed wires or increasingly by wireless connection.

Connectivity does not only refer to network connections, but also the input and out connections to use other devices with the system, such as via USB.

Types of Connectivity

There are many types of connections that a multifunctional copier can have, depending on specific features. These are just a few of the most commonly found ways of connecting the system to external systems:

Ethernet

Ethernet is a fast wired connection between two network terminals, which in this

case could be the multifunctional copier system and a computer. Multiple computers connected to the same multifunctional system would require an Ethernet router to split the connections from the system.

WiFi

Multifunctional

systems that have built-in WiFi, have a wireless receiver and

transmitter to connect to a network that is wireless-enabled. The

system can then communicate with the network terminals wirelessly. For

this to be possible, a wireless router is required to be port

communication between the connecting device; so that, as an example, the

scanner in the system only transmits information to the requesting

computer and does not send the information to all the computers on the

network.

Multifunctional

systems that have built-in WiFi, have a wireless receiver and

transmitter to connect to a network that is wireless-enabled. The

system can then communicate with the network terminals wirelessly. For

this to be possible, a wireless router is required to be port

communication between the connecting device; so that, as an example, the

scanner in the system only transmits information to the requesting

computer and does not send the information to all the computers on the

network.Bluetooth

Bluetooth

is another type of wireless technology which has a lower range than

WiFi, and has slower data communication rates, but enables strong, safe

local transfer of information wirelessly. In the same way as WiFi, a

system with built-in Bluetooth will have a transceiver (an integrated

transmitter and receiver), and ‘pairs’ with Bluetooth-enabled devices,

rather than requiring a network to be established – although networks

can be established.

Bluetooth

is another type of wireless technology which has a lower range than

WiFi, and has slower data communication rates, but enables strong, safe

local transfer of information wirelessly. In the same way as WiFi, a

system with built-in Bluetooth will have a transceiver (an integrated

transmitter and receiver), and ‘pairs’ with Bluetooth-enabled devices,

rather than requiring a network to be established – although networks

can be established.There are different specifications of Bluetooth, starting from the old version 1 to the higher data rates and backward compatibility of v2 and v3, as well as low power v4. Additional specifications include EDR (Enhanced Data Rate) and EIR (Extended Inquiry Response).

USB

A multifunctional copier printer system now quite often have USB ports that allow you print directly from files or connect to smaller USB devices and laptops. Scanner functions on more advanced systems can also scan to file on the USB device. It requires the device to be in close physical proximity to the system by connecting via USB, but is as effective as an Ethernet wired connection.

USB connection cables have different types of connectors depending on terminal requirements.

Telephony

For multifunctional units with a Facsimile function, traditionally this would require some form of telephony connection. In simpler units with the Fax function that requires directly dialing to another Fax number, this may still be the case. However, larger and more contemporary multifunctional units enable you to send faxes through local network connections, where the network server or router is able to communicate fax messages to their destination, and only requires a normal network connection, such as Ethernet or WiFi to transfer the document image to be faxed.

Connectivity features in multifunctional copier units depend on the functionality available, but the common concept is to connect the copier system with external devices or onto a local network of computers and servers. The network may even have multiple systems with scanners, printers and Fax.

As a simple example a local network for printing and scanning can consist of a large number of computers connected in parallel to a couple of different types of multifunctional copier systems, which could be connected to one another also.

In this way, for example a simple low volume or wide format all-in one scanner, copier and printer can be used to send a scanned image to a large printer copier production system in another physical location connected to the local network. The same scanned image can also be sent to a computer terminal, which can send to another computer terminal, all connected onto the network. The network can be connected up by large routing wiring, or completely wirelessly.

More sophisticated networks may involve email and ftp servers as network terminals which further store, process and transfer print, copy and fax images.

For as long as the multifunctional copier system has appropriate connectivity capabilities to operate on a busy network, large organisations are able to connect many different types of systems with such connectivity to various network technologies, such as mail and ftp servers.

In this way, a large print and copy network infrastructure can be supported in an organisation where there are large, varied and secure print, copy, fax and scanning requirements to meet intensive workflow demands. This can include secure electronic document management, instant communication and print of a hard copy document to a different physical location.