POWER ELECTRONICS

Power Electronics (Power Electronics) is defined as an electronic application that focuses on setting up large power electrical equipment by way of conversion of electrical parameters (current, voltage, power). Here is intended circuit electronics applications that use electronic equipment, especially semiconductors that functioned as a switch (switching) to make arrangements by way of conversion of source type AC - AC, AC - DC, DC - DC and DC - AC. Semiconductor devices used are solid-state electronics to make arrangements more efficient the system that has the power and energy were great. Power electronics application has the following characteristics:

1. Application control techniques to get

2. Electronic power is a combination of various disciplines namely Power Engineering, Electronics and control systems technology.

3. Electronic power using power electronics components (solid-state) to control and convert electric power

4. The power electronics circuit consists of input and load (load).

5. The power electronics circuit may consist of one or more converter to change parameters of electricity.

thyristor

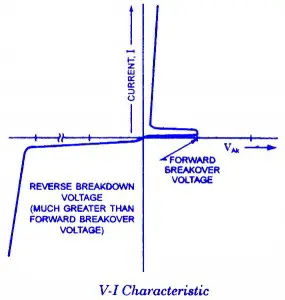

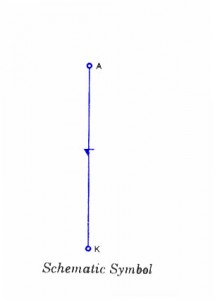

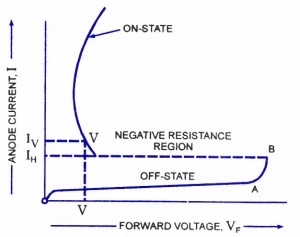

The thyristor is one power semiconductor devais most important and has been used extensively in power electronics circuits. The thyristor is usually used as a switch / bistable, operating between non-conduction state to the conduction. In many applications, the thyristor can be assumed as an ideal switch but in practice thyristor has a limited and specific characteristics.

Various Thyristor

Consists of several kinds of them:

SCR (Silicon Controlled Rectifier)

DIAC

TRIAC (triode AC switch)

PUT (Programmable Uni-junction transistors)

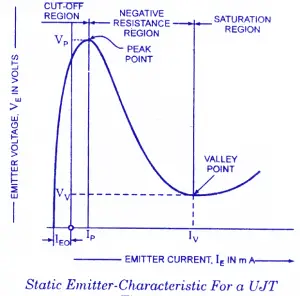

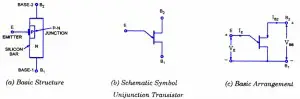

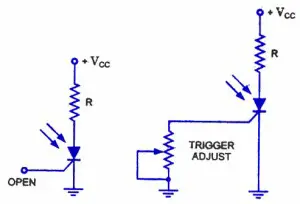

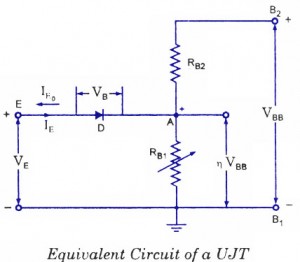

UJT (Uni-Junction Transistor)

GTO (Gate Turn Off Thyristor)

DB-GTO (Distributed Buffer - Ggate Turn-off Thyristor)

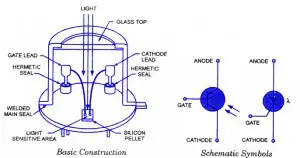

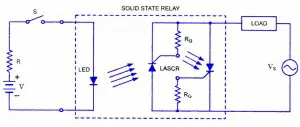

LASCR (Light Activated Silicon Controlled Rectifier)

RCT (Reverse Conduction Thyristor)

SITH (Static Induction Thyristor)

MOS-Controlled Thyristor (MCT)

IGCT (Integrated Gate commutated thyristor)

Composite MOS Static Induction Thyristor / CSMT

MCT (MOS Controlled Thyristor)

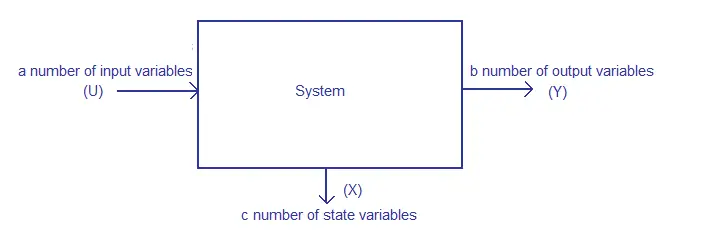

X . I Understanding the power electronics

Understanding the power electronics is one branch of electronics that has nothing to do with how to process and regulate electrical power electronically. The linkage of power electronics on how to cultivate and process the electrical energy, namely the use of electronic devices for converting an electric power to the control and modification of the form of voltage or current so that there forms a transformation other forms. When viewed from the scope of the power electronics include: Computer Components and Semiconductors; Electronics; Electricity System; Electrical circuit theory; Electrical Machinery; Control System; and electro magnetics.

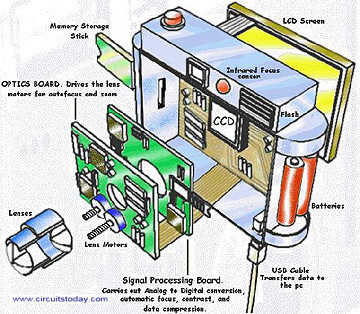

Electronics system is the main base for power electronics applications. Electronic systems intended to demonstrate the electronic equipment, among others, is a semiconductor and other components in an electronic circuit. Create deepen understanding to the power electronics required electronic circuit material whether it be digital or analog.

Electric Power System, also for main building on application where power electronics equipment as well as the system has power (current and voltage) electricity big enough. That is why in order to better understand the power electronics is necessary to better understand what is electric power system with better anyway.

Control systems, power electronics applications Normally used for control applications in the industry. Therefore it takes considerable knowledge regarding technique and control systems sundry equipment used in the industry. Examples of setting more widely used is setting activities of the tools in the industry, setting the rotation speed of the electric motor, the speed setting conveyors, setting torque electric motor, pressure regulation, regulation of flow or velocity gas oil, the temperature setting and setting other parameters.

Computer systems in industrial applications this period much has been integrated together with the computer system. To work on setting an assortment of instruments in the industry that eventually worked wear can be monitored remotely put on display integrated with a data base that is translated by a computer.Power conversion

There are four types of power conversion or commonly called the four types of energy utilization, namely:

Rectifier: useful to change the alternating electrical current into direct current.

DC Choper or commonly referred to as the DC-DC converter. Electricity flows in the direction changed so the direct current that has a different magnitude.

Inverter: that is changing so direct current electrical current alternating in frequency and voltage can be regulated.

AC-AC Converter: useful for the conversion of energy alternating electric current with a certain frequency and voltage alternating current so that the frequency and voltage other. There are two kinds of AC converters, AC voltage regulator which makes the voltage change but constant frequency; then cyclo converter which makes the frequency and voltage can be regulated.

X . II Power Electronics Components

Diode

Transistor

Thyristor

Insulated Gate Bipolar Transistor (IGBT)

Power Electronics Applications

Application examples power electronics for controlling the AC voltage, controlling dimers, as well as applications for the IGBT inverter.

1. Controlling Voltage AC

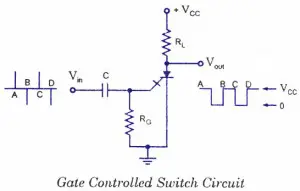

on free phase control method provides an on AC control system. AC line voltage controller is used in order to toggle between the rms value of the AC voltage supplied to the load and also uses Thyristor as a switch. Applications of these equipments among others, are:

Control of heating equipment

290 lighting control

Induction motor speed controller

2. Control Dimer

Control can be done while wearing this method is limited only to the first phase of sheer burden. For a larger load subsequently be continued wearing 3-phase system, whether it is a half-wave alone or in a full-wave (bridge circuit).

3. Application to the IGBT Converter

Cycloconverter circuit when an AC voltage 3 phase DC voltage is rectified so by 6 pieces Diode. Next 9 pieces IGBT build configurations that will create 3 phase AC voltage as well as frequency and voltage that can be set, by controlling the ON time in PWM generator.

X . III Power Electronics Applications In Everyday Life

Power Electronics Applications In Everyday Life - power electronics or power electronics is electronics EAM application contained in electrical equipment settings that have great power by changing the electrical parameters such as voltage, current, up to power.

The intended application is a circuit that use electronic devices, especially semiconductor that has a function as a switch or switching to make the adjustment. The trick is to change the type of source of AC to AC, AC to DC, DC to DC and DC to AC.

Power Electronics Applications

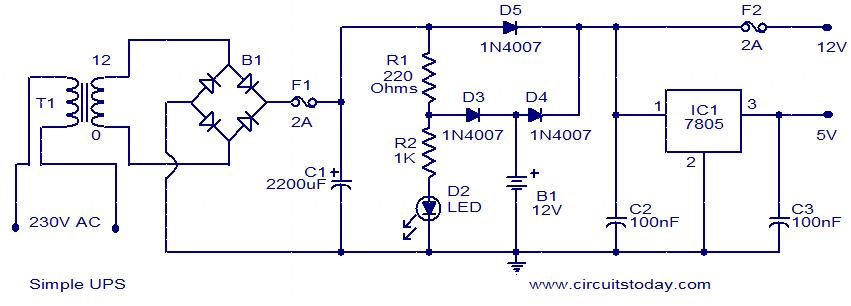

AC to DC converter (rectifier)

AC to DC converter is a circuit used to convert AC current into DC current, which can be controlled or regulated. The converter functions must rectify the electrical current into alternating current direction. Suppose an electrical energy AC 220 V / 50 Hz derived passes to 12 VAC transformer, then rectified by the diode into DC 12V.

AC to AC converter (Cyclo converter or Matrix)

AC to AC converter or commonly referred to Cyclo converter / Matrix is a circuit that can convert AC current to AC current remains that can be controlled or regulated. AC to AC converter has the function of converting electrical energy of alternating current into alternating current with the voltage and frequency to another. Eg AC 220 V with a frequency of 50 Hz is converted into electrical AC 110 V with a frequency of 100 Hz.

DC to DC converter (Chopper)

DC to DC converter is a circuit that can convert DC currents remain a DC current that can be controlled or regulated. Its function is to convert the direct current into different magnitudes. For example a 15V DC power is converted into DC power of 5V.

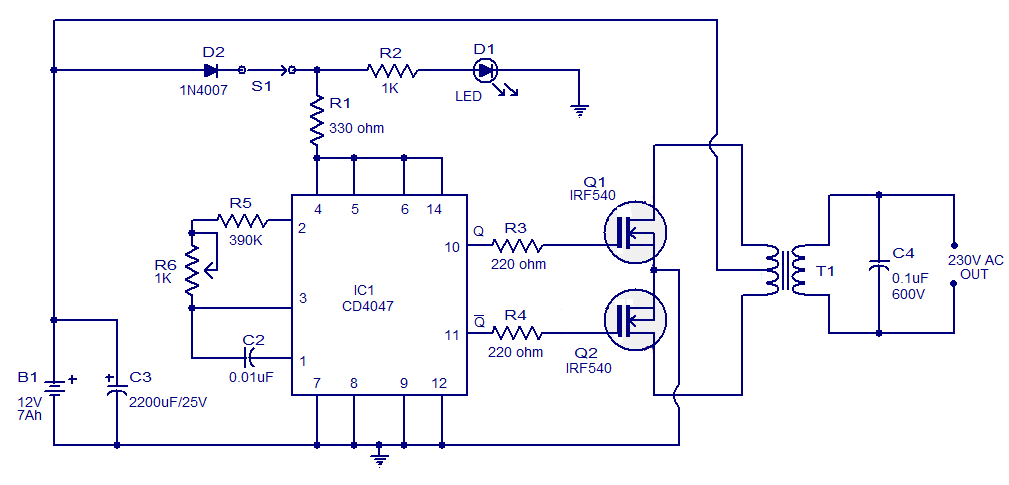

DC to AC converter ( inverter )

DC to AC converter or inverter is commonly called a circuit can change the fixed DC current to AC current that can be controlled or regulated. DC to AC converter has the function to change the direction of electricity into alternating electrical voltage and frequency can be set. Eg 12 V DC power from the accumulator is converted into electricity 220V AC voltage with a frequency of 50 Hz.

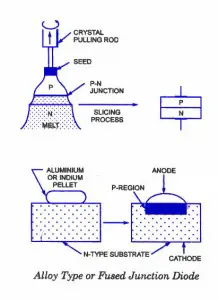

1. Diode or Diode

Probably most of you are already familiar with the electronic components of this one. Yes, the diode is one of the basic electronic components are also included in the category of active electronic components. This component has a function as a diode rectifier in an electronic circuit. Diodes also include one type of power electronics components are most common.

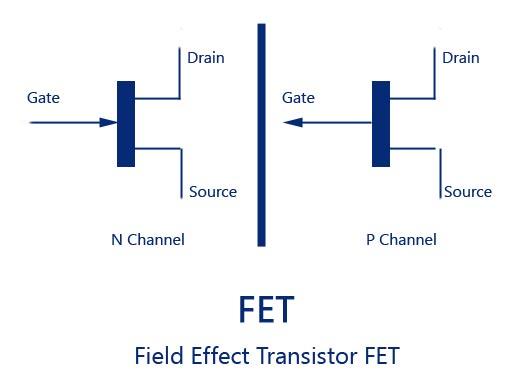

2. Transistor

Transistors are basic electronic components are also entered into the ranks of active electronic components. Components that have the function as an amplifier and switch also includes one type of power electronics components that are often encountered in various kinds of electronic circuits.

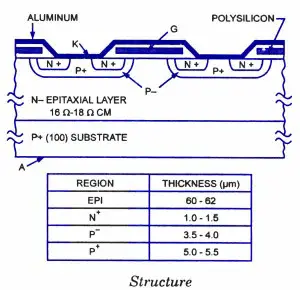

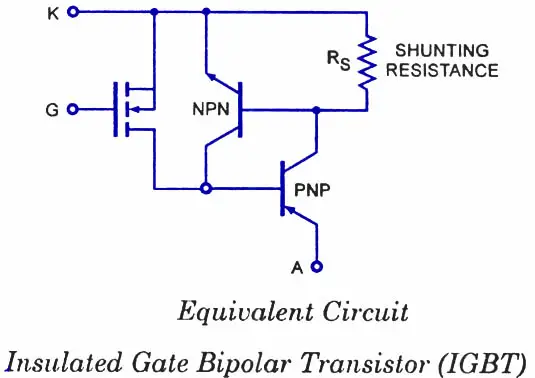

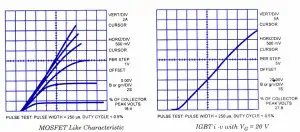

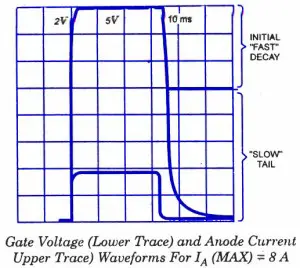

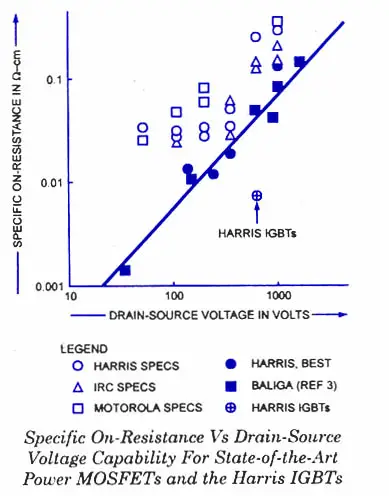

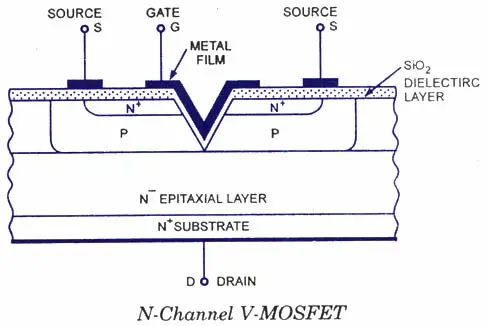

3. IGBT (Insulated Gate Bipolar Transistor)

IGBT is actually one type of transistor. Insulated Gate Bipolar Transistor is a combination of BJT and MOSFET. Many people refer to this component as a bi-polar transistor that has a function as a switch in an electronic circuit.

4. Thyristor

The thyristor is a power electronics component made of semiconductor materials. Components of this one also has a function as a switch or switch in an electronic circuit.

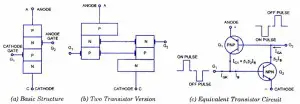

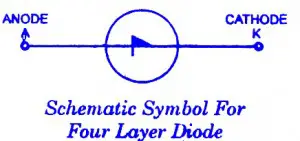

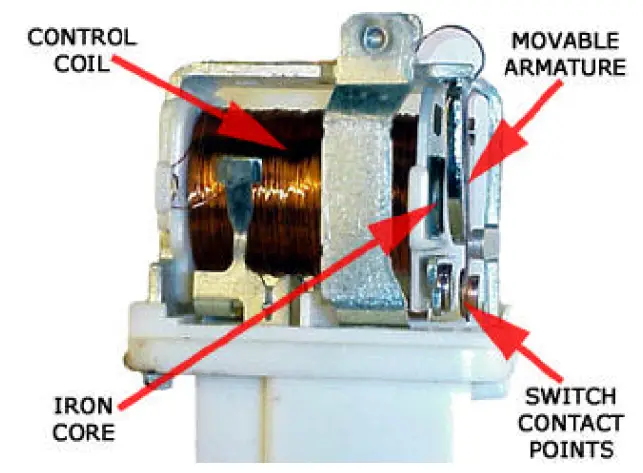

X . IIII POWER Electronic for education

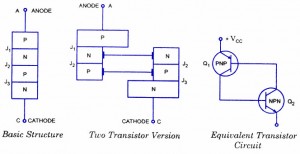

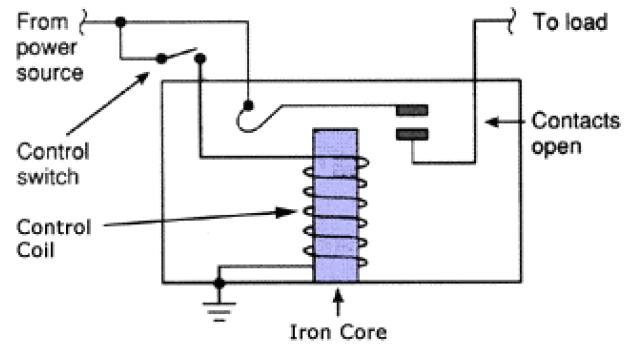

Power Electronics is one area of the study and discusses electronics applications related to electric power equipment is large enough. A wide variety of equipment and real applications in industries that use power source has enormous power capacity such as electric motors, heating, cooling, fun, compressors, pumps, conveyors and other applications.thyristorThyristor is an electronic device that consists of four layers of semiconductor PNPN and has three joint-pn. The thyristor has three terminals, namely the anode, cathode, and gate (gate). Thyristor controlled rectifier is also called, as it has a gate that serves to control the flow.How it Works Thyristor:

Thyristor this will work or deliver electric current from the anode to the cathode when at the gate by currents towards the cathode, so the gate should be given a positive voltage to the cathode. Giving this voltage to ignite the thyristor, and when ignited thyristor will still deliver. Thyristor will be interrupted if the current through the anode to the cathode becomes small or the thyristor gate is connected to ground.Various Thyristor:

Phase-control thyristor (SCR)

Fast-switching thyristor (SCR)

Gate-turn-off thyristor (GTO)

Bidirectional triode thyristor (TRIAC)

Reverse-conducting thyristor (RCT)

Static Induction Thyristor (SITH)

Light-activated silicon-controlled rectifier (LASCR)

FET-controlled thyristor (FET-CTH)

MOS-controlled thyristor (MCT)

Requirements that cause Thyristor drain current (Turned On):

Hot. If the thyristor temperature is high enough, there will be an increase in the number of pairs of electrons - hole, so that the leakage current increases. This will lead to an increase in α1 and α2 increased. Because the regenerative action (α1 + α2) will be heading to the unit value and the thyristor may be on. This can lead to thermal runaway and usually avoided.

Light. If the light allowed the thyristor connection, the pair electron - hole will be increased; and thyristor may be on. How this is done by letting the light of the silicon wafer of the thyristor.

High voltage. If the forward voltage anode to the cathode is greater than the forward breakdown voltage VBO, a leakage current is generated is enough to make the thyristor on. This method is destructive and should be avoided.

Dv / dt. If the rate of rise of voltage anode - cathode is sufficiently high, the charging capacitor connection might be enough to make the thyristor on. Values higher charging currents can damage the thyristors; and devais be protected against dv / dt is high. Manufacturing thyristor maker will determine how large dv / dt can be handled by a thyristor.

Flow gate. If a thyristor given a forward bias voltage, gate current injection by applying a positive gate between the gate terminal and the cathode will be make thyristor on. When the current enhanced gate, a forward blocking voltage will decrease.

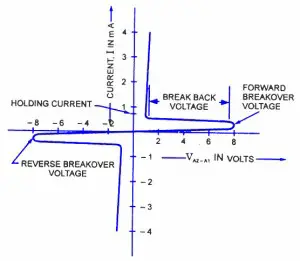

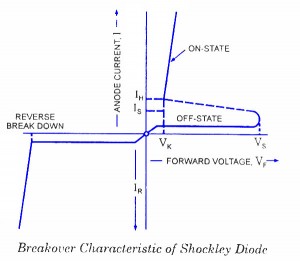

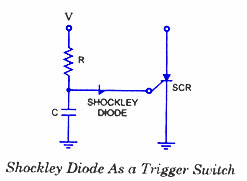

How Thyristor Turned Off:How to make the SCR becomes OFF by lowering the anode-cathode voltage to zero. Because this is the SCR or thyristor is generally not suitable for DC applications. This component is more widely used for the application of AC voltage, because the SCR can be OFF when the AC voltage waveform is at zero.Commutation itself (line commutated):Commutation itself (line commutated), natural technique that is used, because the working voltage used is ac. At any one period of ac voltage will pass twice the point of zero volts is 0 degrees and 180 degrees. Once the voltage passes through the points (trigger) is then automatically triac will undergo commutation. This is one advantage when using triac at working voltage ac.Forced commutation (forced commutated):Forced commutation (Forced commutation), commutation is used for applications working voltage is dc (linear), because the triac once triggered will pass dc current continuously. To condition the occurrence of zero voltage on the triac is needed to set a special circuit containing an array of capacitors and inductors even use more than one fruit triac.The difference between Thyristor and Triac:Triac different from the thyristor, triac which can control the flow in two directions. Two Thyristor Triac is connected in parallel in contrast to the gate terminal together. Unlike the thyristor which just missed the voltage of positive polarity, but Triac can be triggered by positive and negative polarity voltage, and can be turned on by using an alternating voltage at the Gate. Triac is widely used in the circuit and switching control. Triac is only activated when the polarity of the anode and the cathode is more positive than their gate given a positive polarity, and vice versa. Triac can conductive character in two directions. In this case can be considered as two thyristors connected in antiparallel with the gate connection. Because the triac is a bidirectional components, the terminal can not in absolute at anode / cathode.I. Phase-Control Thyristor (phase control thyristor)The thyristor mode generally operates at line-frequency and off by natural commutation. Turn off time, TQ, is in the order of 50 to 100 ms. These devices are very suitable for low speed switching applications and is commonly known as thyristor converters. Because it is actually a thyristor controlled devices are made of silicon, consequently thyristor this type are known as silicon-controlled rectifier (SCR). The voltage is turned on, varies around 1:15 devais V to 600 V and 2.5 V for device 4000V; and for thyristor 5500A, 1200V, approximately 1,25V. Gate amplifier produces common dynamic characteristics dv / dt of 1000V / ms and di / dt of 500 A / ms and simplify circuit design by reducing or minimizing the inductor limiting di / dt and protection circuit dv / dt.

2. Fast-Switching ThyristorUsually thyristor is used in the application of technology switching speed with force-communication (eg. Thyristor this type have time turn off fast, generally in the region of 5 to 50 ms depending on local voltage. The voltage falls forward on the circumstances on varies roughly as an inverse function of the turn-off time TQ. this thyristor mode is also known as thyiristor inversion.This thyristor has a dv / dt high usually 1000V / ms and di / dt of 1000V / ms. Turn-off fast and di / dt is high will be very important to reduce the size and weight of the reactive components and for commutating circuit. On state voltage of the thyristor 2200A, 1800 V is typically around 1.7 V. The thyristor inverter with reverse blocking capability is very limited, approximately 10 V, and the turn-off time is very fast, about 3 to 5 ms, commonly known as Asymmetrical Thyristor (ASCR).

3. Gate-Turn-Off ThyristorGate-Turn-Off Thyristor like SCR can be turned on by providing a positive gate signal. However GTO can be turned off by giving a negative gate signal. GTO is also a device latching and can be built with current and voltage rating similar to SCR, GTO is turned on by providing positive short pulse signal at the gate and turned off by giving a negative short pulse signal at the gate. GTO that has several advantages over SCR:a. Elimination of components commutating the forced-commutation, resulting in reduced cost, weight and volume.b. Reduction of acoustic and electromagnetic due to the loss of commutation chokes.c. Turn-off fast, enabling high switching frequencyd. Improving the efficiency of the converter.In low power applications, the GTO has advantages over the bipolar transistor is:

(1) The ability of blocking a higher voltage;(2) The ratio of the peak current that can be controlled with the average current higher;(3) The ratio of the peak surge current for average current is high, generally 10: 1;(4) Strengthening the state on high (anode current / current gate), generally 600; and(5) The duration of the gate signal pulse. In the surge condition, GTO will likely go into deeper saturation for their regenerative action. Meanwhile, bipolar transistor tends to be out of the state of saturation.GTO has a lower reinforcement during turn-off, generally six, and the negative current pulses require relatively large for a turn-off. When the voltage falls on relatively larger than SCR. The voltage is turned on for an average of 550 GTO A, 1200 V peak magnitude of 3.4 V. Controllable on state ITGO is the peak value on the circumstances that can be turned off by the control gate, off-state voltage is given immediately after the turn-off and dv / dt only will be limited by capacitance of snubber. So GTO is turned off, the load current IL that flows through and fill the snubber capacitor, determine dv / dt is the case with Cs is a snubber capacitance.

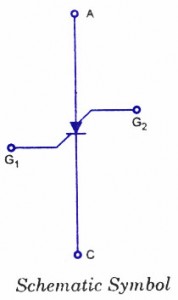

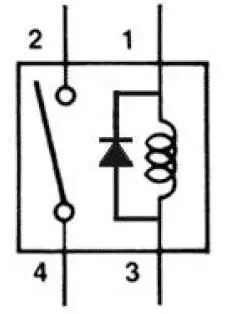

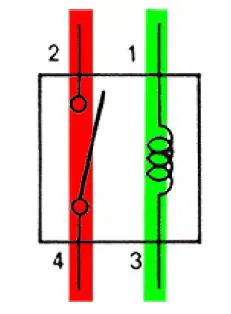

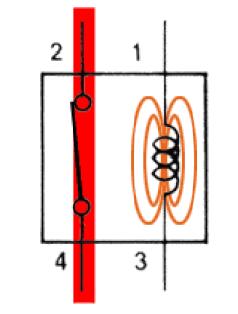

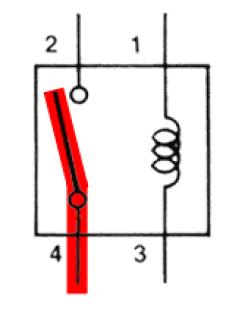

4. Bidirectional Triode Thyristor (TRIAC)TRIAC can be conductive in two directions and are typically used to control ac phase (eg ac voltage controller). It can be considered two thyristors connected in anti parallel with the gate connection.

Because the TRIAC is a bidirectional devais, the terminal can not be determined as the anode / cathode. If the positive terminal of the terminal MT1 MT2, TRIAC can be turned off by giving a positive gate signal between the gate G and MT1. If the negative terminal MT1 MT2, the TRIAC will be turned on by giving a negative pulse signal between the gate G and terminal MT1. No need to have both positive and negative gate signal and TRIAC can be powered either by the gate signal is positive or negative.

5. Reverse Conducting Thyristor (RCT)In many chopper or inverter circuit, anti-parallel diode is connected along SCR to allow reverse current flow due to the inductive load and to improve the current performance of the circuit turn-off commutation. Reverse voltage blocking diode is cut off from the SCR to -1 or 2 V at a steady state. But in a transient state, the reverse voltage can be increased up to 30 V for the voltage induced in the circuit due to the stray inductance in device.An RCT can be seen as a compromise between the characteristics and needs of the circuit device RCT can be considered as a thyristor with built-in anti parallel diode. RCT also known as Asymmetrical thyristor (ASCR). Forward blocking voltage ranging from 400 up to 2000V and current rating moves up to 500A. Reverse blocking voltage is typically around 30 to 40 V. Since the ratio of the forward current through the thyristor against reverse current of diode fixed to a devais, its application is limited by the particular design.

6. Static Induction ThyristorCharacteristics of SITH similar to the characteristics of the MOSFET. SITH is usually turned on by providing a positive gate voltage as usual thyristors on and off by giving a negative voltage on the gate. SITH is device with minority carriers. Consequently SITH has a resistance / voltage drop on the low state and can be made with a voltage rating and a higher current.

SITH has a high switching speed with the ability dv / dt and di / dt is high. on Switching time on the order of 1 to 6 ms. voltage rating can reach 2500 V and the current rating is limited to 500 A. these devices are very sensitive to the production process, a small disturbance in the production process will produce large changes in device Characteristics.

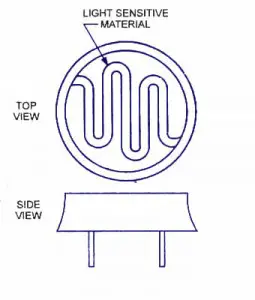

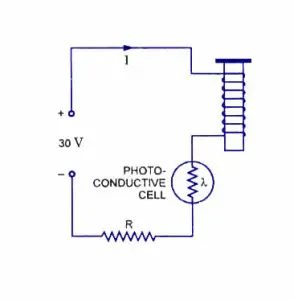

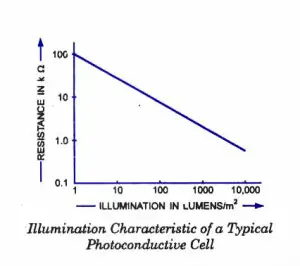

7. Light Activated Silicon Controlled Rectifier (L A S C R)

These devices turned on to provide light radiation directly to a silicon wafer. Hole electron pairs are formed during the radiation process will generate a current trigger on the influence of electric fields. Gate structure is designed to generate enough gate sensitivity to triggering with practical light sources. L A S C R used for current consumption and high voltages. (Example for high voltage dc transmission and static reactive power compensation or reactive volt amperes). LASCR provide full electrical isolation between the light source and device pen trigger switching of power converters., With high-potential floating up to several kilo volts. Voltage rating of LASCR can be as high as 4 kV, 1500 A with pen trigger light power less than 100 mW. di / dt common is 250 A / m s and dv / dt can be as high as 2000 V / m s.

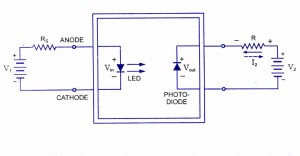

8. FET Controlled ThyristorDevice FET-CHT combine MOSFET and Thyristor in parallel. If a certain voltage supplied to the gate of the MOSFET, typically 3 V, current pen trigger of thyristor will be raised internally. FET - CHT has high-speed swtching, di / dt and dv / dt is high.These devices can be turned like a conventional thyristor, but can be turned off by the control gate. It is indispensable in applications that optical firing is used to generate electrical isolation between the input or control signals and power switching device.

9. The thyristor controled MOS-

MOS-Controlled Thyristor (MCT) combines nature - the regenerative properties of the thyristor and the MOS gate structure. MCT can operate as device controlled by the gate if the current is less than the maximum current that can be controlled. MCT effort to be made off of the current exceeds the value that would result in damage device . For high current values MCT thyristor to be switched off as usual. The pulse width of the gate is not critical for smaller devices whose currents. For large current, turn off the width of the pulse should be larger. Further, the maximum gate current will flow during turn - off. In many applications, including inverter and chopper, gate pulses continuously during the period of on / off is necessary to avoid confusion.An MCT has:1. The forward voltage drop for a state on a low2. Time turn off fast (0.4 m s) and a fast time is usually 1:25 m s for MCT 300A, 500V3. Low switching power dissipation4. Ability blocking voltage low5. The high input impedance of the gate, which will simplify the drive circuitMCT can effectively be installed parallel to the process of switching large currents with only modest changes to the rating current rating device slice there. MCT can not be mobilized with a pulse transformer can be continuous if necessary to avoid confusion.

CONVERTER

Converter is a tool to convert electrical power from one form to another electrical power.AC-DC converter (rectifier):

A circuit that converts AC voltage into DC voltage that can be controlled / regulated. Its function electric rectify alternating current into direct current electricity. Energy flows from the AC power system is one way to DC systems. Example: Power AC 220 V / 50 Hz derived passed into 12VAC transformer and then rectified by the diode into a DC voltage of 12V.Diode rectifier circuit change ac voltage to dc voltage is fixed. The input voltage to the rectifier can be either single phase or three phase and are shown in the following figure:1. The half-wave rectifier, single phase

2. The full-wave rectifier, three phase

3. The half-wave rectifier, three phase

AC-AC converter (Cycl oconverter):A circuit that can convert AC voltage remains an AC voltage that can be controlled / regulated. Its function converts electrical energy of alternating current with a certain frequency and voltage into an alternating current with the voltage and frequency of the other. There are two types of AC converters, namely:• AC voltage regulator (a voltage change, constant frequency)• cyclo converter (voltage and frequency can be adjusted).Example: AC voltage of 220 V and a frequency of 50 Hz into AC voltage of 110 V and a new frequency of 100 Hz.

DC-DC converter (Chopper):A circuit used to convert the DC voltage source remains a DC voltage source that can be controlled / regulated. Direct current power is converted into direct current as well but with different magnitudes. Example: Power DC 15V with electronic components is converted into DC power of 5V.

DC-AC converter ( inverter ):A circuit used to convert the DC voltage source remains a source of AC voltage that can be controlled / regulated. Its function is to change the direct current electricity into alternating current electricity at a voltage and frequency can be set. Example: Power DC 12 V from accumulator with inverter device is converted into electrical voltage AC 220V, 50 Hz frequency.

In the modern era, as now, the development of the electricity needs of the community extends to almost all sectors. Starting from households, public infrastructure, industrial, offices, transportation, and even shopping. Increased demand for electricity must be balanced by an increase in electrical power source, in addition to increased efficiency in the load can also help the effectiveness of the use of electricity itself. In this case the inverter as a power electronics device has an important role in these two cases. First as a provider of electrical power source, the inverter is able to play a role in converting electricity derived from renewable sources power energy into electricity that can be used by end users. Secondly, the inverter is also widely used in electrical devices to optimize the efficiency of such devices, up to utilization of power resources can be optimized.

Some time ago said inverter may still lay ears of the community. However, with seiringnya time, said inverter start prevalent and often heard. Characterized by frequent appearance of the word in advertising some product Inverter household electrical appliances glass screen, such as AC Inverter, inverter refrigerator and so forth. In the ads mentioned that by using the inverter will be found significant electrical power saving compared to previous products that still use conventional systems.

Whereas in the industrial world, Inverter has long been used for various applications, such as conveyor drive motor, drive motor compressor, as UPS and many more. In the field of mass transportation, the inverter is used as propulsion systems or main driving electric trains replaced the technology Rheostatic outdated and wasteful of energy, besides Static inverters are also used to distribute electrical installation replaces the motor-generator sets that simplify treatment in the absence of moving parts inside the inverter. In the world of renewable energy resources, an inverter occupy an important position in bridging the presence of electrical energy from renewable resources by the end user. Because in general the electrical energy from renewable resources can not be used directly by end users. For example, the electrical energy generated by solar cells is a direct voltage (DC) can not directly be distributed and used by the end user loads which generally has a specification input voltage alternating (AC). Another example is the source of wind power, where the wind is not continuous may interfere with the existence of electricity in the network, so it needs special handling so that this energy source can be used, for example, to be stored for all energy storage systems such as batteries, and then from the battery is converted by an inverter streamed to a network.

equirements as inverter products in general, among others:

Endurance test, inverter weighed 50% load for at least 5 hours without any damage and irregularities performance.

Overload test, when the inverter successfully passed the test of excessive load up to 140% for 1 minute.

Ouput THD of less than 4%

ELECTRONIC POWER

Equipment and applications in industries that use large capacity electrical energy such as electric motors, compressors, pumps, conveyor, fan, cooling, heating and others require setting. Power electronics are popular for a variety of conventional arrangements can not fulfill the needs of the industry. Conventional arrangement raises the losses were quite large and are not effective and so we need better regulation mechanism is by using electronic devices.

Power electronics is the science that studies of electronics technology for the control and regulation of electric power equipment major strong currents {her} by way of conversion of current, voltage and power

Power Electronics covers and connects the various fields of science that underlies the development of power electronics, these sciences is the science of electronics, the science of electricity, control science and computer science.

To be able to master the Power Electronics 4 system should at least understand that Electronic Systems, Electrical Power Systems, Control Systems and Computer Systems.

1. Electronic System.Electronic systems is the science which contains the basic applications of basic electronics, which deals with semiconductors and other components in electronic equipment. To deepen the understanding of power electronics material digital or analog electronic circuits.

2. Electric Power System.The electrical power system is the science which deals with the amount of electric power in the electronic equipment, whether it is generated or required. Object or a central goal of power electronics applications are electrical equipment and systems that have the power {} electrical voltages and currents are quite large. Therefore, to better understand the power electronics need a good understanding of the power system.

3. Control System.The control system is the science which deals with the ability to control or manipulate or manipulate the power generated by electronic equipment. Usually needed for controlling industrial applications such as control panels, electrical machinery control, pressure control, speed control motors and others. Because it takes a good understanding of the techniques and systems control a wide range of equipment that is in use in the industry.

4. Computer Systems.

The computer system is the science which deals in computer control. Most current industrial applications have been integrated with the computer system used to control equipment remotely industry and the results can be monitored. Because the power electronics required to master the control of computer systems.

Broadly speaking, the power electronics is divided into two parts, namely the power circuit and control circuits.1. Power is a series circuit consisting of diode components, Thyristor and Power Transistor2. The control circuit is a circuit consisting of diodes, transistors and ICs.

X . IIIII Power circuit example of the working principle of the control circuit can be seen below;

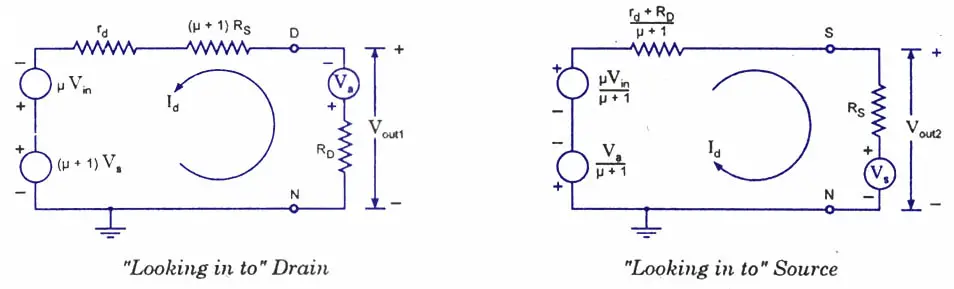

One of the well publicized benefits of an EV is regenerative braking. Regen braking is common on nearly all vehicles now, yet few people seem to realize what happens. The following paragraph is an attempt to explain how it works.

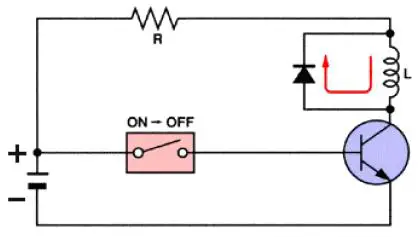

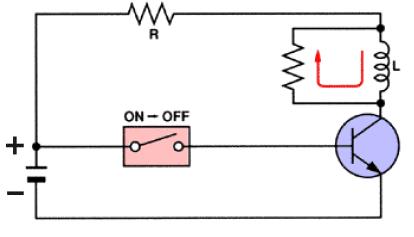

In the circuit shown above is an output pair of MOSFETs Metal Oxide Semiconducting Field Effect Transistors), with the motor being driven. The output from the controller is a pure d.c. voltage. The motor will generate a back e.m.f. which is proportional to its speed of rotation. At zero load, or no acceleration, this back e.m.f. will rise to be equal to the output from the controller.

The MOSFET is a bi-directional switch which conducts resistively (when it is turned on) for both directions of current. So consider the situation when the current is zero and the controller's output is now reduced. The motor's back e.m.f. is now higher than the controller's output voltage - so the motor will try and feed current back into the controller. If it succeeds in so doing the motor will be braked - we will have regenerative braking.

This type of circuit (where hi-side is turned on when the low-side is off) is capable of sourcing current or sinking it. The way this works is that the reversed motor current is now a forward current to the flywheel MOSFET so when this is on it shorts out the motor - whose braking current rises during this period (arrow B, reversed). The Flywheel MOSFET now turns off, but this current must keep flowing - because of the motor's inductance. So it flows as reverse current through the drive MOSFET, recharging the battery as is does so. The extra voltage for this is derived from the energy stored in the motor's inductance. The process of switching from drive to braking is entirely automatic. Moreover it is done entirely by the motor's speed exceeding the drive voltage and without any change of state or switching within the controller. The regen braking is, if you like, a by-product of the design of the controller and almost a complete accident.

If the vehicle is driven down too steep a hill (or the demand speed is suddenly reduced so that very hard braking results) the current generated by the motor could exceed that which the MOSFETs can safely handle. Since this would blow the MOSFETs it must be protected against so all controllers that give regenerative braking are also fitted with a current limit to stop such failure.

In Hybrid Electric Vehicles this problem becomes even more complex because of the unused current from the auxiliary power source. Since the drive motors are not drawing current from the auxiliary power source, that current still must have some place to go. The motor controller should monitor and take into account the excess current from the auxiliary power source, so that in certain situations where too much current is present with regen and APU operating, the regen MOSFET must also be turned off. to protect the motor controller.

In early version of electric vehicles with DC motors, a simple variable resistor type controller governed the acceleration and speed of the vehicle. Full current and power was drawn from the battery all of the time. At lower speeds, when little power was needed, high resistance was used to reduce the current to the motor. This resulted in a large percentage of the battery's energy being wasted as heat dissipated by the resistor. Modern controllers adjust speed and acceleration by and electronic process called pulse width modulation(PWM). Switching devices such as IGBT's(very fast, high current rated transistors) rapidly interrupt, turning on or off as needed, the flow of electricity to the motors. High power is achieved when the intervals(time between pulses) are very short. By increasing the time between pulses, the current is limited.

The wheel motor shown above is manufactured by Technologies M4.

As mentioned above, one of the more interesting designs for motors is to integrate the motor directly into the wheel. These are called wheel motors and may very well become the norm someday as they remove a tremendous amount of mechanical devices from the vehicle by providing propulsion to the wheel...in the wheel!

The motor-wheel assembly is an elegant integration of an electric motor and other components into a package that fits inside a regular-size tire.

The motor-wheel assembly consists of a highly efficient electric motor, a Motor-Wheel Slave Controller (MWSC) including power and control electronics, a brake, wheel bearings, a steerable front suspension interface and a heat sink embedded in the stator. The configuration of the 3-phase synchronous motor consists of a central stator which supports the windings and the inverter, surrounded by an external rotor which supports the permanent magnets.

The wheel is directly mounted on the rotor for direct transmission of torque and enhanced freewheeling. The motor assembly is liquid-cooled to sustain high continuous power demands.

Bus manufacturers will appreciate the packaging advantages and interchangeability of the motor-wheel rear axle, which easily fits within existing wheel housings. The axle deep-offset cross member enables a wider floor aisle area in the low-floor configuration.

Selecting a motor for use in an EV involves many variables. No single type of motor can be considered as the best. When an EV is being designed, questioned must be answered before selecting a specific type of motor. How much power do you need, do you need variable speeds, what is the operating voltage of the battery system, what kind of torque do you need and at what speed, how much physical space can the motor occupy, how much can it cost, what type of environment will the motor be operating in? Once these questions are answer, you can make your motor selection. Once the motor has been identified, a control system must be designed to make the motor functional.

Control Systems

| The most complex and important system in an EV is the control system. The control system is responsible for governing the operation of the electric vehicle. The control system receives inputs from the operator, Controllerfeedback signals from the motor controller and motor and also feedback signals from other systems within the EV. The speed at which the control system must receive data from other systems, process the data in an algorithm and output a response to the given conditions must be accomplished in milli-seconds. This requires the control system to have a microprocessor, just like a computer, to accomplish its tasks. Though no two control systems are identical, most of the feedback signals are similar. The table below lists common components of a control system and the feedback signals that are sent to the microprocessor. | |||||||||||||||||||||||||||

A motor controller. |

|

||||||||||||||||||||||||||

In some advanced control systems, it is possible to limit the amount of current that flows to the motor, based on a switch selection. This allows the operator to adjust to a driving style that fits a particular situation. For instance, if a driver needs a certain range(in miles) from a single charge, the range selection can be set so that the microprocessor will limit the amount of output current from the motor controllers to a preset limit. If the preset limit is 100 amps, the microprocessor will not allow any current above this limit to flow to the motors. In this mode, acceleration ability is sacrificed for range. If the driver is in an area where the vehicle must climb steep grades, the range selector can be set so that the maximum current capability of the motor controller and motor can be used. The range selection feature is a valuable feature that adds to the efficiency of the motor controller. The ultimate goal of a control system is to maximize the energy stored within the traction battery and to prevent unsafe conditions from occurring within the electric vehicle.

Battery Systems

An electric vehicle's battery, with cells visible. |

An electric vehicle's battery defines the range, acceleration ability and recharge

time for the vehicle. Because the battery contains the energy to fuel an electric

vehicle, and because today's batteries do not provide electric vehicles with the same

range potential as ICE vehicles, batteries, and alternative options such as flywheels

and ultra capacitors, are the most heavily studied areas in electric Battery cellvehicle

technology. |

||

| A battery cell normally consists of the 4 principal components shown at the left. A cell contains a positive and negative electrode, electrolyte, and a separator. The positive electrode receives electrons from the external circuit when the cell is discharged. The negative electrode donates electrons to the external circuit as the cell discharges. The electrolyte provides a mechanism for charge to flow between positive and negative electrodes. The separator electrically isolates the positive and negative electrodes. |

| ||

Performance of Vehicle Battery Systems

Each specific type of battery has characteristics which make it either more or less desirable to use in a specific application. Cost is always a major factor and the NiMH battery tops the list in price with flooded lead acid batteries being the most inexpensive. What is lost in the cost translation is the fact that NiMH batteries yield nearly twice the performance (energy density per weight of the battery) than do conventional lead acid batteries. Another factor that must be considered when making a battery comparison is the recharge time. Lead acid batteries require a very long recharge period, as long as 6 to 8 hours. Lead acid batteries, because of their chemical makeup, cannot sustain high current or voltage continuously during charge. The lead plates within the batteries heat rapidly and cool very slowly. Too much heat results in a condition known as "gassing" where hydrogen gas is released from the battery's vent cap. Over time, gassing reduces the effectiveness of the battery and also increases the need for battery maintenance. Batteries such as NiCad and NiMH are not as susceptible to heat and can be recharged very quickly, allowing for high current or high voltage charges which can bring the battery from a 20% state of charge to an 80% state of charge in as quick as 20 minutes.

|

Battery Type

|

Energy Density Whr/kg

|

Power Density W/kg

|

Life Cycles Per Battery

|

Cost on scale of 1 to 10

|

| Current Lead Acid |

35

|

150 |

500

|

1

|

| Advanced Lead Acid |

48

|

150

|

800

|

3

|

| GM Ovonic NiMH |

70

|

220

|

>600

|

8

|

| SAFT NiMH |

70

|

150

|

1,500

|

8

|

| SAFT lithium ion |

120

|

230

|

600

|

9

|

| Lithium polymer |

150

|

350

|

<600

|

10

|

| Zebra sodium-nickel chloride |

86

|

150

|

<1000

|

4

|

| Impact on Vehicle performance |

Range

|

Acceleration

|

Life Cycle Cost, Replacement Cost

|

Initial Cost, Replacement Cost

|

New technology battery systems are also driven by a microprocessor. The microprocessor receives data from sensors within the battery pack. Temperature, current output, battery voltage and fault detection are all fed back to the microprocessor which can then calculate how much energy is remaining in the battery as well as how much has been consumed. Monitoring the temperature and the resistance to the vehicle's ground protects both the battery pack and the passengers from danger.

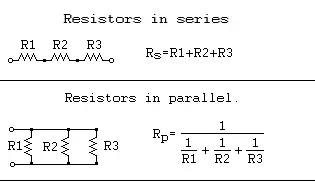

Battery configurations also vary greatly depending on the vehicle and the desired redundancy of the system. Battery packs can be tied together in one long series circuit so that the total pack voltage is the sum of all the cells in the series. Other systems use multiple packs that are of equal voltage and parallel the multiple packs. This provides redundancy to the system. If a cell goes bad in a single pack, the battery management system can disable the output from that pack and the vehicle can continue to be driven off of the remaining battery packs. The vehicle will lose the energy from the faulty pack and range will be affected.

|

Shown to the left is a battery pack consisting of 27 individual 2 volt cells,

in a series circuit configuration to form a pack with a voltage of 54 volts. |

Specific energy is energy density as a function of time measured in watt-hours per unit mass. Specific energy is important because it affects the number of batteries necessary in a particular application, and in turn the mass or weight of the batteries that a vehicle needs to carry on-board to end up with a certain electric-only range. It is the most important factor for EVs because it determines their total range, but not as critical for HEVs which carry the majority of their energy in the form of a gaseous or liquid fuel. Instead, for HEVs, a battery's specific power becomes the critical parameter in selecting a battery.

Since HEVs utilize two different energy sources, energy demands from the batteries

are much less than in EVs. Because hybrids normally only depend on the electrical

energy stored on-board to provide power for acceleration and hill climbing, batteries

are sought that have a high specific power rating and less mass. Specific power, is

power per unit mass, so the ability of the battery to enable high current draws for

short durations with less weight is the desired goal for HEVs. Shown at right is a

chart which compares specific power between battery types. No information was available

for the lithium batteries at this time.

Since HEVs utilize two different energy sources, energy demands from the batteries

are much less than in EVs. Because hybrids normally only depend on the electrical

energy stored on-board to provide power for acceleration and hill climbing, batteries

are sought that have a high specific power rating and less mass. Specific power, is

power per unit mass, so the ability of the battery to enable high current draws for

short durations with less weight is the desired goal for HEVs. Shown at right is a

chart which compares specific power between battery types. No information was available

for the lithium batteries at this time.

Battery chargers replenish the energy used by an electric vehicle much like a gasoline

pump refills a gas tank. One significant difference is that an electric vehicle operator

can fully charge the vehicle overnight, at home, rather than refueling at a gasoline

station. The battery charger is a device which converts the alternating current distributed

by electric utilities to the direct current needed to recharge the battery.

Battery chargers replenish the energy used by an electric vehicle much like a gasoline

pump refills a gas tank. One significant difference is that an electric vehicle operator

can fully charge the vehicle overnight, at home, rather than refueling at a gasoline

station. The battery charger is a device which converts the alternating current distributed

by electric utilities to the direct current needed to recharge the battery.

Battery Memory

It is often heard that batteries have memory. When "memory" is talked about in the same sentence with batteries, it means a battery has failed to produce it's stated capacity. If a battery has a stated capacity of 100 amp-hours, and the cutoff voltage is consistently reached when only 80% or 80 amp-hours has been consumed after having been charged it is often referred to as the memory effect. There are many opinions as to whether or not batteries have memory. The use of the term "memory" to describe the loss of capacity is likely the source of the confusion. A battery's performance can be consistently poor, having a discharge capacity within 2% to 3% during each discharge cycle. But batteries do not get that way from "memory". They are several different causes of this poor performance, and generally it is the battery's caretaker who is responsible for this effect.

Some of the more common causes of performance problems that are attributed to the "memory" effect are;

1. Improper charging, i.e., consistently overcharging or undercharging

2. Exceeding battery temperature thresholds during charging or discharging

So what has happened to the battery that is experiencing a "memory" effect? Because of the different types of batteries and chemicals involved, there is no single generic term that can be applied that describes what causes the poor performance in all batteries. However, what is known is that high temperatures alter the molecular structures of the chemicals involved, which can lead to a higher internal resistance within the battery which leads to voltage depression. Undercharging can lead to a buildup of lead sulfate on the plates of lead-acid batteries which also increases the internal resistance of the battery because currents become constricted and cannot flow through the full surface area of the plates. Overcharging can have the same effect that high temperature has, altering the crystal structures of the chemicals within the battery.

Can the battery's "memory" be erased? In most cases the answer is "yes". By proper execution of several charge/discharge cycles, the memory effect can be destroyed and the battery capacity will return to it's original value. In some cases, however, if a battery has been poorly maintained for an extended period of time(months), it is possible that permanent damage has occurred and the life and capacity of the battery is defined and cannot be corrected.

Types of Charging

There are a number of different types of battery chargers based on the way they control the charging rate.

Constant Voltage

A constant voltage is applied and the current flows into the battery (the highest current occurs when the battery has been fully discharged and steps down to a low current when the battery is nearly charged.) Electronics on constant voltage charges is relatively simple, therefore, these types of chargers tend to be less expensive.

Combination Constant Current/Constant Voltage

The charge cycle starts with a high constant current until the voltage reaches a set value, then changes to a constant voltage control. This is the most sophisticated of the basic types of battery chargers and generally increases the life of a battery by reducing heat during the charging process. These chargers also tend to increase battery performance.

Pulse Charging

One of the advanced charging methods currently being evaluated eliminates the practice of requiring constant current and/or constant voltage by "pulsing" voltage. A series of very high current and voltage pulses are applied until the battery voltage reaches a set value. The major advantage of a pulse charger is the significant reduction in heat which allows the charger to operate at a high voltage rate even when the battery is almost full. Additionally, the reduction in heat results in a reduction in "lost" energy. Thus, pulse charging can significantly reduce charging time and are more energy efficient.

While there are many types of battery chargers available, the vehicle manufacturer will supply or recommend the proper charger for the batteries in the electric vehicle.

Charger Location/Coupling Options

Electric vehicle battery chargers may be onboard (in the electric vehicle) or offboard (at a fixed location). As with many options, there are advantages and disadvantages with both types. If the battery charger is onboard, the batteries can be recharged anywhere there is an electric outlet. The drawback with onboard chargers is the limitation in their power output because of size and weight restrictions dictated by the vehicle design. Offboard charges are limited in their power output only by the ability of the batteries to accept the charge. While the EV owner can shorten the time it takes to recharge the batteries with a high-power, offboard charger, the flexibility to charge at different locations is restricted.

Charging Methods

There are two basic coupling methods used to complete the connection between the utility

power grid, the battery charger, and the vehicle connector. The first is the traditional

plug (called conductive coupling). With this connection, the EV operator plugs his

vehicle into the appropriate outlet (i.e. 110 or 220 volts) to begin charging. This

type of coupling can be used with the charger in the car (onboard) or out of the car

(offboard).

There are two basic coupling methods used to complete the connection between the utility

power grid, the battery charger, and the vehicle connector. The first is the traditional

plug (called conductive coupling). With this connection, the EV operator plugs his

vehicle into the appropriate outlet (i.e. 110 or 220 volts) to begin charging. This

type of coupling can be used with the charger in the car (onboard) or out of the car

(offboard).

The second type of coupling is called inductive coupling. This type of coupling uses a paddle which fits into a socket on the car. Rather than transferring the power by a direct wire connection, power is transferred by induction, which is a magnetic coupling between the windings of two separate coils, one in the paddle, the other mounted in the vehicle.

Inductive Charging

The inductive charger has no direct electrical connection to the vehicle. A weatherproof

paddle transfers power to the vehicle’s charge port via magnetic field . The Delco

off-vehicle chargers provides a safe and easy-to-use system for EV charging. Inserting

the charge coupler is all that is required to initiate charging. Charging can be terminated

at any time by removing the coupler. Bi-directional communication and built-in diagnostics

ensure a safe connection and prevent the vehicle from being driven while connected.

The inductive charger has no direct electrical connection to the vehicle. A weatherproof

paddle transfers power to the vehicle’s charge port via magnetic field . The Delco

off-vehicle chargers provides a safe and easy-to-use system for EV charging. Inserting

the charge coupler is all that is required to initiate charging. Charging can be terminated

at any time by removing the coupler. Bi-directional communication and built-in diagnostics

ensure a safe connection and prevent the vehicle from being driven while connected.

Conductive Charging

With a conductive charger, energy is transferred to the vehicle via metal-to-metal contact. A connector, such as the AVCON (left), safely performs the link between a power supply and the vehicle’s charge port.

Charge Levels

Chargers are also classified by the level of power they can provide to the battery pack:

Level 1 - Common household type of circuit, rated to 120 volts/AC and rated to 15 amps.

Level one chargers use the standard household 3-prong connection and they are usually considered portable equipment.

Level 2 - Permanently wired electric vehicle supply equipment used specially for electric vehicle charging and it is rated up to 240 volts/AC, up to 60 amps, and up to 14.4 kilowatts.

Level 3 - Permanently wired electric vehicle supply equipment used specially for electric vehicle charging and it is rated greater than 14.4 kilowatts. Fast chargers are rated as Level 3 chargers. However, not all Level 3 chargers are considered as fast chargers. This depends on the size of the battery pack to be charged and how much time is required to charge the battery pack. A charger can be considered a fast charger if it is capable of charging an average electric vehicle battery pack in 30 minutes or less.

Battery Management

With so many differences in chargers and charging methods, there existed a need to

monitor the status of the batteries being charged and discharged. Battery Management

Systems (BMS) have been developed which are microprocessor controlled allowing charge

algorithms to be programmed into the system for virtually all the different battery

types. These systems monitor the energy consumed by the vehicle while being driven,

as well as temperature, individual cell voltages and total pack voltage. The same

process is monitored in reverse during charging creating a safety net in the event

of problems with a single cell within the battery pack.

With so many differences in chargers and charging methods, there existed a need to

monitor the status of the batteries being charged and discharged. Battery Management

Systems (BMS) have been developed which are microprocessor controlled allowing charge

algorithms to be programmed into the system for virtually all the different battery

types. These systems monitor the energy consumed by the vehicle while being driven,

as well as temperature, individual cell voltages and total pack voltage. The same

process is monitored in reverse during charging creating a safety net in the event

of problems with a single cell within the battery pack.

With existing electric vehicles and battery chargers, it usually takes from several hours to overnight to recharge an electric vehicle battery pack. The time required to recharge electric vehicle batteries depends on the total amount of energy that can be stored in the battery pack, and the voltage and current (i.e., power) available from the battery charger.

New developments in battery recharging decreases the time required to recharge electric vehicle batteries to as little as 10-15 minutes. For example, pulse battery chargers have demonstrated that the EV battery pack can be recharged in under 20 minutes without damaging it. When this technology is fully deployed, electric charging stations, similar to gas stations, will allow the electric vehicle operator to quickly recharge the battery pack.

This new charger technology, coupled with advanced batteries with a range of 200 miles between recharging, will allow the electric vehicle operator the same freedom of the road currently enjoyed by today's operators of gasoline-powered vehicles.

Accessories (Power windows, heating, air, power steering, etc.)

An EV maintains the same accessory functions as a vehicle utilizing an internal combustion engine. These accessories include radios, lights, heating and air conditioning, power steering, and for larger vehicles such as trucks and buses, an air system. However, the manner in which these devices obtain power is very different. A combustion engine is equipped with a generator for 12 volt power. The engine cooling system is the heat source for the vehicle. Air conditioning and power steering are accomplished using a belt and pulley system which interfaces with a pump for the power steering and a compressor for the air conditioning. Since electric vehicles do not utilize an engine, alternative methods have been developed to work with EVs.

The 12 volt accessory system which supplies power to devices such as lights, radio, windshield wiper and washer system, power windows and door locks or any other electrical device on the vehicle consumes energy from the main traction battery. The accessory system does not operate at the same voltage level as the traction system(the system that provides power to the wheels), but is instead stepped down from a voltage range of 324-216 volts DC to 12 volts DC though a device called a DC to DC converter.

There are several different methods that can be used to heat an electric vehicle. One of the first methods used was known as "resistance" heating. Resistance heating is accomplished using a heat element, similar to heat elements on a stove top or in the oven. The heat element is warmed when electricity is applied, and a fan blows across the element to disperse the heat. The disadvantages of this method included safety and efficiency. Heat elements consume a large amount of energy. Other alternative methods of heating included using heaters which burned a clean fuel such as liquid propane or compressed natural gas. Cooling electric vehicles has been accomplished in the past using standard air conditioning technology similar to window mount home air conditioners. These air conditioners were effective though inefficient. Recent developments in power electronics has enabled vehicle manufacturers to place an efficient reversible heat pump, one that can cool or heat, into electric vehicles.

Power steering on an electric vehicle is accomplished by adding a single speed DC motor and a motor controller. The motor is coupled to the power steering pump through gears or a belt and pulley system. The motor controller's job is to keep the motor spinning at a constant speed under varying loads. The air system on large trucks and buses utilizes this same methodology with the DC motor turning the shaft of an air compressor. What is important to realize here is that the DC motors will only come on and stay on if the vehicle needs air or power steering. If the vehicle is stopped, power steering is not needed and the power steering motor will shut off. Whenever the air tanks are full, that motor will also shut off.

X . IIIIII Types of Chopper Circuits

In chopper circuits,

unidirectional power semiconductors are used. If these semiconductor

devices are arranged appropriately, a chopper can work in any of the

four quadrants. we can classify chopper circuits according to their

working in any of these four quadrants as type A, type B, type C,

type D and type E. Let us now take a look of these classifications and

the characteristics of various classifications.

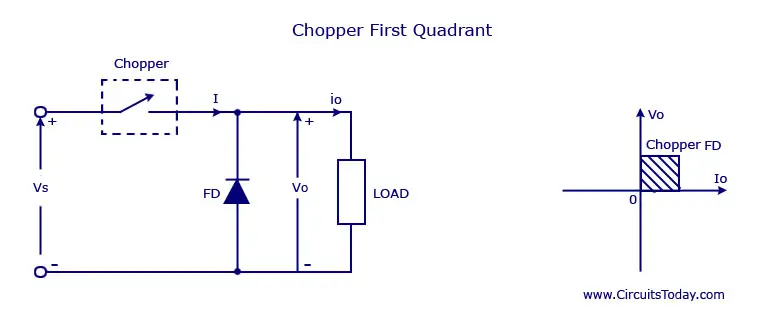

Type A Chopper or First–Quadrant Chopper

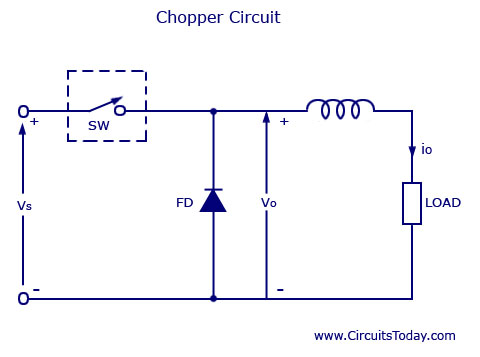

This type of chopper is shown in the figure. It is known as first-quadrant chopper or type A chopper. When the chopper is on, v0 = VS as a result and the current flows in the direction of the load. But when the chopper is off v0 is zero but I0 continues to flow in the same direction through the freewheeling diode FD, thus average value of voltage and current say V0 and I0 will be always positive as shown in the graph.

In type A chopper the power flow will be always from source to the load. As the average voltage V0 is less than the dc input voltage Vs

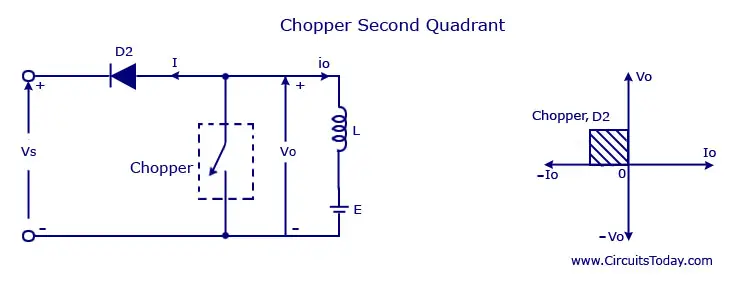

Type B Chopper or Second-Quadrant Chopper

In type B or second quadrant chopper the load must always contain a dc source E . When the chopper is on, v0 is

zero but the load voltage E drives the current through the inductor L

and the chopper, L stores the energy during the time Ton of the chopper . When the chopper is off , v0 =( E+ L . di/dt ) will be more than the source voltage Vs .

Because of this the diode D2 will be forward biased and begins

conducting and hence the power starts flowing to the source. No matter

the chopper is on or off the current I0 will be flowing out of the load and is treated negative . Since VO is positive and the current I0 is negative , the direction of power flow will be from load to source. The load voltage V0 = (E+L .di/dt ) will be more than the voltage Vs so the type B chopper is also known as a step up chopper .

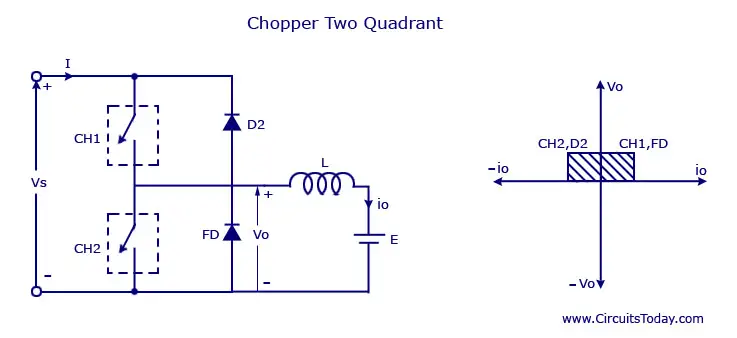

Type -C chopper or Two-quadrant type-A Chopper

Type C chopper is obtained by connecting

type –A and type –B choppers in parallel. We will always get a

positive output voltage V0 as the freewheeling diode FD is

present across the load. When the chopper is on the freewheeling diode

starts conducting and the output voltage v0 will be equal to Vs . The direction of the load current i0 will be reversed. The current i0 will

be flowing towards the source and it will be positive regardless the

chopper is on or the FD conducts. The load current will be negative

if the chopper is or the diode D2 conducts. We can say the chopper and

FD operate together as type-A chopper in first quadrant. In the second

quadrant, the chopper and D2 will operate together as type –B chopper.

The average voltage will be always

positive but the average load current might be positive or negative. The

power flow may be life the first quadrant operation ie from source to

load or from load to source like the second quadrant operation. The two

choppers should not be turned on simultaneously as the combined action

my cause a short circuit in supply lines. For regenerative braking and

motoring these type of chopper configuration is used.

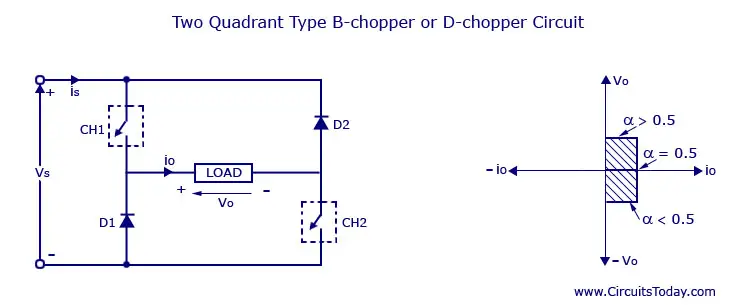

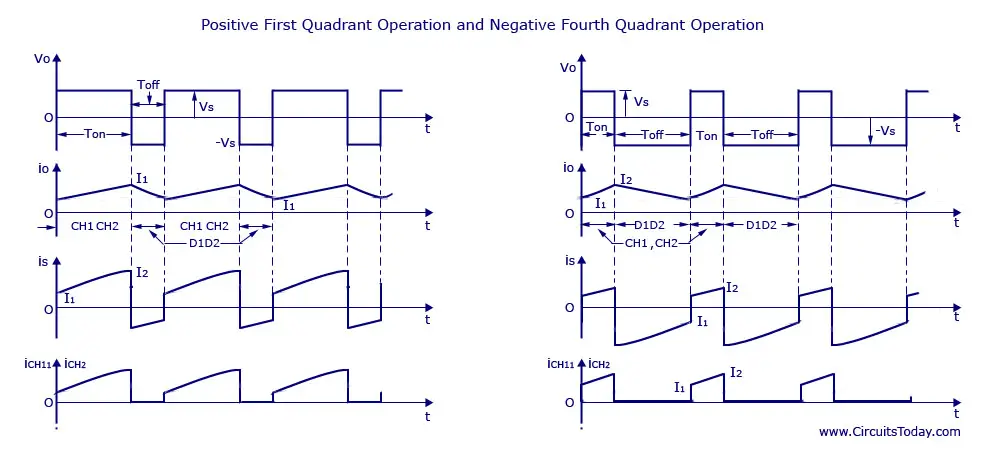

Type D Chopper or Two-Quadrant Type –B Chopper

The circuit diagram of the type D chopper is shown in the above figure. When the two choppers are on the output voltage v0 will be equal to Vs . When v0 = – Vs the two choppers will be off but both the diodes D1 and D2 will start conducting. V0 the average output voltage will be positive when the choppers turn-on the time Ton will be more than the turn off time Toff its

shown in the wave form below. As the diodes and choppers conduct

current only in one direction the direction of load current will be

always positive.

The power flows from source to load as the average values of both v0 and i0 is positive. From the wave form it is seen that the average value of V0 is positive thus the forth quadrant operation of type D chopper is obtained.

From the wave forms the Average value of output voltage is given by

V0= (Vs Ton-VsToff)/T = Vs.(Ton-Toff)/T

V0= (Vs Ton-VsToff)/T = Vs.(Ton-Toff)/T

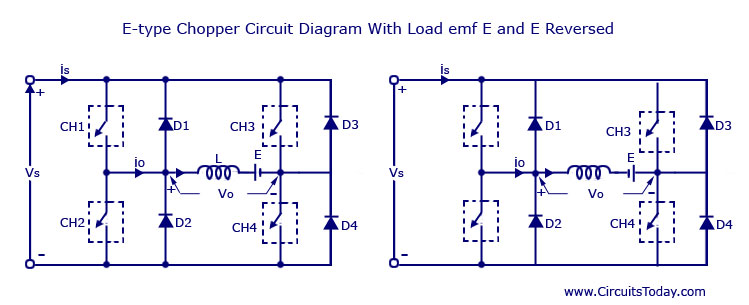

Type –E chopper or the Fourth-Quadrant Chopper

Type E or the fourth quadrant chopper

consists of four semiconductor switches and four diodes arranged in

antiparallel. The 4 choppers are numbered according to which quadrant

they belong. Their operation will be in each quadrant and the

corresponding chopper only be active in its quadrant.

- First Quadrant

During the first quadrant operation the

chopper CH4 will be on . Chopper CH3 will be off and CH1 will be

operated. AS the CH1 and CH4 is on the load voltage v0 will be equal to the source voltage Vs and the load current i0 will begin to flow . v0 and i0 will

be positive as the first quadrant operation is taking place. As soon as

the chopper CH1 is turned off, the positive current freewheels through

CH4 and the diode D2 . The type E chopper acts as a step- down chopper

in the first quadrant.

- Second Quadrant

In this case the chopper CH2 will be

operational and the other three are kept off. As CH2 is on negative

current will starts flowing through the inductor L . CH2 ,E and D4.

Energy is stored in the inductor L as the chopper CH2 is on. When CH2 is

off the current will be fed back to the source through the diodes D1

and D4. Here (E+L.di/dt) will be more than the source voltage Vs . In second quadrant the chopper will act as a step-up chopper as the power is fed back from load to source

- Third Quadrant

In third quadrant operation CH1 will be

kept off , CH2 will be on and CH3 is operated. For this quadrant

working the polarity of the load should be reversed. As the chopper CH3

is on, the load gets connected to the source Vs and v0 and i0 will be negative and the third quadrant operation will takes place. This chopper acts as a step-down chopper

- Fourth Quadrant

CH4 will be operated and CH1, CH2 and

CH3 will be off. When the chopper CH4 is turned on positive current

starts to flow through CH4, D2 ,E and the inductor L will store energy.

As the CH4 is turned off the current is feedback to the source through

the diodes D2 and D3 , the operation will be in fourth quadrant as the

load voltage is negative but the load current is positive. The chopper

acts as a step up chopper as the power is fed back from load to source.

X . IIIIIII Choppers – A general introduction

AC Link Chopper

In the case of an ac link chopper, first

dc is converted to ac with the help of an inverter. After that, AC is

stepped-up or stepped-down by a transformer, which is then converted

back to dc by a diode rectifier. Ac link chopper is costly, bulky and

less efficient as the conversion is done in two stages.

DC Chopper

A DC chopper is a static device that

converts fixed dc input voltage to a variable dc output voltage

directly. A chopper can be said as dc equivalent of an ac transformer

as they behave in an identical manner. This kind of choppers are more

efficient as they involve one stage conversion. Just like a transformer,

a chopper can be used to step up or step down the fixed dc output

voltage. Choppers are used in many applications all over the world

inside various electronic equipments. A chopper system has a high

efficiency, fast response and a smooth control.

Principle of Chopper Operation

A chopper can be said as a high speed

on/off semiconductor switch. Source to load connection and disconnection

from load to source happens in a rapid speed. Consider the figure,

here a chopped load voltage can be obtained from a constant dc supply

of voltage, which has a magnitude Vs. Chopper is the one represented by “SW” inside a dotted square which can be turned on or off as desired.

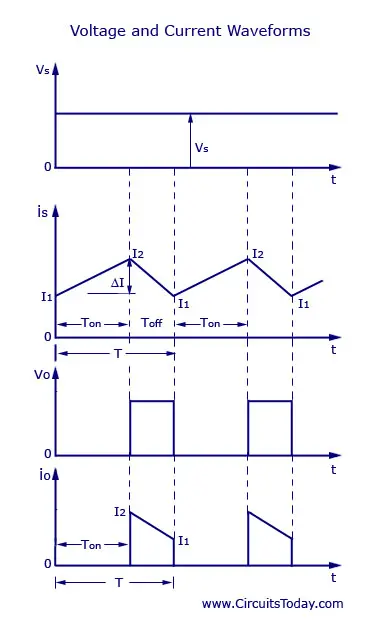

Output Voltage and Current Waveforms

Let us now take a look of the output current and voltage wave forms of a chopper. During the time period Ton the chopper is turned on and the load voltage is equal to source voltage Vs. During the interval Toff the

chopper is off and the load current will be flowing though the

freewheeling diode FD . The load terminals are short circuited by FD and

the load voltage is therefore zero during Toff. Thus, a

chopped dc voltage is produced at the load terminals. We can see from

the graph that the load current is continuous. During the time period Ton, load current rises but during Toff load current decays .

Average load Voltage is given by

V0 = Ton/ (Ton +Toff) * Vs = (Ton/T) V = A Vs………………(1.0)

Ton : on -time

Toff : off- time

T = Ton +Toff= chopping period

A = Ton /T = duty cycle

So we know that the load voltage can be

controlled by varying the duty cycle A. equation 1.0 shows that the

load voltage is independent of load current it can be also written as

V0 = f. Ton .Vs

f= 1/T = chopping frequency

Step – up Choppers

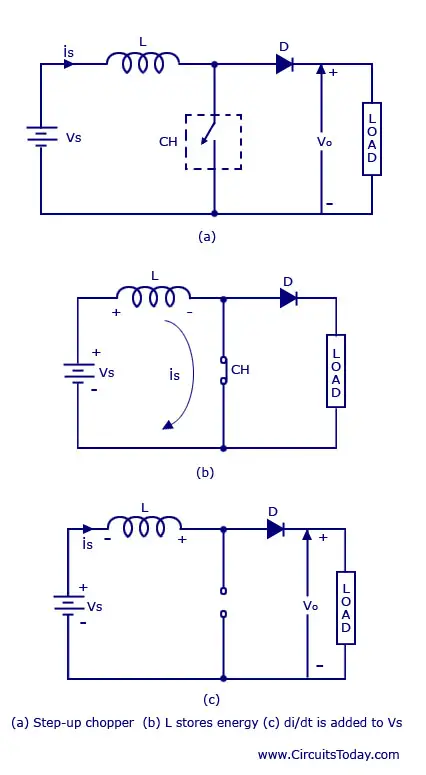

In the case of the chopper circuit (Refer figure named – “chopper circuit”) shown in beginning of this article, V0 or the average output voltage is less than the input voltage Vs so this type of chopper is called a step down chopper. For a step-up chopper we can obtain an average output voltage V0 greater than input voltage. Figure (a) shows the elementary form of a step-up chopper.

Working Principle of a Step-up Chopper

In step-up chopper a large inductor, L is in series with the source voltage Vs. This forms a closed path as shown in the figure (b). During the time period Ton

the chopper is on the inductor stores energy. When the chopper is

turned off the current is forced to flow through the diode and load for a

time Toff and as the inductor current cannot die suddenly.

When the current decreases the polarity of the emf induced in L is

reversed. Fig (c). As a result the total voltage available across the

load is given by the equation V0 = Vs + L (di/dt) . The voltage V0 exceeds

the source voltage and hence the circuit acts as a step-up chopper and

the energy which is stored in L is released to the load.

Voltage and current waveforms

When the chopper is turned ON the current through the inductance L will increase from I1 to I2. As the chopper is on the source voltage is applied to L that is vL = VS .

When the chopper is OFF, the KVL for the figure (c) can be written as

vL – V0+Vs =0 or vL =V0 -Vs where vL is the voltage across L. Variation of source voltage vS , source current IS , load voltage v0 and load current iO is

sketched in the fig (d) . Let us assume that the variation of output

current is linear, the energy input to inductor from the source, during

the time period Ton , is

Win= Vs (I1+I2/2) Ton

During the time Toff the chopper is off, so the energy released by the inductor to the load is

Woff = (V0-Vs)(I1+I2/2).Toff

Let us assume that the system is lossless, then the two energies say Win and Woff are equal.

So equating these two we will get

Vs (I1+I2/2) Ton = (V0-Vs)(I1+I2/2).Toff

Vs Ton = (V0-Vs) Toff

V0Toff = Vs (Toff + Ton) = Vs .T

V0 = VS (T/Toff) = VS (T/T-Ton) =VS (1/(1-A) ………….(2.0)

From the equation 2.0 we can see that

the average voltage across the load can be stepped up by varying the

duty cycle. If the chopper in the figure (a) is always off, A=0 and V0= Vs. If the chopper is always on, A =1 and V0

= infinity as we can see from the graph. In practical applications the

chopper is turned on and off so that the required step-up average output

voltage, more source voltage is obtained.

Figure shows variation of load voltage V0 with duty cycle .

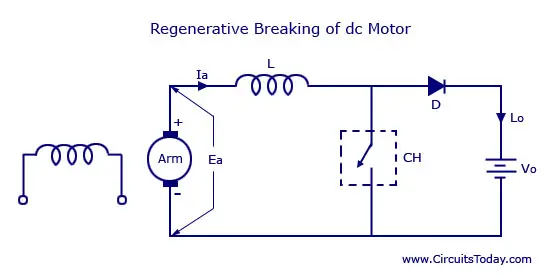

Application of Step-up Chopper

Figure shows regenerative braking of dc motor.

The principle of step-up chopper can be used for the regenerative braking of DC motors. The armature voltage Ea is analogy to the VS and voltage V0

is the dc source voltage. When the chopper is on the inductor L stores

the energy and when it is off the inductor release the energy. If Ea / (1-A) exceeds V0

, the dc machine will work as a dc generator and the armature current

will flow in a direction opposite to the motoring mode. As the power now

is flowing from dc machine to the source V0 it will cause

regenerative breaking of the dc motor. Even at decreasing motor speeds,

regenerative breaking can be provided as the motor armature Ea is directly proportional to the field flux and motor speed.

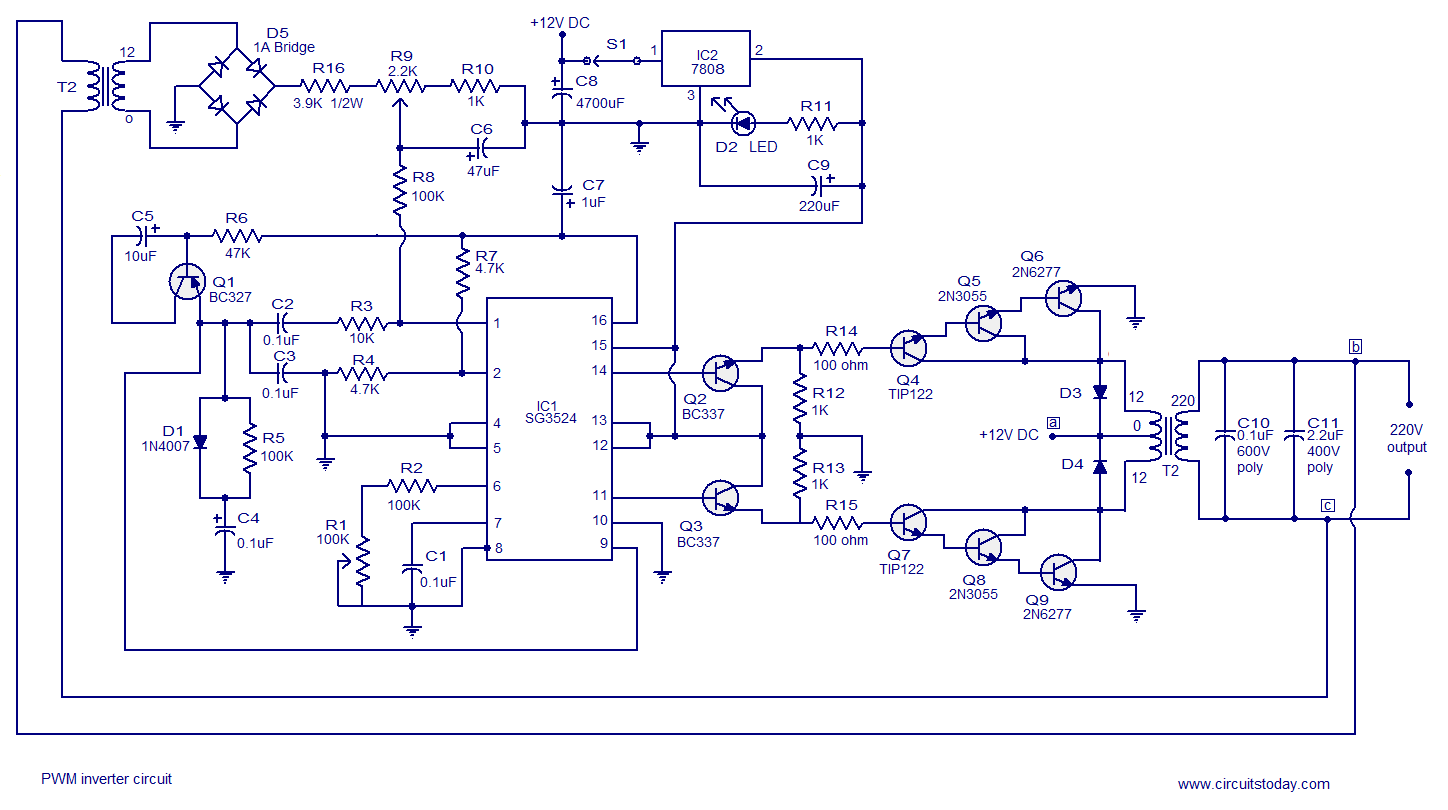

X . IIIIIIII PWM inverter circuit

250W PWM inverter circuit SG3524.

A 250W PWM inverter circuit built around

IC SG3524 is shown here. SG3524 is an integrated switching regulator

circuit that has all essential circuitry required for making a switching

regulator in single ended or push-pull mode. The built in circuitries

inside the SG3524 include pulse width modulator, oscillator, voltage

reference, error amplifier, overload protection circuit, output drivers

etc. SG3524 forms the heart of this PWM inverter circuit which can

correct its output voltage against the variations in the output load. In

a non PWM inverter the change in output load directly affects the

output voltage (when output load increases output voltage decreases and

vice versa), but in a PWM inverter the output voltage remains constant

over a range of output load.

Circuit diagram of 250W PWM inverter.

About the circuit.

Resistor R2 and capacitor C1 sets the

frequency of the ICs internal oscillator. Preset R1 can be used for fine

tuning of the oscillator frequency. Pin 14 and pin 11 are the emitter

terminals of the internal driver transistor of the IC. The collector

terminals of the driver transistors (pin 13 and 12) are tied together

and connected to the +8V rail (output of the 7808). Two 50Hz pulse

trains which are 180 degree out of phase are available at pin 14 and 15

of the IC. These are the signals which drive the subsequent transistor

stages. When signal at pin 14 is high, transistor Q2 is switched on

which in turn makes transistor Q4, Q5, Q6 ON are current flows from the

+12V source (battery) connected at point a (marked with label a) through

the upper half of the transformer (T1) primary and sinks to ground

through the transistors Q4, Q5 and Q6. As a result a voltage is induced

in the transformer secondary (due to electromagnetic induction) and this

voltage contributes to the upper half cycle of the 220V output

waveform. During this period pin 11 will be low and its succeeding

stages will be inactive. When 11 of the IC pin goes high Q3 gets

switched ON and as result Q7, Q8 and Q9 will be also switched ON.

Current flows from the +12V source (marked with label a) through the

lower half of the transformer primary and sinks to the ground through

transistors Q7, Q8, Q9 and the resultant voltage induced at the T2

secondary contributes to the lower half cycle of the 220V output wave

form.

The output voltage regulation section of

the inverter circuit works as follows. The inverter output (output of

T2) is tapped from point’s labelled b, c and supplied to the primary of

the transformer T2. The transformer T2 steps down this high voltage ,

bridge D5 rectifies it and this voltage ( will be proportional to the

inverter’s output voltage) is supplied to the pin1 (inverting input of

the internal error amplifier of the IC) through R8, R9, R16 and this

voltage is compared with the internal reference voltage. This error

voltage will be proportional to the variation of the output voltage from

the desired value and the IC adjusts the duty cycle of the drive

signals ( at pin 14 and 12) in order to bring back the output voltage to

the desired value. Preset R9 can be used for adjusting the inverters

output voltage as it directly controls the amount of voltage fed back

from the inverter output to the error amplifier section.

IC2 and its associated components

produce an 8V supply from the 12V source for powering the IC and its

related circuitries. Diodes D3 and D4 are freewheeling diodes which

protect the driver stage transistors from voltage spikes which are

produced when the transformer (T2) primaries are switched. R14 and R15

limit the base current of Q4 and Q7 respectively. R12 and R13 are

pulldown resistors for Q4 and Q7 which prevents their accidental switch

ON. C10 and C11 are meant for bypassing noise from the inverter output.

C8 is a filter capacitor for the voltage regulator IC 7808. R11 limits

limits the current through the indicator LED D2.

Notes.