Prinsip Kerja Pengereman Regeneratif

Sistem Pengereman Konvensional

Pengereman regeneratif, atau yang lebih dikenal dalam Bahasa Inggris dengan istilah regenerative braking,

menjadi satu model sistem pengereman yang dapat meminimalisir energi

terbuang pada sistem pengereman konvensional. Secara etimologi regenerative berasal dari kata re-generate

yang berarti dibangkitkan kembali atau singkat kata diregenerasi.

Sehingga secara garis besar pengereman regeneratif adalah sebuah sistem

pengereman dengan jalan mengkonversikan energi mekanis sistem menjadi

bentuk energi lain yang dapat disimpan untuk digunakan kembali nanti

pada saat dibutuhkan.Di dunia otomotif dikenal ada dua tipe pengereman regeneratif, yakni tipe elektrik dan tipe mekanik. Penggolongan keduanya adalah berdasarkan bentuk energi yang tersimpan pada sistem pengereman regeneratif. Pengereman regeneratif tipe elektrik menyimpan energi dalam bentuk listrik pada baterai, sedangkan tipe mekanik menyimpan energi dalam bentuk putaran kinetik pada sebuah flywheel (roda gila).

Prinsip Kerja Pengereman Regeneratif

Pengereman Regeneratif Elektrik

Sistem pengereman regeneratif tipe elektrik sangat umum digunakan pada mobil-mobil listrik maupun hybrid. Mobil listrik menggunakan motor listrik sebagai penggerak roda dan baterai sebagai tempat menyimpan energi listrik. Pada saat pengemudi menginjak pedal gas, supply listrik dari baterai masuk ke motor listrik sehingga mobil berakselerasi. Sedangkan pada saat pengemudi melepas pedal gas ataupun menginjak pedal rem, motor listrik akan berubah fungsi menjadi generator sehingga putaran roda mobil seakan-akan terbebani oleh generator tersebut. Pada saat inilah energi kinetik putaran roda terkonversi menjadi energi listrik yang akan disimpan di baterai.

Diagram Sistem KERS Pada Mobil Balap Formula 1

Salah satu aplikasi regenerative braking tipe elektrik ada pada mobil balap Formula 1 yang dikenal dengan nama Kinetic Energy Recovery System dan disingkat menjadi KERS. KERS tersusun atas tiga komponen utama yaitu mesin DC (motor sekaligus generator DC), Electronic Control Unit,

dan baterai. Mesin DC akan aktif menjadi generator hanya pada saat

pengemudi menginjak pedal rem. Pada saat proses pengereman ini, sebagian

energi kinetik digunakan untuk memutar generator, dikonversikan menjadi

energi listrik, dan disimpan di baterai.

Tombol KERS Pada Kemudi Mobil F1

Untuk menggunakan energi yang tersimpan oleh KERS, pengemudi tinggal

menekan tombol KERS pada kemudi. Pada saat tombol tersebut ditekan, ECU

akan mengatur sedemikian rupa sehingga energi listrik yang tersimpan di

dalam baterai tersupply ke mesin DC. Mesin DC akan bekerja sebagai motor

listrik dan menambah daya mesin mobil. Menurut regulasi F1, sistem KERS

dapat menambah daya mesin sebesar 85bhp dalam waktu kurang dari 7

detik.

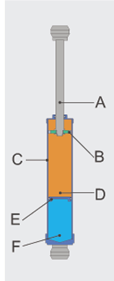

Diagram Sederhana Rangkaian Mesin DC dengan Pengereman Regeneratif

Komponen ECU berfungsi untuk mengontrol mesin DC sehingga ia dapat

berfungsi sebagai motor ataupun generator sesuai dengan keinginan

pengemudi. Gambar diatas adalah rangkaian elektronik sederhana di dalam

ECU sebuah mobil listrik. Rangkaian tersebut dilengkapi dengan komponen

utama MOSFET (Q1-4). MOSFET yang merupakan singkatan dari Metal-Oxide-Semiconductor Field Effect Transistor,

adalah sebuah transistor yang dapat meng-ON-OFF-kan arus bernilai besar

secara cepat dibawah kontrol voltase rendah. Fungsi utama dari MOSFET

mirip dengan saklar DIMMER, kecepatan putaran motor listrik diatur oleh

transistor ini dengan mengatur frekuensi sinyal ON dan OFF supply arus

ke motor listrik. Selain MOSFET rangkaian di atas juga dilengkapi dengan

diode sebagai penyearah arus.

(a)

(b)

(c)

(d)

Aliran Arus Proses Pengereman Regenerative Elektrik

Gambar-gambar di atas adalah skema arah arus listrik rangkaian ECU

pada berbagai kondisi mesin DC termasuk putaran maju, putaran mundur,

serta proses regenerative braking. Gambar (a) adalah kondisi pada saat motor digunakan untuk mobil bergerak maju, dimana Q1 dan Q4 pada posisi ON. Aliran arus listrik sesuai dengan yang ditunjukan oleh garis merah dan melewati kumparan Lf, MOSFET Q1, motor listrik (La), dan MOSFET Q4. Aliran Arus Proses Pengereman Regenerative Elektrik

Saat pengemudi melepas pedal akselerasi, rangkaian akan berposisi sesuai dengan gambar (b). Dimana Q1 dan Q4 berposisi OFF, sehingga tidak ada supply tegangan ke motor. Pada kondisi ini, mesin DC akan bekerja sebagai generator karena ia tetap berputar dengan arah putaran yang sama dengan sebelumnya, sebagai akibat dari kelembaman kendaraan yang masih bergerak. Dengan arah putaran yang sama ini, maka arah arus yang dihasilkan oleh generator adalah melawan arah arus pada gambar (a). Arah arus yang demikian menghasilkan proses pengisian energi listrik ke baterai, dan karena proses ini menimbulkan efek torsi yang arah nya melawan arah putaran mesin DC maka akan menimbulkan efek pengereman pada mesin, di sinilah proses pengereman regeneratif terjadi.

Diagram rangkaian (c) adalah kondisi pada saat mesin DC berfungsi sebagai motor dengan arah putaran yang berlawanan arah dengan kondisi (a). Kondisi ini berguna pada saat kendaraan listrik melakukan manuver reverse atau berjalan mundur. Dengan membalik arah supply arus ke mesin DC akan didapatkan putaran terbalik. Kondisi ini diatur dengan jalan meng-ON-kan MOSFET Q2 dan Q3. Pada saat pengemudi melepas pedal akselerasi, proses pengereman regeneratif kembali terjadi (gambar d). Dimana MOSFET Q2 dan Q3 berada pada posisi OFF, arus listrik berbalik arah melewati diode-diode, dan pengisian baterai kembali terjadi. Proses ini menimbulkan torsi dengan arah melawan arah putaran rotor mesin DC, sehingga torsi ini berfungsi sebagai gaya pengereman.

Pengereman Regeneratif Mekanik

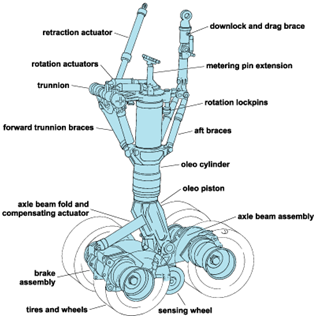

Pengereman regeneratif mekanik menyimpan energi dari proses pengereman ke dalam bentuk energi mekanik. Alat utama yang digunakan untuk menyimpan energi mekanik tersebut yakni sebuah flywheel atau roda gila. Roda gila ini ditempatkan di dalam sebuah tabung vakum bebas udara dengan tujuan untuk meminimalisir gaya gesek pada saat roda gila berputar. Roda gila dihubungkan dengan poros roda mobil oleh transmisi variabel kontinyu (Continuous Variable Transmission/CVT). Untuk lebih jelasnya mari perhatikan gambar komponen-komponen sistem pengereman regeneratif mekanik yang diterapkan pada mobil Volvo berikut.

Roda gila pada sistem pengereman regeneratif kinetik ini tentu tidak

dapat selamanya berputar, karena roda gila akan kehilangan momen

inersianya sepanjang waktu. Karena hal inilah maka sistem pengereman

regeneratif tipe kinetik lebih efisien digunakan pada kondisi traffic yang stop and go. Selain itu, efisiensi roda gila juga ditentukan dengan bobotnya. Maka dari itu Volvo mendesain flywheel-nya

berdiameter 20 cm dengan bobot 6 kg. Roda gila ini berputar di dalam

tabung vakum udara untuk meminimalisir kerugian gesek yang mungkin

terjadi.

Below is a simple block diagram of the speed controller. We'll go through the important parts block by block in detail.

When you watch a film in the cinema, or the television, what you are actually seeing is a series of fixed pictures, which change rapidly enough that your eyes just see the average effect - movement. Your brain fills in the gaps to give an average effect.

Now imagine a light bulb with a switch. When you close the switch, the bulb goes on and is at full brightness, say 100 Watts. When you open the switch it goes off (0 Watts). Now if you close the switch for a fraction of a second, then open it for the same amount of time, the filament won't have time to cool down and heat up, and you will just get an average glow of 50 Watts. This is how lamp dimmers work, and the same principle is used by speed controllers to drive a motor. When the switch is closed, the motor sees 12 Volts, and when it is open it sees 0 Volts. If the switch is open for the same amount of time as it is closed, the motor will see an average of 6 Volts, and will run more slowly accordingly.

As the amount of time that the voltage is on increases compared with the amount of time that it is off, the average speed of the motor increases.

This on-off switching is performed by power MOSFETs. A MOSFET (Metal-Oxide-Semiconductor Field Effect Transistor) is a device that can turn very large currents on and off under the control of a low signal level voltage.

The time that it takes a motor to speed up and slow down under switching conditions is dependant on the inertia of the rotor (basically how heavy it is), and how much friction and load torque there is. The graph below shows the speed of a motor that is being turned on and off fairly slowly:

You can see that the average speed is around 150, although it

varies quite a bit. If the supply voltage is switched fast enough, it won’t

have time to change speed much, and the speed will be quite steady. This is

the principle of switch mode speed control. Thus the speed is set by

PWM – Pulse Width Modulation.

where di/dt is the rate of change of the current. If the

current is suddenly changed by opening a switch, or turning a transistor off,

the inductor will generate a very high voltage across it. For example,

turning off 100 Amps in 1 microsecond through a 100 microHenry inductor

generates 10kV!

Both waveforms have the same average current. However, when we work

out the power dissipation in the stray resistances in our motor and

speed controller, for the DC case:

Both waveforms have the same average current. However, when we work

out the power dissipation in the stray resistances in our motor and

speed controller, for the DC case:

and for the switching case, the average power is

and for the switching case, the average power is

So in the switching waveform, twice as much power is lost in the

stray resistances. In practice the current waveform will not be square

wave like this, but it always remains true that there will be more power

loss in a non-DC waveform.

So in the switching waveform, twice as much power is lost in the

stray resistances. In practice the current waveform will not be square

wave like this, but it always remains true that there will be more power

loss in a non-DC waveform.

The following shows the equivalent circuit of the motor, and the current waveform as the PWM signal switches on and off. This shows the worst case, at 50:50 PWM ratio, and the current rise is shown for a stationary or stalled motor, which is also worst case.

T is the switching period, which is the reciprocal of the switching

frequency. Just taking the falling edge of the current waveform, this

is given by the equation

T is the switching period, which is the reciprocal of the switching

frequency. Just taking the falling edge of the current waveform, this

is given by the equation

τ is the time constant of

the circuit, which is L / R.

So the current at time t = T/2 (i1) must be no less than

P% lower than at t = 0 (i0). This means there is a limiting

condition:

τ is the time constant of

the circuit, which is L / R.

So the current at time t = T/2 (i1) must be no less than

P% lower than at t = 0 (i0). This means there is a limiting

condition:

So:

So:

Let’s try some values in this to see what frequencies we get. A

Ford Fiesta starter motor has the following approximate parameters:

Let’s try some values in this to see what frequencies we get. A

Ford Fiesta starter motor has the following approximate parameters:

A graph can be drawn for this particular motor:

Looking at the above graph, a reasonably low ripple can be achieved

with a switching frequency of as little as 5kHz.

Looking at the above graph, a reasonably low ripple can be achieved

with a switching frequency of as little as 5kHz.

Unfortunately, motor manufacturers rarely publish values of coil inductance in their datasheets, so the only way to find out is to measure it. This requires sensitive LCR bridge test equipment which is rather expensive to buy. However, from the 4QD site, they quote the Lynch motor with an inductance of 39µH as being one of the lowest.

It may help to introduce some terminology here. The

Motor Driver Terminology page

defines some terms.

In this circuit, Q1 and D1 perform the same function as in the

previous circuit. Q2 is turned on in antiphase to Q1. This means that when Q1

is on, Q2 is off, and when Q1 is off, Q2 is on.

In this circuit, when the robot is slowing down, Q1 is off and the motor is acting as a generator. The current can flow backwards (because the motor is generating) through Q2 which is turned on. When Q2 turns off, this current is maintained by the inductance, and current will flow up through D2 and back into the battery. A graph of motor current as the motor is slowing down is shown below:

If you are driving starter motors, or any type of series-field

motor, regeneration is harder to make work. For a motor to work as a

generator, it must have a magnetic field, generated by the field coil. In a

series motor this is in series with the armature coil, so to generate a

voltage, a suitable current must be flowing. The current that will flow depends

on the load, which during regeneration is the battery, so it depends

on how much the battery is charged up - how much current the battery will

draw into it. Alternatively, a dummy resistive load can be switched in

at the approriate time, but this is all a little too complicated for a

robot!

When the relays are in the position shown, current will flow

vertically upwards through the field coil. To reverse the motor the relays are

switched over. Then the current will be flowing vertically downwards through

the field coil, and the motor will go in reverse.

However, when the relays open to reverse the direction, the inductance of the motor generates a very high voltage which will spark across the relay contact, damaging the relay. Relays which can take very high currents are also quite expensive. Therefore this is not a very good solution. A better solution is to use what is termed a full-bridge circuit around either the field winding, or the armature winding. We will put it around the armature winding and leave the field winding in series.

To make the motor go forwards, Q4 is turned on, and Q1 has the PWM

signal applied to it. The current path is shown in the diagram below in red.

Note that there is also a diodee connected in reverse across the field

winding. This is to take the current in the field winding when all four MOSFETs

in the bridge are turned off.

Q4 is kept on so when the PWM signal is off, current can continue

to flow around the bottom loop through Q3's instrinsic diode:

To make the motor go backwards, Q3 is turned on, and Q2 has the PWM

signal applied to it:

Q3 is kept on so when the PWM signal is off, current can continue

to flow around the bottom loop through Q4's intrinsic diode:

For regeneration, when the motor is going backwards for example,

the motor (which is now acting as a generator) is forcing current right

through its armature, through Q2's diode, through the battery (thereby

charging it up) and back through Q3's diode:

When the triangle waveform voltage is greater than the DC level,

the output of the op-amp swings high, and when it is lower, the output

swings low. From the graph it can be seen that if the DC level went higher,

the pulses would get even thinner.

An example circuit for this is shown below. This uses a counter and weighted resistor ladder to generate the triangle wave (in fact it will generate a sawtooth, but you'll still get a PWM signal at the end of it). The actual resistor values which are unavailable (40k, 80k) can be made up with 20k resistors, or close approximations can be used, which may distort the sawtooth somewhat, but this shouldn't matter too much.

The 74HC14 is a Schmitt input inverter, which is connected to act as a

simple oscillator. The frequency of oscillation is roughly

f = 1/(2.PI.R.C)

but it doesn’t matter a great deal within a few tens of percent.

This square wave generated feeds the 74HC163 binary 4-bit counter. All the

preset and clear inputs of this are disabled, so the outputs, QA

to QD just roll around the binary sequence 0000 to 1111 and

rollover to 0000 again. These outputs, which swing from 0v to +5v are fed into

a binary weighted summer amplifier, the leftmost LM324 opamp section

with the 80k, 40k, 20k and 10k resistors. The output voltage of this

amplifier depends on the counter count value and is shown in the table below as

Amp1 output. The opamp following this just multiplies the voltage by

-½

, to make the voltage positive, and bring it back within logic voltage

levels, see the Amp2 output column in the table.

The final, rightmost, opamp compares the voltage with

the demand voltage input, which ranges from 0v to 4.6875v, where 0v

represents 0% PWM ratio and 4.6875v represents 100% PWM ratio. This demand

voltage may range from –12v to +12v but only the 0 to 4.6875 range will adjust

the PWM ratio.

Alternatively, a MOSFET driver which includes a PWM generator can

be used. I know of only one which is not yet released! The SGS Thomson

TD340.

The register must be loaded with the required PWM level by a

microcontroller. It may be replaced by a simple ADC if the level must be

controlled by an analogue signal (as it would from a radio control servo). This

method is only really practical if a microcontroller is being used in your

robot, which can preload the register easily.

You may be able to tap into the PWM signal which comes out of the

radio receiver before it goes into the servo, and use this to drive the

input to the MOSFET driver. However, this gives you no choice of switching

frequency. Alternatively, the potentiometer can generate a voltage to feed into

the PWM generator.

If you are unsure about your servos, or want to modify them, there is an introduction to them on the Seattle Robotics Society page here.

A more advanced method if you have a microcontroller on board the robot is to take the PWM signal from the radio receiver and connect it to a timer input of the micro. The microcontroller should be able to decode this waveform, and generate a proportional analogue output value (if it has ADCs, or if an external ADC is fitted). Another even more advanced method is to send serial communications data through the radio channel. The radio control handset will need to have a microcontroller in. The microcontroller should read the pots and switches on the handset, and send suitable commands out of its UART. This connects to the radio transmitter. At the receiver, the demodulated output is sent to the robot's microcontroller's UART, and the data is decoded. There is a whole chapter on using embedded microcontrollers in a robot here

This circuit shows just the upper MOSFETs of the bridge being

driven for simplicity. The lower MOSFETs are not turned off during a current

limit. There is only one sense resistor required for each motor, and that

should be connected immediately from the battery positive terminal.

A simulation of the current limiting part of this circuit is shown in the diagram below. The V5 threshold voltage was chosen to set a current limit of 30 Amps. The square wave is the PWM voltage (MOSFET gate voltage), and the slopey waveform is the drain (motor) current. The spikey bits at the top of the slopey waveform is when the current limiting is switching in and out.

There is an in-depth document here which describes sense resistors in detail.

Some circuits you may see sample the current going through the main power MOSFET by placing a much lower power MOSFET in parallel with it. There is a circuit on the 4QD site which does this here. This works OK, but the problem is the actual limiting current is dependant on the value of Rds(on) of the MOSFET. If Rds(on) was only half the value we were expecting it to be, then twice as much current would flow before the limiting circuit took effect. Also the Rds(on) value depends very much on the current that is passing through the MOSFET, and on the temperature. Any variation in Rds(on) will change the limiting current.

The Rds(on) figure is quoted as a maximum value on the datasheet, but it is not a design-safe parameter. This means that it is not within defined limits which are published on the datasheet. For example, CMOS digital logic guarantees that the output voltage, Vo, will be between Vcc-0.5v and Vcc, and that figure can be used to design circuits which rely on that figure. However, with Rds(on), we only know that it will be between 0 and the quoted value. We cannot rely on a minimum value of it, yet it is the minimum value which controls the current limit. Therefore, using a separate shunt resistor is a much safer method.

One problem with the circuit presented above is that you may want to provide a larger current during acceleration, or in emergencies. This can be solved by disabling the current limiting using a separate line from any onboard microcontroller, or by adding a circuit which allows an over-current condition for just a short time. The amount of time that this is allowed must be carefully calculated to prevent damage to the MOSFETs, and must take into account the cooling system that you have provided.

An alternative to using the op-amp differential amplifier circuit used above is to use an integrated current sense monitor IC. Several companies make these, I have used the Zetex ZXCT1010. Zetex's range of current monitors can be found here.

As the load torque increases, the speed drops - we are following the line

in the torque speed characteristic from the left hand side towards the right,

drooping down. This is the same as the uncontrolled motor. The motor torque

always equals the load torque when the motor is running at constant speed

(this follows from Newton's first law - "An object in motion tends to

stay in motion with the same speed and in the same direction unless acted

upon by an unbalanced force." The motor torque and load torque must be

balanced out if the speed is not changing).

As the load torque increases, the speed drops - we are following the line

in the torque speed characteristic from the left hand side towards the right,

drooping down. This is the same as the uncontrolled motor. The motor torque

always equals the load torque when the motor is running at constant speed

(this follows from Newton's first law - "An object in motion tends to

stay in motion with the same speed and in the same direction unless acted

upon by an unbalanced force." The motor torque and load torque must be

balanced out if the speed is not changing).

Let's call the current limit value iL and the equivalent torque value on the torque-current graph at this current is TL. When the load torque exceeds TL, the motor can no longer create an equal and opposite torque, and so the load will push the motor backwards in the opposite direction - we are now following the line as it drops downwards into negative speed.

Let's take an example; an opponent's robot is more powerful than ours (or his current limit is set higher), and we are in a pushing match. As each pushes harder, our speed controller reaches its current limit first. Our robot is now pushing at a constant force (since the motor torque is now constant at its highest value). As the opponent pushes harder, our wheels start to rotate backwards, and the pair of robots accelerates backwards at a rate given by Newton's second law:

The speed demand is a DC voltage, which is fed to the PWM generator for motor A. This drives motor A at a speed dependant on the demand voltage. The speed of motor A is sampled using an optical encoder. This has a frequency output, which is proportional to the speed of the motor.

If we assume that motor B is already running at some speed, then the optical encoder on its shaft will be producing a frequency also. The phase comparator compares the two frequencies, effectively comparing the speeds of the two motors. Its output is a signal which gets larger as the two input frequencies get further apart. If the two frequecies are the same, it has a zero output.

The integrator adds the output of the phase comparator to whatever its output was before. For example, if the integrator output was previously 3 volts, and its input is 0 volts, then its output will be 3 volts. If its input changed to –1 volts, then its output would change to 2 volts.

Let’s assume that motor B is running slower than motor A. Then the output of the phase comparator will be positive, and the output of the integrator will start to rise. The speed of motor B will then increase. If it increased to a speed greater than that of motor A, then the output of the phase comparator would become negative, and the output of the integrator would start to fall, thereby reducing the speed of motor B. In this manner, the speed of motor B is kept the same as the speed of motor A, and the robot will go in a straight line (as long as its wheels are the same size!).

This method can be expanded to use any number of wheels. One motor will always be the directly driven one (in this case motor A), and the others will have their speed locked to this one. Note that if the directly driven motor is faster, or more free-running, than the others, then when it is driven at its fastest speed (the PWM signal is always ON), then the other motors will never be able to keep up, and the robot will still swerve. It is best, therefore, to directly drive the slowest motor.

An analogue feedback speed controller such as this is quite difficult to make, and keep stable. It is easier to perform this function using software in an onboard microcontroller....

A suitable encoder is available from Maplin, code CH18U for about

£2 each

The encoder transmitter must be supplied with a suitable current,

and the receiver biased as below:

This will have an output which swings to +5v when the light is

blocked, and about 0.5 volts when light is allowed to pass through the slots in

the disc. These voltages are comptible with normal digital circuitry.

However, because this device is right next to a DC motor, which generates a lot

of electrical noise (since it is switching high currents at the

commutator into the inductive windings – hence high voltages and sparks!), the

output must be low-pass filtered. The phase comparator should have as little

noise as possible at its inputs.

The cutoff frequency for the filter is determined by how many slots are in the disc, and by how fast the disc (and hence the wheel) is intended to rotate. It is given by the equation

where sw is maximum speed of the wheel in rpm,

and n is the number of slots in the disc. The filter can be made from a

simple RC circuit as follows:

Then the R and C values chosen such that

For example, if the maximum wheel speed is 10rpm, and there are 12

slots in the disc, then RC = 0.08, so suitable values of R and C might be

8k2 and 10uF.

An alternative way to measure the speed is using a magnetic sensing device. If your motor or gearing has steel teeth, then sensors are available that can detect and count these as they go by. The Infineon TLE4942 is such a device. I will not go into this anymore since the datasheet at that link describes how to use the device.

Pengereman regeneratif mekanik menyimpan energi dari proses pengereman ke dalam bentuk energi mekanik. Alat utama yang digunakan untuk menyimpan energi mekanik tersebut yakni sebuah flywheel atau roda gila. Roda gila ini ditempatkan di dalam sebuah tabung vakum bebas udara dengan tujuan untuk meminimalisir gaya gesek pada saat roda gila berputar. Roda gila dihubungkan dengan poros roda mobil oleh transmisi variabel kontinyu (Continuous Variable Transmission/CVT). Untuk lebih jelasnya mari perhatikan gambar komponen-komponen sistem pengereman regeneratif mekanik yang diterapkan pada mobil Volvo berikut.

Komponen-komponen Sistem Pengereman Regeneratif Mekanik

Pada sistem Volvo ini, flywheel dikopling dan di-de-kopling

dengan poros roda belakang oleh sistem transmisi CVT. CVT menghubungkan

roda gila dengan poros roda pada saat mobil melambat, memutar roda gila

hingga 60.000 rpm, dan melepas roda gila dengan poros roda pada saat

mobil benar-benar berhenti. Roda gila akan terus berputar, hingga mobil

melakukan akselerasi, pada saat ini CVT kembali menghubungkan roda gila

dengan poros roda untuk menambah tenaga akselerasi mobil. Volvo

mengklaim sistem ini tidak hanya dapat mengurangi konsumsi bahan bakar,

namun juga dapat menambah tenaga akselerasi mobil hingga 80 tenaga kuda.

Sistem KERS Pada Mobil Volvo

Speed Controllers

1. Introduction

The purpose of a motor speed controller is to take a signal representing the demanded speed, and to drive a motor at that speed. The controller may or may not actually measure the speed of the motor. If it does, it is called a Feedback Speed Controller or Closed Loop Speed Controller, if not it is called an Open Loop Speed Controller. Feedback speed control is better, but more complicated, and may not be required for a simple robot design. Motors come in a variety of forms, and the speed controller's motor drive output will be different dependent on these forms. The speed controller presented here is designed to drive a simple cheap starter motor from a car, which can be purchased from any scrap yard. These motors are generally series wound, which means to reverse them, they must be altered slightly .Below is a simple block diagram of the speed controller. We'll go through the important parts block by block in detail.

2. Theory of DC motor speed control

The speed of a DC motor is directly proportional to the supply voltage, so if we reduce the supply voltage from 12 Volts to 6 Volts, the motor will run at half the speed. How can this be achieved when the battery is fixed at 12 Volts? The speed controller works by varying the average voltage sent to the motor. It could do this by simply adjusting the voltage sent to the motor, but this is quite inefficient to do. A better way is to switch the motor's supply on and off very quickly. If the switching is fast enough, the motor doesn't notice it, it only notices the average effect.When you watch a film in the cinema, or the television, what you are actually seeing is a series of fixed pictures, which change rapidly enough that your eyes just see the average effect - movement. Your brain fills in the gaps to give an average effect.

Now imagine a light bulb with a switch. When you close the switch, the bulb goes on and is at full brightness, say 100 Watts. When you open the switch it goes off (0 Watts). Now if you close the switch for a fraction of a second, then open it for the same amount of time, the filament won't have time to cool down and heat up, and you will just get an average glow of 50 Watts. This is how lamp dimmers work, and the same principle is used by speed controllers to drive a motor. When the switch is closed, the motor sees 12 Volts, and when it is open it sees 0 Volts. If the switch is open for the same amount of time as it is closed, the motor will see an average of 6 Volts, and will run more slowly accordingly.

As the amount of time that the voltage is on increases compared with the amount of time that it is off, the average speed of the motor increases.

This on-off switching is performed by power MOSFETs. A MOSFET (Metal-Oxide-Semiconductor Field Effect Transistor) is a device that can turn very large currents on and off under the control of a low signal level voltage.

The time that it takes a motor to speed up and slow down under switching conditions is dependant on the inertia of the rotor (basically how heavy it is), and how much friction and load torque there is. The graph below shows the speed of a motor that is being turned on and off fairly slowly:

2.1. Inductors

Before we go on to discuss the circuits, we must first learn something about the action of inductive loads, and inductors. Inductors do not allow the current flowing through them to change instantly (in the same way capacitors do not allow the voltage across them to change instantly). The voltage dropped across an inductor carrying a current i is given by the equation

2.2. PWM frequency

The frequency of the resulting PWM signal is dependant on the frequency of the ramp waveform. What frequency do we want? This is not a simple question. Some pros and cons are:- Frequencies between 20Hz and 18kHz may produce audible screaming from the speed controller and motors - this may be an added attraction for your robot!

- RF interference emitted by the circuit will be worse the higher the switching frequency is.

- Each switching on and off of the speed controller MOSFETs results in a little power loss. Therefore the greater the time spent switching compared with the static on and off times, the greater will be the resulting 'switching loss' in the MOSFETs.

- The higher the switching frequency, the more stable is the current waveform in the motors. This waveform will be a spiky switching waveform at low frequencies, but at high frequencies the inductance of the motor will smooth this out to an average DC current level proportional to the PWM demand. This spikyness will cause greater power loss in the resistances of the wires, MOSFETs, and motor windings than a steady DC current waveform.

Choosing a frequency based on motor characteristics

One way to choose a suitable frequency is to say, for example, that we want the current waveform to be stable to within ‘p’ percent. Then we can work out mathematically the minimum frequency to attain this goal. This section is a bit mathematical so you may wish to miss it out and just use the final equation.The following shows the equivalent circuit of the motor, and the current waveform as the PWM signal switches on and off. This shows the worst case, at 50:50 PWM ratio, and the current rise is shown for a stationary or stalled motor, which is also worst case.

R = 0.04Ω

L = 70µH

We must also include in the resistance the on-resistance of the

MOSFETs being used, say 2 x 10mΩ, giving a total resistance of R = 0.06

Ω.|

Percentage

|

frequency

|

|

1

|

42 kHz

|

|

5

|

8.2 kHz

|

|

10

|

4 kHz

|

|

20

|

1900 Hz

|

|

50

|

610 Hz

|

Unfortunately, motor manufacturers rarely publish values of coil inductance in their datasheets, so the only way to find out is to measure it. This requires sensitive LCR bridge test equipment which is rather expensive to buy. However, from the 4QD site, they quote the Lynch motor with an inductance of 39µH as being one of the lowest.

3. Speed control circuits

We will start off with a very simple circuit (see the figure below). The inductance of the field windings and the armature windings have been lumped together and called La. The resistance of the windings and brushes is not important to this discussion, and so has not been drawn. Q1 is the MOSFET. When Q1 is on, current flows through the field and armature windings, and the motor rotates. When Q1 is turned off , the current through an inductor cannot immediately turn off, and so the inductor voltage drives a diminishing current in the same direction, which will now flow through the armature, and back through D1 as shown by the red arrow in the figure below. If D1 wasn’t in place, a very large voltage would build up across Q1 and blow it up.

4. Regeneration

In this circuit, energy can flow only one way, from the battery to the motor. When the speed demand of the motor drops suddenly, the momentum of the robot will drive the motor forwards, and the motor will act as a generator. In the circuit above, this power cannot go anywhere. Although this isn’t a problem, it is desirable that this power be put back into the battery. This is called regenerative braking and needs some extra components. The following circuit allows regenerative braking:

In this circuit, when the robot is slowing down, Q1 is off and the motor is acting as a generator. The current can flow backwards (because the motor is generating) through Q2 which is turned on. When Q2 turns off, this current is maintained by the inductance, and current will flow up through D2 and back into the battery. A graph of motor current as the motor is slowing down is shown below:

5. Reversing

To reverse a DC motor, the supply voltage to the armature must be reversed, or the magnetic field must be reversed. In a series motor, the magnetic field is supplied from the supply voltage, so when that is reversed, so is the field, therefore the motor would continue in the same direction. We must switch either the field winding’s supply, or the armature winding’s supply, but not both. One method is to switch the field coil using relays:

However, when the relays open to reverse the direction, the inductance of the motor generates a very high voltage which will spark across the relay contact, damaging the relay. Relays which can take very high currents are also quite expensive. Therefore this is not a very good solution. A better solution is to use what is termed a full-bridge circuit around either the field winding, or the armature winding. We will put it around the armature winding and leave the field winding in series.

6. The full bridge circuit

A full bridge circuit is shown in the diagram below. Each side of the motor can be connected either to battery positive, or to battery negative. Note that only one MOSFET on each side of the motor must be turned on at any one time otherwise they will short out the battery and burn out!

6.1. Reducing the heat in the MOSFETs

When the MOSFETs in the diagrams above are on and current is flowing through them in a top-to-bottom direction, they have a very low resistance and are dissipating hardly any heat at all. However, when the current is flowing bottom-to-top through the intrinsic diodes, there is a fixed voltage across them - the voltage drop of a diode, about 0.8 volts. This causes quite a large power dissipation (volts x amps). A feature of MOSFETs is that they will conduct current from source to drain as well as drain to source, as long as the Vgs is greater than 10-12 volts. Therefore, if the MOSFETs that are carrying reversed current through their diodes are turned on, then they will dissipate a lot less heat. The heat will be dissipated in the wires and the motor itself instead. This extra switching is performed by the TD340 full bridge driver.7. Generating PWM signals

The PWM signals can be generated in a number of ways. It is possible that your radio receiver already picks up a PWM waveform from the handest transmitter. If there is a microcontroller on the robot, this may be able to generate the waveform, although if you have more than a couple of motors, this may be too much of a load on the microcontroller’s resources. Several methods are described below.7.1. Analogue electronics

The PWM signal is generated by comparing a triangular wave signal with a DC signal. The DC signal can range between the minimum and maximum voltagesof the triangle wave.

An example circuit for this is shown below. This uses a counter and weighted resistor ladder to generate the triangle wave (in fact it will generate a sawtooth, but you'll still get a PWM signal at the end of it). The actual resistor values which are unavailable (40k, 80k) can be made up with 20k resistors, or close approximations can be used, which may distort the sawtooth somewhat, but this shouldn't matter too much.

7.2. PWM generator chips

There are ICs available which convert a DC level into a PWM output. Many of these are designed for use in switch mode power supplies. Examples that could be used are:7.3. Digital method

The digital method involves incrementing a counter, and comparing the counter value with a pre-loaded register value. It is basically a digital version of the analogue method above:

7.4. Onboard microcontroller

If you have chosen to use an onboard microcontroller, then as part of your selection process, include whether it has PWM outputs. If it has this can greatly simplify the process of generating signals. The Hitachi H8S series has up to 16 PWM outputs available, but many other types have two or three.8. Interfacing to the high power electronics

There are two sides to the electronics: the low-power side, and the high-power side. The low power electronics includes any onboard microcontroller, the radio control receiver, and PWM generators. The high-power side includes the MOSFET drivers, the MOSFETs themeselves, and any solenoid or pump drivers that you may have. Basically anything that is switching large currents. The low-power electronic devices may be quite sensitive to noise spikes on the power rails, and may malfunction or even be destroyed. It is a good idea to isolate the low-power electronics from the high-power electronics using what is known as opto-isolators or opto-couplers, two names for the same thing! For more information about these, there is a chapter on it here9. Interfacing to the radio control receiver

Many roboteers will be using commercial radio control sets. The receivers of these generally connect to servos, which respond to the radio signal (which may also be PWM):

If you are unsure about your servos, or want to modify them, there is an introduction to them on the Seattle Robotics Society page here.

A more advanced method if you have a microcontroller on board the robot is to take the PWM signal from the radio receiver and connect it to a timer input of the micro. The microcontroller should be able to decode this waveform, and generate a proportional analogue output value (if it has ADCs, or if an external ADC is fitted). Another even more advanced method is to send serial communications data through the radio channel. The radio control handset will need to have a microcontroller in. The microcontroller should read the pots and switches on the handset, and send suitable commands out of its UART. This connects to the radio transmitter. At the receiver, the demodulated output is sent to the robot's microcontroller's UART, and the data is decoded. There is a whole chapter on using embedded microcontrollers in a robot here

10. Current limiting

Current limiting is absolutely essential. If the motor is stalled, it can take huge currents which would destroy the MOSFETs very quickly. The form of current limiting presented here is to measure the current that the motor is taking, and if it is above a preset threshold, turn the MOSFETs in the bridge off. If you have a microcontroller on board which generates the PWM ratio, it would be an advantage if the software could detect the over- current status, and reduce the PWM ratio by, say, 10%. A circuit to perform this function is shown below.

Circuit description

The voltage dropped across the sense resistor is amplified by U1A, which is connected in a differential amplifier circuit. The gain of this is 480k / 1k which is 480. This is a very large gain because the voltage dropped across the sense resistor will be very small. The output of the differential amplifier is then heavily low pass filtered by RxCx. This is because there will be a lot of noise coming from the motor, and we do not want to limit the current if we don't need to. D13 is present to make sure that no negative spikes can affect the following circuitry. U2B compares the filtered signal with a preset value (represented here by V5), and if the current is too high (i.e. the signal is greater than V5), U2B will turn Q1 and Q2 on which clamps the PWM signals from the PWM generator. This will force the MOSFET driver to turn the MOSFET off. Q1 must be repeated four times, one for each of the MOSFET driver channels, but all four transistors can be driven from U2B. D11, R14 and C4 make sure that the MOSFET doesn't turn back on straight away, but takes a few milliseconds. This stops the MOSFET being rapidly turned on and off.10.1. The shunt resistor

The shunt resistor R7 in the cicuit must be a very low value if we want large currents to be able to flow, up to 100 Amps for example. It must not drop too much voltage, thereby robbing power from the motor, and it must be capable of dissipating the power without buring out when large currents are passed through. Some suitable resistors are available from Farnell, code 156-267. These are still too large a resistance (and too low power), so we can place eight in parallel. The power handling capabilty is then increased eightfold, and the resistance decreased eightfold. An alternative is to use a piece of wire of an appropriate thickness and length. This can be calculated using the data on this web site.A simulation of the current limiting part of this circuit is shown in the diagram below. The V5 threshold voltage was chosen to set a current limit of 30 Amps. The square wave is the PWM voltage (MOSFET gate voltage), and the slopey waveform is the drain (motor) current. The spikey bits at the top of the slopey waveform is when the current limiting is switching in and out.

There is an in-depth document here which describes sense resistors in detail.

Some circuits you may see sample the current going through the main power MOSFET by placing a much lower power MOSFET in parallel with it. There is a circuit on the 4QD site which does this here. This works OK, but the problem is the actual limiting current is dependant on the value of Rds(on) of the MOSFET. If Rds(on) was only half the value we were expecting it to be, then twice as much current would flow before the limiting circuit took effect. Also the Rds(on) value depends very much on the current that is passing through the MOSFET, and on the temperature. Any variation in Rds(on) will change the limiting current.

The Rds(on) figure is quoted as a maximum value on the datasheet, but it is not a design-safe parameter. This means that it is not within defined limits which are published on the datasheet. For example, CMOS digital logic guarantees that the output voltage, Vo, will be between Vcc-0.5v and Vcc, and that figure can be used to design circuits which rely on that figure. However, with Rds(on), we only know that it will be between 0 and the quoted value. We cannot rely on a minimum value of it, yet it is the minimum value which controls the current limit. Therefore, using a separate shunt resistor is a much safer method.

One problem with the circuit presented above is that you may want to provide a larger current during acceleration, or in emergencies. This can be solved by disabling the current limiting using a separate line from any onboard microcontroller, or by adding a circuit which allows an over-current condition for just a short time. The amount of time that this is allowed must be carefully calculated to prevent damage to the MOSFETs, and must take into account the cooling system that you have provided.

An alternative to using the op-amp differential amplifier circuit used above is to use an integrated current sense monitor IC. Several companies make these, I have used the Zetex ZXCT1010. Zetex's range of current monitors can be found here.

10.2. Current limited torque speed characteristics

If a DC motor is being driven by a speed controller with current limiting active, what happens to the torque speed characteristic graph? The DC Motors page describes the normal motor torque speed graph, and how the torque of a permanent magnet DC motor is proportional to the current. If the current is limited however, the torque must also be limited, at the value coincident with the limited current on the torque-current graph. The effect that this has on the torque speed graph is shown below:

Let's call the current limit value iL and the equivalent torque value on the torque-current graph at this current is TL. When the load torque exceeds TL, the motor can no longer create an equal and opposite torque, and so the load will push the motor backwards in the opposite direction - we are now following the line as it drops downwards into negative speed.

Let's take an example; an opponent's robot is more powerful than ours (or his current limit is set higher), and we are in a pushing match. As each pushes harder, our speed controller reaches its current limit first. Our robot is now pushing at a constant force (since the motor torque is now constant at its highest value). As the opponent pushes harder, our wheels start to rotate backwards, and the pair of robots accelerates backwards at a rate given by Newton's second law:

F=ma or a=F/m

where F is the difference between the forces of the two

robots pushing, and m is the total mass of the two robots.

11. Feedback Speed Control

To stop a robot swerving in an arc when you want it to go forwards, you need to have feedback control of the motor speeds. This means that the actual speed of each wheel is measured, and compared with all the other wheels. Obviously to go in a straight line, the motor speeds must be equal. However, this does not necessarily mean that the speed demand for each motor should be the same. The motors will have different amounts of friction, and so a ‘stiffer’ motor will require a higher speed demand to go as fast as a more free-running motor. A block diagram of an analogue feedback speed controller is shown below

The speed demand is a DC voltage, which is fed to the PWM generator for motor A. This drives motor A at a speed dependant on the demand voltage. The speed of motor A is sampled using an optical encoder. This has a frequency output, which is proportional to the speed of the motor.

If we assume that motor B is already running at some speed, then the optical encoder on its shaft will be producing a frequency also. The phase comparator compares the two frequencies, effectively comparing the speeds of the two motors. Its output is a signal which gets larger as the two input frequencies get further apart. If the two frequecies are the same, it has a zero output.

The integrator adds the output of the phase comparator to whatever its output was before. For example, if the integrator output was previously 3 volts, and its input is 0 volts, then its output will be 3 volts. If its input changed to –1 volts, then its output would change to 2 volts.

Let’s assume that motor B is running slower than motor A. Then the output of the phase comparator will be positive, and the output of the integrator will start to rise. The speed of motor B will then increase. If it increased to a speed greater than that of motor A, then the output of the phase comparator would become negative, and the output of the integrator would start to fall, thereby reducing the speed of motor B. In this manner, the speed of motor B is kept the same as the speed of motor A, and the robot will go in a straight line (as long as its wheels are the same size!).

This method can be expanded to use any number of wheels. One motor will always be the directly driven one (in this case motor A), and the others will have their speed locked to this one. Note that if the directly driven motor is faster, or more free-running, than the others, then when it is driven at its fastest speed (the PWM signal is always ON), then the other motors will never be able to keep up, and the robot will still swerve. It is best, therefore, to directly drive the slowest motor.

An analogue feedback speed controller such as this is quite difficult to make, and keep stable. It is easier to perform this function using software in an onboard microcontroller....

11.1. Software feedback speed control

To perform the same function as described above in software requires that the software has digital representation of the speed of each wheel, and can finely control the width of the PWM signal sent to each wheel. To get the speed of each wheel, an optical encoder must be used as in the analogue method, but the output of it must be sent to the microcontroller. This is achieved using a counter, clocked by the speed controller, which the microcontroller can read, and can clear. At regular intervals, the microcontroller must read the counter, then clear it. The interval depends on the maximum speed of the robot, the diameter of the wheel, the number of slots in the speed encoder’s disc, and the number of bits of the counter. A complete design using this technique is being worked on and will be presented here when it is complete.11.2. Speed encoders

To start with, we need a device that will measure the speed of the motor shaft. The best way to do this is to fit an optical encoder. This shines a beam of light from a transmitter across a small space and detects it with a receiver the other end. If a disc is placed in the space, which has slots cut into it, then the signal will only be picked up when a slot is between the transmitter and receiver. An example of a disc is shown below

The cutoff frequency for the filter is determined by how many slots are in the disc, and by how fast the disc (and hence the wheel) is intended to rotate. It is given by the equation

An alternative way to measure the speed is using a magnetic sensing device. If your motor or gearing has steel teeth, then sensors are available that can detect and count these as they go by. The Infineon TLE4942 is such a device. I will not go into this anymore since the datasheet at that link describes how to use the device.