The electronics industry is filled with an electronic circuit in the field of control and measurement which is an important aspect for the performance of an electronic circuit, especially in the WET ON / OFF Automatic grid process (Work ---> Energy ---> Time ON / OFF Automatic). all areas of life at this time can come into contact with the performance of electronic equipment for it required a work WET ON / OFF Automatic highly efficient and effective as well as the right quality and the right quantity in which the electronic equipment is needed for the journey journey distant and excavation extracting information qualified in the field of outer space ie engineering machinery electronic and control Avionics ( Space Ships ) and acquisition techniques of quality information both mixed and determine which ones are valuable and useful ( INFORMIX ) , or could we call detector information from technical space, a glimpse here I outline some of the principles of electronics WET ON / OFF Automatic in the field of modern electronics .

Electronic Components

Electronic components are used in the automotive, communication, aerospace and other industries. Miniaturization, higher package density and accelerated development processes have a great impact on the reliability of electronic components.

Electronic components are used in the automotive, communication, aerospace and other industries. Miniaturization, higher package density and accelerated development processes have a great impact on the reliability of electronic components.

Rapid changes of ambient temperature or internal production of heat may occur during operation. This may create high thermal stresses due to the mismatch of the thermal expansion coefficients of the different materials in electronic components.

Shrinking dimensions of flip chip assemblies make inspection of bumps or solder joints always more difficult as standard non destructive control techniques reach their resolution limits.

Electronic speckle pattern interferometry (ESPI) as a non-contact, full-field and 3-dimensional measuring method, copes well with the challenge of deformation measurements on microsystems and electronic components with a sub-micron resolution.

The Basics of Mixers

The Basics of Mixers

Contributed By Electronic Products

2011-10-20

Mixers are used in a variety of RF/microwave applications, including military radar, cellular base stations, and more. An RF mixer is a three-port passive or active device that can modulate or demodulate a signal. The purpose is to change the frequency of an electromagnetic signal while (hopefully) preserving every other characteristic (such as phase and amplitude) of the initial signal. A principal reason for frequency conversion is to allow amplification of the received signal at a frequency other than that of the RF.

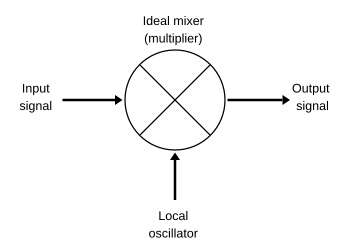

Figure 1: A mixer presented symbolically.

Figure 1 shows the mixer’s three ports: fin1 and fin2 are the input ports while the output port is the both the sum and the difference in frequency of the inputs:

fout = fin1 ± fin2

Figure 2: Representation of downconversion and upconversion.

The three ports (Figure 2) are referred to as the RF input port, LO (local oscillator) input port, and the IF (intermediate frequency) output port. A mixer is also known as a downconverter if the mixer is part of a receiver or as an upconverter if it is part of a transmitter.

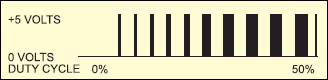

Depending upon the application in which the mixer is being used, the LO is typically driven with either a sinusoidal continuous wave signal or a square wave. In concept, the LO signal acts as a gate of the mixer in which the mixer is considered ON when the LO is a large voltage and OFF when it is a small voltage. The LO can only be an input port, while the RF and IF ports can be interchanged between the second input or output.

When the desired frequency is less than the second input frequency, the process is called downconversion. The RF is then the input while the IF is the output. When the desired output frequency is greater than the second input frequency the process is called upconversion. Here the IF is the input while the RF is the output.

In a receiver, when the LO frequency is less than the RF frequency, it is called low-side injection and the mixer is a low-side downconverter. When the LO frequency is above the RF, it is called high-side injection, and the mixer is a high-side downconverter.

Generally, a passive mixer is made of passive devices, such as diodes. An active mixer is made of active devices, such as transistors. Active or passive implementations are used depending on the application, and there are advantages and disadvantages. As an example, a passive implementation that uses diodes as nonlinear elements or FETs as passive switches, exhibits a conversion loss rather than gain. This may impact the overall noise performance of the system, so in this case an LNA is usually added prior to the mixer.

Passive mixers are widely used due to their simplicity, wide bandwidth, and good intermodulation distortion (IMD) performance. Active mixers are mostly used for RFIC implementation. They are configured to provide conversion gain, good isolation between the signal ports, and require less power to drive the LO port. They can be monolithically integrated with other signal processing circuitry and are less sensitive to load-matching.

There are three basic types of active and passive mixers: unbalanced, single-balanced, and double-balanced.

Some mixer parameters that engineers will find in a datasheet are as follows:

- Conversion loss or gain: Measured in dB, conversion gain measures the signal gain in an active mixer, while conversion loss (known also as CL) measures the insertion loss in a passive mixer. Conversion gain is defined as the ratio of the IF output power to the RF input power. For passive mixers, CL is the most important parameter next to the noise figure. It is defined as the difference in power between the input RF power level and the desired output IF frequency power level. Of course, the lower the CL the better. Typical values of conversion loss range between 4.5 to 9 dB. Other losses that may occur are from transmission line losses, balun mismatch, diode series resistance, and mixer imbalance. In addition, the wider the frequency ranges for the three ports, the worse the CL.

- Input intercept point (IIP3): IIP3 is the RF input power at which the output power of the unwanted intermodulation products and the desired IF output would be equal.

- Spurious: Spurious external signals generate undesired frequencies that may fall into the IF-band. Spur tables provided by manufacturers show the relative amplitudes of each response under given LO drive conditions

- Isolation: This is defined as the amount of power leakage from one port to another. When isolation is high, the leakage between the ports will be small.

- Noise figure (NF): Defined as the added noise generated by the mixer and present at the IF output, the noise figure is the second important parameter (CL is the first) for the passive filter. For a passive mixer, the NF is almost equal to the loss.

- Dynamic range: This is the signal power range over which a mixer provides useful operation.

Selecting a mixer

Mixer selection depends on many factors and, most of all, on the requirements of an application. Determine the LO, RF, and IF frequency ranges involved as well as the LO drive required. Some applications require a specific amount of harmonic distortion. Finally, determine the type of packaging the mixer will have.

A wide selection of mixers can be found on the Digi-Key site. Below are a few examples.

Figure 3: Linear Technology LT5560.

Linear Technology offers the LT5560, a low-power high-performance broadband active mixer. This double-balanced mixer can be driven by a single-ended LO source and requires only –2 dBm of LO power. The balanced design results in low LO leakage to the output, while the integrated input amplifier provides excellent LO-to-IN isolation. The signal ports can be impedance-matched to a broad range of frequencies, which allows the LT5560 to be used as an upconversion or downconversion mixer in a wide variety of applications.

Figure 4: Maxim’s MAX2682 circuit.

The MAX2680/MAX2681/MAX2682 from Maxim Integrated Products are small, low-cost, low-noise downconverting mixers designed for low voltage operation and well-suited for use in portable communications equipment. Signals at the RF input port are mixed with signals at the LO port using a double-balanced mixer. These downconverter mixers operate with RF input frequencies between 400 MHz and 2,500 MHz, and downconvert to IF output frequencies between 10 and 500 MHz.

NXP Semiconductor offers the BGA2022 MMIC mixer that features a wide frequency range: Cellular band (900 MHz), PCS band (1,900 MHz), and WLAN band (2.4 GHz). Specifications (with reference to VS = 2.8 V; IS = 6 mA; PLO = 0 dBm; fRF = 1,800 MHz; fLO = 2080 MHz; fIF = 280MHz) include a high conversion gain of 6 dB typical, a noise figure (DSB) of 12 dB typical, and an output third order intercept point of 7 dBm.

Summary

The purpose of the mixer is to provide both the sum and difference frequency at the output port when two input frequencies are provided at the other two ports. The designer should fully understand all mixer properties to efficiently translate this frequency properly and without any distortions.

Frequency mixer

In electronics, a mixer, or frequency mixer, is a nonlinear electrical circuit that creates new frequencies from two signals applied to it. In its most common application, two signals are applied to a mixer, and it produces new signals at the sum and difference of the original frequencies. Other frequency components may also be produced in a practical frequency mixer.

Mixers are widely used to shift signals from one frequency range to another, a process known as heterodyning, for convenience in transmission or further signal processing. For example, a key component of a superheterodyne receiver is a mixer used to move received signals to a common intermediate frequency. Frequency mixers are also used to modulate a carrier signal in radio transmitters.

Frequency mixer symbol

Types

The essential characteristic of a mixer is that it produces a component in its output which is the product of the two input signals. A device that has a non-linear (e.g. exponential) characteristic can act as a mixer. Passive mixers use one or more diodes and rely on their non-linear relation between voltage and current to provide the multiplying element. In a passive mixer, the desired output signal is always of lower power than the input signals.

Active mixers use an amplifying device (such as a transistor or vacuum tube) to increase the strength of the product signal. Active mixers improve isolation between the ports, but may have higher noise and more power consumption. An active mixer can be less tolerant of overload.

Mixers may be built of discrete components, may be part of integrated circuits, or can be delivered as hybrid modules.

Mixers may also be classified by their topology:

- An unbalanced mixer, in addition to producing a product signal, allows both input signals to pass through and appear as components in the output.

- A single balanced mixer is arranged with one of its inputs applied to a balanced (differential) circuit so that either the local oscillator (LO) or signal input (RF) is suppressed at the output, but not both.

- A double balanced mixer has both its inputs applied to differential circuits, so that neither of the input signals and only the product signal appears at the output.[1] Double balanced mixers are more complex and require higher drive levels than unbalanced and single balanced designs.

Selection of a mixer type is a trade off for a particular application.

Mixer circuits are characterized by their properties such as conversion gain (or loss), and noise figure.

Nonlinear electronic components that are used as mixers include diodes, transistors biased near cutoff, and at lower frequencies, analog multipliers. Ferromagnetic-core inductors driven into saturation have also been used. In nonlinear optics, crystals with nonlinear characteristics are used to mix two frequencies of laser light to create optical heterodynes.

Diode

A diode can be used to create a simple unbalanced mixer. This type of mixer produces the original frequencies as well as their sum and their difference. The significant property of the diode here is its non-linearity (or non-Ohmic behavior), which means its response (current) is not proportional to its input (voltage). The diode does not reproduce the frequencies of its driving voltage in the current through it, which allows the desired frequency manipulation. The current I through an ideal diode as a function of the voltage V across it is given by

where what is important is that V appears in e's exponent. The exponential can be expanded as

and can be approximated for small x (that is, small voltages) by the first few terms of that series:

Suppose that the sum of the two input signals is applied to a diode, and that an output voltage is generated that is proportional to the current through the diode (perhaps by providing the voltage that is present across a resistor in series with the diode). Then, disregarding the constants in the diode equation, the output voltage will have the form

The first term on the right is the original two signals, as expected, followed by the square of the sum, which can be rewritten as , where the multiplied signal is obvious. The ellipsis represents all the higher powers of the sum which we assume to be negligible for small signals.

Suppose that two input sinusoids of different frequencies are fed into the diode, such that and . The signal becomes:

Expanding the square term yields:

Ignoring all terms except for the term and utilizing the prosthaphaeresis (product to sum) identity,

yields,

demonstrating how new frequencies are created from the mixer.

Switching

Another form of mixer operates by switching, with the smaller input signal being passed inverted or non inverted according to the phase of the local oscillator (LO). This would be typical of the normal operating mode of a packaged double balanced mixer, with the local oscillator drive considerably higher than the signal amplitude.

The aim of a switching mixer is to achieve linear operation over the signal level by means of hard switching driven by the local oscillator. Mathematically the switching mixer is not much different from a multiplying mixer, just because instead of the LO sine wave term we would use the signum function. In the frequency domain the switching mixer operation leads to the usual sum and difference frequencies, but also to further terms e.g. ±3fLO, ±5fLO, etc. The advantage of a switching mixer is that it can achieve (with the same effort) a lower noise figure (NF) and larger conversion gain. This is because the switching diodes or transistors act either like a small resistor (switch closed) or large resistor (switch open), and in both cases only a minimal noise is added. From the circuit perspective, many multiplying mixers can be used as switching mixers, just by increasing the LO amplitude. So RF engineers simply talk about mixers and mean switching mixers.

The mixer circuit can be used not only to shift the frequency of an input signal as in a receiver, but also as a product detector, modulator, phase detector or frequency multiplier. For example, a communications receiver might contain two mixer stages for conversion of the input signal to an intermediate frequency and another mixer employed as a detector for demodulation of the signal.

Product detector

A product detector is a type of demodulator used for AM and SSB signals. Rather than converting the envelope of the signal into the decoded waveform like an envelope detector, the product detector takes the product of the modulated signal and a local oscillator, hence the name. A product detector is a frequency mixer.

Product detectors can be designed to accept either IF or RF frequency inputs. A product detector which accepts an IF signal would be used as a demodulator block in a superheterodyne receiver, and a detector designed for RF can be combined with an RF amplifier and a low-pass filter into a direct-conversion receiver.

A simple product detector

The simplest form of product detector mixes (or heterodynes) the RF or IF signal with a locally derived carrier (the Beat Frequency Oscillator, or BFO) to produce an audio frequency copy of the original audio signal and a mixer product at twice the original RF or IF frequency. This high-frequency component can then be filtered out, leaving the original audio frequency signal.

Mathematical model of the simple product detector

If m(t) is the original message, the AM signal can be shown to be

Multiplying the AM signal x(t) by an oscillator at the same frequency as and in phase with the carrier yields

which can be re-written as

After filtering out the high-frequency component based around cos(2ωt) and the DC component C, the original message will be recovered.

Drawbacks of the simple product detector

Although this simple detector works, it has two major drawbacks:

- The frequency of the local oscillator must be the same as the frequency of the carrier, or else the output message will fade in and out in the case of AM, or be frequency shifted in the case of SSB

- Once the frequency is matched, the phase of carrier must be obtained, or else the demodulated message will be attenuated, but the noise will not be.

Frequency of an AM carrier can be accurately determined with a phase-locked loop, but for SSB, the only solution is to construct a highly stable oscillator.

Another example

There are many other kinds of product detectors as well, which are practical if one has access to digital signal processing equipment. For instance, it is possible to multiply the incoming signal by the carrier, times the square of another carrier 90° out of phase with it. This will produce a copy of the original message, and another AM signal at the fourth harmonic, by means of the trigonometric identity

The high-frequency component can again be filtered out, leaving the original signal.

Mathematical model of the detector

If m(t) is the original message, the AM signal can be shown to be

Multiplying the AM signal by the new set of frequencies yields

After filtering out the component based around cos(4ωt) and the DC component C, the original message will be recovered.

A more sophisticated product detector

A more sophisticated product detector can be constructed in a way much like a single-sideband modulator. Two copies of the modulated input signals are created. The first copy is mixed with a local oscillator and low-pass filtered. The second copy is mixed with a 90° phase-shifted copy of the oscillator and the output of this mixer is also 90° phase-shifted and then low-pass filtered. These copies are then combined to produce the original message. This operation is similar to that performed by a dual-phase lock-in amplifier. Example: I-Q Demodulator

Advantages and disadvantages

The product demodulator has some advantages over an envelope detector for AM signal reception.

- The product demodulator can decode overmodulated AM and AM with suppressed carrier.

- A signal demodulated with a product detector will have a higher signal to noise ratio than the same signal demodulated with an envelope detector.

On the other hand, the envelope detector is a simple and relatively inexpensive circuit, and it can provide higher fidelity, since there is no possibility of mistuning the local oscillator.

A product detector (or equivalent) is needed to demodulate SSB signals.

Optical heterodyne detection

Optical heterodyne detection is a method of extracting information encoded as modulation of the phase and/or frequency (wavelength) of electromagnetic radiation in the wavelength band of visible or infrared light. The light signal is compared with standard or reference light from a "local oscillator" (LO) that would have a fixed offset in frequency and phase from the signal if the latter carried null information. "Heterodyne" signifies more than one frequency, in contrast to the single frequency employed in homodyne detection.

The comparison of the two light signals is typically accomplished by combining them in a photodiode detector, which has a response that is linear in energy, and hence quadratic in amplitude of electromagnetic field. Typically, the two light frequencies are similar enough that their difference or beat frequency produced by the detector is in the radio or microwave band that can be conveniently processed by electronic means.

This technique became widely applicable to topographical and velocity-sensitive imaging with the invention in the 1990s of synthetic array heterodyne detection. The light reflected from a target scene is focussed on a relatively inexpensive photodetector consisting of a single large physical pixel, while a different LO frequency is also tightly focussed on each virtual pixel of this detector, resulting in an electrical signal from the detector carrying a mixture of beat frequencies that can be electronically isolated and distributed spatially to present an image of the scene.

Optical heterodyne detection began to be studied at least as early as 1962, within two years of the construction of the first laser.[3]

Contrast to conventional radio frequency (RF) heterodyne detection

It is instructive to contrast the practical aspects of optical band detection to Radio Frequency (RF) band heterodyne detection.

Energy versus electric field detection

Unlike RF band detection, optical frequencies oscillate too rapidly to directly measure and process the electric field electronically. Instead optical photons are (usually) detected by absorbing the photon's energy, thus only revealing the magnitude, and not by following the electric field phase. Hence the primary purpose of heterodyne mixing is to down shift the signal from the optical band to an electronically tractable frequency range.

In RF band detection, typically, the electromagnetic field drives oscillatory motion of electrons in an antenna; the captured EMF is subsequently electronically mixed with a local oscillator (LO) by any convenient non-linear circuit element with a quadratic term (most commonly a rectifier). In optical detection, the desired non-linearity is inherent in the photon absorption process itself. Conventional light detectors—so called "Square-law detectors"—respond to the photon energy to free bound electrons, and since the energy flux scales as the square of the electric field, so does the rate at which electrons are freed. A difference frequency only appears in the detector output current when both the LO and signal illuminate the detector at the same time, causing the square of their combined fields to have a cross term or "difference" frequency modulating the average rate at which free electrons are generated.

Wideband local oscillators for coherent detection

Another point of contrast is the expected bandwidth of the signal and local oscillator. Typically, an RF local oscillator is a pure frequency; pragmatically, "purity" means that a local oscillator's frequency bandwidth is much much less than the difference frequency. With optical signals, even with a laser, it is not simple to produce a reference frequency sufficiently pure to have either an instantaneous bandwidth or long term temporal stability that is less than a typical megahertz or kilohertz scale difference frequency. For this reason, the same source is often used to produce the LO and the signal so that their difference frequency can be kept constant even if the center frequency wanders.

As a result, the mathematics of squaring the sum of two pure tones, normally invoked to explain RF heterodyne detection, is an oversimplified model of optical heterodyne detection. Nevertheless, the intuitive pure-frequency heterodyne concept still holds perfectly for the wideband case provided that the signal and LO are mutually coherent. Indeed, one can obtain narrow-band interference from coherent broadband sources: this is the basis for white light interferometry and optical coherence tomography. Mutual coherence permits the rainbow in Newton's rings, and supernumerary rainbows.

Consequently, optical heterodyne detection is usually performed as interferometry where the LO and signal share a common origin, rather than, as in radio, a transmitter sending to a remote receiver. The remote receiver geometry is uncommon because generating a local oscillator signal that is coherent with a signal of independent origin is technologically difficult at optical frequencies. However, lasers of sufficiently narrow linewidth to allow the signal and LO to originate from different lasers do exist.[4]

Photon Counting

After optical heterodyne became an established technique, consideration was given to the conceptual basis for operation at such low signal light levels that "only a few, or even fractions of, photons enter the receiver in a characteristic time interval".[5] It was concluded that even when photons of different energies are absorbed at a countable rate by a detector at different (random) times, the detector can still produce a difference frequency. Hence light seems to have wave-like properties not only as it propagates through space, but also when it interacts with matter.[6] Progress with photon counting was such that by 2008 it was proposed that, even with larger signal strengths available, it could be advantageous to employ local oscillator power low enough to allow detection of the beat signal by photon counting. This was understood to have a main advantage of imaging with available and rapidly developing large-format multi-pixel counting photodetectors.

Photon counting was applied with frequency-modulated continuous wave (FMCW) lasers. Numerical algorithms were developed to optimize the statistical performance of the analysis of the data from photon counting.

Key benefits

Gain in the detection

The amplitude of the down-mixed difference frequency can be larger than the amplitude of the original signal itself. The difference frequency signal is proportional to the product of the amplitudes of the LO and signal electric fields. Thus the larger the LO amplitude, the larger the difference-frequency amplitude. Hence there is gain in the photon conversion process itself.

The first two terms are proportional to the average (DC) energy flux absorbed (or, equivalently, the average current in the case of photon counting). The third term is time varying and creates the sum and difference frequencies. In the optical regime the sum frequency will be too high to pass through the subsequent electronics. In many applications the signal is weaker than the LO, thus it can be seen that gain occurs because the energy flux in the difference frequency is greater than the DC energy flux of the signal by itself .

Preservation of optical phase

By itself, the signal beam's energy flux, , is DC and thus erases the phase associated with its optical frequency; Heterodyne detection allows this phase to be detected. If the optical phase of the signal beam shifts by an angle phi, then the phase of the electronic difference frequency shifts by exactly the same angle phi. More properly, to discuss an optical phase shift one needs to have a common time base reference. Typically the signal beam is derived from the same laser as the LO but shifted by some modulator in frequency. In other cases, the frequency shift may arise from reflection from a moving object. As long as the modulation source maintains a constant offset phase between the LO and signal source, any added optical phase shifts over time arising from external modification of the return signal are added to the phase of the difference frequency and thus are measurable.

Mapping optical frequencies to electronic frequencies allows sensitive measurements

As noted above, the difference frequency linewidth can be much smaller than the optical linewidth of the signal and LO signal, provided the two are mutually coherent. Thus small shifts in optical signal center-frequency can be measured: For example, Doppler lidar systems can discriminate wind velocities with a resolution better than 1 meter per second, which is less than a part in a billion Doppler shift in the optical frequency. Likewise small coherent phase shifts can be measured even for nominally incoherent broadband light, allowing optical coherence tomography to image micrometer-sized features. Because of this, an electronic filter can define an effective optical frequency bandpass that is narrower than any realizable wavelength filter operating on the light itself, and thereby enable background light rejection and hence the detection of weak signals.

Noise reduction to shot noise limit

As with any small signal amplification, it is most desirable to get gain as close as possible to the initial point of the signal interception: moving the gain ahead of any signal processing reduces the additive contributions of effects like resistor Johnson-Nyquist noise, or electrical noises in active circuits. In optical heterodyne detection, the mixing-gain happens directly in the physics of the initial photon absorption event, making this ideal. Additionally, to a first approximation, absorption is perfectly quadratic, in contrast to RF detection by a diode non-linearity.

One of the virtues of heterodyne detection is that the difference frequency is generally far removed spectrally from the potential noises radiated during the process of generating either the signal or the LO signal, thus the spectral region near the difference frequency may be relatively quiet. Hence, narrow electronic filtering near the difference frequency is highly effective at removing the remaining, generally broadband, noise sources.

The primary remaining source of noise is photon shot noise from the nominally constant DC level, which is typically dominated by the Local Oscillator (LO). Since the Shot noise scales as the amplitude of the LO electric field level, and the heterodyne gain also scales the same way, the ratio of the shot noise to the mixed signal is constant no matter how large the LO.

Thus in practice one increases the LO level, until the gain on the signal raises it above all other additive noise sources, leaving only the shot noise. In this limit, the signal to noise ratio is affected by the shot noise of the signal only (i.e. there is no noise contribution from the powerful LO because it divided out of the ratio). At that point there is no change in the signal to noise as the gain is raised further. (Of course, this is a highly idealized description; practical limits on the LO intensity matter in real detectors and an impure LO might carry some noise at the difference frequency)

Key problems and their solutions

Array detection and imaging

Array detection of light, i.e. detecting light in a large number of independent detector pixels, is common in digital camera image sensors. However, it tends to be quite difficult in heterodyne detection, since the signal of interest is oscillating (also called AC by analogy to circuits), often at millions of cycles per second or more. At the typical frame rates for image sensors, which are much slower, each pixel would integrate the total light received over many oscillation cycles, and this time-integration would destroy the signal of interest. Thus a heterodyne array must usually have parallel direct connections from every sensor pixel to separate electrical amplifiers, filters, and processing systems. This makes large, general purpose, heterodyne imaging systems prohibitively expensive. For example, simply attaching 1 million leads to a megapixel coherent array is a daunting challenge.

To solve this problem, synthetic array heterodyne detection (SAHD) was developed.[2] In SAHD, large imaging arrays can be multiplexed into virtual pixels on a single element detector with single readout lead, single electrical filter, and single recording system. The time domain conjugate of this approach is Fourier transform heterodyne detection,[11] which also has the multiplex advantage and also allows a single element detector to act like an imaging array. SAHD has been implemented as Rainbow heterodyne detection[12][13]in which instead of a single frequency LO, many narrowly spaced frequencies are spread out across the detector element surface like a rainbow. The physical position where each photon arrived is encoded in the resulting difference frequency itself, making a virtual 1D array on a single element detector. If the frequency comb is evenly spaced then, conveniently, the Fourier transform of the output waveform is the image itself. Arrays in 2D can be created as well, and since the arrays are virtual, the number of pixels, their size, and their individual gains can be adapted dynamically. The multiplex disadvantage is that the shot noise from all the pixels combine since they are not physically separated.

Speckle and diversity reception

As discussed, the LO and signal must be temporally coherent. They also need to be spatially coherent across the face of the detector or they will destructively interfere. In many usage scenarios the signal is reflected from optically rough surfaces or passes through optically turbulent media leading to wavefronts that are spatially incoherent. In laser scattering this is known as speckle.

In RF detection the antenna is rarely larger than the wavelength so all excited electrons move coherently within the antenna, whereas in optics the detector is usually much larger than the wavelength and thus can intercept a distorted phase front, resulting in destructive interference by out-of-phase photo-generated electrons within the detector.

While destructive interference dramatically reduces the signal level, the summed amplitude of a spatially incoherent mixture does not approach zero but rather the mean amplitude of a single speckle.[14] However, since the standard deviation of the coherent sum of the speckles is exactly equal to the mean speckle intensity, optical heterodyne detection of scrambled phase fronts can never measure the absolute light level with an error bar less than the size of the signal itself. This upper bound signal-to-noise ratio of unity is only for absolute magnitude measurement: it can have signal-to-noise ratio better than unity for phase, frequency or time-varying relative-amplitude measurements in a stationary speckle field.

In RF detection, "diversity reception" is often used when the primary antenna is coincidentally located at an interference null point: by having more than one antenna one can adaptively switch to whichever antenna has the strongest signal or even incoherently add all of the antenna signals. Simply adding the antennae coherently can produce destructive interference just as happens in the optical realm.

The analogous diversity reception for optical heterodyne has been demonstrated with arrays of photon-counting detectors.[7] For incoherent addition of the multiple element detectors in a random speckle field, the ratio of the mean to the standard deviation will scale as the square root of the number of independently measured speckles. This improved signal-to-noise ratio makes absolute amplitude measurements feasible in heterodyne detection.

However, as noted above, scaling physical arrays to large element counts is challenging for heterodyne detection due to the oscillating or even multi-frequency nature of the output signal. Instead, a single-element optical detector can also act like diversity receiver via synthetic array heterodyne detection or Fourier transform heterodyne detection. With a virtual array one can then either adaptively select just one of the LO frequencies, track a slowly moving bright speckle, or add them all in post-processing by the electronics.

Coherent temporal summation

One can incoherently add the magnitudes of a time series of N independent pulses to obtain a √N improvement in the signal to noise on the amplitude, but at the expense of losing the phase information. Instead coherent addition (adding the complex magnitude and phase) of multiple pulse waveforms would improve the signal to noise by a factor of N, not its square root, and preserve the phase information. The practical limitation is adjacent pulses from typical lasers have a minute frequency drift that translates to a large random phase shift in any long distance return signal, and thus just like the case for spatially scrambled-phase pixels, destructively interfere when added coherently. However, coherent addition of multiple pulses is possible with advanced laser systems that narrow the frequency drift far below the difference frequency (intermediate frequency). This technique has been demonstrated in multi-pulse coherent Doppler LIDAR .

XO__XO Electronic mixer

An electronic mixer is a device that combines two or more electrical or electronic signals into one or two composite output signals. There are two basic circuits that both use the term mixer, but they are very different types of circuits: additive mixers and multiplicative mixers.

Simple additive mixers use Kirchhoff's circuit laws to add the currents of two or more signals together, and this terminology ("mixer") is only used in the realm of audio electronics where audio mixers are used to add together audio signals such as voice signals, music signals, and sound effects.

Multiplicative mixers multiply together two time-varying input signals instantaneously (instant-by-instant). If the two input signals are both sinusoids of specified frequencies f1 and f2, then the output of the mixer will contain two new sinsoids that have the sum f1 + f2 frequency and the difference frequency absolute value |f1 - f2|.

Note: Any nonlinear electronic block driven by two signals with frequencies f1 and f2 would generate intermodulation (mixing) products. A multiplier (which is a nonlinear device) will generate ideally only the sum and difference frequencies, whereas an arbitrary nonlinear block would generate also signals at e.g. 2·f1-3·f2, etc. Therefore, normal nonlinear amplifiers or just single diodes have been used as mixers, instead of a more complex multiplier. A multiplier has usually the advantage of rejecting - at least partly - undesired higher-order intermodulations and larger conversion gain.

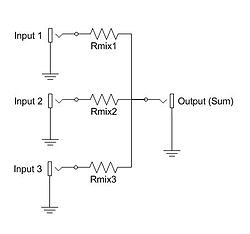

A simple three-channel passive additive mixer. More channels can be added by simply adding more input jacks and mix resistors.

Additive mixers

Mixing console

Additive mixers add two or more signals, giving out a composite signal that contains the frequency components of each of the source signals. The simplest additive mixers are simple resistor networks, and thus purely passive, while more complex matrix mixers employ active components such as buffer amplifiers for impedance matching and better isolation.

Multiplicative mixers

Ideal multiplicative mixers produce an output signal equal to the product of the two input signals. Multiplicative mixers are often used in conjunction with an oscillator in the communications field to modulate signal frequencies. Multiplicative mixers can be coupled with a filter to either up-convert or down-convert an input signal frequency, but they are more commonly used to down-convert to a lower frequency to allow for simpler filter designs, as done in superheterodyne receivers. In many typical circuits, the single output signal actually contains multiple waveforms, namely those at the sum and difference of the two input frequencies and harmonic waveforms. The output signal may be obtained by removing the other signal components with a filter. (see intermediate frequency)

Mathematical treatment

The received signal can be represented as

and that of the local oscillator can be represented as

For simplicity, assume that the output I of the detector is proportional to the square of the amplitude:

The output has high frequency (, and ) and constant components. In heterodyne detection, the high frequency components and usually the constant components are filtered out, leaving the intermediate (beat) frequency at . The amplitude of this last component is proportional to the amplitude of the signal radiation. With appropriate signal analysis the phase of the signal can be recovered as well.

If is equal to then the beat component is a recovered version of the original signal, with the amplitude equal to the product of and ; that is, the received signal is amplified by mixing with the local oscillator. This is the basis for a Direct conversion receiver.

Implementations

Multiplicative mixers have been implemented in a wide variety of ways. The most popular are Gilbert cell mixers, diode mixers, diode ring mixers (ring modulation) and switching mixers. Diode mixers take advantage of the non-linearity of diode devices to produce the desired multiplication in the squared term. It is a very inefficient method as most of the power output is in other unwanted terms which need filtering out. Inexpensive AM radios still use diode mixers.

Electronic mixers are usually made with transistors and/or diodes arranged in a balanced circuit or even a double-balanced circuit. These are readily manufactured by using the technology of either monolithic integrated circuits or hybrid integrated circuits. These are designed for a wide variety of frequency ranges, and they are mass-produced to tight tolerances by the hundreds of thousands, making them relatively cheap components.

These double-balanced mixers are very widely used in microwave communication systems, satellite communication systems, and ultrahigh frequency (UHF) communications transmitters and receivers, and in radar systems transmitters and receivers.

Gilbert cell mixers are just an arrangement of transistors that multiplies the two signals. The switching mixers (below) pass more power and usually insert less distortion.

switching mixers use arrays of field-effect transistors or (in older days) vacuum tubes. These are used as electronic switches, to permit the signal to go one direction, then the other. They are controlled by the signal being mixed. They are especially popular with digitally controlled radios.

What Mixers Are Used with PA Systems?

Mixers are items of equipment that arrange multiple input audio signals in a suitable balance, and they adjust tone quality so that the output audio is easy for the audience to listen to. There are many types and models of mixer.

Types of mixer

Mixers are broadly classified into three types, based on their internal structure.

(1) Analog mixers

Analog mixers adjust the volume and tone of input audio signals. Most of the control knobs and faders are arranged on the top panel, so it is easy to understand the signal flow and what state the audio is in. Operating analog mixers is normally an intuitive process.

(2) Digital mixers

Digital mixers process input audio signals and adjust their volume and tone using digital signal processing technology. Various kinds of tone control that would be impossible using analog equipment can be applied using digital processing. Digital mixers can store the positions of faders and knobs, and recall these positions in an instant. The faders and knobs perform various functions, so the unit itself remains compact, even if the number of channels increases. Generally a digital mixer will require more experience to set up effectively, but will offer far greater functionality than an analog mixer.

(3) Powered mixers

Powered mixers are analog mixers with built-in power amplifiers. For this reason, sound can be played with the mixer directly connected to speakers. In cases where the same equipment is always connected, powered mixers can be used by simply turning the power on, so operation is simplified and convenient.

Reference: All-in-one PA systems

All-in-one PA systems consist of a powered mixer, speakers and speaker cables. They are easy to configure, easy to carry due to their light and compact format, and suited to small events and band lineups.

Input channels

Number of microphone input and line input channels

The number of input channels in a mixer is extremely important, as this indicates the number of microphone and musical instrument signals that can be handled. In addition to the number of input channels in a mixer, it is also important to consider such factors as how many of those input channels are for microphones, whether line input channels are monaural only, and whether inputs will accept stereo signals.

For example, when using a mixer with a band, at least eight channels for input may be required for microphones to pick up the sound of the whole drum kit. In this case, a model that is equipped with enough channels that are compatible with microphones should be chosen.

For example, when using a mixer with a band, at least eight channels for input may be required for microphones to pick up the sound of the whole drum kit. In this case, a model that is equipped with enough channels that are compatible with microphones should be chosen.

A mixer with many stereo channels is useful for connecting multiple devices that output stereo signals, such as synthesizers. Likewise, a mixer that has built-in effectors, such as compressors or reverberation, is recommended for situations where audio such as vocals will be input. Finally, a mixer that is able to connect to a personal computer via USB is recommended for home studio applications.

Differences between microphone input and line input

- Microphone input channel

Audio signals picked up by a microphone are very weak, so they must be amplified by using the head amplifier (GAIN) of the mixer. Connect to the MIC connector.

Note: Phantom power (often labelled as "+48V") is required when using a condenser microphone.

Note: Phantom power (often labelled as "+48V") is required when using a condenser microphone.

- Line input channel

Line level devices such as keyboards and CD players are connected to the LINE connector.

Generally, phone connectors and RCA pin connectors are used in this case.

When both MIC and LINE inputs are available on same channel, use the LINE connector. When the same connector is used for both MIC and LINE, reduce the level by pushing the PAD button so that audio is not distorted (Remember line signals have a higher level than mic signals).

Tips

Sometimes a combination jack is used as both a microphone and a line connector. Activate the PAD when using a line input, to avoid distorting the louder signals.Mixer Functions

This section describes how to adjust the audio of each channel

(1) Equalizers

Mixers are equipped with equalizers that adjust the tone of each channel. Some equalizers have just 2-bands, which can adjust lows and highs. Some are 3-band equalizers, which modify the sound by boosting and cutting lows, mids, and highs. And some 3-band equalizers include a MID-sweep, which can modify the mid frequencies which characterize most musical instruments and voices. The more frequency bands there are, the more detailed the sound production can be.

| Knob | Characteristic | Affected sounds | Boost Effect | Cut Effect |

|---|---|---|---|---|

| HIGH | 10 kHz (+/- 15 dB) | High overtones exceeding the register of the instrument. | Crunchy, metallic echoing increases, and the tone becomes sharp. If boosted too much, will sound noisy. | Tones become smooth. "S" noise canceling is effective. If cut too much, high range transparency will be lost. |

| MID | 3 kHz (+/- 15 dB) | Instrument/vocals high registers | Sound becomes bright and hard. Sound becomes modulated and bright. If boosted too much, sound will become unpleasant. | Audio balance tends toward lows. If cut too much, audio will become dark. |

| 1 kHz (+/- 15 dB) | Instrument/vocals medium registers. | The outline of the audio can be made clear. Audio sounds as if it is projected forward. Emphasizes the attack of toms and bass drums. | Tones become rounded and pleasant. Sounds are more muffled and no longer stand out in the mix. | |

| 500 Hz (+/- 15 dB) | Instrument/vocals medium-low registers. | The sound becomes thicker and more powerful, and tonal balance tends toward lows. If boosted too much, the sound becomes unnatural, as if it were coming out of a telephone. | The sound becomes hard and has a feeling of attack. Tonal balance tends toward highs. If cut too much, the sound becomes thinner. | |

| LOW | 100 Hz (+/- 15 dB) | Instrument low registers. | The sound becomes rounder and deeper, giving it more strength and a sense of scale. If boosted too much, the sound becomes less crisp. | The sound takes on a lighter quality, improving its crispness. Floor noise or howl canceling is effective. |

(2) HPF (High Pass Filter)

The HPF cuts unnecessary low frequencies at the input. Most microphone and mic/line inputs have an HPF function, but some dedicated line inputs may not.

HPFs are often used for hi-hat, snare, and vocals to cut unnecessary low frequencies and therefore create a cleaner sound. They are also used to eliminate unwanted popping noises when picking up voices, such as during speeches.

(3) Pan

This adjusts the output ratio when playing audio from left and right speakers. It is used to widen the sound image, or to position each input relative to their location on the stage. Audio for stereo channels is already set in the stereo image, so a BAL control is used to adjust the balance between the left and right speakers.

(4) Level Faders/knobs

These adjust the volume of each channel, group, stereo output, etc. Fader-type controls allow for quick operation. Though some mixers use knob-type volume controllers.

How to output audio from the mixer?

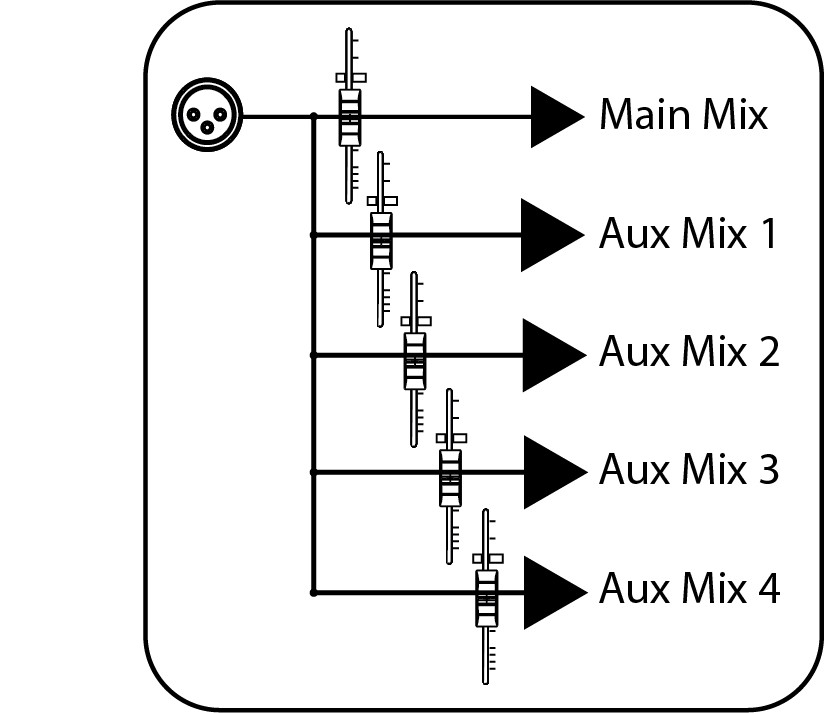

Mixers can output various separate channels of audio, depending on the needs of the event, such as sending audio meant for the audience to the main speakers and audio meant for the performers to the monitor speakers on stage:

STEREO OUT is normally used to send signals to the audience; AUX SENDs for performers' monitor speakers and external devices; MONITOR OUT is for monitor speakers used when mixing audio in the studio; GROUP OUT for outputting several signals together; REC OUT for connecting with recording devices; and PHONES for connecting headphones.

STEREO OUT is normally used to send signals to the audience; AUX SENDs for performers' monitor speakers and external devices; MONITOR OUT is for monitor speakers used when mixing audio in the studio; GROUP OUT for outputting several signals together; REC OUT for connecting with recording devices; and PHONES for connecting headphones.

(1) AUX bus

The AUX bus is a circuit used to send signals to external devices. It can be used to send signals to performers' monitor speakers separately from the main output, or to send signals to external effects and recording devices. A mixer with many AUX sends should be chosen if there are many people in the band or if separate monitor signals with individual balances need to be sent to the performers.

(2) GROUP bus

The GROUP bus is a circuit for controlling multiple channels at once. For example, if there are eight microphones (for eight channels) placed around a drum set and you want to raise or lower the volume of the entire set, it would be difficult to accurately raise or lower the faders for all eight channels. If these channels are all set to a single group, the volume of the entire drum set can be raised or lowered, while maintaining the same balance, merely by raising or lowering the fader for the group.

(3) STEREO bus

The STEREO bus is a circuit for combining each input coming into the mixer or each GROUP bus signal, adjusting the overall level, and outputting the audio through stereo output connectors.

Sample Function Mixer : Music Electronic

This document is intended for A-100 users who want to learn a little bit about the technical details of the A-100. We will start with some electronic basics and introduce at first the most important electronic parts used in the A-100 circuits. Then we will show how some basic circuits (like attenuators, amplifiers, mixers, inverters and so on) can be realized with these parts. The following paragraph will show some simple modifications of A-100 modules: e.g. changing the sensitivity of CV or audio inputs, increasing or decreasing output levels (e.g. VCAs or mixers with maximum amplification > 1), adding offset feature to mixers, changing between DC and AC coupled inputs/outputs, adding feedback inserts for VC resonance to all filters and many more.

This page starts September 2004. New items will be added little by little. If you have any suggestion for this page please send your ideas to hardware@doepfer.de. We will try to fulfil all wishes, providing they are possible and will not contain confidential information.

Additional information about technical details (e.g. CV/gate control principles, A-100 bus, A-100 power supply) and mechanical details (frontpanel measures, A-100 frame concept) is available in these documents:

The A-100 service manual is available only for A-100 customers (see price list for current price). The words - mainly building, testing and adjustment notes for the manufacturer - are in German but the schematics, silk screen and bill of material are international.

Other pages of interest for DIY:

| |||||||

1. Electronic Parts

(For some parts different signs are shown. Normally the left one is used in USA or Japan, the right one in Germany or Europe) | |||||||

Fixed resistors

A resistor is determinded by these parameters:

In the A-100 normally only resistors with 1/4W (250mW) and 5%, 1% or 0.1% tolerance are used. For the value and tolerance of a resistor normally a color code is used (should we add the color code at this place ?).

| |||||||

Potentiometers

Potentiometers are available as rotary potentiometers or fader types. Normally, a potentiometer has 3 terminals: two end terminals and a slider terminal (upper picture). The slider touches a resistance surface that is located between the end terminals. Sometimes the second end terminal is not shown (lower picture) if only one end terminal is required, e.g. if the part works only as a variable resistor rather than a voltage divider.

A potentiometer is determined by these parameters:

The characteristics - sometimes even called law - is a very important parameter of a potentiometer. This parameter describes the connection between the rotary angle (resp. fader position for fader potentiometers) and the resistance value between terminal 1 and slider terminal. Typical characteristics are linear, logarithmic and inverse logarithmic. Sometimes special characteristics are used (e.g. S-type law) but these are not very common. For audio attenuation normally logarithmic potentiometers are used as the human ear senses the loudness of an audio signal in a logarithmic way too. The same applies to potentiometers that are used to control time parameters (e.g. attack/decay/release time of an envelope generator). For attenuation of control signals normally linear potentiometers are used. For special functions inverse logarithmic potentiometers are used (e.g. resonance/emphasis control in filter circuits).

Another special type is a stereo potentiometer: two potentiometers with one common axis. The values for the two potentiometers vary in the same way. Used e.g. for manually controlled filters or stereo applications. Other special types of potentiometers are not described here (e.g. dual potentiometers with 2 concentric axis, or potentiometers with additional terminals) as they are not used in the A-100.

A very special circuit is a so-called vactrol. This is a combination of a light depending resistor (LDR) and LED both put into a small 100% light-proof case. For details please refer to the vactrol document.

The above pictures shows the type of potentiometers used in the A-100 system. These potentiometers are equipped with a mounting bracket that increases the mechanical stability. For most of the A-100 modules the potentiometers (together with the sockets) are used to mount the pc boards to the front panels.

The A-100 potentiometers are available as spare parts with these values: 10K (A and B), 50K (A, B and C), 500k (B), 1M (A and B) with A = logarithmic (audio type), B = linear and C = inverse logarithmic (ususally for filter resonance controls used). For prices please look at the price list. | |||||||

Trimming potentiometers

The electronic function of a "normal" potentiometer and a trimming potentiometer is the same. The only difference is the mechanical appearance: trimming potentiometers are normally much smaller and have a very short axis that is adjusted with a screw driver. Trimming potentiometers are used to adjust parameters that have to bet set once at the factory and that are normally not controlled by the user (e.g. offset frequency and scale of a VCO, maximum/minimum limitation of values, adjustment of click/pop feedthrough of sound processing devices like VCA, VCF, ring modulator, frequency shifters and so on). Sometimes users replace trimming potentiometers with normal ones to have access to such additional parameters.

Trimming potentiometers are available normally only linear. Apart from that they are defined by the same parameters as normal potentiometers. | |||||||

Capacitors

A capacitor is determinded by these parameters:

In the A-100 all types of capacitors are used. Value, voltage and tolerance are normally written as normal characters on the component (e.g. 4n7 63V). But even color codes and number codes are used (e.g. 103 means 10x1000=10000). Sometimes it is difficult to find the value of a capacitor. E.g. "100" without additional pF/nF could mean 100pF or 100nF. Some experience is required to find out the correct value if the declaration on the component is not readable, or complete. To be certain of a capacitors value, one could use a capacitor measuring instrument such as a multimeter with capacitor measuring option.

So-called electrolytic capacitors are used for values of 1uF and more as the other types of capacitors would be too large. Normally electrolytic capacitors are polarized (i.e. one has to pay attention to positive and negative terminal of the part). If there are "+" or "-" signs in a schematic this means that an electrolytic capacitor is used. The three examples on the left with "+" and "-" signs denote an electrolytic capacitor.

Other types of capacitors (e.g. variable capacitors) are not used in the A-100.

| |||||||

Diodes

Electronic part that works as one-way for electric current. The triangle terminal (left) of the symbol is the positive side (or anode), the single vertical line (right) is the negative terminal (or cathode). Used e.g. for clipping, rectifying or overvoltage protection. Even light emitting versions (LED) available in different colors (red, green, yellow, orange, blue, white). In this case the brightness is approximately proportional to the current.

A very special circuit is a so-called vactrol. This is a combination of a light depending resistor (LDR) and LED both put into a small 100% light-proof case. For details please refer to the vactrol document.

| |||||||

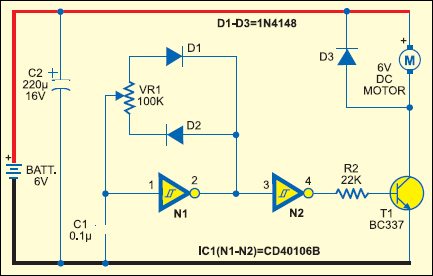

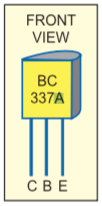

Transistors

Different types of transistors are available, e.g. bipolar npn or pnp, field effect (FET). A transistor can be used with the suitable circuit (i.e. with additional resistors and capacitors) e.g. as amplifier, switch or current source.

| |||||||

Operational Amplifiers

Operational amplifiers are special integrated circuits that make available a standard amplifier with 2 inputs (inverting and non-inverting input) and high amplification (typ. > 1000). Circuits with one, two or more opamps (abbreviation for operational amplifier) are available. The following table shows the pin-out of the most popular types of single, dual and quad opamps.

The power supply pins (marked with the "+" and "-" triangles) of the integrated circuit in question have to be connected to +12V and -12V for A-100 applications. In schematics the power supply pins of opamps are often omitted. The left opamp symbol includes the power supply pins. The right symbol is without the power supply pins.

Unused OpAmps (if e.g. only 3 devices of a quad opamp are used) have to be terminated in this way: non-inverting input has to be connected to GND, inverting input and output have to be connected (directly or even via resistor in the 1k...100k range). | |||||||

Switches

A lot of different switches are available. There exist different distinguishing marks, e.g.:

The pictures show from top to bottom the symbols for a simple on/off switch (SPDT with one ON contact only) , a change-over switch (SPDT with two ON contacts), a rotary switch with 3 positions, a change-over switch with middle position (SPDT with ON-OFF-ON) and a rotary switch witch 5 positions.

| |||||||

Jack sockets

Standard sockets used in the A-100 for all inputs and outputs. Provided that a plug is inserted into the socket the GND and tip terminals of the plug are connected to the corresponding terminals of the socket. The tip is normally the "hot" pin, i.e. the terminal leading the CV resp. audio signal. The sockets are equipped with switching contacts (the arrow in the symbol). Both the GND and tip terminal are switched but only the switching feature of the tip terminal is used in some A-100 modules. Provided that no plug is inserted into the socket the switched tip contact (arrow terminal in the left symbol) is connected to the "normal" tip contact (the terminal represented by the horizontal line in the left symbol). As soon as a plug is inserted this connection is interrupted and the signal at the tip of the plug is connected to the tip terminal of the socket. This feature can be used for default connections (i.e. connection within a module that is established provided that no plug is inserted into the corresponding socket). Example: internal default connections of the A-109 signal processor. This function is often called "normalling" or "normalizing".

The above pictures show the type of jack sockets used in the A-100 system. For most of the A-100 modules the sockets (together with the potentiometers) are used to mount the pc boards to the front panels. The A-100 sockets are available as spare parts. For prices please look at the price list.

| |||||||

Power Supply

For each circuit, a power supply is required. The three symbols to the left side denote +12V, -12V and GND. Some circuits may require no power supply (e.g. multiples or the simple attenuator below) or only a positive supply. All circuits that use operational amplifiers require all three +12V, GND and -12V. Some modules even require +5V (mainly "digital" modules with digital circuits - like microprocessors, memories, or logic circuits - which often require a +5V power supply).

| |||||||

2. Basic circuits

| |

Simple attenuator

This is a simple passive attenuator (i.e. no power supply required). J1 is the input socket, J2 the output socket. A typical value for P2 is 10k...100k. A linear or logarithmic type can be used for P2 (logarithmic especially for audio applications as the loudness characteristics of the human ear is approx. logarithmic).

| |

Simple lowpass

This is a simple passive lowpass with 6dB/octave slope. A non-inverting amplifier can be added at the output (and even at the input) to make the circuit independent of input/output impedance (i.e. the "loads" connected to J1 resp. J2). Replacing of R1 by a vactrol leads to simple voltage controlled lowpass filter. Replacing R1 by a potentiometer leads to a simple manually controlled lowpass filter

Frequency of the lowpass: f = 1/(2 * Pi * R1 * C1) with Pi = 3.14

Example: R1 = 47kOhm, C1 = 10nF -> f ~ 340 Hz | |

Simple highpass

This is a simple passive highpass with 6dB/octave slope. A non-inverting amplifier can be added at the output (and even at the input) to make the circuit independent of input/output impedance (i.e. the "loads" connected to J1 resp. J2). Replacing of R1 by a vactrol leads to simple voltage controlled highpass filter. Replacing R1 by a potentiometer leads to a simple manually controlled highpass filter

Frequency of the highpass: f = 1/(2 * Pi * R1 * C1) with Pi = 3.14

Example: R1 = 10k, C1 = 2,2n -> f ~ 7.2 kHz | |

Non-inverting amplifier

This is a simple non-inverting amplifier: The term "non inverting" means that the polarity of input and output signal are the same. In other words: a positive input signal applied to J1 will cause a positive output signal at J2 and a negative input signal applied to J1 will cause a negative output signal at J2.

The amplification of this circuit is 1 + R1/R2.

Example 1: R1 = 0 Ohm (connection), R2 omitted -> A = 1 Example 2: R1 = 47k, R2 = 47k -> A = 2 Example 3: R1 = 100k, R2 = 10k -> A = 11

If R1 or R2 is replaced by a potentiometer the amplification can be adjusted. If e.g. R1 in the last example is replaced by a 100k potentiometer the amplification is adjustable in the range 1...11. This circuit can be used to built an simple amplifier if the desired audio or CV signal is too small for a certain application.

Attention ! The minimum amplification of this circuit is 1 (no real attenuation possible provided that no external attenuator is used).

| |

Inverting amplifier

This is a simple inverting amplifier: The term "inverting" means that the polarity of input and output signal are opposite. In other words: a positive input signal applied to J1 will cause a negative output signal at J2 and a negative input signal applied to J1 will cause a positive output signal at J2.

The amplification of this circuit is - R2/R1 (" - " indicates the opposite polarity of input and output)

Example 1: R1 = R2 = 47k -> A = - 1 Example 2: R1 = 10k, R2 = 100k -> A = - 10 If R2 is replaced by a potentiometer the amplification can be adjusted. If e.g. R2 in the last example is replaced by a 100k potentiometer the amplification is adjustable in the range 0...-10. This circuit can be used to built an simple (inverting !) amplifier if the desired audio or CV signal is too small for a certain application.

The minimum amplification of this circuit is zero (if R2 = 0). To obtain a non-inverted output another inverting amplifier with amplification - 1 has to be used.

The inverting amplifier can be extended by adding more input sockets (J1) and corresponding input resistors (R1). The right terminals of all input resistors are connected to the inverting input (-) of the operational amplifier O1. The relation between the corresponding input resistor R1 and R2 (the same for all inputs) defines the sensitivity of the input in question. If all resistors have the same value (e.g. 100 kOhm) the amplification is "1" for all inputs. Lowering R1 (e.g. 47k or 22k) increases the sensitivity of the input in question. Increasing R2 (e.g. 220k or 1M) increases the amplification resp. sensitivity for all inputs simultaneously.The minus terminal of the operational amplifier is often called "virtual GND" in this circuit as the voltage measured at this point is very close to GND within a few millivolts - independent of the incoming voltages!

The first circuit example (chapter 3: "CV mixer with offset function") shows a typical application of inverting amplifiers with several inputs.

| |

Voltage clamping / limiting / clipping

This is a circuit that limits an incoming voltage to the range U1-UD2 ... U2+UD1. The voltage U1 has to be less than U2. UD1 and UD2 are the forward voltages of the diodes D1 and D2. To keep these voltages as small as possible Schottky diodes (e.g. BAT42) ore germanium diodes are recommended because their forward voltages are in the 0.2...0.3V range. R works as a serial protection resistor. A typical value for R is 1k.

A typical application is the limitation of an analog voltage to 0...+5V (e.g. for the inputs of Pocket Electronic or USB64). In this case U1 is connected to GND and U2 to +5V.

Another application is sound distortion by voltage clipping. If U1 and U2 are variable voltages (e.g. outputs of operational amplifiers of one of the circuits in this document) the clipping levels can be voltage controlled too.

| |

3. Circuit examples

| |||||

| |||||

| |||||

| |||||

| |||||

| |||||

| |||||

4. Module modifications

| |

| 4.1. General modifications (not for one module only) | |

| 4.1.1. Changing the sensitivity of manual controls, control voltage inputs and audio inputs | |

| The following picture shows the control voltage input circuit for most of the A-100 modules: | |

P1 is the manual control of the corresponding parameter (e.g. tune for a VCO, frequency for a VCF, manual gain for a VCA, manual phase shift for a phaser and so on). P1 generates the voltage U1.

J1 is the (first) input socket for the external control voltage. P2 is the corresponding attenuator. The slider of P2 outputs the voltage U2. Additional CV inputs with our without attenuators may be available (e.g. two or more CV inputs for frequency control for a VCF). The dashed line in the picture is the common point in the circuit where all CV's are added. The output voltage of the circuit (output of O1) is used to control the corresponding parameter (tune, filter frequency, gain ...) of the module in question. The output voltage is defined by:

The relations R3/R1 resp. R3/R2 determine the sensitivity of the corresponding control (P1) resp. input (J1/P2). If for example all resistors are 47k (a common value in the A-100) the sensitivity is 1 for each input. Provided that R3 remains unchanged the resistors R1 and R2 determine the sensitivity of the corresponding control resp. input. Reducing the resistance of R1 resp. R2 increases the sensitivity of the manual control (P1) resp. input (J1/P2). Increasing the resistance of R1 resp. R2 reduces the sensitivity. To modify the sensitivity of a control knob (P1) or CV input (J1/P2) the corresponding resistor R1 resp. R2 simply has to be changed.

Changing the resistance of R3 has the opposite effect and affects the sensivity of both the manual control and CV input. | |

| The audio input circuit for most A-100 modules is similar but the manual control P1 is absent (a DC offset would not make sense for an audio input, audio signals are AC signals). Normally only one audio input is available but there are exceptions (e.g. VCA A-130 and A-131, signal processor A-109). To change the sensitivity of an audio input simply the resistor R2 connected to the slider P2 of the audio input has to be replace. A smaller value will increase the sensitivity and consequently lead to clipping/distortion for higher input levels. Especially for the first A-100 VCFs and VCAs (A-120, A-121, A-122 and first versions of A-130, A-131) the audio inputs have been designed to avoid distortion with standard A-100 signals (e.g. VCO). Lowering the input resistors will allow distortion for these moduls too.Even the input resistors of CV or audio mixers (e.g. A-138a/b) can be changed to allow "real" amplification (i.e. > 1). The factory values of the resistors in the mixer modules A-138a/b allow a maximum amplification of about 1 (which is not really amplification). Reducing the input resistors (R2 type) or increasing the feedback resistor (R3 type) will increase the amplification of the circuit. The factory values of the corresponding resistors (R1, R2, R3) for all modules can be found in the A-100 service manual. Normally they are in the 100k range (~ 47k...220k). | |

| 4.1.2. Insert sockets for external resonance control of filters, phasers and similar modules | |

| To enable voltage control of resonance for filters insert sockets in the feedback loop can be used. | |

The left picture shows the resonance control in a filter or phaser circuit. Essentially it is an attenuator that controls the feedback of the circuit. To enable external control of the resonance external access to the feedback loop is recessary.

For resonance control normally C-law potentiometers are used (i.e. inverse logarithmic, e.g. 47kC). | |

This is the first solution how to install the insert sockets (pre resonance control). J1 is connected to the slider of the resonance control. Provided that no plug is inserted into J2 the function of the module is unchanged as the switching contact of J2 is active.

As soon as a plug is inserted into J2 the default connection is interrupted and the signal fed to J2 is used as feedback signal. Consequently J1 and J2 can be used to insert e.g. an external VCA to control the resonance. J1 has to be connected to the audio input of the VCA, J2 to the audio output of the VCA. The resonance control can be used to adjust the maximum resonance available with different gain settings of the external VCA. But not only a VCA but any audio processing module can be inserted into the feedback loop (e.g. phaser, spring reverb, waveshaper, limiter, wave multiplier, divider, ring modulator, frequency shifter, or even another filter).

| |

This is another solution how to install the insert sockets (post resonance control).

The location of the resonance control at the pc board for all modules in question can be found in the A-100 service manual.

| |

| 4.1.3. Changing between AC and DC coupling | ||||

There are two types of coupling between electronic circuits:

Example: minimum frequency = 50Hz, in/output resistance = 10kOhm -> C ~ 2 uF (u = micro = 1/1000000). A usual value would be 2.2uF in this example. AC coupling is normally used for audio signals. For audio signals AC coupling has the advantage that unwanted DC shares in the signal are removed. For some AC processing circuits (e.g. amplifiers, filters) DC voltages are not allowed in the input signal. Therefore very often a capacitor can be found in the input stage of such circuits. DC coupling means that both DC and AC parts of a signal are transmitted. For control voltages (normally) only DC coupling can be used as even fixed voltages (e.g. coming from a manual control) have to be transmitted. In a module patch each A-100 module can be treated as an electronic circuit that is connected to another one. Consequently one has to take into consideration the type of coupling (AC or DC) between modules as the strict differentiation between AC and DC applications os softened for some A-100 modules. E.g. a VCA can be used to process audio signals (i.e. normally AC coupled signals) as well as slowly changing CV voltages (e.g. envelope or modulation amount). Therefore one needs to know if a VCA used is AC or DC coupled. Another example is a divider (e.g. A-115 or A-163) as even these module can be used to process audio or (slow) clock/gate signals. | ||||

Luckily it is not very complicated to switch between AC and DC coupling. All one has to do is to bride (i.e. short circuit) the capacitor in case of an AC coupled in/output. The left picture shows how the switch is connected in parallel to the AC coupling capacitor (the broken line resistor symbol represents the load to GND that is always available in each circuit as reference to GND). If AC coupling is required for a DC coupled in/output simply a capacitor has to be added.

From the schematics it can be seen if an in/output is AC or DC coupled. We will add this information also to the user's manual for modules that may be used for both types of coupling.

For some circuits resp. modules changing from AC to DC coupling is not possible. E.g. the "old" VCAs A-130 and A-131 (those with CEM3381 or CEM3382) are AC coupled as the special CEM circuits cannot be DC coupled because of the internal negative reference voltage. The "new" VCAs A-130 and A-131 (those with CA3080) are DC coupled and can be used to process CV signals too.

A list with the type of coupling for all modules in question will follow soon. For most of the modules the question about the type of coupling does not arise. E.g. all filters are AC coupled and all CV generating and processing modules (e.g. ADSR, LFO, slew limiter, Theremin, Ribbon controller, random voltage) are DC coupled. But for other modules the type of coupling is not obvious (e.g. VCA, divider, waveshaper).

| ||||

| 4.1.4. Subsequent bus normalling of modules | ||||

Only the modules A-110 (Standard VCO), A-111 (High end VCO), A-140 (ADSR), A-185 (Bus Access) and A-190 (Midi Interface) have access to the CV and Gate signal of the A-100 bus. A-185 and A-190 are used to "write" the bus, i.e. they output the signals to the bus. A-110, A-111 and A-140 are able to "read" the bus, i.e. they pick up the signals CV (A-110, A-111) resp. Gate (A-140) from the bus. For details please refer to the user manuals of these modules. If other modules should be able to "write" or "read" the bus the module in question has to be modified.Examples:

| ||||

| ||||

| ||||

| 4.1.5. Subsequent socket normalling of modules | ||||

| coming soon ....(how to make use of unused switching contacts of sockets for module pre-patching) | ||||

| 4.2. Specific modifications for certain modulesImportant note: Warranty is void if these modifications are carried out by the customer ! | |

| 4.2.1. A-128 filter bank modification: single outputs | |

| This document shows how to add single outputs to the filter bank A-128 | |

| 4.2.2. A-136 Modification: bypassing the internal pre-amplifier | |