Belt (mechanical)

A belt is a loop of flexible material used to link two or more rotating shafts mechanically, most often parallel. Belts may be used as a source of motion, to transmit power efficiently or to track relative movement. Belts are looped over pulleys and may have a twist between the pulleys, and the shafts need not be parallel.

In a two pulley system, the belt can either drive the pulleys normally in one direction (the same if on parallel shafts), or the belt may be crossed, so that the direction of the driven shaft is reversed (the opposite direction to the driver if on parallel shafts). As a source of motion, a conveyor belt is one application where the belt is adapted to carry a load continuously between two points.

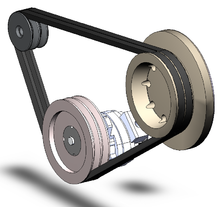

A pair of v-belts

A pair of v-belts flat belt

flat belt

The mechanical belt drive, using a pulley machine, was first mentioned in the text the Dictionary of Local Expressions by the Han Dynasty philosopher, poet, and politician Yang Xiong (53–18 BC) in 15 BC, used for a quilling machine that wound silk fibers on to bobbins for weavers' shuttles.[1] The belt drive is an essential component to the invention of the spinning wheel.The belt drive was not only used in textile technologies, it was also applied to hydraulic powered bellows dated from the 1st century AD .

Power transmission[edit]

Belts are the cheapest utility for power transmission between shafts that may not be axially aligned. Power transmission is achieved by specially designed belts and pulleys. The demands on a belt-drive transmission system are huge, and this has led to many variations on the theme. They run smoothly and with little noise, and cushion motor and bearings against load changes, albeit with less strength than gears or chains. However, improvements in belt engineering allow use of belts in systems that only formerly allowed chains or gears.

Power transmitted between a belt and a pulley is expressed as the product of difference of tension and belt velocity:

where, T1 and T2 are tensions in the tight side and slack side of the belt respectively. They are related as

where, μ is the coefficient of friction, and α is the angle (in radians) subtended by contact surface at the centre of the pulley.

Pros and cons

Belt drives are simple, inexpensive, and do not require axially aligned shafts. They help protect machinery from overload and jam, and damp and isolate noise and vibration. Load fluctuations are shock-absorbed (cushioned). They need no lubrication and minimal maintenance. They have high efficiency (90–98%, usually 95%), high tolerance for misalignment, and are of relatively low cost if the shafts are far apart. Clutch action is activated by releasing belt tension. Different speeds can be obtained by stepped or tapered pulleys.

The angular-velocity ratio may not be constant or equal to that of the pulley diameters, due to slip and stretch. However, this problem has been largely solved by the use of toothed belts. Working temperatures range from −31 °F (−35 °C) to 185 °F (85 °C). Adjustment of center distance or addition of an idler pulley is crucial to compensate for wear and stretch.

Flat belts

Flat belts were widely used in the 19th and early 20th centuries in line shafting to transmit power in factories.[4] They were also used in countless farming, mining, and logging applications, such as bucksaws, sawmills, threshers, silo blowers, conveyors for filling corn cribs or haylofts, balers, water pumps (for wells, mines, or swampy farm fields), and electrical generators. Flat belts are still used today, although not nearly as much as in the line-shaft era. The flat belt is a simple system of power transmission that was well suited for its day. It can deliver high power at high speeds (500 hp at 10,000 ft/min, or 373 kW at 51 m/s), in cases of wide belts and large pulleys. But these wide-belt-large-pulley drives are bulky, consuming lots of space while requiring high tension, leading to high loads, and are poorly suited to close-centers applications, so V-belts have mainly replaced flat belts for short-distance power transmission; and longer-distance power transmission is typically no longer done with belts at all. For example, factory machines now tend to have individual electric motors.

Because flat belts tend to climb towards the higher side of the pulley, pulleys were made with a slightly convex or "crowned" surface (rather than flat) to allow the belt to self-center as it runs. Flat belts also tend to slip on the pulley face when heavy loads are applied, and many proprietary belt dressings were available that could be applied to the belts to increase friction, and so power transmission.

Flat belts were traditionally made of leather or fabric. Today most are made of rubber or synthetic polymers. Grip of leather belts is often better if they are assembled with the hair side (outer side) of the leather against the pulley, although some belts are instead given a half-twist before joining the ends (forming a Möbius strip), so that wear can be evenly distributed on both sides of the belt. Belts ends are joined by lacing the ends together with leather thonging (the oldest of the methods),[5][6] steel comb fasteners and/or lacing,[7] or by gluing or welding (in the case of polyurethane or polyester). Flat belts were traditionally jointed, and still usually are, but they can also be made with endless construction.

Rope drives

In the mid 19th century, British millwrights discovered that multi-grooved pulleys connected by ropes outperformed flat pulleys connected by leather belts. Wire ropes were occasionally used, but cotton, hemp, manila hemp and flax rope saw the widest use. Typically, the rope connecting two pulleys with multiple V-grooves was spliced into a single loop that traveled along a helical path before being returned to its starting position by an idler pulley that also served to maintain the tension on the rope. Sometimes, a single rope was used to transfer power from one multiple-groove drive pulley to several single- or multiple-groove driven pulleys in this way.

In general, as with flat belts, rope drives were used for connections from stationary engines to the jack shafts and line shafts of mills, and sometimes from line shafts to driven machinery. Unlike leather belts, however, rope drives were sometimes used to transmit power over relatively long distances. Over long distances, intermediate sheaves were used to support the "flying rope", and in the late 19th century, this was considered quite efficient.

Round belts

Round belts are a circular cross section belt designed to run in a pulley with a 60 degree V-groove. Round grooves are only suitable for idler pulleys that guide the belt, or when (soft) O-ring type belts are used. The V-groove transmits torque through a wedging action, thus increasing friction. Nevertheless, round belts are for use in relatively low torque situations only and may be purchased in various lengths or cut to length and joined, either by a staple, a metallic connector (in the case of hollow plastic), gluing or welding (in the case of polyurethane). Early sewing machines utilized a leather belt, joined either by a metal staple or glued, to great effect.

V belts

V belts (also style V-belts, vee belts, or, less commonly, wedge rope) solved the slippage and alignment problem. It is now the basic belt for power transmission. They provide the best combination of traction, speed of movement, load of the bearings, and long service life. They are generally endless, and their general cross-section shape is roughly trapezoidal (hence the name "V"). The "V" shape of the belt tracks in a mating groove in the pulley (or sheave), with the result that the belt cannot slip off. The belt also tends to wedge into the groove as the load increases—the greater the load, the greater the wedging action—improving torque transmission and making the V-belt an effective solution, needing less width and tension than flat belts. V-belts trump flat belts with their small center distances and high reduction ratios. The preferred center distance is larger than the largest pulley diameter, but less than three times the sum of both pulleys. Optimal speed range is 1,000–7,000 ft/min (300–2,130 m/min). V-belts need larger pulleys for their thicker cross-section than flat belts.

For high-power requirements, two or more V-belts can be joined side-by-side in an arrangement called a multi-V, running on matching multi-groove sheaves. This is known as a multiple-V-belt drive (or sometimes a "classical V-belt drive").

V-belts may be homogeneously rubber or polymer throughout, or there may be fibers embedded in the rubber or polymer for strength and reinforcement. The fibers may be of textile materials such as cotton, polyamide (such as Nylon) or polyester or, for greatest strength, of steel or aramid (such as Technora, Twaron or Kevlar).

When an endless belt does not fit the need, jointed and link V-belts may be employed. Most models offer the same power and speed ratings as equivalently-sized endless belts and do not require special pulleys to operate. A link v-belt is a number of polyurethane/polyester composite links held together, either by themselves, such as Fenner Drives' PowerTwist, or Nu-T-Link (with metal studs). These provide easy installation and superior environmental resistance compared to rubber belts and are length-adjustable by disassembling and removing links when needed.

Multi-groove belts

A multi-groove, V-Ribbed, or polygroove belt is made up of usually between 3 and 24 "V" shaped sections alongside each other. This gives a thinner belt for the same drive surface, thus it is more flexible, although often wider. The added flexibility offers an improved efficiency, as less energy is wasted in the internal friction of continually bending the belt. In practice this gain of efficiency causes a reduced heating effect on the belt, and a cooler-running belt lasts longer in service. Belts are commercially available in several sizes, with usually a 'P' (sometimes omitted) and a single letter identifying the pitch between grooves. The 'PK' section with a pitch of 3.56 mm is commonly used for automotive applications.

A further advantage of the polygroove belt that makes them popular is that they can run over pulleys on the ungrooved back of the belt. Though this is sometimes done with V-belts with a single idler pulley for tensioning, a polygroove belt may be wrapped around a pulley on its back tightly enough to change its direction, or even to provide a light driving force.

Any V-belt's ability to drive pulleys depends on wrapping the belt around a sufficient angle of the pulley to provide grip. Where a single-V-belt is limited to a simple convex shape, it can adequately wrap at most three or possibly four pulleys, so can drive at most three accessories. Where more must be driven, such as for modern cars with power steering and air conditioning, multiple belts are required. As the polygroove belt can be bent into concave paths by external idlers, it can wrap any number of driven pulleys, limited only by the power capacity of the belt.

This ability to bend the belt at the designer's whim allows it to take a complex or "serpentine" path. This can assist the design of a compact engine layout, where the accessories are mounted more closely to the engine block and without the need to provide movable tensioning adjustments. The entire belt may be tensioned by a single idler pulley.

Ribbed belt

A ribbed belt is a power transmission belt featuring lengthwise grooves. It operates from contact between the ribs of the belt and the grooves in the pulley. Its single-piece structure is reported to offer an even distribution of tension across the width of the pulley where the belt is in contact, a power range up to 600 kW, a high speed ratio, serpentine drives (possibility to drive off the back of the belt), long life, stability and homogeneity of the drive tension, and reduced vibration. The ribbed belt may be fitted on various applications: compressors, fitness bikes, agricultural machinery, food mixers, washing machines, lawn mowers, etc.

Film belts

Though often grouped with flat belts, they are actually a different kind. They consist of a very thin belt (0.5–15 millimeters or 100–4000 micrometres) strip of plastic and occasionally rubber. They are generally intended for low-power (less than 10 watts), high-speed uses, allowing high efficiency (up to 98%) and long life. These are seen in business machines, printers, tape recorders, and other light-duty operations.

Timing belts

Timing belts (also known as toothed, notch, cog, or synchronous belts) are a positive transfer belt and can track relative movement. These belts have teeth that fit into a matching toothed pulley. When correctly tensioned, they have no slippage, run at constant speed, and are often used to transfer direct motion for indexing or timing purposes (hence their name). They are often used instead of chains or gears, so there is less noise and a lubrication bath is not necessary. Camshafts of automobiles, miniature timing systems, and stepper motors often utilize these belts. Timing belts need the least tension of all belts and are among the most efficient. They can bear up to 200 hp (150 kW) at speeds of 16,000 ft/min (4,900 m/min).

Timing belts with a helical offset tooth design are available. The helical offset tooth design forms a chevron pattern and causes the teeth to engage progressively. The chevron pattern design is self-aligning and does not make the noise that some timing belts make at certain speeds, and is more efficient at transferring power (up to 98%).

Disadvantages include a relatively high purchase cost, the need for specially fabricated toothed pulleys, less protection from overloading, jamming, and vibration due to their continuous tension cords, the lack of clutch action (only possible with friction-drive belts), and the fixed lengths, which do not allow length adjustment (unlike link V-belts or chains).

Specialty belts

Belts normally transmit power on the tension side of the loop. However, designs for continuously variable transmissions exist that use belts that are a series of solid metal blocks, linked together as in a chain, transmitting power on the compression side of the loop.

Rolling roads

Belts used for rolling roads for wind tunnels can be capable of 250 km/h (160 mph).[16]

Standards for use

The open belt drive has parallel shafts rotating in the same direction, whereas the cross-belt drive also bears parallel shafts but rotate in opposite direction. The former is far more common, and the latter not appropriate for timing and standard V-belts unless there is a twist between each pulley so that the pulleys only contact the same belt surface. Nonparallel shafts can be connected if the belt's center line is aligned with the center plane of the pulley. Industrial belts are usually reinforced rubber but sometimes leather types. Non-leather, non-reinforced belts can only be used in light applications.

The pitch line is the line between the inner and outer surfaces that is neither subject to tension (like the outer surface) nor compression (like the inner). It is midway through the surfaces in film and flat belts and dependent on cross-sectional shape and size in timing and V-belts. Calculating pitch diameter is an engineering task and is beyond the scope of this article. The angular speed is inversely proportional to size, so the larger the one wheel, the less angular velocity, and vice versa. Actual pulley speeds tend to be 0.5–1% less than generally calculated because of belt slip and stretch. In timing belts, the inverse ratio teeth of the belt contributes to the exact measurement. The speed of the belt is:

Speed = Circumference based on pitch diameter × angular speed in rpm

Selection criteria

Belt drives are built under the following required conditions: speeds of and power transmitted between drive and driven unit; suitable distance between shafts; and appropriate operating conditions. The equation for power is

- power [kW] = (torque [N·m]) × (rotational speed [rev/min]) × (2π radians) / (60 s × 1000 W).

Factors of power adjustment include speed ratio; shaft distance (long or short); type of drive unit (electric motor, internal combustion engine); service environment (oily, wet, dusty); driven unit loads (jerky, shock, reversed); and pulley-belt arrangement (open, crossed, turned). These are found in engineering handbooks and manufacturer's literature. When corrected, the power is compared to rated powers of the standard belt cross-sections at particular belt speeds to find a number of arrays that perform best. Now the pulley diameters are chosen. It is generally either large diameters or large cross-section that are chosen, since, as stated earlier, larger belts transmit this same power at low belt speeds as smaller belts do at high speeds. To keep the driving part at its smallest, minimal-diameter pulleys are desired. Minimum pulley diameters are limited by the elongation of the belt's outer fibers as the belt wraps around the pulleys. Small pulleys increase this elongation, greatly reducing belt life. Minimal pulley diameters are often listed with each cross-section and speed, or listed separately by belt cross-section. After the cheapest diameters and belt section are chosen, the belt length is computed. If endless belts are used, the desired shaft spacing may need adjusting to accommodate standard-length belts. It is often more economical to use two or more juxtaposed V-belts, rather than one larger belt.

In large speed ratios or small central distances, the angle of contact between the belt and pulley may be less than 180°. If this is the case, the drive power must be further increased, according to manufacturer's tables, and the selection process repeated. This is because power capacities are based on the standard of a 180° contact angle. Smaller contact angles mean less area for the belt to obtain traction, and thus the belt carries less power.

Belt friction

Belt drives depend on friction to operate, but excessive friction wastes energy and rapidly wears the belt. Factors that affect belt friction include belt tension, contact angle, and the materials used to make the belt and pulleys.

Belt tension

Power transmission is a function of belt tension. However, also increasing with tension is stress (load) on the belt and bearings. The ideal belt is that of the lowest tension that does not slip in high loads. Belt tensions should also be adjusted to belt type, size, speed, and pulley diameters. Belt tension is determined by measuring the force to deflect the belt a given distance per inch of pulley. Timing belts need only adequate tension to keep the belt in contact with the pulley.

Belt wear

Fatigue, more so than abrasion, is the culprit for most belt problems. This wear is caused by stress from rolling around the pulleys. High belt tension; excessive slippage; adverse environmental conditions; and belt overloads caused by shock, vibration, or belt slapping all contribute to belt fatigue.

Belt vibration

Vibration signatures are widely used for studying belt drive malfunctions. Some of the common malfunctions or faults include the effects of belt tension, speed, sheave eccentricity and misalignment conditions.The effect of sheave Eccentricity on vibration signatures of the belt drive is quite significant. Although, vibration magnitude is not necessarily increased by this it will create strong amplitude modulation. When the top section of a belt is in resonance, the vibrations of the machine is increased. However, an increase in the machine vibration is not significant when only the bottom section of the belt is in resonance. The vibration spectrum has the tendency to move to higher frequencies as the tension force of the belt is increased.

Belt dressing

Belt slippage can be addressed in several ways. Belt replacement is an obvious solution, and eventually the mandatory one (because no belt lasts forever). Often, though, before the replacement option is executed, retensioning (via pulley centerline adjustment) or dressing (with any of various coatings) may be successful to extend the belt's lifespan and postpone replacement. Belt dressings are typically liquids that are poured, brushed, dripped, or sprayed onto the belt surface and allowed to spread around; they are meant to recondition the belt's driving surfaces and increase friction between the belt and the pulleys. Some belt dressings are dark and sticky, resembling tar or syrup; some are thin and clear, resembling mineral spirits. Some are sold to the public in aerosol cans at auto parts stores; others are sold in drums only to industrial users.

Specifications

To fully specify a belt, the material, length, and cross-section size and shape are required. Timing belts, in addition, require that the size of the teeth be given. The length of the belt is the sum of the central length of the system on both sides, half the circumference of both pulleys, an d the square of the sum (if crossed) or the difference (if open) of the radii. Thus, when dividing by the central distance, it can be visualized as the central distance times the height that gives the same squared value of the radius difference on, of course, both sides. When adding to the length of either side, the length of the belt increases, in a similar manner to the Pythagorean theorem. One important concept to remember is that as D1 gets closer to D2 there is less of a distance (and therefore less addition of length) until its approaches zero.

On the other hand, in a crossed belt drive the sum rather than the difference of radii is the basis for computation for length. So the wider the small drive increases, the belt length is higher.

V-belt profiles

Metric v-belt profiles:

| Classic profile | Width | Height | Angle* | Remarks |

|---|---|---|---|---|

| Z | 10mm | - | - | |

| A | 13mm | 15mm | 40° | 12.7mm = 0.5 inch width, 38° angle if inches |

| B | 17mm | 11mm | 40° | 16.5mm = 21/32 inch width, 38° angle if inches |

| C | 22mm | 14mm | 40° | 22.2mm = 7/8 inch width, 38° angle if inches |

| D | 32mm | 19mm | 40° | 31.75mm = 1.25 inch width, 38° angle if inches |

| E | 38mm | 25mm | 40° | 38.1mm = 1.5 inch width, 38° angle if inches |

| Narrow-profile | Width | Height | Angle* | Remarks |

| SPZ | 10mm | 8mm | 34° | |

| SPA | 13mm | - | - | |

| SPB | 17mm | - | - | |

| SPC | 22mm | - | - | |

| High-Performance Narrow-profile | Width | Height | Angle* | Remarks |

| XPZ | 10mm | - | - | |

| XPA | 13mm | - | - | |

| XPB | 17mm | - | - | |

| XPC | 22mm | - | - |

- Common pulley design is to have a higher angle of the first part of the opening, above the so called "pitch line".

E.g. the pitch line for SPZ could be 8.5mm from the bottom of the "V". In other words 0-8.5mm is 34° and 38° from 8.5 and above

Timing Belt

A timing belt, timing chain or cambelt is a part of an internal combustion engine that synchronizes the rotation of the crankshaft and the camshaft(s) so that the engine's valves open and close at the proper times during each cylinder's intake and exhaust strokes. In an interference engine the timing belt or chain is also critical to preventing the piston from striking the valves. A timing belt is usually a toothed belt -- a drive belt with teeth on the inside surface. A timing chain is a roller chain.

Many modern production automobile engines use a timing belt[i] to synchronize crankshaft and camshaft rotation; some engines, particularly cam in block designs, used gears to drive the camshaft, but this was rare for OHC designs. The use of a timing belt or chain instead of gear drive enables engine designers to place the camshaft(s) further from the crankshaft, and in engines with multiple camshafts a timing belt or chain also enables the camshafts to be placed further from each other. Timing chains were common on production automobiles through the 1970s and 1980s, when timing belts became the norm, but timing chains have seen a resurgence in recent years. Timing chains are generally more durable than timing belts – though neither is as durable as gear drive – however, timing belts are lighter, less expensive, and operate more quietly.

Timing Belt

Timing Belt Engine applications

In the internal combustion engine application the timing belt or chain connects the crankshaft to the camshaft(s), which in turn control the opening and closing of the engine's valves. A four-stroke engine requires that the valves open and close once every other revolution of the crankshaft. The timing belt does this. It has teeth to turn the camshaft(s) synchronised with the crankshaft, and is specifically designed for a particular engine. In some engine designs the timing belt may also be used to drive other engine components such as the water pump and oil pump.

Types

Gear or chain systems are also used to connect the crankshaft to the camshaft at the correct timing. However, gears and shafts constrain the relative location of the crankshaft and camshafts. Even where the crankshaft and camshaft(s) are very close together, as in pushrod engines, most engine designers use a short chain drive rather than a direct gear drive. This is because gear drives suffer from frequent torque reversal as the cam profiles "kick back" against the drive from the crank, leading to excessive noise and wear. Fibre or nylon covered gears, with more resilience, are often used instead of steel gears where direct drive is used. Commercial engines and aircraft engines use steel gears only, as a fibre or nylon coated gear can fail suddenly and without warning.[1]

A belt or chain allows much more flexibility in the relative locations of the crankshaft and camshafts.

While chains and gears may be more durable, rubber composite belts are quieter in their operation (in most modern engines the noise difference is negligible), are less expensive and more efficient, by dint of being lighter, when compared with a gear or chain system. Also, timing belts do not require lubrication, which is essential with a timing chain or gears. A timing belt is a specific application of a synchronous belt used to transmit rotational power synchronously.

Timing belts are typically covered by metal or polymer timing belt covers which require removal for inspection or replacement. Engine manufacturers recommend replacement at specific intervals. The manufacturer may also recommend the replacement of other parts, such as the water pump, when the timing belt is replaced because the additional cost to replace the water pump is negligible compared to the cost of accessing the timing belt. In an interference engine, or one whose valves extend into the path of the piston, failure of the timing belt (or timing chain) invariably results in costly and, in some cases, irreparable engine damage, as some valves will be held open when they should not be and thus will be struck by the pistons.

Indicators that the timing chain may need to be replaced include a rattling noise from the front of the engine.

Failure[

Timing belts must be replaced at the manufacturer's recommended distance and/or time periods. Failure to replace the belt can result in complete breakdown or catastrophic engine failure, especially in interference engines.[4]The owner's manual maintenance schedule is the source of timing belt replacement intervals, typically every 30,000 to 50,000 miles (50,000 to 80,000 km).[5] It is common to replace the timing belt tensioner at the same time as the belt is replaced.

The usual failure modes of timing belts are either stripped teeth (which leaves a smooth section of belt where the drive cog will slip) or delamination and unraveling of the fiber cores. Breakage of the belt, because of the nature of the high tensile fibers, is uncommon. Often overlooked, debris and dirt that mix with oil and grease can slowly wear at the belt and materials advancing the wear process, causing premature belt failure.[7] Correct belt tension is critical - too loose and the belt will whip, too tight and it will whine and put excess strain on the bearings of the cogs. In either case belt life will be drastically shortened. Aside from the belt itself, also common is a failure of the tensioner, and/or the various gear and idler bearings, causing the belt to derail.

When an automotive timing belt is replaced, care must be taken to ensure that the valve and piston movements are correctly synchronized. Failure to synchronize correctly can lead to problems with valve timing, and this in turn, in extremes, can cause collision between valves and pistons in interference engines. This is not a problem unique to timing belts since the same issue exists with all other cam/crank timing methods such as gears or chains.

Construction and design

A timing belt is typically rubber with high-tensile fibres (e.g. fiberglass or Twaron/Kevlar) running the length of the belt as tension members.[8] The belt itself is constructed in sturdy materials such as molded polyurethane, neoprene or welded urethane with various standard, non-standard or metric pitches.[9] The distance between the centers of two adjacent teeth on the timing belt is referred to as the pitch.

Rubber degrades with higher temperatures, and with contact with motor oil. Thus the life expectancy of a timing belt is lowered in hot or leaky engines. Newer or more expensive belts are made of temperature resistant materials such as "highly saturated nitrile" (HSN).[citation needed] The life of the reinforcing cords is also greatly affected by water and antifreeze. This means that special precautions must be taken for off road applications to allow water to drain away or be sealed from contact with the belt.

Older belts have trapezoid shaped teeth leading to high rates of tooth wear. Newer manufacturing techniques allow for curved teeth that are quieter and last longer.

Aftermarket timing belts may be used to alter engine performance. OEM timing belts may stretch at high rpm, retarding the cam and therefore the ignition.[11] Stronger, aftermarket belts, will not stretch and the timing is preserved. In terms of engine design, "shortening the width of the timing belt reduce[s] weight and friction"

Continuously variable transmission

A continuously variable transmission (CVT), also known as a shiftless transmission, single-speed transmission, stepless transmission, pulley transmission, or, in case of motorcycles, a 'twist-and-go', is an automatic transmission that can change seamlessly through a continuous range of effective gear ratios. This contrasts with other mechanical transmissions that offer a fixed number of gear ratios. The flexibility of a CVT with suitable control may allow the input shaft to maintain a constant angular velocity even as the output speed varies.

A belt-driven design offers approximately 88% efficiency,[1] which, while lower than that of a manual transmission, can be offset by lower production cost and by enabling the engine to run at its most efficient speed for a range of output speeds. When power is more important than economy, the ratio of the CVT can be changed to allow the engine to turn at the RPM at which it produces greatest power. This is typically higher than the RPM that achieves peak efficiency. In low-mass low-torque applications (such as motor scooters) a belt-driven CVT also offers ease of use and mechanical simplicity.

A CVT does not strictly require the presence of a clutch. Nevertheless, in some vehicles (e.g. motorcycles), a centrifugal clutch is added[2] to facilitate a "neutral" stance, which is useful when idling or manually reversing

Uses

Motorized vehicles

Simple rubber belt (non-stretching fixed circumference manufactured using various highly durable and flexible materials) CVTs are commonly used in small motorized vehicles, where their mechanical simplicity and ease of use outweigh their comparative inefficiency. Nearly all snowmobiles, utility vehicles, golf carts and motor scooters use CVTs, typically the rubber belt or variable pulley variety.

CVTs were banned from Formula 1 in 1994 because of concerns that the best-funded teams would dominate if they managed to create a viable F1 CVT.

More recently,, CVT systems have been developed for go-karts and have proven to increase performance and engine life expectancy. The Tomcar range of off-road vehicles also utilizes the CVT system.

Some vehicles that offer CVT are the Chrysler Pacifica hybrid, the Ford C-MAX hybrid, the Mitsubishi Lancer, the Dodge Caliber, the Toyota Corolla, the Scion iQ, the Honda Insight, Fit, CR-Z hybrid, CR-V, Capa, Honda Civic, Honda Accord, the Nissan Tiida/Versa (SL, SV, and Note S Plus or higher models), Cube, Juke, Sentra, Altima, Maxima, 2013 1.2 Note, Rogue, X-Trail, Murano, Pathfinder, Sunny and the non-Mexican Micra, the Jeep Patriot and Compass, the Suzuki SX4 S-Cross, and the Subaru Forester, Impreza, Legacy, Outback and Crosstrek, Suzuki Kizashi, Toyota Allion 2009 onwards, Toyota Premio 2009 onwards, Toyota Avalon, Toyota Mark X, etc.

CVTs should be distinguished from power-sharing transmissions (PSTs), as used in newer hybrid cars, such as the Toyota Prius, Highlander and Camry, the Nissan Altima, and newer-model Ford Escape Hybrid SUVs. CVT technology uses only one input from a prime mover and delivers variable output speeds and torque, whereas PST technology uses two prime mover inputs and varies the ratio of their contributions to output speed and power. These transmissions are fundamentally different.

Farm equipment, namely harvester combines, used variable belt drives as early as the 1950s, as well. Many small tractors and self-propelled mowers for home and garden also use simple rubber belt CVT. Hydrostatic systems are more common on the larger units—the walk-behind self-propelled mowers are of the slipping belt variety.

Ratcheting CVT converting rotary motion to oscillating motion and back to rotary motion using roller clutches are well adapted to reciprocating engines when the oscillating movement is synchronized with that of the pistons. This solution could have a bright future because such ratcheting CVT are also IVT (providing the clutch function), and have a very high energy efficiency. They could help automakers comply with the future emission standards, while also improving the reciprocating engines performance.

Downsizing electric engines

Instead of being dimensioned according to the maximum torque (eg that required for starting, or in case of momentary mechanical overload), the motors using this type of CVT may be dimensioned by matching the maximum power with the maximum desired speed (that of a vehicle by example). Such CVT is used only at startup or in case of mechanical overload, and may be disconnected most of the time, the engine transfering the torque directly to the output. New concepts adapting the transmission ratio to the resistant torque and centrifugal clutch may be used to make these changes automatic.

Bicycles

A ratchet CVT has been proposed for bicycles The crankset causes a lever to swing, which in turn causes the reciprocating movement of a double rack that rotates the wheel as it moves backward and as it moves toward the wheel.

Medium and high power transfers

Hydrostatic CVTs are common in small to medium-sized agricultural and earthmoving equipment. As the engines in these machines are typically run at constant power settings to provide hydraulic power or to power machinery, losses in mechanical efficiency are offset by enhanced operational efficiency, such as reduced forward-reverse shuttle times in earthmoving operations. Transmission output is varied to control both travel speed and direction. This is particularly beneficial in equipment designed to pivot or skid steer through differential power application as the required differential steering action can easily be supplied by independent CVTs, allowing steering to be accomplished without braking losses or loss of tractive effort and allowing the machine to pivot in place. In mowing or harvesting operations a CVT allows the forward speed of the tractor or combine harvester to be adjusted independently of the engine speed. This allows the operator to slow or accelerate as needed to accommodate variations in thickness of the crop.

Power generating systems

CVTs have been used in aircraft electrical power generating systems since the 1950s and in Sports Car Club of America (SCCA) Formula 500 race cars since the early 1970s.

Some drill presses and milling machines contain a pulley-based CVT system where the output shaft has a pair of manually adjustable conical pulley halves through which a wide drive belt from the motor loops. The pulley on the motor, however, is usually fixed in diameter, or may have a series of given-diameter steps to allow a selection of speed ranges. A handwheel on the drill press, marked with a scale corresponding to the desired machine speed, is mounted to a reduction gearing system for the operator to precisely control the width of the gap between the pulley halves. This gap width thus adjusts the gearing ratio between the motor's fixed pulley and the output shaft's variable pulley, changing speed of the chuck. A tensioner pulley is implemented in the belt transmission to take up or release the slack in the belt as the speed is altered. In most cases, the speed must be changed with the motor running.

Doubly-fed induction generators are usually coupled with multi-stage gearboxes to increase the rotational speed. These gearboxes might be replaced by fully CVT in the future, but only fully geared one because they are the only ones providing a sufficient mechanical efficiency

A CVT and flywheel may be inserted between an energy source (eg a wind turbine) and the electricity generator. When the energy source is sufficient, the generator is connected directly to the CVT which serves to regulate its speed of rotation. When it is too low, the generator is disconnected and the energy stored in the flywheel. It is only when the speed of the flywheel is sufficient that the kinetik energy is converted into electricity, intermittently, but always at the optimal speed of the generator.

Winches and hoists

It's also an application of CVTs, especially for those adapting the transmission ratio to the resistant torque.

Types

Variable-diameter pulley (VDP) or Reeves drive

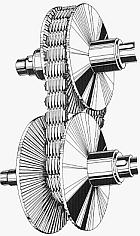

In this most common CVT system,[6] there are two V-belt pulleys that are split perpendicular to their axes of rotation, with a V-belt running between them. The gear ratio is changed by moving the two sheaves of one pulley closer together and the two sheaves of the other pulley farther apart. The V-shaped cross section of the belt causes it to ride higher on one pulley and lower on the other. This changes the effective diameters of both pulleys, which changes the overall gear ratio. As the distance between the pulleys and the length of the belt does not change, both pulleys must be adjusted (one bigger, the other smaller) simultaneously in order to maintain the proper amount of tension on the belt. Simple CVTs combining a centrifugal drive pulley with a spring loaded driven pulley often use belt tension to effect the conforming adjustments in the driven pulley. The V-belt needs to be very stiff in the pulley's axial direction in order to make only short radial movements while sliding in and out of the pulleys. The Chinese gy6-type scooter uses this type of CVT drive system.

Steel reinforced v-belts are sufficient for low-mass low-torque applications like utility vehicles and snowmobiles but higher mass and torque applications such as automobiles require a chain. Each element of the chain must have conical sides that fit the pulley when the belt is running on the outermost radius. As the chain moves into the pulleys the contact area gets smaller. As the contact area is proportional to the number of elements, chain belts require lots of very small elements. The shape of the elements is governed by the static of a column. The pulley-radial thickness of the belt is a compromise between maximum gear ratio and torque. For the same reason the axis between the pulleys is as thin as possible. In a chain-based CVT a film of lubricant is applied to the pulleys. It needs to be thick enough so that the pulley and the chain never touch and it must be thin in order not to waste power when each element dives into the lubrication film. Additionally, the chain elements stabilize about 12 steel bands. Each band is thin enough so that it bends easily. If bending, it has a perfect conical surface on its side. In the stack of bands each band corresponds to a slightly different gear ratio, and thus they slide over each other and need oil between them. Also the outer bands slide through the stabilizing chain, while the center band can be used as the chain linkage.[note 1]

Push-Belt

While some CVTs transmit torque only through the tension of the belt or chain, a push-belt CVT transmits torque both through "pulling" belt ring tension and also "pushing" link element compression.

Toroidal or roller-based (Extroid)

Toroidal CVTs are made up of discs and rollers that transmit power between the discs. The discs can be pictured as two almost conical parts, point to point, with the sides dished such that the two parts could fill the central hole of a torus. One disc is the input, and the other is the output. Between the discs are rollers which vary the ratio and which transfer power from one side to the other. When the roller's axis is perpendicular to the axis of the near-conical parts, it contacts the near-conical parts at same-diameter locations and thus gives a 1:1 gear ratio. The roller can be moved along the axis of the near-conical parts, changing angle as needed to maintain contact. This will cause the roller to contact the near-conical parts at varying and distinct diameters, giving a gear ratio of something other than 1:1. Systems may be partial or full toroidal. Full toroidal systems are the most efficient design while partial toroidals may still require a torque converter, and hence lose efficiency.

Some toroidal systems like the torotrak, are also infinitely variable, and the direction of thrust can be reversed within the CVT.

Diagrams:

Examples:

- Nissan Extroid CVT (pdf on Nissan-Global site)

Magnetic or mCVT

A magnetic continuous variable transmission system was developed at the University of Sheffield in 2006 and later commercialized.[11] mCVT is a variable magnetic transmission which gives an electrically controllable gear ratio. It can act as a power split device and can match a fixed input speed from a prime-mover to a variable load by importing/exporting electrical power through a variator path. The mCVT is of particular interest as a highly efficient power-split device for blended parallel hybrid vehicles, but also has potential applications in renewable energy, marine propulsion and industrial drive sectors.

Infinitely variable transmission (IVT)

A subset of CVT designs are called infinitely variable transmissions (IVT or IVTs), in which the range of ratios of output shaft speed to input shaft speed includes a zero ratio that can be continuously approached from a defined "higher" ratio. A zero output speed (low gear) with a finite input speed implies an infinite input-to-output speed ratio, which can be continuously approached from a given finite input value with an IVT. Low gears are a reference to low ratios of output speed to input speed. This low ratio is taken to the extreme with IVTs, resulting in a "neutral", or non-driving "low" gear limit, in which the output speed is zero. Unlike neutral in a normal automotive transmission, IVT output rotation may be prevented because the back-driving (reverse IVT operation) ratio may be infinite, resulting in impossibly high backdriving torque; in a ratcheting IVT, however, the output may freely rotate in the forward direction.

Friction

In the early decades of the 20th century, several tractors and small locomotives were built with friction-disk transmissions with an output disk rolling on the face of the input disk. For disks of identical diameter, the effective gear ratio could be varied from 1:1 when the point of contact was at the perimeter of the input disk, to infinity when the point of contact was at the center, to -1:1 when the point of contact was at the opposite extreme. The transmission on early Plymouth locomotives worked this way, while on tractors using friction disks, the range of reverse speeds was typically limited.

Epicyclic gearing

Many IVTs result from the combination of a CVT with a planetary gear system which enforces an IVT output shaft rotation speed which is equal to the difference between two other speeds within the IVT. This IVT configuration uses its CVT as a continuously variable regulator (CVR) of the rotation speed of any one of the three rotators of the planetary gear system (PGS). If two of the PGS rotator speeds are the input and output of the CVR, there is a setting of the CVR that results in the IVT output speed of zero. The maximum output/input ratio can be chosen from infinite practical possibilities through selection of additional input or output gear, pulley or sprocket sizes without affecting the zero output or the continuity of the whole system. The IVT is always engaged, even during its zero output adjustment.

IVTs can in some implementations offer better efficiency in the preferred range of operation when compared to other CVTs because most of the power flows through the planetary gear system and not the controlling CVR. Torque transmission capability can also be increased. Staging power splits is also possible for further increase in efficiency, torque transmission capability and better maintenance of efficiency over a wide gear ratio range.

Examples

Hydristor

An example of a true IVT is the Hydristor because the front unit connected to the engine can displace from zero to 27 cubic inches (440 cm3) per revolution forward and zero to −10 cubic inches (−160 cm3) per revolution reverse. The rear unit is capable of zero to 75 cubic inches (1,230 cm3) per revolution. However, whether this design enters production remains to be seen.fact Another example of a true IVT that has been put into recent production and which continues under commercial development[ is that of Torotrak.

Guigan

A French inventor, Franck Guigan, filed patent applications in 2017 for a method based on variable diameter gears (PCT/FR2017000174). This new method eliminates any oscillatory movement that could cause vibration. It is a true IVT as the variable diameter of the crown allows the transmission ratio to vary from any positive value to any negative value passing through a ZERO position. It also works as a regenerative braking system, which can be used as a kinetic energy recovery system. It also allows to combine two engines, for example a combustion engine and an electric one.

Franck Guigan filed in 2018 patent applications for a method based on oscillating racks combined with freewheels, which gave rise to many different transmissions.

This transmission is also a true IVT as the transmission ratio can be ZERO, which means that it allows not to use any clutch. Although there is an oscillatory movement, some of these transmissions are absolutely homokinetic, which means the rotation of the output shaft is at all times exactly proportional to the one of the input shaft. The MultiRack transmission shown on the right will work most of the time in "direct drive" mode, the output shaft being directly connected to the input and the racks remaining stationary, and it is only in case of mechanical overload, that the CVT will come into play. A new feature is that the transmission ratio may be permanently adapted to the resistive torque. This is what allows to use downsized engines (e.g. electric), that are lighter, less bulky and more economical to build and to use. Not only does this device guarantee the constant supply of sufficient torque, but it also protects the engine.

In both cases, the transmission ratio can be chosen manually or computer-determined.

Ratcheting

The ratcheting CVT is a transmission that relies on static friction and is based on a set of elements that successively become engaged and then disengaged between the driving system and the driven system, often using oscillating or indexing motion in conjunction with one-way clutches or ratchets that rectify and sum only "forward" motion. The transmission ratio is adjusted by changing linkage geometry within the oscillating elements, so that the summed maximum linkage speed is adjusted, even when the average linkage speed remains constant. Power is transferred from input to output only when the clutch or ratchet is engaged, and therefore when it is locked into a static friction mode where the driving & driven rotating surfaces momentarily rotate together without slippage.

One type of ratcheting CVT that is not dependent on friction uses a scotch yoke mechanism to convert rotation to linear oscillation. The magnitude of oscillation, sometimes called "stroke", depends on the distance of the crank pin in the scotch yoke mechanism from the axis of rotation. The stroke is altered by altering the distance of the crank pin from the axis of rotation. This linear oscillation is converted back to rocking motion using a rack and pinion. This rocking motion is rectified to rotation using either computer controlled clutch, sprag clutch or one-way bearing. The main advantage of this type of CVT is that it is not dependent on friction to transmit power. One drawback here is that the input to output ratio is sinusoidal and not constant. However, patented designs exist to overcome this drawback by altering the instantaneous rotational speed of the scotch yoke mechanism using non-circular gears. An example of a non-friction-dependent ratcheting CVT having a constant input to output ratio, is patent protected under U.S. Patent 9,970,520B2.

These CVTs can transfer substantial torque, because their static friction actually increases relative to torque throughput, so slippage is impossible in properly designed systems. Efficiency is generally high, because most of the dynamic friction is caused by very slight transitional clutch speed changes. The drawback to ratcheting CVTs is vibration caused by the successive transition in speed required to accelerate the element, which must supplant the previously operating and decelerating, power transmitting element.

Ratcheting CVTs are distinguished from VDPs and roller-based CVTs by being static friction-based devices, as opposed to being dynamic friction-based devices that waste significant energy through slippage of twisting surfaces. An example of a ratcheting CVT is one prototyped as a bicycle transmission protected under U.S. Patent 5,516,132 in which strong pedalling torque causes this mechanism to react against the spring, moving the ring gear/chainwheel assembly toward a concentric, lower gear position. When the pedaling torque relaxes to lower levels, the transmission self-adjusts toward higher gears, accompanied by an increase in transmission vibration.

The ratcheting IVT dates back to before the 1930s; the original design converts rotary motion to oscillating motion and back to rotary motion using roller clutches.[17] The stroke of the intermediate oscillations is adjustable, varying the output speed of the shaft. The fundamental limitation is that when the torque transfers between the separate oscillatory paths the change in deflection causes high vibration at higher torques. The original design is still manufactured today, and an example and animation of this IVT can be found here.[18] Paul B. Pires created a more compact (radially symmetric) variation that employs a ratchet mechanism instead of roller clutches, so it does not have to rely on friction to drive the output. An article and sketch of this variation can be found here [19]

Hydrostatic

Hydrostatic transmissions use a variable displacement pump and a hydraulic motor. All power is transmitted by hydraulic fluid. These types can generally transmit more torque, but can be sensitive to contamination. Some designs are also very expensive. However, they have the advantage that the hydraulic motor can be mounted directly to the wheel hub, allowing a more flexible suspension system and eliminating efficiency losses from friction in the drive shaft and differential components. This type of transmission is relatively easy to use because all forward and reverse speeds can be accessed using a single lever.

An integrated hydrostatic transaxle (IHT) uses a single housing for both hydraulic elements and gear-reducing elements. This type of transmission has been effectively applied to a variety of inexpensive and expensive versions of ridden lawn mowers and garden tractors.

One class of riding lawn mower that has recently gained in popularity with consumers is zero turning radius mowers. These mowers have traditionally been powered with wheel hub mounted hydraulic motors driven by continuously variable pumps, but this design is relatively expensive.

Some heavy equipment may also be propelled by a hydrostatic transmission; e.g. agricultural machinery including foragers, combines, and some tractors. A variety of heavy earth-moving equipment, e.g. compact and small wheel loaders, track type loaders and crawler tractors, skid-steered loaders and asphalt compactors use hydrostatic transmission. Hydrostatic CVTs are usually not used for extended duration high torque applications because of the heat that is generated by the flowing oil, although there are a variety of oil cooler designs to help counter this problem.

The Honda DN-01 motorcycle is the first road-going consumer vehicle with hydrostatic drive that employs a variable displacement axial piston pump with a variable-angle swashplate.

AGCO Corporation has employed a hydrostatic CVT transmission in agricultural equipment. The transmission splits power between hydrostatic and mechanical transfer to the output shaft via a planetary gear in the forward direction of travel. In reverse the power transfer is fully hydrostatic.

Naudic incremental (iCVT)

This is a chain-driven system. Although an iCVT works, it has the following weakness:

High frictional losses

The variator pulley of an iCVT is choked using two small choking pulleys. Here one choking pulley is positioned on the tense side of the chain of the iCVT. Hence there is a considerable load on that choking pulley, the magnitude of which is proportional to the tension in its chain. Each choking pulley is pulled up by two chain segments, one chain segment to the left and one to the right of the choking pulley; here if the two chain segments are parallel to each other, then the load on the choking pulley is twice the tension in the chain. But since the two chain segments are most likely not parallel to each other during operations of an iCVT, it is estimated that the load on a choking pulley is between 1 and 1.8 times of the tension of its chain.

Also, a choking pulley is very small so that its moment arm is very small. A larger moment arm reduces the force needed to rotate a pulley. For example, using a long wrench, which has a large moment arm, to open a nut requires less force than using a short wrench, which has a small moment arm. Assuming that the diameter of a choking pulley is twice the diameter of its shaft, which is a generous estimate, then the frictional resistance force at the outer diameter of a choking pulley is half the frictional resistance force at the shaft of a choking pulley.

Shock and durability

The transmission ratio of an iCVT has to be changed one increment within less than one full rotation of its variator pulley. This means that the transmission diameter of the variator pulley, made generally from rubber, has to be changed from a diameter that has a circumferential length that is equal to an integer number of teeth to another diameter that has a circumferential length that is equal to an integer number of teeth; such as changing the transmission diameter of the variator pulley from a diameter that has a circumferential length of 7 teeth to a diameter that has a circumferential length of 8 teeth for example. This is because if the transmission diameter of the variator pulley does not have a circumferential length that is equal to an integer number of teeth, such as a circumferential length of 71⁄2 teeth for example, improper engagement between the teeth of the variator pulley and its chain will occur. For example, imagine having a bicycle pulley with 71⁄2 teeth; here improper engagement between the bicycle pulley and its chain will occur when the tooth behind the 1⁄2 tooth space is about to engage with its chain, since it is positioned a distance of 1⁄2 tooth too late relative to its chain.

Regarding the previous paragraph, the chain of an iCVT forms an open loop on its variator pulley that partially covers its variator pulley such that an open section, which is not covered by the chain, exist. This is similar to a sprocket of a bicycle where there is a section of the sprocket that is covered by its chain, and a section of the sprocket that is not covered by its chain. During one complete rotation, the toothed section of the variator pulley of an iCVT passes by the open section and re-engages with the chain. Here if the transmission diameter of the variator pulley does not represent an integer number of teeth, improper re-engagement between the teeth of the variator pulley and its chain will occur. Also, the transmission diameter of the variator pulley cannot be changed while the toothed section of the variator pulley is covering the entire open section of its chain loop. Since this is similar to where a plate is glued across the open section of a chain loop, which does not allow expansion or contraction of the chain loop as required for transmission diameter change of the variator pulley. Therefore, the transmission diameter of the variator pulley has to be changed one increment during an interval where the variator pulley rotates from an initial position where a portion of the toothed section of the variator pulley is positioned at the open section of the chain loop but not covering the entire open section, to the final position where the toothed section of the variator pulley passes by the open section of the chain loop and is about to re-engage with the chain. Since it takes less than one full rotation to rotate the variator pulley from its initial position to its final position mentioned in the previous sentence, the transmission diameter of the variator pulley has to be changed one increment within less than one full rotation.

In addition, as the transmission diameter is increased, the chain has to be pushed up the inclined surfaces of the pulley halves of the variator pulley, while the tension in the chain tends to pull the chain towards the opposite direction. Hence a large force, which is larger than the tension in the chain, is required to change the transmission diameter. Since the transmission ratio has to be changed within less than one full rotation of the variator pulley, a large force has to be applied on the pulley halves within a very short duration. If for example the variator pulley rotates at 3600 rpm, which is equivalent to 60 revolutions per second, then the force required to change the transmission ratio has to be applied within 1/60 seconds. This would be similar to hitting something with a hammer. Therefore, here significant shock loads are applied to the variator pulley during transmission ratio change that increases the transmission diameter. These shock loads may cause comfort problems for the driver of the vehicle using an iCVT. Also an iCVT has to be designed as to be able to resist these shock loads which would most likely increases the cost and weight of an iCVT.

Torque transfer ability and reliability

The teeth of the variator pulley of an iCVT are formed by pins that extend from one pulley half to the other pulley half and slide in the grooves of the pulley halves of the variator pulley. Here torque from the chain is transferred to the pins and then from the pins to the pulley halves. Since the pins are round and the grooves are curved, line contact between the pins and the grooves are used to transfer force from the pins to the grooves. The amount of force that can be transmitted between two parts depend on the contact area of the two parts. Since the contact areas between the pins and their grooves are very small, the amount of force that can be transmitted between them, and hence also the torque capacity of an iCVT, is limited.

Another possible problem with an iCVT is that the pins of the variator pulley can fall-out when they are not engaged with their chain, and wear of the pins and the grooves of the pulley halves can cause some serious performance and reliability problems.

Cone

A cone CVT varies the effective gear ratio using one or more conical rollers. The simplest type of cone CVT, the single-cone version, uses a wheel that moves along the slope of the cone, creating the variation between the narrow and wide diameters of the cone.

The more-sophisticated twin cone mesh system is also a type of cone CVT.

In a CVT with oscillating cones, the torque is transmitted via friction from a variable number of cones (according to the torque to be transmitted) to a central, barrel-shaped hub. The side surface of the hub is convex with a specific radius of curvature which is smaller than the concavity radius of the cones. In this way, there will be only one (theoretical) contact point between each cone and the hub at any time.

A new CVT using this technology, the Warko, was presented in Berlin during the 6th International CTI Symposium of Innovative Automotive Transmissions, on 3–7 December 2007.

A particular characteristic of the Warko is the absence of a clutch: the engine is always connected to the wheels, and the rear drive is obtained by means of an epicyclic system in output.[24] This system, named “power split”,[25]allows the engine to have a "neutral gear": when the engine turns (connected to the sun gear of the epicyclic system), the variator (i.e., the planetary gears) will compensate for the engine rotation, so the outer ring gear (which provides output) remains stationary.

Radial roller

The working principle of this CVT is similar to that of conventional oil pumps, but, instead of pumping oil, common steel rollers are compressed.

The motion transmission between rollers and rotors is assisted by an adapted traction fluid, which ensures the proper friction between the surfaces and slows down wearing thereof. Unlike other systems, the radial rollers do not show a tangential speed variation (delta) along the contact lines on the rotors. From this, a greater mechanical efficiency and working life are claimed.

Planetary

In a planetary CVT, the gear ratio is shifted by tilting the axes of spheres in a continuous fashion, to provide different contact radii, which in turn drive input and output discs. The system can have multiple "planets" to transfer torque through multiple fluid patches. One commercial implementation is the NuVinci Continuously Variable Transmission.

Flash combat

Leonardo da Vinci, in 1490, conceptualized a stepless continuously variable transmission. Milton Reeves invented a variable-speed transmission for saw milling in 1879, which he applied to his first car in 1896.[29]The first patent for a friction-based belt CVT for a car was filed in Europe by Daimler and Benz in 1886, and a US patent for a toroidal CVT was granted in 1935.

In 1910, Zenith Motorcycles built a V-twin engined motorcycle with the Gradua-Gear, which was a CVT. In 1912, the British motorcycle manufacturer Rudge-Whitworth built the Rudge Multigear. The Multi was a much improved version of Zenith’s Gradua-Gear.

An early application of CVT was in the British Clyno car, introduced in 1923.

In 1926, George Constantinesco produced the Constantinesco car with a smooth, efficient, inertial masses CVT, which he had invented in 1923, built into the two-cylinder engine.

During the late 1940s and early 1950s, Charles H. Miner of Denver, CO made significant developments in creating a CVT by inventing the "Variable Speed Clutch Pulley". He filed and was granted multiple US patents for his CVT system using steel balls and centrifugal force to manipulate the moveable side of the power end of his V-belt clutch. He formed a manufacturing company (Miner Pulley) in Denver and built clutch pulleys until he sold the company to Warner Clutch due to health reasons. See US Patent US2974544 A for diagrams and details.

A CVT, called Variomatic, was designed and built by Hub van Doorne, co-founder of Van Doorne's Automobiel Fabriek (DAF), in the late 1950s, specifically to produce an automatic transmission for a small, affordable car. The first DAF car using van Doorne's CVT, the DAF 600, was produced in 1958.[33] Van Doorne's patents were later transferred to a company called VDT (Van Doorne Transmissie B.V.) when the passenger car division was sold to Volvo in 1975; its CVT was used in the Volvo 340. In 1995, VDT was acquired by Robert Bosch GmbH.

For the 1965 model year, Wheel Horse Products, Inc., of South Bend, Indiana, USA, introduced the first garden tractors equipped with an hydraulic CVT. The models 875 and 1075 included an Eaton-manufactured variable-displacement swash-plate pump and fixed-displacement gear-type hydraulic motor combined into a single compact package, which attached directly to the patented Wheel Horse Unidrive™ transaxle. Reverse was produced by reversing the flow of the pump through over-centering of the swash plate. Acceleration was limited and smoothed through use of pressure accumulator and relief valves located between the pump and motor, to prevent the sudden changes in speed possible with a direct hydraulic coupling. Subsequent versions included fixed swash plate motors, and ball pumps and were sourced from both Eaton and Sundstrand Corp.

Many snowmobiles use a rubber belt CVT. In 1974, Rokon offered a motorcycle with a rubber belt CVT.

CVTs are used in some all terrain vehicles. The first ATV equipped with CVT was Polaris's Trail Boss in 1985.

In February 1987, Subaru released the Justy in Tokyo with an electronically controlled continuously variable transmission (ECVT) developed by Fuji Heavy Industries which owns Subaru, and Van Doorne's Transmissie in The Netherlands. One and a half years later in November 1988, Subaru also brought out the Justy 4WD ECVT, a Justy with part-time 4WD and the ECVT gearbox. Production was limited to 500 units per month as Van Doorne's could only produce this many steel belts for them. In June, supplies increased to 3,000 per month and Subaru responded by installing the extra volume into transmissions for their Rex microcar.[34] In 1989 the Justy became the first production car in the U.S. to offer CVT technology. While the Justy saw only limited success, Subaru continues to use CVT in its kei cars to this day,[when?] while also supplying it to other manufacturers.[35] Subaru offers CVT (Lineartronic) on 2014 Outback, Legacy, Forester, Impreza, and Crosstrek.

In summer 1987, the Ford Fiesta and Fiat Uno became the first mainstream European cars to be equipped with steel-belted CVT (as opposed to the less robust rubber-belted DAF design). This CVT, the Ford CTX was developed by Ford, Van Doorne, and Fiat, with work on the transmission starting in 1976.

The 1992 Nissan March contained Nissan's N-CVT based on the Fuji Heavy Industries ECVT.[35] In the late 1990s, Nissan designed its own CVT that allowed for higher torque and included a torque converter. This gearbox was used in a number of Japanese-market models. Nissan is also the only car maker to bring a roller-based CVT to the market in recent years.[when?] Their toroidal CVT, named the Extroid, was available in the Japanese market Y34 Nissan Gloria and V35 Skyline GT-8. However, the gearbox was not carried over when the Cedric/Gloria was replaced by the Nissan Fuga in 2004. The Nissan Murano, introduced in 2003, and the Nissan Rogue, introduced in 2007, also use CVT in their automatic transmission models. In a Nissan press release, dated 12 July 2006, Nissan announced a large-scale shift to CVT transmissions when they selected their XTronic CVT technology[37] for all automatic versions of the Versa, Cube, Sentra, Altima and Maxima vehicles in North America, making the CVT a mainstream transmission system. One major motivator for Nissan to make a switch to CVTs was as a part of their 'Green Program 2010' aimed at reducing CO2 emissions by 2010. The CVT found in Nissan’s Maxima, Murano and the V6 version of the Altima is considered to be the world's first "3.5 L class" belt CVT and can hold much higher torque loads than other belt CVTs.[38]

After studying pulley-based CVT for years, Honda[39] also introduced their own version on the 1995 Honda Civic VTi. Dubbed Honda Multi Matic, this CVT gearbox accepted higher torque than traditional pulley CVTs, and also includes a torque converter for "creep" action. The CVT is employed in the Honda City ZX that is manufactured in India and Honda City Vario manufactured in Pakistan.

In 1996, Fendt, a Germany-based tractor manufacturer, released the first ever heavy-duty tractor to be equipped with a hydrostatic type CVT with the Fendt Vario 926.[40] A year later Fendt was acquired by AGCO Corporation which expanded the use of the transmission to the Challenger Tractor, Massey Ferguson, and TerraGator[41] brands of machinery, which are also owned by AGCO. Well over 100,000 agricultural tractors have been manufactured with this transmission design.[40]

Toyota used a Power Split Transmission (PST) in the 1997 Prius, and all subsequent Toyota and Lexus hybrids sold internationally continue to use the system (marketed under the Hybrid Synergy Drive name). The HSD is also referred to as an electronically controlled continuously variable transmission (eCVT). The PST allows either the electric motor or the internal combustion engine (ICE) or both to propel the vehicle. In ICE-only mode, part of the engine's power is mechanically coupled to the drivetrain, with the other part going through a generator and a motor. The amount of power being channeled through the electrical path determine the effective gear ratio. Toyota also offers a non-hybrid CVT called Multidrive for models such as Avensis.

Audi has, since 2000, offered a chain-type CVT (multitronic) as an option on some of its larger-engine models, for example the A4 3.0 L V6.

Fiat in 2000 offered a Cone-type CVT as an option on its hit model Fiat Punto (16v 80 PS ELX,Sporting) and Lancia Y (1.2 16V).

BMW used a belt-drive CVT (manufactured by ZF Friedrichshafen) as an option for the low- and middle-range MINI in 2001, forsaking it only on the supercharged version of the car where the increased torque levels demanded a conventional automatic gearbox. The CVT could also be manually "shifted" if desired with software-simulated shift points.

GM introduced its version of CVT known as VTi in 2002. It was used in the Saturn Vue and Saturn Ion models.

In 2002 the Suzuki Burgman 650 was the largest-displacement scooter in the world, and first two-wheel vehicle to feature an electrically controlled CVT.[42][43]

Mercedes-Benz introduced their version of the CVT Transmission, known as "Autotronic" back in 2004 for the 2005 model year A-Class. And later in 2005 for the 2006 model year B-Class. "Autotronic" is one of the most compact CVT Transmissions in the world.

Ford introduced a chain-driven CVT known as the CFT30 in their 2005 Ford Freestyle, Ford Five Hundred and Mercury Montego. The transmission was designed in cooperation with German automotive supplier ZF Friedrichshafen and was produced in Batavia, Ohio at Batavia Transmissions LLC (a subsidiary of Ford Motor Company) until 22 March 2007. The Batavia plant also produced the belt-driven CFT23 CVT which went in the Ford Focus C-MAX, which didn't have much success because of gearbox failures, as it was coupled to the 1.6 TDCi turbodiesel engine, which had a higher torque rating than the CVT can handle. Ford also sold Escort and Orion models in Europe with CVTs in the 1980s and 1990s.

Contract agreements were established in 2005 between MTD Products and Torotrak for the first full toroidal system to be manufactured for outdoor power equipment such as jet skis, ski-mobiles and ride-on mowers.

The 2007 Dodge Caliber and the related Jeep Compass and Jeep Patriot employ a CVT using a variable pulley system as their optional automatic transmission.

The 2008 Mitsubishi Lancer model is available with CVT transmission as the automatic transmission. DE and ES models receive a standard CVT with Drive and Low gears; the GTS model is equipped with a standard Drive and also a Sportronic mode that allows the driver to use 6 different preset gear ratios (either with the shifter or steering wheel-mounted paddle shifters).

The 2009 SEAT Exeo is available with a CVT automatic transmission (multitronic) as an option for the 2.0 TSI 200 hp (149 kW) petrol engine, with selectable 'six-speeds'.

In 2010, the US Patent Office issued patent number 7,647,768 B1 for a series of hydraulic torque converters that use hydraulic friction rather than mechanical friction as a CVT.

In 2016, FCA US LLC announced the 2017 Chrysler Pacifica Hybrid minivan which uses a CVT instead of the 9-speed automatic found in gasoline versions.

For the 2019 Toyota Corolla Hatchback Toyota created an all new CVT with a "launch gear" or a physical 1st gear from a conventional automatic transmission alongside the CVT pulley. From 0-25 mph the transmission would stay in this launch gear to aid in acceleration from a stop and improve durability of the CVT. After 25 mph, the transmission would switch over to the CVT pulley

XO___XO e- Belt for conceptually of Transmission Lines in Digital and Analog Electronic Systems

the analysis of transmission lines in the basic skills to design high-speed digital and high-frequency analog systems. It does little good to write sophisticated software if the hardware is unable to process the instructions. This problem will increase as the speeds and frequencies of these systems continue to increase seemingly without bound.

objectives :

| Various applications of transmission lines. | |

| How to measure complex impedance at high frequencies where phase measurement is unreliable. | |

| How and why to use sections of transmission line as reactive elements in the high frequency circuits. | |

| Use of Smith chart and to design transmission line sections for realizing reactive impedances. |

| Measurement of Unknown Impedance | |

The unknown impedance which is to be measured is connected at the end of the transmission line as shown in Figure below. The transmission line is excited with a source of desired frequency

| |

| |

We know that at point B on the transmission line where the voltage is minimum, the impedance is real and its value is

| |

| |

| Substituting for | |

| |

| Separating real and imaginary parts we get | |

| |

| Measurement of Unknown Impedance (Practical Consideration) | |

While practically implementing the above scheme one would also notice that invariably the location of unknown impedance

| |

To overcome this problem the measurement is carried out in two steps. First, the standing wave pattern is obtained with the unknown load as explained above. Now replace the unknown impedance by an ideal short-circuit and obtain the standing wave pattern again. The two standing wave patterns are shown as below

| |

| |

At the short circuit point (which is also the location of the unknown impedance) the voltage

| |

| |

One can note here that

| |

| Transmission Line as a Circuit Element | ||

At frequencies of hundreds and thousands of MHz where lumped elements are hard to realize, the use of sections of transmission line as reactive elements may be more convenient.

| ||

| ||

The turns in the wire of the inductor have small distributed capacitors. | ||

As the frequency increases, the capacitance begins to play a role in the response of the circuit and beyond the resonant frequency, the capacitance predominates the response. That is the inductance coil effectively behaves like a capacitor.

| ||

| Similarly, for a capacitance, there exist lead inductance. As the frequency increases, the lead inductance starts dominating over the capacitance and beyond the resonant frequency of the LC combination, the capacitor effectively behaves like an inductor. | ||

| So, it is clear that at high frequencies, realization of reactive element is not that simple. | ||

| On the other hand at high frequencies, the wavelength and the length of the transmission line section reduces and becomes more manageable. | ||

| ||

| Use of Smith Chart for calculating | |

| From the impedance relation we can see that if a line of length | |

| |

| The input impedance of a loss-less line can be written as | |

Since the range of 'tan' and 'cot' functions is from

| |

Now if a reactance

| |

| |

| Smith chart can be used to find | |

| Choose suitable characteristics impedance of the line, | |

| Normalize the reactance to be realized (X) by | |

| (a) | Mark the reactance jx to be realized on the Smith chart to get point 'X' in Figure. |

| (b) |

Move in anticlockwise direction from point X to the short circuit (SC) point on the Smith chart to get

|

| (c) | Move from X in the anticlockwise direction upto open circuit (OC) to get |

(d) | Note here that instead of reactance if we had to realize a normalized susceptance b, the procedure is identical except that SC and OC points are interchanged. |

| |

| Line length and their Equivalent Reactants | |

| The following figure shows the range of transmission line lengths and the corresponding reactances which can be realized at the input terminals of the line. | |

| |

recap :

. How to measure complex impedance at high frequencies where phase measurement is unreliable