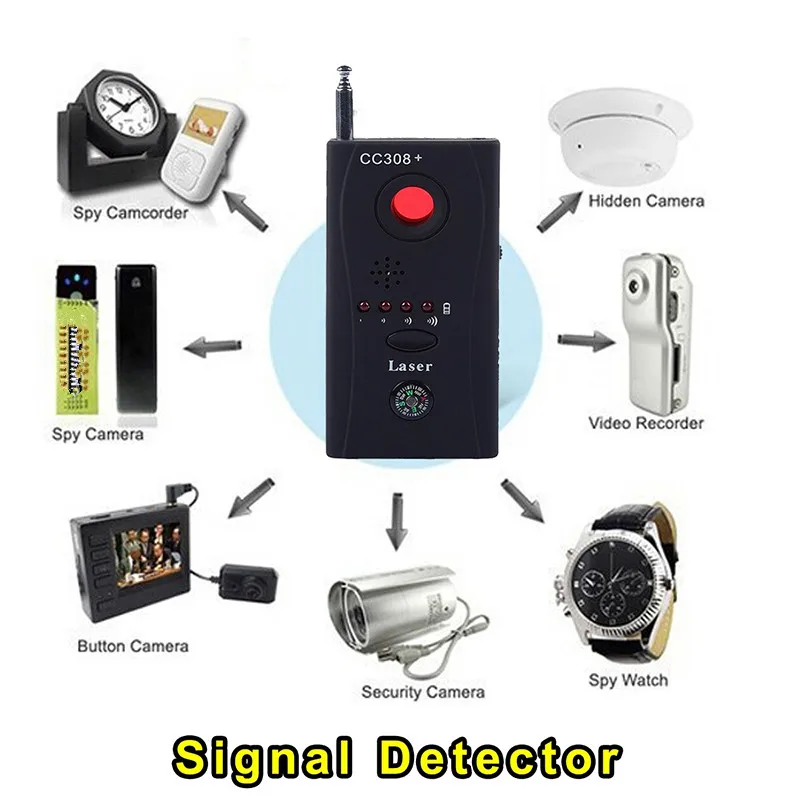

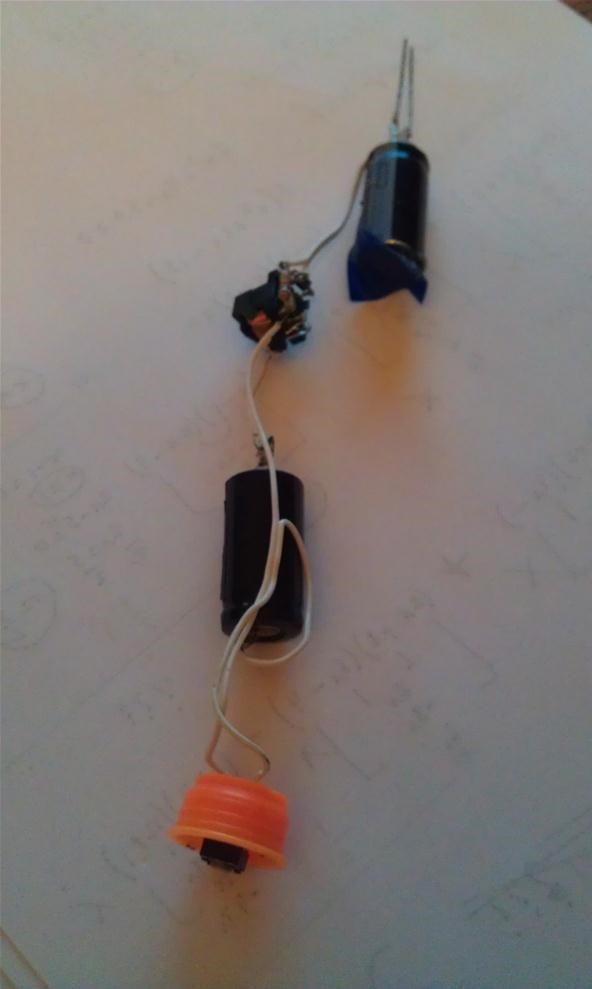

Signal tracer To seek interference and damage to audio and video electronics circuits

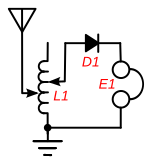

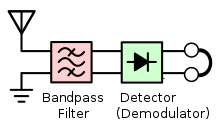

Simple signal tracking circuit

Simple signal tracking circuit

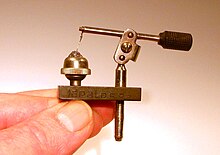

PACO Z-80 signal tracer probe

The signal tracker consists of a detector (taking back the low frequency of the high frequency carrier) and an ear phone. This signal tracker is used to search for circuit breakage by using the ear - phone.

By

tracing the circuit from start-up to end-level by using a signal tracer

earphone, the principle works like a medical device that is a

stethoscope to examine the human body, with this signal tracker

detectable which circuit level is damaged, by drawing conclusions from

the inactivity of the earphone It, also this tracker can be used to look for damage to the sound circuit, where the test signal is disrupted.

When and how to use signal-tracing techniques ?

Xample signal tracing to simple amplifier :

By comparing the Vi and Vo readings, we can determine the strengthening. This method is also called Input-Output Method / Output-Input Method.

By

changing the output amplitudes of the signal generator, we can see

whether the amplifier is linear in the input signal region.

With the load impedance variation (RL), we can see whether the linear gain on the load changes.

By changing the frequency of the signal generator, we can determine the frequency response of the amplifier.

With

this simple arrangement, the important characteristics of the amplifier

can be measured by the signal-tracing system, at amplitude and

frequency, from input to amplifier output.

In

some electronic devices, external signaling is not always necessary,

especially when the signal that should exist on the equipment can be

easily known. This method is called passive signal-tracing method .

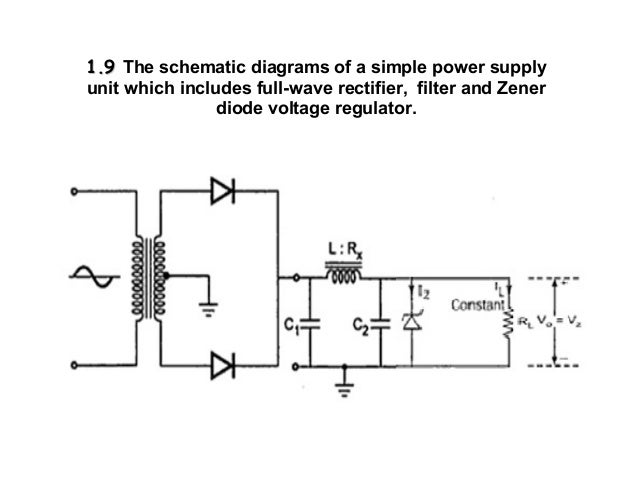

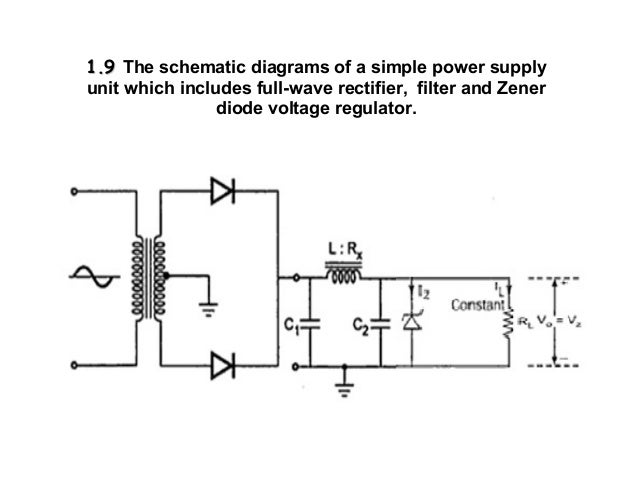

Xample Passive Tracing Signal Method A Power Supply :

The mesh voltage is measured with an AC voltmeter on the wall outlet, on the fuse, and on the switch. If there is a 220 V AC voltage at the primary end of the

transformer, then it is certain that the plug, cable, fuse and switch

are in good condition.

The mesh voltage is measured with an AC voltmeter on the wall outlet, on the fuse, and on the switch. If there is a 220 V AC voltage at the primary end of the

transformer, then it is certain that the plug, cable, fuse and switch

are in good condition.

AC signal on the secondary of the transformer can be measured on each side (secondary of transformer no CT) to ground. If there is a voltage on the secondary transformer of appropriate

magnitude, then it can be ascertained that the transformer is in good

condition.

Next, use the meter switch on the DC scale. Measure the voltage on C1 and on C2. If there is no DC voltage on C1 or C2, it means that the capacitor is short-circuited. When the L winding is open, then there is only a DC voltage at C1, but not in C2. When

C1 and C2 are open (break), or when CR1 and CR2 directors are open, or

both are short-circuited, the measured DC voltage is incorrect. Under such conditions, it is necessary to measure resistance to ensure the damaged component.

The

second way is the opposite of the first way, ie starting from the

measurement of DC voltage on capacitor C2, followed by measurement of DC

voltage on capacitor C1 and so on. The result is the same because the measurement uses only voltmeter only.

The following example is an FM radio whose block diagram shown in figure does not work.

Examination of power supply and voltage at static state of the circuit has been done. The damage is in the area between the antenna and the audio amplifier. In the passive method, normal signals are considered to be present or known. However,

since the antenna and tuning (which are thought to give normal signals

to the system) are within the system itself, external signals must be

assigned as normal signals and use speakers as signal indicators. This method is called an active signal-tracing method or signal injection.

Examination of power supply and voltage at static state of the circuit has been done. The damage is in the area between the antenna and the audio amplifier. In the passive method, normal signals are considered to be present or known. However,

since the antenna and tuning (which are thought to give normal signals

to the system) are within the system itself, external signals must be

assigned as normal signals and use speakers as signal indicators. This method is called an active signal-tracing method or signal injection.

First step:

The signal generator is connected to the RF tuner, and the antenna is removed; The signal generator and tuner are set at the same frequency. If

you do not hear anything on the loudspeaker, move the signal generator

at point A. change the frequency of the generator signal at 10.7 MHz

(Standard for FM radio). When the sound is heard (tone of the generator signal), this means damage to the RF tuner.

If not heard something, move the generator signal to the amplifier

output, ie at point B. At this point, the amplitude of the generator

signal must be increased to compensate for the gain of the middle

amplifier.

At point C, the normal signal is an audio signal. Therefore, the signal generator entered through this point must be at the audio frequency.

At point D the generator signal should be strong enough to drive the loudspeaker. The

loudspeaker can be tested by checking the voltage on the amplifier

driver and minimizing it momentarily with the corresponding resistor

between voltage and ground. This should generate a click sound on the loudspeaker.

The second way:

The check is done from the speakers to the tuner. To

determine whether using the first or second way can be preliminary, for

example: by briefly amplifying the audio amplifier input with ground

using a screwdriver or the end of a clip, this should produce a

loudspeaker click (if the loudspeaker and audio amplifier are working

properly).

If you do not hear the sound, then the

second way is the best choice, because the damage must exist between the

loudspeaker and the audio amplifier.

When you hear

a click, you can still continue the examination in a second way from

point C, or in the first way, since both have the same chance of

checking speed.

Means:

The signal-tracing method requires input signals on the suspect area, and can be measured accurately. Signal-tracing always requires at least one test kit and generally two.

Methods of voltage and resistance

In general, voltage and resistance measurements are performed to check for suspected damaged tissue or components. Voltage measurements require equipment with ON conditions, whereas resistance measurements are made when the equipment is OFF.

Usually

circuit diagrams and datasheets indicate the voltage required for

normal operating conditions at a particular test point. By making such measurements, usually the location of damage to the network and components can be known.

Resistance measurement is a very useful method for checking electronics components. A simple resistance measurement can be used to ensure continuous

wiring, the correct value approach of the transformer, inductor, winding

as well as the value approach of the large capacitor.

The

majority of resistors used in electronic equipment are carbon

composition types and they tend to change in value due to age and heat. When

this happens often perhaps the measurement of resistor resistance or

other components in the circuit, should be assured by examination on the

circuit image. The parallel impedance does not give an incorrect measurement, when a

resistor increases in magnitude or open, it is relatively simple to

determine this.

Voltage and Barrier Techniques are often used anywhere after the

symptom-function technique refers to a particular circuit or component

as a source of damage, or when a signaltracing technique has localized a

defect in this way.

mean :Voltage

and Barrier methods are used to pinpoint a component or circuit

breakage and generally require company data for component and voltage

values.

The half-splitting method

This method is suitable for series with series blocks / open loop system (elongated) because it will be very fast when looking for damage. For example: function generator circuit, radio transmitter / receiver, etc.

The

step: starting from the center of the system, and successively on each

of the middle half of the part of the system that has been separated

until it is found to be damaged.

Block 1 ---> block 2 ---> block 3 ---->block 4 ----->block 5 ----> block 6 ----> block 7 ----> block8

As an insight

material that in the electronics block diagram shows the signal flow,

while the schematic circuit shows the flow of current and voltage, flow

chart is the flow of the program or function.

8 Block Sub Serial System Series

Check the output of block 4, if it works fine, means blocks 1 through 4 there is no problem.

If it does not work, then check block 2 output (middle of blocks

1-4), and if good means check out block 3 output, and if good means

block 4 is damaged.

Check Output of block 8, if it works well, means block 5 to block 8 is no problem.

If it does not work, then check the output of block 6 (middle of

blocks 1-4), and if good means check out the output of block 7, and if

good, then block 8 is damaged.

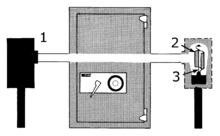

Loop breaking method

Electronic systems or sub-systems with feedback, very difficult to trace the damage without breaking the loop. Appropriate DC voltage or signal, shall be injected at the point where the loop is disconnected.

Voltages and signals through the circuit, should be used to monitor errors.

Inverted voltage or signal can be changed, to see the change of circuit response from normal state.

Typically, the loop is broken at the point where the signal is at small power, so it can be injected properly.

This technique can be used for example on a PLL (phase lock loop), such as :

The power supply and reference oscillator output should be checked first before the loop is disconnected. In this case the output should be abnormal or unstable or missing, so we can be sure that the VCO is not good. Next we can do the loop termination at the appropriate point. So

the loop termination here is not necessarily the feedback section, but

is sought in small signal areas that are easily injected with existing

equipment.

The power supply and reference oscillator output should be checked first before the loop is disconnected. In this case the output should be abnormal or unstable or missing, so we can be sure that the VCO is not good. Next we can do the loop termination at the appropriate point. So

the loop termination here is not necessarily the feedback section, but

is sought in small signal areas that are easily injected with existing

equipment.

Substitution method

In this method it is usually necessary to sold or replace parts as the final stage of the damage tracking process.

There

are two main stages in the substitution method that must be done,

namely: use the correct replacement components, and connect correctly to

the circuit.

Prior to the replacement, it

is advisable to check with other methods as described previously, to be

sure which component is damaged.

Do a voltage measurement to make sure that the voltage that is supposed to exist really exists. The

voltage checks performed on the combined components of resistors and

capacitors, will be able to show whether they are damaged or just one of

them.

In practice, we are usually very difficult to

find a replacement component in the form of ICs, transistors, and diodes

that exactly match the replaced components. To solve this, you need to find equivalent data of IC type, transistor, or diode in semiconductor user manual.

If

the replaced component has a special type, for example: transformer,

coil-deflection yoke, and other special components, it is necessary to

look for a completely suitable replacement component (no equivalent).

PRINCIPLE OF DAMAGE TRACK / FAILURE

PRINCIPLE OF DAMAGE TRACK / FAILURE

1. Maintenance Process in Industry

2. Specifications

3. Reliability and Failure

4. Method-Tracking Method of Damage

5. Problem-Solving Analysis

6. Active Component Testing

7. Circuit Checking and Testing

X . I

Detector (radio) / tracker

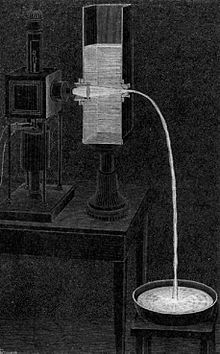

In

electronics, a

detector is an older term for an

electronic component in a

radio receiver that extracts

information contained in a

modulated radio wave, a

demodulator. The term dates from the first three decades of radio (1886-1916). Unlike modern radio stations which transmit sound (an

audio signal) on the radio

carrier wave, the first radio transmitters transmitted information by

wireless telegraphy, using different length pulses of radio waves to spell out text messages in

Morse code.

So early radio receivers did not have to extract an audio signal

(sound) from the incoming radio signal, but only detect the presence or

absence of the radio signal, to produce clicks in the receiver's

earphones representing the Morse code symbols. The device that did this

was called a

detector. A variety of different detector devices, such as the

coherer,

electrolytic detector, and

magnetic detector, were used during the wireless telegraphy era.

After sound (

amplitude modulation, AM) transmission began around 1920, the term evolved to mean a

demodulator, a nonlinear

rectifier (usually a

crystal diode or a

vacuum tube) which extracted the

audio signal from the radio frequency

carrier wave. This is its current meaning, although modern detectors usually consist of

semiconductor diodes,

transistors, or

integrated circuits.

In a

superheterodyne receiver the term is also sometimes used to refer to the

mixer, the tube or transistor which converts the incoming radio frequency signal to the

intermediate frequency. The mixer is called the

first detector, while the demodulator that extracts the audio signal from the intermediate frequency is called the

second detector.

A coherer detector, useful only for Morse code signals.

Amplitude modulation detectors

Envelope detector

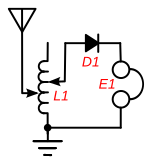

A simple envelope detector

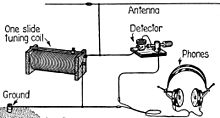

A simple crystal radio with no tuned circuit can be used to listen to strong AM broadcast signals

One major technique is known as envelope detection. The simplest form of

envelope detector is the diode detector that consists of a

diode

connected between the input and output of the circuit, with a resistor

and capacitor in parallel from the output of the circuit to the ground

to form a low pass filter. If the resistor and capacitor are correctly

chosen, the output of this circuit will be a nearly identical

voltage-shifted version of the original signal.

An early form of envelope detector was the

cat's whisker, which was used in the

crystal set

radio receiver. A later version using a crystal diode is still used in

crystal radio sets today. The limited frequency response of the headset

eliminates the RF component, making the low pass filter unnecessary.

More sophisticated envelope detectors include the

plate detector,

grid-leak detector and transistor equivalents of them,

infinite-impedance detectors (

peak detector circuits), and

precision rectifiers.

Product detector

A

product detector is a type of

demodulator used for

AM and

SSB signals, where the original carrier signal is removed by multiplying the received signal with a signal at the

carrier frequency

(or near to it). Rather than converting the envelope of the signal into

the decoded waveform by rectification as an envelope detector would,

the product detector takes the product of the modulated signal and a

local oscillator, hence the name. By

heterodyning,

the received signal is mixed (in some type of nonlinear device) with a

signal from the local oscillator, to give sum and difference frequencies

to the signals being mixed, just as a

first mixer stage in a

superhet would produce an

intermediate frequency; the

beat frequency in this case, the low frequency

modulating signal is recovered and the unwanted high frequencies

filtered out from the output of the product detector.

Product detector circuits are

analog multipliers and so essentially

ring modulators or

synchronous detectors and closely related to some

phase-sensitive detector circuits. They can be implemented using something as simple as

ring of diodes or a single dual-gate

Field Effect Transistor to anything as sophisticated as an

Integrated Circuit containing a

Gilbert cell.

Frequency and phase modulation detectors

AM detectors cannot demodulate

FM and

PM signals because both have a

constant amplitude. However an AM radio may detect the sound of an FM broadcast by the phenomenon of

slope detection

which occurs when the radio is tuned slightly above or below the

nominal broadcast frequency. Frequency variation on one sloping side of

the radio tuning curve gives the amplified signal a corresponding local

amplitude variation, to which the AM detector is sensitive. Slope

detection gives inferior distortion and noise rejection compared to the

following dedicated FM detectors that are normally used.

Phase detector

A

phase detector is a

nonlinear device whose output represents the

phase

difference between the two oscillating input signals. It has two inputs

and one output: a reference signal is applied to one input and the

phase or frequency modulated signal is applied to the other. The output

is a signal that is proportional to the phase difference between the two

inputs.

In phase demodulation the information is contained in the amount and rate of phase shift in the

carrier wave.

The Foster-Seeley discriminator

The

Foster-Seeley discriminator is a widely used FM detector. The detector consists of a special center-tapped

transformer feeding two diodes in a full wave DC

rectifier

circuit. When the input transformer is tuned to the signal frequency,

the output of the discriminator is zero. When there is no deviation of

the carrier, both halves of the center tapped transformer are balanced.

As the FM signal swings in frequency above and below the carrier

frequency, the balance between the two halves of the center-tapped

secondary is destroyed and there is an output voltage proportional to

the frequency deviation.

Ratio detector

A ratio detector using solid-state diodes

The ratio detector

is a variant of the Foster-Seeley discriminator, but one diode conducts

in an opposite direction, and using a tertiary winding in the preceding

transformer. The output in this case is taken between the sum of the

diode voltages and the center tap. The output across the diodes is

connected to a large value capacitor, which eliminates AM noise in the

ratio detector output. The ratio detector has the advantage over the

Foster-Seeley discriminator that it will not respond to

AM signals,

thus potentially saving a limiter stage; however the output is only 50%

of the output of a discriminator for the same input signal. The ratio

detector has wider bandwidth but more distortion than the Foster-Seeley

discriminator.

Quadrature detector

In quadrature detectors, the received FM signal is split into two signals. One of the two signals is then passed through a

high-reactance capacitor,

which shifts the phase of that signal by 90 degrees. This phase-shifted

signal is then applied to an LC circuit, which is resonant at the FM

signal's unmodulated, "center," or "carrier" frequency. If the received

FM signal's frequency equals the center frequency, then the two signals

will have a 90-degree

phase difference

and they are said to be in "phase quadrature" — hence the name of this

method. The two signals are then multiplied together in an analog or

digital device, which serves as a

phase detector;

that is, a device whose output is proportional to the phase difference

between two signals. In the case of an unmodulated FM signal, the phase

detector's output is — after the output has been

filtered;

that is, averaged over time — constant; namely, zero. However, if the

received FM signal has been modulated, then its frequency will vary from

the center frequency. In this case, the resonant LC circuit will

further shift the phase of the signal from the capacitor, so that the

signal's total phase shift will be the sum of the 90 degrees that's

imposed by the capacitor and the positive or negative phase change

that's imposed by the LC circuit. Now the output from the phase detector

will differ from zero, and in this way, one recovers the original

signal that was used to modulate the FM carrier.

This detection process can also be accomplished by combining, in an

exclusive-OR (XOR) logic gate, the original FM signal and a

square wave

whose frequency equals the FM signal's center frequency. The XOR gate

produces an output pulse whose duration equals the difference between

the times at which the square wave and the received FM signal pass

through zero volts. As the FM signal's frequency varies from its

unmodulated center frequency (which is also the frequency of the square

wave), the output pulses from the XOR gate become longer or shorter. (In

essence, this quadrature detector converts an FM signal into a

pulse-width modulated

(PWM) signal.) When these pulses are filtered, the filter's output

rises as the pulses grow longer and its output falls as the pulses grow

shorter. In this way, one recovers the original signal that was used to

modulate the FM carrier.

Other FM detectors

Less common, specialized, or obsolescent types of detectors include:

- Travis or double tuned circuit discriminator using two non-interacting tuned circuits above and below the nominal center frequency

- Weiss discriminator which uses a single LC tuned circuit or crystal

- Pulse count discriminator which converts the frequency to a train of

constant amplitude pulses, producing a voltage directly proportional to

the frequency.

Phase-locked loop detector

The

phase-locked loop detector requires no frequency-selective LC network to accomplish demodulation. In this system, a

voltage controlled oscillator (VCO) is

phase locked by a

feedback loop,

which forces the VCO to follow the frequency variations of the incoming

FM signal. The low-frequency error voltage that forces the VCO's

frequency to track the frequency of the modulated FM signal is the

demodulated audio output.

X . II

CRYSTAL RADIO AND DETEKTOR

A

crystal radio receiver, also called a

crystal set or

cat's whisker receiver, is a very simple

radio receiver, popular in the early days of radio. It needs no other power source but that received solely from the power of

radio waves received by a wire

antenna. It gets its name from its most important component, known as a

crystal detector, originally made from a piece of crystalline mineral such as

galena. This component is now called a

diode.

Crystal radios are the simplest type of radio receiver an

Tutup d can be made with a few inexpensive parts, such as a wire for an antenna, a

coil of copper wire for adjustment, a capacitor, a crystal detector, and

earphones. Crystal radios are distinct from ordinary radios as they are

passive receivers, while other radios use a separate source of

electric power such as a

battery or the

mains power to

amplify

the weak radio signal so as to make it louder. Thus, crystal sets

produce rather weak sound and must be listened to with sensitive

earphones, and can only receive stations within a limited range.

Today they

are still sold as educational devices, and there are groups of

enthusiasts devoted to their construction

.

Crystal radios receive

amplitude modulated (AM) signals, and can be designed to receive almost any

radio frequency band, but most receive the

AM broadcast band. A few receive

shortwave bands, but strong signals are required. The first crystal sets received

wireless telegraphy signals broadcast by

spark-gap transmitters at frequencies as low as 20 kHz.

1970s-era crystal radio marketed to children. The earphone is on left.

The antenna wire, right, has a clip to attach to metal objects such as a

bedspring, which serve as an additional antenna to improve reception.

Bright clouds

A family listening to a crystal radio in the 1920s

Greenleaf Whittier Pickard's US Patent 836,531 "Means for receiving intelligence communicated by electric waves" diagram

Radio receiver, Basel, Switzerland, 1914

NBS Circular 120 Home Crystal Radio Project

Crystal radio used as a backup receiver on a World War II

Liberty ship

Crystal radio was invented by a long, partly obscure chain of

discoveries

in the late 19th century that gradually evolved into more and more

practical radio receivers in the early 20th century. The earliest

practical use of crystal radio was to receive

Morse code radio signals transmitted, from

spark-gap transmitters, by early

amateur radio

experimenters. As electronics evolved, the ability to send voice

signals by radio caused a technological explosion in the years around

1920 that evolved into today's radio

broadcasting industry.

Early years

Early radio telegraphy used

spark gap and

arc transmitters as well as

high-frequency alternators running at

radio frequencies. The

coherer was the first means of detecting a radio signal. These, however, lacked the sensitivity to detect weak signals.

In the early 20th century, various researchers discovered that certain metallic

minerals, such as

galena, could be used to detect radio signals.

Pickard's detector was revolutionary in that he found that a fine pointed wire known as a "

cat's whisker", in delicate contact with a mineral, produced the best semiconductor effect (that of

rectification).

A crystal detector includes a crystal, a special thin wire that

contacts the crystal, and the stand that holds those components in

place. The most common crystal used is a small piece of

galena;

pyrite

was also often used, as it was a more easily adjusted and stable

mineral, and quite sufficient for urban signal strengths. Several other

minerals also performed well as detectors. Another benefit of crystals

was that they could

demodulate amplitude modulated signals.

This device brought

radiotelephones and

voice broadcast

to a public audience. Crystal sets represented an inexpensive and

technologically simple method of receiving these signals at a time when

the embryonic radio broadcasting industry was beginning to grow.

Crystodyne

crystodyne applying voltage

biases to various kinds of crystals for manufacture of radio detectors. The result was astonishing: with a

zincite (

zinc oxide) crystal he gained amplification. This was

negative resistance phenomenon, decades before the development of the

tunnel diode. After the first experiments, Losev built regenerative and

superheterodyne receivers, and even transmitters.

A crystodyne could be produced in primitive conditions; it can be made in a rural forge, unlike

vacuum tubes

and modern semiconductor devices. However, this discovery was not

supported by authorities and soon forgotten; no device was produced in

mass quantity beyond a few examples for research.

"Foxhole radios"

"Foxhole radio" used on the Italian Front in World War 2. It uses a

pencil lead attached to a safety pin pressing against a razor blade for a

detector.

In addition to mineral crystals, the oxide coatings of many metal surfaces act as

semiconductors

(detectors) capable of rectification. Crystal radios have been

improvised using detectors made from rusty nails, corroded pennies, and

many other common objects.

Design

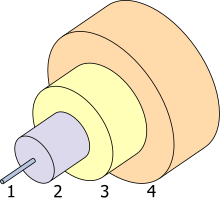

Block diagram of a crystal radio receiver

A crystal radio can be thought of as a radio receiver reduced to its essentials. It consists of at least these components:

- An antenna in which electric currents are induced by the radio waves.

- A resonant circuit (tuned circuit) which serves to select the frequency of the desired radio station out of all the radio signals received by the antenna. The tuned circuit consists of a coil of wire (called an inductor) and a capacitor

connected together, so as to create a circuit that resonates at the

frequency of the desired station, and hence "tune" in that station. One

or both of the coil or capacitor is adjustable, allowing the circuit to

be tuned to different frequencies. In some circuits a capacitor is not

used, as the antenna also serves as the capacitor. The tuned circuit has

a resonant frequency

and allows radio waves at that frequency to pass to the detector, while

rejecting waves at all other frequencies. Such a circuit is also known

as a bandpass filter.

- A semiconductor crystal (detector) that demodulates the radio signal to get the audio signal (modulation). The crystal detector is a nonlinear impedance that functions as a square law detector[citation needed]. The detector's output is converted to sound by the earphone. Early sets used a cat's whisker detector, consisting of a fine wire touching the surface of a sample of crystalline mineral such as galena. It was this component that gave crystal sets their name.

- An earphone

to convert the audio signal to sound waves so they can be heard. The

low power produced by a crystal receiver is insufficient to power a loudspeaker, hence earphones are used.

Pictorial diagram from 1922 showing the circuit of a crystal radio. This common circuit did not use a tuning

capacitor, but used the capacitance of the antenna to form the

tuned circuit

with the coil. The detector might have been a piece of galena with a

whisker wire in contact with it on a part of the crystal, making a diode

contact

As a crystal radio has no power supply, the sound power produced by the earphone comes solely from the

transmitter of the radio station being received, via the radio waves captured by the antenna. The power available to a receiving antenna decreases with the square of its distance from the

radio transmitter. Even for a powerful commercial

broadcasting station, if it is more than a few miles from the receiver the power received by the antenna is very small, typically measured in

microwatts or

nanowatts. In modern crystal sets, signals as weak as 50

picowatts at the antenna can be heard. Crystal radios can receive such weak signals without using

amplification only due to the great sensitivity of human

hearing, which can detect sounds with an intensity of only 10

−16 W/cm

2.

Therefore, crystal receivers have to be designed to convert the energy

from the radio waves into sound waves as efficiently as possible. Even

so, they are usually only able to receive stations within distances of

about 25 miles for

AM broadcast stations, although the

radiotelegraphy signals used during the

wireless telegraphy era could be received at hundreds of miles, and crystal receivers were even used for transoceanic communication during that period.

Commercial passive receiver development was abandoned with the advent

of reliable vacuum tubes around 1920, and subsequent crystal radio

research was primarily done by

radio amateurs and hobbyists.

Many different circuits have been used. The following sections discuss the parts of a crystal radio in greater detail.

Antenna

The antenna converts the energy in the electromagnetic

radio waves to an

alternating electric current

in the antenna, which is connected to the tuning coil. Since in a

crystal radio all the power comes from the antenna, it is important that

the antenna collect as much power from the radio wave as possible. The

larger an antenna, the more power it can intercept. Antennas of the type

commonly used with crystal sets are most effective when their length is

close to a multiple of a quarter-

wavelength of the radio waves they are receiving. Since the length of the waves used with crystal radios is very long (

AM broadcast band waves are 182-566

m or 597–1857 ft. long) the antenna is made as long as possible, from a

long wire, in contrast to the

whip antennas or ferrite

loopstick antennas used in modern radios.

Serious crystal radio hobbyists use "inverted L" and

"T" type antennas,

consisting of hundreds of feet of wire suspended as high as possible

between buildings or trees, with a feed wire attached in the center or

at one end leading down to the receiver.

However more often random lengths of wire dangling out windows are

used. A popular practice in early days (particularly among apartment

dwellers) was to use existing large metal objects, such as

bedsprings,

fire escapes, and

barbed wire fences as antennas.

Ground

The wire antennas used with crystal receivers are

monopole antennas which develop their output voltage with respect to ground. The receiver thus requires a connection to

ground

(the earth) as a return circuit for the current. The ground wire was

attached to a radiator, water pipe, or a metal stake driven into the

ground. In early days if an adequate ground connection could not be made a

counterpoise was sometimes used. A good ground is more important for crystal sets than it is for powered receivers, as crystal sets are designed to have a low

input impedance

needed to transfer power efficiently from the antenna. A low resistance

ground connection (preferably below 25 Ω) is necessary because any

resistance in the ground reduces available power from the antenna.

In contrast, modern receivers are voltage-driven devices, with high

input impedance, hence little current flows in the antenna/ground

circuit. Also,

mains powered

receivers are grounded adequately through their power cords, which are

in turn attached to the earth by way of a well established ground.

Tuned circuit

The earliest crystal receiver circuit did not have a

tuned circuit

The

tuned circuit, consisting of a coil and a

capacitor connected together, acts as a

resonator, similar to a tuning fork.

Electric charge, induced in the antenna by the radio waves, flows

rapidly back and forth between the plates of the capacitor through the

coil. The circuit has a high

impedance at the desired radio signal's frequency, but a low impedance at all other frequencies.

Hence, signals at undesired frequencies pass through the tuned circuit

to ground, while the desired frequency is instead passed on to the

detector (diode) and stimulates the earpiece and is heard. The frequency

of the station received is the

resonant frequency f of the tuned circuit, determined by the

capacitance C of the capacitor and the

inductance L of the coil:

By varying either the inductor (L) or the capacitance (C), the

circuit can be adjusted to different frequencies. In inexpensive sets,

the inductor was made variable via a spring contact pressing against the

windings that could slide along the coil, thereby introducing a larger

or smaller number of turns of the coil into the circuit. Thus the

inductance could be varied, "tuning" the circuit to the frequencies of different radio stations.Alternatively, a

variable capacitor is used to tune the circuit. Some modern crystal sets use a

ferrite core tuning coil, in which a ferrite

magnetic core is moved into and out of the coil, thereby varying the inductance by changing the

magnetic permeability (this eliminated the less reliable mechanical contact).

The antenna is an integral part of the tuned circuit and its

reactance contributes to determining the circuit's resonant frequency. Antennas usually act as a

capacitance, as antennas shorter than a quarter-wavelength have

capacitive reactance. Many early crystal sets did not have a tuning capacitor, and relied instead on the capacitance inherent in the wire antenna (in addition to significant

parasitic capacitance in the coil) to form the tuned circuit with the coil.

The earliest crystal receivers did not have a tuned circuit at all,

and just consisted of a crystal detector connected between the antenna

and ground, with an earphone across it. Since this circuit lacked any frequency-selective elements besides the broad

resonance

of the antenna, it had little ability to reject unwanted stations, so

all stations within a wide band of frequencies were heard in the

earphone

(in practice the most powerful usually drowns out the others). It was

used in the earliest days of radio, when only one or two stations were

within a crystal set's limited range.

Impedance matching

"Two

slider" crystal radio circuit.

and example from 1920s. The two sliding contacts on the coil allowed

the impedance of the radio to be adjusted to match the antenna as theradio was tuned, resulting in stronger reception

An important principle used in crystal radio design to transfer maximum power to the earphone is

impedance matching. The maximum power is transferred from one part of a circuit to another when the

impedance of one circuit is the complex conjugate of that of the other; this implies that the two circuits should have equal resistance. However, in crystal sets, the impedance of the antenna-ground system (around 10-200

ohms ) is usually lower than the impedance of the receiver's tuned circuit (thousands of ohms at resonance),

and also varies depending on the quality of the ground attachment,

length of the antenna, and the frequency to which the receiver is tuned.

Therefore, in improved receiver circuits, in order to match the

antenna impedance to the receiver's impedance, the antenna was connected

across only a portion of the tuning coil's turns. This made the tuning coil act as an

impedance matching transformer (in an

autotransformer

connection) in addition to providing the tuning function. The antenna's

low resistance was increased (transformed) by a factor equal to the

square of the turns ratio (the ratio of the number of turns the antenna

was connected to, to the total number of turns of the coil), to match

the resistance across the tuned circuit.

In the "two-slider" circuit, popular during the wireless era, both the

antenna and the detector circuit were attached to the coil with sliding

contacts, allowing (interactive) adjustment of both the resonant frequency and the turns ratio.

Alternatively a multiposition switch was used to select taps on the

coil. These controls were adjusted until the station sounded loudest in

the earphone.

Problem of selectivity

Direct-coupled circuit with impedance matching

One of the drawbacks of crystal sets is that they are vulnerable to interference from stations near in

frequency to the desired station; that is to say, they have low

selectivity.

Often two or more stations are heard simultaneously. This is because

the simple tuned circuit does not reject nearby signals well; it allows a

wide band of frequencies to pass through, that is, it has a large

bandwidth (low

Q factor) compared to modern receivers.

The crystal detector worsened the problem, because it has relatively low

resistance, thus it "loaded" the tuned circuit

, damping the oscillations (lowering the response), and reducing its

Q.

In many circuits, the selectivity was improved by connecting the

detector and earphone circuit to a tap across only a fraction of the

coil's turns. This reduced the impedance loading of the tuned circuit, as well as improving the impedance match with the detector.

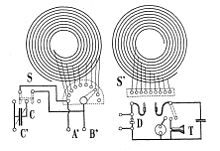

Inductive coupling

Inductively-coupled circuit with impedance matching. This type was used in most quality crystal receivers

Amateur-built crystal receiver with "loose coupler" antenna transformer, Belfast, around 1914

In more sophisticated crystal receivers, the tuning coil is replaced with an adjustable air core

antenna coupling transformer which improves the

selectivity by a technique called

loose coupling.

This consists of two

magnetically coupled coils of wire, one (the

primary) attached to the antenna and ground and the other (the

secondary)

attached to the rest of the circuit. The current from the antenna

creates an alternating magnetic field in the primary coil, which induced

a current in the secondary coil which was then rectified and powered

the earphone. Each of the coils functions as a

tuned circuit; the primary coil

resonated

with the capacitance of the antenna (or sometimes another capacitor),

and the secondary coil resonated with the tuning capacitor. Both the

primary and secondary were tuned to the frequency of the station. The

two circuits interacted to form a

resonant transformer.

Reducing the

coupling between the coils, by physically separating them so that less of the

magnetic field of one intersects the other, reduces the

mutual inductance, narrows the bandwidth, and results in much sharper, more selective tuning than that produced by a single tuned circuit.

However, the looser coupling also reduced the power of the signal

passed to the second circuit. The transformer was made with adjustable

coupling, to allow the listener to experiment with various settings to

gain the best reception.

One design common in early days, called a "loose coupler", consisted of a smaller secondary coil inside a larger primary coil

. The smaller coil was mounted on a

rack

so it could be slid linearly in or out of the larger coil. If radio

interference was encountered, the smaller coil would be slid further out

of the larger, loosening the coupling, narrowing the bandwidth, and

thereby rejecting the interfering signal.

The antenna coupling transformer also functioned as an

impedance matching transformer,

that allowed a better match of the antenna impedance to the rest of the

circuit. One or both of the coils usually had several taps which could

be selected with a switch, allowing adjustment of the number of turns of

that transformer and hence the "turns ratio".

Coupling transformers were difficult to adjust, because the three

adjustments, the tuning of the primary circuit, the tuning of the

secondary circuit, and the coupling of the coils, were all interactive,

and changing one affected the others.

Crystal detector

Galena cat's whisker detector

How the crystal detector works.

(A) The

amplitude modulated radio signal from the tuned circuit. The rapid oscillations are the

radio frequency carrier wave. The

audio signal (the sound) is contained in the slow variations (

modulation)

of the amplitude (hence the term amplitude modulation, AM) of the

waves. This signal cannot be converted to sound by the earphone, because

the audio excursions are the same on both sides of the axis, averaging

out to zero, which would result in no net motion of the earphone's

diaphragm.

(B) The crystal

conducts current better in one direction than the other, producing a

signal whose amplitude does not average to zero but varies with the

audio signal.

(C) A bypass capacitor is used to remove the radio frequency carrier pulses, leaving the audio signal

Circuit with detector bias battery to improve sensitivity and buzzer to adjust cat's whisker

The crystal

detector demodulates the radio frequency signal, extracting the

modulation (the

audio signal which represents the sound waves) from the radio frequency

carrier wave. In early receivers, the detector was a

cat's whisker detector consisting of a fine metal wire, the "cat's whisker", on an adjustable arm that touched a pea-sized lump of

semiconducting mineral. The point of contact between the wire and the crystal produced a diode effect. The cat's whisker detector was a crude

Schottky diode that allowed current to flow better in one direction than in the opposite direction. Modern crystal sets use modern

semiconductor diodes. The crystal functions as an

envelope detector,

rectifying the

alternating current radio signal to a pulsing

direct current,

the peaks of which trace out the audio signal, so it can be converted

to sound by the earphone, which is connected to the detector.

The rectified current from the detector has

radio frequency

pulses from the carrier frequency in it, which are blocked by the high

inductive reactance and do not pass well through the coils of early date

earphones. Hence, a small

capacitor called a

bypass capacitor

is often placed across the earphone terminals; its low reactance at

radio frequency bypasses these pulses around the earphone to ground. In some sets the earphone cord had enough capacitance that this component could be omitted.

In a cat's whisker detector only certain sites on the crystal surface

functioned as rectifying junctions, and the device was very sensitive

to the pressure of the crystal-wire contact, which could be disrupted by

the slightest vibration.

Therefore, a usable contact point had to be found by trial and error

before each use. The operator dragged the wire across the crystal

surface until a radio station or "static" sounds were heard in the

earphones.

Alternatively, some radios

(circuit, right) used a battery-powered

buzzer attached to the input circuit to adjust the detector.

The spark at the buzzer's electrical contacts served as a weak source

of static, so when the detector began working, the buzzing could be

heard in the earphones. The buzzer was then turned off, and the radio

tuned to the desired station.

Galena (lead sulfide) was probably the most common crystal used in cat's whisker detectors, but various other types of crystals were also used, the most common being

iron pyrite (fool's gold, FeS

2),

silicon,

molybdenite (MoS

2),

silicon carbide (carborundum, SiC), and a

zincite-

bornite (ZnO-Cu

5FeS

4) crystal-to-crystal junction trade-named

Perikon.

Crystal radios have also been improvised from a variety of common objects, such as blue steel

razor blades and

lead pencils, rusty needles, and pennies In these, a

semiconducting layer of oxide or sulfide on the metal surface is usually responsible for the rectifying action.

In modern sets, a

semiconductor diode is used for the detector, which is much more reliable than a cat's whisker detector and requires no adjustments.

Germanium diodes (or sometimes

Schottky diodes) are used instead of

silicon diodes, because their lower forward voltage drop (roughly 0.3V compared to 0.6V

) makes them more sensitive.

All semiconductor detectors function rather inefficiently in crystal

receivers, because the low voltage input to the detector is too low to

result in much difference between forward better conduction direction,

and the reverse weaker conduction. To improve the sensitivity of some of

the early crystal detectors, such as silicon carbide, a small

forward bias voltage was applied across the detector by a battery and

potentiometer.

The bias moves the diode's operating point higher on the detection

curve producing more signal voltage at the expense of less signal

current (higher impedance). There is a limit to the benefit that this

produces, depending on the other impedances of the radio. This improved

sensitivity was caused by moving the DC operating point to a more

desirable voltage-current operating point (impedance) on the junction's

I-V curve. The battery did not power the radio, but only provided the biasing voltage which required little power.

Earphones

The requirements for earphones used in crystal sets are different

from earphones used with modern audio equipment. They have to be

efficient at converting the electrical signal energy to sound waves,

while most modern earphones sacrifice efficiency in order to gain

high fidelity reproduction of the sound. In early homebuilt sets, the earphones were the most costly component.

The early earphones used with wireless-era crystal sets had

moving iron drivers that worked in a way similar to the horn

loudspeakers of the period; modern loudspeakers use a moving-coil principle. Each earpiece contained a permanent

magnet about which was a coil of wire which formed a second

electromagnet. Both magnetic poles were close to a steel diaphram of the speaker. When the

audio signal from the radio was passed through the electromagnet's windings, current was caused to flow in the coil which created a varying

magnetic field

that augmented or diminished that due to the permanent magnet. This

varied the force of attraction on the diaphragm, causing it to vibrate.

The vibrations of the diaphragm push and pull on the air in front of it,

creating sound waves. Standard headphones used in telephone work had a

low

impedance,

often 75 Ω, and required more current than a crystal radio could

supply. Therefore, the type used with crystal set radios (and other

sensitive equipment) was wound with more turns of finer wire giving it a

high impedance of 2000-8000 Ω.

Modern crystal sets use

piezoelectric crystal earpieces, which are much more sensitive and also smaller.

They consist of a

piezoelectric

crystal with electrodes attached to each side, glued to a light

diaphragm. When the audio signal from the radio set is applied to the

electrodes, it causes the crystal to vibrate, vibrating the diaphragm.

Crystal earphones are designed as

ear buds

that plug directly into the ear canal of the wearer, coupling the sound

more efficiently to the eardrum. Their resistance is much higher

(typically megohms) so they do not greatly "load" the tuned circuit,

allowing increased

selectivity of the receiver. The piezoelectric earphone's higher resistance, in parallel with its capacitance of around 9 pF, creates a

filter that allows the passage of low frequencies, but blocks the higher frequencies.

In that case a bypass capacitor is not needed (although in practice a

small one of around 0.68 to 1 nF is often used to help improve quality),

but instead a 10-100 kΩ resistor must be added in parallel with the

earphone's input.

Although the low power produced by crystal radios is typically insufficient to drive a

loudspeaker, some homemade 1960s sets have used one, with an audio

transformer to match the low impedance of the speaker to the circuit.

Similarly, modern low-impedance (8 Ω) earphones cannot be used

unmodified in crystal sets because the receiver does not produce enough

current to drive them. They are sometimes used by adding an audio

transformer to match their impedance with the higher impedance of the

driving antenna circuit.

Use as a power source

A

crystal radio tuned to a strong local transmitter can be used as a

power source for a second amplified receiver of a distant station that

cannot be heard without amplification.

There is a long history of unsuccessful attempts and unverified

claims to recover the power in the carrier of the received signal

itself. Traditional crystal sets use half-wave

rectifiers. As

AM signals have a

modulation factor of only 30% by voltage at peaks

, no more than 9% of received signal power (

)

is actual audio information, and 91% is just rectified DC voltage.

Given that the audio signal is unlikely to be at peak all the time, the

ratio of energy is, in practice, even greater. Considerable effort was

made to convert this DC voltage into sound energy. Some earlier attempts

include a one-

transistor

amplifier in 1966. Sometimes efforts to recover this power are confused

with other efforts to produce a more efficient detection. This history continues now with designs as elaborate as "inverted two-wave switching power unit".

X . IIII

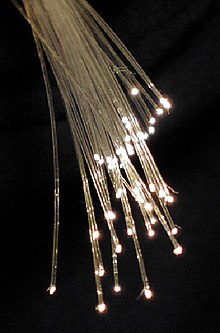

Electro-optical sensor

in detector aplication

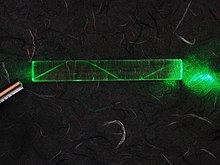

Electro-optical sensors are electronic detectors that convert

light, or a change in light, into an electronic signal. They are used in many industrial and consumer applications, for example:

Function

An

optical sensor converts light rays into electronic signals. It measures

the physical quantity of light and then translates it into a form that

is readable by an instrument. An optical sensor is generally part of a

larger system that integrates a source of light, a measuring device and

the optical sensor. This is often connected to an electrical trigger.

The trigger reacts to a change in the signal within the light sensor. An

optical sensor can measure the changes from one or several light beams.

When a change occurs, the light sensor operates as a photoelectric

trigger and therefore either increases or decreases the electrical

output. An optical switch enables signals in optical fibres or

integrated optical circuits

to be switched selectively from one circuit to another. An optical

switch can operate by mechanical means or by electro-optic effects,

magneto-optic effects as well as by other methods. Optical switches are

optoelectronic devices which can be integrated with integrated or

discrete microelectronic circuits.

Types of Optical Sensors and Switches

There are many different kinds of optical sensors, the most common types are:

- Photoconductive devices convert a change of incident light into a change of resistance.

- Photovoltaics, commonly known as solar cells, convert an amount of incident light into an output voltage.

- Photodiodes convert an amount of incident light into an output current.

- Phototransistors are a type of bipolar transistor

where the base-collector junction is exposed to light. This results in

the same behaviour of a photodiode, but with an internal gain.

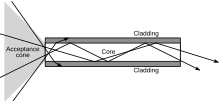

Optical Switches are usually used in

optical fibers, where the

electro-optic effect is used to switch one circuit to another. These switches can be implemented with, for example,

microelectromechanical systems or

piezoelectric systems.

Applications

Electro-optical

sensors are used whenever light needs to be converted to energy.

Because of this, electro-optical sensors can be seen almost anywhere.

Common applications are

smartphones where sensors are used to adjust screen brightness, and

smartwatches in which sensors are used to measure the wearer's heartbeat.

Optical sensors can be found in the energy field to monitor

structures that generate, produce, distribute, and convert electrical

power. The distributed and nonconductive nature of optical fibres makes

optical sensors perfect for oil and gas applications, including pipeline

monitoring. They can also be found in wind turbine blade monitoring,

offshore platform monitoring, power line monitoring and downhole

monitoring. Other applications include the civil and transportation

fields such as bridge, airport landing strip, dam, railway, airplane,

wing, fuel tank and ship hull monitoring.

Among other applications, optical switches can be found in thermal

methods which vary the refraction index in one leg of an interferometer

in order to switch the signal, MEMS approaches involving arrays of

micromirrors that can deflect an optical signal to the appropriate

receiver, piezoelectric beam steering liquid crystals which rotate

polarized light depending on the applied electric field and

acousto-optic methods which change the refraction index as a result of

strain induced by an acoustic field to deflect light.

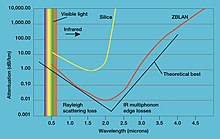

Another important application of optical sensor is to measure the

concentration of different compounds by both visible and

infrared spectroscopy.

Light fixture

A large number of light fixtures and lamps at a store.

A

light fixture (US English),

light fitting (UK English), or

luminaire is an electrical device used to create artificial light by use of an

electric lamp.

All light fixtures have a fixture body and a light socket to hold the

lamp and allow for its replacement. Fixtures may also have a switch to

control the light, either attached to the lamp body or attached to the

power cable. Permanent light fixtures, such as dining room chandeliers,

may use a wall switch to turn them on and off; as such, these fixtures

may have no switch on the fixture itself. Fixtures require an

electrical connection to a power source, typically

AC mains

power, but also battery power for camping or emergency lights.

Permanent lighting fixtures may be directly wired. Moveable lamps have a

plug and cord so that they can be plugged into a wall socket. Light fixtures may also have other features, such as

reflectors for directing the light, an

aperture (with or without a

lens), an outer shell or housing for lamp alignment and protection, an

electrical ballast or

power supply,

and a shade to diffuse the light or direct it towards a workspace

(e.g., a desk lamp). A wide variety of special light fixtures are

created for use in the

automotive lighting industry,

aerospace, marine and

medicine sectors.

Portable light fixtures are often called "lamps", as in

table lamp or

desk lamp. In

technical terminology, the

lamp is the light source, which is typically called the

light bulb. The term

luminaire is recommended by the

International Electrotechnical Commission (IEC) for technical use.

a bright cloud

Fixture manufacturing began soon after production of the incandescent

light bulb. When practical uses of fluorescent lighting were realized

after 1924, the three leading companies to produce various fixtures were

Lightolier,

Artcraft Fluorescent Lighting Corporation, and Globe Lighting in the United States.

Fixture types

Light fixtures are classified by how the fixture is installed, the light function or lamp type.

Free-standing or portable

- Table lamp fixtures, standard lamp fixtures, and office task light luminaires.

- Floor Lamp

- Torch lamp or torchières are floor lamps with an upward facing shade. They provide general lighting to the rest of the room.

- Gooseneck lamp

- Bouillotte lamp: see Bouillotte

Fixed

- Ceiling Dome — Also called the light source(s) are hidden behind a

translucent dome typically made of glass, with some combination of

frosting and surface texturing to diffuse the light. These can be flush

mount fixtures which are mounted right up against the ceiling, or

semi-flush fixtures which are separated by a small distance (usually

about 3-12").

- Open ceiling dome — the translucent dome is suspended a short

distance below the ceiling by a mechanism that is hidden with the

exception of a screw-knob or other device appearing on the outer dome

face, and pulling this knob releases the dome

- Enclosed ceiling dome The translucent dome mates with a ring that is mounted flush with the ceiling

- Recessed light

— the protective housing is concealed behind a ceiling or wall, leaving

only the fixture itself exposed. The ceiling-mounted version is often

called a downlight.

- "Cans" with a variety of lamps — this term is jargon for inexpensive downlighting

products that are recessed into the ceiling, or sometimes for uplights

placed on the floor. The name comes from the shape of the housing. The

term "pot lights" is often used in Canada and parts of the US.

- Cove light — recessed into the ceiling in a long box against a wall.

- Troffer — recessed fluorescent light fixtures, usually rectangular in shape to fit into a drop ceiling grid.

- Surface-mounted light — the finished housing is exposed, not flush with surface

- Chandelier

- Pendant light — suspended from the ceiling with a chain or pipe

- Sconce — provide up or down lights; can be used to illuminate artwork, architectural details; commonly used in hallways or as an alternative to overhead lighting.

- Track lighting fixture — individual fixtures ("track heads") can be positioned anywhere along the track, which provides electric power.

- Under-cabinet light — mounted below kitchen wall cabinets

- Display Case or Showcase light — shows merchandise on display within

an enclosed case such as jewelry, grocery stores, and chain stores.

- Ceiling fan - May sometimes have a light, often referred to as a light kit mounted to it.

- Emergency lighting or exit sign — connected to a battery backup or to an electric circuit that has emergency power if the mains power fails

- High- and low-bay lighting — typically used for general lighting for industrial buildings and often big-box stores

- Strip lights or Industrial lighting — often long lines of fluorescent lamps used in a warehouse or factory

A garden

solar lamp is an example of landscape lighting

- Outdoor lighting and landscape lighting — used to illuminate walkways, parking lots, roadways, building exteriors and architectural details, gardens, and parks.

- High-mast, usually pole- or stanchion-mounted — for landscape, roadways, and parking lots

- Bollard

— A type of architectural outdoor lighting that is a short, upright

ground-mounted unit typically used to provide cutoff type illumination

for egress lighting, to light walkways, steps, or other pathways.

- Solar lamp

- Street light

- Yard light

Special-purpose lights

Lamp types

Old table lamps at Archaeological Museum, Sri Lanka

- Xenon arc lamp, Yablochkov candle

- Fluorescent lamp, compact fluorescent lamp (CFL), Induction lamp, blacklight.

- Betty lamp, butter lamp, carbide lamp, gas lighting, kerosene lamp, oil lamp, rush light, torch, candle, Limelight, gas mantle

- Safety lamps: Davy lamp & Geordie lamp

- Mercury-vapor lamp, Metal-halide (HMI, HQI, CDM), Sodium vapor or "high-pressure sodium"

- A-lamp, Parabolic aluminized reflector lamp (PAR), reflector lamp (R), bulged reflector lamp (BR) (refer to lamp shapes)

Light-fixture controls

Position sensor :

A position

sensor

is any device that permits position measurement. It can either be an

absolute position sensor or a relative one (displacement sensor).

Position sensors can be linear, angular, or multi-axis.

Some position sensors available today:

Flash (photography)

Video demonstration of high speed flash photography.

A

flash is a device used in

photography producing a flash of

artificial light (typically 1/1000 to 1/200 of a second) at a

color temperature of about 5500 K (

Kelvin)

[citation needed]

to help illuminate a scene. A major purpose of a flash is to illuminate

a dark scene. Other uses are capturing quickly moving objects or

changing the quality of light.

Flash refers either to the flash of light itself or to the

electronic flash unit

discharging the light. Most current flash units are electronic, having

evolved from single-use flashbulbs and flammable powders. Modern

cameras often activate flash units automatically.

Flash units are commonly built directly into a camera. Some cameras

allow separate flash units to be mounted via a standardized "accessory

mount" bracket (a

hot shoe). In professional studio equipment, flashes may be large, standalone units, or

studio strobes, powered by special battery packs or connected to

mains power. They are either synchronized with the camera using a

flash synchronization

cable or radio signal, or are light-triggered, meaning that only one

flash unit needs to be synchronized with the camera, and in turn

triggers the other units, called

slaves.

Types of flash

Flash-lamp

Studies of

magnesium by Bunsen and

Roscoe

in 1859 showed that burning this metal produced a light with similar

qualities to daylight. The potential application to photography inspired

Edward Sonstadt to investigate methods of manufacturing magnesium so

that it would burn reliably for this use. He applied for patents in 1862

and by 1864 had started the Manchester Magnesium Company with Edward

Mellor. With the help of engineer

William Mather,

who was also a director of the company, they produced flat magnesium

ribbon, which was said to burn more consistently and completely so

giving better illumination than round wire. It also had the benefit of

being a simpler and cheaper process than making round wire.

[1] Mather was also credited with the invention of a holder for the ribbon, which formed a lamp to burn it in.

[2] A variety of magnesium ribbon holders were produced by other manufacturers, such as the

Pistol Flashmeter,

which incorporated an inscribed ruler that allowed the photographer to

use the correct length of ribbon for the exposure they needed. The

packaging also implies that the magnesium ribbon was not necessarily

broken off before being ignited.

Vintage AHA smokeless flash powder lamp kit, Germany

An alternative to ribbon was

flash powder, a mixture of magnesium powder and

potassium chlorate, introduced by its German inventors

Adolf Miethe

and Johannes Gaedicke in 1887. A measured amount was put into a pan or

trough and ignited by hand, producing a brief brilliant flash of light,

along with the smoke and noise that might be expected from such an

explosive event. This could be a life-threatening activity, especially

if the flash powder was damp. An electrically triggered flash lamp was invented by

Joshua Lionel Cowen

in 1899. His patent describes a device for igniting photographers’

flash powder by using dry cell batteries to heat a wire fuse. Variations

and alternatives were touted from time to time and a few found a

measure of success in the marketplace, especially for amateur use. In

1905, one French photographer was using intense non-explosive flashes

produced by a special mechanized

carbon arc lamp to photograph subjects in his studio,

but more portable and less expensive devices prevailed. On through the

1920s, flash photography normally meant a professional photographer

sprinkling powder into the trough of a T-shaped flash lamp, holding it

aloft, then triggering a brief and (usually) harmless bit of

pyrotechnics.

Flashbulbs

Flashbulbs have ranged in size from the diminutive AG-1 to the massive No. 75.

The AG-1 flashbulb, introduced in 1958, used wires protruding from its

base as electrical contacts; this eliminated the need for a separate

metal base.

Flashcubes, Magicubes and Flipflash

Flashcube fitted to a Kodak Instamatic camera, showing both unused (left) and used (right) bulbs

Undersides of Flashcube (left) and Magicube (right) cartridges

"Flip flash" type cartridge

Electronic flash

Electronic

flash was developed in the late 1950s while flashbulbs were still in

general use. Early units were expensive and often large and heavy as the

power unit was a separate unit to the flash gun head and was powered by

a large

lead-acid battery,

and usually carried by the photographer by means of a shoulder strap.

Towards the end of the 1960s, the size had dropped to the point where

they were matching the size of conventional bulb flash guns (though the

price, having dropped, was still an obstacle). The electronic flash

system eventually superseded bulb guns as prices came down, rendering

flashbulbs virtually obsolete.

A typical electronic flash unit has

electronic circuitry to charge a high-capacity

capacitor to several hundred

volts.

When the flash is triggered by the shutter's flash synchronization

contact, the capacitor is discharged almost instantaneously through a

flash tube,

producing a flash of very brief duration almost instantaneously (i.e.,

the flash duration, often around 1/1000 of a second, is shorter than

most practical shutter speeds, and full brightness is reached before the

shutter has time to close appreciably).

Synchronization

of full flash brightness with maximum shutter opening was problematic

with bulbs which took an appreciable time to ignite and reach full

brightness; electronic flash does not have these difficulties.

Simple electronic flash units are often mounted on or near the camera; many inexpensive

cameras have an electronic flash unit built in.

Two professional xenon tube flashes

Some lenses have built-in (ring-)flash lights for shadow free macro photography, but there are also accessory ring flashes available.

In a photographic studio, more powerful and flexible studio flash systems are used. They usually contain a

modeling light, an

incandescent light bulb

close to the flash tube; the continuous illumination of the modeling

light lets the photographer visualize the effect of the flash. A system

may comprise multiple synchronised flashes for multi-source lighting.

The strength of a flash device is often indicated in terms of a

guide number designed to simplify exposure setting. The energy released by larger studio flash units, such as

monolights, is indicated in

watt-seconds.

The Nikon brand name for its electronic flash units,

Speedlight, is frequently used as a generic term for electronic flash equipment.

High speed flash

An

air-gap flash is a high-voltage device that discharges a flash of light with an exceptionally short duration, often much less than one

microsecond.

These are commonly used by scientists or engineers for examining

extremely fast-moving objects or reactions, famous for producing images

of

bullets tearing through light bulbs and balloons (see

Harold Eugene Edgerton). An example of a process by which to create a high speed flash is the

exploding wire method.

A photo of a

Smith & Wesson Model 686 firing, taken with a high speed

air-gap flash.

The photo was taken in a darkened room, with camera's shutter open and

the flash was triggered by the sound of the shot using a microphone.

Multi-flash

A

camera that implements multiple flashes can be used to find depth edges

or create stylized images. Such a camera has been developed by

researchers at the

Mitsubishi Electric Research Laboratories

(MERL). Successive flashing of strategically placed flash mechanisms

results in shadows along the depths of the scene. This information can

be manipulated to suppress or enhance details or capture the intricate

geometric features of a scene (even those hidden from the eye), to

create a non-photorealistic image form. Such images could be useful in

technical or medical imaging.

Flash intensity

Unlike

flashbulbs, the intensity of an electronic flash can be adjusted on

some units. To do this, smaller flash units typically vary the capacitor

discharge time, whereas larger (e.g., higher power, studio) units

typically vary the capacitor charge. Color temperature can change as a

result of varying the capacitor charge, thus making color corrections

necessary. Due to advances in semiconductor technology, some studio

units can now control intensity by varying the discharge time and

thereby provide consistent color temperature.

Flash intensity is typically measured in stops or in fractions (1,

1/2, 1/4, 1/8 etc.). Some monolights display an "EV Number", so that a

photographer can know the difference in brightness between different

flash units with different watt-second ratings. EV10.0 is defined as

6400 watt-seconds, and EV9.0 is one stop lower, i.e. 3200 watt-seconds.

Flash duration

Flash duration is commonly described by two numbers that are expressed in fractions of a second:

- t.1 is the length of time the light intensity is above 0.1 (10%) of the peak intensity

- t.5 is the length of time the light intensity is above 0.5 (50%) of the peak intensity

For example, a single flash event might have a t.5 value of 1/1200

and t.1 of 1/450. These values determine the ability of a flash to

"freeze" moving subjects in applications such as sports photography.

In cases where intensity is controlled by capacitor discharge time,

t.5 and t.1 decrease with decreasing intensity. Conversely, in cases

where intensity is controlled by capacitor charge, t.5 and t.1 increase

with decreasing intensity due to the non-linearity of the capacitor's

discharge curve.

Flash LED used in phones

High-current flash

LEDs

are used as flash sources in camera phones, although they are not yet

at the power levels to equal xenon flash devices (that are rarely used

in phones) in still cameras. The major advantages of LEDs over xenon

include low voltage operation, higher efficiency, and extreme

miniaturization. The LED flash can also be used for illumination of

video recordings or as an

autofocus assist lamp in low-light conditions.

Focal-plane-shutter synchronization

Electronic flash units have compatibility issues with

focal-plane shutters.

Focal-plane shutters expose using two curtains that cross the sensor.

The first one opens and the second curtain follows it after a delay

equal to the nominal shutter speed. A typical modern focal-plane shutter

takes about 1/200 s to cross the sensor, so at exposure times shorter

than this only part of the sensor is uncovered at any one time.

Electronic flash can have durations as short as 50 µs, so at such short

exposure times only part of the sensor is exposed. This limits the

shutter speed to about 1/200 s when using flash. In the past,

slow-burning single-use flash bulbs allowed the use of focal-plane

shutters at maximum speed because they produced continuous light for the

time taken for the exposing slit to cross the film gate. If these are

found they cannot be used on modern cameras because the bulb must be

fired *before* the first shutter curtain begins to move (M-sync); the

X-sync used for electronic flash normally fires only when the first

shutter curtain reaches the end of its travel.

High-end flash units address this problem by offering a mode, typically called

FP sync or HSS (

High Speed Sync),

which fires the flash tube multiple times during the time the slit

traverses the sensor. Such units require communication with the camera

and are thus dedicated to a particular camera make. The multiple flashes

result in a significant decrease in guide number, since each is only a

part of the total flash power, but it's all that illuminates any