DEBIT IN Superconductivity

| Linear network analysis | |

|---|---|

| Elements | |

| Components | |

| Series and parallel circuits | |

| Impedance transforms | |

| Generator theorems | Network theorems |

| Network analysis methods | |

| Two-port parameters | |

Superconductivity is a phenomenon of exactly zero electrical resistance and expulsion of magnetic flux fields occurring in certain materials, called superconductors, when cooled below a characteristic critical temperature. It was discovered by Dutch physicist Heike Kamerlingh Onnes on April 8, 1911, in Leiden. Like ferromagnetism and atomic spectral lines, superconductivity is a quantum mechanical phenomenon. It is characterized by the Meissner effect, the complete ejection of magnetic field lines from the interior of the superconductor as it transitions into the superconducting state. The occurrence of the Meissner effect indicates that superconductivity cannot be understood simply as the idealization of perfect conductivity in classical physics.

The electrical resistance of a metallic conductor decreases gradually as temperature is lowered. In ordinary conductors, such as copper or silver, this decrease is limited by impurities and other defects. Even near absolute zero, a real sample of a normal conductor shows some resistance. In a superconductor; the resistance drops abruptly to zero when the material is cooled below its critical temperature. An electric current flowing through a loop of superconducting wire can persist indefinitely with no power source.[1][2][3][4]

In 1986, it was discovered that some cuprate-perovskite ceramic materials have a critical temperature above 90 K (−183 °C).[5] Such a high transition temperature is theoretically impossible for a conventional superconductor, leading the materials to be termed high-temperature superconductors. The cheaply-available coolant liquid nitrogen boils at 77 K, and thus superconduction at higher temperatures than this facilitates many experiments and applications that are less practical at lower temperatures .

A magnet levitating above a high-temperature superconductor, cooled with liquid nitrogen. Persistent electric current flows on the surface of the superconductor, acting to exclude the magnetic field of the magnet (Faraday's law of induction). This current effectively forms an electromagnet that repels the magnet.

A magnet levitating above a high-temperature superconductor, cooled with liquid nitrogen. Persistent electric current flows on the surface of the superconductor, acting to exclude the magnetic field of the magnet (Faraday's law of induction). This current effectively forms an electromagnet that repels the magnet.  Video of a Meissner effect in a high-temperature superconductor (black pellet) with a NdFeB magnet (metallic) .

Video of a Meissner effect in a high-temperature superconductor (black pellet) with a NdFeB magnet (metallic) .  A high-temperature superconductor levitating above a magnet

A high-temperature superconductor levitating above a magnet There are many criteria by which superconductors are classified. The most common are:

Response to a magnetic field

A superconductor can be Type I, meaning it has a single critical field, above which all superconductivity is lost and below which the magnetic field is completely expelled from the superconductor; or Type II, meaning it has two critical fields, between which it allows partial penetration of the magnetic field through isolated points. These points are called vortices. Furthermore, in multicomponent superconductors it is possible to have combination of the two behaviours. In that case the superconductor is of Type-1.5.By theory of operation

It is conventional if it can be explained by the BCS theory or its derivatives, or unconventional, otherwise.By critical temperature

A superconductor is generally considered high-temperature if it reaches a superconducting state when cooled using liquid nitrogen – that is, at only Tc > 77 K) – or low-temperature if more aggressive cooling techniques are required to reach its critical temperature.By material

Superconductor material classes include chemical elements (e.g. mercury or lead), alloys (such as niobium-titanium, germanium-niobium, and niobium nitride), ceramics (YBCO and magnesium diboride), superconducting pnictides (like fluorine-doped LaOFeAs) or organic superconductors (fullerenes and carbon nanotubes; though perhaps these examples should be included among the chemical elements, as they are composed entirely of carbon).Elementary properties of superconductors

Most of the physical properties of superconductors vary from material to material, such as the heat capacity and the critical temperature, critical field, and critical current density at which superconductivity is destroyed.On the other hand, there is a class of properties that are independent of the underlying material. For instance, all superconductors have exactly zero resistivity to low applied currents when there is no magnetic field present or if the applied field does not exceed a critical value. The existence of these "universal" properties implies that superconductivity is a thermodynamic phase, and thus possesses certain distinguishing properties which are largely independent of microscopic details.

Zero electrical DC resistance

Cross section of a preform superconductor rod from abandoned Texas Superconducting Super Collider (SSC).

Superconductors are also able to maintain a current with no applied voltage whatsoever, a property exploited in superconducting electromagnets such as those found in MRI machines. Experiments have demonstrated that currents in superconducting coils can persist for years without any measurable degradation. Experimental evidence points to a current lifetime of at least 100,000 years. Theoretical estimates for the lifetime of a persistent current can exceed the estimated lifetime of the universe, depending on the wire geometry and the temperature.[3]

In a normal conductor, an electric current may be visualized as a fluid of electrons moving across a heavy ionic lattice. The electrons are constantly colliding with the ions in the lattice, and during each collision some of the energy carried by the current is absorbed by the lattice and converted into heat, which is essentially the vibrational kinetic energy of the lattice ions. As a result, the energy carried by the current is constantly being dissipated. This is the phenomenon of electrical resistance and Joule heating.

The situation is different in a superconductor. In a conventional superconductor, the electronic fluid cannot be resolved into individual electrons. Instead, it consists of bound pairs of electrons known as Cooper pairs. This pairing is caused by an attractive force between electrons from the exchange of phonons. Due to quantum mechanics, the energy spectrum of this Cooper pair fluid possesses an energy gap, meaning there is a minimum amount of energy ΔE that must be supplied in order to excite the fluid. Therefore, if ΔE is larger than the thermal energy of the lattice, given by kT, where k is Boltzmann's constant and T is the temperature, the fluid will not be scattered by the lattice. The Cooper pair fluid is thus a superfluid, meaning it can flow without energy dissipation.

In a class of superconductors known as type II superconductors, including all known high-temperature superconductors, an extremely low but nonzero resistivity appears at temperatures not too far below the nominal superconducting transition when an electric current is applied in conjunction with a strong magnetic field, which may be caused by the electric current. This is due to the motion of magnetic vortices in the electronic superfluid, which dissipates some of the energy carried by the current. If the current is sufficiently small, the vortices are stationary, and the resistivity vanishes. The resistance due to this effect is tiny compared with that of non-superconducting materials, but must be taken into account in sensitive experiments. However, as the temperature decreases far enough below the nominal superconducting transition, these vortices can become frozen into a disordered but stationary phase known as a "vortex glass". Below this vortex glass transition temperature, the resistance of the material becomes truly zero.

Superconducting phase transition

Similarly, at a fixed temperature below the critical temperature, superconducting materials cease to superconduct when an external magnetic field is applied which is greater than the critical magnetic field. This is because the Gibbs free energy of the superconducting phase increases quadratically with the magnetic field while the free energy of the normal phase is roughly independent of the magnetic field. If the material superconducts in the absence of a field, then the superconducting phase free energy is lower than that of the normal phase and so for some finite value of the magnetic field (proportional to the square root of the difference of the free energies at zero magnetic field) the two free energies will be equal and a phase transition to the normal phase will occur. More generally, a higher temperature and a stronger magnetic field lead to a smaller fraction of the electrons in the superconducting band and consequently a longer London penetration depth of external magnetic fields and currents. The penetration depth becomes infinite at the phase transition.

The onset of superconductivity is accompanied by abrupt changes in various physical properties, which is the hallmark of a phase transition. For example, the electronic heat capacity is proportional to the temperature in the normal (non-superconducting) regime. At the superconducting transition, it suffers a discontinuous jump and thereafter ceases to be linear. At low temperatures, it varies instead as e−α/T for some constant, α. This exponential behavior is one of the pieces of evidence for the existence of the energy gap.

The order of the superconducting phase transition was long a matter of debate. Experiments indicate that the transition is second-order, meaning there is no latent heat. However, in the presence of an external magnetic field there is latent heat, because the superconducting phase has a lower entropy below the critical temperature than the normal phase. It has been experimentally demonstrated[9] that, as a consequence, when the magnetic field is increased beyond the critical field, the resulting phase transition leads to a decrease in the temperature of the superconducting material.

Calculations in the 1970s suggested that it may actually be weakly first-order due to the effect of long-range fluctuations in the electromagnetic field. In the 1980s it was shown theoretically with the help of a disorder field theory, in which the vortex lines of the superconductor play a major role, that the transition is of second order within the type II regime and of first order (i.e., latent heat) within the type I regime, and that the two regions are separated by a tricritical point.[10] The results were strongly supported by Monte Carlo computer simulations.[11]

Meissner effect

When a superconductor is placed in a weak external magnetic field H, and cooled below its transition temperature, the magnetic field is ejected. The Meissner effect does not cause the field to be completely ejected but instead the field penetrates the superconductor but only to a very small distance, characterized by a parameter λ, called the London penetration depth, decaying exponentially to zero within the bulk of the material. The Meissner effect is a defining characteristic of superconductivity. For most superconductors, the London penetration depth is on the order of 100 nm.The Meissner effect is sometimes confused with the kind of diamagnetism one would expect in a perfect electrical conductor: according to Lenz's law, when a changing magnetic field is applied to a conductor, it will induce an electric current in the conductor that creates an opposing magnetic field. In a perfect conductor, an arbitrarily large current can be induced, and the resulting magnetic field exactly cancels the applied field.

The Meissner effect is distinct from this—it is the spontaneous expulsion which occurs during transition to superconductivity. Suppose we have a material in its normal state, containing a constant internal magnetic field. When the material is cooled below the critical temperature, we would observe the abrupt expulsion of the internal magnetic field, which we would not expect based on Lenz's law.

The Meissner effect was given a phenomenological explanation by the brothers Fritz and Heinz London, who showed that the electromagnetic free energy in a superconductor is minimized provided

This equation, which is known as the London equation, predicts that the magnetic field in a superconductor decays exponentially from whatever value it possesses at the surface.

A superconductor with little or no magnetic field within it is said to be in the Meissner state. The Meissner state breaks down when the applied magnetic field is too large. Superconductors can be divided into two classes according to how this breakdown occurs. In Type I superconductors, superconductivity is abruptly destroyed when the strength of the applied field rises above a critical value Hc. Depending on the geometry of the sample, one may obtain an intermediate state[12] consisting of a baroque pattern[13] of regions of normal material carrying a magnetic field mixed with regions of superconducting material containing no field. In Type II superconductors, raising the applied field past a critical value Hc1 leads to a mixed state (also known as the vortex state) in which an increasing amount of magnetic flux penetrates the material, but there remains no resistance to the flow of electric current as long as the current is not too large. At a second critical field strength Hc2, superconductivity is destroyed. The mixed state is actually caused by vortices in the electronic superfluid, sometimes called fluxons because the flux carried by these vortices is quantized. Most pure elemental superconductors, except niobium and carbon nanotubes, are Type I, while almost all impure and compound superconductors are Type II.

London moment

Conversely, a spinning superconductor generates a magnetic field, precisely aligned with the spin axis. The effect, the London moment, was put to good use in Gravity Probe B. This experiment measured the magnetic fields of four superconducting gyroscopes to determine their spin axes. This was critical to the experiment since it is one of the few ways to accurately determine the spin axis of an otherwise featureless sphere.Back to cloud basic of superconductivity

Heike Kamerlingh Onnes (right), the discoverer of superconductivity. Paul Ehrenfest, Hendrik Lorentz, Niels Bohr stand to his left.

Great efforts have been devoted to finding out how and why superconductivity works; the important step occurred in 1933, when Meissner and Ochsenfeld discovered that superconductors expelled applied magnetic fields, a phenomenon which has come to be known as the Meissner effect.[16] In 1935, Fritz and Heinz London showed that the Meissner effect was a consequence of the minimization of the electromagnetic free energy carried by superconducting current.[17]

London theory

The first phenomenological theory of superconductivity was London theory. It was put forward by the brothers Fritz and Heinz London in 1935, shortly after the discovery that magnetic fields are expelled from superconductors. A major triumph of the equations of this theory is their ability to explain the Meissner effect,[18] wherein a material exponentially expels all internal magnetic fields as it crosses the superconducting threshold. By using the London equation, one can obtain the dependence of the magnetic field inside the superconductor on the distance to the surface.[19]There are two London equations:

Conventional theories (1950s)

During the 1950s, theoretical condensed matter physicists arrived at an understanding of "conventional" superconductivity, through a pair of remarkable and important theories: the phenomenological Ginzburg-Landau theory (1950) and the microscopic BCS theory (1957).[20][21]In 1950, the phenomenological Ginzburg-Landau theory of superconductivity was devised by Landau and Ginzburg.[22] This theory, which combined Landau's theory of second-order phase transitions with a Schrödinger-like wave equation, had great success in explaining the macroscopic properties of superconductors. In particular, Abrikosov showed that Ginzburg-Landau theory predicts the division of superconductors into the two categories now referred to as Type I and Type II. Abrikosov and Ginzburg were awarded the 2003 Nobel Prize for their work (Landau had received the 1962 Nobel Prize for other work, and died in 1968). The four-dimensional extension of the Ginzburg-Landau theory, the Coleman-Weinberg model, is important in quantum field theory and cosmology.

Also in 1950, Maxwell and Reynolds et al. found that the critical temperature of a superconductor depends on the isotopic mass of the constituent element.[23][24] This important discovery pointed to the electron-phonon interaction as the microscopic mechanism responsible for superconductivity.

The complete microscopic theory of superconductivity was finally proposed in 1957 by Bardeen, Cooper and Schrieffer.[21] This BCS theory explained the superconducting current as a superfluid of Cooper pairs, pairs of electrons interacting through the exchange of phonons. For this work, the authors were awarded the Nobel Prize in 1972.

The BCS theory was set on a firmer footing in 1958, when N. N. Bogolyubov showed that the BCS wavefunction, which had originally been derived from a variational argument, could be obtained using a canonical transformation of the electronic Hamiltonian.[25] In 1959, Lev Gor'kov showed that the BCS theory reduced to the Ginzburg-Landau theory close to the critical temperature.

Generalizations of BCS theory for conventional superconductors form the basis for understanding of the phenomenon of superfluidity, because they fall into the lambda transition universality class. The extent to which such generalizations can be applied to unconventional superconductors is still controversial.

follower basic cloud

The first practical application of superconductivity was developed in 1954 with Dudley Allen Buck's invention of the cryotron.[28] Two superconductors with greatly different values of critical magnetic field are combined to produce a fast, simple switch for computer elements.Soon after discovering superconductivity in 1911, Kamerlingh Onnes attempted to make an electromagnet with superconducting windings but found that relatively low magnetic fields destroyed superconductivity in the materials he investigated. Much later, in 1955, G.B. Yntema [29] succeeded in constructing a small 0.7-tesla iron-core electromagnet with superconducting niobium wire windings. Then, in 1961, J.E. Kunzler, E. Buehler, F.S.L. Hsu, and J.H. Wernick [30] made the startling discovery that, at 4.2 kelvin, a compound consisting of three parts niobium and one part tin, was capable of supporting a current density of more than 100,000 amperes per square centimeter in a magnetic field of 8.8 tesla. Despite being brittle and difficult to fabricate, niobium-tin has since proved extremely useful in supermagnets generating magnetic fields as high as 20 tesla. In 1962 T.G. Berlincourt and R.R. Hake [31][32] discovered that alloys of niobium and titanium are suitable for applications up to 10 tesla. Promptly thereafter, commercial production of niobium-titanium supermagnet wire commenced at Westinghouse Electric Corporation and at Wah Chang Corporation. Although niobium-titanium boasts less-impressive superconducting properties than those of niobium-tin, niobium-titanium has, nevertheless, become the most widely used “workhorse” supermagnet material, in large measure a consequence of its very-high ductility and ease of fabrication. However, both niobium-tin and niobium-titanium find wide application in MRI medical imagers, bending and focusing magnets for enormous high-energy-particle accelerators, and a host of other applications. Conectus, a European superconductivity consortium, estimated that in 2014, global economic activity for which superconductivity was indispensable amounted to about five billion euros, with MRI systems accounting for about 80% of that total.

In 1962, Josephson made the important theoretical prediction that a supercurrent can flow between two pieces of superconductor separated by a thin layer of insulator.[33] This phenomenon, now called the Josephson effect, is exploited by superconducting devices such as SQUIDs. It is used in the most accurate available measurements of the magnetic flux quantum Φ0 = h/(2e), where h is the Planck constant. Coupled with the quantum Hall resistivity, this leads to a precise measurement of the Planck constant. Josephson was awarded the Nobel Prize for this work in 1973.

In 2008, it was proposed that the same mechanism that produces superconductivity could produce a superinsulator state in some materials, with almost infinite electrical resistance.[34]

High-temperature superconductivity

Until 1986, physicists had believed that BCS theory forbade superconductivity at temperatures above about 30 K. In that year, Bednorz and Müller discovered superconductivity in a lanthanum-based cuprate perovskite material, which had a transition temperature of 35 K (Nobel Prize in Physics, 1987).[5] It was soon found that replacing the lanthanum with yttrium (i.e., making YBCO) raised the critical temperature to 92 K.[35]This temperature jump is particularly significant, since it allows liquid nitrogen as a refrigerant, replacing liquid helium.[35] This can be important commercially because liquid nitrogen can be produced relatively cheaply, even on-site. Also, the higher temperatures help avoid some of the problems that arise at liquid helium temperatures, such as the formation of plugs of frozen air that can block cryogenic lines and cause unanticipated and potentially hazardous pressure buildup.[36][37]

Many other cuprate superconductors have since been discovered, and the theory of superconductivity in these materials is one of the major outstanding challenges of theoretical condensed matter physics.[38] There are currently two main hypotheses – the resonating-valence-bond theory, and spin fluctuation which has the most support in the research community.[39] The second hypothesis proposed that electron pairing in high-temperature superconductors is mediated by short-range spin waves known as paramagnons.[40][41][dubious ]

Since about 1993, the highest-temperature superconductor has been a ceramic material consisting of mercury, barium, calcium, copper and oxygen (HgBa2Ca2Cu3O8+δ) with Tc = 133–138 K.[42][43] The latter experiment (138 K) still awaits experimental confirmation, however.

In February 2008, an iron-based family of high-temperature superconductors was discovered.[44][45] Hideo Hosono, of the Tokyo Institute of Technology, and colleagues found lanthanum oxygen fluorine iron arsenide (LaO1−xFxFeAs), an oxypnictide that superconducts below 26 K. Replacing the lanthanum in LaO1−xFxFeAs with samarium leads to superconductors that work at 55 K.[46]

In May 2014, hydrogen sulfide (H

2S) was predicted to be a high-temperature superconductor with a transition temperature of 80 K at 160 gigapascals of pressure.[47] In 2015, H

2S has been observed to exhibit superconductivity at below 203 K but at extremely high pressures — around 150 gigapascals.

Applications

Video of superconducting levitation of YBCO

In the 1950s and 1960s, superconductors were used to build experimental digital computers using cryotron switches. More recently, superconductors have been used to make digital circuits based on rapid single flux quantum technology and RF and microwave filters for mobile phone base stations.

Superconductors are used to build Josephson junctions which are the building blocks of SQUIDs (superconducting quantum interference devices), the most sensitive magnetometers known. SQUIDs are used in scanning SQUID microscopes and magnetoencephalography. Series of Josephson devices are used to realize the SI volt. Depending on the particular mode of operation, a superconductor-insulator-superconductor Josephson junction can be used as a photon detector or as a mixer. The large resistance change at the transition from the normal- to the superconducting state is used to build thermometers in cryogenic micro-calorimeter photon detectors. The same effect is used in ultrasensitive bolometers made from superconducting materials.

Other early markets are arising where the relative efficiency, size and weight advantages of devices based on high-temperature superconductivity outweigh the additional costs involved. For example, in wind turbines the lower weight and volume of superconducting generators could lead to savings in construction and tower costs, offsetting the higher costs for the generator and lowering the total LCOE.[49]

Promising future applications include high-performance smart grid, electric power transmission, transformers, power storage devices, electric motors (e.g. for vehicle propulsion, as in vactrains or maglev trains), magnetic levitation devices, fault current limiters, enhancing spintronic devices with superconducting materials,[50] and superconducting magnetic refrigeration. However, superconductivity is sensitive to moving magnetic fields so applications that use alternating current (e.g. transformers) will be more difficult to develop than those that rely upon direct current. Compared to traditional power lines superconducting transmission lines are more efficient and require only a fraction of the space, which would not only lead to a better environmental performance but could also improve public acceptance for expansion of the electric grid.

Battery charger

A battery charger, or recharger, is a device used to put energy into a secondary cell or rechargeable battery by forcing an electric current through it.

The charging protocol (how much voltage or current for how long, and what to do when charging is complete, for instance) depends on the size and type of the battery being charged. Some battery types have high tolerance for overcharging (i.e., continued charging after the battery has been fully charged) and can be recharged by connection to a constant voltage source or a constant current source, depending on battery type. Simple chargers of this type must be manually disconnected at the end of the charge cycle, and some battery types absolutely require, or may use a timer to cut off charging current at some fixed time, approximately when charging is complete. Other battery types cannot withstand over-charging, being damaged (reduced capacity, reduced lifetime) or overheating or even exploding. The charger may have temperature or voltage sensing circuits and a microprocessor controller to safely adjust the charging current and voltage, determine the state of charge, and cut off at the end of charge.

A trickle charger provides a relatively small amount of current, only enough to counteract self-discharge of a battery that is idle for a long time. Slow battery chargers may take several hours to complete a charge; high-rate chargers may restore most capacity much faster, but high rate chargers can be more than some battery types can tolerate. Such batteries require active monitoring of the battery to protect it from overcharge. Electric vehicles ideally need high-rate chargers; for public access, installation of such chargers and the distribution support for them is an issue in the proposed adoption of electric cars.

This unit charges the batteries until they reach a specific voltage and then it trickle charges the batteries until it is disconnected.

C-rates

Charge and discharge rates are often denoted as C or C-rate, which is a measure of the rate at which a battery is charged or discharged relative to its capacity. As such the C-rate is defined as the charge or discharge current divided by the battery's capacity to store an electrical charge. While rarely stated explicitly, the unit of the C-rate is h−1, equivalent to stating the battery's capacity to store an electrical charge in unit hour times current in the same unit as the charge or discharge current. The C-rate is never negative, so whether it describes a charging or discharging process depends on the context.For example, for a battery with a capacity of 500 mAh, a discharge rate of 5000 mA (i.e. 5 A) corresponds to a C-rate of 10 (per hour), meaning that such a current can discharge 10 such batteries in one hour. Likewise, for the same battery a charge current of 250 mA corresponds to a C-rate of 1/2 (per hour), meaning that this current will increase the state of charge of this battery by 50% in one hour.[3]

Since the unit of the C-rate is typically implied, some care is required with its notation to avoid confusing it with the battery's capacity to store a charge, which in the SI has unit coulomb with unit symbol C.

If both the (dis)charge current and the battery capacity in the C-rate ratio is multiplied by the battery voltage, the C-rate becomes a ratio of the (dis)charge power to the battery's energy capacity. For example, when the 100 kWh battery in a Tesla Model S P100D is undergoing supercharging at 120 kW the C-rate is 1.2 (per hour) and when that battery delivers its maximum power of 451 kW, its C-rate is 4.51 (per hour).

Very high C-rates, 1 per hour or higher, generally require the charger to carefully monitor battery parameters such as terminal voltage and temperature to prevent overcharging and damage to the cells. Such high charging rates are possible only with some battery types. Others will be damaged or possibly overheat or catch fire. Some may even explode.[citation needed] For example, an automobile SLI (starting, lighting, ignition) lead-acid battery carries several risks of explosion.

Types of battery chargers

Simple chargers

A simple charger works by supplying a constant DC or pulsed DC power source to a battery being charged. A simple charger typically does not alter its output based on charging time or the charge on the battery. This simplicity means that a simple charger is inexpensive, but there are tradeoffs. Typically, a carefully designed simple charger takes longer to charge a battery than otherwise because it is set to use a lower charging rate to prevent damage. Even so, many batteries left on a simple charger for too long will be weakened or destroyed due to over-charging. These chargers also vary in that they can supply either a constant voltage, or a constant current, to the battery.Simple AC-powered battery chargers usually have much higher ripple current and ripple voltage than other kinds of battery chargers because they are inexpensively designed and built. Generally, when the ripple current is within a battery's manufacturer recommended level, the ripple voltage will also be well within the recommended level. The maximum ripple current for a typical 12 V 100 Ah VRLA lead acid battery is 5 amps. As long as the ripple current is not excessive (more than 3 to 4 times the battery manufacturer recommended level), the expected life of a ripple-charged VRLA battery will be within 3% of the life of a constant DC-charged battery.[4]

Fast chargers

Fast chargers make use of control circuitry to rapidly charge the batteries without damaging any of the cells in the battery. The control circuitry can be built into the battery (generally for each cell) or in the external charging unit, or split between both. Most such chargers have a cooling fan to help keep the temperature of the cells at safe levels. Most are also capable of acting as standard overnight chargers if used with standard NiMH cells that do not have the special control circuitry.Inductive chargers

Inductive battery chargers use electromagnetic induction to charge batteries. A charging station sends electromagnetic energy through inductive coupling to an electrical device, which stores the energy in the batteries. This is achieved without the need for metal contacts between the charger and the battery. It is commonly used in electric toothbrushes and other devices used in bathrooms. Because there are no open electrical contacts, there is no risk of electrocution. At present, this charging technique is only applicable to small batteries, not to high capacity systems.Intelligent chargers

A "smart charger" should not be confused with a "smart battery". A smart battery is generally defined as one containing some sort of electronic device or "chip" that can communicate with a smart charger about battery characteristics and condition. A smart battery generally requires a smart charger it can communicate with (see Smart Battery Data). A smart charger is defined as a charger that can respond to the condition of a battery, and modify its charging actions accordingly.Some smart chargers are designed to charge:

- "smart" batteries.

- "dumb" batteries, which lack any internal electronic circuitry.

For Ni-Cd and NiMH batteries, the voltage across the battery increases slowly during the charging process, until the battery is fully charged. After that, the voltage decreases, which indicates to an intelligent charger that the battery is fully charged. Such chargers are often labeled as a ΔV, "delta-V," or sometimes "delta peak", charger, indicating that they monitor the voltage change.

The problem is, the magnitude of "delta-V" can become very small or even non-existent if (very) high capacity rechargeable batteries are recharged. This can cause even an intelligent battery charger to not sense that the batteries are actually already fully charged, and continue charging. Overcharging of the batteries will result in some cases. However, many so called intelligent chargers employ a combination of cut off systems, which are intended to prevent overcharging in the vast majority of cases.

A typical intelligent charger fast-charges a battery up to about 85% of its maximum capacity in less than an hour, then switches to trickle charging, which takes several hours to top off the battery to its full capacity.[5]

Motion-powered charger

A pedal powered charger for mobile phones, fitted into desks has been created by a Belgian company WeWatt, for installation in public spaces, such as at airports, railway stations and universities have been installed in a number of countries on several continents.[7]

Pulse chargers

Some chargers use pulse technology in which a series of voltage or current pulses is fed to the battery. The DC pulses have a strictly controlled rise time, pulse width, pulse repetition rate (frequency) and amplitude. This technology is said to work with any size, voltage, capacity or chemistry of batteries, including automotive and valve-regulated batteries.[8] With pulse charging, high instantaneous voltages can be applied without overheating the battery. In a Lead–acid battery, this breaks down lead-sulfate crystals, thus greatly extending the battery service life.[9]Several kinds of pulse charging are patented.[10][11][12] Others are open source hardware.

Some chargers use pulses to check the current battery state when the charger is first connected, then use constant current charging during fast charging, then use pulse charging as a kind of trickle charging to maintain the charge.[13]

Some chargers use "negative pulse charging", also called "reflex charging" or "burp charging". Such chargers use both positive and brief negative current pulses. There is no significant evidence, however, that negative pulse charging is more effective than ordinary pulse charging.

Solar chargers

Solar chargers convert light energy into DC current. They are generally portable, but can also be fixed mount. Fixed mount solar chargers are also known as solar panels. Solar panels are often connected to the electrical grid, whereas portable solar chargers are used off-the-grid (i.e. cars, boats, or RVs).Timer-based(HI) chargers

Often a timer charger and set of batteries could be bought as a bundle and the charger time was set to suit those batteries. If batteries of lower capacity were charged then they would be overcharged, and if batteries of higher capacity were charged they would be only partly charged. With the trend for battery technology to increase capacity year on year, an old timer charger would only partly charge the newer batteries.

Timer based chargers also had the drawback that charging batteries that were not fully discharged, even if those batteries were of the correct capacity for the particular timed charger, would result in over-charging.

Trickle chargers

A trickle charger is typically a low-current (5–1,500 mA) battery charger. A trickle charger is generally used to charge small capacity batteries (2–30 Ah). These types of battery chargers are also used to maintain larger capacity batteries (> 30 Ah) that are typically found on cars, boats, RVs and other related vehicles. In larger applications, the current of the battery charger is sufficient only to provide a maintenance or trickle current (trickle is commonly the last charging stage of most battery chargers). Depending on the technology of the trickle charger, it can be left connected to the battery indefinitely. Some battery chargers that can be left connected to the battery without causing the battery damage are also referred to as smart or intelligent chargers. Note that not all battery types can tolerate trickle charging after being fully charged; most Li-ion batteries are damaged by trickle charging.Universal battery charger–analyzers

The most sophisticated types are used in critical applications (e.g. military or aviation batteries). These heavy-duty automatic “intelligent charging” systems can be programmed with complex charging cycles specified by the battery maker. The best are universal (i.e. can charge all battery types), and include automatic capacity testing and analyzing functions too.USB-based chargers

Since the Universal Serial Bus specification provides for a five-volt power supply, it is possible to use a USB cable to connect a device to a power supply. Products based on this approach include chargers for cellular phones, portable digital audio players, and tablet computers. They may be fully compliant USB peripheral devices adhering to USB power discipline, or uncontrolled in the manner of USB decorations.Although portable solar chargers obtain energy from the sun only, they still can (depending on the technology) be used in low light (i.e. cloudy) applications. Portable solar chargers are typically used for trickle charging, although some solar chargers (depending on the wattage), can completely recharge batteries. Other devices may exist, which combine this with other sources of energy for added recharging efficacy.

Powerbank

Powerbanks are popular for charging smartphones and mobile tablet devices. A powerbank is a portable device that can supply power from its built-in batteries through a USB port. They usually recharge with USB power supply. Technically, a powerbank consists of rechargeable Lithium-ion or Lithium-Polymer batteries installed in a protective casing, guided by a printed circuit board (PCB) which provides various protective and safety measures. Due to its general purpose, powerbanks are also gaining popularity as a branding and promotional tool. Different brands and promotional companies use it as a promotional tool and provide a customized product.

Many powerbanks use the common 18650 size lithium-ion battery which may or may not be user-replaceable.

- Capacity in Wh: Total power capacity measured by multiplying mAh by voltage.[14]

- Capacity in mAh:[15] mAh stands for milli Ampere-hour and measures the amount of power flow that can be supplied by a certain powerbank at a specific voltage. Many manufacturers rate their products at 3.7 V, the voltage of cell(s) inside. Since USB outputs at 5 V, calculations at this voltage will yield a lower mAh number. For example, a battery pack advertised with a 3000 mAh capacity (at 3.7 V) will produce 2220 mAh at 5 V. Power losses due to efficiency of the charging circuitry also occur.[16]

- Simultaneous charging and discharging: need to specify if the powerbank can be used while it is charging.

- Number of output USB ports: This specifies the number of devices that can be charged simultaneously.

- Output current rating: This specifies the current rating that it can charge maximum. The higher the number, the better the powerbank. This can vary from output port to output port.

- Input Current Rating: Input current rating is the amount of current the powerbank is able to draw at its maximum level while getting charged.

- Safety Protections: Over Voltage Protection, Over Charge Protections, Over Current Protections, Over Heat Protections, Short-Circuit Protections and Over Discharge Protections are the common safety measures observed with standard powerbanks.

- LED Indications: The Led glows as per indicating the amount of charging ability left with the powerbank.

Compatibility

Although a standard exists for USB chargers,[17] there are two areas of common incompatibility.- The connector on the device to be charged. There are several current and many obsolete connectors, including:

- The Micro USB connector

- The Mini USB connector

- The lightning connector

- The J10 connector

- Various sizes of coaxial power connector, particularly the smaller sizes

- The 3.5 mm jack and 2.5 mm jack

- and others. It is essential that the connectors on the device and charger match exactly.

- The charging port. This may be smart or dumb, and each in various current ratings. Compatibility varies. A mismatched charger will charge more slowly, and sometimes not at all.

Applications

Since a battery charger is intended to be connected to a battery, it may not have voltage regulation or filtering of the DC voltage output. Battery chargers equipped with both voltage regulation and filtering are sometimes termed battery eliminators.Battery charger for vehicles

There are two main types of chargers used for vehicles:- To recharge a fuel vehicle's starter battery, where a modular charger is used; typically an 3-stage charger.

- To recharge an electric vehicle (EV) battery pack; see Charging station.

Electric vehicle batteries

Electric vehicle battery chargers come in a variety of brands and characteristics. Zivan, Manzanita Micro, Elcon, Quick Charge, Rossco, Brusa, Delta-Q, Kelly, Lester and Soneil are the top 10 EV chargers in 2011 according to EVAlbum.com. These chargers vary from 1 kW to 7.5 kW maximum charge rate. Some use algorithm charge curves, others use constant voltage, constant current. Some are programmable by the end user through a CAN port, some have dials for maximum voltage and amperage, some are preset to specified battery pack voltage, amp-hour and chemistry. Prices range from $400 to $4500.A 10 amp-hour battery could take 15 hours to reach a fully charged state from a fully discharged condition with a 1 amp charger as it would require roughly 1.5 times the battery's capacity.

Public EV charging stations provide 6 kW (host power of 208 to 240 VAC off a 40 amp circuit). 6 kW will recharge an EV roughly 6 times faster than 1 kW overnight charging.

Rapid charging results in even faster recharge times and is limited only by available AC power, battery type, and the type of charging system.[18]

Onboard EV chargers (change AC power to DC power to recharge the EV's pack) can be:

- Isolated: they make no physical connection between the A/C electrical mains and the batteries being charged. These typically employ some form of Inductive charging. Some isolated chargers may be used in parallel. This allows for an increased charge current and reduced charging times. The battery has a maximum current rating that cannot be exceeded

- Non-isolated: the battery charger has a direct electrical connection to the A/C outlet's wiring. Non-isolated chargers cannot be used in parallel.

- Charge stations

- Non-contact magnetic charging

Mobile phone charger

Pay-per-charge kiosk, illustrating the variety of mobile phone charger connectors

Users of publicly accessible charging kiosks must be able to cross-reference connectors with device brands/models and individual charge parameters and thus ensure delivery of the correct charge for their mobile device. A database-driven system is one solution, and is being incorporated into some designs of charging kiosks.

Mobile phones can usually accept a relatively wide range of voltages[citation needed], as long as it is sufficiently above the phone battery's voltage. However, if the voltage is too high, it can damage the phone. Mostly, the voltage is 5 volts or slightly higher, but it can sometimes vary up to 12 volts when the power source is not loaded.[citation needed].

There are also human-powered chargers sold on the market, which typically consists of a dynamo powered by a hand crank and extension cords. A French startup offers a kind of dynamo charger inspired by the ratchet that can be used with only one hand.[20] There are also solar chargers, including one that is a fully mobile personal charger and panel, which you can easily transport.

China, the European Commission and other countries are making a national standard on mobile phone chargers using the USB standard.[21] In June 2009, 10 of the world's largest mobile phone manufacturers signed a Memorandum of Understanding to develop specifications for and support a microUSB-equipped common External Power Supply (EPS) for all data-enabled mobile phones sold in the EU.[22] On October 22, 2009, the International Telecommunication Union announced a standard for a universal charger for mobile handsets (Micro-USB).[23]

Stationary battery plants

Telecommunications, electric power, and computer uninterruptible power supply facilities may have very large standby battery banks (installed in battery rooms) to maintain critical loads for several hours during interruptions of primary grid power. Such chargers are permanently installed and equipped with temperature compensation, supervisory alarms for various system faults, and often redundant independent power supplies and redundant rectifier systems. Chargers for stationary battery plants may have adequate voltage regulation and filtration and sufficient current capacity to allow the battery to be disconnected for maintenance, while the charger supplies the DC system load. Capacity of the charger is specified to maintain the system load and recharge a completely discharged battery within, say, 8 hours or other interval.Use in experiments

A battery charger can work as a DC power adapter for experimentation. It may, however, require an external capacitor to be connected across its output terminals in order to "smooth" the voltage sufficiently, which may be thought of as a DC voltage plus a "ripple" voltage added to it. There may be an internal resistance connected to limit the short circuit current, and the value of that internal resistance may have to be taken into consideration in experiments.Prolonging battery life

What practices are best depend on the type of battery. NiCd cells must be fully discharged occasionally, or else the battery loses capacity over time due to a phenomenon known as "memory effect." Once a month (once every 30 charges) is sometimes recommended. This extends the life of the battery since memory effect is prevented while avoiding full charge cycles which are known to be hard on all types of dry-cell batteries, eventually resulting in a permanent decrease in battery capacity.Most modern cell phones, laptops, and most electric vehicles use Lithium-ion batteries. These batteries last longest if the battery is frequently charged; fully discharging them will degrade their capacity relatively quickly. When storing however, lithium batteries degrade more while fully charged than if they are only 40% charged. As with all battery types, degradation also occurs faster at higher temperatures. Degradation in lithium-ion batteries is caused by an increased internal battery resistance due to cell oxidation. This decreases the efficiency of the battery, resulting in less net current available to be drawn from the battery. However, if Li-ION cells are discharged below a certain voltage a chemical reaction occurs that make them dangerous if recharged, which is why probably all such batteries in consumer goods now have an "electronic fuse" that permanently disables them if the voltage falls below a set level. The electronic fuse draws a small amount of current from the battery, which means that if a laptop battery is left for a long time without charging it, and with a very low initial state of charge, the battery may be permanently destroyed.

Motor vehicles, such as boats, RVs, ATVs, motorcycles, cars, trucks, and more use lead–acid batteries. These batteries employ a sulfuric acid electrolyte and can generally be charged and discharged without exhibiting memory effect, though sulfation (a chemical reaction in the battery which deposits a layer of sulfates on the lead) will occur over time. Typically sulfated batteries are simply replaced with new batteries, and the old ones recycled. Lead–acid batteries will experience substantially longer life when a maintenance charger is used to "float charge" the battery. This prevents the battery from ever being below 100% charge, preventing sulfate from forming. Proper temperature compensated float voltage should be used to achieve the best results.

Battery management system

A battery management system (BMS) is any electronic system that manages a rechargeable battery (cell or battery pack), such as by protecting the battery from operating outside its Safe Operating Area, monitoring its state, calculating secondary data, reporting that data, controlling its environment, authenticating it and / or balancing it.[1]

A battery pack built together with a battery management system with an external communication data bus is a smart battery pack. A smart battery pack must be charged by a smart battery charger

Functions

Monitor

A BMS may monitor the state of the battery as represented by various items, such as:- Voltage: total voltage, voltages of individual cells, minimum and maximum cell voltage or voltage of periodic taps

- Temperature: average temperature, coolant intake temperature, coolant output temperature, or temperatures of individual cells

- State of charge (SOC) or depth of discharge (DOD), to indicate the charge level of the battery

- State of health (SOH), a variously-defined measurement of the overall condition of the battery

- Coolant flow: for air or fluid cooled batteries

- Current: current in or out of the battery

Electric Vehicle Systems: Energy Recovery

- The BMS will also control the recharging of the battery by redirecting the recovered energy (i.e.- from regenerative braking) back into the battery pack (typically composed of a few batteries, each composed of a few cells).

Computation

Additionally, a BMS may calculate values based on the above items, such as:- Maximum charge current as a charge current limit (CCL)

- Maximum discharge current as a discharge current limit (DCL)

- Energy [kWh] delivered since last charge or charge cycle

- Internal impedance of a cell (to determine open circuit voltage)

- Charge [Ah] delivered or stored (sometimes this feature is called Coulomb counter)

- Total energy delivered since first use

- Total operating time since first use

- Total number of cycles

Communication

The central controller of a BMS communicates internally with its cell level hardware, or externally with high level hardware such as laptops or HMI.High level external communication are simple and use several methods:

- Different types of Serial communications.

- CAN bus communications, commonly used in automotive environments.

- DC-BUS - Serial communication over power-line

- Different types of Wireless communications.[2]

Distributed or modular BMSs must use some low level internal cell-controller (Modular architecture) or controller-controller (Distributed architecture) communication. These types of communications are difficult, especially for high voltage systems. The problem is voltage shift between cells. The first cell ground signal may be hundreds of volts higher than the other cell ground signal. Apart from software protocols, there are two known ways of hardware communication for voltage shifting systems, Optical-isolator and wireless communication. Another restriction for internal communications is the maximum number of cells. For modular architecture most hardware is limited to maximum 255 nodes. For high voltage systems the seeking time of all cells is another restriction, limiting minimum bus speeds and losing some hardware options. Cost of modular systems is important, because it may be comparable to the cell price.[3] Combination of hardware and software restrictions results to be a few options for internal communication:

- Isolated serial communications

- wireless serial communications

Protection

A BMS may protect its battery by preventing it from operating outside its safe operating area, such as:- Over-current (may be different in charging and discharging modes)

- Over-voltage (during charging)

- Under-voltage (during discharging), especially important for lead–acid and Li-ion cells

- Over-temperature

- Under-temperature

- Over-pressure (NiMH batteries)

- Ground fault or leakage current detection (system monitoring that the high voltage battery is electrically disconnected from any conductive object touchable to use like vehicle body)

- Including an internal switch (such as a relay or solid state device) which is opened if the battery is operated outside its safe operating area

- Requesting the devices to which the battery is connected to reduce or even terminate using the battery.

- Actively controlling the environment, such as through heaters, fans, air conditioning or liquid cooling

Battery connection to load circuit

A BMS may also feature a precharge system allowing a safe way to connect the battery to different loads and eliminating the excessive inrush currents to load capacitors.The connection to loads is normally controlled through electromagnetic relays called contactors. The precharge circuit can be either power resistors connected in series with the loads until the capacitors are charged. Alternatively, a switched mode power supply connected in parallel to loads can be used to charge the voltage of the load circuit up to a level close enough to battery voltage in order to allow closing the contactors between battery and load circuit. A BMS may have a circuit that can check whether a relay is already closed before precharging (due to welding for example) to prevent inrush currents to occur.

Optimization[edit]

In order to maximize the battery's capacity, and to prevent localized under-charging or over-charging, the BMS may actively ensure that all the cells that compose the battery are kept at the same voltage or State of Charge, through balancing. The BMS can balance the cells by:- Wasting energy from the most charged cells by connecting them to a load (such as through passive regulators)

- Shuffling energy from the most charged cells to the least charged cells (balancers)

- Reducing the charging current to a sufficiently low level that will not damage fully charged cells, while less charged cells may continue to charge (does not apply to Lithium chemistry cells)

- Modular charging [4]

Topologies

BMS technology varies in complexity and performance:- Simple passive regulators achieve balancing across batteries or cells by bypassing charging current when the cell's voltage reaches a certain level. The cell voltage is a poor indicator of the cell's SOC (and for certain Lithium chemistries such as LiFePO4 it is no indicator at all), thus, making cell voltages equal using passive regulators does not balance SOC, which is the goal of a BMS. Therefore, such devices, while certainly beneficial, have severe limitations in their effectiveness.

- Active regulators intelligently turning on and off a load when appropriate, again to achieve balancing. If only the cell voltage is used as a parameter to enable the active regulators, the same constraints noted above for passive regulators apply.

- A complete BMS also reports the state of the battery to a display, and protects the battery.

- Centralized: a single controller is connected to the battery cells through a multitude of wires

- Distributed: a BMS board is installed at each cell, with just a single communication cable between the battery and a controller

- Modular: a few controllers, each handing a certain number of cells, with communication between the controllers

The requirements for a BMS in mobile applications (such as electric vehicles) and stationary applications (like stand-by UPSs in a server room) are quite different, especially from the space and weight constraint requirements, so the hardware and software implementations must be tailored to the specific use. In the case of electric or hybrid vehicles, the BMS is only a subsystem and cannot work as a standalone device. It must communicate with at least a charger (or charging infrastructure), a load, thermal management and emergency shutdown subsystems. Therefore, in a good vehicle design the BMS is tightly integrated with those subsystems. Some small mobile applications (such as medical equipment carts, motorized wheelchairs, scooters, and fork lifts) often have external charging hardware, however the on-board BMS must still have tight design integration with the external charger.

Various Battery balancing methods are in use, some of them based on state of charge theory.

Battery Management System

Advanced battery technologies such as lithium ion, Lipo & Lifepo4 require Battery Management Systems to ensure safety and long life performance of the battery packs. Lian Innovative lithium Battery management system is the most configurable and modular one available in the market. We started to develop custom lithium ion battery packs a long time ago. It results in in-depth knowledge of Lithium Battery Management System. The other competitor doesn’t build battery packs, so how could they know what really works? Lian Innovative has introduced a range of scalable and highly configurable battery management systems which could be used as Electric Vehicle, Solar energy, Marine vessels, Large lithium ion battery packs, Uninterruptable Power System and Hybrid Vehicles battery management system.

require Battery Management Systems to ensure safety and long life performance of the battery packs. Lian Innovative lithium Battery management system is the most configurable and modular one available in the market. We started to develop custom lithium ion battery packs a long time ago. It results in in-depth knowledge of Lithium Battery Management System. The other competitor doesn’t build battery packs, so how could they know what really works? Lian Innovative has introduced a range of scalable and highly configurable battery management systems which could be used as Electric Vehicle, Solar energy, Marine vessels, Large lithium ion battery packs, Uninterruptable Power System and Hybrid Vehicles battery management system.Our product is designed at its core to operate in the environments with harsh electrical noise. Its performances are excellent as battery management system for electric vehicles. The advanced design allows our product to withstand very significant EMI that other BMS cannot.

Lian Innovative lithium Battery Management Systems are the outcome of eight years of experience delivering custom lithium battery management systems. It has evolved to the point where we can claim it to be one of the most reliable and effective lithium ion, Lipo, Lifepo4 battery management systems available on the market. Various models are designed for applications ranging from Large lithium battery packs grid energy storage systems, telecom power backup, Marine vessels, UAVs & UUVs and Electric Vehicle battery management system. Lian Innovative battery management systems could be used as off the shelf plug and play product, Semi-custom versions or full custom design version.

In our custom projects, we work very closely with our customer in order to deliver a custom turnkey Battery Management System solution within tight timescales and budgets. We have more than eight years of experience in designing Battery Management System for large lithium battery packs and many lessons learned from more than 12 projects worldwide.

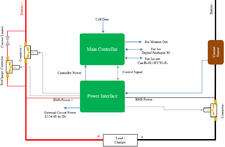

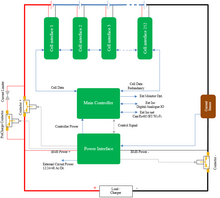

Lithium Battery Management Systems Structure

Our BMS has three fully modular sections. Each one can be selected to be most suited to the user needs.- The Central Controller Unit (CCU).

- The Power Controller Unit (PCU).

- The Cell Boards (CB).

The main function of the PCU is to connect/disconnect battery from load or charger. It also measures current and voltage of the battery pack and limits the inrush current of capacitors. PCU model depends on battery pack specs. For different pack voltage and current, different PCU must be selected. Please consult us for further info.

The CB function is to monitor the cell’s voltage and temperature and to balance it if needed. There are three different types of CB offered by Lian innovative. Selection is based on the layout of the cells and can be selected by the user to mostly suited for the application.

Central Controller Unit

The CCU main function is to control the whole system. The user interfacing, storing data, monitoring cells, activation of the contactors and all other standard tasks are done by CCU. Lian Innovative Battery Management Systems CCU is equipped with an SD card which can log all details of battery packs. It is ideal for unmanned mobile robots. After missions, the operator can be informed about each cell performance. It can also be used by Battery Management System manufacturer companies as a witness during guaranty period. We have developed algorithms that will allow the Lithium Battery Management System to identify normal aging and performance trends of cells versus those that are non-typical. Maximum life cycle and reliability will be achieved by monitoring

the whole system. The user interfacing, storing data, monitoring cells, activation of the contactors and all other standard tasks are done by CCU. Lian Innovative Battery Management Systems CCU is equipped with an SD card which can log all details of battery packs. It is ideal for unmanned mobile robots. After missions, the operator can be informed about each cell performance. It can also be used by Battery Management System manufacturer companies as a witness during guaranty period. We have developed algorithms that will allow the Lithium Battery Management System to identify normal aging and performance trends of cells versus those that are non-typical. Maximum life cycle and reliability will be achieved by monitoring  cell performance and compared with the expected ranges from cycle to cycle. In the case where an abnormal trend is identified, the CCU will take appropriate action to inform users of the situation to increase reliability and safety.

cell performance and compared with the expected ranges from cycle to cycle. In the case where an abnormal trend is identified, the CCU will take appropriate action to inform users of the situation to increase reliability and safety.Various isolated and protected Analog and Digital IO have been provided on the system which can be setup easily by the user. Full protection is provided on central controller boards to cover user mistakes such as reverse polarity, over voltage, etc.

Central Controller Unit Specs:

- Full battery protections

- Balancing Lithium ion batteries (different kinds)

- In site Auto/Manual configurable

- Cell performances log and analyzes

- Logs and reports up to thousands hour of full details of cells and pack

- State of Charge (SOC), State of Health (SOH),

- Automatic %SOC calibration

- Operational status and full alarm status indicators

- Auto sleep function to put battery modules to sleep when not in use

- Built in self Balancing Lithium batteries algorithms to maintain battery pack balance and optimize the charging function

- Configurable Opto-isolated digital and analog I/O

- Low power consumption

- Internal alarm buzzer for audible warning

- Communication flexibility with a variety of communication ports

- Various ignition configurable

- Firmware revision updates capability

- Self-healing – abnormal conditions “clear” without intervention when condition subsides

Power Control Unit

Old battery management systems do not include power control unit. Supplier advises the user to find some contactors, relays, fuses, shunts and other parts, connect them with some copper connectors assembling them together and run the battery. Lian Innovative discovered that most of the customers have lots of problem in power units that leads to some critical safety problem or system failure.

do not include power control unit. Supplier advises the user to find some contactors, relays, fuses, shunts and other parts, connect them with some copper connectors assembling them together and run the battery. Lian Innovative discovered that most of the customers have lots of problem in power units that leads to some critical safety problem or system failure.Lian Innovative is the first company to offer Power Control Units that integrated all parts and circuits needed to connect/disconnect the battery pack from load/charger. It fully compatible with CCU and no engineering is needed to use it in the system.

In some applications, users need an Auxiliary 12/24/48 volts supply to run the PcBs and circuits. Some battery experts advise them to use another low voltage battery, that results to increase weight, costs and reduces the reliability and etc. Lian Innovative is the first company that integrated an advanced, reliable, DC-DC converter to PCU that not only supply the power of its internal circuits but also can supply users external circuits power. This advanced option makes the system designs as simple and reliable as possible.The PCU provides the ability to differentiate in-rush currents (such as engine start) from short-circuiting currents. Direct hardware monitoring ensures a quick response to short-circuit or overcurrent conditions as witnessed by the main battery shunt. Special contactors can connect and disconnect heavy loads from battery pack safely and reliably. A current limiter is provided to be used on systems with high capacitors in parallel to the load.

Lots of options and sizes available to helps users to select the best-suited choice for their applications. It is totally cost effective, safe, time effective and fault proof solution that helps the users to integrate the battery management system easily and with less engineering.

Power Control Unit Specs:

- Aux power supply can be up to 750w, 48 volt

- Handle up to 1000A 900Vdc

- Precise pack current measurement by Shunt sensor

- Precise pack voltage measurement

- Safely and reliably connects/disconnects battery pack to load/charger

- Inrush current limiter

- DC fuse included

- Reverse voltage protected

- protection against inductive load disconnection

| Switching Current | Switching Voltage | Aux Power supply voltage | Aux Power supply power | Inductive loading switch | Dc Line Fuse | Dual line Relay | Capactive load switching | Dimension mmxmmxmm | |

| PCU500 | 500A+ | 900Vdc | 5/12/24/48 | 250/500/750 | yes | 750A | yes | yes | 270x220x103 |

| PCU200 | 200A | 350VDC | 5/12/24/48 | 250/500/750 | yes | 300A | yes | yes | 260x190x103 |

| PCU100 | 100A | 350Vdc | 5/12/24/48 | 250/500/750 | yes | 150A | yes | yes | 240x190x103 |

| PCU60 | 60A | 350Vdc | 5/12/24/48 | 250/500/750 | yes | 90A | yes | yes | 220x170x103 |

Cell Boards

Three different cell boards introduced by Lian Innovative for various applications, distributed wired, distributed wireless and integrated board. They cover all needs of different battery packs including Hybrid Vehicle, Marine vessels, Autonomous Underwater Vehicles, Large lithium battery packs, Uninterruptable Power System, EV Battery Management system, and etc. Full protection is provided on the cell monitoring boards to cover user mistakes such as reverse polarity, over voltage, etc.. . .

InnoCab, Distributed Wired cell monitoring

Innocab is a distributed cell monitoring  board which suited for large lithium battery packs with considerable distance between cells or battery packs of which the configuration or voltage may vary during the design and development.

board which suited for large lithium battery packs with considerable distance between cells or battery packs of which the configuration or voltage may vary during the design and development.

board which suited for large lithium battery packs with considerable distance between cells or battery packs of which the configuration or voltage may vary during the design and development.

board which suited for large lithium battery packs with considerable distance between cells or battery packs of which the configuration or voltage may vary during the design and development.InnoCab Battery Management System unique specs:

- Fully configurable from 1 to 252 cells

- large lithium battery packs for lithium ion/Lipo/Lifepo4 battery packs from 3.7Vdc to 1000Vdc

- No engineering needs to setup and use

- Auto sleep function to put battery modules to sleep when not in use

- Temperature compensated voltage measurements resolution down to 1 mV with 10 mV accuracy in full temperature range

- temperature measurement resolution down to 0.1 C and 1 C accuracy.

- Cell balancing current up to 2A

- Voltage and temperature of each

cell to ensure the safety and long life

- Highly redundancy for data cable disconnection, or one cell monitor board crash

- Fail safe network guarantees that if one cell monitor board crashes the others can continue their job

- Epoxy-encased cell modules resist dust and moisture

- LED indicators on each cell

. . .

InnoLess, Distributed Wireless cell monitoring

Innocab is wireless distributed Battery Management system which suited for battery packs with a very large distance between cells, or for whom which not happy with bird nested wiring or very high voltage battery packs which electrical shock hazard concerns for the user, repairmen, and maintenance service men.

Battery Management system which suited for battery packs with a very large distance between cells, or for whom which not happy with bird nested wiring or very high voltage battery packs which electrical shock hazard concerns for the user, repairmen, and maintenance service men.InnoLess BMS specs are as below:

- Fully configurable from 1 to 252 cells

- Battery Management System for lithium ion, Lifepo4 battery packs from 3.7Vdc to 1000Vdc

- No engineering needs to setup and use

- Voltage and temperature of each cell to ensure the safety and long life

- Auto sleep function to put battery modules to sleep when not in use

- Temperature compensated voltage

measurements resolution down to 1 mV with 10 mV accuracy in full temperature range

- temperature measurement resolution down to 0.1 C and 1 C accuracy.

- Cell balancing current up to 2A

- Highly redundancy for wireless connection, or one cell monitor board crash

- Fail safe network guaranties that if one cell monitor board crashes the others can continue their job

- Epoxy-encased cell modules resist dust and moisture

- LED indicators on each cell

. . .

InnoTeg, Integrated cell monitoring

Innoteg is advanced integrated  Battery Management System which suited for economical mass productions battery packs that price is the main parameter.

Battery Management System which suited for economical mass productions battery packs that price is the main parameter.

Battery Management System which suited for economical mass productions battery packs that price is the main parameter.

Battery Management System which suited for economical mass productions battery packs that price is the main parameter.InnoTeg unique specs:

- Fully configurable from 5 to 252 cells

- Battery Management System for lithium ion, Lifepo4 battery packs from 20Vdc to 1000Vdc

- Voltage of each cell and temperature of each 14 cells to ensure the safety and long life

- Auto sleep function to put battery modules to sleep when not in use

- Temperature compensated voltage measurements resolution down to 1 mV with 10 mV accuracy in full temperature range

- Temperature measurement resolution down to 0.1 C and 1 C accuracy.

- Cell balancing current up to 0.5A

Underwater Robot Engineering, Consulting, and Optimization

Problem definition:Our client reports that his old underwater robots range which expected to be more than 55 miles are about 35 miles. And its velocity is 6 Knots which is supposed to be 8.5 Knots. These two parameters were nominal and no one can be witnessed that the underwater robot was qualified for when they were new. then the problem was totally vague. The problem was some kind of blind engineering consulting.

Winning the contract

The user had no view about the source of the problem. It was impossible to tests the underwater robot in the field before the contract. He just looks someone to analyses and solves the problem in shortest time and lowest price. Here Lian Innovative entered to the problem by offering shortest time and lowest price just by analyzing the problem not by doing field tests.

Startup

Lian Innovative analyzed the system and draw a complete energy transfer line from batteries of the underwater robot to the Hull of the underwater robot.

Each subsystem performance and efficiency tested in the system, and separately to understand assembly problems if there were any. Surprisingly results showed that overall efficiency from battery pack to Hull was less than 23% !!! That was too low for an underwater robot which its energy comes from expensive batteries.

Field tests

After it, Lian Innovative focused on energy consumption of the hull. At first, the towing test (drag test) in the sea was done. Total drag force was measured in different speeds precisely and carefully.

Lab test

In the next step, Lian Innovative designed and developed a scaled model of the underwater robot, and did the towing test in the tank.

Field test reports confirmed the underwater  robot model test results. It revealed that the drag force is beyond what was expected from theory and analyses. Froud No. and Reynolds No. carefully computed and discovered that the main factor which increases the drag force is Up-welling Fluid.

robot model test results. It revealed that the drag force is beyond what was expected from theory and analyses. Froud No. and Reynolds No. carefully computed and discovered that the main factor which increases the drag force is Up-welling Fluid.

In synchronous with our client, we decided to change the underwater robot nose shape. Six different standard nose performances were investigated. All of them designed and manufactured to be used on downscaled model.

change the underwater robot nose shape. Six different standard nose performances were investigated. All of them designed and manufactured to be used on downscaled model.

The drag force of all models in different speeds  precisely measured by towing test. Two of them with lowest drag force was selected, and other factors such as manufacturability and maneuverability were carefully investigated and tested.

precisely measured by towing test. Two of them with lowest drag force was selected, and other factors such as manufacturability and maneuverability were carefully investigated and tested.

precisely measured by towing test. Two of them with lowest drag force was selected, and other factors such as manufacturability and maneuverability were carefully investigated and tested.

precisely measured by towing test. Two of them with lowest drag force was selected, and other factors such as manufacturability and maneuverability were carefully investigated and tested.

Results show that proposed underwater  robot nose reduces the drag force to 53% of the main nose. That was great!!!

robot nose reduces the drag force to 53% of the main nose. That was great!!!

robot nose reduces the drag force to 53% of the main nose. That was great!!!

robot nose reduces the drag force to 53% of the main nose. That was great!!!

By huge investigation and having experienced  consultant engineers, it revealed that the rudder and elevator airfoils and their bases were not optimum in water streamline and have a considerable effect on underwater robot performance. Engineering consultation and training, let the client understand the side effects of the problem. He accepted the problem analyses deeper.

consultant engineers, it revealed that the rudder and elevator airfoils and their bases were not optimum in water streamline and have a considerable effect on underwater robot performance. Engineering consultation and training, let the client understand the side effects of the problem. He accepted the problem analyses deeper.

With client acceptance, Lian Innovative  developed a newly designed control surfaces and repeat the drag tests by the towing test. Results show that finalized model drag forces were about 32% of the main model. Wonderful!!!

developed a newly designed control surfaces and repeat the drag tests by the towing test. Results show that finalized model drag forces were about 32% of the main model. Wonderful!!!

Field Verification Test

To prove our model test results, we need to