In the processing of gold and copper seeds which are usually obtained from mining materials in the form of rock rocks in the processing are bound in one compound and we can separate the metal compounds in atomic atoms using mercury which will be separated between gold and copper which are both metals This noble is commonly used for high quality electronic component components both in terms of sound as well as image and control; let's discuss the process made : Many space and telecommunication industry use Gold and recent trend is to use gold in mobile phone , computers and etc to make performance better .

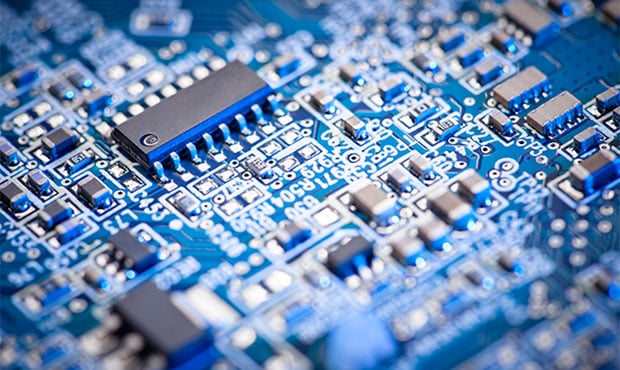

Gold conducts electricity, does not tarnish, is very easy to work, can be drawn into wire. Industrial use of gold is in the manufacture of electronics. Gold is the highly efficient conductor that can carry these tiny currents and remain free of corrosion. Electronic components made with gold are highly reliable. Gold is used in connectors, switch and relay contacts, soldered joints, connecting wires and connection strips.

A small amount of gold is used in almost every sophisticated electronic device. This includes cell phones, calculators, personal digital assistants, global positioning system (GPS) units, and other small electronic devices. Most large electronic appliances such as television sets also contain gold.

Gold is used in many places in the standard desktop or laptop computer. The rapid and accurate transmission of digital information through the computer and from one component to another requires an efficient and reliable conductor. Gold meets these requirements better than any other metal.

THE USE OF GOLD PLATING IN ELECTRONIC

Most of the electronics we use in our daily lives contain at least a little bit of gold. While this precious metal is widely known for its beautiful, shiny appearance, it also has quite a few functional purposes that make it a sought-after material in a variety of industries.

The electronics sector, though, is the main consumer of gold today. Even though that gold is rarely seen, it plays a critical role in keeping the components of your devices functioning properly over time. Electronic parts aren’t typically made entirely of gold because of the material’s cost. More often, manufacturers use electroplating to apply a thin layer of gold over the main material that comprises the component.

Frequently used in combination with nickel plating, the thin layer of gold protects the component from corrosion, heat, wear and helps ensure a reliable electrical connection. At Sharretts Plating Company, 99% of our gold plating work serves the electronics industry. Over the last eight decades, we’ve perfected our gold plating, also called Au plating, processes and offer both electroplating and immersion plating.

In the rest of this article, we’ll look in more detail at the processes, benefits and uses of gold plating for electronics and electrical components.

WHAT IS GOLD PLATING?

At SPC, we’ve developed and applied many gold plating processes. We use electro-deposition, which is commonly known as electroplating and uses an electric current to apply the coating. We also use immersion plating, which doesn’t use electricity.

To plate an item with electro-deposition, we connect the gold to the anode, the positively charged electrode, of an electrical circuit. We also connect the substrate, the material that we’ll be plating, to the cathode, which is the negatively charged electrode. We then immerse both pieces in an electrolytic solution.

Then, we apply a DC current to the anode. This oxidizes the metal atoms in the gold and dissolves them into the solution. The dissolved ions are reduced at the cathode, and they then deposit onto the substrate.

TYPES OF GOLD PLATING BATHS

There are three basic types of gold plating baths:

- Alkaline: An alkaline bath is a non-cyanide solution that uses sodium gold sulfite as the source of the gold ions. It has a pH level ranging from 9.0 to 13.0. Alkaline solutions produce a hard and bright deposit and reduce the co-deposition of base metals. Adding complexing agents can improve conductivity.

- Acid: Acid baths, which have a low pH of 3.0 to 6.0, produce exceptionally pure gold deposits. In fact, these deposits can be up to 99.999% pure. Acid gold baths allow for the formation of alloys with base metals, but you can also prevent this with complexing agents.

- Neutral: Neutral baths, which have a pH between 6.0 and 8.0, are typically used for plastic or ceramic substrates because they don’t contain free cyanide, which can damage these more delicate materials.

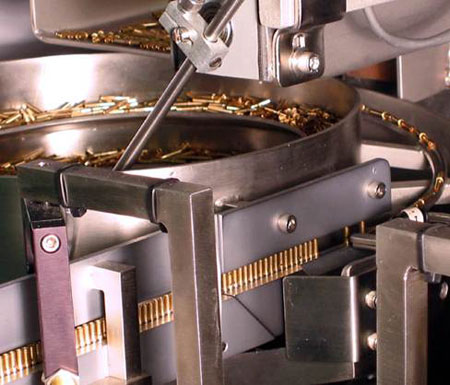

REEL-TO-REEL GOLD ELECTROPLATING

We most frequently use reel-to-reel electroplating, also known as continuous electroplating, when applying gold to a material. We use this method to plate reels of raw material before they get shaped into electronic components. It can coat strips of manufactured parts.

We load the reels onto our equipment and feed it through our electroplating processes before re-reeling it. Reel-to-reel plating can cover an entire substrate or be used more precisely to plate specific parts.

GOLD RACK ELECTROPLATING

At SPC, we also build our own racking equipment, which allows us to meet the precise requirements of our clients’ projects. Rack plating is ideal for fragile components or larger, more complex projects. However, it can be difficult to create a uniform deposit, and discoloration may appear where the item attaches to the rack.

The process involves hanging the substrate on a rack that uses hooks to apply the electrical current and hold the items in place. Once everything is properly attached, we lower the rack into the electrolytic bath, depositing the plating material.

GOLD BARREL ELECTROPLATING

Barrel electroplating is useful for quickly and economically applying a uniform coating to a substrate. This method is less precise than other methods, and works best when the entire surface of an item needs to be plated. It’s also not ideal for large or fragile components, as the piece may be too large for the barrel or become damaged during the plating process.

In this method, we place the component to be plated in a barrel that contains the plating bath, as well as bars that provide the electrical contact. Machinery rotates the substrate in the barrel while electrical current is applied, resulting in a complete and uniform deposit.

GOLD IMMERSION PLATING

For some applications, we use immersion plating, which doesn’t involve an electrical current. We dip the substrate into an electrolyte solution with gold ions, which causes the dissolution of ions from the substrate material. This releases electrons, allowing the gold ions to deposit onto the substrate. The gold ions replace the ions of the less noble metal, which typically results in a thin coating that has similar properties to electroplated gold.

PROPERTIES OF GOLD PLATING

While gold’s aesthetic appeal does contribute to its value, in the electronics industry, its functionality is what makes it such a prized material. Gold has several physical properties that lend themselves perfectly to use in electronic components. Manufacturers typically apply gold plating to connection points within electronic devices because it improves conductivity and protects the component, which helps that reliable connection last longer.

These properties include:

- Corrosion Resistance: One of gold plating’s most valuable attributes is its ability to resistant the corrosion that affects so many other metals. Gold is among the least reactive of all metals and won’t react with oxygen and rust like other metals do. Gold may tarnish slightly, but this isn’t damaging and can be removed by polishing. Resistance to corrosion is critical for electrical components because oxidation may cause a less reliable electrical connection. Its non-corrosive capabilities enable it to retain the smooth surface that’s needed for a strong connection.

- Expanded Connection Area: Gold is also highly ductile and malleable. This means it can stretch out into thin wire and will deform when placed under pressure, allowing it to spread out and cover more surface area. This creates a larger connection area, which leads to more reliable connectivity. Even with repeated use, gold’s flexibility helps electronic devices to continue to function correctly.

- Protection From Heat: Au plating is suitable for applications that involve high temperatures and will protect other materials from damage caused by heat. Gold has a melting point of 1943 degrees Fahrenheit, or 1062 degrees Celsius. It conducts heat well, in addition to electricity, and will continue to function appropriately even under intense temperatures. This makes it a useful for electronics that may become hot when used. For applications likely to involve frequent and intense heat, making the plating layer thicker will increase its resistance to heat.

- Reflectivity: Gold’s reflective properties make it ideal for use in components such as semiconductor parts, including reflector rings and reflector arrays. Gold reflects higher amounts of UV radiation below 0.35 µm than other metals do. It also reflects infrared radiation with wavelengths above 0.7 µm, which helps keep electronics cool. These reflective properties have made gold plating an integral part of spacecraft and satellite design.

- Resistance to Wear: Applying a gold plating to a piece of equipment can help it last longer, as the coating will protect the component itself from wearing away. Gold isn’t susceptible to fretting degradation, which wears away material due to repeated low amplitude relative motion. This can lead to corrosion, and then resistance. Because gold doesn’t corrode, it won’t become damaged due to fretting, protecting the layer beneath it. Gold is resistant to wear, so your plating will last a substantial amount of time. Like anything, it will eventually wear off naturally, buy when it does, you can easily re-plate the piece of equipment.

USE CASES FOR GOLD PLATING IN ELECTRONICS

You can find gold in all sorts of electronics including smartphones, laptops and desktop computers. One ton of smartphones, or about 10,000 phones, contains approximately 10 troy ounces of gold, which is equal to around three fifths of a pound. From 200 laptops, you could get about five troy ounces of gold, which is worth roughly $8000.

Gold’s ability to improve and sustain electrical connectivity makes it ideal for all types of applications in electronics. Manufacturers can apply it to any place that must facilitate an electrical connection to improve its reliability. You can find Au plating on the outside of devices, such as on electrical connectors. Most of the gold in electronics, however, is located inside the devices in the circuit boards.

Electronics companies use gold plating to enhance the conductivity of the circuit board and protect it from corrosion. Keeping a reliable connection within the circuit board is crucial to the reliable operation of any device.

Semiconductor components, such as top chucks, reflector rings and reflector arrays, are another area where gold plating is especially useful. Semiconductors, such as transistors, chips and other control parts, are partially conductive and may use plating to make a device more electrically efficiently. It also helps to protect these vital components from outside elements.

Because semiconductor chips are so small and fragile, the electroplating used for them varies slightly from the standard procedures. The chip must be handled carefully to avoid breaking any of the tiny wires inside, which would cause a faulty component. Even dust particles getting into the chip can result in a malfunction.

Because of this, the room where semiconductor plating takes place must have 0.01% of the amount of dust normally in outside air. The electrolytic bath must also be thoroughly filtered to remove any dust or other small particles.

In fact, in all electronics plating procedures, it’s necessary to prepare the substrate surface adequately to prevent the deposition of ionic and nonionic residue. These residues can reduce conductivity and even prevent the metal coating from adhering properly. Although the process of removing these residues required using hazardous organic solvents in the past, today we use eco-friendly, high-pressure water systems to prepare the surfaces of electronics for electroplating.

THE BENEFITS OF UNDERLAYERS FOR GOLD PLATING

As useful as gold is, it’s even more useful when combined with other metals. A layer of nickel is often placed on a substrate directly under the gold plating layer. This underlayer provides several benefits:

- It acts as an extra layer of protection against corrosion that may creep in through pores located in thin areas of the gold plating. It also helps prevent existing corrosion from spreading.

- It prevents other metals, such as zinc and copper, from diffusing into the gold where they may oxidize.

- It adds to the thickness of the plating. Because gold is relatively expensive, adding a thicker underlayer can reduce costs while still allowing access to the benefits of gold. This extra thickness also increases the plating’s overall durability.

Another common way to increase durability is to add a small amount of cobalt or nickel directly to the gold. This substance is referred to as hard gold — it’s relatively common and highly durable. Pure gold is often called soft gold.

Gold plating doesn’t need to be thick to be effective. In most cases, the gold should be as thin as possible without comprising any of its useful properties. For most connector manufacturing uses, a 0.8 micron layer of gold over a 1.3 micron layer of nickel should provide enough durability. Based on the application, however, you may need to vary the thickness of the plating.

The needs of your project will also determine whether you should choose hard gold or soft gold. For applications where durability is the most important aspect, hard gold is the best option. If you want a malleable coating, or if durability isn’t a priority, soft gold may be the right choice.

CHOOSING GOLD FOR ELECTRICAL COMPONENT PLATING

When it comes to metal plating for electronics, gold is an ideal choice. It offers the resistance to corrosion, wear and heat, as well as the enhanced conductivity vital to properly functioning electronic equipment.

Gold is used in electronics mainly in the form of

electroplating chemicals, gold bonding wire and sputter

targets. Smaller quantities are used in hybrid inks and solders.

The largest use of gold in electronics is as an electroplated

coating on connectors and contacts. This is followed by gold

bonding wires within semiconductor packages. Other uses

include hybrid circuits, solderable coatings for printed circuit

boards and components, as gold-based solders and for metal

layers on semiconductors as conductor tracks and contact pads.

Connectors and Contacts

Gold is used on connectors and contacts because it has

excellent corrosion resistance, high electrical conductivity

(only copper and silver are better) and, alloyed with small

amounts of nickel or cobalt, has good wear resistance. For

low voltage, low current and low contact force applications,

gold is the best material.

The resistivity of metals for electrical contacts is

important, but the contact resistance which depends on

other factors may be more significant. Some examples are

given in Table 1. The contact resistance figures are taken

from reference 2. These figures are very dependent on the

test conditions, in particular the contact pressure and so

contact resistance data from other sources may not be

comparable.

Table 1 Resistivity and Contact Resistance of Some Contact Materials

Contact Material Resistivity Contact Resistance

cm (2) m

Pure gold 2.4 x 10-8 0.8

Cobalt hardened gold 2.4 x 10-8 2.6 - 2.8

Palladium on nickel 1.08 x 10-7 3.1 - 5.8

Silver 1.6 x 10-8 Not determined

Resistance to oxidation and corrosion is important for

connector and contact materials. A useful guide to the

susceptibility of metals in these respects is their standard

electrode potential although this is not a reliable guide for

susceptibility to tarnishing in sulphide atmospheres where

silver is particularly liable to attack. The values for a selection

of metals are given in Table 2 (3). A large positive value

indicates good resistance to corrosion and a large negative

value, indicates a high reactivity but the situation is not as

simple as this as some metals including aluminium and nickel

form very thin, highly protective oxides which prevent further

attack once they are formed. However these oxides are

usually insulators.

A wide range of materials can be used for connectors and

contacts and the most appropriate choice will depend on

many criteria which include: current, voltage, contact force,

wear, fretting (due to vibration and thermal cycling),

environmental conditions (temperature, corrosive gases, etc.)

and of course cost (4). The number of times that a connector

or contact makes and breaks is also important as it will affect

wear. Often a compromise between performance and cost is

made. The most commonly used materials for low current

and voltage are listed in Table 3 and are compared with gold.

The total area actually making contact in a closed

connector or a pair of contacts is usually very small in

comparison with the apparent dimensions as contact is

made at only a few very small locations. This increases the

resistance across the contacts and so the passage of current

will generate heat. Increased contact pressure increases the

area making contact and so lowers resistance. The voltage

and contact pressure both affect localised heating which in

turn can lead to surface oxidation (but not of gold) or

melting of the surface. Arcing can also occur. All of these will

affect the life of the contact (6).

Oxidation or corrosion will affect less noble alloying

elements added to gold but these are used to modify its

properties such as the hardness or the rate of dissolution in liquid solders. Where a thin gold coating is deposited onto

another metal, this will diffuse into the gold and eventually

reach the outer surface where it can corrode or oxidise. The

time this takes depends on the thickness of the gold layer,

the temperature and the nature of the substrate metal. Silver

and copper will diffuse faster than nickel and so gold is

usually electroplated onto nickel (7). For hostile

environments, the gold thickness will need to be increased.

Electrical connectors are used to connect a wide range of

equipment such as in computers, mobile phones and cars.

Computers have plug-in printed circuit boards with gold

plated ‘finger’ connectors and the various parts of the

computer, monitor, printer, etc are connected by plug-in

sockets which usually have gold plated pins and sockets.

Some examples are shown in Figure 1.

Cars have an increasing number of electrical components

which need reliable electrical connections. These include the

air bag accelerometers, engine management systems and a

variety of pressure and other sensors. Car manufacturers

need high reliability and the environment within a car,

especially close to the engine, is hostile with a high

temperature and so frequently gold is the only suitable

material for these conditions. Most other metals would

oxidise or corrode. Most connectors are used for very small

currents at low voltage and so an increase in contact

resistance as a result of oxidation, corrosion or fretting will

affect the function of the components.

Table 2 Standard Electrode Potentials of Metals

Metal Standard Electrode Potential (volts) Comments

Gold Au+ → Au: + 1.68 Very inert and resistant to oxidation and corrosion

Palladium Pd2+ → Pd: +0. 83 Resistance to corrosion and oxidation less than for gold

Silver Ag+ → Ag: + 0.80 Good resistance to oxidation and corrosion but susceptible to

sulphide and chloride attack.

Copper Cu2+ → Cu : + 0.34 Readily oxidises in air and corrodes where moisture is present

Tin Sn2+ → Sn : - 0.136 Forms a thin inert and protective oxide but is easily

damaged because tin is relatively soft

Nickel Ni2+ → Ni : - 0.23 Readily forms a thin but inert and highly protective oxide.

This prevents further oxidation but is a good electrical

insulator

Aluminium Al3+ → Al : - 1.7 Aluminium is very reactive but rapidly forms a thin and

inert oxide which is highly protective

Figure 1

Gold plated computer D plug and connector pins on a computer PCB .

Table 2 Standard Electrode Potentials of Metals

Metal Standard Electrode Potential (volts) Comments

Gold Au+ → Au: + 1.68 Very inert and resistant to oxidation and corrosion

Palladium Pd2+ → Pd: +0. 83 Resistance to corrosion and oxidation less than for gold

Silver Ag+ → Ag: + 0.80 Good resistance to oxidation and corrosion but susceptible to

sulphide and chloride attack.

Copper Cu2+ → Cu : + 0.34 Readily oxidises in air and corrodes where moisture is present

Tin Sn2+ → Sn : - 0.136 Forms a thin inert and protective oxide but is easily

damaged because tin is relatively soft

Nickel Ni2+ → Ni : - 0.23 Readily forms a thin but inert and highly protective oxide.

This prevents further oxidation but is a good electrical

insulator

Aluminium Al3+ → Al : - 1.7 Aluminium is very reactive but rapidly forms a thin and

inert oxide which is highly protective

Comparison of Connector and Contact Materials

Coating MaterialPerformance

Gold Pure gold is fairly soft so hard gold is usually used. Pure gold is not susceptible to corrosion or

oxidation but alloying elements may be. Hard gold which is alloyed with 0.4% Co cannot be used at

200°C as it forms an insulating oxide whereas gold hardened with nickel is satisfactory at this

temperature (5). Gold is usually electroplated onto nickel.

Silver Often used as substitute for gold due to its lower cost but is susceptible to tarnishing from minute

traces of sulphide. It is fairly soft so wear resistance is not good.

Tin Even cheaper than silver but is very soft, and more susceptible to corrosion. Initial contact resistance

is higher than gold and deteriorates if oxidation or corrosion occurs. Particularly poor where fretting

occurs.

Palladium/Nickel Originally introduced as a lower cost alternative to gold but now palladium is more expensive but is

nevertheless used as it has very good wear resistance. It is however susceptible to oxidation,

corrosion and the formation of insulating films, particularly at higher temperatures. Usually,

palladium is electroplated onto a layer of electroplated nickel.

Gold/Palladium/Nickel A thin gold flash is used on palladium to reduce oxidation and corrosion

Gold alloys Used for electrical contacts and applied by cladding. Dilution of gold reduces costs but the

conductivity is not as high as pure gold. Alloys have good corrosion resistance.

Copper and its alloys Clean unoxidised copper has very good conductivity but oxidation and corrosion can occur rapidly

giving an insulating oxide coating. Useful where higher contact force is available and for power

transmission.

Internet communication uses high frequency signals to

pass data between users. This requires very good and reliable

electrical connections and so gold is used for coating

connector pins and for sockets in telecommunications

generally.

Wire Bonding

Most semiconductor packages use very fine gold wires to make

electrical connections between the semiconductor chip and

the leadframe within the package (8). These wires are typically

2mm long and 25μm thick so only about 20 nanograms of

gold is used per wire. However, some ICs can have over 200

wire bond connections and it is estimated that about 80,000

million ICs were manufactured in 2001 (9), which in total

accounts for a large quantity of gold. The quantity of gold used

for wire bonding is continually increasing as more and more ICs

are manufactured. Gold Fields Mineral Services estimate that

demand for gold bonding wire has doubled since 1994 to

about 100 tonnes in 2000 and the continuing long term

demand for new consumer electronics will ensure that this

growth continues (1).

Wire bonding is carried out thermosonically, which uses a

combination of heat and ultrasonic energy, or ultrasonically

without heat. The use of heat alone is rarely used and is

relatively slow. Gold is used for several reasons. Bonding with

gold can be carried out thermosonically with very high

reliability. This is essential where possibly millions of devices

having over 100 leads are manufactured. Manufacturers do

not want to carry out complex and costly tests on every device and so rely on being able to achieve a very high yield

of good ICs. Another advantage with gold is that ball bonds

can be made at a rate of 20 bonds per second. Aluminium is

also used for wire bonding (ultrasonically) but reliable ball

bonds cannot be made and so wedge bonds have to be used

which occupy more space than ball bonds and can be

bonded at a rate of only 8 per second. Gold does not oxidise

or corrode so packages do not need to be hermetically

sealed.

Research into lower cost metals is being carried out.

Copper is difficult to use as it forms an inert oxide which

prevents bonding. Silver is not used as it does not form good . ball bonds, and is susceptible to tarnishing and to

electromigration which can lead to short circuiting between

electrical connections. The interface between silver wire

bonds and the aluminium bonding pads on chips is

susceptible to galvanic corrosion, especially under humid

conditions. Research into silver/gold alloys is being carried

out but reliability is still an issue (10).

Gold Solders

Silicon chips which produce a significant amount of heat

such as those used in power amplifiers need to lose this heat

to prevent damage. Generally, any device that produces

more than 5 watts needs a good thermally conducting

pathway to loose this heat and prevent overheating. This is

achieved by bonding the chip to the package using a solder

alloy. There are two main choices, tin/lead solders and gold

alloys. Eutectic tin/lead forms good bonds and is relatively

ductile but is unsuitable if the component leads are soldered

with standard solder to a PCB or other parts. High melting

point solders having a high lead content can be used but

bonds can be porous with voids, which lead to stresses and

hotspots in the joint. The properties of the more commonly

used die attach solders are listed in Table 4.

The gold solders have better thermal conductivity than tin

or lead based solders and they also have higher melting

temperatures than the lead-free alloys. Thermal fatigue can

also be a problem in power semiconductor components.

Gold alloy solders have better fatigue properties than high

lead content alloys but of course are more costly. However, a

typical IC will use only 2 - 3 mg of gold (11). These gold alloys

are the only lead-free solder alternative to high melting point

lead-rich solder alloys with melting points in the 280 - 360°C

range.

Gold tin solder is also used to hermetically seal some types

of packaging. One example is laser diodes used for internet

communications using 80Au20Sn for the package lid seal as

well as the die attach solder. Solderable Coatings

Gold is wetted very easily by liquid solders and so is used as a

protective solderable coating. Once a printed circuit board

(PCB) has been manufactured, the copper circuitry rapidly

oxidises and it soon becomes impossible for solder to wet the

surface using an electronics flux. Therefore PCB

manufacturers nearly always coat their boards with a

protective coating to protect them during storage. One of

the most popular is electroless nickel, followed by immersion

gold (12). This is more costly than some of the alternatives

but gives superior performance. Organic solderability

preservatives (OSP) are popular because they are low cost but

the protective coating is very susceptible to damage by

fingerprints and light rubbing. Tin and silver coatings are also

available and are less susceptible to damage than OSPs but

more susceptible to tarnishing or corrosion than nickel/gold.

Nickel gold forms a very flat surface and is suitable for

soldering bare chips directly onto the PCB. Another

advantage is that the gold colour makes inspection easier,

but rework can be more difficult. The thickness of gold used

is typically 0.08μm so very little gold is used on each PCB.

When soldered, this very small quantity of gold dissolves into

the solder and remains in solution so does not affect joint

reliability. The solder forms a strong bond to the nickel which

dissolves much more slowly in liquid solder than gold or

copper. Nickel cannot be used alone without the thin

immersion gold layer as it oxidises on exposure to air to form

a thin layer of a very stable oxide which prevents solder

wetting the surface. Extremely corrosive fluxes, which would

alleviate this problem, are unsuitable for electronic circuits.

Electromigration is a process that can affect printed circuit

boards, hybrid PCBs and some electronic components under

certain conditions such as high humidity, an electrical potential

and ionic material, such as flux residues (13). Silver is particularly

prone to electromigration but most other metals will also do this

under certain conditions. Even aluminium conductors within

semiconductor integrated circuits have been known to suffer

from electromigration. Electromigration of gold is very rare and

occurs only if chloride ions are present. Electromigration appears

as a filamental growth of metal that runs between two

conductors and is an electrochemical process. Metal from the

anode dissolves and diffuses under the influence of an applied

current and is electroplated onto the negative electrode.

Anode reaction - metal dissolution with release of electrons:

M = Mn+ + neCathode

reaction - metal electroplating, consumes electrons:

Mn+ + ne-

= M . The relatively large positive electrode potential of gold

makes these reactions less likely to occur than with other

more reactive metals.

Hybrid Circuits

Where the higher production cost is justified, hybrid circuits

are used as they have many advantages over plastic laminate

PCBs. Hybrids are normally used to save space and weight but

thermal dissipation is better. Signal paths are shorter so that

circuits are faster, they can use less power and they have

enhanced performance at high frequencies, and are

therefore often used for microwave circuits. It is possible to

build resistors, capacitors and inductors into inner layers

which saves space on the outer layers. Some types can be

made with hundreds of individual layers and circuits can

safely be used at over 100°C, neither of which is possible for

standard FR4 PCBs.

Hybrid circuits use metal inks to create the conductors.

Gold, silver, palladium, platinum and their alloys are used as

circuits and need to be fired at 850°C during manufacture.

The inks or pastes contain metals in the form of fine powders.

As a conductor, gold is the best material as it has high

conductivity and excellent resistance to corrosion. However it

is more expensive than silver which is an even better

conductor but can suffer from tarnishing and

electromigration problems. Despite these potential

difficulties, many hundreds of times as much silver is used as

gold. Gold is, however, usually used for wire bond pads. A

hybrid circuit can be overall a lower cost option than a plastic

laminate board. Bosch have developed an ABS module which

is designed to be fitted close to the engine. This avoids the

need for an expensive cable so that the overall cost is lower.

One of the advantages with hybrid circuits is that a very

fine pitch can be achieved although the limit is currently

about 400μm (line + space) for screen printed circuitry. There are new products on the market from Dupont and from

Heraeus for making finer lines using photolithographic

techniques but these involve several process steps and create

effluents and are therefore relatively expensive. An

alternative is to print directly with the ERA μ-Screen (14, 15).

This can print 50μm gold lines and 50μm spaces and the

edges of lines are much smoother than screen printed lines

which are affected by the weave of the mesh screens. This

gives superior performance with high frequency circuits.

Sputter Coated Gold

Gold can be coated onto a wide variety of substrates including

metals, ceramics and plastics using various vacuum coating

techniques. With sputtering, gold is used in the form of a

‘target’ which is a specially shaped piece of gold. High energy

ions eject atoms of gold from the surface and these are

deposited onto the material which is being coated. The

quantity of gold that is sputtered has increased significantly

over the last few years, mainly due to the introduction of

Read/Write CDs and DVDs. These have a very thin pure gold

coating that is deposited by sputtering. Gold is used because

it is the best optical reflector with excellent resistance to

corrosion and tarnishing.

Gold is also sputter coated onto gallium arsenide (GaAs)

integrated circuits as the conducting pathways. Gold is not

used on silicon as it reacts with the silicon (for which

aluminium and more recently copper conductors are used)

but it can be used on GaAs and other compound

semiconductors unlike aluminium which interacts (16). The

use of GaAs ICs has increased significantly recently as a result

of new uses in mobile phones, internet communications and

DVD players. GaAs is used because signal speeds are up to 40

times faster than with silicon.

There is a rapid growth in the use of

microelectromechanical systems (MEMS) devices for a wide

range of applications (17). These include crash sensors in

automobiles, optical switches for the internet and pressure

sensors for automobiles and medical applications. Their use

in mobile phones is predicted to grow rapidly as MEMS

switches and other devices are introduced. Most optical

switches are coated with a thin layer of gold, using a vacuum

technique, to make a reflecting mirror surface. Most MEMS

switches operate with a very low contact force and so only

gold can be used to obtain a low contact resistance.

Recycling of Gold from Electronics

The EU is planning to introduce the Waste from Electrical and

Electronic Equipment (WEEE) directive which will require . manufacturers to recycle electronic and electrical equipment

at the ‘end of life’. Currently, only equipment that can be

recycled economically is recycled and the most valuable

component in often gold, particularly in IT and telecom scrap.

The final form of the directive is still unclear but manufacturers

will have to pay for their products to be recycled and any

recovered gold will contribute to cost savings (18).

Conclusions

Gold has a wide variety of uses in electronics because of its

unique physical and chemical properties:

•It has excellent resistance to corrosion and oxidation,

whereas silver tarnishes in atmospheres containing minute

traces of sulphide. Palladium oxidises especially at higher

temperatures and can catalyse the polymerisation of

hydrocarbons and form insulating films. Most other metals

including copper, nickel, iron and cobalt will oxidise in air

and corrode in the presence of moisture and ions,

particularly halides.

•The inertness of gold makes it invaluable as a solderable

coating to maintain the solder wetting properties of PCBs

and component leads. It also allows gold to be used within

the human body as it is not affected by body fluids and is

completely non-toxic.

•The electrical resistivity of gold is the lowest of all metals

except for silver and copper but both of these readily

tarnish causing the contact resistance to increase. For low

current, low voltage conditions and low contact force,

gold is frequently the best choice technically and in some

applications such as automotive and RF connectors and

MEMS switch contacts, it is the only choice.

•Pure gold is a relatively soft metal and so is not ideal for

contacts where wear occurs. Hard gold has been

developed for wear applications but better results are

obtained if this is electroplated onto Pd/Ni layers.

•Gold’s ductile properties combined with the lack of an air

formed oxide allows fine gold wires to be used for wire

bonding within semiconductor ICs. No other metal has the

same reliability at the highest production rates.

•Gold is also used for its light reflecting properties in optical

devices such as optical switches and Read/Write CDs and

DVDs.

The only significant disadvantage of gold that

sometimes discourages its more widespread use is relatively

high metal price compared with base metals such as

copper and nickel. Usually, however, only very small

quantities of gold are used in each product so the effect on

the total cost is often insignificant whereas improved

reliability can result in significant savings.

Most Computers & electronic devices contain circuit boards inside that will contain many types of precious metals. Printed Circuit Boards, Connectors and Components have high levels of precious metal content.

VALUABLE & PRECIOUS METALS – WHERE THEY ARE IN COMPUTERS:

- Gold – Printed Circuit Boards, Computer Chips (CPU), connectors / fingers

- Silver – Printed Circuit Boards, Computer Chips, keyboard membranes, some capacitors

- Platinum – Hard Drives, Circuit board components

- Palladium – Hard Drives, Circuit board components (capacitors)

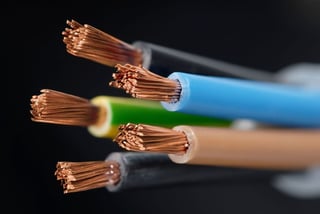

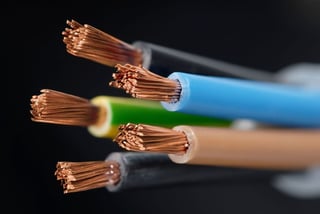

- Copper – CPU heat sinks, wiring and cables, Printed Circuit Boards, Computer Chips

- Nickel – Circuit board components

- Tantalum – Circuit board components (some capacitors)

- Cobalt – Hard Drives

- Aluminum – Printed Circuit Boards, Computer Chips, Hard Drives, CPU heat sinks

- Tin – Printed Circuit Boards, Computer Chips

- Zinc – Printed Circuit Boards

- Neodymium – Hard Drives (magnets)

EXTRACTION

Chemical extraction of Gold, Silver, Platinum, Palladium and Rhodium can be extracted from such components and the removal and disposal of hazardous materials including Mercury, Cadmium, Beryllium Oxide and Batteries (NiCd, Lithium etc.) is also undertaken.

Elements found in trace amounts include Americium, Antimony, Arsenic, Barium, Bismuth, Boron, Cobalt, Europium, Gallium, Germanium, Gold, Indium, Lithium, Manganese, Nickel, Niobium, Palladium, Platinum, Rhodium, Ruthenium, Selenium, Silver, Tantalum, Terbium, Thorium, Titanium, Vanadium, and Yttrium.

Almost all electronics contain Lead and Tin (as solder) and Copper (as wire and printed circuit board tracks), though the use of lead-free solder is now spreading rapidly.

Computer components containing valuable metals include Motherboards, connector cards, graphic cards, memory cards, CPU’s and other various small electronic components, connectors/cables & Hard drives.

Computer CPU’s (processors) have the most precious metal value by weight, followed by Memory (RAM) & Circuit Board Fingers / Connectors / Pins, then Circuit Boards (Motherboards), then cables / wires, with hard drives & whole computers being last.

CD/DVD drives, monitors, cases, keyboards/mouse, printers, scanners & power supplies typically do not contain enough precious metal to be considered of value.

LIST OF CHEMICAL ELEMENTS USED IN COMPUTERS & ELECTRONICS:

Magnesium, Radium, Barium, Niobium, Osmium, Cobalt, Manganese, Titanium, Hafnium, Tungsten, Germanium, Gold, Silver, Copper, Mercury, Bismeth, Silicon, Gallium, Zinc, Iorn, Sulfur, Phosphorus, Cadmium, Palladium, Tantalum, Platinum, Aluminum, Carbon, Lead, Nickel, Boron, Chromium, Potassium, Fancium, Casium, Sodium, Lithium, Calcium, Nitrogen, Oxygen , Arsenic, neodymium, Selenium, & Tin.

Gold and Gold Alloys in Electronics

Overview

.jpg)

Gold is the material of choice in many electronic applications, especially in telecommunications, information technology and other high performance and safety critical applications. Examine your mobile phone and you will almost certainly see goldplated contacts. Take apart an old computer and there will probably be gold plated edge connectors on the circuit boards. As a result of the growth of these sectors, long term annual consumption of gold in electronics is increasing. During 2007, it was estimated that around 280 tonnes of gold found its way into electronics and electrical components. Where the voltages are small, the circuitry complex or the required reliability high, gold is usually the preferred choice.

Material Properties of Gold

The beneficial material properties of gold include outstanding resistance to corrosion, the ease with which it can be worked and high thermal and electrical conductivity. Only silver and copper are better conductors of electricity, but do not have comparable resistance to tarnishing or corrosion. In conditions under which most other metals either tarnish or corrode away, gold remains inert and extremely durable.

.gif)

So where resistance to tarnish or corrosion is essential, it is therefore common to either use gold or a gold alloy, or to plate gold onto a less noble metal. For electronic applications, the resistance of gold to environmental effects is perhaps its most important property. It means that the technical performance of gold bonding wires or gold electroplating remain essentially unaltered with time.

Optimum Use of Gold

In general, the more sophisticated the equipment and the greater the need for reliability, the greater the requirement to exploit the advantages of gold as a material. This means that in telecommunications, computers, automotive electronics and defence systems where safety is critical, gold is indispensable.

Research and development is continuing to study the optimum use of gold in the electronic sector, including the development of high strength connecting wires and improved wetting solder alloys. Innovations required for information technology in the future will be highly integrated electronic devices, designed and fabricated on the nanometre scale (one billionth of a metre).

Gold will be an indispensable element for nanoscale electronic devices because it is resistant to oxidation and mechanically robust at the incredibly small dimensions defined by nanotechnology.The reliability of gold is an essential characteristic for the increasing use of electronic components in cars.

What Metals Are In Your Electronics?

Some people might not know that there are precious metals in your electronic devices but there are some very valuable metals that can be found in your e-waste. Used electronic devices can be reused, recycled, resold, and salvaged. If you choose to recycle your electronic devices not only are making sure that your are protecting your data, you’re also making money off these precious metals that are in these devices. Making sure that you recycle your electronics is very important because the number of people and companies recycling their electronics is low. There are two billion smartphone users upgrade to a new phone roughly every 11 months and barley 10% of those phones get recycled. These phones are just put to waste in a drawer or in a landfill.

By recycling your e-waste the precious metals it allows for these precious metals to be reused, therefore reducing the need to mine and process new materials. Which ultimately has a negative affects the environment. Some of the precious metals that are in these electronic devices include:

Gold: Gold is used in printed circuit boards, cell phones, computer chips (CPU), connectors and fingers.

Silver: SIlver is used in printed circuit boards, cell phones, computer chips, keyboard membranes and some capacitors.

Platinum: Platinum is used in hard drives and circuit boards components.

Palladium: Palladium is used in cell phones, hard drives, circuit board components and capacitors.

Copper: Copper is used in CPU heat sinks, wiring cables, cell phones, printed circuit boards and computer chips.

Nickel: Nickel is used in to circuit board components.

Tantalum: Tantalum is used in circuit board components and some capacitors.

Cobalt: Cobalt is included hard drives.

Aluminum: Aluminum is used in printed circuit boards, computer chips, hard drive, CPU heat sinks.

Tin: Tin is used in printed circuit boards and computer chips.

Zinc: Zinc is used in printed circuit boards.

Neodymium: Neodymium is used in hard drives.

The amount of precious metals that are found in electronic devices can be substantial. The EPA estimates for every 1 millions cell phones recycled you can get these amounts of precious metals:

- 35,274 pounds of copper

- 772 pounds of silver

- 75 pounds of gold

- 33 pounds of palladium

When looking at electronics you should be looking at recycling, the computer components with the highest precious metal content by weight:

- Computer CPU’s (Processors)

- Memory (RAM) & Circuit Fingers/ Connectors/ Pins

- Circuit Boards (Motherboard)

- Cables/WIres

- Hard Drives

- Whole Computers

- Cell Phones

Mayer Metals Corporation is based in the Metro Detroit area and provides business to business electronic waste recycling. We provide our customers with:

- Data Security Solutions

- Hard Drive Shredding

- Environmentally Responsible Recycling via an R2 Certified Facility

- Competitive Prices

USE OF GOLD PLATING IN ELECTRONICS

The use of gold plating in the electronics industry has been an ongoing part of the expansion of more complex digital electronics and equipment throughout many industry sectors. According to BullionStreet, over 320 tons of gold are used each year in the electronics industry. This includes gold in PCs, mobile phones, tablets and other devices. The overall use of gold in electronics is via gold plating. Gold plating is primarily used on contacts for switches, relays, and connectors

Gold has the combined elements of electrical conductivity, ductility, and doesn’t corrode at high or low temperatures. The corrosion resistance of gold is one of the key factors that it is used for in electronics. According to GoldAvenue, gold’s resistance to corrosion offers “atomically clean metal surface which has an electrical contact resistance close to zero, while its high thermal conductivity ensures rapid dissipation of heat when gold is used for contacts.”

Several guidelines have been established by AMP Incorporated for the use of gold plating in electrical contacts. Below is a summary of some of these guidelines.

High Reliability Applications and Gold Plating – For connector applications in electronics that require reliability, it is important for the separable contact interface to be shielded from environmental deterioration. An application of gold onto the interface of a separable connector provides a long, stable and very low contact resistance for the component.

Corrosive Environments and Gold Plating – Corrosive environments such as high humidity locations or an environment that contains corrosive pollutants like chlorine or sulfur gases will attack and degrade metals like nickel. This corrosion will interfere with electrical contact. Gold doesn’t break down in these conditions. However, if the gold plating is too thin or porous, it will break up, so it is important for the plating to be done at the correct thickness for full protection and with a suitable under layer metal.

Suitable Under Layer Metals for Gold Plating –In order to avoid degradation of gold plating, especially in corrosive environments as mentioned above, gold plating should be applied over an under layer of a quality metal like nickel. An under layer of nickel will act as the following for a gold plated surface:

- Pore-Corrosion Inhibitor – Nickel as an underplate prevents corrosion via pores in thin areas of gold plating.

- Corrosion Creep Inhibitor – Provides a barrier against corrosion

- Diffusion Barrier – Prevents diffusion of other metals like copper or zinc into the gold surface.

- Mechanically Supporting Under Layer for Contacting Surfaces – Nickel increases gold plating’s durability.

Thickness of Gold Plating Based on Requirements of Electronic Component – The determination of the correct gold plating thickness depends on the application of the electronic component. Despite the decline in the price of gold in recent months, keeping the plating thickness as low as feasible is a good place to begin when determining the overall thickness of the plating. According to the AMP report, “In general, a 0.8 micron (30 micro inches) coating of hard gold over a minimum of 1.3 microns (50 micro inches) of nickel gives a degree of durability considered adequate for most connector applications. Thin coatings of 0.03 - 0.1 microns (1 - 4 micro inches) of hard or soft gold over nickel underplate should be used only for applications in which the risk of fretting is minimal. Increasing the thickness of a gold coating tends to decrease the porosity which reduces the contacts’ vulnerability to pore corrosion.

Gold Plated Contacts Effective at High Temperatures – With gold’s properties, it is an effective protection for electronic contacts exposed to high temperatures (>125⁰C/>257°F). To be certain of protection against elevated temperatures, the nominal gold and nickel thickness should be increased.

These are just a few guidelines for the use of gold plating in electronics. Each application of the electronic component that is to be plated should be determined to make certain that all factors are considered and planned for prior to plating in order to obtain the target performance.

XO__XO Copper , Silver

, Silver and Gold

and Gold

, Silver

, Silver and Gold

and Gold

Copper, silver and gold are found in elemental or "native" form at the earth's surface. The best nuggets have been picked up already, since the land has been scoured for them wherever there are people who appreciate them. They are called the currency metals, since they have been used in coins since the beginning of money. The three largest U.S. coins in each of the metals are shown at the right. The large cent was issued 1793-1857, and weighs 11g. The Peace Dollar was minted 1921-1935, and weighs 27g. The St. Gaudens Double Eagle, $20, was minted 1907-1933, and weighs 34 g. At today's prices, the metal in these coins is worth $0.02, $4.27 and $405.61. Now, however, copper alloys predominate in the miserable debased coins of no artistic merit we use every day. They are also called noble metals, and all others base metals. They are the royal family of the periodic table, family IB. Their alchemical symbols are the signs of the three brightest planets, the sun, the moon and Venus, their colors yellow, white and red.

Copper, silver and gold are found in elemental or "native" form at the earth's surface. The best nuggets have been picked up already, since the land has been scoured for them wherever there are people who appreciate them. They are called the currency metals, since they have been used in coins since the beginning of money. The three largest U.S. coins in each of the metals are shown at the right. The large cent was issued 1793-1857, and weighs 11g. The Peace Dollar was minted 1921-1935, and weighs 27g. The St. Gaudens Double Eagle, $20, was minted 1907-1933, and weighs 34 g. At today's prices, the metal in these coins is worth $0.02, $4.27 and $405.61. Now, however, copper alloys predominate in the miserable debased coins of no artistic merit we use every day. They are also called noble metals, and all others base metals. They are the royal family of the periodic table, family IB. Their alchemical symbols are the signs of the three brightest planets, the sun, the moon and Venus, their colors yellow, white and red.

All three are not only delightful in appearance and resistant to corrosion, but can be hammered into ornaments of artistic distinction. The three are ductile, capable of being drawn into fine wires, and malleable, capable of being hammered into thin sheets. Gold, indeed, is outstandingly ductile and malleable, able to be drawn into wires thinner than a hair and beaten into sheets thin enough to transmit light. All three metals are important in technology, especially in electronics.

Copper and silver, and perhaps even gold, harden when they have been worked, and it becomes impossible to work them further, even with great effort, without danger of cracking and crumbling. This work hardening is seen even when you bend the lid of a tin can back and forth to break it off. However, if the metal is heated sufficiently to allow the metal to recrystallize, on cooling it will be restored to its original soft, workable state. This process of annealing could have been the first metallurgical practice discovered. Copper anneals at a temperature of 200°C - 750°C, the pure native copper at lower rather than higher temperatures. These temperatures are less than a red heat, and are obtained in any common fire.

However, the artisans were still limited to the size of the nugget that was picked up. Large objects required large nuggets, and were correspondingly more valuable than a handful of small objects of the same weight. To make larger objects, the metal has to be melted and poured into a mould. The temperature required to melt the noble metals is close to 1000°C, practically a "white heat." This requires a fire blown by bellows or some other means, though in favorable circumstances a good natural draft might suffice. The fusion of metals could have been the second metallurgical process discovered.

It should be mentioned that most stories about the history of metallurgy are just that: stories. There is no detailed evidence of methods, only the rare object found in excavations, often misidentified, mislabeled and misinterpreted by those unversed in metallurgy or chemistry. Nobody knows the order of discovery, or who the discoverers were. From the scraps of information, a story is constructed on the basis of our current understanding of metals, just as I did in making annealing the first discovery, and fusion the second. This is logical, but not proved. We have much better evidence from classical times, but still do not know much in detail.

Copper knives and weapons were made in pre-dynastic Egypt, perhaps as long ago as 6000 BC by some authorities. Pipes and tubes were found from 2750 BC, and a bronze mirror dates from 1800 BC. However, metals were rare in Egypt, and a non-metallic culture predominated. The smelting of metals from ores is a significant and much later discovery than the use of native metals, annealing and fusion. This is discussed at more length in Tin. This metallurgy may have originated in Mesopotamia around 2000 BC, and perhaps also in India. The Phoenicians made smelted copper and tin available to the Mediterranean world, and with it the alloy bronze, around 1800-1500 BC. I would like to have better estimates of these dates, but the authorities seem to be in disagreement, and not all that knowledgeable about metals anyway.

Although copper was probably originally encountered in nature as the native metal, it was also probably the first to be extracted by smelting from ores. Zippe proposes that this was discovered when heat was used to break rocks for the native copper they contained, since stone tools would not suffice, and some of the ore, so different in appearance from metallic copper, was reduced. Copper was the first metal whose ores were mined, and some of the earliest mines have left traces, as in the Sinai peninsula.

Copper

Copper was the predominant early metal, especially after the technique of smelting it from its ores and trade made it widely available. It is still the third most important industrial metal, after iron and aluminium. Our word "copper" comes from the Plattdeutsch coper or koper, still used in Dutch. In Latin, it was known as cyprium aes, "brass from Cyprus" or "brass of Venus." Aes was the Latin for all coppery-bronzy-brassy alloys, which I have translated as "brass," though what we call brass was a later development, but still Classical. Copper in particular was also called adhenus, as was a copper pot. However, the Venusian name stuck in the West, and gave us cobre in Spanish, cuivre in French and Kupfer in German. In Welsh it is copr, which suggests that this word comes from old Celtic, and is unassociated with Venus. In Russian, copper is med', a quite different word, whose etymology might give us valuable information.

Greek, also, had a different word. Here, the equivalent of aes was calkos, "chalcos," named after the copper mines at Chalcis in Euboea. This stem is often seen as referring to copper, notably in mineralogy. "Chalcopyrite" is copper pyrites. The word was applied to iron as well after its introduction, long before the coining of sideros, "sideros." The word for steel is caluy, clearly related to chalcos. The Phoenicians, and others, worked copper mines and smelters in Cyprus, Kupris. Venus, or Aphrodite, the Kupris, was born there, always loved the island, and was its patron. She is very often referred to as Cypris. The word "cuprium" could have come either from the island or the goddess, and it is impossible to make a distinction. The word cuprum was probably later Latin, and gave us the chemical symbol Cu. The alchemical symbol was the sign of Venus, shown in the title of this article. The Phoenicians were surely the ones who spread the knowledge and use of copper around the Mediterranean, and their metallurgical procedures were probably kept secret.

The fact that pure copper and its alloys were not distinguished in ancient words shows that a fundamental difference was not appreciated. Our recognition of chemical elements is recent, and quite foreign to earlier thought. Most ancient "copper" is indeed bronze, containing tin but also lead and zinc. The alloys have a somewhat lower melting point than pure copper, and so would be easier to work, besides being much harder and more usable as tools and weapons. Zippe concludes from the various names of copper and its alloys used by different peoples the probable multiple discovery of its smelting. He also remarks, quite to the point, that it is just as possible that a source of a metal was named after the metal as that the metal was named after a place.

Copper is often described as a "red" metal, though its actual color is an orange-red of lower intensity, not a bright signal red. It is not a spectral color by any means, but a particular impure one requiring its own name, such as "copper-red." The red color is produced by the density of electrons being insufficient to cause a high plasma frequency, so the shorter wavelengths are not reflected as efficiently as the longer, redder ones. The red color is unique to copper and its alloys.

Copper has atomic number 29, atomic weight 63.57, and density 8.94 g/cc. Its naturally-occurring isotopes have mass numbers 63 (69%) and 65 (31%). The electron configuration has one 4s electron outside a filled 3d shell in the ground state. However, the energies of the 3d and 4s orbitals are about equal, so a 3d94s2 configuration is as favored as a 3d104s. Copper exhibits valences +1 (cuprous) and +2 (cupric), with the +2 predominating. Copper metal has a face-centered cubic structure, with a = 0.361 nm. Each ion has donated one electron to the Fermi sphere. The work function of copper is about 4.7 eV (tabulated values vary from 3.85 to 4.86). The Fermi energy is 7.0 eV. The electrical resistivity of annealed copper is 1.7241 μΩ-cm, of hard-drawn, 1.771 μΩ-cm, and the temperature coefficients are 0.00393 and 0.00382 per °C, respectively. For pure copper, the resistivity is 1.683 μΩ-cm. The thermal conductivity is 0.923 cal/cm-s-K, and the linear coefficient of expansion is 16.42 x 10-6 per °C. The specific heat is 0.0918 cal/g-K. The melting point of copper is 1083°C, boiling point 2325°C, and the heat of fusion is 50.6 cal/g. Its hardness is 3.0 on the Mohs scale. The tensile strength of annealed copper is about 30 ksi, of hard-drawn copper, 60 ksi. The Young's modulus is 16 x 106 psi.

For most uses, copper is alloyed with other metals, though copper usually predominates. Bronze is discussed in Tin and brass in Zinc. Copper-nickel alloys are used in coinage. Aluminium makes the excellent aluminium bronze. Pure copper is used for electrical conductors, since any alloy usually greatly increases the resistivity. Silver, cadmium and zinc have the least effect. 1% Cd decreases the conductivity to 94%, while hardening and strengthening the copper. Cadmium copper is used for contact wires. Arsenic, a common hardening addition to copper, has a large effect. 0.1% As lowers the conductivity to 75% of the value for pure copper, 0.5% As to 40%. Arsenic raises the softening (annealing) temperature to around 550°C from 190°C for pure copper. Arsenical copper with 0.5% As is used in boiler fireboxes, tubes and rivets to give strength at elevated temperatures. More arsenic embrittles the copper, and is very undesirable. Speculum metal, 89 Cu 33 Sn, is white and can be polished to make good mirrors. It was known in antiquity and used for mirrors.

Copper, like the other members of the royal family, is unreactive, with an electrode potential of 0.47V. It is not attacked by nonoxidizing acids or alkalies. In moist air, however, it may be attacked even by dilute acids. The CO2 in moist air creates a layer of CuCO3·Cu(OH)2, a basic copper carbonate called verdigris of a greenish color, called a patina, considered to be attractive. Otherwise, as in household copper, oxygen and sulphur make a film of black CuO or CuS tarnish. This happens very slowly, and the copper is not corroded. If regularly polished, it remains shiny and attractive.

The process of "flashing" a deep red surface layer of glass containing colloidal copper oxide was discovered in Bohemia around 1842, and became an alternative to the ruby glass that was a colloidal suspension of gold. This process was widely used to make signal lenses and similar products in place of the more expensive ruby glass. Note that the colour here is superficial, while in ruby glass it is a body colour. Copper also makes green, blue and brown pigments.

Cuprous oxide, Cu2O is red, and cuprous sulphide, Cu2S is black. Both are very insoluble. In any soluble cuprous compound, auto-oxidation generally occurs, 2Cu+ → Cu + Cu++, producing the cupric salt. Cupric oxide, CuO is produced by heating copper in air, or by strongly heating any oxygen-containing cupric salt. CuS is produced in an analogous way. In solution, the copper ion forms complex ions, such as Cu(H2O)4++, or Cu(NH3)4++. These are flat, square ions, of blue color. The water ion is medium blue, the ammonia ion dark blue.

Soluble copper compounds are all very poisonous. Indeed, they are often used as insecticides and algacides. This is not unexpected, since most heavy metal ions are also poisonous. Copper, however, seems to have escaped the notice of chemophobes who have persecuted lead and mercury.

Copper tarnish is composed of CuO, and the basic carbonate if moisture and air are present. It can be removed by solutions containing the ammonium ion, which forms the soluble ammonia complex. The commercial preparation Brasso is an example. Other copper polishes use different means not revealed on the labels, but boast that they do not contain ammonia. Copper polishes should not be used on silver, since they will attack it. Copper polishes seem to attack the copper as well, but not seriously. Kitchen ammonia does not seem to remove copper tarnish. Lemon juice, salt and vinegar, however, seem to remove tarnish well. None of the three works on its own, but all three together do. Mechanical scouring is also recommended for copper.

Cupric sulphate, CuSO4·5H2O, called bluestone or blue vitriol, is soluble in 0°C water to 24.3%, in 100°C water to 205%. The blue color requires the water. The anhydrous salt, prepared by heating, is white or pale green. Its solutions are slightly acidic, and are strong germicides and fungicides. Bordeaux mixture is a garden insecticide that contains copper sulphate. The triclinic crystals are easily grown. This is the substance that supplies the copper ions in a Daniell cell or gravity cell. The sulphate can be recovered by dissolving the copper cathodes of the cells in sulphuric acid, so the copper is continuously regenerated as the zinc is burned. The Daniell and gravity cells are discussed in Electrochemistry.

Copper is easily electrolytically plated from an acid solution of Cu(SO)4, since it is below hydrogen on the electrochemical scale, or from an alkaline solution of potassium cuprocyanide, KCu(CN)2. It will not give cathodic protection to iron, so care must be taken that the coating is continuous to avoid corrosion at pinholes. The copper layer is usually excellent, and can be a base for other plating for decorative effect. Chromium plating, which is always porous and non-protective, is conveniently done on a thin copper plate, or on nickel on top of the copper. Many automotive parts are zinc die-castings, plated with copper, nickel and finally chromium. Chromium is protected by a thin, invisible adherent layer of Cr2O3 like aluminium, but this does not rob its lustre after polishing of the plated layer.

Cuprous oxide was used in one kind of metallic rectifier, a predecessor of the semiconductor diodes of today. A plate of copper was strongly oxidized on one side to produce a thick layer of CuO. This was heat-treated so that a thin layer of Cu2O would grow between the Cu and the CuO. Then the CuO was stripped off with acid, and a contact of lead or similar material applied. The copper base plate acted as an n-type material, while the Cu2O was p-type, and a pn-junction was formed. This junction had a forward bias voltage of a few tenths of a volt, a reverse breakdown voltage of 5V or 6V, and a rather low maximum operating temperature. A stack of such elements could be assembled for higher voltages. The reverse current was larger than would be tolerated now, but was satisfactory for battery chargers and other similar devices. Similar rectifiers were made from Cu2S on magnesium, and selenium on iron or aluminium. These were quite satisfactory for low voltages and moderate currents, but have been completely replaced by the cheaper silicon diodes with far superior characteristics.

The United States was once the leading producer of copper, but the mines of Michigan, Montana, Utah, Nevada and Arizona are now exhausted, and most copper has to be imported. The copper nugget shown at the left is like those that were found in Upper Michigan, and provided the purest copper available, "Lake copper," for many years (image ©Amethyst Galleries). Rich copper ores are very rare, and much effort has been expended to make the more widely available lean ores economic. Most copper now comes from enriched zones that are mined in open pits as earth containing less than 1% copper, not as rich vein minerals of 20% Cu and more. The primary ores are sulphides and oxides, usually mixed with iron. Chalcocite is Cu2S, chalcopyrite CuFeS2, covellite CuS, and bornite Cu3FeS3. The oxides are cuprite Cu2O, tenorite CuO, malachite CuCO3·Cu(OH)2(mineral verdigris), azurite 2CuCO3·Cu(OH)2, and the silicate chrysocolla CuSiO3·2H2O. Many of these minerals make attractive specimens, because of their green and blue colors, and can be carved into ornaments. They are not seen as crystals or massive forms in the ore mined today, but widely disseminated in an earthy matrix.

The United States was once the leading producer of copper, but the mines of Michigan, Montana, Utah, Nevada and Arizona are now exhausted, and most copper has to be imported. The copper nugget shown at the left is like those that were found in Upper Michigan, and provided the purest copper available, "Lake copper," for many years (image ©Amethyst Galleries). Rich copper ores are very rare, and much effort has been expended to make the more widely available lean ores economic. Most copper now comes from enriched zones that are mined in open pits as earth containing less than 1% copper, not as rich vein minerals of 20% Cu and more. The primary ores are sulphides and oxides, usually mixed with iron. Chalcocite is Cu2S, chalcopyrite CuFeS2, covellite CuS, and bornite Cu3FeS3. The oxides are cuprite Cu2O, tenorite CuO, malachite CuCO3·Cu(OH)2(mineral verdigris), azurite 2CuCO3·Cu(OH)2, and the silicate chrysocolla CuSiO3·2H2O. Many of these minerals make attractive specimens, because of their green and blue colors, and can be carved into ornaments. They are not seen as crystals or massive forms in the ore mined today, but widely disseminated in an earthy matrix.

The sulphide ores are roasted to drive off the sulphur, arsenic and antimony, then calcined with sand or lime to slag off iron and more sulphur, producing a black matte consisting mainly of sulphides, like Cu2S. The matte is reduced in a blast furnace with air and the sulphur it contains to produce blister copper. Oxide ores are reduced with carbon. The blister copper is then dissolved in H2SO4, which can be made from the gases evolved in roasting and reduction, and the solution electrolyzed to produce cathodes of pure electrolytic copper. Gold and silver are usually recovered from the electrolysis sludge, and help the economics of the process. Modern smelting is much different from ancient smelting, since the ores treated are much leaner. Electrolytic copper was once traded principally in "wire bar," which was ready for the wire-drawing process. It is now supplied as "refined cathodes," which are continuous-cast at the beginning of wire drawing. The price is often quoted for 100 lb cathodes. The current price of copper is about $0.77 per pound.

Early copper smelting in the United States was established in the vicinity of New York, and the copper was used in the brass works in the Housatonic Valley of Connecticut. Electrolytic reduction favored locations on the coal fields of western Pennsylvania where power could be produced cheaply, and even later in the far west where hydroelectric power was used. This expanded greatly with the creation of government-subsidized electricity from large hydroelectric projects, since there was otherwise no need for the electricity produced, and it was all but given away to create a little benefit to the cost-benefit ratio. Free enterprise thrives with government's aid to channel the public's wealth into private pockets, then as now.

Silver

Silver is the same as Dutch zilver, German Silber, and the Anglo-Saxon seolfor, except for the orthography. The sound is the same, except for the well-known s/z and b/v alternatives. The Greek argyros and Latin argentum are clearly cognate, and Latin would even have used argyrum, with its normal transliteration of a Greek word. These give argento in Italian, and argent in French. Spanish is different, using plata instead. In Welsh, silver is arian, a Celtic word probably also related to argyros. In Russian, we have cerebro, with still another root. This suggests that silver was earlier than copper in daily life, and had a name in Indo-European. The alchemical symbol for silver is the sign of the Moon, a white crescent.

Silver is a white metal, like tin and cadmium, which resemble it, but are softer and lighter. When polished and untarnished, it has excellent, uniform reflectivity and so was preferred for mirrors. The white color is different from this perfect reflectivity, and is seen on matte surfaces. It was by far the earliest and most used coinage metal, and its name in many languages also is the simple word for money of any kind: j'ai de l'argent--I have money. In America, plata is money, though in Spain it is dinero, from the Arabic dinars that were once familiar there.

Silver has atomic number 47, atomic weight 107.880, and density 10.5 g/cc. Its naturally-occurring isotopes have mass numbers 107 (52%) and 109 (48%). The electron configuration has one 5s electron outside a filled 4d shell in the ground state, just like copper. However, the energies of the 4d and 5s orbitals are about equal, so a 4d95s2 configuration is as favored as a 4d105s. Silver exhibits valence +1 in most of its compounds, and forms complex ions. Silver metal has a face-centered cubic structure, with a = 0.408 nm. Each ion has donated one electron to the Fermi sphere. The work function of silver is about 3.7 eV (tabulated values range from 3.0 to 4.75). The Fermi energy is 5.5 eV. The electrical resistivity of silver is 1.62 μΩ-cm and the temperature coefficient is 0.0038 per °C. The thermal conductivity is 0.974 cal/cm-s-K, and the linear coefficient of expansion is 18.6 x 10-6 per °C. The electrical and thermal conductivities are slightly greater than those of copper, and the largest of any metal's. The specific heat is 0.0558 cal/g-K. The melting point of silver is 961°C, boiling point 1955°C, and the heat of fusion is 24.3 cal/g. Its hardness is 2.7 on the Mohs scale. The tensile strength of cast silver is about 40 ksi, of hard-drawn, 51 ksi. The Young's modulus is 10.3 x 106 psi.

Silver has a relatively simple chemistry. It dissolves in concentrated nitric acid to form colorless silver nitrate, AgNO3, called lunar caustic. This is a powerful antiseptic. Adding sodium hydroxide to a solution of silver nitrate precipitates brown Ag2O, which is only slightly soluble. Adding silver oxide to halogen acids makes the silver halides, such as AgCl, which, like most silver compounds, are insoluble. Silver chloride is white, and the bromide is pale yellow. On exposure to light, they gradually turn black by the photochemical reduction of the silver to metal. Silver forms soluble ammonia Ag(NH3)2+, thiosulphate Ag(S2O3)2--- and cyanide Ag(CN)2- complex ions. The thiosulphate ion is used to dissolve undeveloped AgBr and "fix" a photographic image. The cyanide ion is used in silver plating and in the cyanidation process for the recovery of silver. Silver fulminate, Ag2(CNO)2, is a powerful explosive. It has been formed in small amounts when mirrors are chemically silvered.

The salt KAg(CN)2, potassium argenticyanide, is soluble, and is made the electrolyte in a silver plating bath. The object to be plated forms the cathode (the negative electrode) and the anode can be silver or an inert substance. For every electron entering the cathode from the external circuit, one atom of silver is reduced. The concentration of uncomplexed silver ions is very small in the argenticyanide solution, which aids the deposition of a dense and uniform coat of silver. Many precautions must be observed to get a good result, among them thorough cleaning of the surface to be plated, and plating on a suitable metal, such as copper or nickel. Silver is plated at a current density of 5-15 A/sqft, which requires 1-2V. Each Faraday of charge, 96 480 C, deposits 108 grams of silver.

Silver is used for tableware, a practice that used to be much more common than it is now. The best silverware is made from Sterling, 0.925 fine silver, and has an excellent appearance, though it was expensive. To bring silver within the reach of more of the public, Sheffield Plate was introduced in 1743. Silver was melted onto brass or copper ingots, and the ingots were then rolled, giving a thin cladding of silver on the base metal, greatly reducing the cost of items made from it, which were as beautiful as solid Sterling. This was the earliest industrial use of cladding, which has become a very useful process. In Alclad, the pure aluminium cladding gives corrosion resistance to the underlying Duralumin allow. A later method of making inexpensive silverware was also introduced in Sheffield, the EPNS or electro-plated nickel silver process that uses electroplating.