Automotive electronic systems are highlighted.

Electronic systems that are applicable to all automotive electronic

systems, such as structure (architecture) and the principles of

quantitative performance analysis . This now science of electronics divided Two major categories of electronic systems—analog or continuous time and digital or discrete time . The relatively low cost of digital electronics coupled with the high

performance achievable relative to analog electronics has led modern

automotive electronic system designers to choose digital rather than

analog realizations for new systems to be electronic automotive instrumentation and control systems .

Semiconductor devices are made from silicon or germanium purposely contaminated with impurities that change the conductivity of the material. Transistors are semiconductor devices that are used as active devices in electronic circuits. In some automotive applications, the extreme temperatures may significantly affect transistor operation. For such applications, the circuit may include components that automatically compensate for changes in transistor operation.

microcomputers and how they are used in instrumentation and control systems ; microcomputer fundamentals, microcomputer equipment, microcomputer inputs and outputs, computerized instrumentation, and computerized control systems . microcomputer for Automotive applications include linearization of sensor data, multiplication, and calibration conversion.

electronic control of the automotive engine. It also explains that an automotive engine control has both open- and closed-loop operating modes. A closed-loop control system requires measurements of certain output variables that tell the controller the state of the system being controlled, whereas an open-loop system does not. the various electronic engine control functions separately and explains how each function is implemented by a separate control system. Some of the important engine variables discussed here are mass air flow, fuel flow rate, spark timing, power, and intake manifold pressure.

The configuration and control for an automotive engine control system are determined in part by the set of sensors that is available to measure the variables. the operation of the sensors and actuators used throughout a modern car. Special emphasis is placed on sensors and actuators used for power train (i.e., engine and transmission) applications since these systems normally employ the largest number of such devices.

sensors found in other subsystems on modern cars. Automotive electronics have many examples of electronic control in virtually every subsystem. Modern automotive electronic control systems use microcontrollers based on microprocessors to implement almost all control functions. Each of these subsystems requires one or more sensors and actuators in order to operate. Fundamentally, an electronic control system uses measurements of the plant variable being regulated for feedback control. Temperature is an important parameter throughout the automotive system. In operation of an electronic fuel control system, it is vital to know the temperature of the coolant, the temperature of the inlet air, and the temperature of the exhaust gas oxygen sensor.

control systems such as digital engine control systems. It describes representative control systems that are not necessarily based on the system of any given manufacturer, thereby giving the reader an understanding of the configuration and operating principles of a generic representative system. The microcontroller under program control is possible for generating the electrical signals that operate the fuel injectors and trigger the ignition pulses.

secondary functions of the digital engine control systems. The digital engine control system has been made possible by a rapid evolution of technology, and innovations such as integrated engine control system, oxygen sensor improvements, fuel injection timing, automatic transmission control, torque converter lock-up control, traction control, and hybrid vehicle power train control and then hybrid vehicle control systems in which propulsive power comes from an IC engine or an electric engine, or a combination of both.

motion control mechanics, beginning with control of motion along the longitudinal axis in the form of a cruise control system. The primary purpose of the semi-active suspension system is to provide a good ride for as much of the time as possible without sacrificing handling. Vehicle motion refers to its translation along and rotation about all three axes (i.e., longitudinal, lateral, and vertical). Rotations of a vehicle around these three axes correspond to angular momentum of the car body in roll, yaw, and pitch. Roll refers to angular displacement about the longitudinal axis; yaw refers to angular displacement about the vertical axis; and pitch refers to angular momentum about the lateral axis. In a traditional cruise control system, the tractive force due to the powertrain is balanced against the total drag forces to maintain a constant speed. Electronic controls have recently been developed with the capability to regulate the motion along and about all three axes. In an advanced cruise control system, brakes are also automatically applied as required to maintain speed when going down a hill of sufficiently steep grade.

Automotive instrument and telematics : electronic instrumentation and telematics. It presents an overview of typical automotive electronic instrumentation. In addition to providing measurements for display, modern automative instrumentation performs limited diagnosis of problems with various subsystems. Communication within the vehicle takes the form of digital data links between various electronic subsystems. Communication to and from the vehicle spans all communication from voice and digital data via cell or satellite phone systems to digital data sent from land or satellite. The chapter presents an overview of typical automotive electronic instrumentation. Low-cost solid-state electronics, including microprocessors, display devices, and sensors, have brought about major changes in the automotive instrumentation. The inputs to a instrumentation computer include sensors for measuring various vehicle variables as well as diagnostic inputs from the other critical electronic subsystems. Automobile Internet connectivity opens a limitless range of services for the driver, from on-line navigation help to on-line diagnostic and/or road service for mechanical problems. One of the major issues in telematics is how to present information and services to the driver without distracting him or her from the driving tasks. In certain automobile models, the instrumentation computer can perform the important function of diagnosis of the electronic engine control system.

The trend in automotive maintenance is for the automobile manufacturer to distribute all required documentation including parts list as well as repair procedures in electronic format via a dedicated communication link or via CD supplied to the mechanic. The development of electronic engine control has increased the complexity of diagnosis and maintenance. One important application for digital communication in automobiles is the serial data link from the power train controller to an off-board diagnostic workstation. The diagnostic charts that outline repair procedures are explained, as are on-board diagnostic systems. The best diagnostic methods use special purpose computers that are themselves microprocessor-based. There are two nonmicroprocessor diagnostic instruments that are still used in garages and repair shops: the timing light and the engine analyzer. The former is used to measure and set ignition timing and the latter is used for several tuneup tasks. A higher level of diagnosis than the on-board diagnosis is done with an external computer-based system that is available in a service shop.

the future of the automotive electronic systems. Future applications of telematics are described. One of the interesting potential future developments in the application of electronics to automobiles is navigation. The fundamental control strategy for fuel metering has not changed, although the technological changes have improved the performance and reliability of the electronically controlled engine.

the technical improvements : include knock control, linear solenoid idle speed control, sequential fuel injection, distributorless ignition, self-diagnosis for fail-safe operation, back-up microprocessor (MPU), and hybrid vehicles. New mechanisms and electromechanical actuators have been developed to improve volumetric efficiency via induction systems, variable valve timing, variable nozzle turbochargers, and throttle actuators.

------------------------------------------------------------------------------------------------------------------------

Operational and maintenance control in the development of the car first :

![]()

Operational control and maintenance in the development of the car used to be divided into 3 parts:

1. Mechanical engine system

2. propulsion energy system

3. drive control system

all three functions manually program settings .

Engine mechanical system consists of:

1. tires and hand tools

2. Machines

3. Lubrication system

4. Cooling system

5. Combustion system

Propulsion energy system:

1. Carburetor

2. Ignition system

3. Car electrical and electronic installation

4. Steering system

5. Battery and generator

6. dynamo starter

Drive control system:

1. clutch and acceleration

2. As axle

3.car frame and springs

4. Bolts and nuts

5. brake

All 16 systems are open loop controlled manually, and will be replaced by electronic components analog , digital , SM Technology with closed loops using a microcomputer as I explained above so that they can be modified with machine learning drive maintenance and artificial intelligence.

Closed Loop Control

---------------------------------------------------------------------------------------------------------------------------

Hardware meets software: from classic mechanical systems to a fully interlinked high-end control unit

POWERTRAIN

Today, thanks to smart interlinking by the Electronic Chassis Platform (ECP), innovative chassis systems such as electromechanical Active Roll Stabilization (eAWS), the predictive active suspension and Dynamic All-wheel Steering (DAS) are able to unfold their full potential.

In the Audi e-tron, the integrated Brake Control System (iBRS) emphasizes the fact that efficiency will become the third variable in chassis development alongside ride comfort and sportiness. As a high-tech control unit, the future vehicle dynamics computer can simultaneously actuate up to 90 components.

On the road toward an integrated vehicle dynamics brain

Audi consistently drives the idea of integrating chassis and powertrain technology. In the future, an integrated vehicle dynamics processor will handle longitudinal and lateral dynamics control as well as energy and powertrain management: recuperating energy during a braking event, determining the damper compression rate within milliseconds and keeping the vehicle precisely on track – all practically at the same time. The development objective for future chassis generations is clear: besides an even greater spread between sportiness and comfort, the integration of efficiency technologies will play a central role.

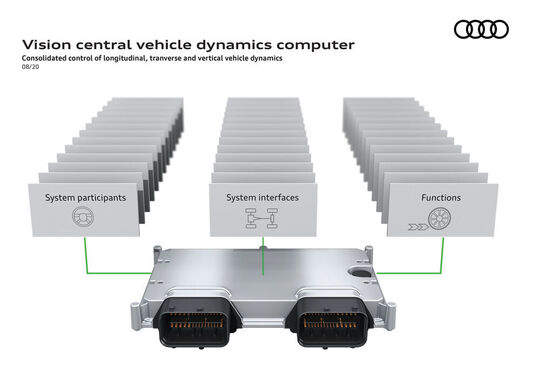

The future vehicle dynamics processor will be centrally controlling nearly all functions in longitudinal, lateral and vertical dynamics: chassis, powertrain and recuperation functions, and be clearly more powerful than today’s ECP, for instance. It will operate about ten times as fast as current systems and be able to control up to 90 system participants – compared to about 20 in the case of the current ECP. New as well will be its modular usability for diverse types of powertrains, in other words, ICE-powered, hybrid or electric vehicles, as well as front, all-wheel or rear-wheel drive systems for electric models. As a result, the central vehicle dynamics computer, in addition to car-to-x functions, will enable function-on-demand features as well. Its precise data computation will also execute the requirements of advanced driver assistance functions.

Chassis technology development at Audi emphasizes intensified interlinking of individual mechatronic chassis components and vehicle functions using smart electronic control. The Electronic Chassis Platform (ECP) made its debut in the Audi Q7 in 2015. Today, it interlinks the individual component assemblies of the chassis systems in Audi’s mid-size, full-size and luxury models. Due to this smart ECP interlinking of chassis technologies that have undergone continuous further development such as permanent quattro all-wheel drive, the adaptive air suspension and Dynamic All-wheel Steering, Audi has forged a successful link between superior ride comfort and high-level driving dynamics.

Interlinking as an enabler – previously unknown flexibility, from comfortable to sporty

A perfect example that illustrates the enormous effort Audi invests in the technical design of the chassis is the electric roll stabilization used in the Audi SQ7 and SQ8. Due to smart interlinking, the system can unfold its full potential. Body roll of the full-size SUV during cornering and load changes is reduced to a minimum. In addition, it provides the Audi full-size SUVs with amazingly high lateral dynamics capabilities resulting in an impressive driving experience for the driver.

In fast cornering situations, due to the electronic adjustment of the stabilizer bar, body roll is reduced because the stabilizer, within milliseconds, smoothly lifts the vehicle side that is on the outside of a corner against the centrifugal forces with a moment of up to 1,200 Newton meters. This makes higher cornering speeds possible and clearly reduces load change reactions as well. During straight-line driving, for instance on uneven road surfaces, a planetary gear system disconnects the two halves of the stabilizer, which enhances ride comfort. As a central control unit, the Electronic Chassis Platform also matches information from other chassis technologies in the SQ7 and SQ8, such as the all-wheel steering system, the air suspension and the quattro sport differential. The driver experiences this close collaboration of the Audi chassis systems in the form of high handling precision and agility.

Another chassis highlight with a decidedly comfort-enhancing function is used in the Audi A8. Here the active suspension operates: a fully active, electromechanically operated suspension system. Per wheel, it has one electric motor that is supplied by the 48-volt primary electrical system. The control signals for the active suspension are sent by the Electronic Chassis Platform every five milliseconds. A belt drive and compact strain wave gearing convert the torque of the electric motor to 1,100 Nm and transfer it to a steel torque tube. From the end of the torsion bar, the force reaches the chassis via a lever and a coupling rod. At the front axle, it acts on the air spring strut of the adaptive air suspension and on the rear axle, on the transverse control arm (wishbone).

In this way, every wheel of the Audi A8 can be separately subjected to or relieved of additional loads and adapted to the respective roadway. As a result, it actively controls the position of the body in any driving situation. Due to the flexibility of the active suspension, driving characteristics are expanded to an all-new range. When the driver selects dynamic mode in the Audi drive select system, the car becomes sportier: it firmly turns into corners, the roll angles are only about half as big compared to the normal suspension, and the body hardly dips during braking events. In comfort mode, however, it smoothly floats across surface irregularities of any kind. In order to calm the bodywork, the active suspension constantly – adapted to the respective driving situation – supplies energy to or removes energy from the body. Thus, drivers and passengers are practically “disconnected” from mechanical powertrain and driving effects.

Braking is a winner – the integrated Brake Control System in the Audi e-tron

The integrated Brake Control System (iBRS) of the Audi e-tron models illustrates the increasing intertwinement of chassis and powertrain technology. As a result, efficiency becomes the third objective of chassis development alongside comfort and sportiness.

The recuperation system, for instance, contributes up to 30 percent to the range of the electric SUV. The iBRS includes the two electric motors as well as the hydraulically integrated braking system in this process and is the first to combine three different types of recuperation: manual overrun recuperation using paddle shifters, automatic overrun recuperation using the predictive efficiency assistant and brake recuperation with a smooth transition between electric and hydraulic deceleration. The Audi e-tron recuperates up to 0.3 g exclusively via the electric motors without using the conventional brake – this is the case in more than 90 percent of all deceleration events. As a result, practically all normal braking maneuvers are energetically fed back into the battery.

Drivers can select the level of overrun recuperation in the Audi e-tron in three stages using the paddle shifters. On the lowest level, the car coasts without additional drag torque when the driver’s foot is lifted off the accelerator pedal. On the highest level, the electric SUV noticeably reduces speed – the driver can decelerate and accelerate strictly via the accelerator pedal, resulting in the so-called one-pedal feel. The brake pedal does not have to be used in this case of deceleration. The wheel brakes only come into play below the threshold of 10 km/h, when the brake pedal actuation exceeds 0.3 g or when the battery is fully charged and thus no brake recuperation is possible.

Due to a new electrohydraulic actuation concept, which Audi uses in an electrically propelled production automobile as the first manufacturer to do so worldwide, the driver can no longer perceive the transition from electrical brake recuperation via the electric traction motors to the mechanical braking effect via the hydraulically operated conventional friction brake. This “brake blending” results in an effectively variable pedal feel with a clearly defined, constant pressure point, just like in a vehicle with a conventional internal combustion engine and hydraulic wheel brakes. The brake pedal is not connected to the hydraulic system, the transition from the motor brake through the electric motors to the conventional brake is smooth and can no longer be felt by the driver’s foot.

This is enabled by a complex electrohydraulic system: a hydraulic piston in the compact brake module generates additional pressure and braking force that complements the recuperation torque. In an automated emergency braking event, only 150 milliseconds elapse between the time deceleration is initiated and the maximum brake pressure is applied between the linings and discs. Depending on the driving situation, the electrohydraulically integrated Brake Control System decides whether the Audi e-tron will decelerate by means of the electric motors, the wheel brake or a combination of both – electrically and individually on each axle. With this system the electric SUV makes specific use of its maximum recuperation potential.

Interlinking is emphasized in the integrated Brake Control System as well, with the iBRS being supported by the efficiency assistant that is provided as standard equipment. The system recognizes the traffic environment and route using radar sensors, camera images, navigation data and car-to-x information. As soon as it would make sense for the driver to lift his foot from the right pedal, respective information will be provided in the Audi virtual cockpit. In interaction with optional adaptive cruise assist, the efficiency assistant can also predictively decelerate and accelerate the electric SUV.

---------------------------------------------------------------------------------------------------------------------------

Advances in Automotive Instrumentation

Automotive instrumentation had been limited primarily to functional driver gages. For the most part, this consisted of things like the fuel gauge, battery gauge, oil pressure gauge, speedometer, and coolant gauge. Some simple gauges were later replaced with warning lights to create a cleaner dashboard appearance. Eventually, instrumentation received its most dramatic change by becoming an electronic information center of the vehicle.

Today’s automotive instrumentation is dramatically different from the early days. Vehicles are now manufactured to provide information and diagnostics, such as low tire pressure, check engine, door ajar, fuel pump pressure, outside ambient temperature, brake fluid level, and more. The biggest changes to instrumentation are solid-state sensors, microprocessors, and solid-state display devices. These sensors are designed to convert a non-electrical signal to an equivalent current or voltage.

In modern vehicles, measurements from various switches and sensors are delivered to a digital computer. Although instrumentation ensures a safer and more comfortable ride, one of the primary purposes is to diagnose a problem before it gets out of hand. As an example, the control system for the power train runs continual diagnostics. If it recognizes an issue, a fault code that indicates the type and location of the issue is set.

Today, the styling and design of the driver cockpit and instrumentation has also become a key differentiator between vehicles. Car companies utilize 3d prototyping, cnc prototyping, and other engineering services to develop working functional cosmetic mockups of these instrument cockpits in order to verify that it meets the designers and the customer needs prior to going to production.

Critical Manufacturing

The

automotive industry depends on state-of-the-art vehicles manufactured

using high-quality parts and components. As the instrumentation systems

continue to grow more and more complex, manufacturing requirements

continue to grow as well. Whether for race cars, show cars, work trucks,

or vehicles that people drive on a daily basis, the parts and components

must meet exact specifications. One small defect could have a huge

impact on the overall product.

In addition to quality materials, you

want an engineering team that has experience and expertise in designing

parts and components for automotive instrumentation. Production is also

critical, whether this involves plastics or metals. We are seeing that

precision automotive aluminum castings are now increasingly being used

in advanced instrumentation in addition to precisely molded plastic

parts and electronics.

---------------------------------------------------------------------------------------------------------------------------

Automotive Devices

Automobiles have been making tremendous progress in terms of safety, environmental performance, and the utilization of information technology. Now, a suite of driver-assist technologies that enhance both vehicle and driver safety are attracting much attention, such as collision avoidance, parking assist and self-driving.

Automotive devices offers various automotive semiconductor devices, including the image recognition processors, and which are designed to improve driving safety. Toshiba provides leading-edge semiconductor technologies from a future perspective to deliver comprehensive driver assistance solutions that emulate human eyes and other intricate human senses.

Digital Devices

To built-in our latest digital processing technologies in a single chip, we can realize e.g. a more simple/ efficiency motor control processing in a power train system, an image synthesis /processing from multi camera inputs or an interface format converter to be suitable for an LCD panel, and a gap filler of an information transactions between legacy peripheral devices and the latest SoC /network interface.

Analog Devices

![]()

A 0.13-μm BiCD process that can integrate analog circuitry with large logic and power (DMOS) devices on the same chip.The BiCD process helps reduce the size and power consumption of automotive systems. With the ever-increasing computerization of electric vehicles (EVs) and hybrid electric vehicles (HEVs), demand for electronic devices for motor and other applications is increasing.In addition to the 0.13-μm BiCD process, Toshiba offers analog devices with a wide range of current and voltage ratings as well as circuit technologies that are optimized for various applications.

Wireless Devices

RF ICs for automotive communication applications provide a wireless communication capability to operate automotive devices and monitor operating conditions. Their applications include remote keyless entry (RKE) systems that remotely lock and unlock car doors and tire pressure monitoring systems (TPMS) that monitor the air pressure of vehicle tires and show warnings for low and high pressure on the instrument cluster.

![]()

------------------------------------------------------------------------------------------------------------------------

Expanding Automotive Electronic Systems In-vehicle Networks Controller Area Network

Electronic system and control monitoring :

Motor vehicles are equipped with an increasing number of functions, making automotive electronics more complex. modern solutions for safe and smart energy and data management within the vehicle electrical system. Increasing vehicle functionality means that more and more electric and electronic ancillaries are fitted. More power is required, and there is more load on the battery. Therefore, energy management and reliable state-of-charge monitoring are becoming even more important. powerful power management systems that make sure the vehicle is supplied with ample power and starts easily at all times.

Central Gateway ( CGW ) Body Electronics

Perfectly keyless for passengers car body electronics

smartphone and vehicle work in conjunction to perform the locking and unlocking

process reliably and with precision .

Body computer module

DC / DC Converter for start / stop system

Electronic mobilizer body electronics

Electronics battery sensor

Comfort Actuator body electronics

Infotainment and cockpit solutions body electronics

--------------------------------------------------------------------------------------------------------------------------

Designing Resilient Electronics

Eliminating downtime in safety- and mission-critical applications.

Electronic systems in automobiles, airplanes and other industrial applications are becoming increasingly sophisticated and complex, required to perform an expanding list of functions while also becoming smaller and lighter. As a result, pressure is growing to design extremely high-performance chips with lower energy consumption and less sensitivity to harsh environmental conditions.

If this sounds difficult, it gets even harder from here. In the past, many of these systems relied on chips developed at older process nodes or, in the case of cars and airplanes, mechanical systems. But as more data is generated and processed under a wider range of operating conditions, particularly for mission-critical and safety-critical applications, the entire semiconductor ecosystem is being driven to develop IC designs that are more resilient to everything from extreme heat and cold to longer life cycles and higher utilization rates within those lifetimes . “Semiconductors for automotive electronics must meet even stricter requirements including extended temperature range, device robustness and safety . From an IP design perspective, reliability is built in from the start using device models for extended temperature and aging. If needed, in applications like automotive, potential points of failure are identified and remediated with circuits that are fault tolerant, and in some cases redundant functions .

The idea of resiliency has been around for some time, particularly in

error-correcting memory. But developing chips that can gracefully fail

over to other chips requires an entire ecosystem, from the semiconductor

foundry (qualified process nodes), device packaging, underlying

semiconductor IP to the certification bodies that ensure compliance. System complexities are increasing across all verticals including industrial automation, automotive and aviation,

many of the required elements have been ‘single function’ which means they consume more physical space and weight, as well as consume more power. To help manage physical space, weight, and power consumption, we are beginning to see a trend where these functions are consolidated.”

For example, in the automotive segment ECU’s are being consolidated into domain controllers. Avionics is making the transition from single core to multicore SoCs. And manufacturing is combining multiple automation functions such as programmable logic controllers, human-machine interfaces and safety functions into a single box.

“This naturally drives a need for increased compute coupled with high safety integrity levels, while resulting in smaller footprint developments and requiring lower comparative power consumption and thermal designsDesigning a lock-step feature in application CPUs is a great example of a solution to this challenge, and Arm is continuing to work closely with the ecosystem to solve these challenges. Harsh environmental conditions add an extra vector to the design, and these can be augmented by additional measures added in at the silicon development stage.”

Traditionally, reliability and risk mitigation meant adding guard banding to assure requirement were maintained. But as an increasing number of these chips move to advanced geometries, this is no longer a viable solution.

The key design techniques used to address these issues is to embed a fabric of in-chip monitors to give visibility into on-chip conditions. “This is an essential step, and it enables optimization of power, performance and/or reliability at bring up of new silicon and later in mission mode. Gone are the days of including a single temperature sensor and assuming everything will be fine. The latest fin FET designs typically include tens of temperature and voltage sensors plus process speed detectors, monitoring conditions at critical circuits across the die. Of course, designers simulate and sign off performance, but with so much circuitry being software-driven, worst-case conditions can be difficult to predict and significantly different in reality to those simulated. Embedding a fabric of in-chip monitors is increasingly seen as standard design practice on advanced semiconductor, especially finFET nodes, and should be considered early in the design flow. It’s an essential step for minimizing guard bands and optimization.

Industrial concerns

Resiliency includes far more than the functioning of a particular gate or IP block, however. A functioning chip is of little value if the data flow is interrupted anywhere in a system. While communication techniques have greatly evolved and improved in

the last few decades, the focus has generally been on transferring

increasing amounts of data over either designated wires, such as

Ethernet or Fiber Optics, or wirelessly such as WiFi or LTE . Moreover, existing systems were not designed with communications needs

in mind. There is often no dedicated high-performance wiring available.

wireless communications implementations that are defined by their

sensitivity, power line is more prone to sources of tonal noise, such as

switching power supplies connected to the medium, as well as impulse

noise introduced by turning on and off industrial equipment .

Resiliency in automotive

so much focus on the electrification within the automotive ecosystem, there is a tremendous amount of attention being paid to resilience with vehicles, and the design infrastructure of automotive systems. Safety, reliability and quality are the primary goals of resilience here.

“Resilience applies to the capability of the system to continue operations in the space of some sort of disruption, and that’s a little different from the automotive goal of safe operation.This means full system resilience is full operational maintenance after some sort of a system disruption. That’s a separate goal from continued safe operation. Within the context of the automotive IP segment, there is a difference between that full system resilience and safe operation.” For example, in automotive, it’s known that if there is a failure, there are multiple responses to that failure, which could be full continued operation, partial operation, or some sort of a safe state.

Safety for automotive is more like minimizing risks due to hazards if there is some sort of malfunction. The official definition is the absence of unreasonable risk due to hazards, so that’s what we want to manage in safety — how the car or the system responds to hazards, and whether or not they cause unreasonable risk, And then the response to that could be continued operation, like a fully resilient system. It could be controlling that system to go into a safe state, and that’s a little different from full system resilience. Going into a safe state could be like an autonomous vehicle pulling over to the side of the road and turning itself off. That’s responding to the hazard by going into a safe state, and that’s a little different from system resilience, and full continued operation in case of that. So there’s a difference between resilience and managing safety. Our customers are 100% focused on the products that are developed for automotive, especially in the safety-critical systems. Some systems in the car are not safety-critical, but for those that are compliant to the functional safety.

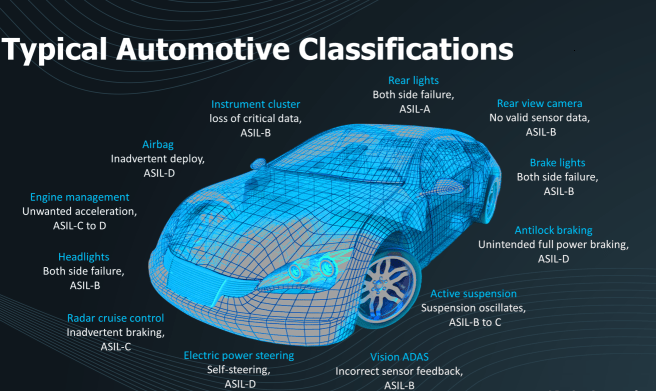

For automotive, it’s a two-step process, One is the early step to set the safety goal, identify if the system is safety-critical and the amount of criticality. There’s an early safety review. That’s the required ASIL level. ASIL has two functions — to set the goal of the safety, and to measure how well you have accomplished that goal. In the early stage, it’s defining the goals, and then defining the safety requirements of that system, and then executing to the safety requirements, such as designing safety mechanisms. So the first step is not so much execution of the plan, but setting a safety plan, setting the safety goals, setting those safety requirements. That series of steps are more a systematic approach.”

Additionally, safety and resiliency have two aspects. One is the systematic aspect, the development flow that is followed, First you have to define a safety development flow. Then, you have to have a system in place to ensure that the design teams follow those safety flows. Those are typically a quality management system. It is a requirement to have these flows, and it’s a systematic requirement. Connected to this, there should be some sort of monitoring to make sure the flows are followed, typically covered by a quality management system.

After that comes the execution of the safety plan, which is the actual design of those safety mechanisms that were set in the goals and requirements earlier on in those planning stages. Part of the execution should examine the safety level. If it’s a mid-level ASIL, it’s a matter of how much risk is in the system that could cause harm. This is the other aspect of safety, namely whether there is a risk that could cause harm to the public, the driver, or anyone associated with that system.

Automotive car concept body electronic

These complex systems already are installed in semi-autonomous vehicles,

as well as early-stage fully autonomous vehicles. But designing and

verifying these immensely complex systems is possibly even more complex

than the systems themselves because they need to include what the

systems are supposed to do, while accounting for electromigration, electrostatic discharge, thermal reliability, statistical EM budgeting, electrical overstress, aging — and functional safety.

The solution of body electronic in automotive car :

With the transformation of automotive electronics systems from a

chip, package and circuit board perspective, along with the increasing

sophistication of avionics, industrial automation, networking

applications — resilient design is only becoming more challenging. The

path forward must include an understanding of the design challenges,

plans and systems for implementing resiliency, and novel chip-level

approaches. Add to that list new ways to leverage IP for safety and

security and implementing the right tools to cover all scenarios.

How this looks even five years in the future remains to be seen. As systems evolve, so do the requirements for how to keep a system from breaking down and causing other problems. Even the concept of resiliency may change across various applications as those systems evolve and become increasingly autonomous. But it’s clear that all of this will become much more challenging for the entire supply chain, and the tasks that need to be solved will become significantly harder.

--------------------------------------------------------------------------------------------------------------------------

Electronics of the present

The decade of the 2010s brought new capabilities to vehicles like early driver assistance features, such as traffic alerts and lane departure warnings, along with WiFi- and cellular-based LTE data hotspots.

Increasingly sophisticated navigation services now delivered traffic warnings, route planning, and Yelp-linked local business reviews and recommendations. Aftermarket dash cams became extremely common (especially in places like Russia) to protect drivers in cases of legal liability.

Some of the biggest introductions of the decade were systems like Google's Android Auto, Apple's CarPlay, and Nokia's MirrorLink. These allow a car's dashboard/head unit screen to function as a display and controller for Android, iOS, or Symbian devices and their apps.

Apps for internet radio that drivers and passengers could access via their cellphones soon began to compete with satellite radio. Apps for streaming subscription music services such as Spotify gave riders additional choices for sounds on the road.

Televisions made their way into cars as early as 1965, but only recently have viewing screens often multiplexed and connected to smartphones—become a common sight in vehicles. The latest ones even link to the car's GPS navigation to give passengers "are we there yet?" updates.

Heads-up displays, which project or overlay information onto the interior of a car's windshield, began to be much more common in autos after first appearing in the 1990s. Today, they're able to display augmented-reality (AR) pictures and text that help drivers to navigate.

Under the hood, today's ECUs incorporate microprocessors and can control electronic brakes, transmission, valve timing, and anti-theft systems, among other functions. Some ECUs are reprogrammable via computers to allow for engine monitoring, supercharging, turbocharging, fuel-injection upgrades, exhaust system modifications, gear shift remapping, and more.

And finally, it's now clear that we're on a path to completely autonomous self-driving vehicles. Advanced Driver-Assistance Systems (ADAS) features like automated lighting, lane-departure warning, pedestrian crash avoidance mitigation (PCAM), automatic lane centering, blind-spot detection, collision avoidance, and connection to smartphones for navigation directions have started to make their way into many vehicles.

Companies like Apple, Tesla, and Waymo (the latter owned by Google parent Alphabet) have tested Society of Automotive Engineers (SAE) "sleeping driver" Car Autonomy Level 4 features, like the ability to intelligently steer, cruise, and change lanes.

These same companies are working feverishly on SAE "steering-wheel-optional" Autonomy Level 5 fully driverless functionality for their upcoming vehicles.

Some firms such as Waymo and Aptiv are already operating smartphone-ordered SAE Autonomy Level 5 "robo-taxi" services in places like Las Vegas, Nevada, and Phoenix, Arizona (where some of Waymo's vehicles are completely driverless).

---------------------------------------------------------------------------------------------------------------------------

Electronics of the future

it seems clear the future of cars is about autonomous driving, sharing, electric power, and links to external networks (so-called "vehicle-to-everything," or V2X, connections). Automotive electronics will be leveraged for all four of these.

Laser-based light detection and ranging, or LiDAR, may finally solve the navigation problems of autonomous self-driving once and for all if costs can come down low enough for production vehicles.

While electric cars rely on batteries for their power, ECUs of the future will manage battery usage, charge monitoring, and scheduling of recharging times for powering up.

ECUs will also likely more fully control valves in engines to reduce weight, bulk, and friction in motors via the elimination of lifters, cams, rockers, and timing sets.

More and more, passengers in autonomous and shared vehicles will make use of infotainment (information plus entertainment) systems that will be customizable to the preferences and playlists of each individual. Glass surfaces that are currently transparent may transform into screens for media entertainment, games, or information services that feature AR enhancement of outdoor surroundings.

It's known that BMW and Fiat Chrysler will be partnering with Amazon on Fire TV entertainment systems for cars. Meanwhile, Tesla has struck a deal with Netflix to stream content to its vehicles to be played back for passengers while a car is either driving or stationary.

All in all,

the future of car electronics looks rich and bright, and there will

surely be many innovations that will benefit both passengers and drivers

in the coming decades as cars become smarter, safer, shared, and more

efficient.

--------------------------------------------------------------------------------------------------------

Vehicle Telematics

Telematics technology is being increasingly used in the automotive segment for vehicle tracking and monitoring, infotainment, and much more. Between 80 and 85 percent of telematics solutions and devices that includes infotainment, solutions, and aftermarket solutions cater to the automotive industry.

What is vehicle telematics?

The word "telematics" is a broad term, derived from the French word télématique, which itself is a portmanteau of the French words for telecommunications and informatics, or computing science. These days, when you hear the word telematics as it relates to commercial applications, it's implied that it refers to vehicles. Telematics at present includes (but is not limited to):

- Technology to send, receive and store information

- Technology that communicates with and controls remote objects

- Satellite navigation systems integrated with computers and/or mobile devices

- Telecommunications and informatics systems capable of controlling vehicles in motion

Current examples of telematics systems in cars are:

- Diagnostic electronics

- Intelligent electric vehicle (EV) charging controllers and power consumption monitors

- Global Navigation Satellite Systems (GNSS) receivers

- Vehicle/trailer/container tracking hardware and software

- Car safety/warning systems, including eCall (short for Emergency Call) and Automatic Collision Notification (ACN) subsystems

- Automated driving assistants

- Onboard concierge services

- Internet data connections

- Integrated cellular phones

- Satellite radio

Today, most telematics information is carried over 2G, 3G and 4G LTE cellular connections to vehicles and over WiFi (specifically, 802.11p), Bluetooth and Ultra-wideband (UWB) wireless networks supporting WAVE (Wireless Access for Vehicular Environments) within and between vehicles and roadside infrastructure. WAVE is designed to interface with and enhance civil Intelligent Transportation Systems (ITS), equipment that will manage traffic and transport networks.

Main advantages of telematics data

One of the main advantages of telematics data is that it's usually "always-on" and can be provided or accessed in near-real-time, delivering immediate and significant value to drivers, fleet owners, private third parties and regulatory authorities. Indeed, telematics is one of the fastest-growing components of the automotive industry as carmakers compete to build more and more smart functionality into their vehicles. Electronics companies owning a significant share of the installed base of Telematic Control Units (TCUs) include LG and Harman International (a subsidiary of Samsung) in South Korea, Bosch and Continental in Germany and Denso in Japan.Much telematics equipment is shielded within crash-resistant/hacker-resistant TCU "black boxes," which sometimes connect to drivers' smartphones. Often, telematics-equipped vehicles feature roof-, exterior- or display-mounted cellular antennas for increased communication signal strength.

Applications of telematics

At present, the most popular uses of telematics are internet connectivity via mobile devices such as smartphones, intelligent driving navigation/concierge services and vehicular diagnostic/breakdown reporting systems. While there is a long list of other applications of telematics, major ones include:

- Intelligent fuel location/allocation

- Local business search/recommendation

- En route news/weather/traffic updates

- In-vehicle entertainment

- Real-time data communications

- Location reporting/sharing and theft response

- Wireless safety and hazard alerts

- Emergency/roadside assistance request systems

- Vehicle performance measurement

- Freight trailer/container tracking

More applied uses of telematics fall within the categories of:

Fleet management

Entire fleets of transport vehicles from trucks to vans to cars to ships can be tracked and diagnosed to optimize maintenance, fuel management, driver downtime, safety and financing. This can lower costs and risks inherent in fleet investment, transportation, efficiency, productivity and regulatory compliance.

Carsharing

Services such as Zipcar, Car2Go, Lyft, Uber, etc. presently employ telematics technology to track Pay-as-You-Drive (PAYD) vehicles, bill users and help new customers find empty cars.

Auto insurance

Car sensors and smartphone apps can provide vehicle operation and driver behavior data to insurance companies so they may more accurately judge risks and price insurance for specific vehicles and individuals. This is known as Usage-Based Insurance (UBI), sometimes also known as PAYD Insurance. Factors taken into account can include driving times, routes, distances, speeds, acceleration, braking and other variables. For some drivers willing to supply their telematics data or integrate insurance company hardware or software into their vehicle and/or mobile device, premiums have been reduced by as much as 30 percent.

Anticipated opportunities and challenges

In the future, telematics will integrate additional technologies such as camera, radar and LiDAR (Light Detection and Ranging) environmental sensors and artificial intelligence to enable assisted and autonomous driving. Advanced driverless maneuvering such as complex turning, collision avoidance and/or multiple-vehicle "platooning" (synchronized movements of grouped vehicles) will become possible and likely very common.

The rollout of dedicated 5G cellular channels for use with telematics will happen by 2026; some telematics TCU makers such as Harman are enabling over-the-air (OTA) activation for 5G-capable 4G TCUs being sold or integrated into vehicles now. 5G will bring with it higher speeds, lower network latency and richer/denser connections to telematics systems, resulting in better responsiveness, greater than 1Gb/s data throughput and more powerful applications.

One challenge for companies wanting to build, share and integrate telematics equipment is concerns about the security and privacy of data that's passed on and/or stored (often in the cloud). Encryption is standard for many telematics equipment makers sending or supplying such data to external receivers as well as for connections between internal Electronic Control Units (ECUs) within vehicles. In the European Union, General Data Protection Regulation (GDPR) laws protect individuals' data from collection and processing that's not deemed strictly necessary. To comply with GDPR laws, companies collecting or using telematics data need to develop and spell out clearly defined data protection policies.

---------------------------------------------------------------------------------------------------------

Antenna technology

Performance tests of automotive antennas are a complex measurement task. Networked vehicle functions, broadband services and higher frequencies push conventional RF measurement technology to its limits.

In the early 1970s, a chrome-plated telescopic antenna mounted prominently on the left front fender of an Opel Rekord C was sufficient. Their only task was to provide the car radio on board with a more or less interference-free reception of one of the local radio stations via VHF between 87.5 and 108.0 MHz. But these times are - almost nostalgia - probably finally passé.

The history of automotive antennas at Hirschmann (now TE Connectivity) began in 1939 when the company presented its first automotive antenna in Berlin. As a result, the supplier of telescopic antennas enjoyed an excellent reputation in the industry, not least due to its Auta 6000 series. Compared to this, antennas of current vehicle generations have to perform significantly better.

The developers are focusing on modules that support more broadband services than VHF and combined transmission/reception units. In addition, much higher frequencies come into play to generate as a large bandwidth as possible for faster transmission of ever-larger amounts of data. In connection with antennas for mobile use and the new mobile radio standard 5G, frequency bands up to 6 GHz are currently relevant. TE Connectivity develops the entire portfolio of antennas for the automotive industry at the Neckartenzlingen site. The Swiss technology group offers several solutions for each service and adapts them individually to the requirements of its customers. The result is an antenna tailored to each vehicle model.

Complex vehicle functions require better antennas

The increasing networking of vehicle functions, off board applications and innovations in infotainment, Internet connectivity and mobile telephony are leading to a drastic increase in the complexity of current architectures. And as one of their key components, they are based on powerful antennas. More precisely, on different types of antennas with very specific functions. These include services such as AM, FM and DAB radio, mobile radio, WLAN and Bluetooth for coupling individual devices on board as well as GNSS (Global Navigation Satellite System) and Car2X communication.

The latter uses radio links for data transfer between vehicles and between vehicles and their transport infrastructure for the safe, efficient and intelligent mobility of tomorrow. New times have long since dawned for the quality assurance of modern automotive antennas. This is because deficits in terms of reliability or reception or transmission quality today have far more serious consequences than simply the interruption of a captivating broadcast.

With the complexity of current automotive antennas, the demands on their mandatory real performance tests are also growing. All modules must function reliably in their real installation situation on the road. Therefore, after comprehensive simulations and stationary laboratory tests, for example in EMC measuring chambers and in radomes, a protected antenna dome, there is no way around final mobile tests on the road. Last year, the supplier's development engineers became aware of a new development from Narda Safety Test Solutions regarding the specific requirements for their mobile applications: the Signal Shark. This is a handheld signal analyzer for real-time.

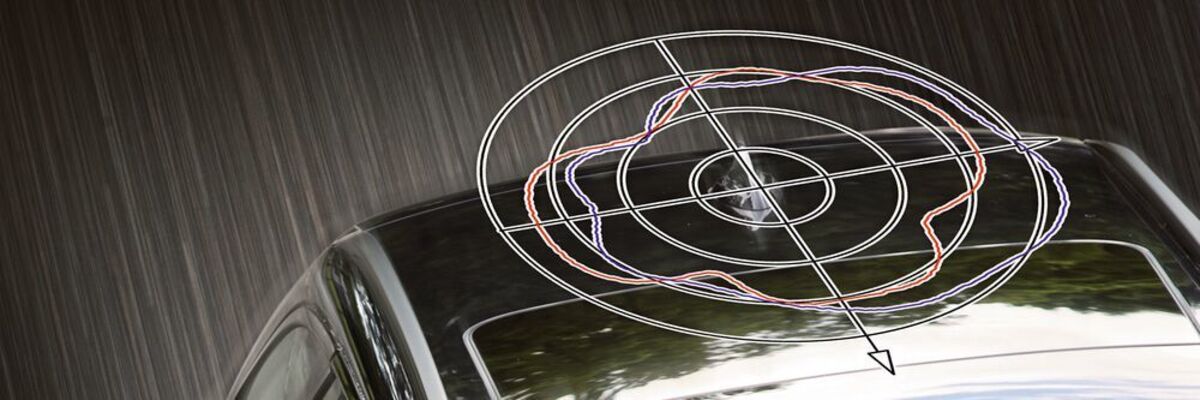

Test description for antenna patterns

![The resulting circle diagram in the documentation of a measurement provides TE engineers with valuable information on how well an antenna receives a signal depending on the direction of irradiation in the real installation situation. It shows the "antenna gain" (G), the instantaneous value of the field strength measured at the antenna output in [dBµV]. The resulting circle diagram in the documentation of a measurement provides TE engineers with valuable information on how well an antenna receives a signal depending on the direction of irradiation in the real installation situation. It shows the "antenna gain" (G), the instantaneous value of the field strength measured at the antenna output in [dBµV].](https://cdn1.vogel.de/unsafe/540x0/smart/images.vogel.de/vogelonline/bdb/1618900/1618943/original.jpg)

In the documentation of a measurement, the resulting circle diagram provides TE engineers with valuable information on how well an antenna receives a signal depending on the direction of irradiation in the real installation situation. It shows the antenna gain (G), the instantaneous value of the field strength measured at the antenna output in [dBµV].

In these mobile performance tests, the so-called antenna pattern (pattern) is measured. The pattern gives the developers valuable information about the antenna gain (G). This indicates how well the antenna of a particular model of the vehicle receives a signal depending on the direction of beam input, or in other words, what power actually arrives from the emitted signal. In practice, a vehicle equipped with a variety of test antennas will be driven on a circuit within a wide, reflection-free area.

At the same time, a transmitter (signal generator) emits a signal with a defined power from a distance of approximately 100 m alternately with vertical and horizontal polarization in the direction of the test vehicle. Parallel to this, an electronic gyro sensor and an additional compass record the angle at which the vehicle is illuminated. This gives the TE engineers a pie chart showing the instantaneous value of the received field strength [in dBµV (decibel microvolts) or dBm (decibel milliwatts)] at the antenna output over the corresponding angle of incidence.

Measurements in the open air on a test site present measurement

technicians with different challenges than in laboratories. The complete

test setup including all connecting elements must be suitable for the

situation in the test vehicle and the adverse conditions of a test

drive. With a view to precise measurement results, it is imperative that

the entire system measures robustly and error-free even when

accelerations, decelerations and centrifugal forces are acting and

everything in the vehicle wobbles and vibrates. And such tests do not

only take place on luxury limousines in dignified surroundings. Tractors

also want to be measured today.

Original and current HF measurement technology

The RF measurement solution used to date meant a large, elaborately wired construction consisting of a measurement receiver rated up to 3 GHz and a separate RF switch, an additional laptop and an external gyro sensor. The safe recording of reliable measurement results with the required reliability was regularly associated with a high technical effort for the TE engineers. When changing vehicles within a test series, for example, all the measuring equipment that had to be transported as a whole had to be dismantled and reassembled each time. The construction had to be professionally wired for the individual measurements on the test site with a lot of time and effort and, if possible, stably accommodated in the test vehicle. Until then, the complex procedure involved in mobile antenna testing was regarded as comparatively complicated and costly in terms of handling and, accordingly, slow and cost-intensive.

Compared to this, the main achievements of the Narda SignalShark, which was used for the first time at TE, were quickly obvious. Literally. As a first consequence, the entire handling of the mobile antenna tests has been significantly streamlined since then. With all the positive consequences. The handheld analyzer, which is equally suitable for mobile and stationary use, has reduced the number of devices and thus the overall cabling effort to a minimum. Its intelligence - apart from the electronic compass - is in the form of a powerful computer integrated in the device. In addition, its four switchable RF inputs eliminate the need for a cumbersome external RF switch. In this way, measurement technicians effectively avoid potential sources of error from the past. Follow-up measurements of further antenna modules of other vehicle models, for example, no longer require the time-consuming and costly replugging of all connecting elements. In addition, significantly fewer connectors are exposed to mechanical loads during operation. The measurements become more robust and less error-prone.

Investigating the interference radiation of a vehicle

With the mobile equipment of the past, frequency ranges beyond 3 GHz were not feasible. Due to the developments and trends in automotive antennas, TE had to expand the frequency range. The SignalShark detects and analyzes, classifies and localizes RF signals between 8 kHz and 8 GHz. It thus opens up new, current and future applications in automotive engineering for the company. Due to its versatility, TE employees use the SignalShark as a spectrum analyzer beyond the pure antenna application. For example, they can easily detect the interference radiation situation of a specific vehicle model.

In an appropriate mode, the useful signal can be analyzed or potential interferers can be detected. This and the maximum mobility of the handheld enable them, for example, to quickly and reliably evaluate modified installation situations from a radiation point of view directly at the customer's site and immediately propose concrete solutions. The best antenna is of no use if it is installed directly next to an auxiliary spotlight whose switching power supply massively disturbs the reception. Useful hints for a suitable installation location for a certain antenna module improve the service performance of TE engineers.

Occasionally capture signals without gaps

With its real-time bandwidth (RTBW) of up to 40 MHz, the SignalShark allows measurement engineers to perform fast measurements. Significantly faster than with conventional spectrum analyzers. This means that the receiver is able to capture even short, sporadically occurring signals in real-time within this 40 MHz without missing a single event. This is ensured by a POI (Probability of Intercept) of 100% for signals with a signal duration greater than 3.125 µs. The RTBW is particularly advantageous in automotive engineering in that today many power supplies in motor vehicles are designed as switching power supplies, and switched processes emit extremely short times and many faults.

With the SignalShark measuring instrument, TE employees can also easily enter their sensitive EMC chambers and carry out measurements and optimizations during operation. The reason for this is the good shielding of the SignalShark. This makes it immune to field strengths of up to 100 V/m. Thus, it is possible to work in the environment of strong field sources without any problems. And good shielding offers radiation protection in both directions so that the reverse conclusion is also permissible: Those who are protected against external field strengths also protect their direct surroundings from their own. The SignalShark can operate as an extremely quiet computer. Because in EMC chambers in which the emissions of test equipment are examined, everything that emits itself is prohibited.

Measuring device controls itself

With the SignalShark, the computer is integrated as a Windows 10 computer. Not only the complete control of the device is disclosed and remote control commands are described, but the measuring device can also control itself remotely. TE offers the possibility to implement own measuring programs easily by the pre-installed programming language Python. The device can be adapted to the developer's tasks. The external compass is supplied with power and read directly from the SignalShark via the USB bus. The reading of the compass and the combination of the compass values with the measured values of the spectrum analysis are done on the SignalShark itself.

---------------------------------------------------------------------------------------------------------------------------

Memory requirements of automotive systems

Networking, comfort, safety: The demand for high-quality storage systems in modern vehicles is rising rapidly. But which type is best suited for which application?.

The design of automobiles is becoming ever more complex as they are given more and more functions, such as driver assistance systems (ADAS), graphic dashboard units (GIC), air-conditioning and infotainment systems. Each of these subsystems requires non-volatile memory, for example, to store information during a reset or when switching the power supply, thus ensuring reliable and safe operation. The non-volatile memory contains, for example, executable code or other important data such as constants, calibration data and safety-relevant information that is to be retrieved at a later point in time.

There are different types of non-volatile memory, such as NOR Flash, NAND Flash, EEPROM (Electronically Erasable Programmable Read-Only Memory), FRAM (Ferroelectric Random Access Memory), MRAM (Magnetic RAM) and NVSRAM (Non-Volatile Synchronous RAM). Each memory type has advantages and disadvantages in terms of performance criteria such as memory density, read/write bandwidth, interface frequency, rewritability, data retention, power consumption in the various operating modes (active, standby/sleep, hibernate), waiting time, sensitivity to external electromagnetic interference, etc. To understand the real non-volatile memory requirements in these new automotive systems, engineers need to consider real-world applications:

- Hardly any driver will be willing to wait for minutes before driving off because, after boarding, the dashboard has to boot to display the speedometer, fuel gauge, etc. graphs.

- A driver has set the positions of the seat and steering wheel, the temperature and his favourite radio station on the radio. The vehicle must save this configuration before switching off the power supply to the subsystems. A loss of the settings would be uncomfortable and annoying for the driver.

- A vehicle is involved in an accident even though it is equipped with driver assistance systems. The driver or car should be able to provide important data for accident detection, such as the status of various sensors in the seconds before the accident.

With driver assistance systems, it is extremely important to capture the data of certain sensors in real-time and store it permanently in the non-volatile memory. Similarly, the settings of the infotainment system must be instantaneously stored so that they are not lost in the event of a power failure. Both GIS and infotainment systems work with high-quality graphics and therefore require large amounts of overlay data that are part of the boot sequence and are stored and read from an external non-volatile memory.

In addition to application-level requirements, non-volatile memory must also have sufficient rewritability to log data over a period of at least 20 years. In addition, subsystems should be equipped with memory components certified to AEC-Q100. Only then can they obtain the certifications and qualifications required in the automotive sector. Functional safety (ISO 26262) is another important aspect of safety-critical applications.

Requirements for the memory of driver assistance systems

Among other things, driver assistance systems should help prevent accidents. The integrated safety functions, for example, draw the driver's attention to too short a distance. In hazardous situations, the functions implemented can also (temporarily) take control of the car and, for example, initiate emergency braking. But they also provide support during normal driving. Adaptive functions can, for example, automatically switch on the headlights, regulate driving speed, automate braking, transmit warnings from GPS and traffic radio, connect to smartphones, alert the driver to other vehicles or hazards, keep the vehicle in the lane or even monitor the "blind spot". All these functions use non-volatile memory.

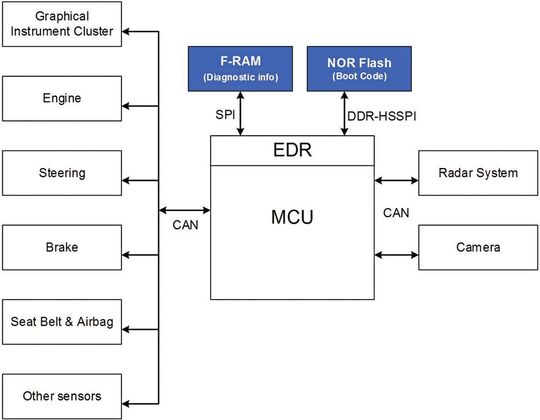

Figure 1 shows a driver assistance system in which FRAM and NOR Flash are used. External NOR Flash is usually used to store the boot code. Various sensors in the driver assistance system send data at regular intervals via the CAN bus (Controller Area Network) to the microcontroller unit (MCU). Using adaptive algorithms, the MCU determines whether there is a risk of collision or whether it has already occurred.

The runtime variables of the processing algorithms and the current status of the sensors are stored in the RAM of the MCU. If the algorithm detects an accident, the control module must immediately trigger the airbags with power from the backup system. This ensures that the airbags are triggered even if the normal power supply fails. The status of the sensors during the accident should also be stored immediately in a non-volatile memory. This information can be extremely valuable for later determining the cause of the accident. Automobile manufacturers can use this data to improve their safety systems.

Recording important data in the event of an accident

Event Data Recorders (EDR) are systems that collect data from important subsystems immediately before and upon the occurrence of a critical event. EDR can be part of the same ADAS MCU - or another MCU that receives the sensor data and communicates with the ADAS MCU. Multi-core chips such as the Cypress Traveo MCU can dedicate one core to the EDR function. The data collected by the EDR includes the severity of the collision. Pressure sensors at the front of the vehicle use pressure sensors to measure the force of the impact.

The vehicle speed, engine speed, steering movements, position of the accelerator pedal, status of the brakes, status of the seat belts, tire pressure, warning signals and finally the deployment of the airbags are also included. This data should be recorded for a few seconds before and during the accident. The MCU must not start saving status values when an event occurs. Rather, it must record this data continuously. To do this, EDR requires non-volatile memory, which can be rewritten almost indefinitely.

This is where FRAM comes in. It stores data practically latency-free in about 10 µs. For comparison: EEPROM usually requires several 10 ms for writing and is therefore unsuitable for safety-critical applications. The combination of immediate writing and high clock speeds makes FRAM a good choice for applications where a large amount of data has to be stored quickly. When using SPI, developers can freely determine how many bytes should be written into the FRAM. If one or two bytes are stored at any memory location in a FRAM, the write cycle time is approximately 1 µs.

Unlike EEPROM or Flash, FRAM works without a side buffer. FRAM writes each data byte immediately after receiving the eighth bit. For the engineers, this means that they do not have to worry about the size of page buffers and how they change during the transition to the next memory density. FRAM can be rewritten about 1014 times and is, therefore, several orders of magnitude larger than EEPROM with 106 or FLASH with 105 write operations. This makes FRAM suitable for predictive data logging in which data is constantly written. In addition, FRAM requires very little power for write and read operations (about 300 µA at 1 MHz) and is therefore suitable for driver assistance systems in which data must be stored during a power failure due to an accident, even with low-capacity power supplies or from capacitors. The standby currents of FRAM (typically 100 µA) are also significantly lower compared to other non-volatile memories.

Memory requirements of valve units

The armature unit displays important information such as speed, engine speed, fuel supply, and engine temperature in digital form or graphically or analogically via pointer instruments with the aid of stepper motors. It also contains warning symbols, e.g. for battery condition, temperatures, low oil pressure, brake failure, and safety symbols, e.g. warnings when the seat belt is not fastened, tyre pressure is too low, doors are not locked, and displays for switched-on headlights, as an indication of upshift, when the handbrake is applied, as well as non-critical information such as interior and exterior temperatures, total and trip meters, etc.

Latest armature units also have a head-up display (HUD). It reduces the risk of losing sight of the road and gives the driver extra time to identify and react to hazards. This display can be limited to the most important information, such as speed and navigation, as well as the warning symbols with the highest priority.

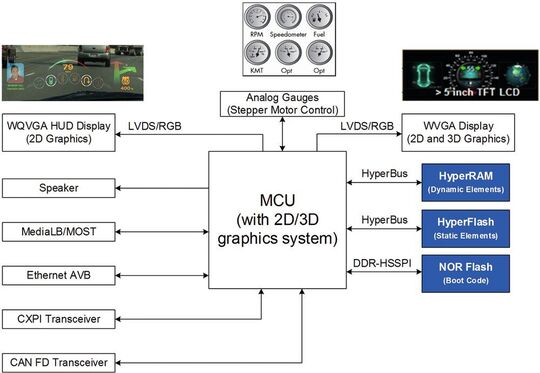

Figure 2 shows a simplified block diagram of a valve unit with HyperRAM and HyperFlash at HyperBus interfaces and NOR Flash at the DDR-HSSPI interface. The unit's MCU is connected to other subsystems via various communication protocols such as CAN-FD, CXPI (Clock eXtension Peripheral Interface), Ethernet AVB and MediaLB (Media Local Bus)/MOST (Media Oriented Systems Transport) to receive information for display.

After switching on the power supply, the safety engine of the valve unit checks the authenticity of the firmware. The MCU software is then executed in XiP mode (eXecuting in Place) from the external HyperFlash via the HyperBus interface or from the NOR Flash via the DDR-HSSPI interface (Double Data Rate - High Speed Serial Peripheral Interface). XiP functionality allows the MCU to execute code directly from external memory without first copying it from the external flash to the internal RAM. This increases response speed.

Memory with NOR Flash/HyperFlash can be programmed with an output address for the program code and starts in reading mode after a preset delay in clock cycles after switching on. As soon as the MCU is supplied with power, it can immediately access the code to be executed instead of first having to pass an address and the read command for a few clock cycles. Static elements can be taken from an external HyperFlash and displayed as a basic level in the LCD of the valve unit. Automotive MCUs such as Traveo from Cypress support additional options for decompressing these static HMI elements during readout without first having to pass via RAM. Dynamic content with faster update rates, e.g. pointers, can be retrieved from the external HyperRAM.

Requirements of climate and infotainment systems

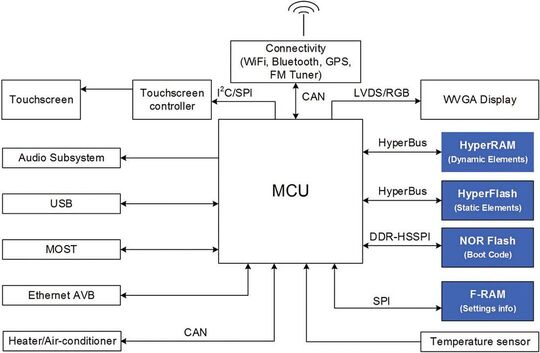

The HVAC system (heating, ventilation, air conditioning) ensures pleasant temperatures and ventilation in the passenger compartment. Apps on the infotainment system serve as user interfaces for setting the HVAC system, playing music, entering destinations in a navigation program, setting seat and steering wheel positions or adjusting the lighting mood in the passenger compartment. Some of the latest car models include a fingerprint reader to authenticate and identify the driver. This allows the climate and infotainment system settings to be quickly adapted to the driver's preferences. Figure 3 shows a climate and infotainment system with all memory elements connected to the main MCU. There are three further subsystems compared to the dashboard:

- Touchscreen controller for detecting finger touches,

- Heating/air conditioning system to control the temperature in the passenger compartment,

- Controller for the various connectivity options in the vehicle (Bluetooth, GPS, WiFi, GSM, FM tuner, etc.).

HyperFlash and HyperRAM are often used to store high-quality graphics. The boot code is in NOR Flash and settings in FRAM. This means that the settings can be called up reliably even if the vehicle's electrical system is switched off and on again immediately.

---------------------------------------------------------------------------------------------------------------------------

Properties of different memory interfaces

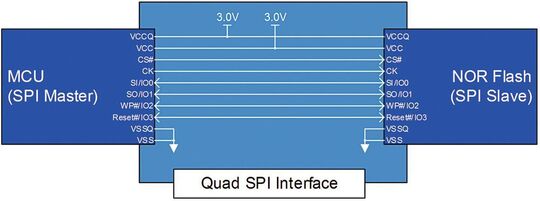

Each MCU with SPI interface can access NOR Flash. NOR Flash such as Cypress S25FL256L have an SPI with multi I/O options and support both DDR (Double Data Rate) and QPI (Quad Peripheral Interface). Multiple Flash devices can be connected to the same bus and addressed individually using a chip select (CS) signal (Fig. 4).

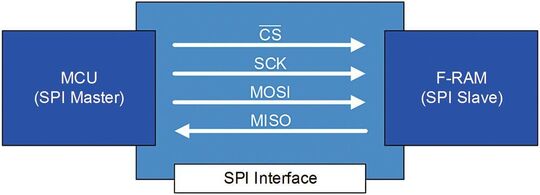

The MCU can use low-level hardware drivers (LLD) to read, program and delete data. The architecture is optimized for fast access times and high program speeds. Figure 5 illustrates access to FRAM via a simple SPI interface. Serial FRAM can currently be clocked up to 40 MHz.

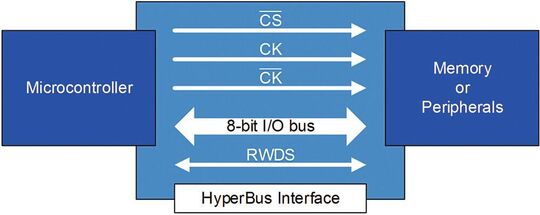

Because the serial data throughput correlates with the serial clock, SPI is well suited for MCU-based systems that require high data rates. Microcontrollers without their own SPI interface can access it via GPIO via bit-banging. HyperFlash and HyperRAM can be accessed via a HyperBus interface with 12 signals. When reading, HyperBus allows a 4 times higher throughput (333 MBit/s compared to 66.5 MBit/s) compared to Quad-SPI with one third of the lines required for parallel NOR Flash. This interface works with differential task signals (CK, CK#), Read/Write Data Strobe (RWDS), Chip Select and an 8-bit data bus figure 6 .

----------------------------------------------------------------------------------------------------------------------------Qualcomm

Semiconductor powerhouse Qualcomm’s AV scalable platform is called the Snapdragon Ride. The Snapdragon name denotes the company’s proprietary line of systems-on-a-chip (SoCs). These are highly energy-efficient, air-cooled neural processing engines, with multiple hardware performance accelerators, large data pipes, and a seamless development software infrastructure.

Qualcomm already uses other Snapdragon chips for voice-controlled, AI-enhanced vehicle cockpit, infotainment, and wireless connectivity systems it sells to 19 of the largest 25 carmaker OEMs.

Qualcomm insists that its comprehensive AV platform is ready for SAE Level 4 and 5 autonomous applications. The company claims “human-like driving planner assertiveness” and “low cost of development [for OEMs].” Qualcomm makes use of the Blackberry QNXOS for Safety and Hypervisor components.

“We’ve spent the last several years researching and developing our new autonomous platform and accompanying driving stack, identifying challenges, and gathering insights from data analysis to address the complexities automakers---------------------------------------------------------------------------------------------------------------------------

Tesla

Elon Musk, the enigmatic CEO and co-founder of Tesla, has said that by late 2020, his company would have as many as one million SAE Level 5 (fully autonomous) shareable—but individually owned—vehicles on the road, all using the firm’s proprietary Autopilot AV platform.

However, many industry observers consider Musk’s statement to be a wild exaggeration. Musk has since qualified his words by saying that fully autonomous operation would be on a case-by-case basis due to varying country and state regulations.

While Tesla has certainly been conducting extensive real-world AV testing, the status and refinement of its platform beyond what’s being built into present-year Tesla models are significant unknowns.

Another unknown is whether Tesla would share or license its Autopilot platform with other carmakers in the future. Autopilot currently delivers SAE Level 3 functionality (conditional automation) in 2020 model year Tesla vehicles.

In 2019, at an event Tesla calls Autonomy Day, the company claimed that the second-generation Full Self-Driving (FSD) computer component of its Autopilot was superior to NVIDIA’s formidable Pegasus platform (see above) because it runs on two chips, versus Pegasus’ one.

But speed-wise, the FSD is still not as fast as NVIDIA’s Pegasus. For now, at least, it seems these two companies are close to neck-and-neck performance-wise. (Tesla formerly used NVIDIA components before developing its own.)

-------------------------------------------------------------------------------------------------------------------------

MobilEye/Intel

Venerable microprocessor maker Intel has been involved in the auto industry for some time via technology supplied for advanced driver assistance systems (ADAS) for dozens of carmaker OEMs. By 2019, Intel had ADAS components installed in more than 34 million vehicles worldwide, enabling up to Society of Automotive Engineers (SAE) Autonomy Level 2 (“hands-free driving”).

Intel and MobilEye have purposely designed their platform to employ separate end-to-end camera, radar, and LiDAR systems. Each system is independently capable of providing reliable and sufficient data prior to this data being fused.

REM, RoadBook, and RSS

MobilEye’s retrofittable 8 Connect and Road Experience Management (REM)-enabled Global RoadBook are used for crowdsourced environmental data collection and mapping.