Toothbrush

A toothbrush is a dental instrument used for cleaning teeth, ideally in conjunction with toothpaste or mouthwash. The toothbrush consists of a plastic handle and nylon bristles attached to the head of the brush. Contemporary designs offer a variety of styles and shapes in a market that has swelled to $600 million in the mid-1990s, in part because of price increases, but also because toothbrushes are replaced frequently. On average each person in the United States purchases three toothbrushes every two years, although the American Dental Association (ADA) recommends that brushes be changed every three to four months. The best-selling toothbrushes during the 1990s were the Oral-B brand, produced by Gillette Co.; a range of toothbrushes from the Colgate Palmolive Co.; and the Reach toothbrush made by Johnson & Johnson.

Modern medical research has shown that brushing teeth properly can prevent cavities, gingivitis, and periodontal, or gum, disease, which causes at least one-third of adult tooth loss. Gum disease occurs when plaque builds up, forming a gelatinous film that coats the teeth and gums. Plaque consists of about 75% bacteria, and it grows quickly. If teeth are not brushed correctly and frequently, it could lead to the calcification of saliva minerals, forming tartar.

Brushing one's teeth has long been considered an important part of dental hygiene. As long ago as 3000 B.C. ancient Egyptians constructed crude toothbrushes from twigs and leaves to clean their teeth. Similarly, other cultures such as the Greeks, Romans, and Indians cleaned their teeth with twigs. Some would fray one end of the twig so that it could penetrate between the teeth more effectively. By the 15th century the Chinese had designed a more sophisticated toothbrush complete with a brush attached to a handle. A century later the English nobility were using toothbrushes fashioned out of silver.

Toothbrush design has gone through few substantial changes in its long history. Until the early 1900s, toothbrush bristles were generally made of Siberian hog hair. But in 1938, the soft-bristled Miracle Tuft Toothbrush was invented. Within a decade, Oral-B was mass producing soft-bristled toothbrushes. In 1961, the electric toothbrush was introduced. Beginning in the late 1970s, the toothbrush industry started churning out a variety of new designs. They included variations in bristle shape, size, and texture, as well as unconventional handle styles.

Styles of Toothbrushes

By the 1990s, countless styles of toothbrushes filled the shelves of supermarkets and drug stores, many claiming their superiority over other brands. Consumers could choose from toothbrushes with soft or hard bristles, with natural or synthetic bristles, and in a variety of sizes, colors, and configurations. For instance, the Reach toothbrush by Johnson & Johnson was the first toothbrush designed with an angled handle which was intended to make brushing back teeth easier. A later variation on the Reach brush included bristles in a zigzag design.

Colgate also offered an angled brush. One model, called Rippled Bristles, was designed to reach the plaque trapped between teeth. Gillette designed the Oral-B Indicator

The injection molding process involves forcing melted plastic pellets into a toothbrush mold and cooling it. The handle, head, and even the small holes are automatically formed.

An environmentally sound toothbrush was designed by Jack Hokanson. His Hoke2 brush featured a non-disposable handle with a replaceable bristle head. Some of the most uniquely shaped brushes include the Radius, which featured a wide handle designed for an easier grasp and a large, shoe-brush shaped head packed with bristles. The Collis Curve toothbrush featured bristles which curved inward so that they would hug the teeth, allowing the user to brush the front and back of the teeth at the same time.

Improvements in electric toothbrushes included battery-operated models, rotating heads, and tufts of rotating bristles. A hightech electronic toothbrush, called the Interplak, featured two rows of bristles with tufts that would spin at 4200 rpm, constantly reversing direction, and pulsating against the teeth. The Interplak, as its name suggests, was designed to remove plaque.

Although many dental experts believe that almost any type of soft-bristled brush is

The Manufacturing

Process

Contemporary toothbrushes are produced mechanically. Generally, toothbrushes consist of plastic handles and nylon or natural boar bristles.

Molding the handles

- 1 Plastic is mixed and shaped into pellets. The pellets are then placed in an injection molding machine, which heats the plastic until it is melted. A rotating screw or plunger forces the liquid plastic into the handle molds. The molds form the entire handle, including the small holes, called cores, into which the bristles are inserted. The molds are securely clamped, and pressure is applied to the molds while the plastic cools. Once the molds have adequately cooled, the clamps are removed, and small pins push the handles out of the molds.

The filling machine

- 2 The bristles, which are usually made of nylon, are positioned into the core of the handle automatically. The bristles are then stapled into the core with tiny metal staples.

Trimming the bristles

- 3 Next, the toothbrush passes through a trimming machine which slices the bristles to the correct length and shape for the particular design.

Packaging the toothbrushes

- 4 The toothbrushes are packaged into cardboard and/or plastic containers. Labels are attached to the package, providing product information such as bristle hardness, as well as recommendations for usage. If the brand is approved by the American Dental Association, the Seal of Acceptance is also stamped on the container.

- 5 Finally, the packaged toothbrushes are bundled into larger shipping boxes or crates and transported to distributors.

Quality Control

The American Dental Association tests a number of toothbrushes and other dental products each year. The ADA measures the efficiency and comfort of toothbrushes and those which meet with their standards are awarded the "ADA Seal of Acceptance." By the mid-1990s the ADA approved more than 45 different toothbrush brands.

The toothbrush is an oral hygiene instrument used to clean the teeth and gums that consists of a head of tightly clustered bristles mounted on a handle, which facilitates the cleansing of hard-to-reach areas of the mouth. Toothpaste, which often contains fluoride, is commonly used in conjunction with a toothbrush to increase the effectiveness of toothbrushing. Toothbrushes are available with different bristle textures, sizes and forms. Most dentists recommend using a toothbrush labelled "soft", since hard bristled toothbrushes can damage tooth enamel and irritate the gums. Toothbrushes have usually been made from synthetic fibers since they were developed, although animal bristles are still

sometimes used

XXX . XXX static mixer/stainless steel electric heating mixing tank electronic toothpaste mixer

electronic instrument and control toothpaste mixer

Toothpaste homogeneous emulsifier/cream emulsifying mixer/ body lotion emulsifier blender

Quick Details

- Condition: New

- Mixer Type: Homogenizer

- Product Type: Cosmetic

- Application: Viscous Fluid

- Place of Origin: Guangdong, China (Mainland)

- Brand Name: Lianhe

- Model Number: VME-series

- Max. Loading Capacity: customized

- Voltage: 220V/380V 50Hz

- Power(W): 15-88KW

- Dimension(L*W*H): customized

- Certification: CE

- Warranty: 1 year

- After-sales Service Provided: Engineers available to service machinery overseas

- application: liquid,ointmet ,cream in cosmetic

- additonal capabilities: mixing&emulsifying

- lifting: hydraulic lift

- control: button/PLC

- contact material: SUS316L

- surface material: SUS304

- agitator: scraped

- blender: 0-63r/m speed adjustable

- homogenizer: 3000R/M

- outlet: tilting system

Machine composition:

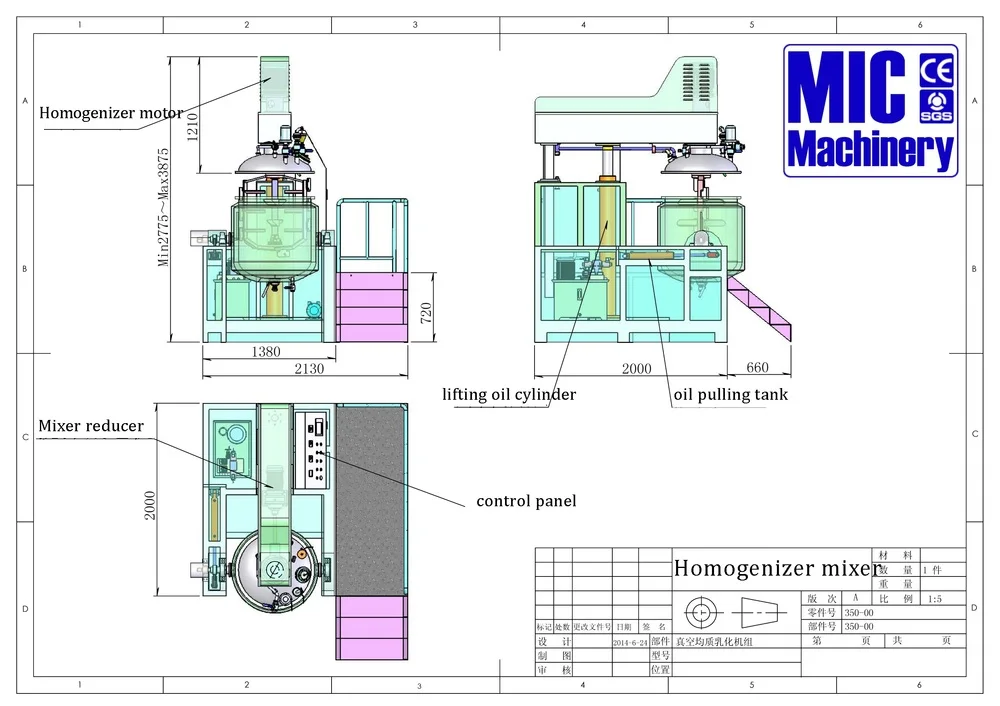

The vacuum homogenizer is mainly composed of main tank, water tank, oil tank, vacuum system, lifting system and operation platform, etc..

Technical parameter:

| Model | Effective capacity | Emulsify | Agitator | Dimension(MM) | Total power(KW) | ||||||

| KW | R/min | KW | R/min | Length | Width | Height | Maxh | Electric heating | Steam heating | ||

| VME-20 | 20 | 0.75 | 0-3000 | 0.37 | 0-40 | 1800 | 1600 | 1850 | 2700 | 9 | 3 |

| VME-50 | 50 | 2.2 | 0-3000 | 0.37 | 0-40 | 2700 | 2000 | 2015 | 2700 | 25 | 5 |

| VME-100 | 100 | 3 | 0-3000 | 1.5 | 0-40 | 2920 | 2120 | 2200 | 3000 | 27 | 9 |

| VME-150 | 150 | 3 | 0-3000 | 1.5 | 0-40 | 3110 | 2120 | 2200 | 3100 | 27 | 9 |

| VME-200 | 200 | 4 | 0-3000 | 1.5 | 0-40 | 3150 | 2200 | 2200 | 3100 | 40 | 12 |

| VME-350 | 350 | 4 | 0-3000 | 2.2 | 0-40 | 3650 | 2650 | 2550 | 3600 | 50 | 16 |

| VME-500 | 500 | 5.5 | 0-3000 | 2.2 | 0-40 | 3970 | 2800 | 2700 | 3950 | 50 | 16 |

| VME-1000 | 1000 | 11 | 0-3000 | 4 | 0-40 | 3900 | 3400 | 3150 | 4550 | 100 | 30 |

| VME-2000 | 2000 | 15 | 0-3000 | 7.5 | 0-40 | 4850 | 4300 | 3600 | no rise and fall | 120 | 50 |

Features:

The vacuum emulsifier is professionally designed according to the ointment manufacturing process of

cosmetics and ointments etc. products through

introducing advanced technology from abroad. The machine unit is composed of pre-treating boiler,

vacuum emulsifying and blending boiler, vacuum pump,

hydraulic system, dumping system, electric control system and work platform etc. The machine unit is

featured by simple operation, stable performance, good homogenizing performance, high production

efficiency, convenient cleaning, reasonable structure, small land area and high automatic degree etc

Usage:

It is suitable for production of ointment and cream products in cosmetic and pharmaceutical plants.

The emulsifying effect is more prominent for materials

of high base viscosity and high solid content.

Advantage:

1. Homogenizer's design mainly stem from Japanese technology.

2. Completely Meet GMP

3. Material contact part all use SUS316L

4. Using Japan NSK bearings

5. Siemens Inverter, power-saving, machine-protect, keeping the machine working stably

6. Burgmamn mechanical seal, seal good, long working life, keep the homogenizer work 24 hours continually.

7. Slow stirring axle adopts 2 sets of mechanical seal and 2 sets frame oil seal, make the seal saver.

8. Stirring scrap and middle stirring rotating the opposite direction make the mixing more equally

9. Safety protecting functions, make the produce saver

10. Install a fall buffer unit on the hydro-cylinder in the hydraulic system; keep the cover up and down stable.

toothpaste making machines

Vacuum paste making mixer pot emulsifier dental toothpaste pharmaceutical cosmetic mixing equipment

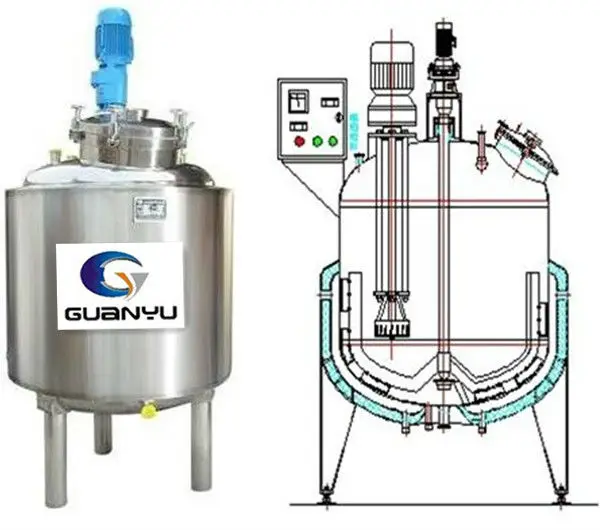

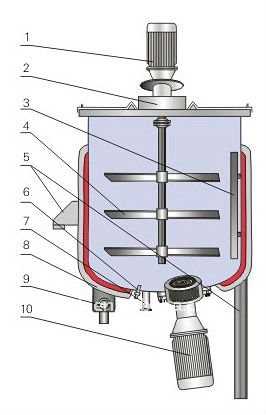

Vacuum homogenizing machine is available for heating, melting, homogenizing and emulsifying. It is best choice for face cream, wash cream, cosmetics materials; it is an ideal device for paste-cream products of middle and high grades. This equipment includes oil phase boiler, water phase and emulsifying vessels, operation platform and control tank.

the important problem is Scattered particle larger diameter and have air into the material when mix the heavy body emulsifications and the specialties is produce cream, ointment, emulsion series In the process. the larger diameter of particle cause the material labialization and lack luster; if the air into the material cause the material have air bubble、bacterium pollution、apt oxidize and made the material not smoothly. Regarding to the two problems, our factory had developed YX-ZG series Vacuum Emulsifying Mixer Series that the main systems are homogenizer & Middle(Fixed) Stirrer & Scrapers residues stirrer, so make up into the best mixing way and in order to reach and mix the mater perfectly. Adopt the vacuum pump to draw out air form material, ensure produce the material is rich gloss , fine and smooth and prolongs quality product with good malleability .

Formation:

YX-ZG series Vacuum Emulsifying Mixer Series is composed of emulsification boiler(fluctuating cover, overturn kettle form or outside circle form), water boiler, oil water, vacuum system, heating and temperature control systems, cooling systems, electric machinery control systems. ect,

Work Elements:

After the materials are in the water boiler and oil boiler to heating & mixing then draw into the emulsification boiler by the vacuum pump, through the middle(fixed) stirrer & teflon Scrapers residues stirrer in the emulsification boiler that sweep the residues on the wall of the boiler, so make the produces of wiped off become the new interface constantly, then the blade cut off 、compress、fold round 、mixing and running to the homogenizer, according to the high shear wheel and the cutting case to strong cutting off、impact、Without rules mobility, etc. the material by cutting in the cut interstices and turn to a particle of 200nm-2um prompt, because the emulsification boiler is under vacuum state, the bubble that the supplies produce in the course of mixing is taken away in time.

Features:

The pot cover is automatic rising type, the material was directed draw into the emulsifying boiler from oil boiler and water boiler based on a pipe that is under vacuum, the discharge is based on the turn the emulsifying boiler. And the heating system is electric heating or steam heating that the temperature is automation control. Put the cool water into the intercalated bed so cooling the material, simple operation and safety( at the outside have a warm layer). The homogenizer and the blade stirring can together work or separate work.. the material sliming、emulsification、mixing、dispersing,etc. what will finished during short time. Contact position adopt high-quality stainless steel (medical use adopt 316L material make with supplies, the polishing of surface of the mirror of interior surface, mix the hygiene of the device in vacuum, it accords with the normal hygiene standard manufacture of GMP to adopt that is most ideal production equipment.).

Basic parameter of vacuum toothpaste making equipment:

Name

|

YX-ZG750L

| YX-ZG1000L | YX-ZG1300L | |

Emulsifying Pot

|

Design Volume (L)

|

750

| 1000L | 1300L |

Capacity (L)

|

620L

|

840

| 1000L | |

Scraper Stirring Power (KW)

|

4

|

4

| 4 | |

Scraper Stirring Speed (rpm)

|

0-65

|

0-65

| 0-30 | |

Homogenizer Power (KW)

|

11

|

15

| 18.5 | |

Electrical Heating Power (KW)

|

24

|

24

| 24 | |

Homogenizer Speed (rpm)

|

2800

|

2800

| 2800 | |

Water Pot

|

Design Volume (L)

|

500

| 650 | 800 |

Capacity (L)

|

450

|

600

| 650 | |

Power (KW)

|

1.1

|

1.5

| 1.5 | |

Speed (rpm)

|

1400

|

1400

| 1400 | |

Electrical Heating Power (KW)

|

18

|

18

| 18 | |

Oil Pot

|

Design Volume (L)

|

400

| 500 | 650 |

Capacity (L)

|

250

|

300

| 500 | |

Power (KW)

|

1.1

|

1.5

| 1.5 | |

Speed (rpm)

|

1400

|

1400

| 1400 | |

Electrical Heating Power (KW)

|

12

|

12

| 18 |

The Process of Toothpaste Making

Toothpaste processing methods vary depending on the product type and ingredients used.

A typical toothpaste manufacturing process could be described as follows:

• The liquid base is prepared first – water, sorbitol/glycerin and other liquid ingredients.

• Rheology modifiers may be pre-mixed with a non-aqueous liquid ingredient such as glycerin or the flavoring oil, or dry blended with other powdered ingredients to aid dispersion.

• The active ingredient, sweetener and preservative are added and dispersed.

• The abrasive/filler is then added. This may be supplied as slurry, or premixed with part of the water prior to blending with the liquid base.

• Flavoring and coloring are added

• The detergent is added last under slow speed agitation to minimize foaming. It is typically in solid form to avoid adding water to the formulation at this stage.

Toothpaste processing methods vary depending on the product type and ingredients used.

A typical toothpaste manufacturing process could be described as follows:

• The liquid base is prepared first – water, sorbitol/glycerin and other liquid ingredients.

• Rheology modifiers may be pre-mixed with a non-aqueous liquid ingredient such as glycerin or the flavoring oil, or dry blended with other powdered ingredients to aid dispersion.

• The active ingredient, sweetener and preservative are added and dispersed.

• The abrasive/filler is then added. This may be supplied as slurry, or premixed with part of the water prior to blending with the liquid base.

• Flavoring and coloring are added

• The detergent is added last under slow speed agitation to minimize foaming. It is typically in solid form to avoid adding water to the formulation at this stage.

Machine in customer factory for running :

Wooden case packing of vacuum paste making machine for ocean shipping:

Toothpaste making line video for our Indonesian customer

Previous: double nozzles tubes filling sealing machine fully automatic two color filler sealer plastic hose equipment .

oothpastes are generally either white abrasive pastes or clear gels. Although the formulations differ they share many common ingredients. These include: liquid base (typically sorbitol or glycerin), fillers and abrasives, rheology modifiers, detergent, active ingredients like fluoride, flavor, sweetener, coloring and preservatives.

Gel toothpastes can be manufactured using a Silverson mixer, and several stages of white toothpaste manufacture can also benefit from high shear mixing.

A method is disclosed for the manufacture of a toothpaste containing an ingredient mixture of a calcium carbonate abrasive, a thickener and an aqueous humectant wherein there is sequentially added the calcium carbonate abrasive dispersed in a high solids aqueous dispersion containing 50 to 80% by weight calcium carbonate to the aqueous humectant and thereafter adding the binder and binding the ingredients before any further ingredients are added to the mixture to produce the toothpaste.

Alternative Options for Brushing Teeth with Baking Soda:

Baking Soda and Vinegar. Dissolve first the baking soda in water and add a few drops of white vinegar and a pinch of salt. Brush for two minutes and rinse thoroughly.

Baking Soda and Strawberry. Strawberries contain powerful anti-oxidant properties and work in harmony with whitening teeth. Mash up one whole ripe strawberry into a pulp and then add enough baking soda to make a paste. Apply to your toothbrush and brush for two minutes. Rinse mouth and toothbrush thoroughly.

Baking Soda and Toothpaste. Mix a small amount of baking soda with your desired toothpaste to make a paste. Dip toothbrush into the paste (an alternative is to simply sprinkle baking soda on top of the toothpaste on your brush). Brush for two minutes and rinse thoroughly.

Hydrogen Peroxide Teeth Whitening With Baking Soda. Hydrogen peroxide is known to have whitening and bleaching effects. Mix half a teaspoon of hydrogen peroxide with a teaspoon of baking soda to form a paste. Dip the toothbrush into the paste. Brush for two minutes and rinse thoroughly.

Baking Soda and Salt. Add 1 teaspoon of table salt to 3 teaspoons of baking soda. Salt’s abrasive effect enhances the plaque removal and whitening process. Apply a desired amount in the toothbrush and brush for two minutes. Rinse per usual after done brushing.

Baking Soda, Peppermint Extract and Glycerin. The mixture of these three creates fresh tasting toothpaste. Mix 3 teaspoons of vegetable glycerin with a few drops of peppermint oil to start with. Add in 1/2 teaspoon of salt along with 5 teaspoons of baking soda. Mix the ingredients completely. Apply to toothbrush, brush for two minutes and rinse thoroughly.

Baking Soda and Lemon Juice or Lime Juice. Citric acid in these fruits is an effective bleaching agent. Mix half a teaspoon of baking soda with half a teaspoon of freshly squeezed lemon or lime juice. Brush your teeth and leave the mixture for about a minute before rinsing thoroughly. Most dentists do not recommend this method because the corrosive properties of the citric acid damage the teeth.

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

at a glance the electronic toothpaste mixer

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

Tidak ada komentar:

Posting Komentar